Microstructure and Mechanical Properties of Laser Welded Al-Si Coated Hot-Press-Forming Steel Joints

Abstract

1. Introduction

2. Experimental Procedures

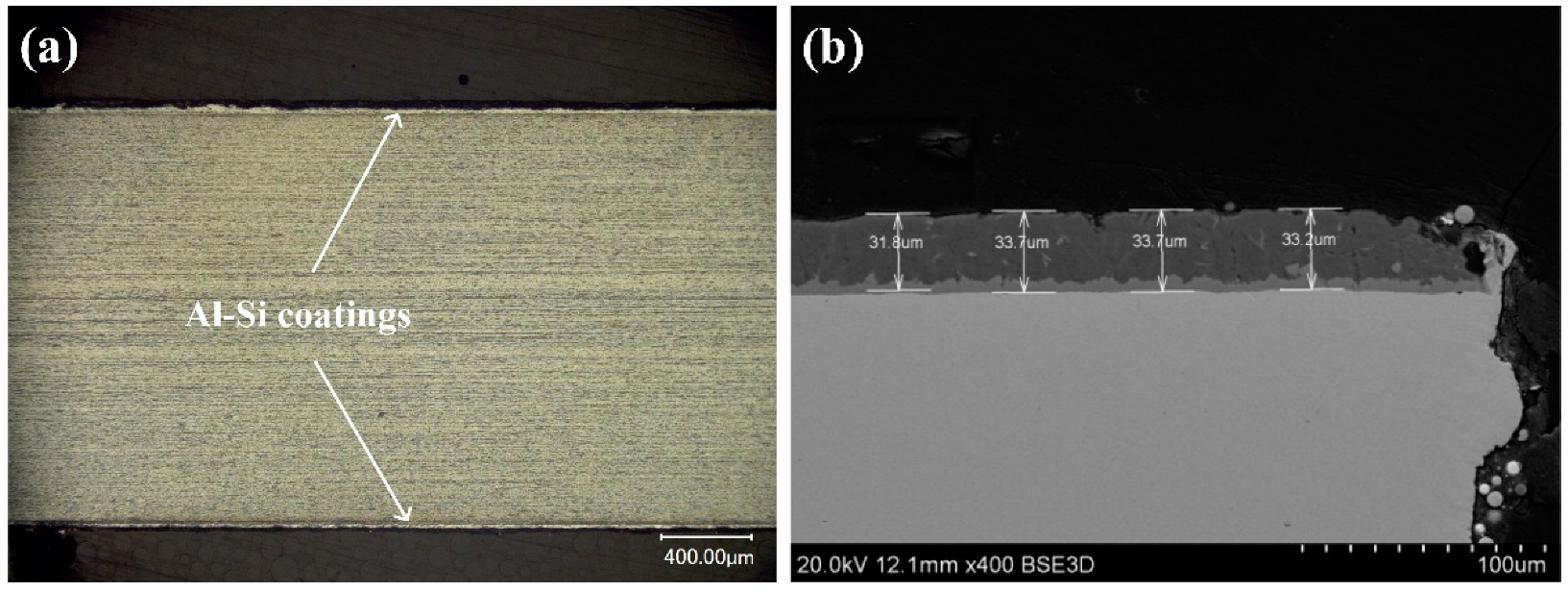

2.1. Materials

2.2. Welding Process

2.3. Microstructures and Chemical Compositions

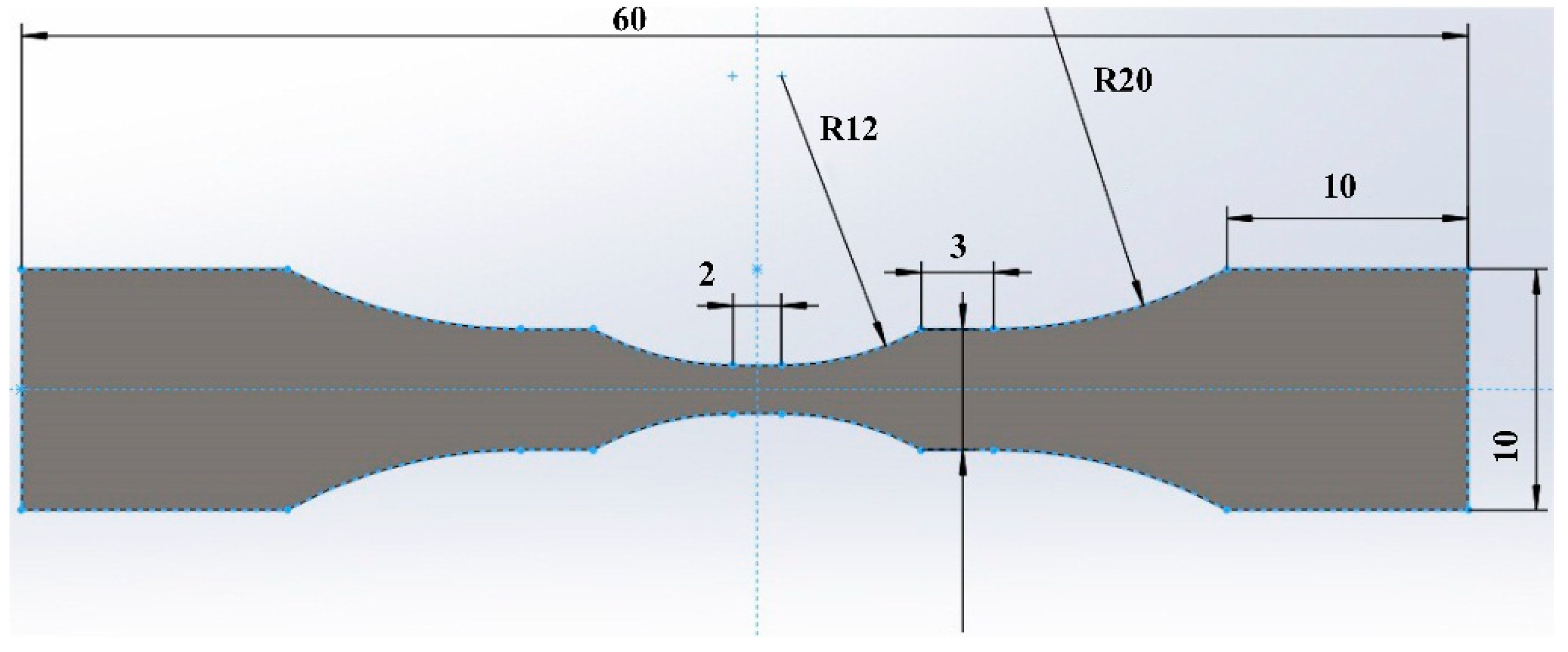

2.4. Mechanical Measurements

3. Results and Discussion

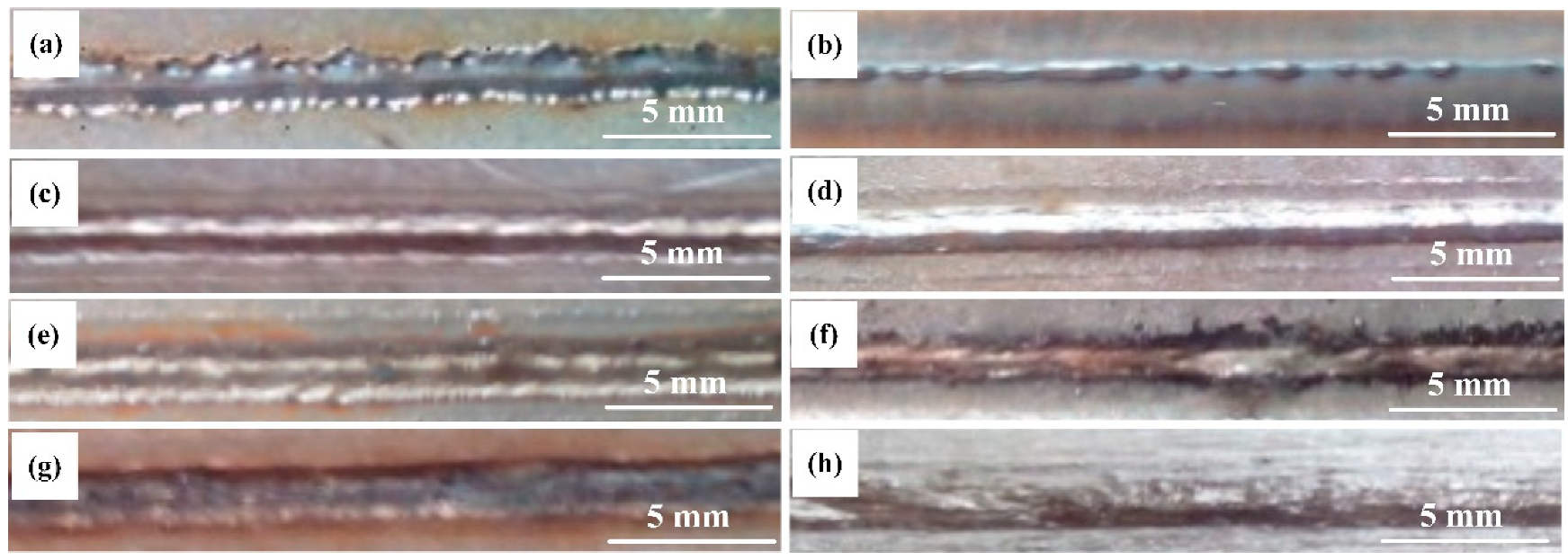

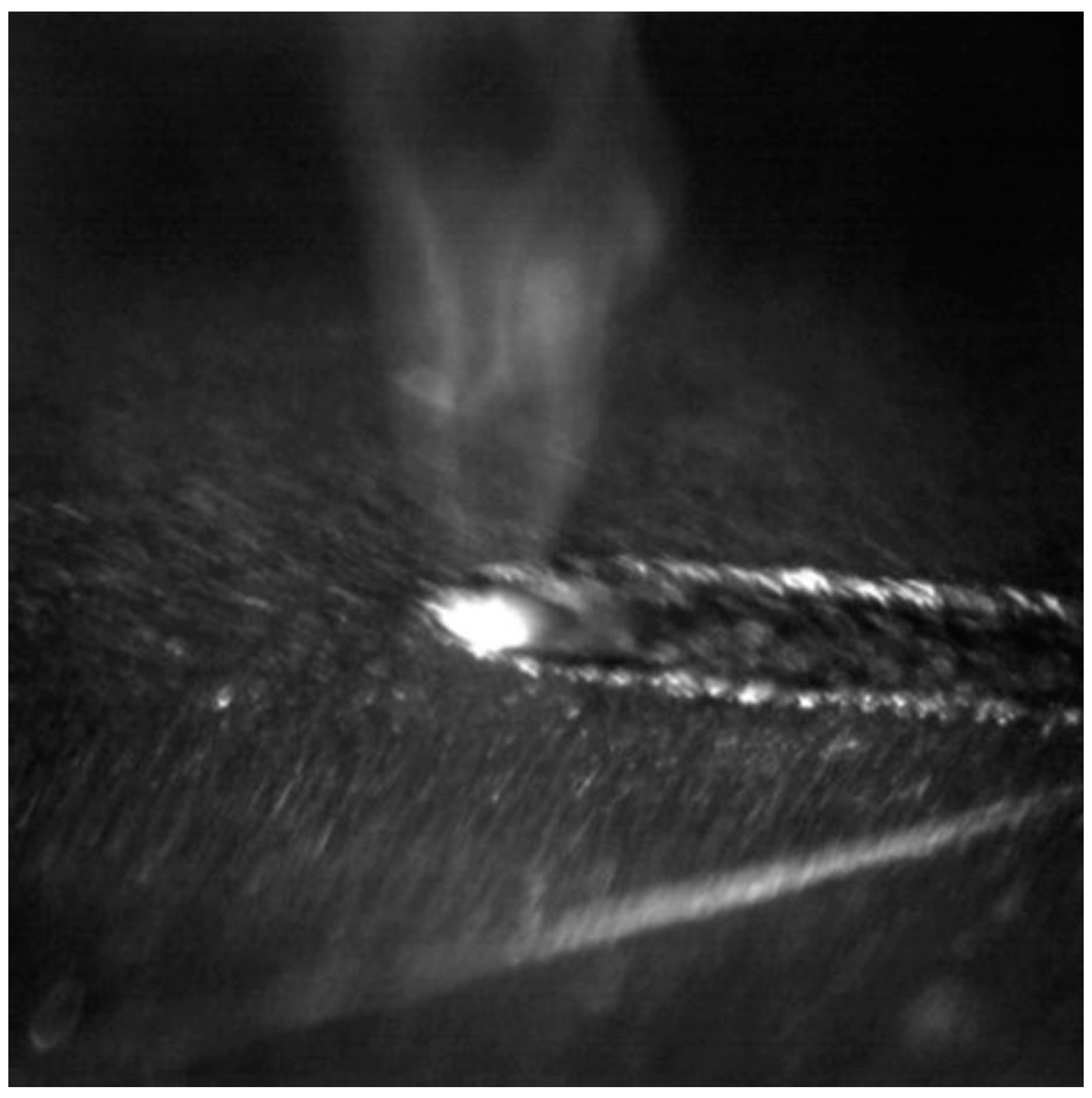

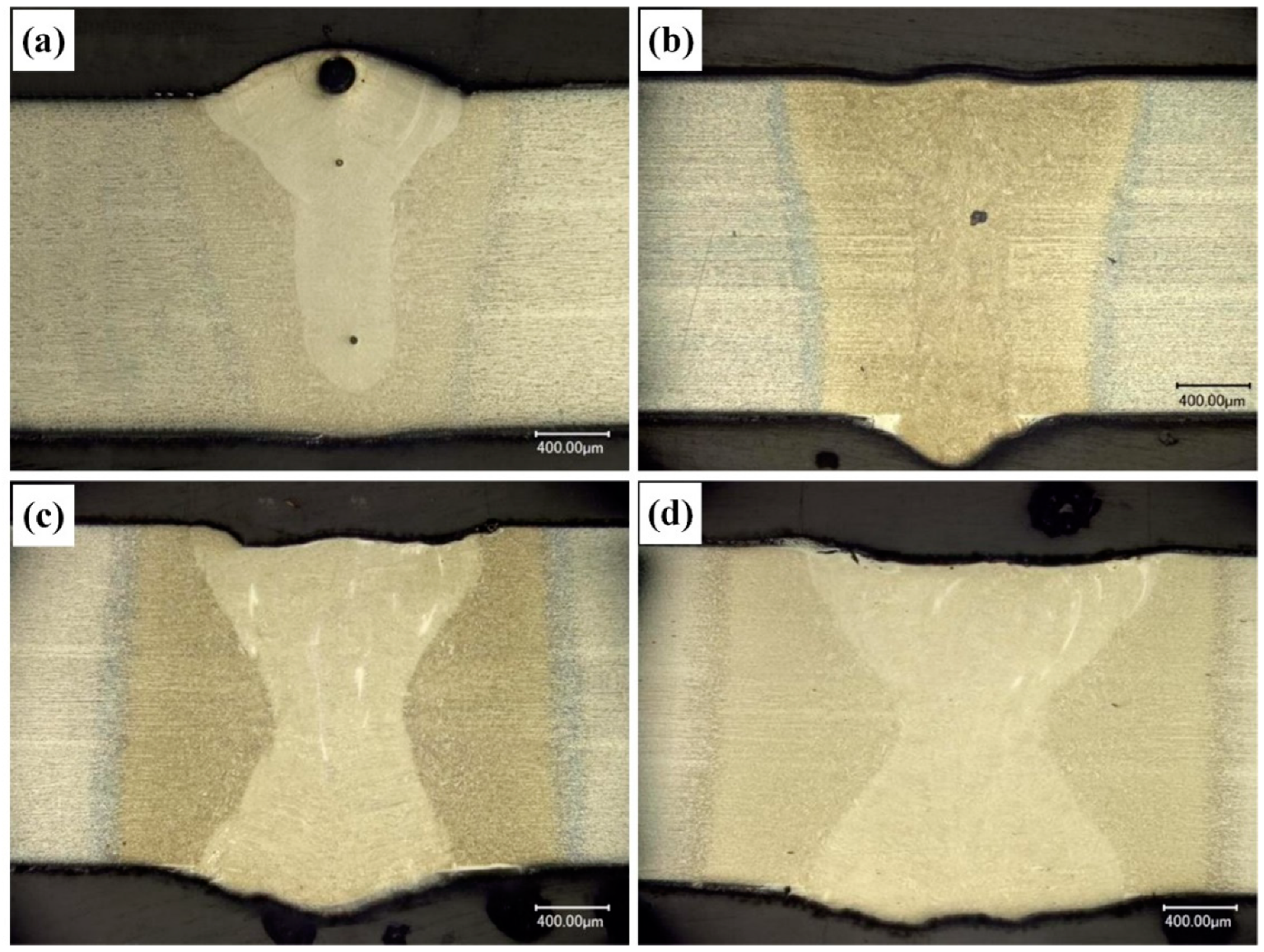

3.1. Weld Appearances

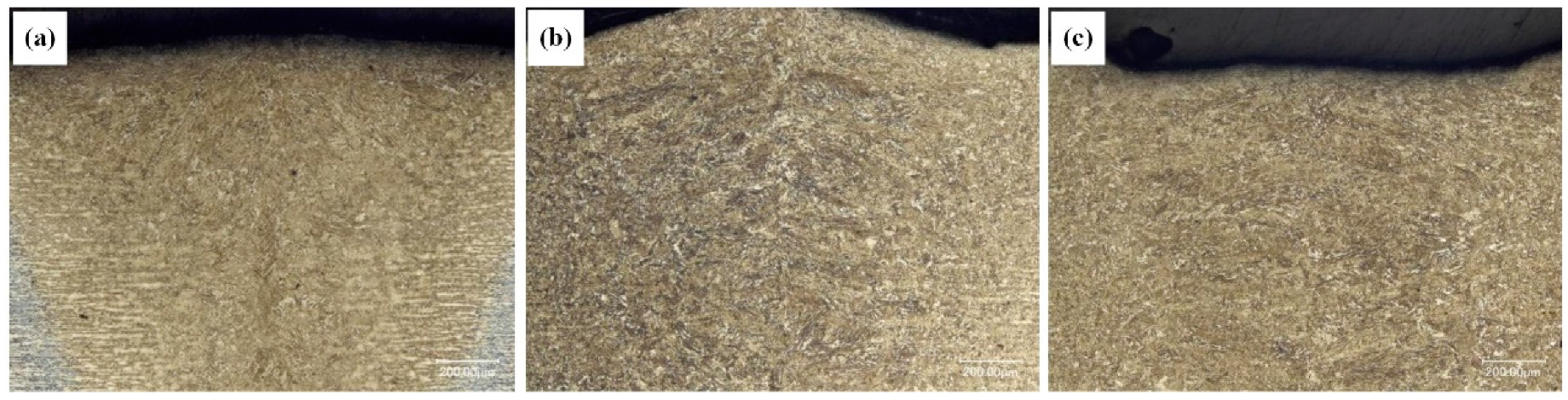

