Comparative Study on Welding Characteristics of Laser-CMT and Plasma-CMT Hybrid Welded AA6082-T6 Aluminum Alloy Butt Joints

Abstract

1. Introduction

2. Materials and Experimental details

2.1. Materials

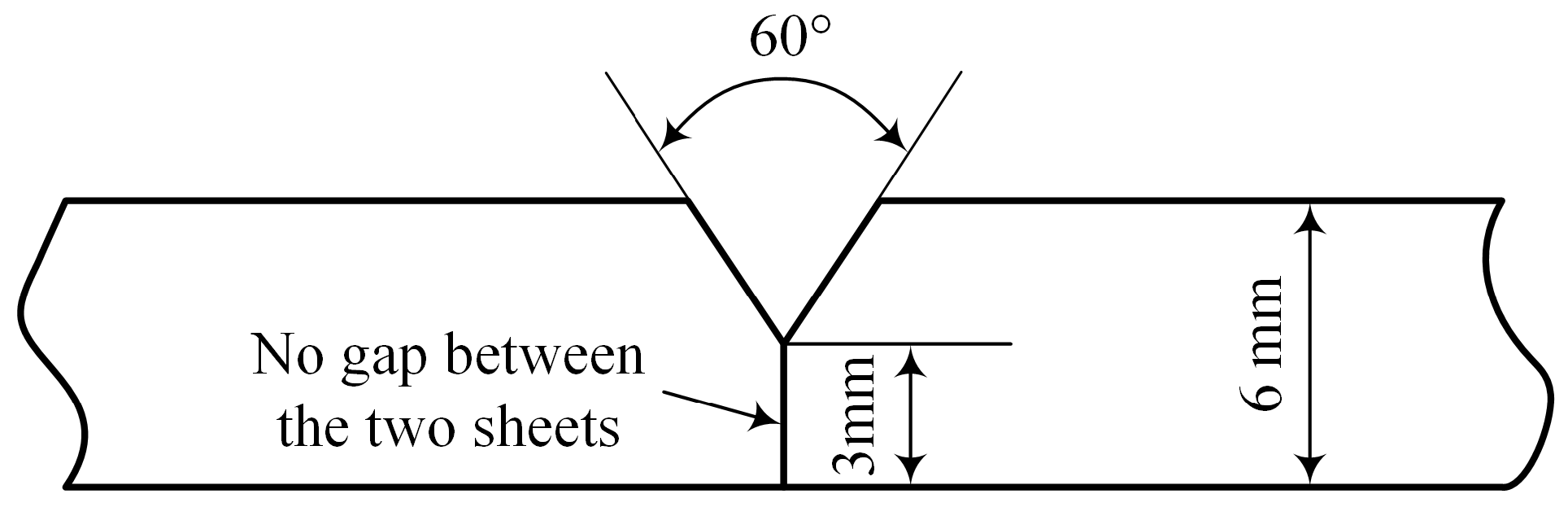

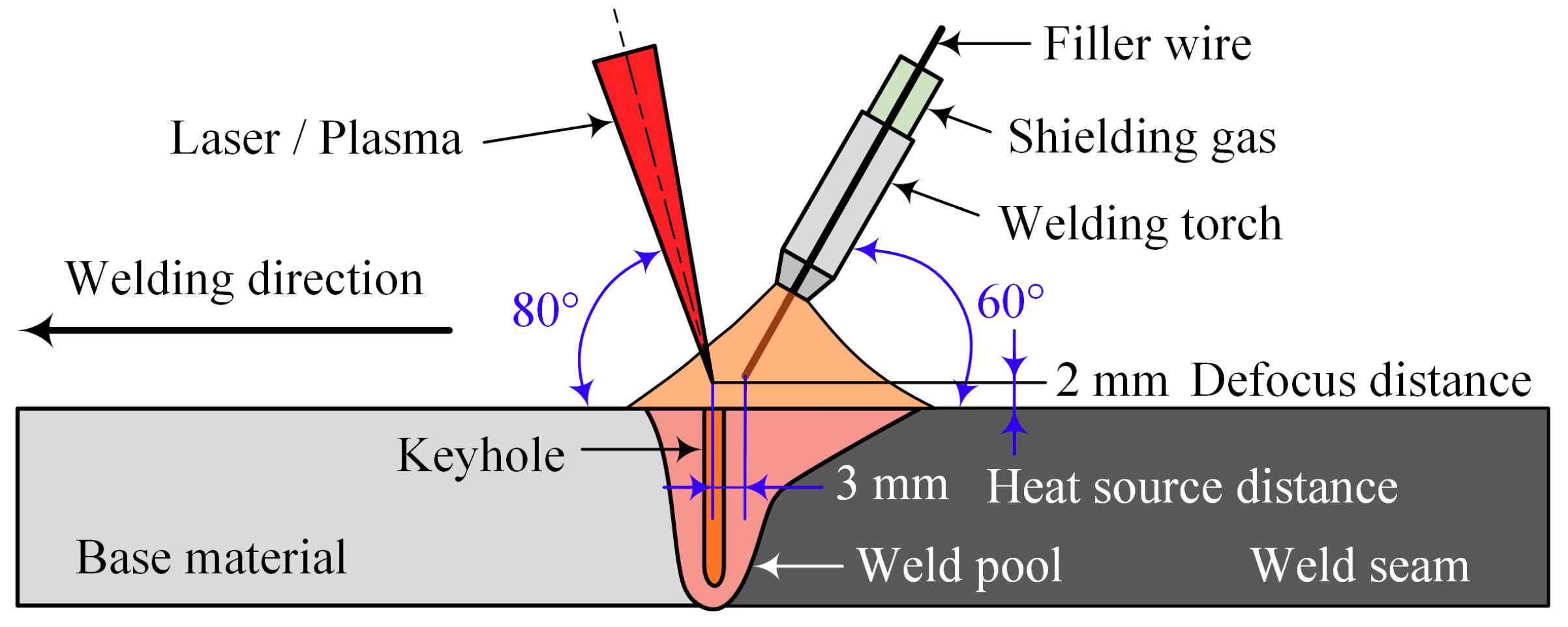

2.2. Welding Method and Apparatus

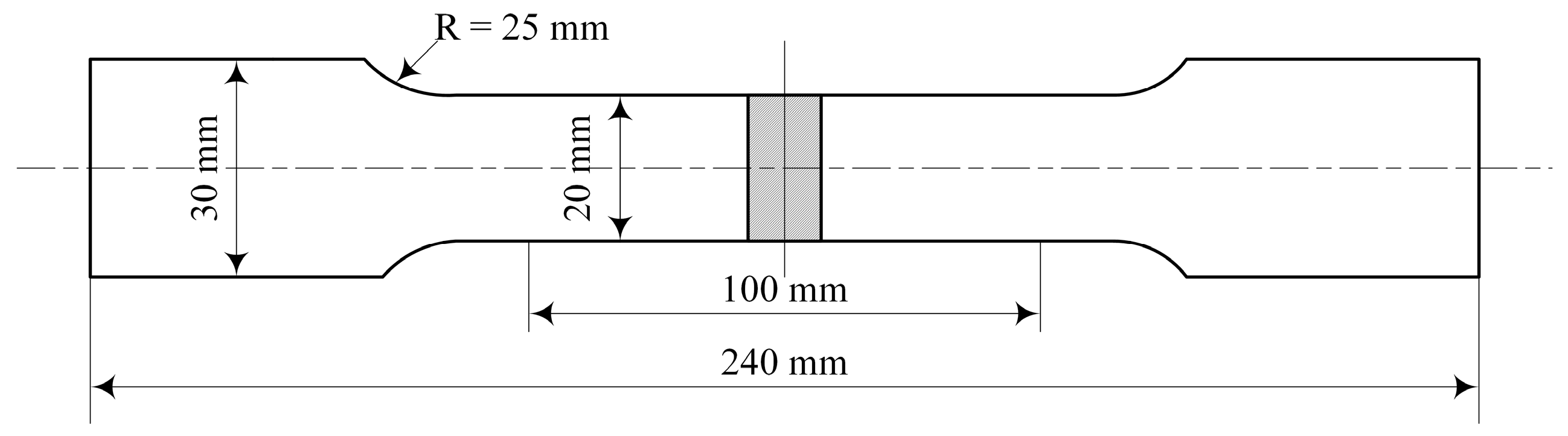

