1. Introduction

Recently, the production of difficult-to-cut materials has increased in various engineering industries. There are difficult-to-cut materials that have properties such as a high corrosion resistance, thermal resistance, good specific strength, etc. [

1,

2]. However, these materials are difficult to machine due to these very higher properties. Nickel-based super-alloys are metallic materials with a high temperature strength, toughness, and resistance to deterioration in corrosive or oxidizing environments [

3,

4,

5].

Thermally assisted machining is a method of machining difficult-to-cut materials such as titanium alloys, nickel-based alloys and ceramics materials. According to the heat source type, machining can be classified into categories of induction assisted milling (IAM), laser-assisted milling (LAM), electrochemical assisted machining (ECAM) and plasma assisted milling (PAM). Thermally assisted machining uses heat sources to heat the workpiece and soften it. These machining methods have some advantages, such as a decrease in the cutting force and an improvement of surface roughness and energy saving compared to the conventional machining method [

6,

7,

8,

9,

10].

However, tool wear is an issue that causes short tool life in the area of difficult-to-cut materials. Especially when machining nickel-based alloys, various types of tool wear are generated, such as mechanical wear, adhesive wear, abrasive wear, diffusion wear and oxidation wear. In conclusion, the tool life is shortened [

11,

12,

13]. In order to reduce these problems, Pimenov examined the effect of the rate flank wear teeth face mills in the processing by using the regression analysis model [

14]. Zhang et al. carried out a tool life and cutting force analysis with Inconel 718 under dry and minimum quantity cooling lubrication cutting condition [

15]. Pimenov et al. carried out an automatic prediction study of required surface roughness by monitoring the wear in the face milling by using artificial intelligence methods [

16].

However, research on optimal parameters has been lacking in the area of induction assisted milling. The selection of optimal machining parameters is an essential parameter for any process of difficult-to-cut machining. The selection of optimal parameters has an influence on the surface quality, the required cutting force and the cutting cost. Chamarthi et al. performed an investigation analysis of plasma arc cutting parameters such as voltage, cutting speed and plasma gas flow on a 12 mm hardox-400 plate workpiece [

17]. Calleja et al. made improvements to the strategies and parameters for the multi-axis laser cladding operation [

18]. Kim et al. predicted the cutting force and preheating-temperature for the laser-assisted milling of Inconel 718 and AISI 1045 steel and proposed effective machining conditions for the laser-assisted milling of Inconel 718 and AISI 1045 steels [

19]. Venkatesan and Ramanujam took a statistical approach by using the multi-objective optimization method for the optimization of the influencing parameters in laser-assisted machining with the Inconel alloy [

20]. Abbas et al. carried out a study on the minimization of turning time for high-strength steel with a given surface roughness using the Edgeworth–Pareto optimization method [

21]. In this study, the response optimization method was used to determine the optimal machining parameters. This method is useful when evaluating the effect of multiple parameters on the response.

Due to its excellent abrasion and corrosion resistance, TiN coating is widely used to increase the cutting tool life. Al

2O

3 coating as a chemically inactive material has low thermal conductivity and excellent wear resistance. Additionally, it can function as a thermal diffusion barrier to increase the plastic deformation resistance. TiAlN or AlTiN (for aluminum contents higher than 50%) coating is aimed at the high-efficiency machining of difficult-to-cut materials, rather than at attempting to induce an increase in the tool life. In order to effectively perform dry machining, a coating tool is required to have a high oxidation resistance that can withstand the high-temperatures generated during machining. Additionally, a coating tool material is required to have excellent mechanical properties such as abrasion resistance and impact resistance [

22]. Aslantas et al. carried out the analysis of the wear mechanism and tool life in turning hardened alloy steel by coated and uncoated Al

2O

3/TiCN mixed ceramic tools [

23]. Liu et al. carried out a tool wear analysis in the high-speed machining of titanium alloys under dry and minimum quantity lubrication conditions by nc-AlTiN/a-Si

3N

4 and nc-AlCrN/a-Si

3N

4 coated tools. The results of the experiments were to propose dry and minimum quantity lubrication conditions according to the main wear typed for the two coated carbide tools [

24].

