One-Shot Drilling Analysis of Stack CFRP/UNS A92024 Bonding by Adhesive

Abstract

1. Introduction

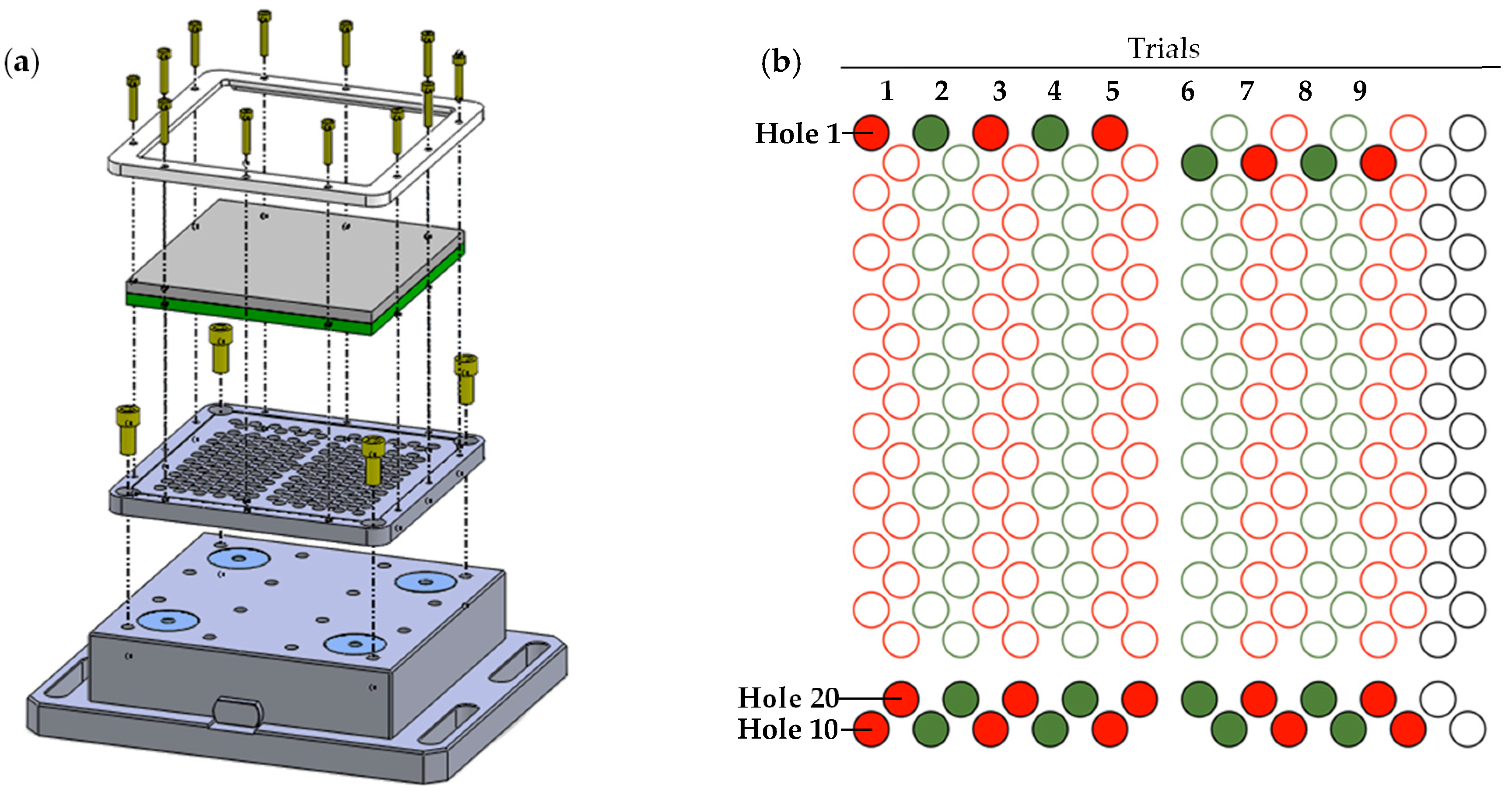

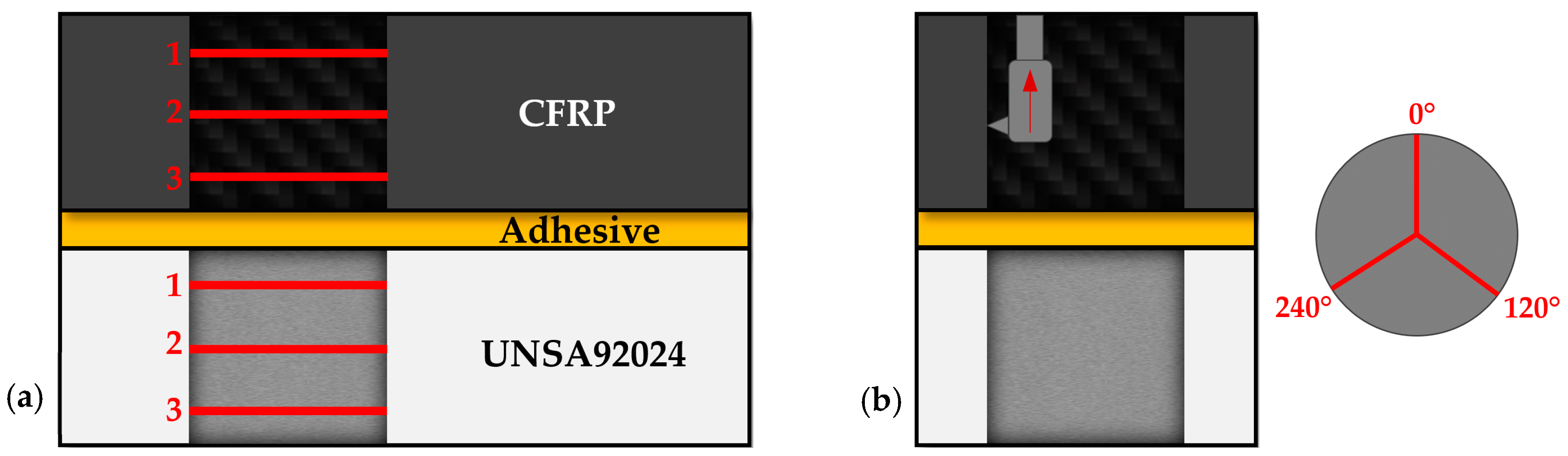

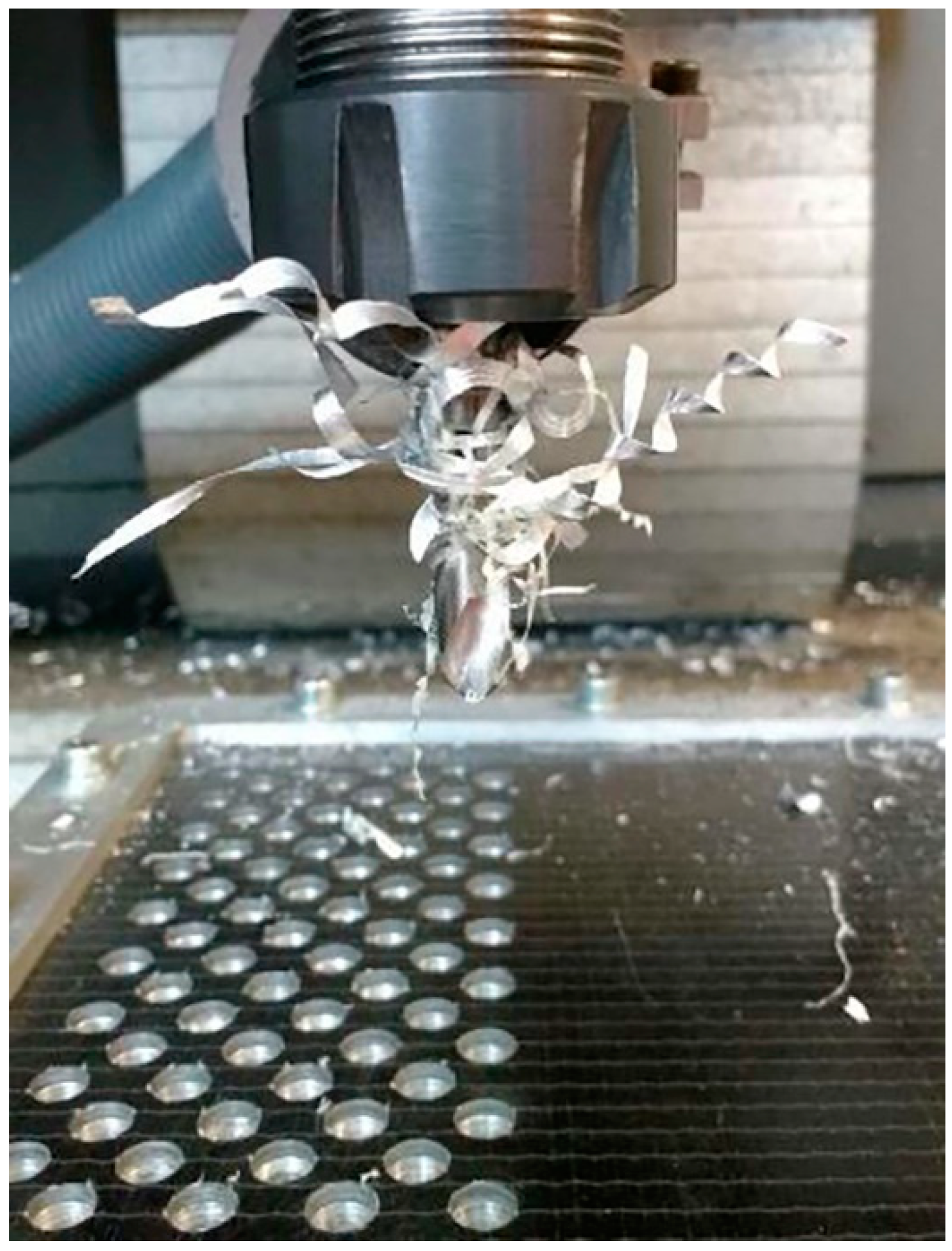

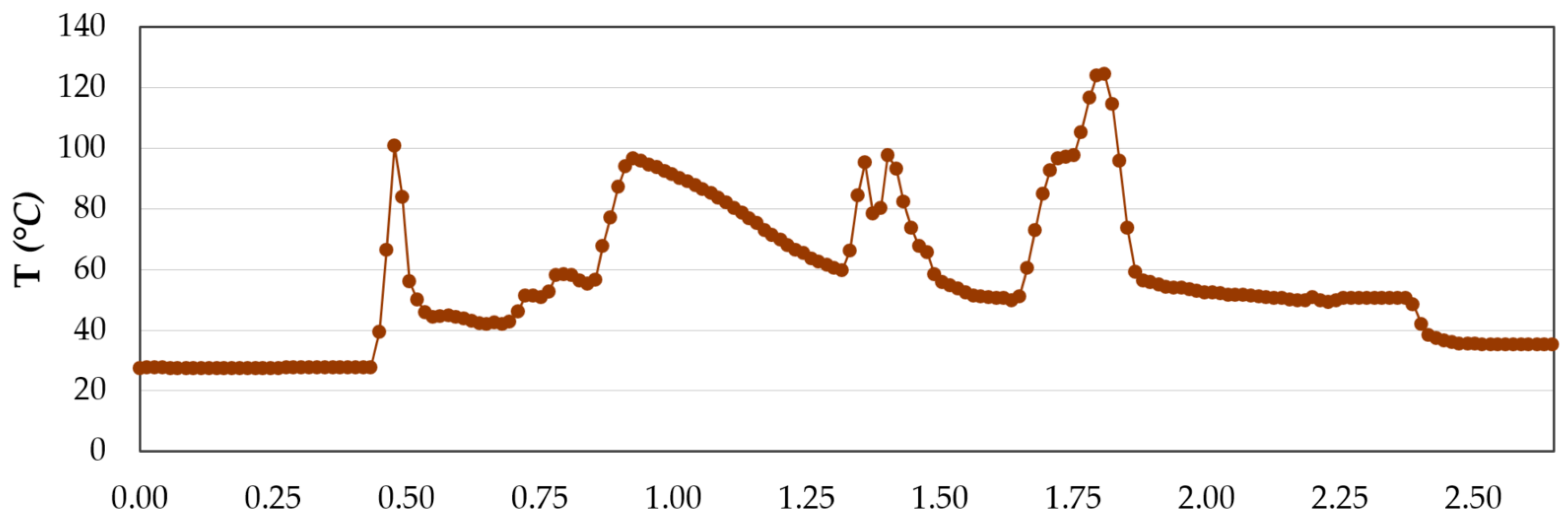

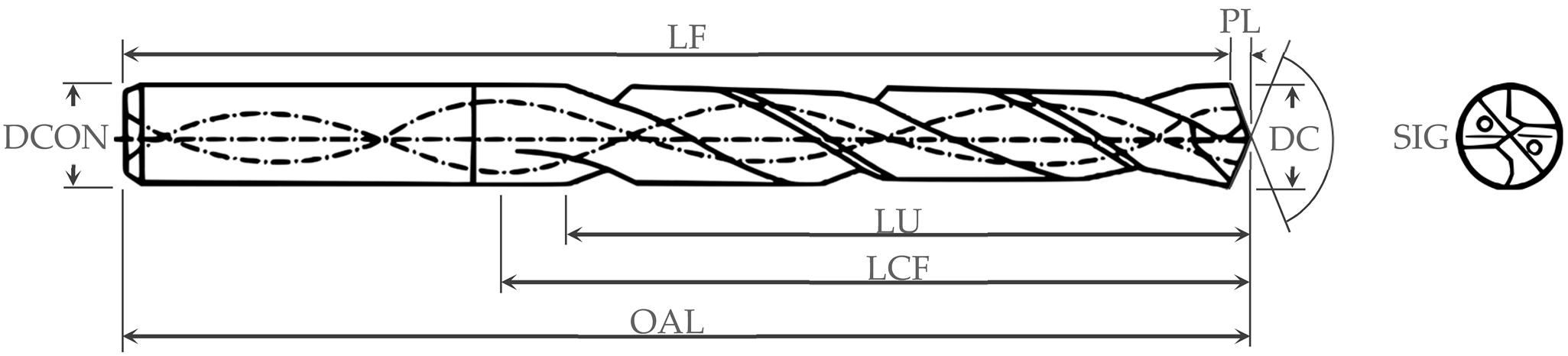

2. Materials and Methods

3. Results and Discussion

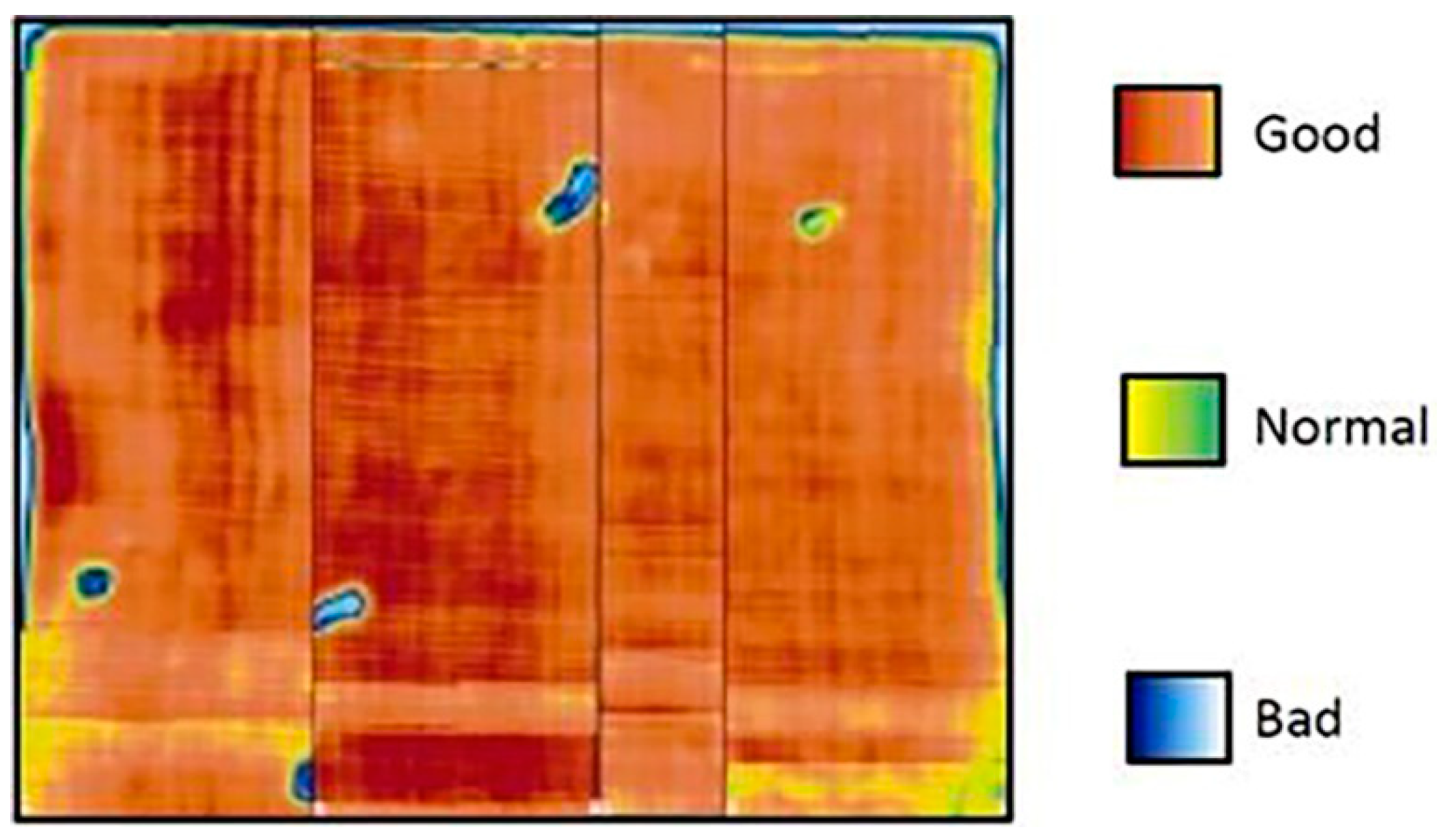

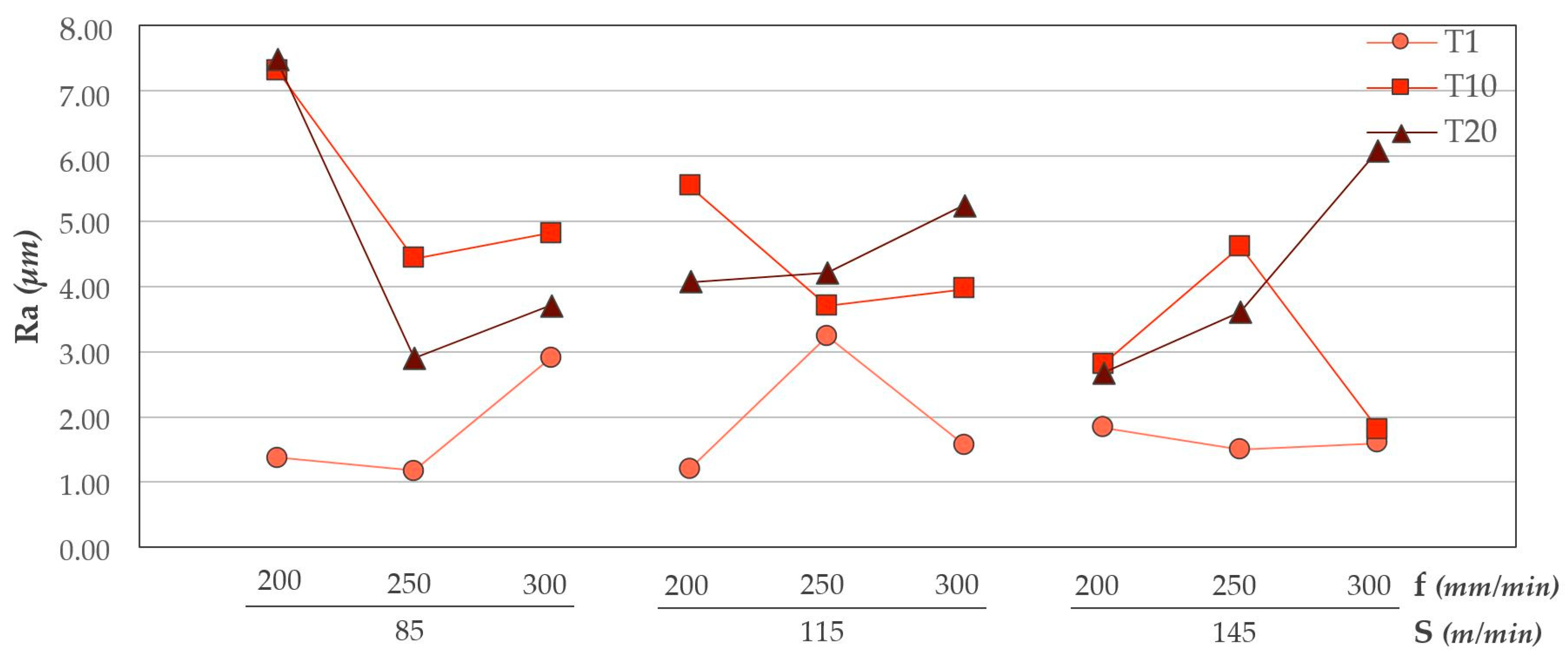

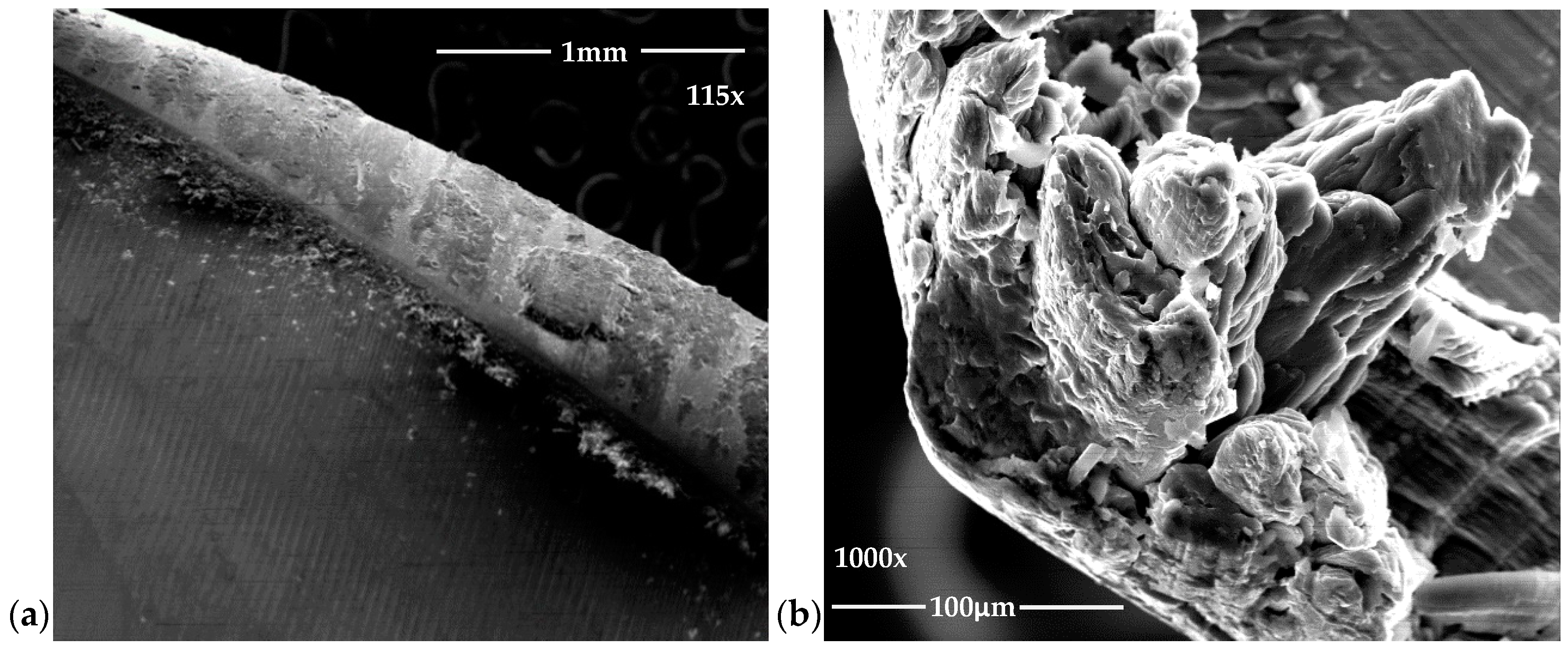

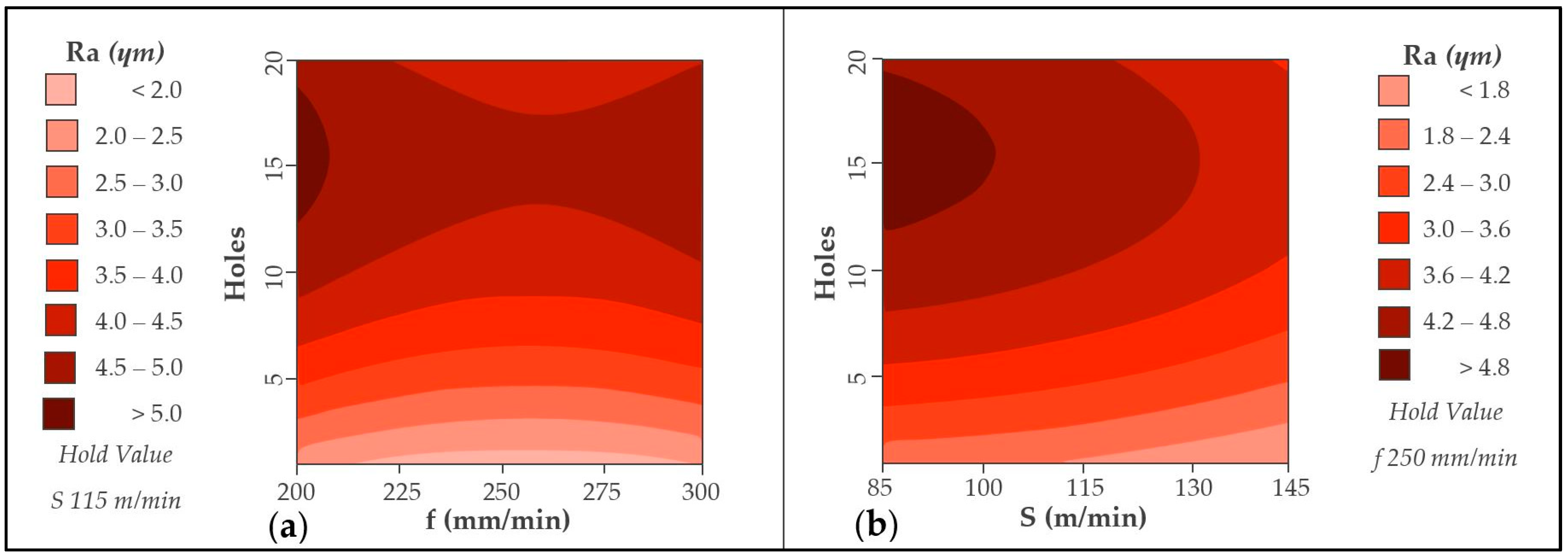

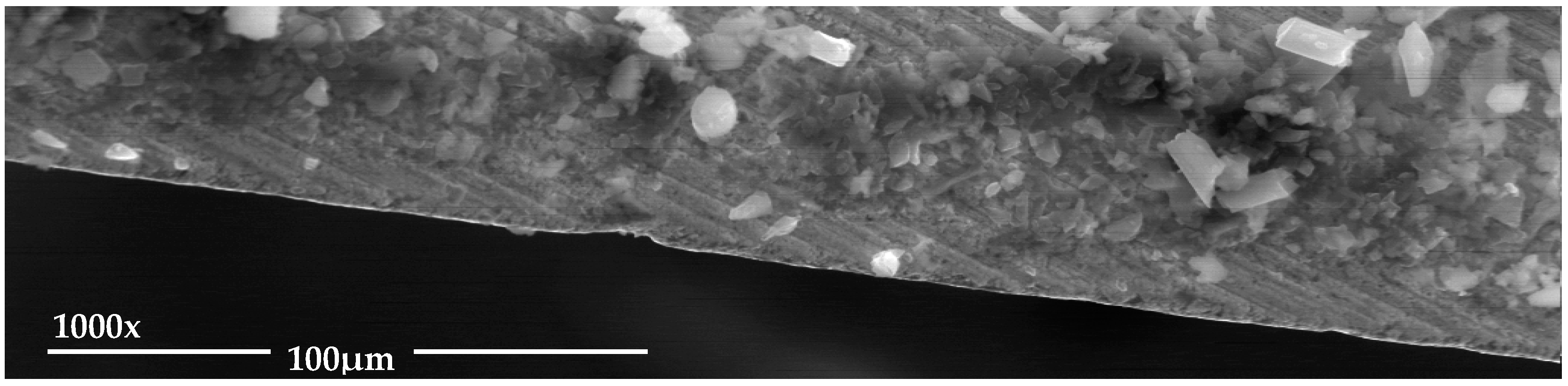

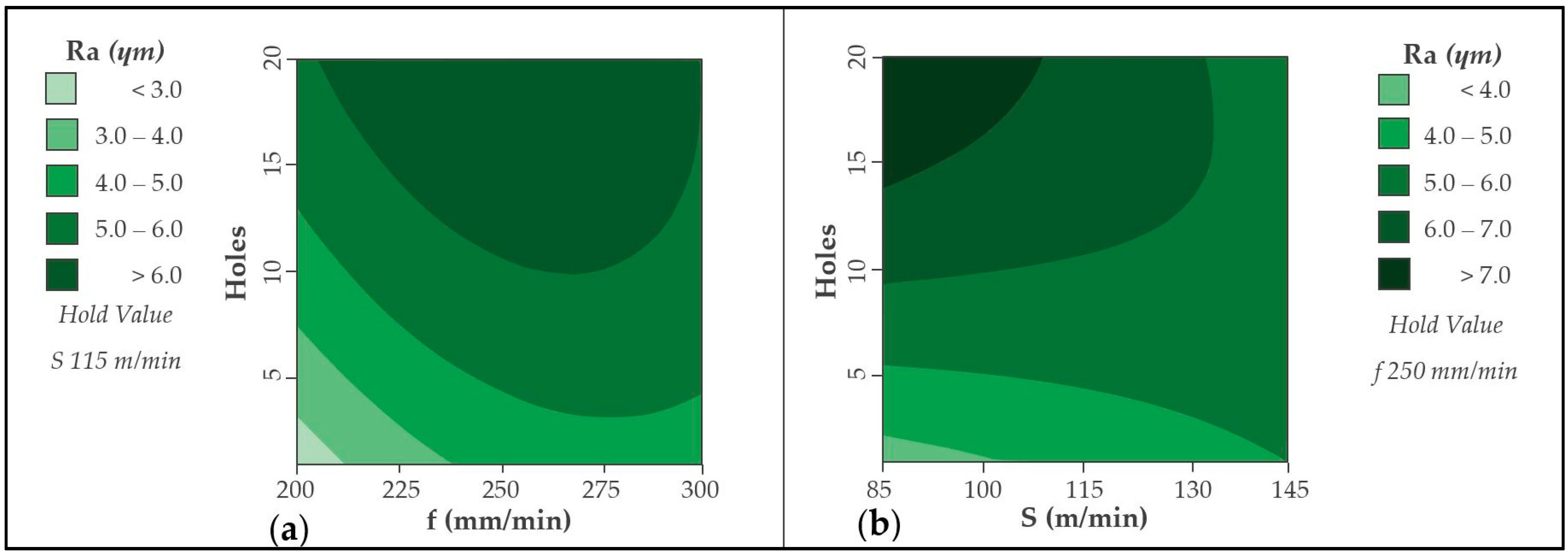

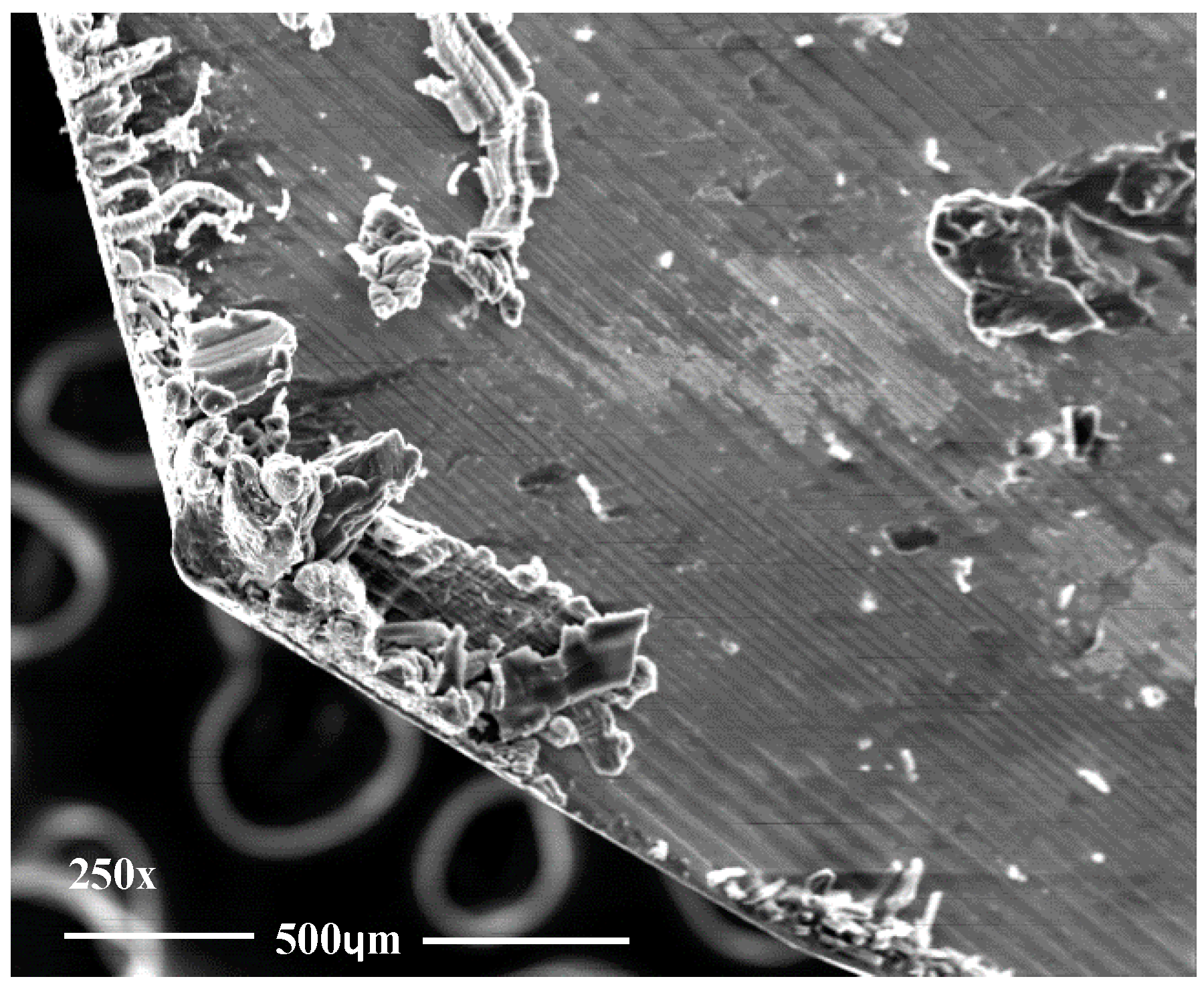

3.1. Surface Quality

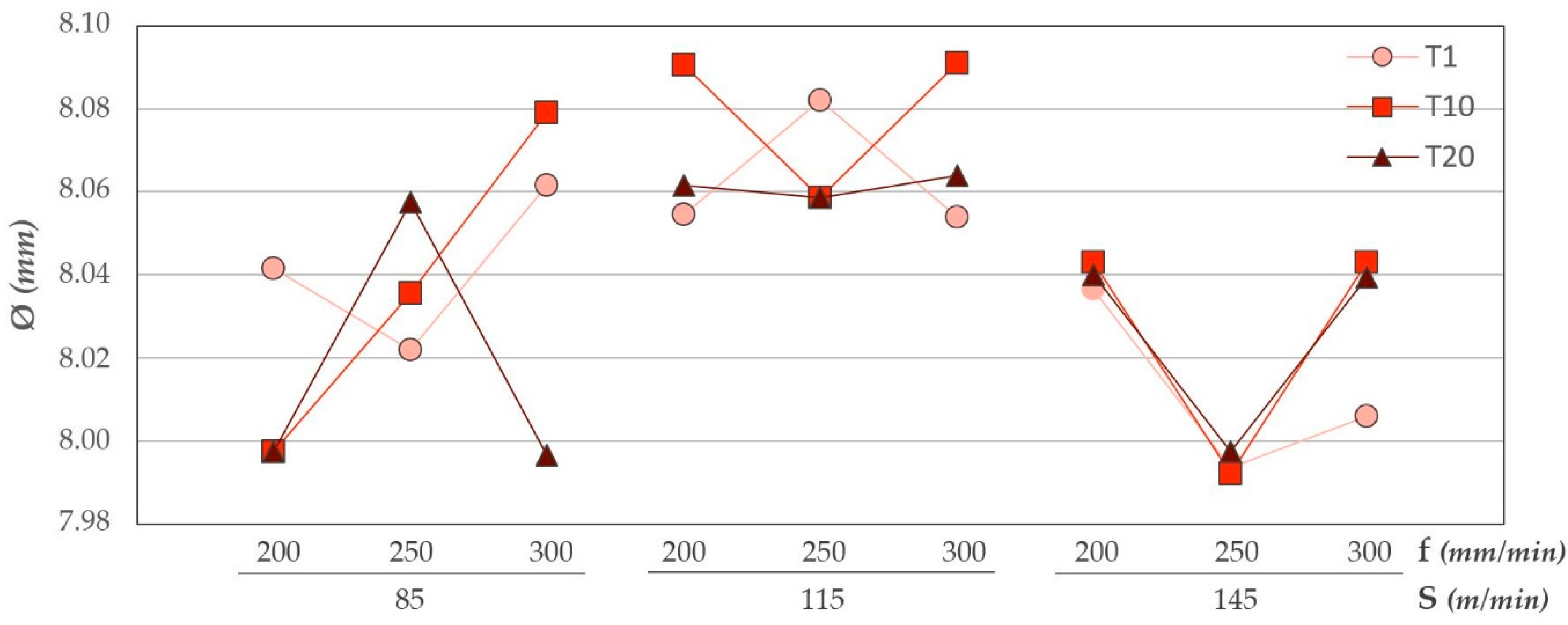

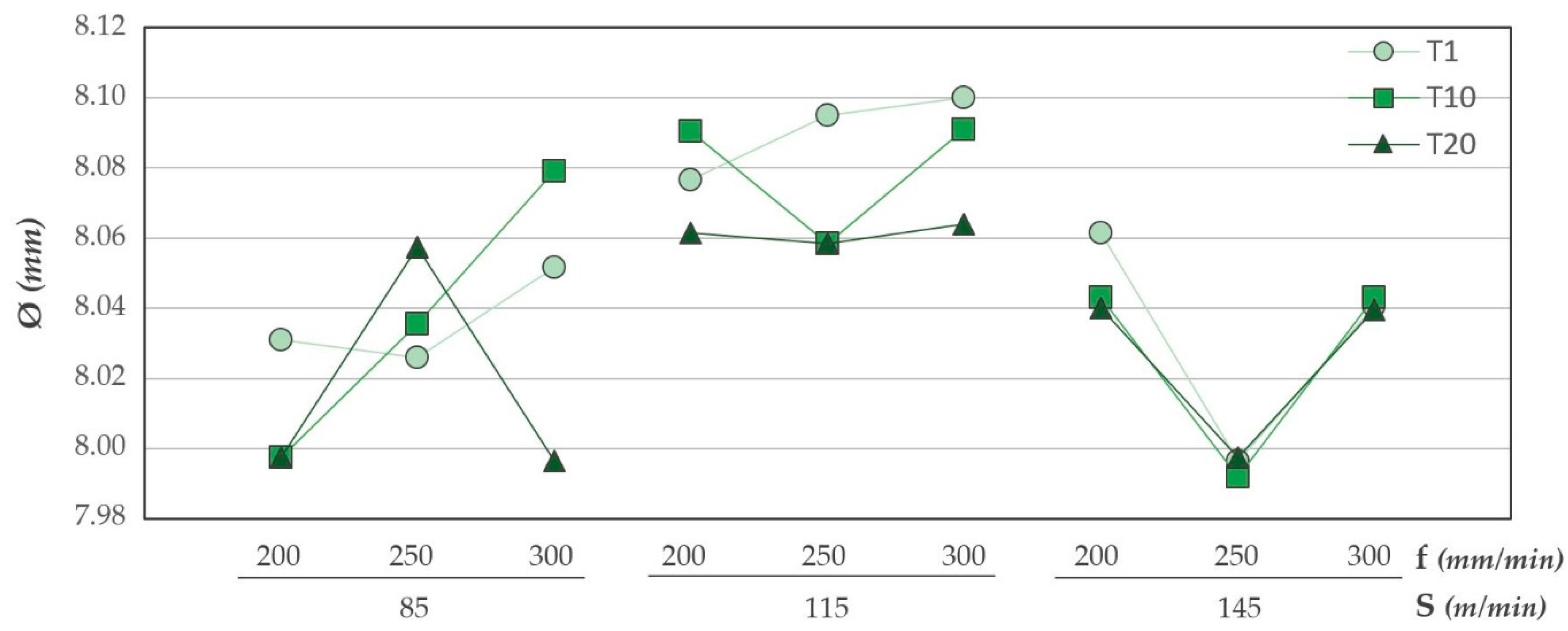

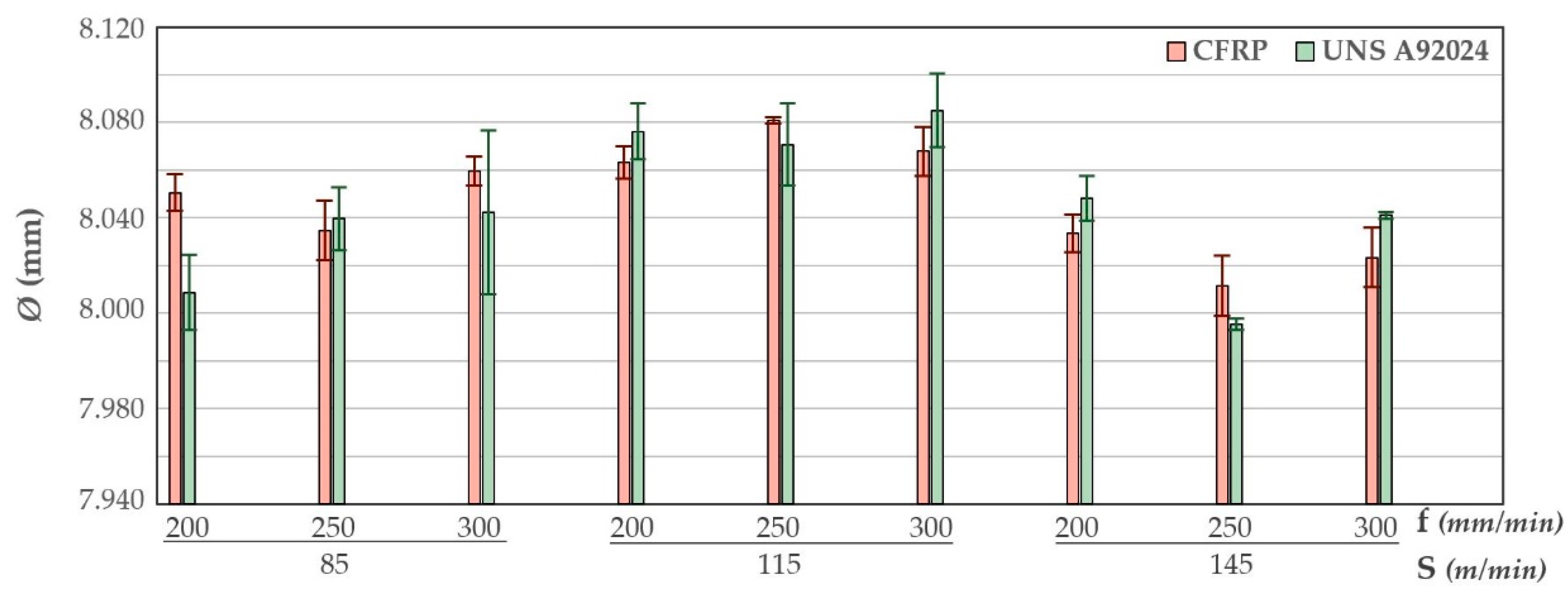

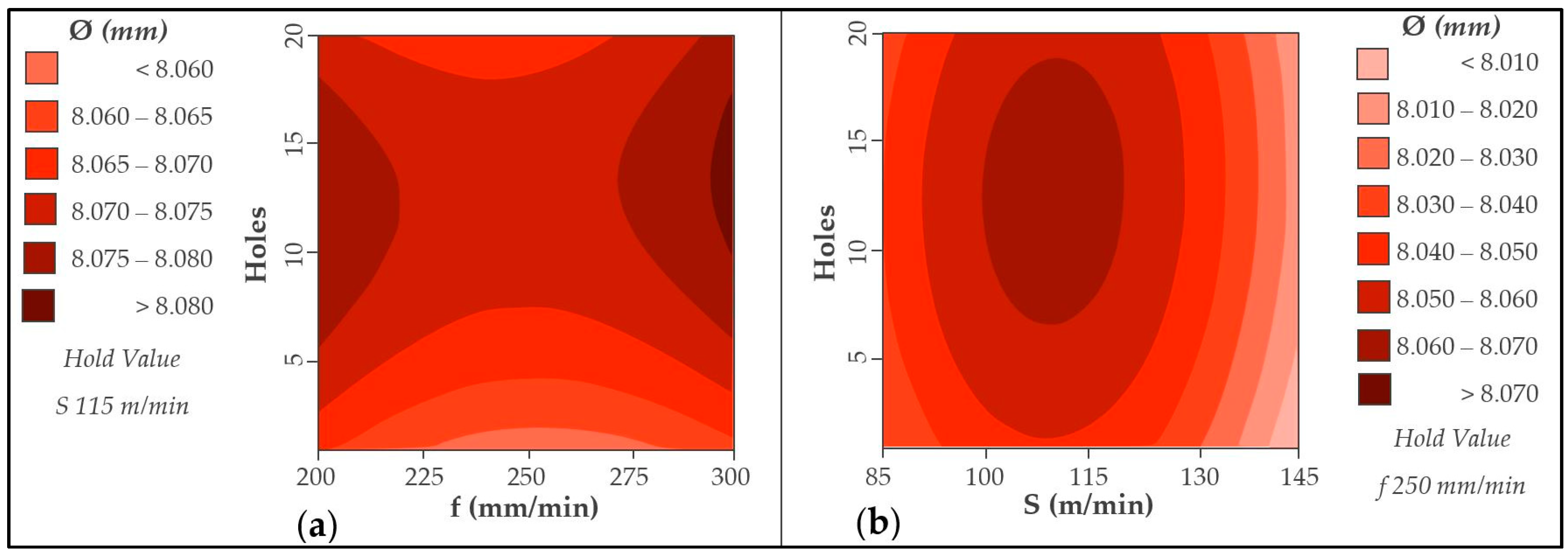

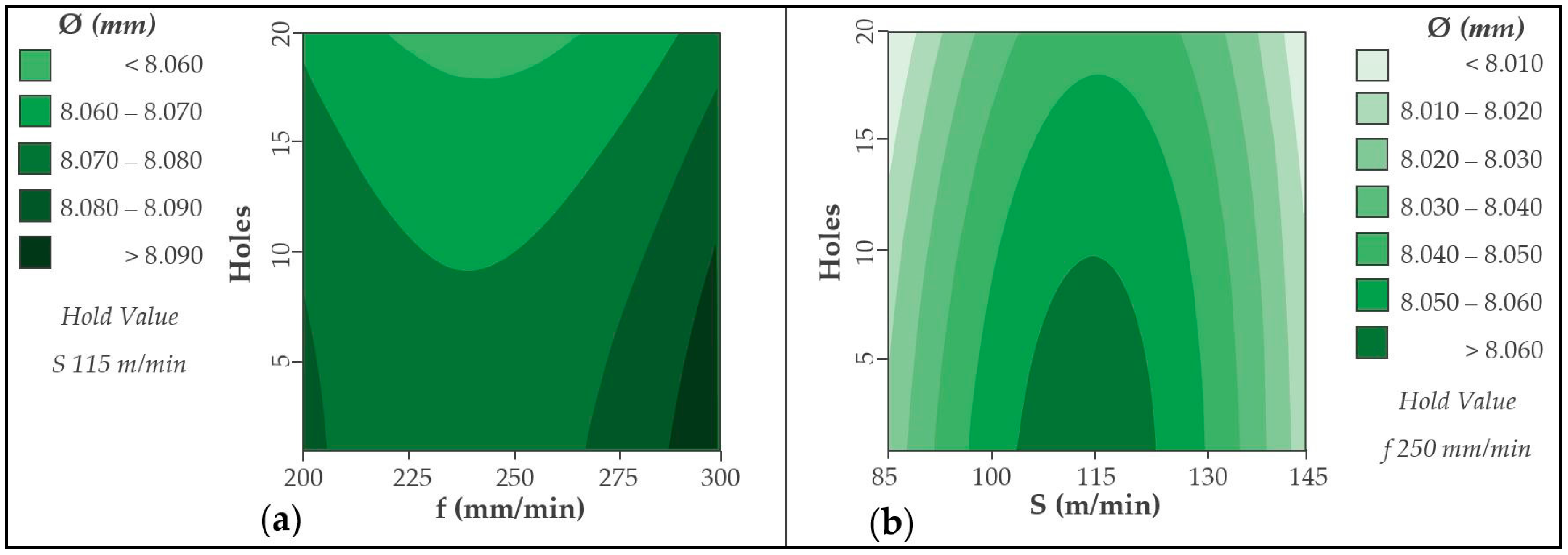

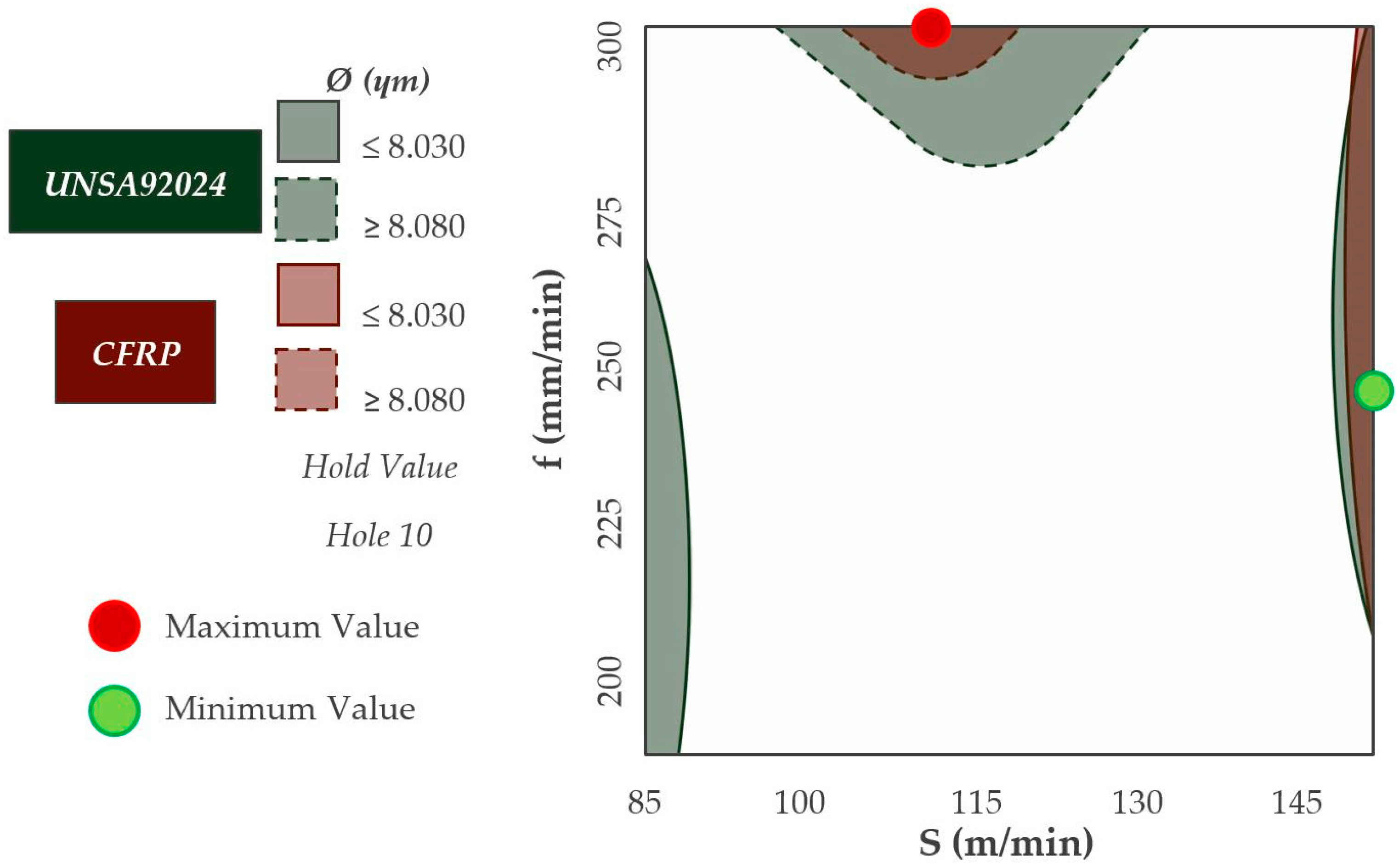

3.2. Diameters