2.3. Testing Examination

3. Results and Discussion

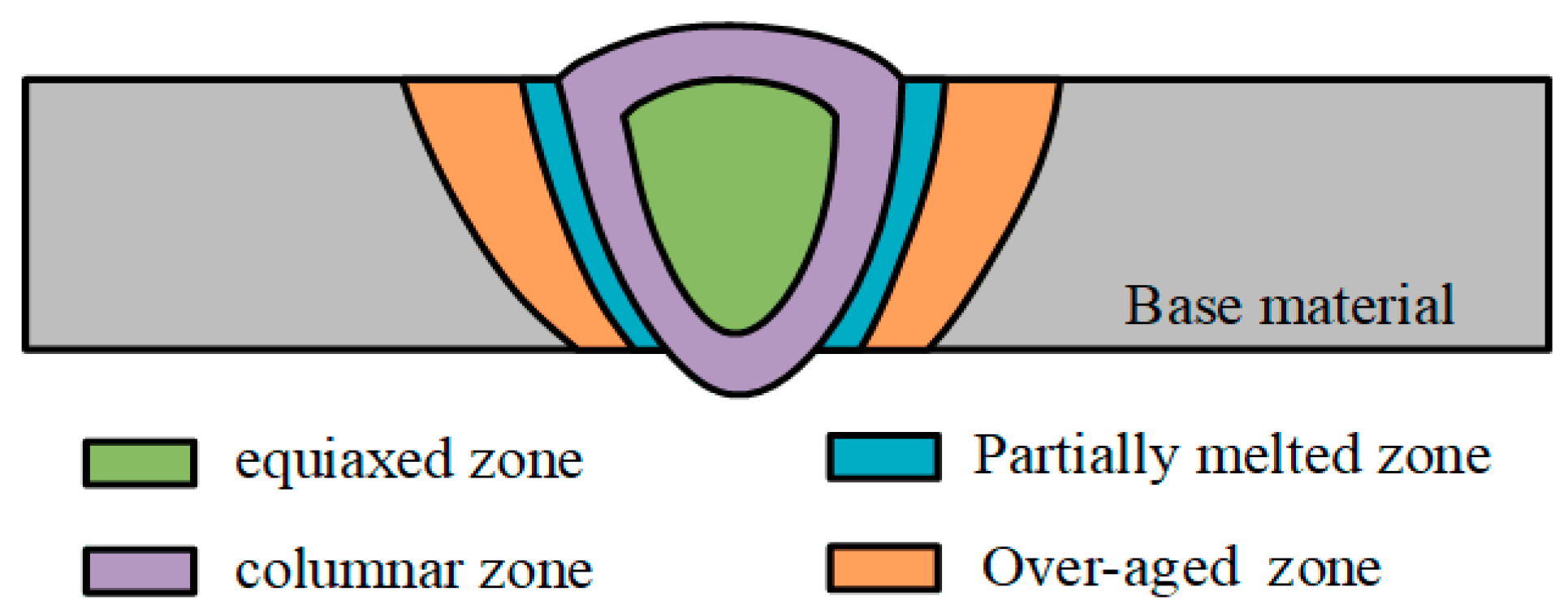

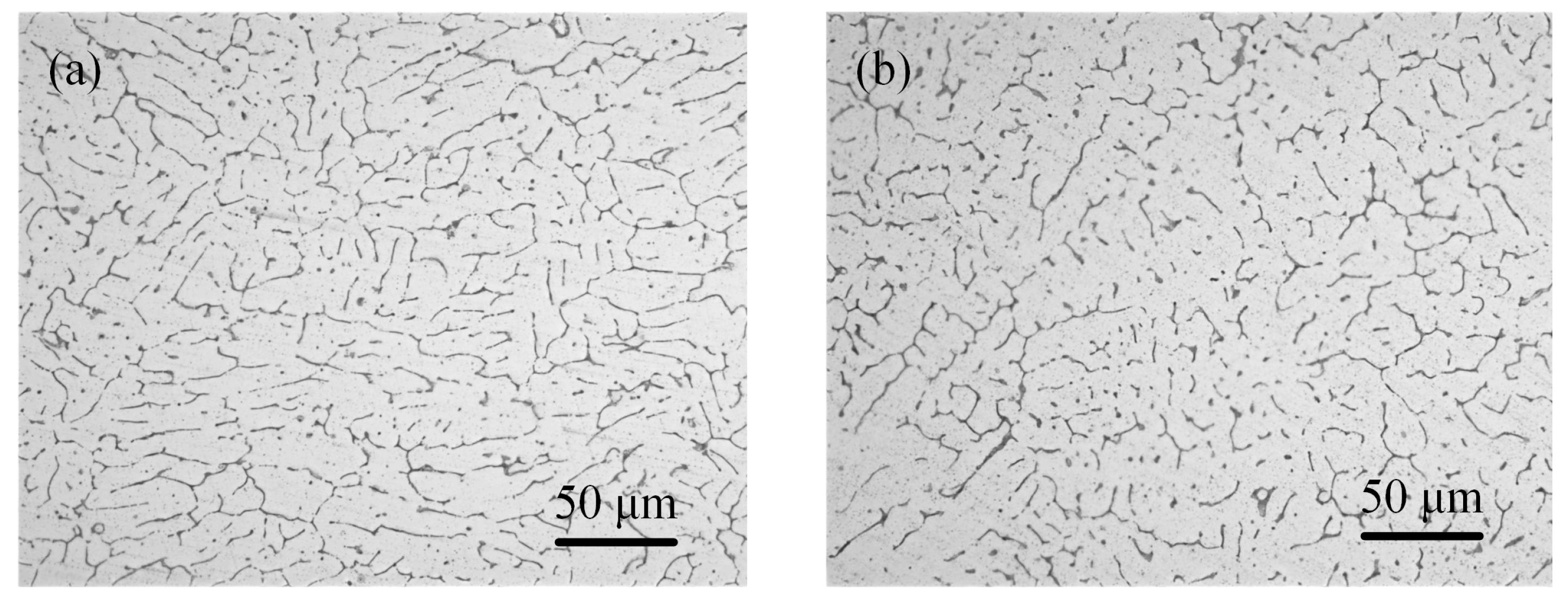

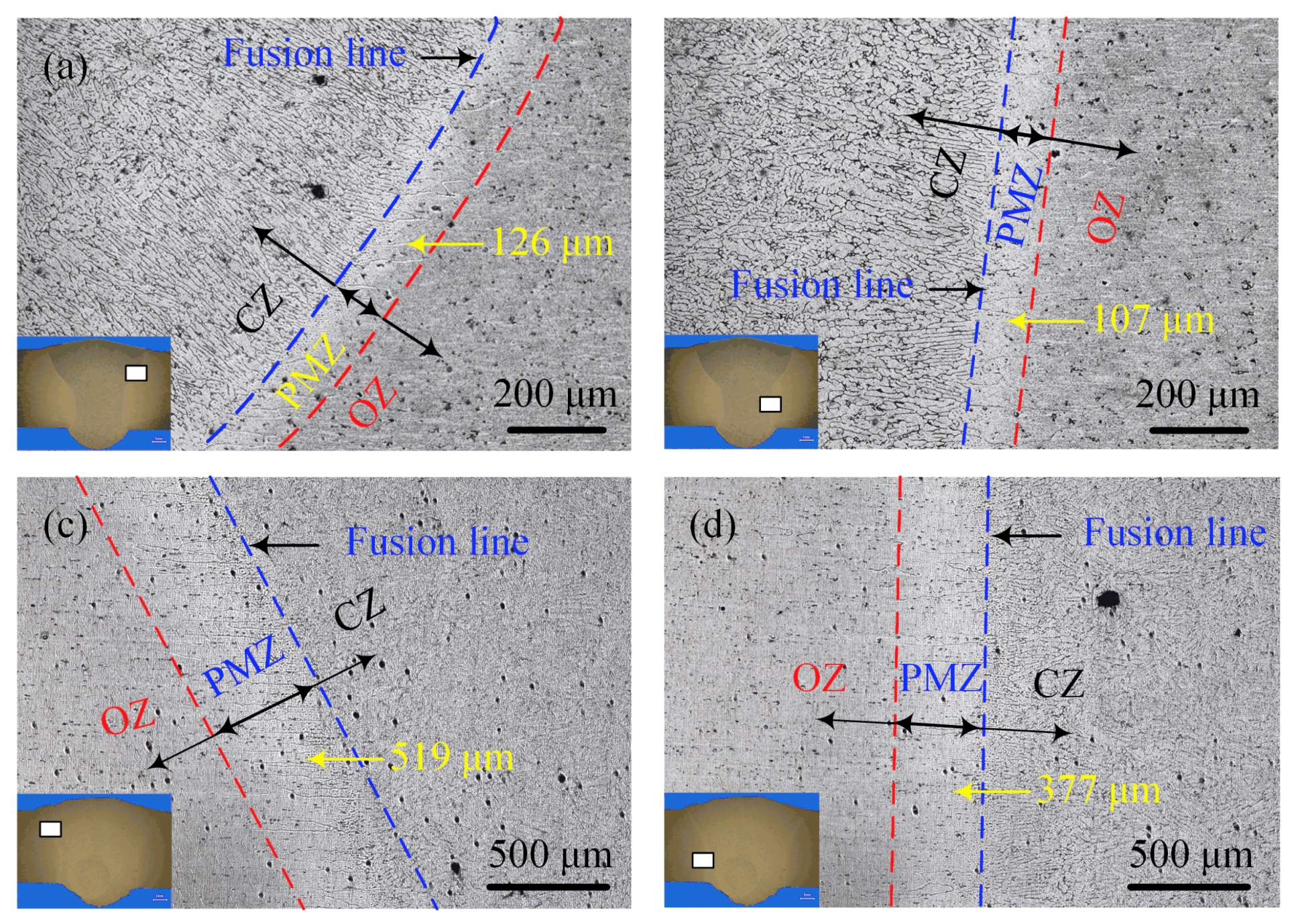