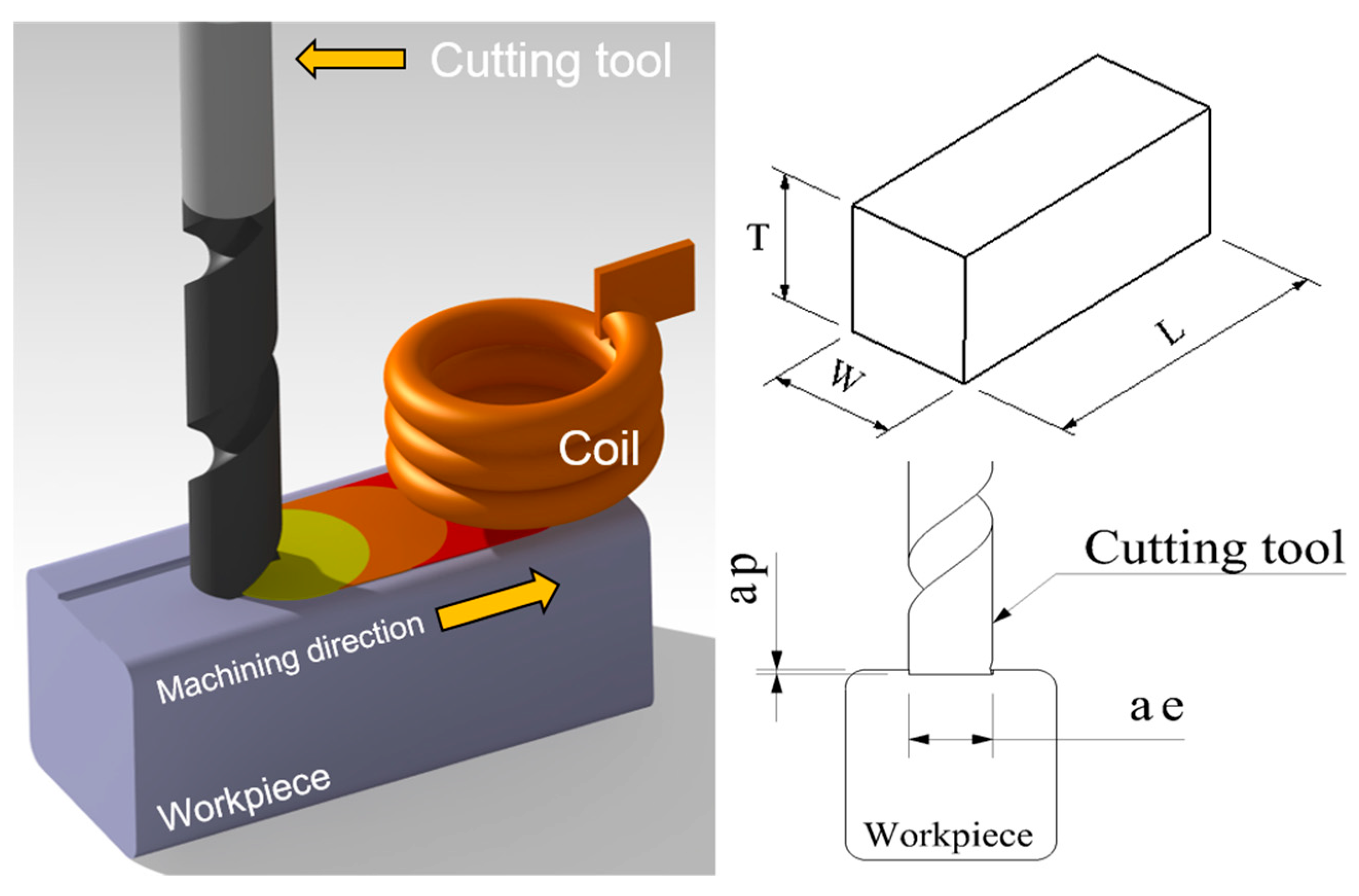

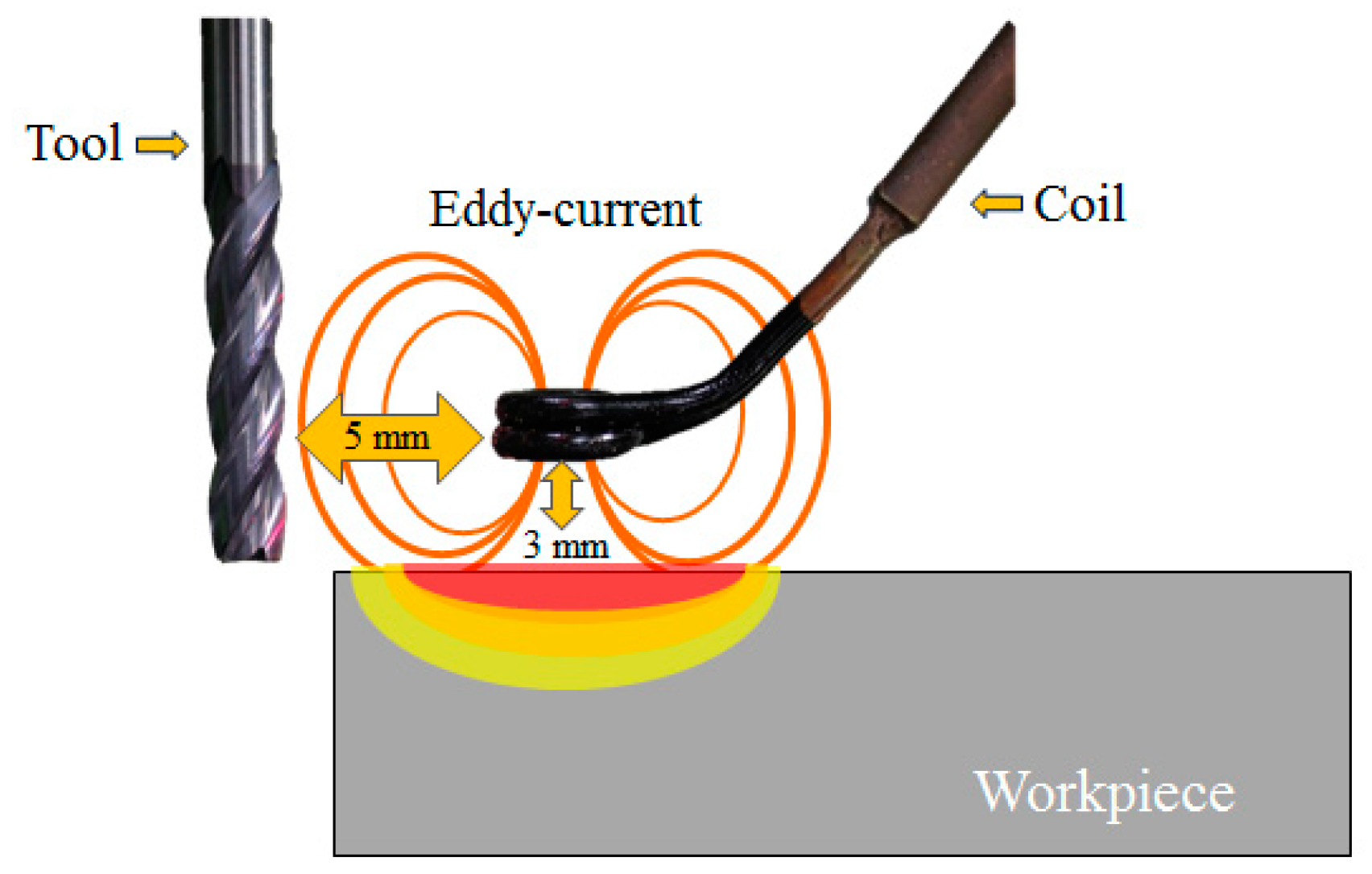

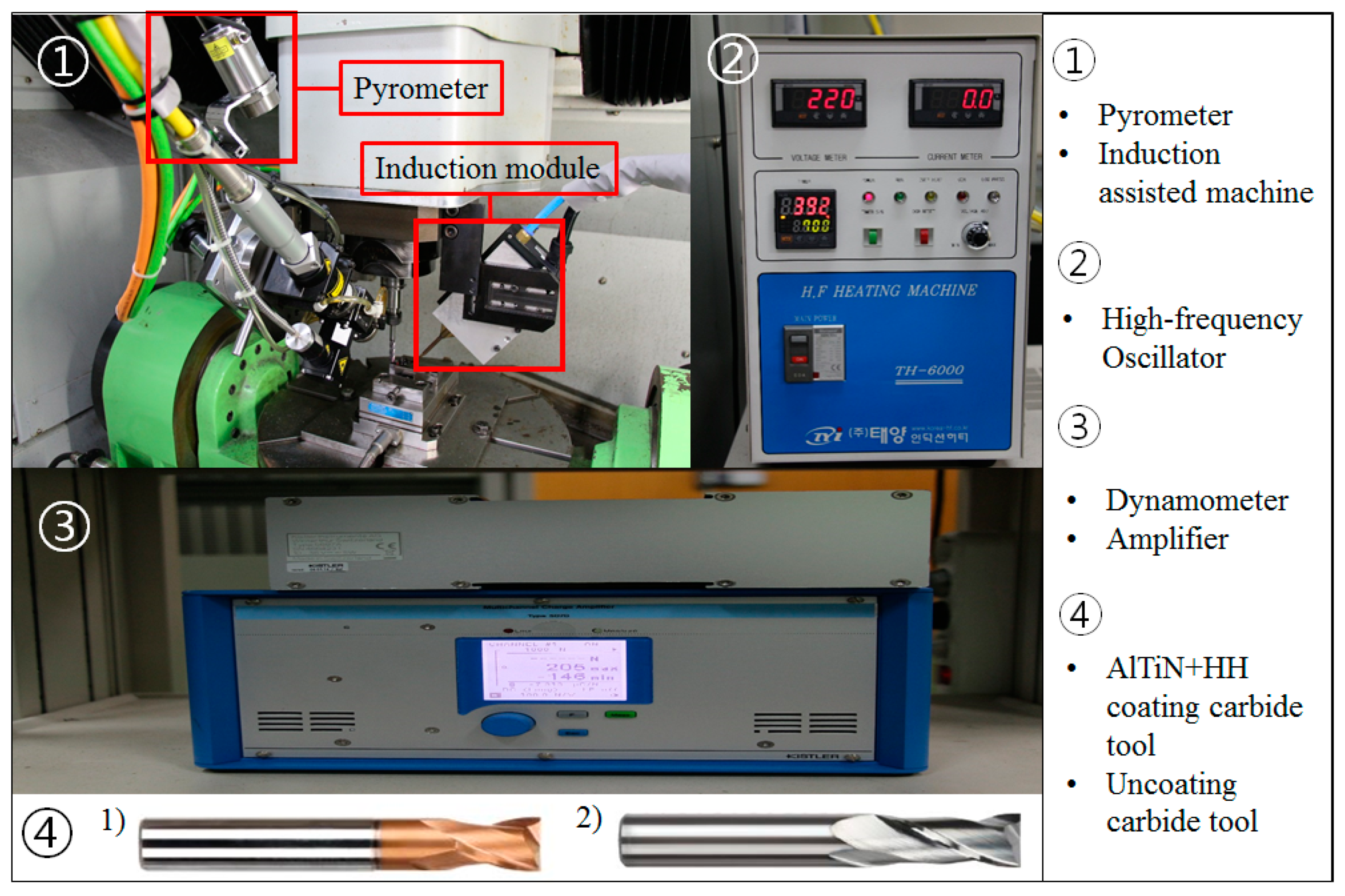

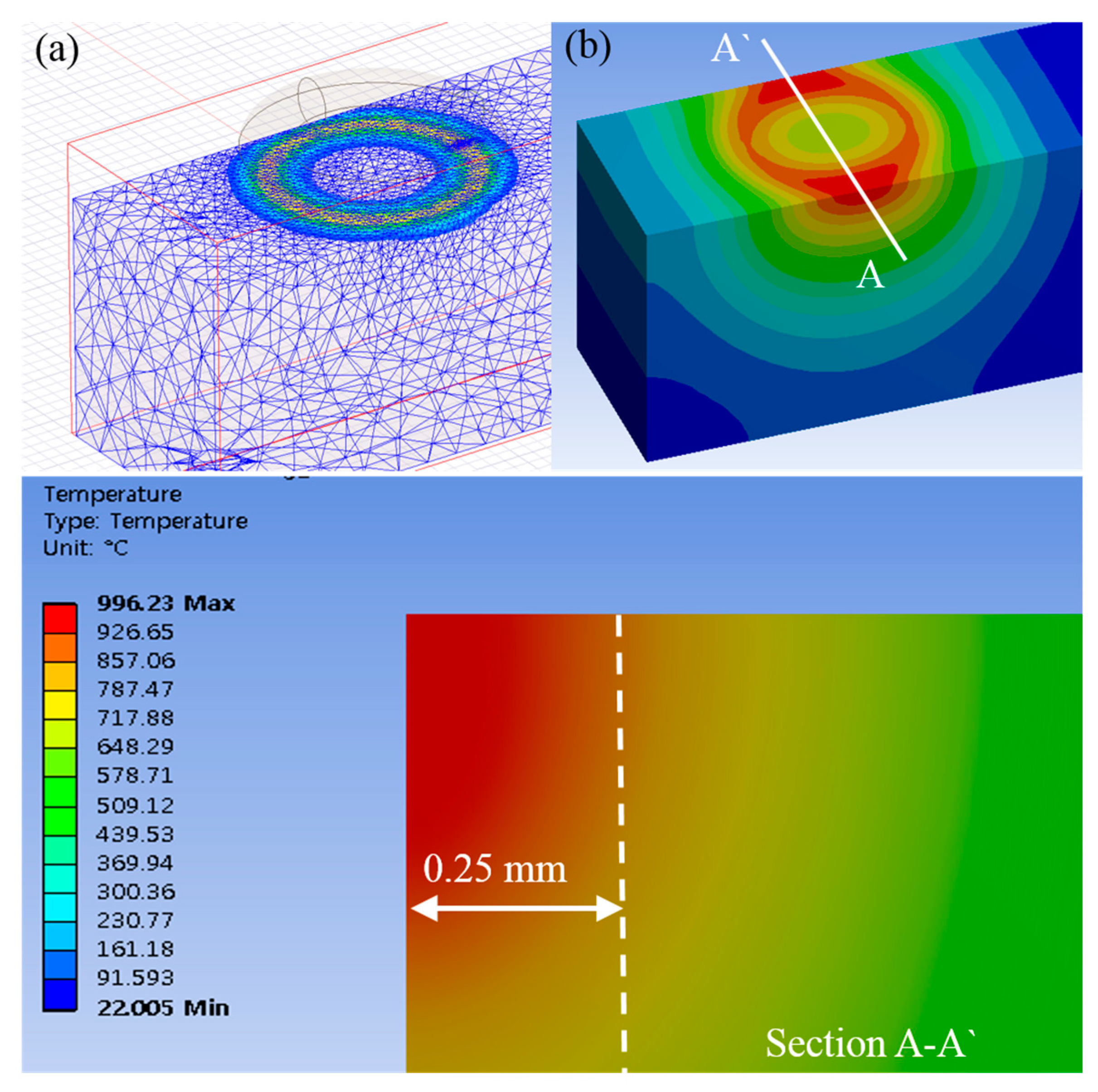

In this study, an experiment was performed to determine the optimal machining parameters and to analyze the thermal effect and machinability of Inconel 718 under various milling conditions in the IAM. To investigate the thermal effects of tools and machinability in the IAM, the experiments were performed by using an AlTiN+HH (high heat special coating) coated carbide tool and of an uncoated carbide tool. The tool can be heated by an induction heat source, and the adhesive wear of the tool can be accelerated by the coating material. Therefore, the uncoated tool and the coated tool were compared to analyze the mechanism of tool wear by high-temperature induction assisted milling. Finite element analysis (FEA) was performed to find an effective depth of cut. The influence of the machining parameters on cutting force, surface roughness and tool wear was analyzed using the Taguchi method. The cutting force was measured by dynamometer and the surface roughness was measured by the shape measuring device. The tool wear was evaluated on the flank wear by microscope in accordance with ISO 8688-2: tool life testing in milling [

25]. For the determination of the optimal machining parameters, the response optimization method was performed. An efficient machining condition to increase machinability was proposed and discussed.

5. Experimental Results and Discussion

The experimental results for cutting force, surface roughness, tool wear and the signal to noise (S/N) ratio are shown in

Table 5,

Table 6 and

Table 7, for the coated tool and the uncoated tool.

