Autogenous Shrinkage, Microstructure, and Strength of Ultra-High Performance Concrete Incorporating Carbon Nanofibers

Abstract

:1. Introduction

2. Experimental Investigation

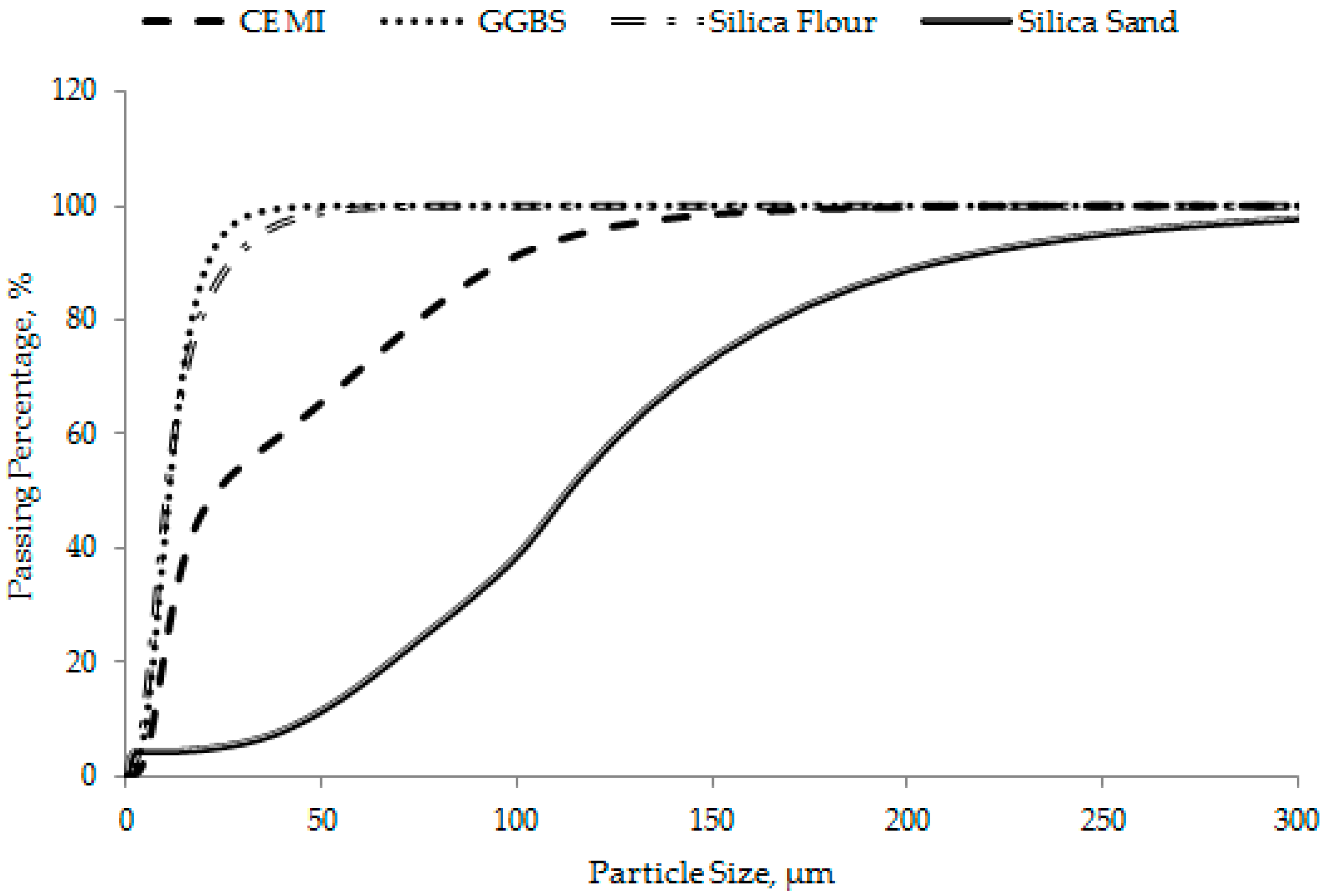