3.1. Macro and Microstructure

3.2. Mechanical Properties

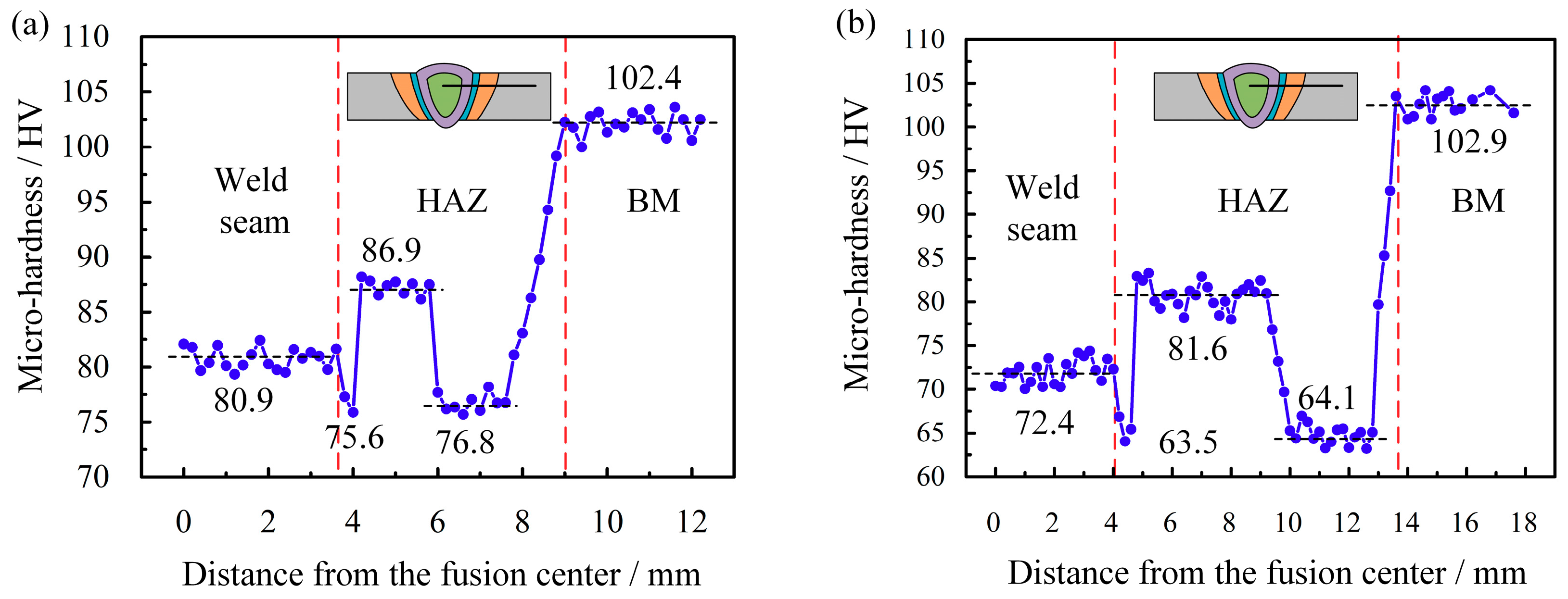

3.2.1. Micro-hardness

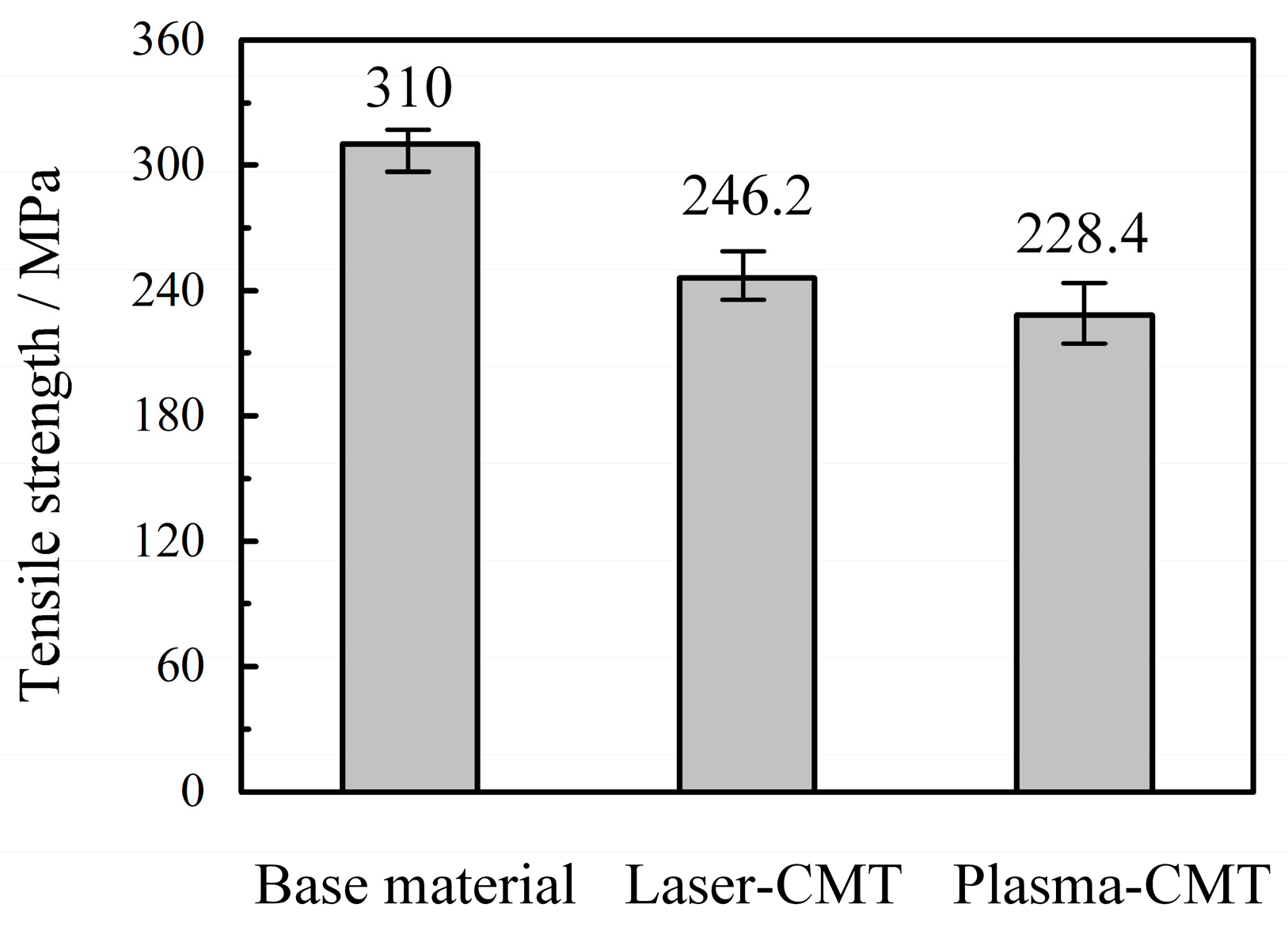