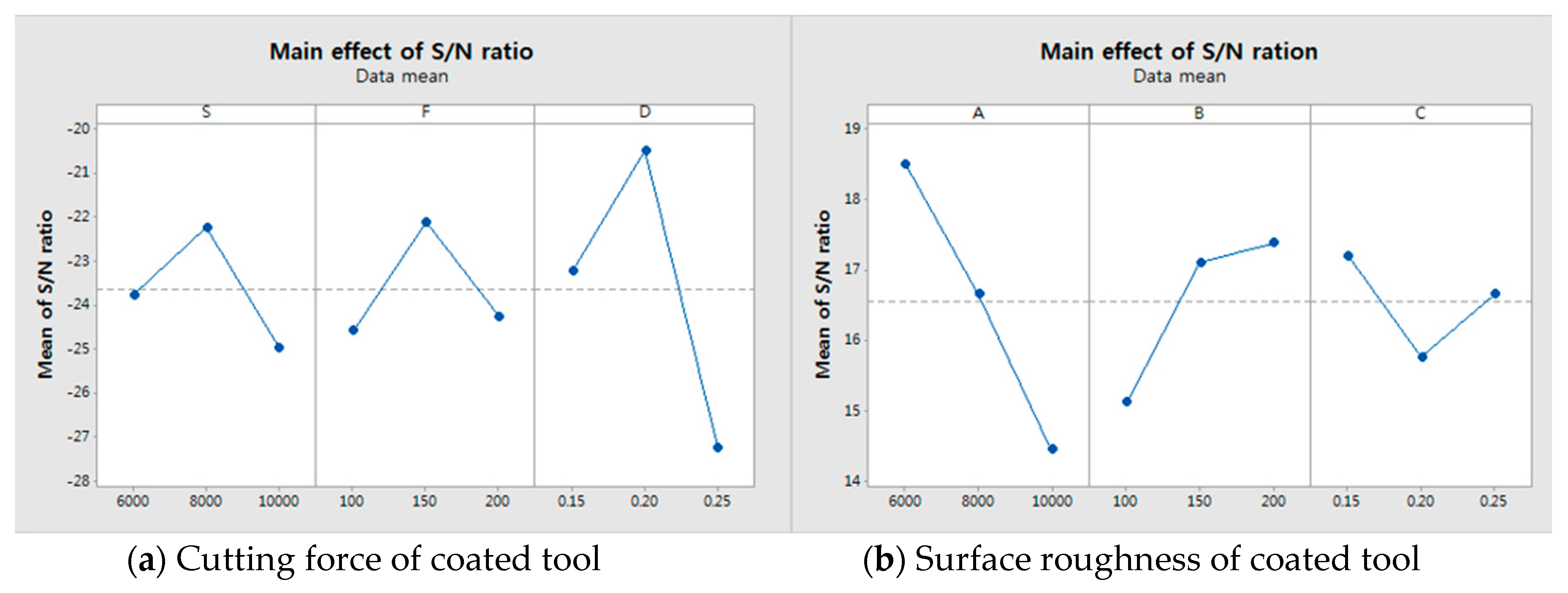

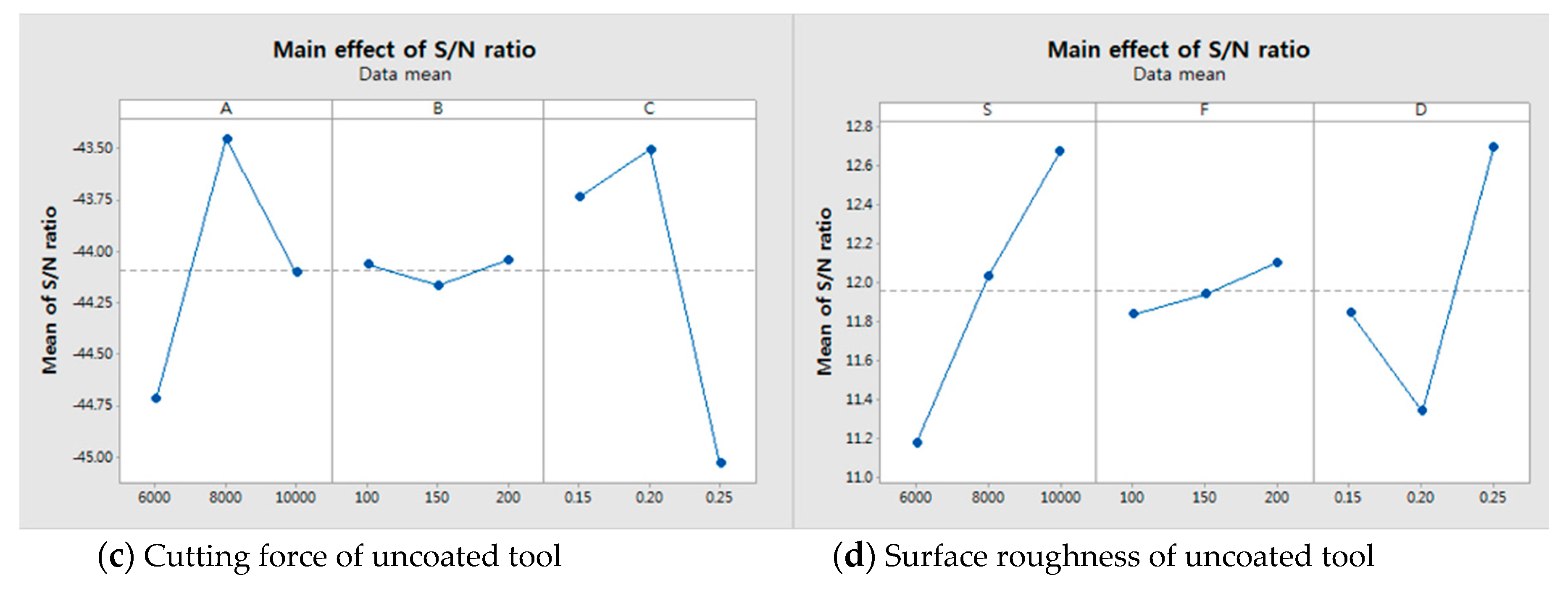

Figure 6 and

Figure 7 show the main effect of S/N ratio of cutting force, surface roughness and tool wear. All the measurements were performed after machining for the same machining length. The cutting force was measured by the dynamometer and amplifier. The dynamometer was installed under the workpiece and fixture. The measured cutting force of the dynamometer is given by Equation (2),