2.1. Constituent Materials and Concrete Mixes

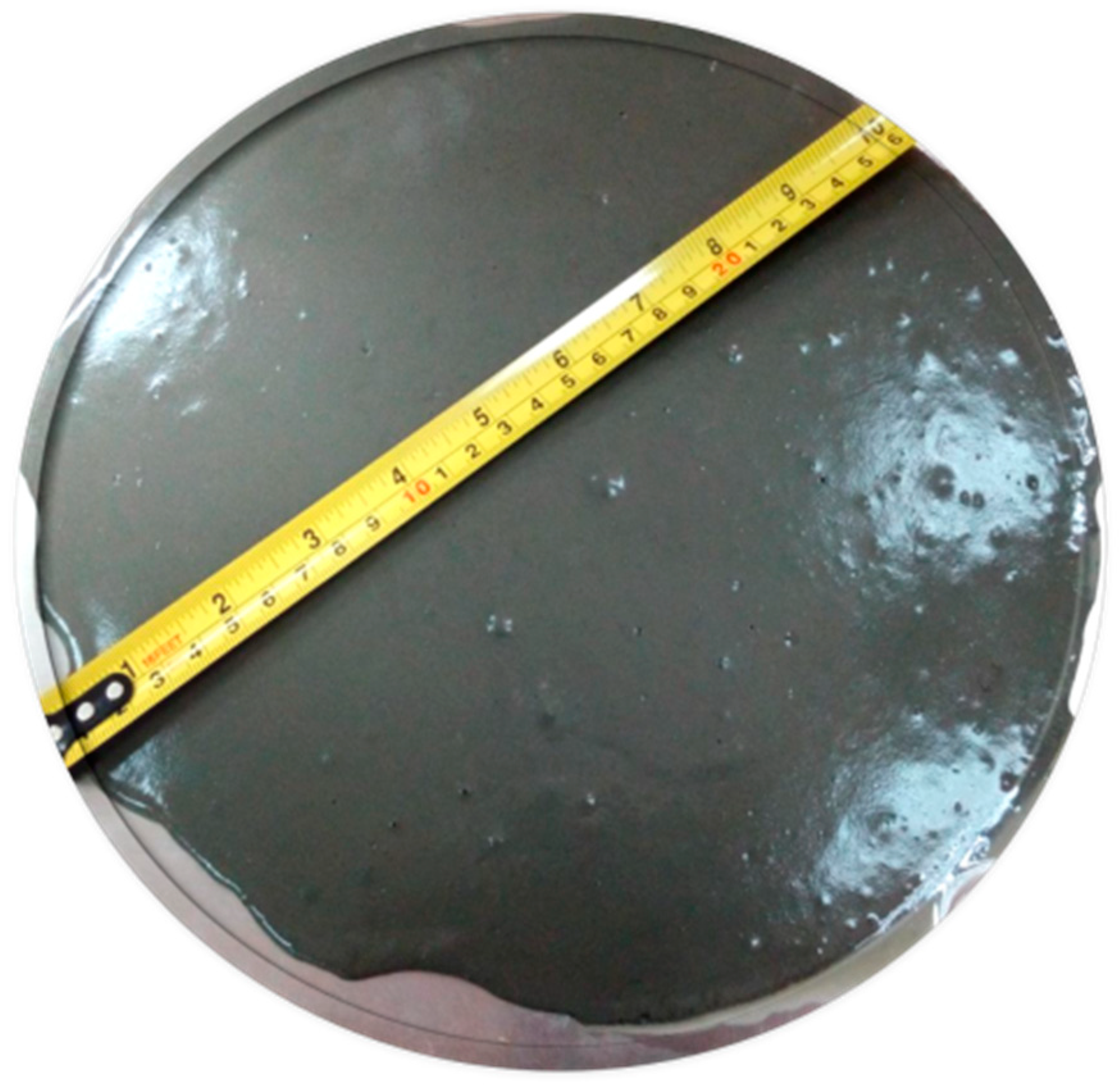

2.2. Flow Table Test

2.3. Compression Test

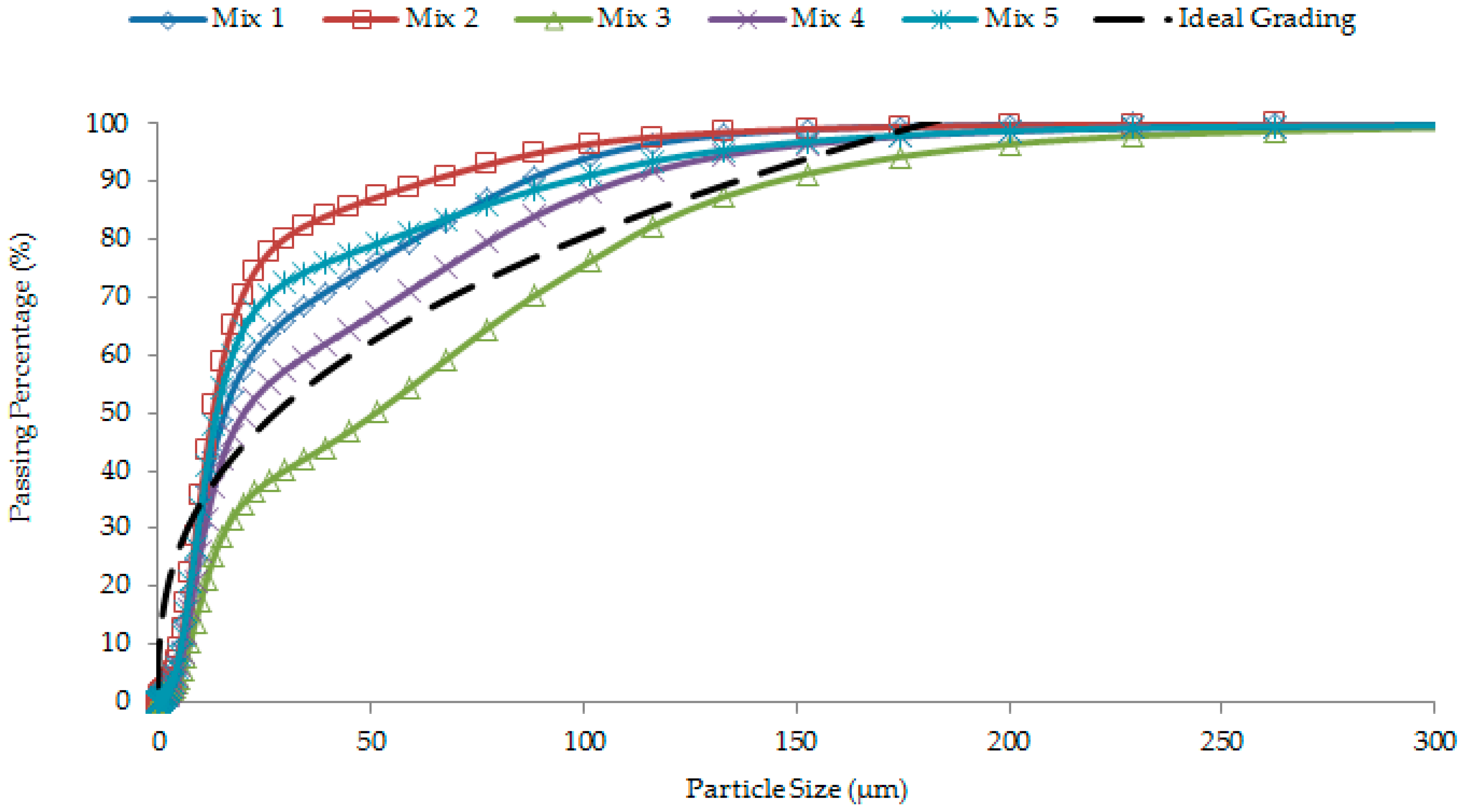