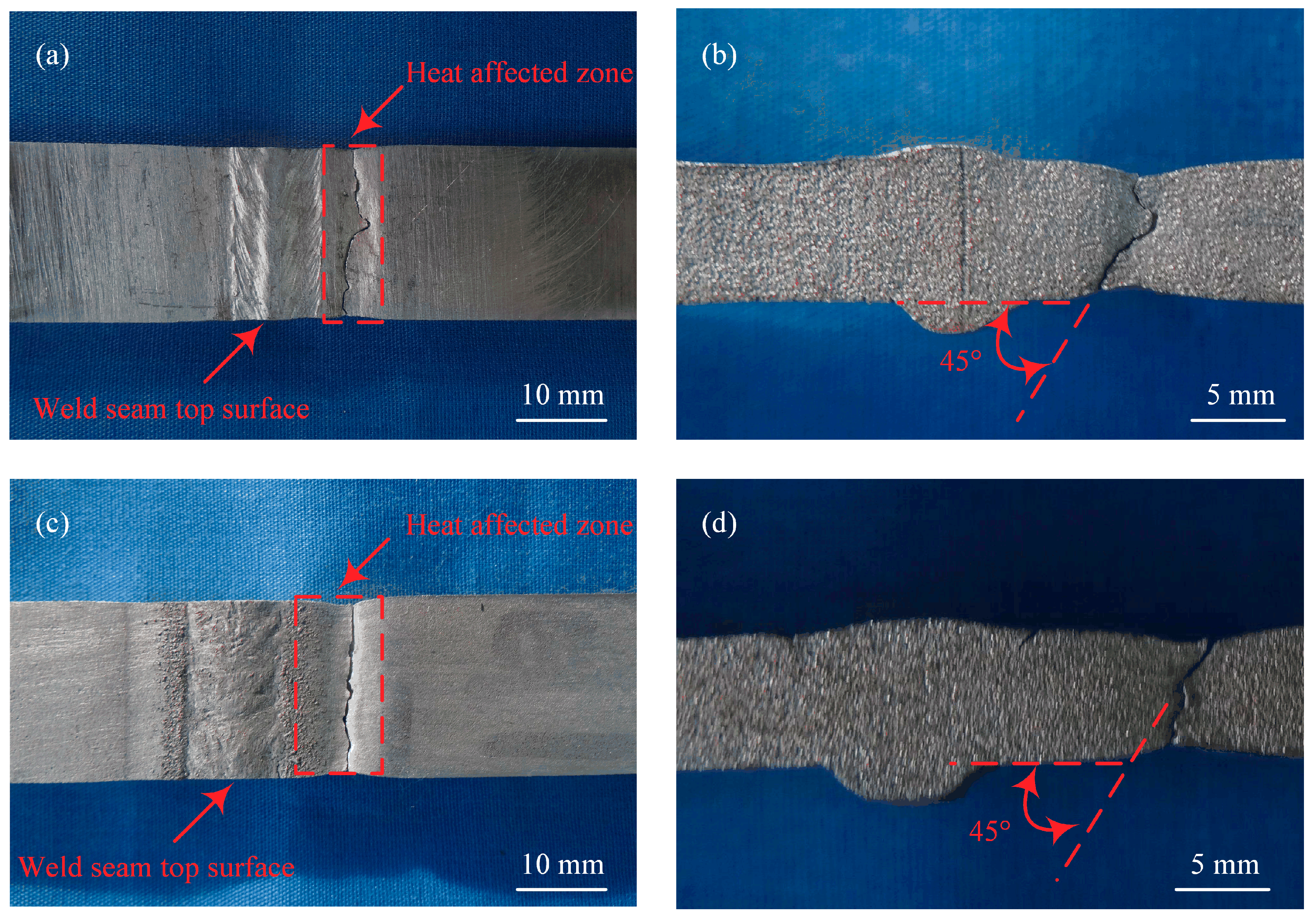

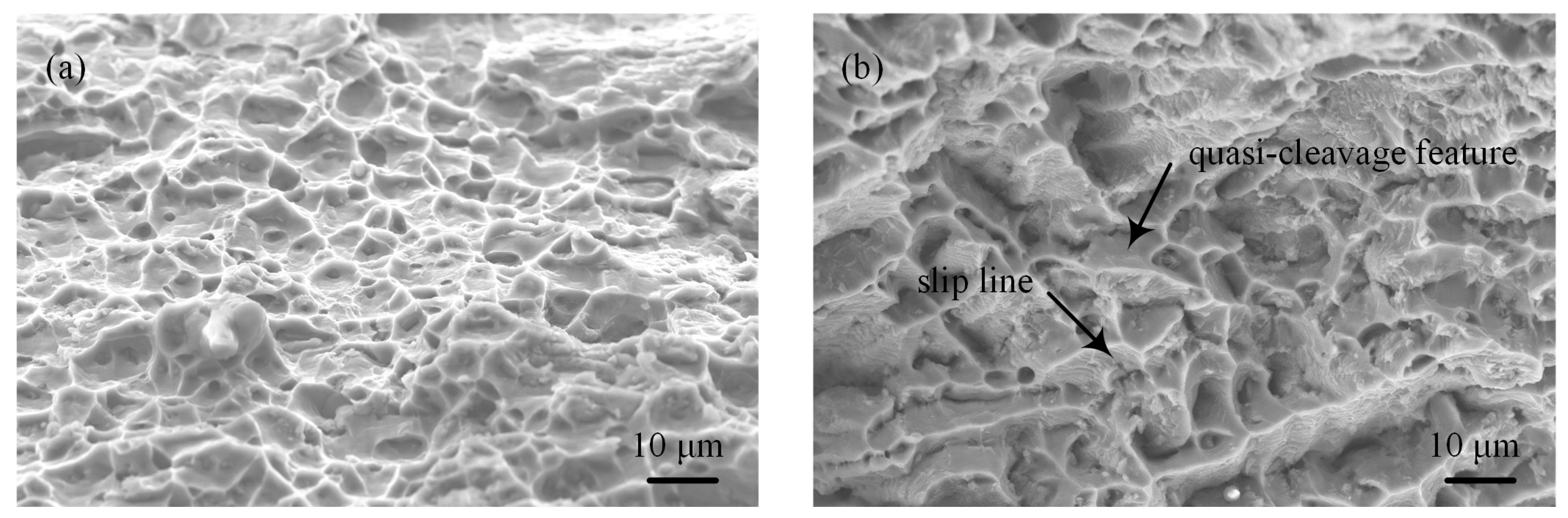

3.2.2. Tensile Strength

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gou, G.; Huang, N.; Chen, H.; Liu, H.; Tian, A.; Guo, Z. Research on corrosion behavior of A6N01S-T5 aluminum alloy welded joint for high-speed trains. J. Mech. Sci. Technol. 2012, 26, 1471–1476. [Google Scholar] [CrossRef]