where

Fx is the tangential force and

Fy is the radial force. A piezoelectric sensor was used for the dynamometer. The initial load was set to be zero. The surface roughness was measured by the shape measuring device. The surface roughness was measured as the arithmetic mean deviation of the profile (Ra) and 0.8 mm of the cut-off value, 4.5 mm of the evaluation length and a stylus tip radius of 2 mm. The evaluation length was analyzed repeatedly 5 times and the average value was selected as the surface roughness. The tool wear was measured by the flank wear using a microscope (SOMETECH Inc., Seoul, Korea, IMS-345). The evaluation of the tool wear was measured as well as the evaluated in the worst case in both flutes. The quality characteristics are classified into three types: nominal-is-best characteristics, larger-the-better characteristics and smaller-the-better characteristics. In this study, the smaller-the-better characteristics were used. The smaller-the-better characteristics are shown in Equation (3).

where n is the number of observations and

Y is the observed data.

5.1. S/N Ratio Analysis

According to the cutting force measurement results, the cutting force of the coated tool was approximately 1000% lower than that of the uncoated tool. The cutting force and the S/N ratio of the cutting force are shown in

Table 5; the cutting force of the coated tool had the highest value of 28.62 N and the lowest value of 11.24 N. The uncoated tool had the highest value of 191.04 N and the lowest value of 138.86 N. Both the coated tool and the uncoated tool, for identical machining conditions, had highest values of S

1F

3D

3 and lowest values of S

2F

1D

2. For the coated and uncoated tools, the cutting force of the S/N ratio had the highest values of −21.73 dB and −43.45 dB. In the surface roughness measurement results, the surface roughness of the coated tool was found to be approximately 260% lower than that of the uncoated tool. The S/N ratio of the surface roughness is shown in

Table 6; the surface roughness of the uncoated tool had its highest value at S

1F

2D

2 (0.310 µm) and its lowest value at S

3F

1D

3 (0.226 µm). The coated tool had its highest value at S

3F

1D

3 (0.212 µm) and its lowest value at S

3F

1D

3 (0.115 µm). The coated and uncoated tools had surface roughness S/N ratios that exhibited the highest values of 18.52 dB and 12.69 dB, respectively. For the tool wear measurement results, the tool wear of the coated tool was up to approximately 390% lower than that of the uncoated tool. The tool wear and S/N ratio of the tool wear are shown in

Table 7. The tool wear of the coated tool had its highest value at S

2F

3D

1 (0.340 mm) and its lowest value at S

1F

3D

3 (1.075 mm). When the machining condition was S

2F

1D

2, the coated and uncoated tool to S/N ratio of tool wear had the highest values of 12.327 dB and 1.774 dB, respectively.

5.2. Main Effect Plot

We used the main effects plot to examine the differences between level means for one or more parameters. There is a main effect when different levels of a parameter affect the response differently. The larger the slope of the main effect plot is, the greater the magnitude of the main effect. Therefore,

Figure 6 and

Figure 7 show the main effects. The

Figure 6a,b show main effects of S/N ratio in the cutting force and the surface roughness of coated tool. The

Figure 6c,d show main effects of S/N ratio in the cutting force and the surface roughness of uncoated tool. The

Figure 7a,b show main effects of S/N ratio in the tool wear of coated and uncoated tool. It has been determined from

Figure 6a that the optimum levels were S

2 (S:8000), F

2 (f:150) and D

2 (ap:0.2) and

Figure 6b shows that the optimum levels were S

3 (S:10,000), F

3 (f:200) and D

3 (ap:0.25).

Figure 6c shows that the optimum levels were S

2 (S:8000), F

3 (f:200) and D

2 (ap:0.2).

Figure 6d shows that the optimum levels were S

1 (S:6000), F

3 (f:250) and D

1 (ap:0.15). When comparing the coated tool with the uncoated tool, the cutting force shows a similar pattern but the surface roughness shows a different pattern. In the case of the tool wear,

Figure 7a shows that the optimum level is S

3F

2D

3, i.e., spindle speed is 10,000 rpm, the feed rate is 150 mm/min and the depth of cut is 0.25 mm.

Figure 7b shows that the optimum level is S

2F

1D

2, i.e., the spindle speed is 8000 rpm, the feed rate is 100 mm/min and the depth of cut is 0.2 mm.

5.3. Analysis of Variance

Analysis of Variance (ANOVA) is used to test the hypothesis that the means of two or more populations are equal. ANOVA assesses the importance of one or more parameters by comparing the response variable means at different parameter levels. ANOVA was performed to study the relative nature of the parameters. An ANOVA with 95% confidence was used.

Table 8 shows the ANOVA results for cutting force, surface roughness and tool wear on the coated tool. It was observed that the depth of cut is the main contributing factor to the cutting force. The contributions of the cutting force were as follows: spindle speed at 19%, feed rate at 6% and depth of cut at 65%. It was observed that the spindle speed is the main contributing factor to the surface roughness. The contributions of the surface roughness were as follows: spindle speed at 59%, feed rate at 25% and depth of cut at 8%. It was observed that the spindle speed is the main contributing factor to tool wear. The contributions of tool wear were as follows: spindle speed at 37%, feed rate at 31% and depth of cut at 26%.