2.4. Optimization of Particle Packing

2.5. One-Dimensional Autogenous Shrinkage Test

2.6. Image Analysis for Entrapped Air

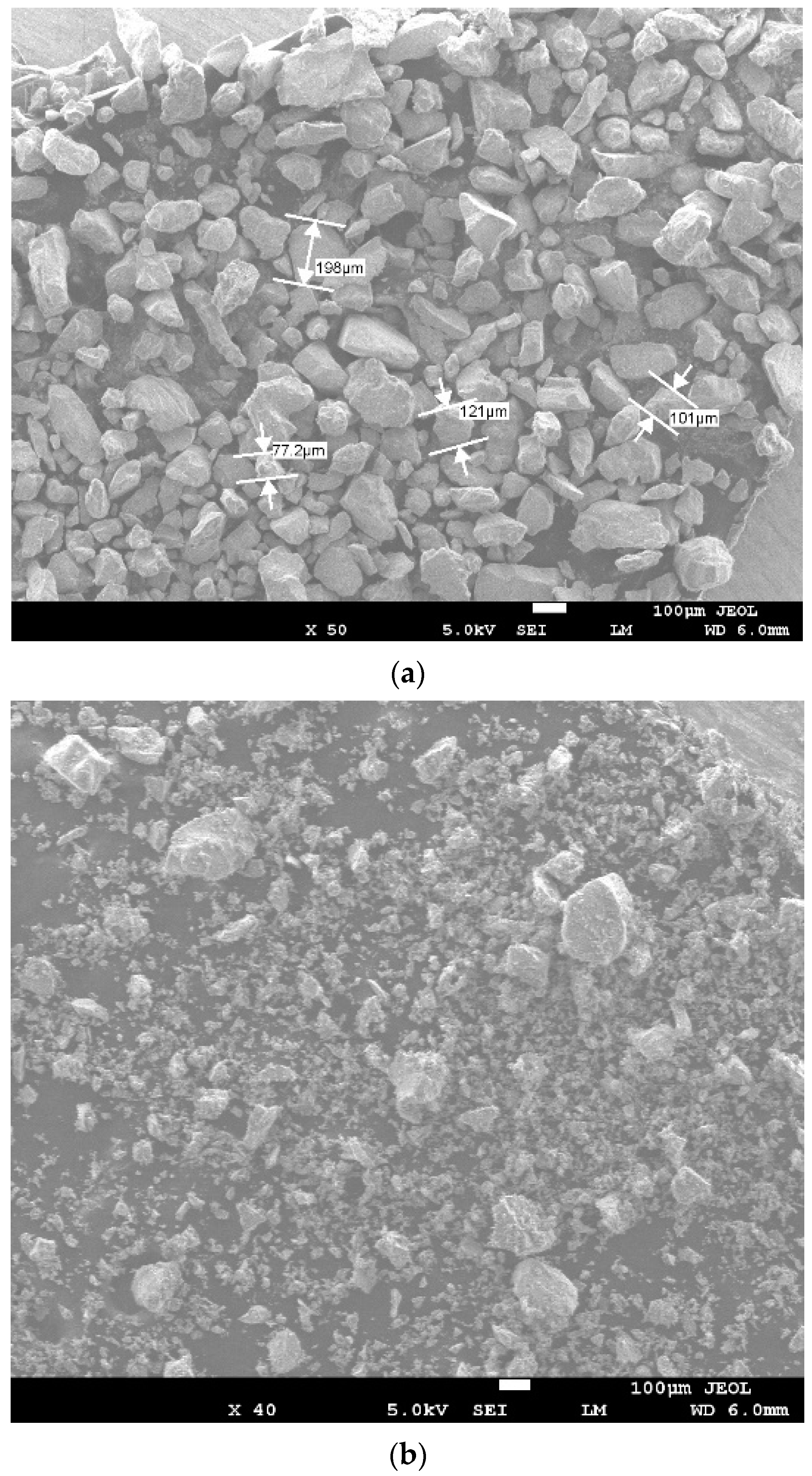

2.7. Microstructural/Nanostructural Analysis