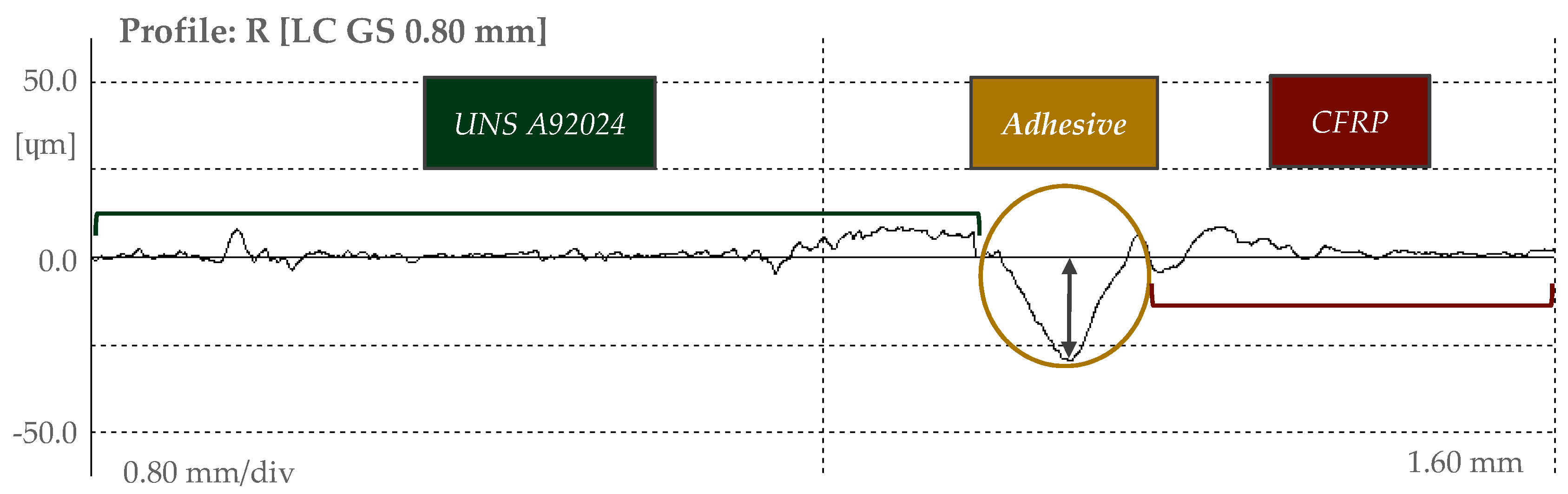

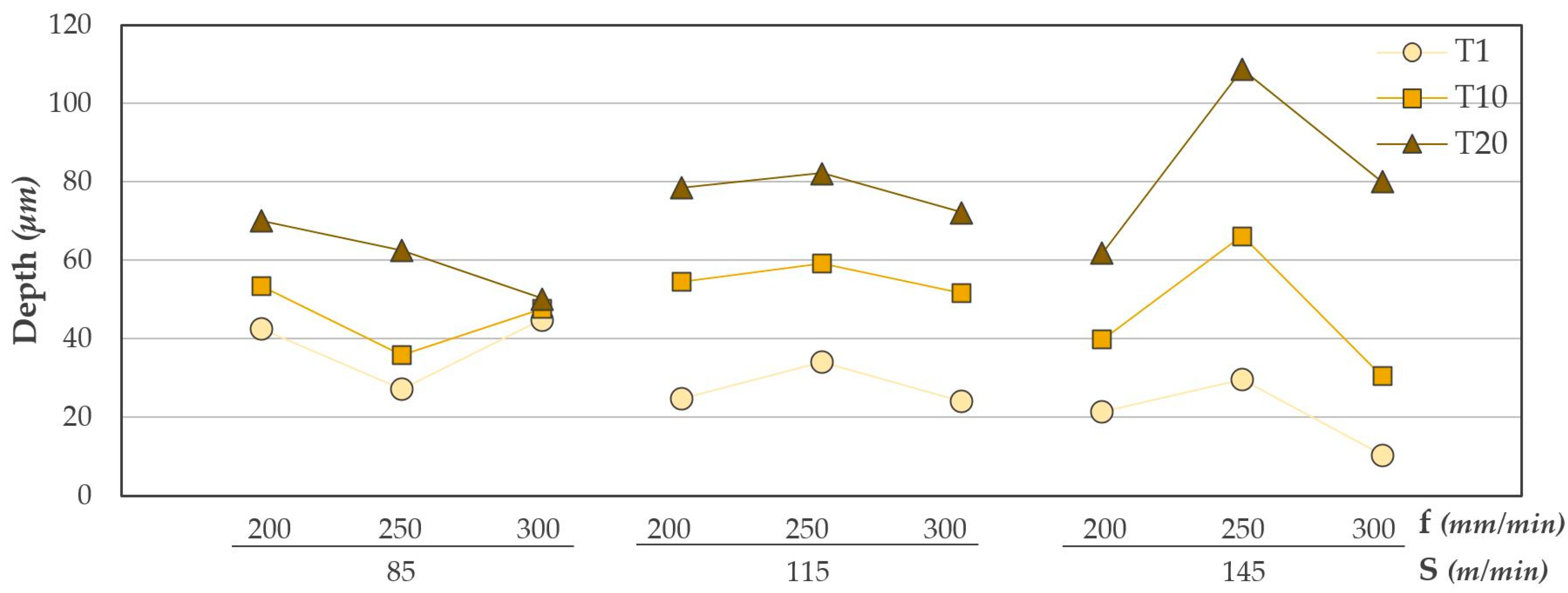

3.3. Adhesive

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Cirillo, P.; Marino, A.; Natale, C.; Di Marino, E.; Chiacchio, P.; De Maria, G. A low-cost and flexible solution for one-shot cooperative robotic drilling of aeronautic stack materials. IFAC PapersOnLine 2017, 50, 4602–4609. [Google Scholar] [CrossRef]

- Gómez-Parra, A.; Álvarez-Alcón, M.; Salguero, J.; Batista, M.; Marcos, M. Analysis of the evolution of the built-up edge and built-up layer formation mechanisms in the dry turning of aeronautical aluminium alloys. Wear 2013, 302, 1209–1218. [Google Scholar] [CrossRef]

- Wang, C.-Y.; Chen, Y.-H.; An, Q.-L.; Cai, X.-J.; Ming, W.-W.; Chen, M. Drilling temperature and hole quality in drilling of CFRP/aluminum stacks using diamond coated drill. Int. J. Precis. Eng. Manuf. 2015, 16, 1689–1697. [Google Scholar] [CrossRef]