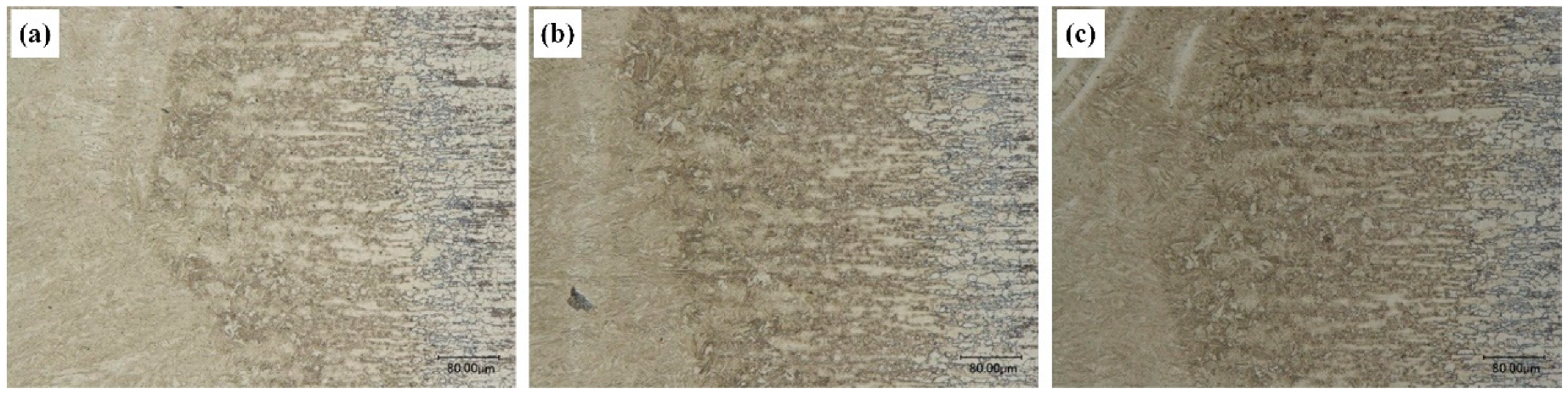

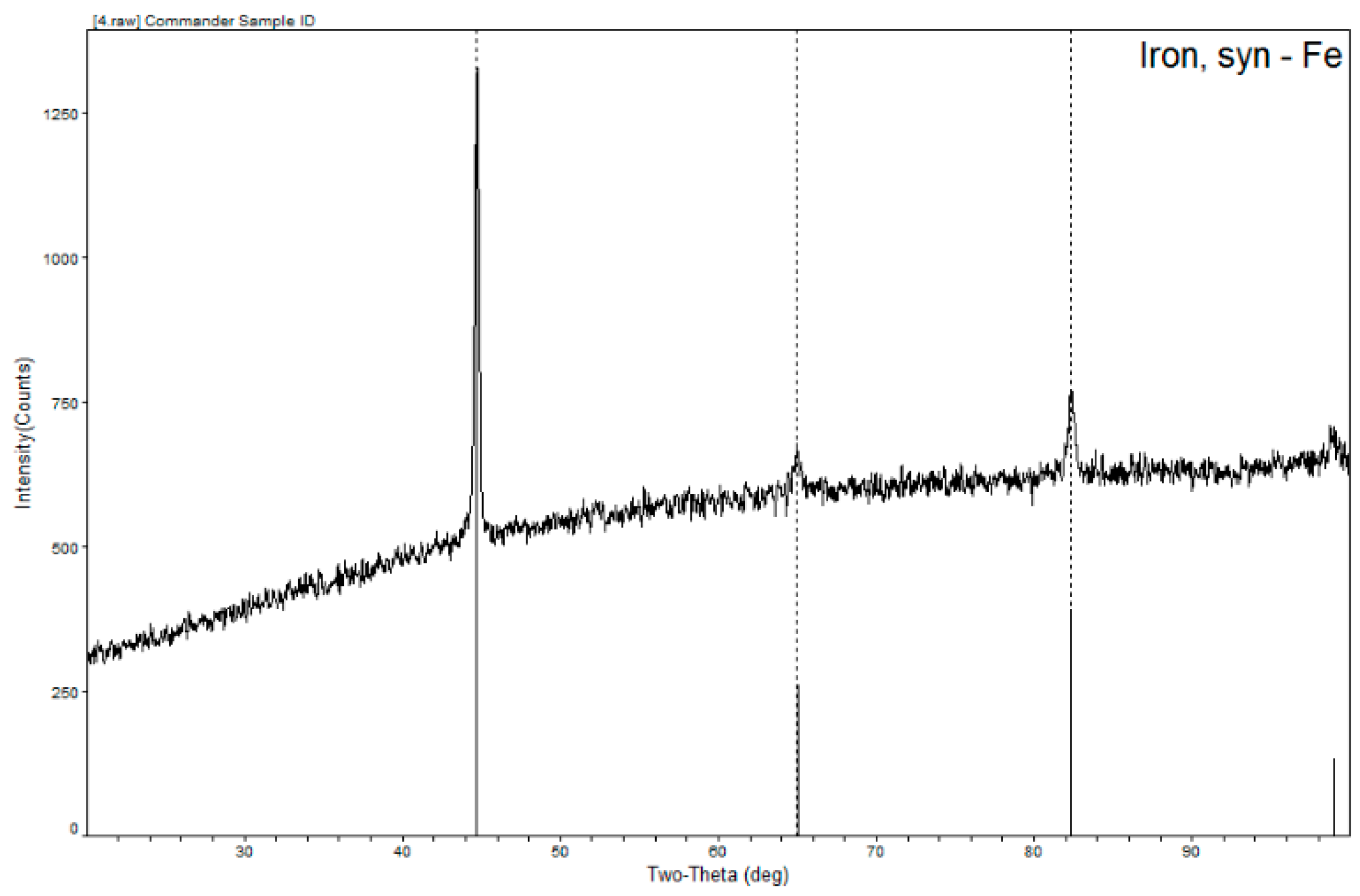

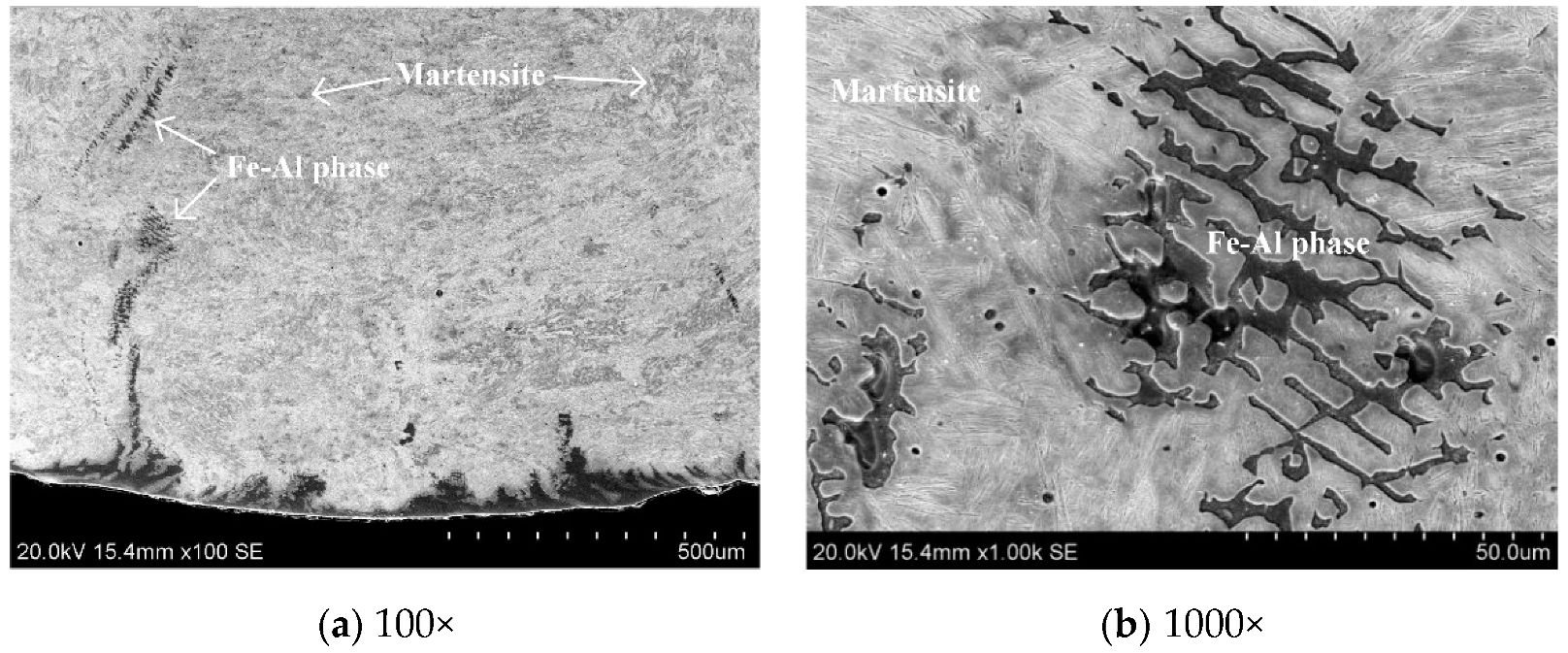

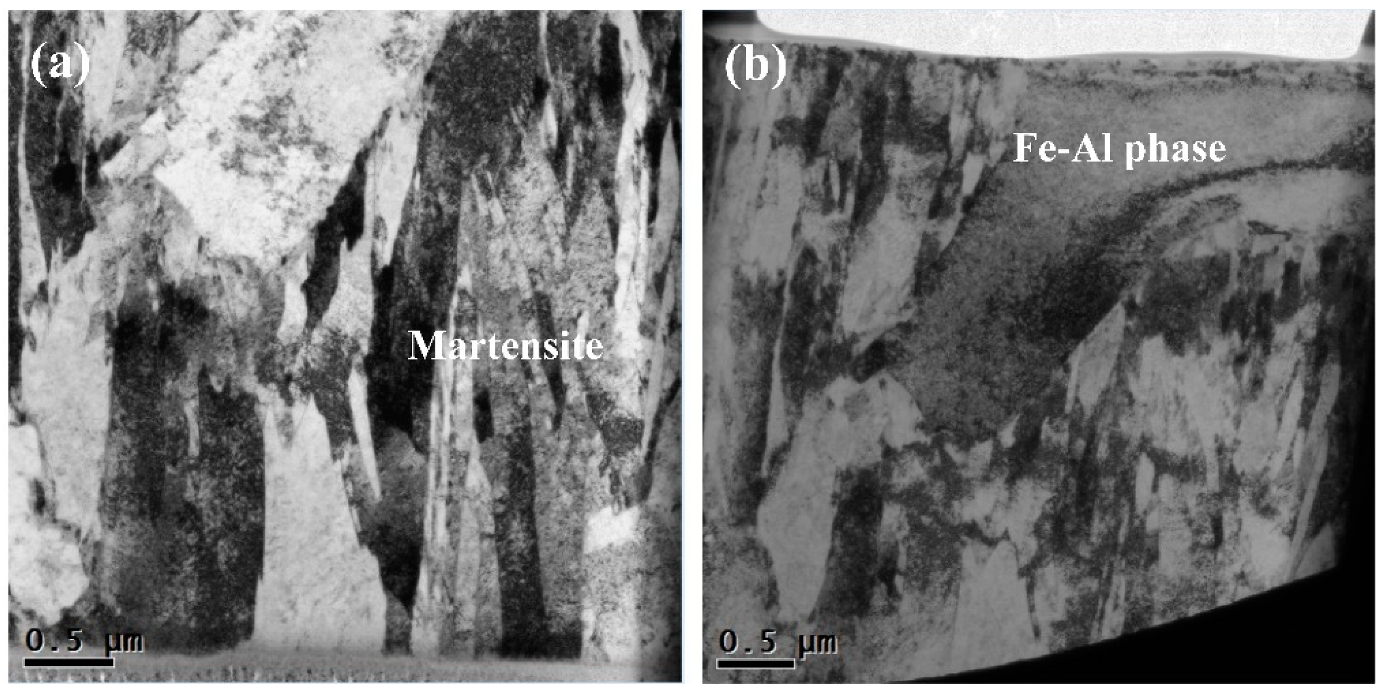

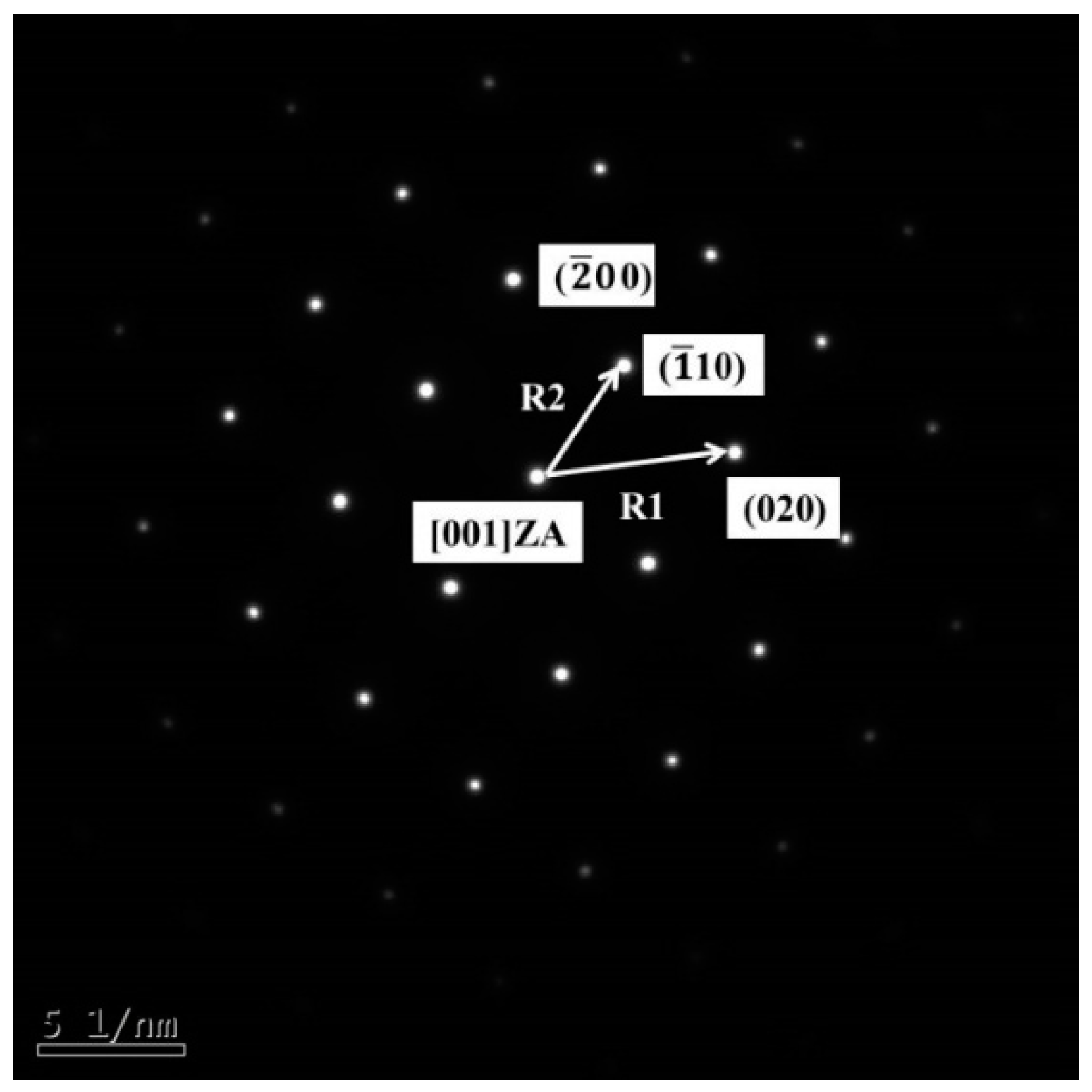

3.2. Crystallization Behavior and Microstructure Characteristics of the Joints

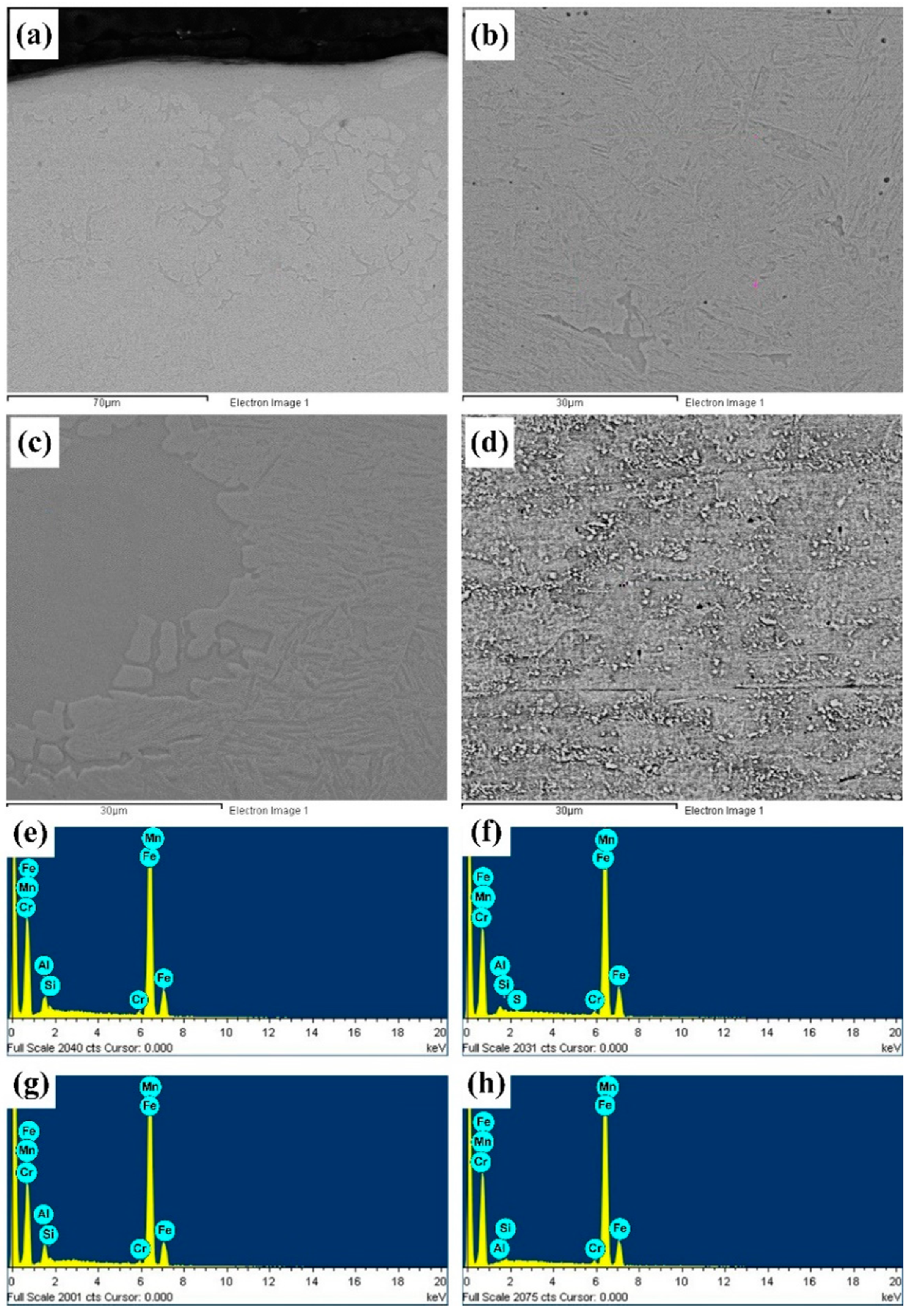

3.3. Chemical Compositions and Phase Analysis of the Joints

3.4. Hardness Values

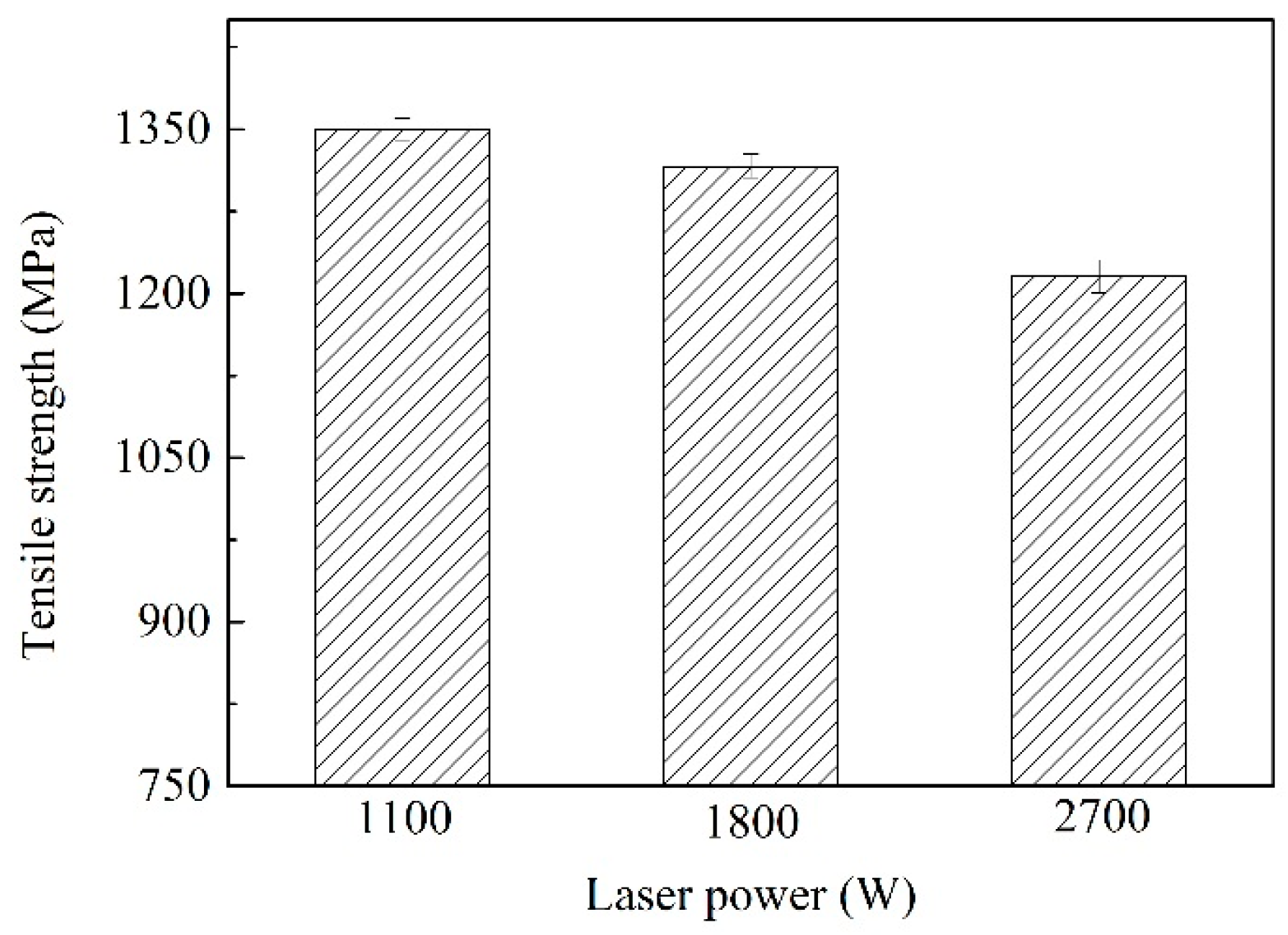

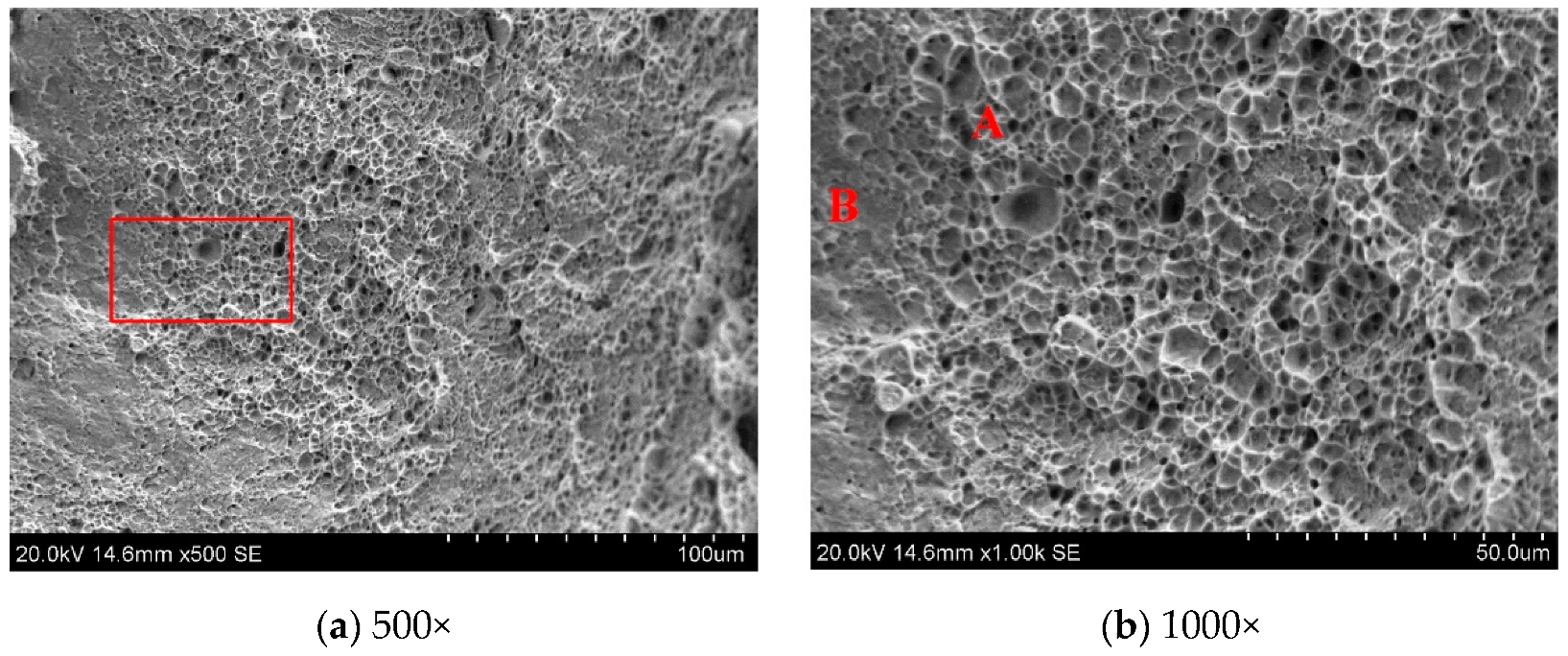

3.5. Tensile Strength

4. Conclusions