3. Results and Discussion

3.1. Flowability of UHPC

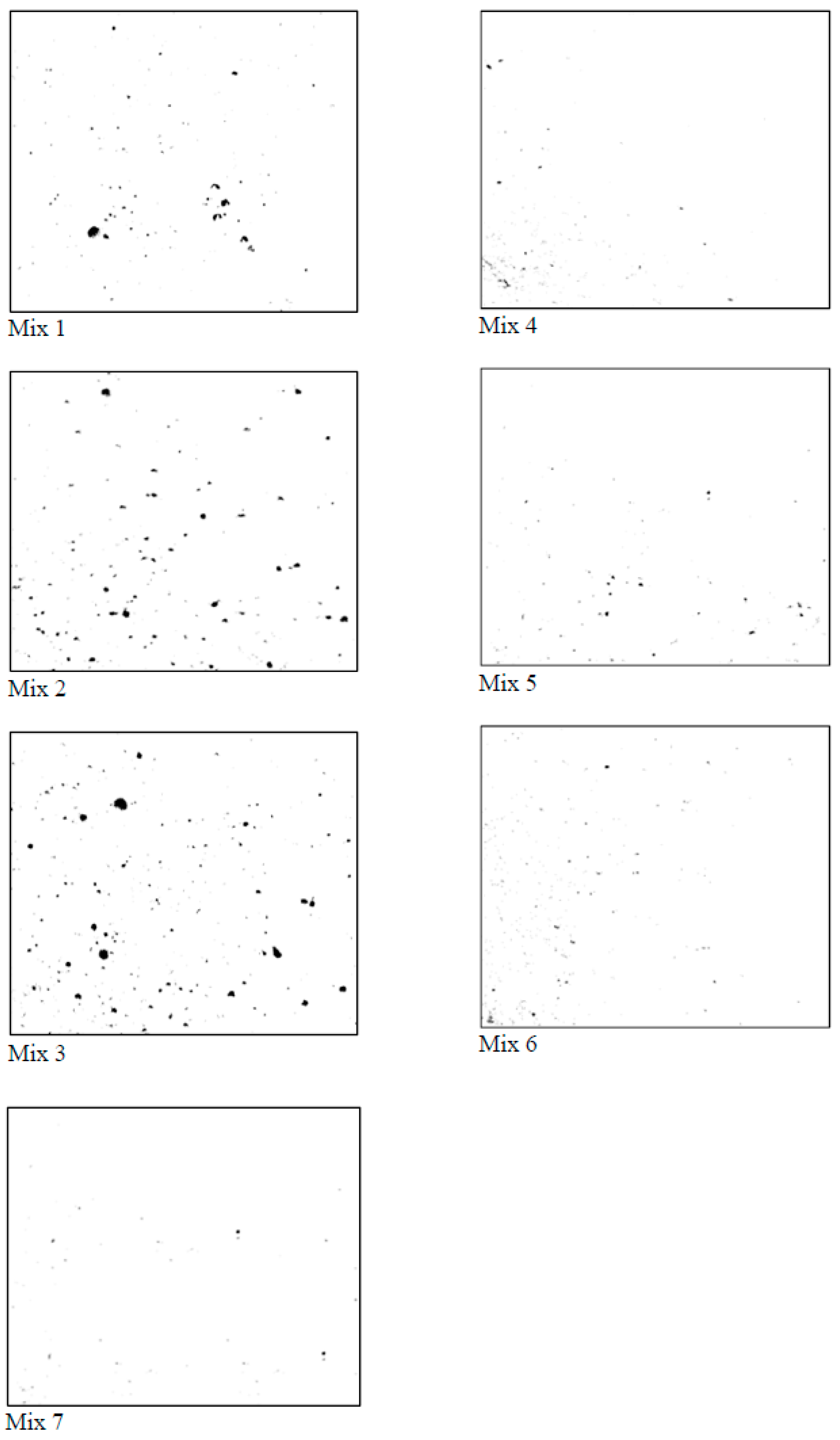

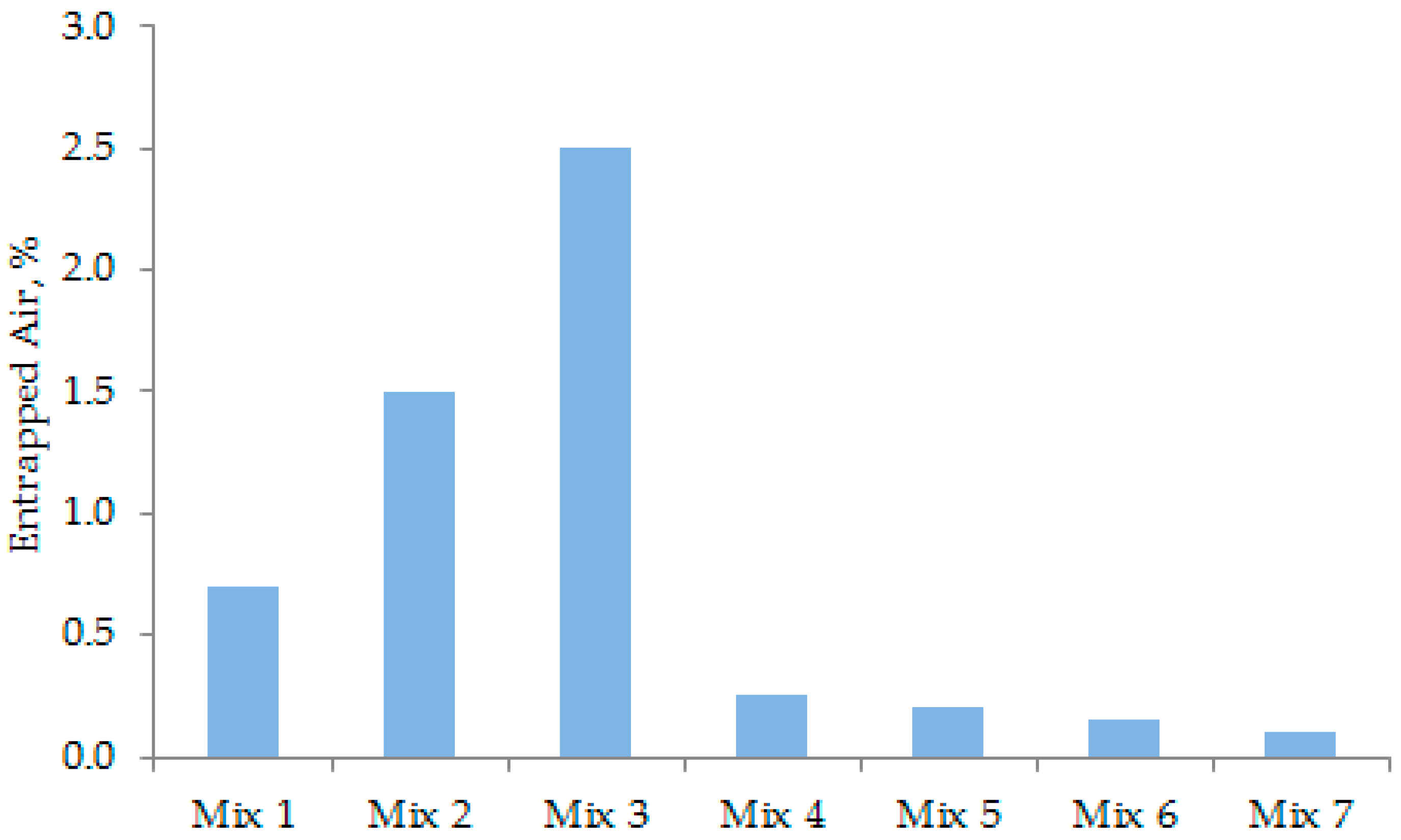

3.2. Entrapped Air of UHPC

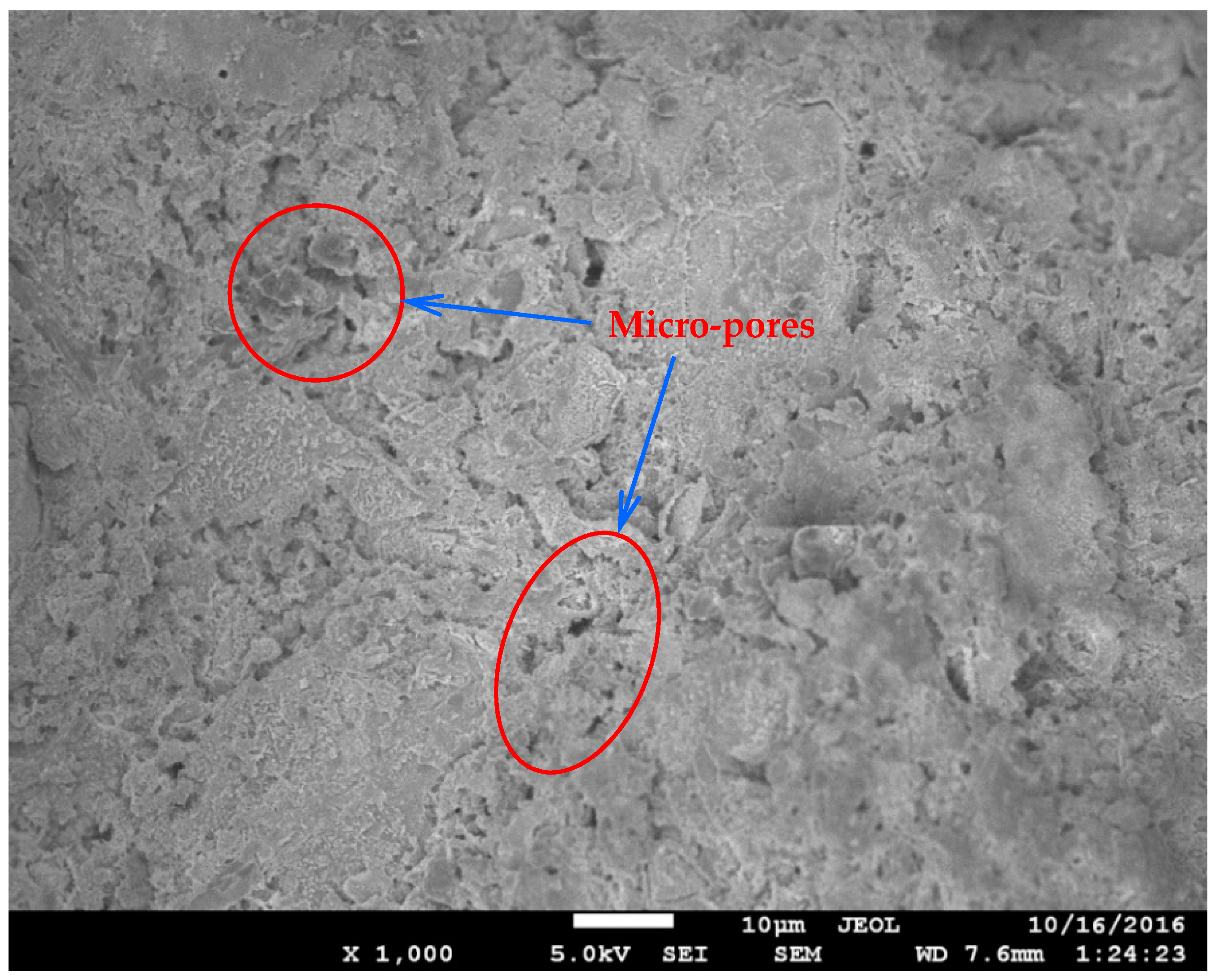