- Zitoune, R.; Krishnaraj, V.; Collombet, F. Study of drilling of composite material and aluminium stack. Compos. Struct. 2010, 92, 1246–1255. [Google Scholar] [CrossRef]

- Nagaraja, R.; Rangaswamy, T. Drilling of CFRP and GFRP composite laminates using one shot solid carbide step drill K44. AIP Conf. Proc. 2018, 020025. [Google Scholar] [CrossRef]

- Salguero, J.; Ponce, M.B.; Fernandez-Vidal, S.R.; Mayuet, P.; Rosales, E.I.; Marcos, M. Cutting Speed and Feedrate Based Analysis of Cutting Forces in the One Shot Drilling (OSD) of CFRC/Al Hybrid Stacks. In Proceedings of the Volume 2B: Advanced Manufacturing; ASME: Montreal, QC, Canada, 2014; Paper No. IMECE2014-38027; p. V02BT02A057. 7p, ISBN 978-0-7918-4644-5. [Google Scholar] [CrossRef]

- Fernández-Vidal, S.R.; Mayuet, P.; Rivero, A.; Salguero, J.; Del Sola, I.; Marcos, M. Analysis of the effects of tool wear on dry helical milling of Ti6Al4V alloy. Procedia Eng. 2015, 132, 593–599. [Google Scholar] [CrossRef]