- The stability of laser welding on the Al-Si coated HPF steel was poor, and metal steam generated due to the burning loss of Al-Si coating was observed. At a laser power of 1.1 kW and a welding speed of 1.5 m/min, the formation of weld was the best.

- During the welding process, the Al-Si coating on the specimen surface was melted, and drawn into the weld. The generated Fe-Al phase was not uniformly distributed in the weld. According to selected area electron diffraction analysis, the Fe-Al phase was determined to be the solid solution of α-Fe and Al.

- The hardness in the Fe-Al phase distribution zone was lower (330.7 HV). The hardness in the middle weld was 484.4 HV, higher than that in the upper weld (459.8 HV) and lower weld (461.4 HV). When the laser power was 1.1 kW, the highest average hardness in the weld zone was 466.53 HV.

- As the laser power increased, the tensile property of weld showed a downward trend. When the laser power was 1.1 kW, the weld had the best tensile property, namely, 1349.9 MPa. Fracture pattern of welds was the quasi-cleavage fracture.

Author Contributions

Funding

Conflicts of Interest

References

- Xing, Z.W.; Bao, J.; Yang, Y.Y. Numerical simulation of hot stamping of quenchable boron steel. Mater. Sci. Eng. A 2009, 499, 28–31. [Google Scholar] [CrossRef]