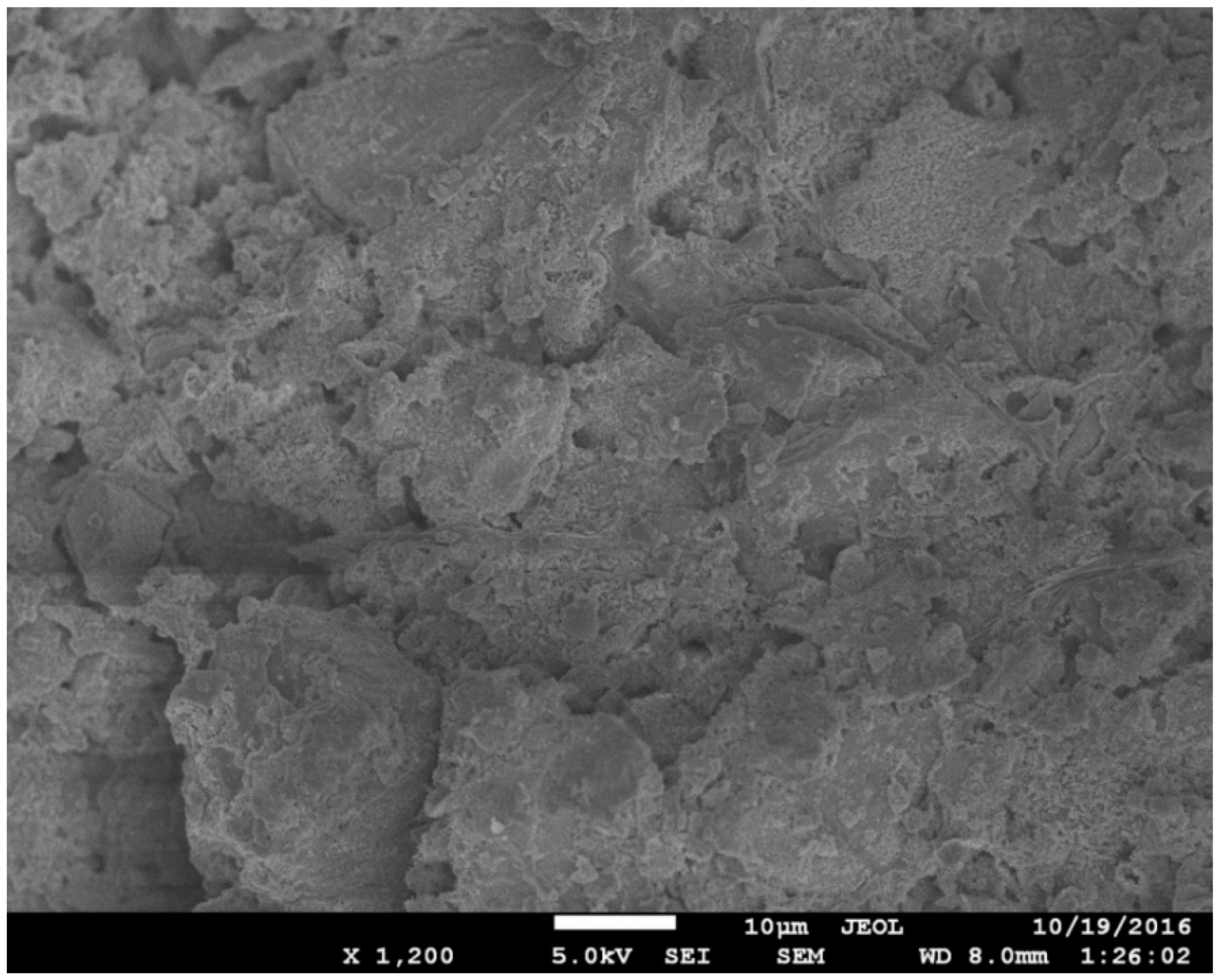

3.3. Microstructure/Nanostructure of UHPC

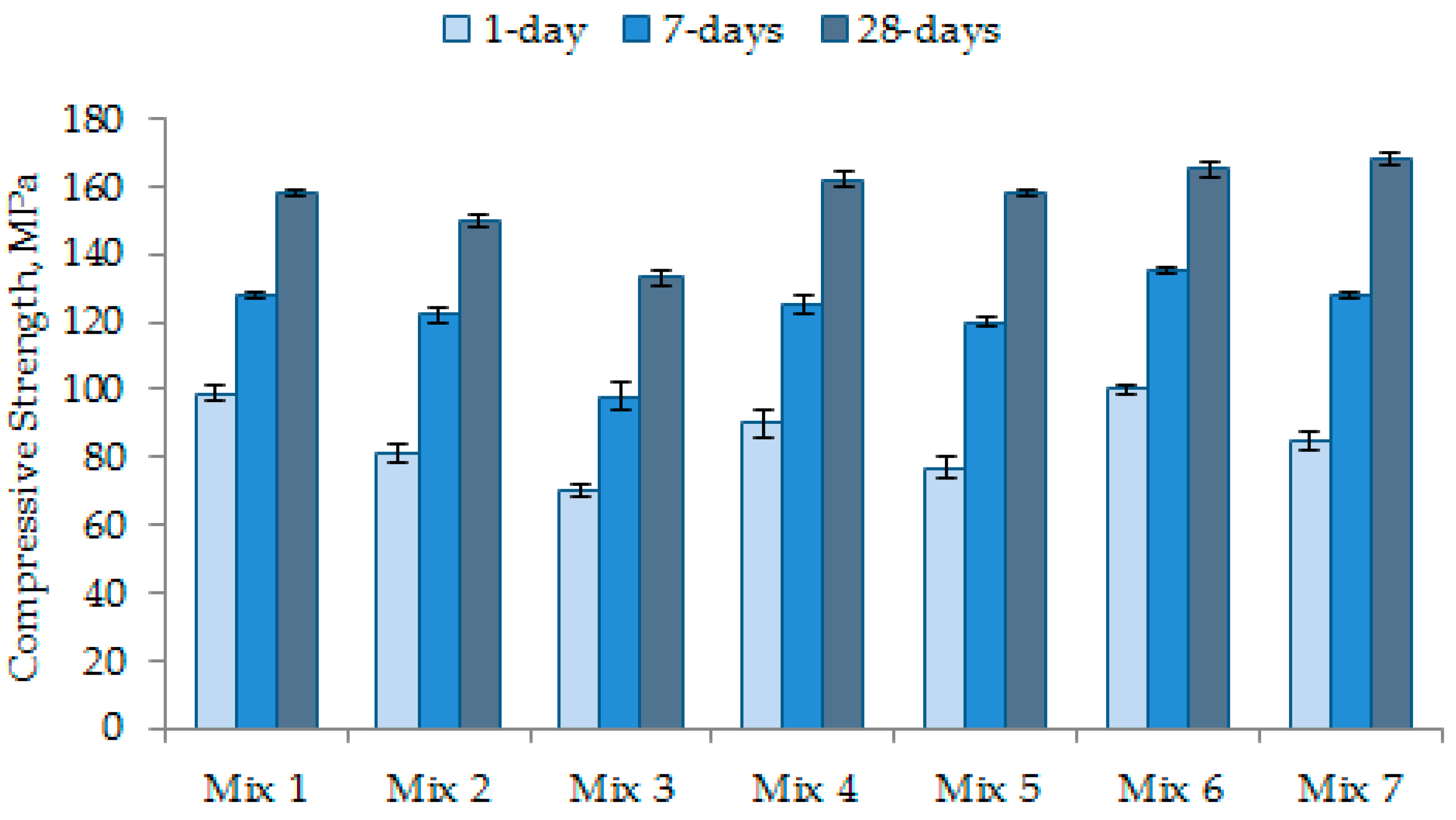

3.4. Strength Development of UHPC

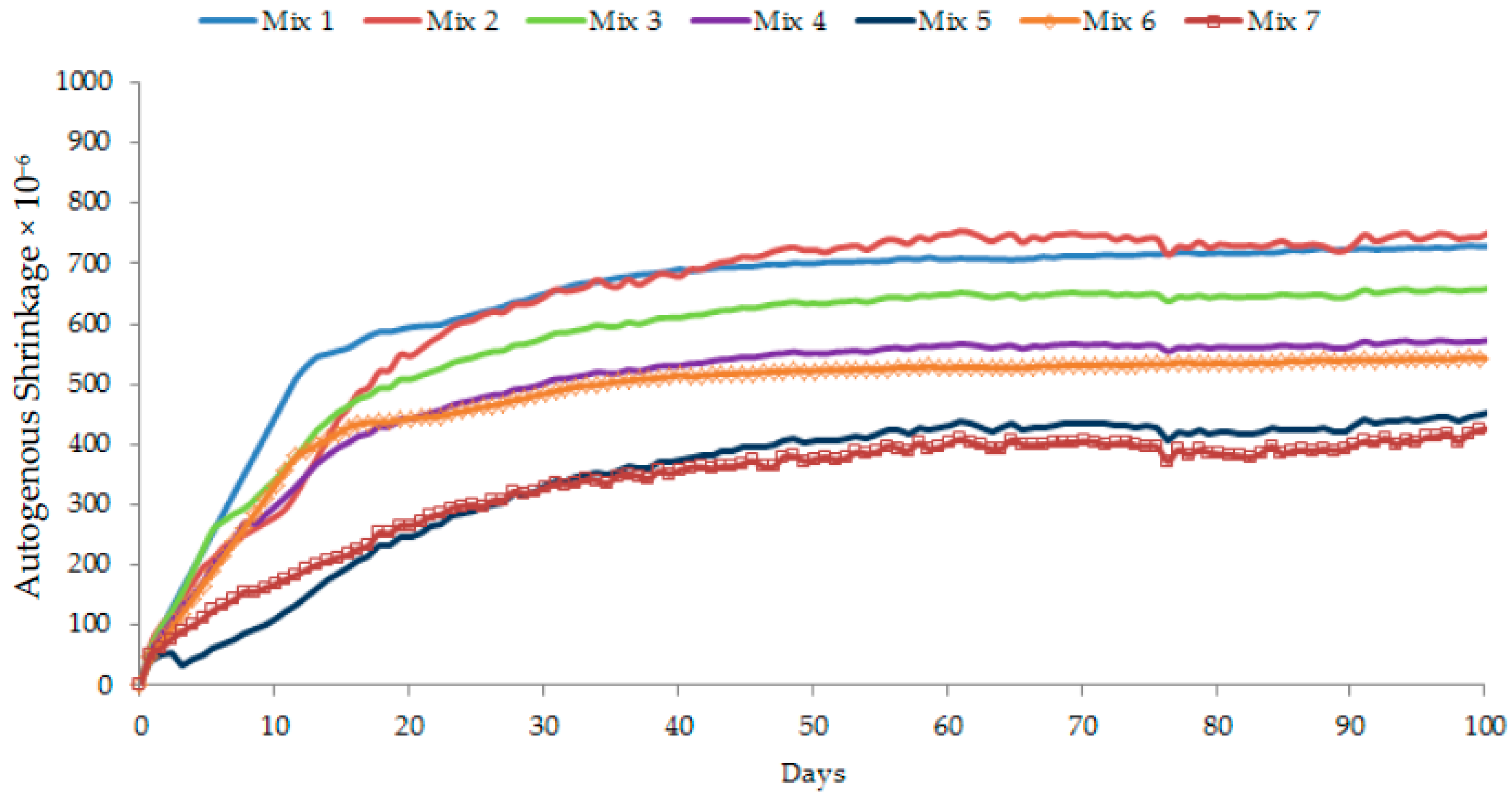

3.5. Autogenous Shrinkage of UHPC

4. Conclusions

- The flow or flowability of concrete mix directly indicates its entrapped air content. A higher flowability contributes to reducing the entrapped air in concrete.