Table 9 shows the ANOVA results of cutting force, surface roughness and tool wear on the uncoated tool. It was observed that the depth of cut is the main contributing factor to the cutting force. The contributions to the cutting force were as follows: spindle speed at 35%, feed rate at 0.1% and depth of cut at 63%. It was observed that the spindle speed is the main contributing factor to the surface roughness. The contributions to the surface roughness were as follows: spindle speed at 48%, feed rate at 2% and depth of cut at 38%. It was observed that the spindle speed is the main contributing factor to the tool wear. The contributions to the tool wear were as follows: spindle speed at 48%, feed rate at 20% and depth of cut at 26%. In the contribution of the cutting force, the depth of cut has the most influence due to the decrease of the tool vibration according to the depth of heat affected zone. In the contributions of the surface roughness and tool wear, the coating blocked the heat transfer to the coated tool. So, the influence of the feed rate is increased in the coated tool. The F-test accurate only for normally distributed data. However, the three factors with three levels used in this study were not normally distributed. Therefore, the F-test was not suitable. We have performed the test for equation variance. It is possible for the null hypothesis of the variances to be equal.

Table 10 shows the

p-value of the test for equal variance.

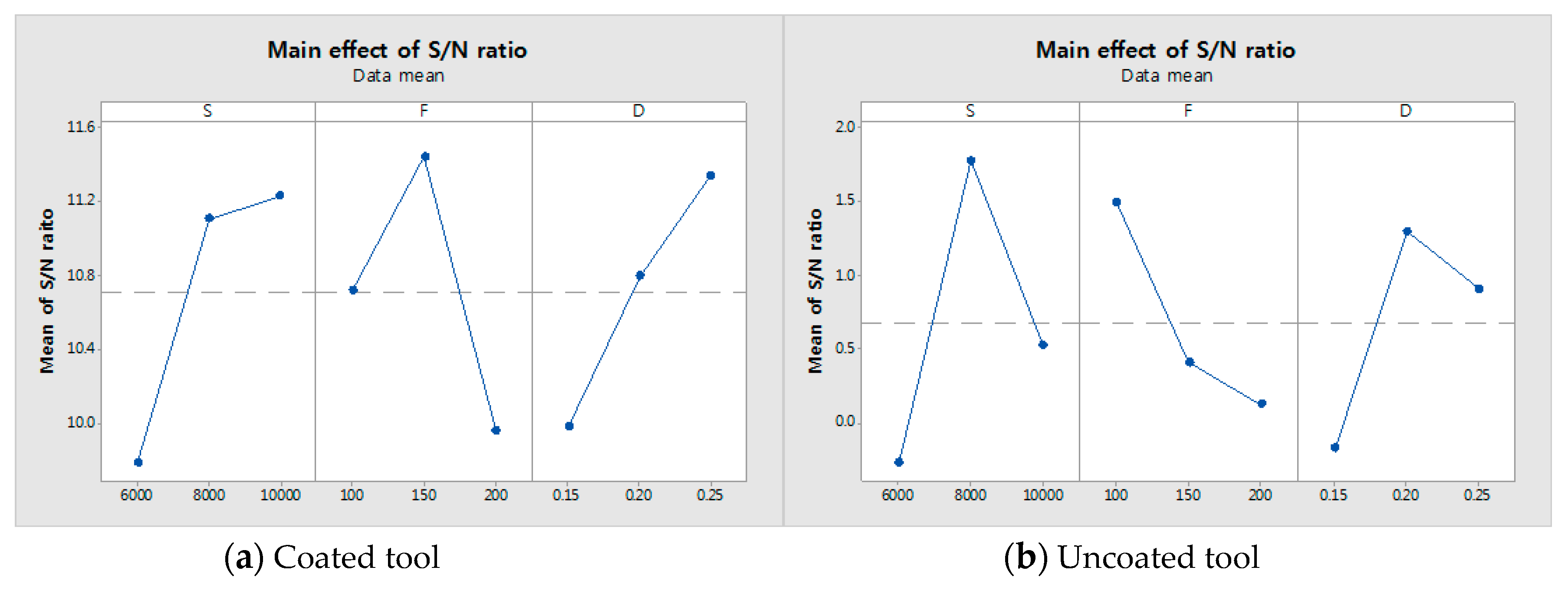

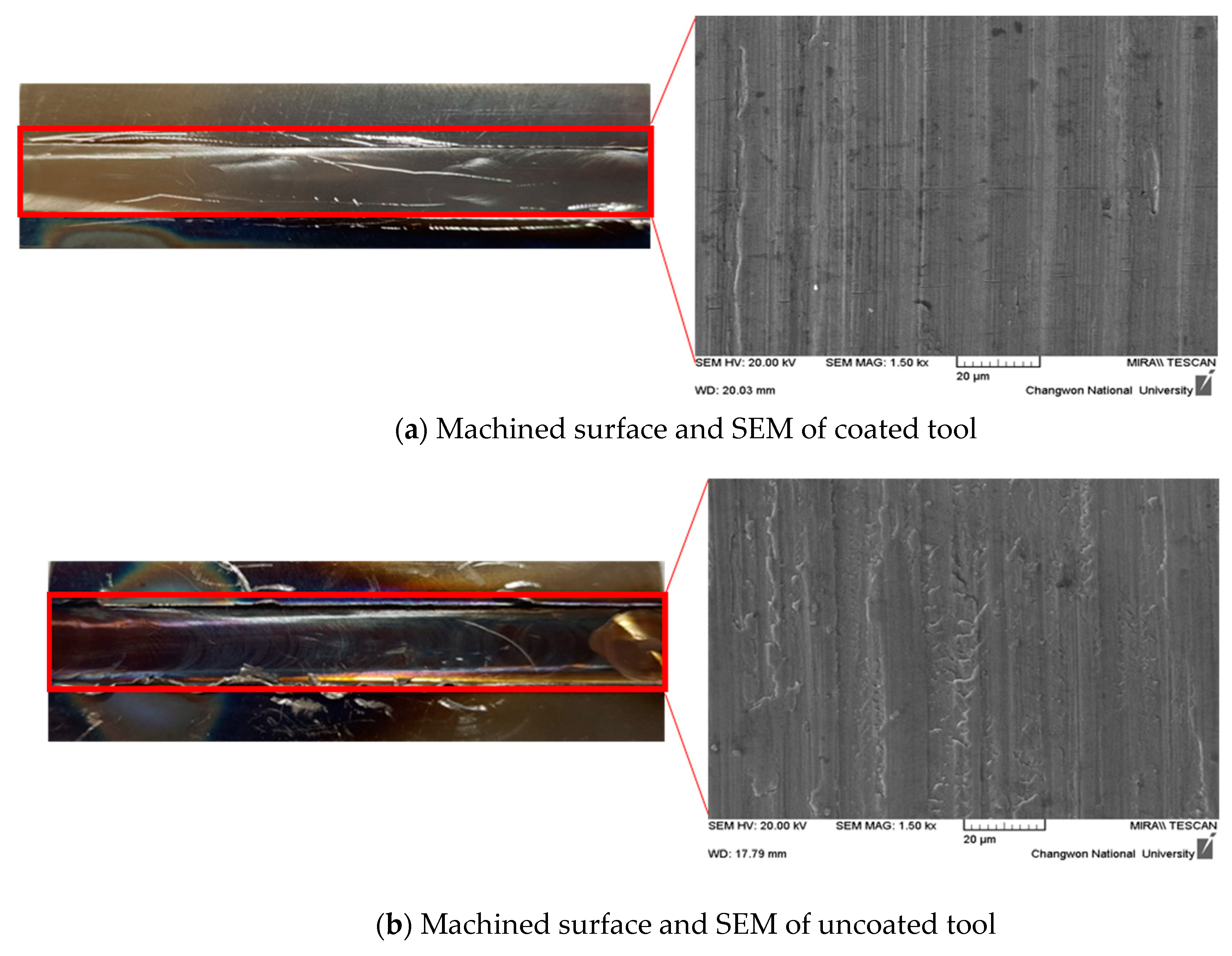

5.4. Tool Wear and Machined Surface

For the machining of Inconel 718 using carbide tools, diffusion loss occurs due to heat.

Figure 8 shows the tool wear as found in the microscope measurement results.

Figure 8 shows the measured parameters for level 7, i.e., the spindle speed is 10,000 rpm, the feed rate is 100 mm/min and the depth of cut is 0.25 mm both for the coated tool and the uncoated tool. The

Figure 8a shows tool wear of coated tool and 8b shows tool wear of uncoated tool. Generally, the heat generated during machining is mainly transferred to the chip and cutting tool, and less than 10% of the generated heat is transferred to the workpiece. According to