- Lawcock, G.; Ye, L.; Mai, Y.; Sun, C. The effect of adhesive bonding between aluminum and composite prepreg on the mechanical properties of carbon-fiber- reinforced metal laminates. Compos. Sci. Technol. 2006, 57, 35–45. [Google Scholar] [CrossRef]

- Cano, R.J.; Loos, A.C.; Jensen, B.J.; Britton, S.M.; Tuncol, G.; Long, K. Epoxy/glass and polyimide (LaRC PETI-8)/carbon fiber metal laminates made by the VARTM process. SAMPE J. 2011, 47, 50–58. [Google Scholar]

- Huang, Z.; Sugiyama, S.; Yanagimoto, J. Adhesive-embossing hybrid joining process to fiber-reinforced thermosetting plastic and metallic thin sheets. Procedia Eng. 2014, 81, 2123–2128. [Google Scholar] [CrossRef]

- Martinsen, K.; Hu, S.J.; Carlson, B.E. Joining of dissimilar materials. CIRP Ann. Manuf. Technol. 2015, 64, 679–699. [Google Scholar] [CrossRef]

- Samaei, M.; Zehsaz, M.; Chakherlou, T.N. Experimental and numerical study of fatigue crack growth of aluminum alloy 2024-T3 single lap simple bolted and hybrid (adhesive/bolted) joints. Eng. Fail. Anal. 2016, 59, 253–268. [Google Scholar] [CrossRef]