- Liu, S.; Li, J.; Mi, G.; Wang, C.; Hu, X. Study on laser-MIG hybrid welding characteristics of A7N01-T6 aluminum alloy. Int. J. Adv. Manuf. Technol. 2016, 87, 1135–1144. [Google Scholar] [CrossRef]

- Borrego, L.P.; Costa, J.D.; Jesus, J.S.; Loureiro, A.R.; Ferreira, J.M. Fatigue life improvement by friction stir processing of 5083 aluminium alloy MIG butt welds. Theor. Appl. Fract. Mech. 2014, 70, 68–74. [Google Scholar] [CrossRef]

- Jiang, Z.; Hua, X.; Huang, L.; Wu, D.; Li, F.; Zhang, Y. Double-sided hybrid laser-MIG welding plus MIG welding of 30-mm-thick aluminium alloy. Int. J. Adv. Manuf. Technol. 2018, 97, 903–913. [Google Scholar] [CrossRef]

- Leo, P.; Renna, G.; Casalino, G.; Olabi, A.G. Effect of power distribution on the weld quality during hybrid laser welding of an Al-Mg alloy. Opt. Laser Technol. 2015, 73, 118–126. [Google Scholar] [CrossRef]

- Bunaziv, I.; Akselsen, O.M.; Salminen, A.; Unt, A. Fiber laser-MIG hybrid welding of 5 mm 5083 aluminum alloy. J. Mater. Process Technol. 2016, 233, 107–114. [Google Scholar] [CrossRef]

- Miao, H.; Yu, G.; He, X.; Li, S.; Chen, X. Comparative study of hybrid laser-MIG leading configuration on porosity in aluminum alloy bead-on-plate welding. Int. J. Adv. Manuf. Technol. 2017, 91, 2681–2688. [Google Scholar] [CrossRef]

- Costa, J.D.M.; Jesus, J.S.; Loureiro, A.; Ferreira, J.A.M.; Borrego, L.P. Fatigue life improvement of MIG welded aluminium T-joints by friction stir processing. Int. J. Fatigue 2014, 61, 244–254. [Google Scholar] [CrossRef]

- Acherjee, B. Hybrid laser arc welding: State-of-art review. Opt. Laser Technol. 2018, 99, 60–71. [Google Scholar] [CrossRef]

- Lee, H.K.; Park, S.H.; Kang, C.Y. Effect of plasma current on surface defects of plasma-MIG welding in cryogenic aluminum alloys. J. Mater. Process Technol. 2015, 223, 203–215. [Google Scholar] [CrossRef]

- Yan, S.; Chen, H.; Zhu, Z.; Gou, G. Hybrid laser-Metal Inert Gas welding of Al-Mg-Si alloy joints: Microstructure and mechanical properties. Mater. Des. 2014, 61, 160–167. [Google Scholar] [CrossRef]

- Nielsen, S.E. High Power Laser Hybrid Welding-Challenges and Perspectives. Phys. Procedia 2015, 78, 24–34. [Google Scholar] [CrossRef]

- Liu, S.; Liu, F.; Xu, C.; Zhang, H. Experimental investigation on arc characteristic and droplet transfer in CO2 laser-metal arc gas (MAG) hybrid welding. Int. J. Heat Mass Transf. 2013, 62, 604–611. [Google Scholar] [CrossRef]

- Kim, C.H.; Ahn, Y.N.; Lee, K.B. Droplet transfer during conventional gas metal arc and plasma-gas metal arc hybrid welding with Al 5183 filler metal. Curr. Appl. Phys. 2012, 12, S178–S183. [Google Scholar] [CrossRef]

- Cai, D.; Han, S.; Zheng, S.; Luo, Z.; Zhang, Y.; Wang, K. Microstructure and corrosion resistance of Al 5083 alloy hybrid plasma-MIG welds. J. Mater. Process Technol. 2018, 255, 530–535. [Google Scholar] [CrossRef]

- Lee, H.K.; Chun, K.S.; Park, S.H.; Kang, C.Y. Control of surface defects on plasma-MIG hybrid welds in cryogenic aluminum alloys. Int. J. Nav. Arch. Ocean 2015, 7, 770–783. [Google Scholar] [CrossRef]

- Selvi, S.; Vishvaksenan, A.; Rajasekar, E. Cold metal transfer (CMT) technology—An overview. Def. Technol. 2018, 14, 28–44. [Google Scholar] [CrossRef]

- Lamas, J.; Frostevarg, J.; Kaplan, A.F.H. Gap bridging for two modes of laser arc hybrid welding. J. Mater. Process Technol. 2015, 224, 73–79. [Google Scholar] [CrossRef]

- British Standards Institution. Destructive Tests on Welds in Metallic Materials-Transverse Tensile Test. ISO 4136; International Organization for Standardization: Geneva, Switzerland, 2001. [Google Scholar]