- The higher entrapped air content decreases the compressive strength as the air-voids act as a weak link in stress transfer.

- The ideal particle distribution, which is close to the modified Andreasen and Andersen grading greatly contributes to achieving high compressive strength.

- The fine particle grading increases the autogenous shrinkage in the matrix of concrete due to a greater specific surface area and more fine pores.

- CNFs provide nano-bridges in fine cracks to compensate the autogenous shrinkage caused by silica flour.

- CNFs improve the microstructure or nanostructure of the overall matrix in concrete through good dispersion and uniform distribution of the nanofibers.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lim, J.L.G.; Raman, S.N.; Hamid, R.; Zain, M.F.M.; Lai, F.C. Synthesis of ultra-high performance cementitious composite incorporating carbon nanofibers. In Proceedings of the 6th International Conference on Structural Engineering and Construction Management, Kandy, Sri Lanka, 11–13 December 2015; pp. 8–13. [Google Scholar]

- Wille, K.; Naaman, A.E.; Parra-Montesinos, G.J. Ultra-high performance concrete with compressive strength exceeding 150 MPa (22 ksi): A simpler way. ACI Mater. J. 2011, 108, 46–54. [Google Scholar]

- Raman, S.N. New generation concrete in construction: 150 MPa and beyond. In Between: Form + Being; Mohamed, M.F., Raman, S.N., Eds.; Faculty of Engineering and Built Environment, UKM: Bangi, Malaysia, 2012; pp. 120–123. [Google Scholar]

- Prem, P.R.; Bharatkumar, B.H.; Iyer, N.R. Mechanical properties of ultra-high performance concrete. Int. J. Civ. Environ. Struct. Constr. Arch. Eng. 2012, 6, 676–685. [Google Scholar]

- Acker, P.; Behloul, M. Ductal® technology: A large spectrum of properties, a wide range of applications. In Proceedings of the International Symposium on Ultra High Performance Concrete, Kassel, Germany, 13–15 September 2004; pp. 11–23. [Google Scholar]

- Graybeal, B.; Davis, M. Cylinder or cube: Strength testing of 80 to 200 MPa (116 to 29 ksi) ultra-high-performance-fiber-reinforced concrete. ACI Mater. J. 2008, 105, 603–609. [Google Scholar]

- Golewski, G.L. Generalized fracture toughness and compressive strength of sustainable concrete including low calcium fly ash. Materials 2017, 10, 1393. [Google Scholar] [CrossRef] [PubMed]

- Tazawa, E.; Miyazawa, S. Influence of cement and admixture on autogenous shrinkage of cement paste. Cem. Concr. Res. 1995, 25, 281–287. [Google Scholar] [CrossRef]

- Brouwers, H.J.H.; Radix, H.J. Self-compacting concrete: Theoretical and experimental study. Cem. Concr. Res. 2005, 35, 2116–2136. [Google Scholar] [CrossRef]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Effect of nano-silica on the hydration and microstructure development of ultra-high performance concrete (UHPC) with a low binder amount. Constr. Build. Mater. 2014, 65, 140–150. [Google Scholar] [CrossRef]

- Fennis, S.A.A.M.; Walraven, J.C.; den Uijl, J.A. The use of particle packing models to design ecological concrete. Heron 2009, 54, 185–204. [Google Scholar]

- Wei, Y.; Hansen, W.; Biernacki, J.J.; Schlangen, E. Unified shrinkage model for concrete from autogenous shrinkage test on paste with and without ground-granulated blast-furnace slag. ACI Mater. J. 2011, 108, 13–20. [Google Scholar]

- Jiang, C.; Yang, Y.; Wang, Y.; Zhou, Y.; Ma, C. Autogenous shrinkage of high performance concrete containing mineral admixtures under different curing temperatures. Constr. Build. Mater. 2014, 61, 260–269. [Google Scholar] [CrossRef]

- Lim, S.N.; Wee, T.H. Autogenous shrinkage of ground granulated blast furnace slag concrete. ACI Mater. J. 2000, 97, 587–593. [Google Scholar]

- Meng, W.; Khayat, K.H. Mechanical properties of ultra-high-performance concrete enhanced with graphite nanoplatelets and carbon nanofibers. Compos. B Eng. 2016, 107, 113–122. [Google Scholar] [CrossRef]

- Li, W.W.; Ji, W.M.; Wang, Y.C.; Liu, Y.; Shen, R.X.; Xing, F. Investigation on the mechanical properties of a cement-based material containing carbon nanotube under drying and freeze-thaw conditions. Materials 2015, 8, 8780–8792. [Google Scholar] [CrossRef] [PubMed]

- Iijima, S. Helical microtubules of graphitic carbon. Nature 1991, 354, 56–58. [Google Scholar] [CrossRef]

- Lim, J.L.G.; Raman, S.N.; Lai, F.C.; Zain, M.F.M.; Hamid, R. Synthesis of nano cementitious additives from agricultural wastes for the production of sustainable concrete. J. Clean. Prod. 2017, 171, 1150–1160. [Google Scholar] [CrossRef]

- Siddique, R.; Mehta, A. Effect of carbon nanofibers on properties of cement mortars. Constr. Build. Mater. 2014, 50, 116–129. [Google Scholar] [CrossRef]

- Collins, F.; Lambert, J.; Duan, W.H. The influences of admixtures on the dispersion, workability, and strength of carbon nanotubes-OPC paste mixtures. Cem. Concr. Compos. 2012, 34, 201–207. [Google Scholar] [CrossRef]

- Chen, Z.; Lim, J.L.G.; Yang, E.H. Ultra high performance cement-based composites incorporating low dosage of plasma synthesized carbon nanofibers. Mater. Des. 2016, 108, 479–487. [Google Scholar] [CrossRef]