- Lee, J.H.; Lee, G.M.; Yun, S.H. A study on the Fatigue Propeties of Boron Steel (AISI 51B20). J. Korean Soc. Precis. Eng. 2001, 18, 174–178. [Google Scholar]

- Kim, J.T.; Jeon, Y.P.; Kim, B.M.; Kang, C.G. Die design for a center pillar part by process analysis of hot stamping and its experimental verification. Int. J. Precis. Eng. Manuf. 2012, 13, 1501–1507. [Google Scholar] [CrossRef]

- Mohan Iyengar, R.; Fedewa, B.; Wang, Y.-W.; Maatz, D.F.; Hughes, R.L. Implications of Hot-Stamped Boron Steel Components in Automotive Structures. SAE Tech. Pap. 2008. [CrossRef]

- Choi, H.S.; Kim, B.M.; Park, G.H.; Lim, W.S.; Lee, S.B. Optimization of resistance spot weld condition for single lap joint of hot stamped 22MnB5 by taking heating temperature and heating time into consideration. Trans. Korean Soc. Mech. Eng. A 2010, 34, 1367–1375. [Google Scholar] [CrossRef]

- Karbasian, H.; Tekkaya, A.E. A review on hot stamping. J. Mater. Process. Technol. 2010, 210, 2103–2118. [Google Scholar] [CrossRef]

- Ghiotti, A.; Bruschi, S.; Sgarabotto, F.; Bariani, P.F. Tribological performances of Zn-based coating in direct hot stamping. Tribol. Int. 2014, 78, 142–151. [Google Scholar] [CrossRef]

- Park, T.J.; Kong, J.P.; Uhm, S.H.; Woo, I.S.; Lee, J.S.; Kang, C.Y. Effect of Al-Si coating layer on the penetration and microstructures of ferritic stainless steel, 409L GTA welds. J. Mater. Process. Technol. 2011, 211, 415–423. [Google Scholar] [CrossRef]

- Yoon, T.J.; Oh, M.H.; Shin, H.J.; Kang, C.Y. Comparison of microstructure and phase transformation of laser-welded joints in Al-10wt% Si-coated boron steel before and after hot stamping. Mater. Charact. 2017, 128, 195–202. [Google Scholar] [CrossRef]