- Higgins, A. Adhesive bonding of aircraft structures. Int. J. Adhes. Adhes. 2000, 20, 367–376. [Google Scholar] [CrossRef]

- Zhang, K.; Yang, Z.; Li, Y. A method for predicting the curing residual stress for CFRP/Al adhesive single-lap joints. Int. J. Adhes. Adhes. 2013, 46, 7–13. [Google Scholar] [CrossRef]

- Kuo, C.L.; Soo, S.L.; Aspinwall, D.K.; Carr, C.; Bradley, S.; M’Saoubi, R.; Leahy, W. Development of single step drilling technology for multilayer metallic-composite stacks using uncoated and PVD coated carbide tools. J. Manuf. Process. 2018, 31, 286–300. [Google Scholar] [CrossRef]

- Ashrafi, S.A.; Sharif, S.; Farid, A.A.; Yahya, M. Performance evaluation of carbide tools in drilling CFRP-Al stacks. J. Compos. Mater. 2013, 48, 2071–2084. [Google Scholar] [CrossRef]

- D’Orazio, A.; El Mehtedi, M.; Forcellese, A.; Nardinocchi, A.; Simoncini, M. Tool wear and hole quality in drilling of CFRP/AA7075 stacks with DLC and nanocomposite TiAlN coated tools. J. Manuf. Process. 2017, 30, 582–592. [Google Scholar] [CrossRef]

- Krishnaraj, V.; Prabukarthi, A.; Ramanathan, A.; Elanghovan, N.; Kumar, M.S.; Zitoune, R.; Davim, J.P. Optimization of machining parameters at high speed drilling of carbon fiber reinforced plastic (CFRP) laminates. Compos. Part. B Eng. 2012, 43, 1791–1799. [Google Scholar] [CrossRef]

- Giasin, K.; Ayvar-Soberanis, S.; Hodzic, A. Evaluation of cryogenic cooling and minimum quantity lubrication effects on machining GLARE laminates using design of experiments. J. Clean. Prod. 2016, 135, 533–548. [Google Scholar] [CrossRef]

- Kuo, C.; Li, Z.; Wang, C. Multi-objective optimisation in vibration-assisted drilling of CFRP/Al stacks. Compos. Struct. 2017, 173, 196–209. [Google Scholar] [CrossRef]