- Zhang, C.; Li, G.; Gao, M.; Yan, J.; Zeng, X.Y. Microstructure and process characterization of laser-cold metal transfer hybrid welding of AA6061 aluminum alloy. Int. J. Adv. Manuf. Technol. 2013, 68, 1253–1260. [Google Scholar] [CrossRef]

- Gao, M.; Cao, Y.; Zeng, X.Y.; Lin, T.X. Mechanical properties and microstructures of hybrid laser MIG welded dissimilar Mg-Al-Zn alloys. Sci. Technol. Weld. Join. 2010, 15, 638–645. [Google Scholar] [CrossRef]

- Liu, F.; Wang, X.; Zhou, B.; Huang, C.; Lu, F. Corrosion resistance of 2060 aluminum-lithium alloy LBW welds filled with Al-5.6Cu Wire. Materials 2018, 11, 1988. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.B.; Tao, W.; Li, L.Q.; Chen, Y.B.; Li, F.Z.; Zhang, Y.L. Double sided laser beam welded T joints for aluminum aircraft fuselage panels Process, microstructure, and mechanical properties. Mater. Des. 2012, 33, 652–658. [Google Scholar] [CrossRef]

- Kuo, T.Y.; Lin, H.C. Effects of pulse level of Nd-YAG laser on tensile properties and formability of laser weldments in automotive aluminum alloys. Mater. Sci. Eng. A 2006, 416, 281–289. [Google Scholar] [CrossRef]

- Zhang, X.; Li, L.; Chen, Y.; Yang, Z.; Chen, Y.; Guo, X. Effects of pulse parameters on weld microstructure and mechanical properties of extra pulse current aided laser welded 2219 aluminum alloy joints. Materials 2017, 10, 1091. [Google Scholar] [CrossRef] [PubMed]

- Yang, Z.; Zhao, X.; Tao, W.; Jin, C.; Huang, S.; Wang, Y.; Zhang, E. Comparative study on successive and simultaneous double-sided laser beam welding of AA6056/AA6156 aluminum alloy T-joints for aircraft fuselage panels. Int. J. Adv. Manuf. Technol. 2018, 97, 845–856. [Google Scholar] [CrossRef]

- Prasad, R.K.; Ramanaiah, N.; Viswanathan, N. Partially melted zone cracking in AA6061 welds. Mater. Des. 2008, 29, 179–186. [Google Scholar] [CrossRef]

- Li, F.; Feng, S.; Li, M.; Zhu, Y. Softening phenomenon of heat-affected zone in laser welding of 6082 Al alloys with filler wire. Chin. J. Lasers 2018, 45, 1102007. [Google Scholar]

| Materials | Si | Fe | Cu | Mn | Mg | Cr | Zn | Ti | Al |

|---|---|---|---|---|---|---|---|---|---|

| AA6082-T6 | 0.97 | 0.37 | 0.07 | 0.67 | 1.02 | 0.01 | 0.06 | 0.01 | Bal. |

| ER5356 | 0.10 | 0.4 | 0.1 | 0.15 | 4.8 | 0.1 | 0.1 | 0.13 | Bal. |

| Parameters | Laser-CMT Hybrid Welding | Plasma-CMT Hybrid Welding |

|---|---|---|

| Laser power/W | 2000 | |

| Plasma current/A | 130 | |

| Plasma voltage/V | 29 | |

| Plasma gas flow rate/l/min | 7 | |

| CMT current/A | 205 | 201 |

| CMT Voltage/V | 23 | 23 |

| Welding speed/m/min | 1.0 | 0.7 |

| Wire feeding speed/m/min | 12 | 9 |

| Welding Method | WA/mm | WL/WP/mm | DA/mm | DL/DP/mm | RF/mm | RB/mm |

|---|---|---|---|---|---|---|

| Laser-CMT | 7.48 | 3.46 | 2.97 | 2.99 | 0.76 | 1.61 |

| Plasma-CMT | 11.26 | 6.86 | 3.23 | 2.73 | 0.98 | 1.98 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xin, Z.; Yang, Z.; Zhao, H.; Chen, Y. Comparative Study on Welding Characteristics of Laser-CMT and Plasma-CMT Hybrid Welded AA6082-T6 Aluminum Alloy Butt Joints. Materials 2019, 12, 3300. https://doi.org/10.3390/ma12203300

Xin Z, Yang Z, Zhao H, Chen Y. Comparative Study on Welding Characteristics of Laser-CMT and Plasma-CMT Hybrid Welded AA6082-T6 Aluminum Alloy Butt Joints. Materials. 2019; 12(20):3300. https://doi.org/10.3390/ma12203300

Chicago/Turabian StyleXin, Zhibin, Zhibin Yang, Han Zhao, and Yuxin Chen. 2019. "Comparative Study on Welding Characteristics of Laser-CMT and Plasma-CMT Hybrid Welded AA6082-T6 Aluminum Alloy Butt Joints" Materials 12, no. 20: 3300. https://doi.org/10.3390/ma12203300

APA StyleXin, Z., Yang, Z., Zhao, H., & Chen, Y. (2019). Comparative Study on Welding Characteristics of Laser-CMT and Plasma-CMT Hybrid Welded AA6082-T6 Aluminum Alloy Butt Joints. Materials, 12(20), 3300. https://doi.org/10.3390/ma12203300