Figure 8a, the wear of the coated tool is insignificant. However, the uncoated tool is negatively influenced by the friction heat and radiant heat of the induction heat source.

Figure 8b shows the worn tool after machining.

Figure 9a,b show the machined surfaces and scanning electron microscope of the coated and uncoated tools. When an AlTiN+HH coated tool is used in machining, the machined surface has no heat affected zone, as can be seen in

Figure 9a. However, when the uncoated tool is used in machining, the machined surface has a heat affected zone, as can be seen in

Figure 9b. The heat affected zone shows chemical and structural modifications. So, this phenomenon is very important in the area of thermally assisted machining. However, the uncoated tool has a rougher surface roughness than that of the coated tool, causing the uncoated tool to have a surface build up in a built-up-edge (BUE). When the uncoated tool was used, the heat generated during IAM was transferred to the workpiece more than to the coated tool. The analysis results of the machined surface showed that the coating was effectively blocked the heat generated during IAM.

5.5. Response Optimization

Based on the design of the experimental results, we carried out a response optimization. The goal was to achieve a minimum and weights are shown in

Table 11. The result of the response optimization is depicted in

Table 12. The parameters of the coated tool S

2F

2D

2 were observed, i.e., a spindle speed if 8000 rpm, a feed rate of 150 mm/min, a depth of cut of 0.2 mm and a composite desirability of 0.78. Desirability assessed how well a combination of variables satisfies the goals defined for the response. The uncoated tool was S

2F

1D

2, i.e., a spindle speed of 8000 rpm, a feed rate of 100 mm/min, a depth of cut of 0.2 mm and a composite desirability of 0.79. The coated tool and uncoated tool both have the same spindle speed and depth of cut. The coated tool had a higher feed rate than the uncoated tool. The machining time can be decreased by using the coated tool in IAM.