- Shimoda, K.; Hinoki, T.; Kohyama, A. Effect of carbon nanofibers (CNFs) content on thermal and mechanical properties of CNFs/SiC nanocomposites. Compos. Sci. Technol. 2010, 70, 387–392. [Google Scholar] [CrossRef]

- Ardanuy, M.; Rodríguez-Perez, M.A.; Algaba, I. Electrical conductivity and mechanical properties of vapor-grown carbon nanofibers/trifunctional epoxy composites prepared by direct mixing. Compos. Part B 2011, 42, 675–681. [Google Scholar] [CrossRef]

- Wang, H.; Gao, X.; Liu, J.; Ren, M.; Lu, A. Multi-functional properties of carbon nanofiber reinforced reactive powder concrete. Constr. Build. Mater. 2014, 187, 699–707. [Google Scholar] [CrossRef]

- Wu, L.; Farzadnia, N.; Shi, C.; Zhang, Z.; Wang, H. Autogenous shrinkage of high performance concrete: A review. Constr. Build. Mater. 2017, 149, 62–75. [Google Scholar] [CrossRef]

- Kim, G.M.; Yoon, H.N.; Lee, H.K. Autogenous shrinkage and electrical characteristics of cement pastes and mortars with carbon nanotube and carbon fiber. Constr. Build. Mater. 2018, 177, 428–435. [Google Scholar] [CrossRef]

- Yehia, M.M.; Ihsanullah, A.S.; Al-Ansari, T.; Atieh, M.A. A review of carbon nanomaterials’ synthesis via the chemical vapor deposition (CVD) method. Materials 2018, 11, 822. [Google Scholar]

- ASTM International. ASTM C230/C230M-14. Standard Specification for Flow Table for Use in Tests of Hydraulic Cement; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- ASTM International. ASTM C109/C109M-16. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar]

- Yu, R.; Spiesz, P.; Brouwers, H.J.H. Development of an eco-friendly ultra-high performance concrete (UHPC) with efficient cement and mineral admixtures uses. Cem. Concr. Compos. 2015, 55, 383–394. [Google Scholar] [CrossRef]

- Chini, A.R.; Villavicencio, E.J. Detection of microcracks in concrete cured at elevated temperature. In Proceedings of the International Conference on Recent Advances in Concrete Technology, Washington, DC, USA, 19–21 September 2007; pp. 131–140. [Google Scholar]

- Mindess, S.; Young, J.F.; Darwin, D. Concrete, 2nd ed.; Prentice-Hall: Upper Saddle, NJ, USA, 2003. [Google Scholar]

- Yazdanbakhsh, Z.; Grasley, B.; Tyson, R.; Al-Rub, K.A. Distribution of carbon nanofibers and nanotubes in cementitious composites. Transp. Res. Rec. 2010, 2142, 89–95. [Google Scholar] [CrossRef]

- Makar, J.M.; Chan, G.W. Growth of cement hydration products on single walled carbon nanotubes. J. Am. Ceram. Soc. 2009, 92, 1303–1310. [Google Scholar] [CrossRef]

- Nasibulin, A.G.; Shandakov, S.D.; Nasibulina, L.I.; Cwirzen, A.; Mudimela, P.R.; Cwirzen, K.H. A novel cement-based hybrid material. New J. Phys. 2009, 11, 1–11. [Google Scholar] [CrossRef]

| Properties | OPC | GGBS | Silica Sand | Silica Flour |

|---|---|---|---|---|

| Specific gravity | 3.15 | 2.99 | 2.60 | 2.60 |

| Specific surface area (m2/kg) | 365 | 410 | 120 | 600 |

| SiO2 (%) | 21.00 | 39.00 | 98.7 | 99.5 |

| Al2O3 (%) | 5.31 | 12.50 | 0.3 | 0.1 |

| Fe2O3 (%) | 3.44 | 0.30 | 0.3 | 0.1 |

| CaO (%) | 65.00 | 39.50 | - | - |

| MgO (%) | 1.50 | 4.10 | 0.4 | 0.1 |

| SO3 (%) | 0.26 | - | - | - |

| Na2O (%) | 0.50 | 0.35 | - | - |

| K2O (%) | 0.25 | 0.75 | 0.3 | 0.1 |

| Mix | Cement | GGBS | Silica Flour | Silica Sand | Water | SP | CNFs |

|---|---|---|---|---|---|---|---|

| 1 | 1.00 | - | 0.40 | - | 0.22 | 0.012 | - |

| 2 | 0.50 | 0.50 | 0.40 | - | 0.22 | 0.008 | - |

| 3 | 1.00 | - | - | 0.40 | 0.22 | 0.010 | - |

| 4 | 1.00 | - | 0.25 | 0.15 | 0.22 | 0.012 | - |

| 5 | 0.50 | 0.50 | 0.25 | 0.15 | 0.22 | 0.008 | - |

| 6 | 1.00 | - | 0.25 | 0.15 | 0.22 | 0.011 | 0.00067 |

| 7 | 0.50 | 0.50 | 0.25 | 0.15 | 0.22 | 0.008 | 0.00067 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lim, J.L.G.; Raman, S.N.; Safiuddin, M.; Zain, M.F.M.; Hamid, R. Autogenous Shrinkage, Microstructure, and Strength of Ultra-High Performance Concrete Incorporating Carbon Nanofibers. Materials 2019, 12, 320. https://doi.org/10.3390/ma12020320

Lim JLG, Raman SN, Safiuddin M, Zain MFM, Hamid R. Autogenous Shrinkage, Microstructure, and Strength of Ultra-High Performance Concrete Incorporating Carbon Nanofibers. Materials. 2019; 12(2):320. https://doi.org/10.3390/ma12020320

Chicago/Turabian StyleLim, Jacob L. G., Sudharshan N. Raman, Md. Safiuddin, Muhammad Fauzi Mohd. Zain, and Roszilah Hamid. 2019. "Autogenous Shrinkage, Microstructure, and Strength of Ultra-High Performance Concrete Incorporating Carbon Nanofibers" Materials 12, no. 2: 320. https://doi.org/10.3390/ma12020320

APA StyleLim, J. L. G., Raman, S. N., Safiuddin, M., Zain, M. F. M., & Hamid, R. (2019). Autogenous Shrinkage, Microstructure, and Strength of Ultra-High Performance Concrete Incorporating Carbon Nanofibers. Materials, 12(2), 320. https://doi.org/10.3390/ma12020320