- Wang, H.; Sun, J.; Li, J.; Lu, L.; Li, N. Evaluation of cutting force and cutting temperature in milling carbon fiber-reinforced polymer composites. Int. J. Adv. Manuf. Technol. 2016, 82, 1517–1525. [Google Scholar] [CrossRef]

- Kyratsis, P.; Markopoulos, A.; Efkolidis, N.; Maliagkas, V.; Kakoulis, K. Prediction of thrust force and cutting torque in drilling based on the response surface methodology. Machines 2018, 6, 24. [Google Scholar] [CrossRef]

- Uddin, M.; Basak, A.; Pramanik, A.; Singh, S. Evaluating hole quality in drilling of Al 6061 alloys. Materials 2018, 11, 2443. [Google Scholar] [CrossRef] [PubMed]

- Bleicher, F.; Wiesinger, G.; Kumpf, C.; Finkeldei, D.; Baumann, C.; Lechner, C. Vibration assisted drilling of CFRP/metal stacks at low frequencies and high amplitudes. Prod. Eng. 2018, 12, 289–296. [Google Scholar] [CrossRef]

- Jallageas, J.; K’Nevez, J.Y.; Chérif, M.; Cahuc, O. Modeling and optimization of vibration-assisted drilling on positive feed drilling unit. Int. J. Adv. Manuf. Technol. 2013, 67, 1205–1216. [Google Scholar] [CrossRef]