- Pereira, A.B.; Santos, R.O.; Varvalho, B.S.; Butuc, M.C.; Vincze, G.; Moreiza, L.P. The Evaluation of Laser Weldability of the Third-Generation Advanced High Strength Steel. Metals 2019, 9, 1051. [Google Scholar] [CrossRef]

- Jokisch, T.; Marko, A.; Gook, S.; Üstündag, Ö.; Gumenyuk, A.; Rethmeier, M. Laser welding of SLM-manufactured tubes made of IN625 and IN718. Materials 2019, 12, 2967. [Google Scholar] [CrossRef] [PubMed]

- Zhang, J.J.; Hu, R.Z.; Pang, S.Y.; Huang, A.G. Distribution of Al Element of Ti-6Al-4V Joints by Fiber Laser Welding. Coatings 2019, 9, 566. [Google Scholar] [CrossRef]

- Guo, N.; Cheng, Q.; Zhang, X.; Fu, Y.L.; Huang, L. Microstructure and Mechanical Properties of Underwater Laser Welding of Titanium Alloy. Materials 2019, 12, 2703. [Google Scholar] [CrossRef] [PubMed]

- Üstündağ, Ö.; Avilov, V.; Gumenyuk, A.; Rethmeier, M. Improvement of Filler Wire Dilution Using External Oscillating Magnetic Field at Full Penetration Hybrid Laser-Arc Welding of Thick Materials. Metals 2019, 9, 594. [Google Scholar] [CrossRef]

- Spena, P.R.; Angelastro, A.; Casalino, G. Hybrid laser arc welding of dissimilar TWIP and DP high strength steel weld. J. Manuf. Processes 2019, 39, 233–240. [Google Scholar] [CrossRef]

- Xia, H.B.; Zhao, X.Y.; Tan, C.W.; Chen, B.; Song, X.G.; Li, L.Q. Effect of Si content on the interfacial reactions in laser welded-brazed Al/steel dissimilar butted joint. J. Mater. Process. Technol. 2018, 258, 9–21. [Google Scholar] [CrossRef]

- Zhao, X.Y.; Tan, C.W.; Xiao, L.Y.; Xia, H.B.; Chen, B.; Song, X.G.; Li, L.Q.; Feng, J.C. Effect of the Ni coating thickness on laser welding-brazing of Mg/steel. J. Alloys Compd. 2018, 769, 1042–1058. [Google Scholar] [CrossRef]

- Tan, C.W.; Zang, C.W.; Xia, H.B.; Zhao, X.Y.; Zhang, K.P.; Meng, S.H.; Chen, B.; Song, X.G.; Li, L.Q. Influence of Al additions in Zn-based filler metals on laser welding–brazing of Al/steel. J. Manuf. Processes 2018, 34, 251–263. [Google Scholar] [CrossRef]

- Choi, J.K.; Kim, J.K.; Shin, S.M.; Kim, C.H.; Rhee, S.H. A study on laser welding characteristics of 1500 MPa grade ultra high strength steel for automotive application. J. Korean Soc. Laser Process. 2010, 13, 19–26. [Google Scholar]

- Kim, C.; Kang, M.J.; Park, Y.D. Laser welding of Al-Si coated hot stamping steel. Procedia Eng. 2011, 10, 2226–2231. [Google Scholar] [CrossRef]

- Canourgues, J.F.; Pic, A.; Verrier, P.; Vierstraete, R.; Ehling, W.; Thommes, B. Plate. U.S. Patent 8,614,008, 24 December 2013. [Google Scholar]

- Moon, J.H.; Seo, P.K.; Kang, C.G. A study on mechanical properties of laser-welded blank of a boron sheet steel by laser ablation variable of Al-Si coating layer. Int. J. Precis. Eng. Manuf. 2013, 14, 283–288. [Google Scholar] [CrossRef]

- Li, F.; Chen, X.G.; Lin, W.H.; Pan, H.; Jin, X.; Hua, X.M. Nanosecond laser ablation of Al-Si coating on boron steel. Surf. Coat. Technol. 2017, 319, 129–135. [Google Scholar] [CrossRef]

- Kwon, M.S.; Kang, C.Y. Segregation and Microstructure in the Fusion zones of Laser joints of Al-10% Si coated Boron Steel. J. Korean Inst. Met. Mater. 2016, 54, 40–48. [Google Scholar]

- Kang, M.J.; Kim, Y.M.; Kim, C.H. Effect of heating parameters on laser welded tailored blanks of hot press forming steel. J. Mater. Process. Technol. 2016, 228, 137–144. [Google Scholar] [CrossRef]

| Parameter | Value |

|---|---|

| Laser power (kW) | 0.9–2.7 |

| Welding speed (m/min) | 1.5 |

| Focal length (mm) | 250 |

| Defocusing distance (mm) | −1 |

| Type of shielding gas | Ar |

| Gas flow (L/min) | 10–30 |

| Laser Power (kW) | Weld Penetration (mm) | Weld Width (mm) | Width of Heat Affect Zone (mm) |

|---|---|---|---|

| 0.9 | 1.72 | 1.61 | 1.82 |

| 1.1 | 2 | 1.58 | 1.96 |

| 1.8 | 2 | 1.69 | 2.34 |

| 2.7 | 2 | 1.92 | 2.80 |

| Locations | Al | Si | Mn | Fe |

|---|---|---|---|---|

| Top | 4.35 | 1.35 | 1.46 | 92.70 |

| Middle | 1.93 | 0.74 | 1.69 | 92.83 |

| Bottom | 4.89 | 0.92 | 1.23 | 92.90 |

| Base material | 0.00 | 0.53 | 1.54 | 97.53 |

| Position | Top | Middle | Bottom | Base Material | Fe-Al Phase |

|---|---|---|---|---|---|

| Average value | 459.8 HV | 484.4 HV | 461.4 HV | 185.3 HV | 330.7 HV |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, X.; Lei, Z.; Chen, Y.; Jiang, M.; Tian, Z.; Bi, J.; Lin, S. Microstructure and Mechanical Properties of Laser Welded Al-Si Coated Hot-Press-Forming Steel Joints. Materials 2019, 12, 3294. https://doi.org/10.3390/ma12203294

Chen X, Lei Z, Chen Y, Jiang M, Tian Z, Bi J, Lin S. Microstructure and Mechanical Properties of Laser Welded Al-Si Coated Hot-Press-Forming Steel Joints. Materials. 2019; 12(20):3294. https://doi.org/10.3390/ma12203294

Chicago/Turabian StyleChen, Xi, Zhenglong Lei, Yanbin Chen, Meng Jiang, Ze Tian, Jiang Bi, and Sanbao Lin. 2019. "Microstructure and Mechanical Properties of Laser Welded Al-Si Coated Hot-Press-Forming Steel Joints" Materials 12, no. 20: 3294. https://doi.org/10.3390/ma12203294

APA StyleChen, X., Lei, Z., Chen, Y., Jiang, M., Tian, Z., Bi, J., & Lin, S. (2019). Microstructure and Mechanical Properties of Laser Welded Al-Si Coated Hot-Press-Forming Steel Joints. Materials, 12(20), 3294. https://doi.org/10.3390/ma12203294