- Sorrentino, L.; Turchetta, S.; Bellini, C. In process monitoring of cutting temperature during the drilling of FRP laminate. Compos. Struct. 2017, 168, 549–561. [Google Scholar] [CrossRef]

| |||||||||

|---|---|---|---|---|---|---|---|---|---|

| DC (mm) | LU (mm) | DCON (mm) | SIG (°) | PL (mm) | OAL (mm) | LF (mm) | LCF (mm) | Helix Angle (°) | Material |

| 7.92 | 25.00 | 8.00 | 118.00 140.00 | 1.20 | 80.00 | 78.80 | 30.00 | 29.82 | Carbidre Substrate Uncoated |

| Orientation (°) | Reinforcement | Matrix | Tensile Strength (MPa) | ILSS (MPa) | Tg (°C) |

|---|---|---|---|---|---|

| 0/90 | DowAksa A42 carbon fiber 49 Vol % | Epoxy DOW Voraforce 5300 51 Vol % | 871 | 52 | 121 |

| Composition | Density (g/cc) | Ultimate Tensile Strength (Mpa) | Yield Tensile Strength (Mpa) | Elongation at Break (%) | Modulus of Elasticity (GPa) |

|---|---|---|---|---|---|

| Al 90.7–94.7%, Cu 3.8–4.9%, Mg 1.2–1.8%, Mn 0.30–0.90%, Zn 0.25%, Ti 0.15%, other 0.15% | 2.78 | 425 | 310 | ≥10 | 73.1 |

| Polymerization | Operating Temperature (°C) | Tg (°C) | Elongation at Break (%) | Fixture Time (min) | Full Cure (h) | Lap Shear Strength (MPa) | Tensile Strength at Break (MPa) | Tensile Modulus (MPa) |

|---|---|---|---|---|---|---|---|---|

| Room Temp. | −40/150 | 86 | 50 | 120 | 24 | 16 | 8–10 | 180 |

| Trial | S (m/min) | f (mm/min) | Holes Machined 1 | Lubrication |

|---|---|---|---|---|

| 1 | 85 | 200 | 20 | Dry |

| 2 | 85 | 250 | 20 | Dry |

| 3 | 85 | 300 | 20 | Dry |

| 4 | 115 | 200 | 20 | Dry |

| 5 | 115 | 250 | 20 | Dry |

| 6 | 115 | 300 | 20 | Dry |

| 7 | 145 | 200 | 20 | Dry |

| 8 | 145 | 250 | 20 | Dry |

| 9 | 145 | 300 | 20 | Dry |

| Trial | Hole | Ø [mm (±µm)] | Ra [µm (±µm)] | Depth [µm (±µm)] | ||

|---|---|---|---|---|---|---|

| CFRP | Al | CFRP | Al | Adhesive | ||

| 1 | 1 | 8.031 (±0.816) | 8.042 (±0.408) | 1.38 (±0.033) | 1.62 (±0.065) | 42.584 (±0.781) |

| 10 | 7.998 (±1.225) | 8.050 (±0.816) | 7.32 (±0.033) | 6.23 (±0.041) | 27.136 (±0.887) | |

| 20 | 7.998 (±0.408) | 8.060 (±0.002) | 7.47 (±0.024) | 12.22 (±0.139) | 44.910 (±0.678) | |

| 2 | 1 | 8.026 (±0.816) | 8.022 (±1.633) | 1.18 (±0.065) | 2.71 (±0.163) | 24.730 (±0.906) |

| 10 | 8.036 (±2.041) | 8.052 (±1.225) | 4.43 (±0.065) | 7.35 (±0.163) | 33.924 (±0.746) | |

| 20 | 8.057 (±0.408) | 8.031 (±0.408) | 2.90 (±0.098) | 4.53 (±0.122) | 23.937 (±0.737) | |

| 3 | 1 | 8.052 (±0.408) | 8.062 (±1.225) | 2.92 (±0.049) | 3.20 (±0.114) | 21.322 (±0.431) |

| 10 | 8.079 (±0.816) | 8.066 (±1.225) | 4.82 (±0.057) | 5.40 (±0.220) | 29.644 (±0.707) | |

| 20 | 7.997 (±1.225) | 8.052 (±1.225) | 3.72 (±0.147) | 4.97 (±0.147) | 10.351 (±0.687) | |

| 4 | 1 | 8.077 (±1.225) | 8.055 (±1.225) | 1.20 (±0.122) | 3.58 (±0.147) | 53.363 (±0.296) |

| 10 | 8.091 (±0.408) | 8.071 (±0.816) | 5.53 (±0.008) | 3.57 (±0.204) | 35.714 (±0.485) | |

| 20 | 8.062 (±1.225) | 8.064 (±1.633) | 4.06 (±0.147) | 3.68 (±0.131) | 47.633 (±0.892) | |

| 1 | 8.095 (±2.449) | 8.082 (±1.633) | 3.23 (±0.016) | 4.82 (±0.057) | 54.542 (±0.532) | |

| 5 | 10 | 8.059 (±0.408) | 8.079 (±0.816) | 3.71 (±0.114) | 6.06 (±0.122) | 59.167 (±0.558) |

| 20 | 8.059 (±1.289) | 8.081 (±0.816) | 4.21 (±0.041) | 7.98 (±0.090) | 51.512 (±0.401) | |

| 1 | 8.100 (±1.633) | 8.054 (±2.449) | 1.57 (±0.024) | 4.04 (±0.073) | 39.640 (±0.719) | |

| 6 | 10 | 8.091 (±0.816) | 8.071 (±0.408) | 3.96 (±0.220) | 5.28 (±0.139) | 66.190 (±0.441) |

| 20 | 8.064 (±0.816) | 8.079 (±0.816) | 5.25 (±0.106) | 6.66 (±0.033) | 30.546 (±0.552) | |

| 7 | 1 | 8.062 (±1.225) | 8.037 (±0.408) | 1.84 (±0.090) | 2.28 (±0.049) | 70.171 (±0.474) |

| 10 | 8.043 (±0.816) | 8.041 (±0.816) | 2.81 (±0.057) | 2.38 (±0.163) | 62.413 (±0.550) | |

| 20 | 8.040 (±1.633) | 8.023 (±0.408) | 2.67 (±0.155) | 2.58 (±0.090) | 50.236 (±0.575) | |

| 8 | 1 | 7.997 (±1.225) | 7.994 (±1.225) | 1.50 (±0.016) | 5.12 (±0.090) | 78.464 (±0.495) |

| 10 | 7.992 (±1.633) | 8.020 (±2.449) | 4.61 (±0.024) | 6.15 (±0.139) | 82.222 (±0.603) | |

| 20 | 7.998 (±0.408) | 8.021 (±0.816) | 3.61 (±0.180) | 6.19 (±0.057) | 72.189 (±0.612) | |

| 9 | 1 | 8.041 (±0.408) | 8.006 (±1.633) | 1.59 (±0.016) | 6.09 (±0.171) | 61.680 (±0.457) |

| 10 | 8.043 (±0.816) | 8.035 (±1.225) | 1.82 (±0.057) | 5.76 (±0.163) | 108.765 (±0.257) | |

| 20 | 8.040 (±1.225) | 8.030 (±0.408) | 6.08 (±0.106) | 6.94 (±0.057) | 80.120 (±0.596) | |

| Source | DF | Adj SS | Adj MS | F-Value | P-Value |

|---|---|---|---|---|---|

| CFRP | |||||

| S (m/min) | 1 | 5.1554 | 5.1554 | 2.65 | 0.122 |

| f (mm/min) | 1 | 0.3655 | 0.3655 | 0.19 | 0.670 |

| Drills | 1 | 30.8374 | 30.8374 | 15.88 | 0.001 |

| Error | 17 | 33.0218 | 1.9425 | ||

| Total | 26 | 83.1892 | |||

| UNS A92024 | |||||

| S (m/min) | 1 | 1.416 | 1.4164 | 0.53 | 0.478 |

| f (mm/min) | 1 | 5.606 | 5.6057 | 2.08 | 0.167 |

| Drills | 1 | 27.602 | 27.6024 | 10.26 | 0.005 |

| Error | 17 | 45.741 | 2.6906 | ||

| Total | 26 | 127.240 | |||

| Source | DF | Adj SS | Adj MS | F-Value | P-Value |

|---|---|---|---|---|---|

| CFRP | |||||

| S (m/min) | 01 | 0.002912 | 0.002912 | 17.56 | 0.001 |

| f (mm/min) | 01 | 0.000008 | 0.000008 | 0.05 | 0.834 |

| Drills | 01 | 0.000425 | 0.000425 | 2.57 | 0.128 |

| Error | 17 | 0.002818 | 0.000166 | ||

| Total | 26 | 0.014807 | |||

| UNS A92024 | |||||

| S (m/min) | 01 | 0.000017 | 0.000017 | 0.03 | 0.863 |

| f (mm/min) | 01 | 0.000616 | 0.000616 | 1.11 | 0.307 |

| Drills | 01 | 0.001531 | 0.001531 | 2.76 | 0.115 |

| Error | 17 | 0.009441 | 0.000555 | ||

| Total | 26 | 0.028340 |

| Source | DF | Adj SS | Adj MS | F-Value | P-Value |

|---|---|---|---|---|---|

| ADHESIVE | |||||

| Model | 9 | 11168.5 | 1240.94 | 9.22 | 0.000 |

| S (m/min) | 1 | 16.6 | 16.6 | 0.12 | 0.730 |

| f (mm/min | 1 | 68.1 | 68.06 | 0.51 | 0.487 |

| Drills | 1 | 9235.4 | 9235.4 | 68.60 | 0.000 |

| S (m/min) *Drills | 1 | 1225.5 | 1225.47 | 9.10 | 0.008 |

| Error | 17 | 2288.6 | 134.62 | ||

| Total | 26 | 13457.1 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bañon, F.; Sambruno, A.; Fernandez-Vidal, S.; Fernandez-Vidal, S.R. One-Shot Drilling Analysis of Stack CFRP/UNS A92024 Bonding by Adhesive. Materials 2019, 12, 160. https://doi.org/10.3390/ma12010160

Bañon F, Sambruno A, Fernandez-Vidal S, Fernandez-Vidal SR. One-Shot Drilling Analysis of Stack CFRP/UNS A92024 Bonding by Adhesive. Materials. 2019; 12(1):160. https://doi.org/10.3390/ma12010160

Chicago/Turabian StyleBañon, Fermin, Alejandro Sambruno, Sergio Fernandez-Vidal, and Severo Raul Fernandez-Vidal. 2019. "One-Shot Drilling Analysis of Stack CFRP/UNS A92024 Bonding by Adhesive" Materials 12, no. 1: 160. https://doi.org/10.3390/ma12010160

APA StyleBañon, F., Sambruno, A., Fernandez-Vidal, S., & Fernandez-Vidal, S. R. (2019). One-Shot Drilling Analysis of Stack CFRP/UNS A92024 Bonding by Adhesive. Materials, 12(1), 160. https://doi.org/10.3390/ma12010160