Evaluate the Fatigue Life of CFRC Subjected to Coupled Thermo–Mechanical Loading

Abstract

1. Introduction

2. Theoretical Aspects

3. Materials and Work Method

3.1. Materials

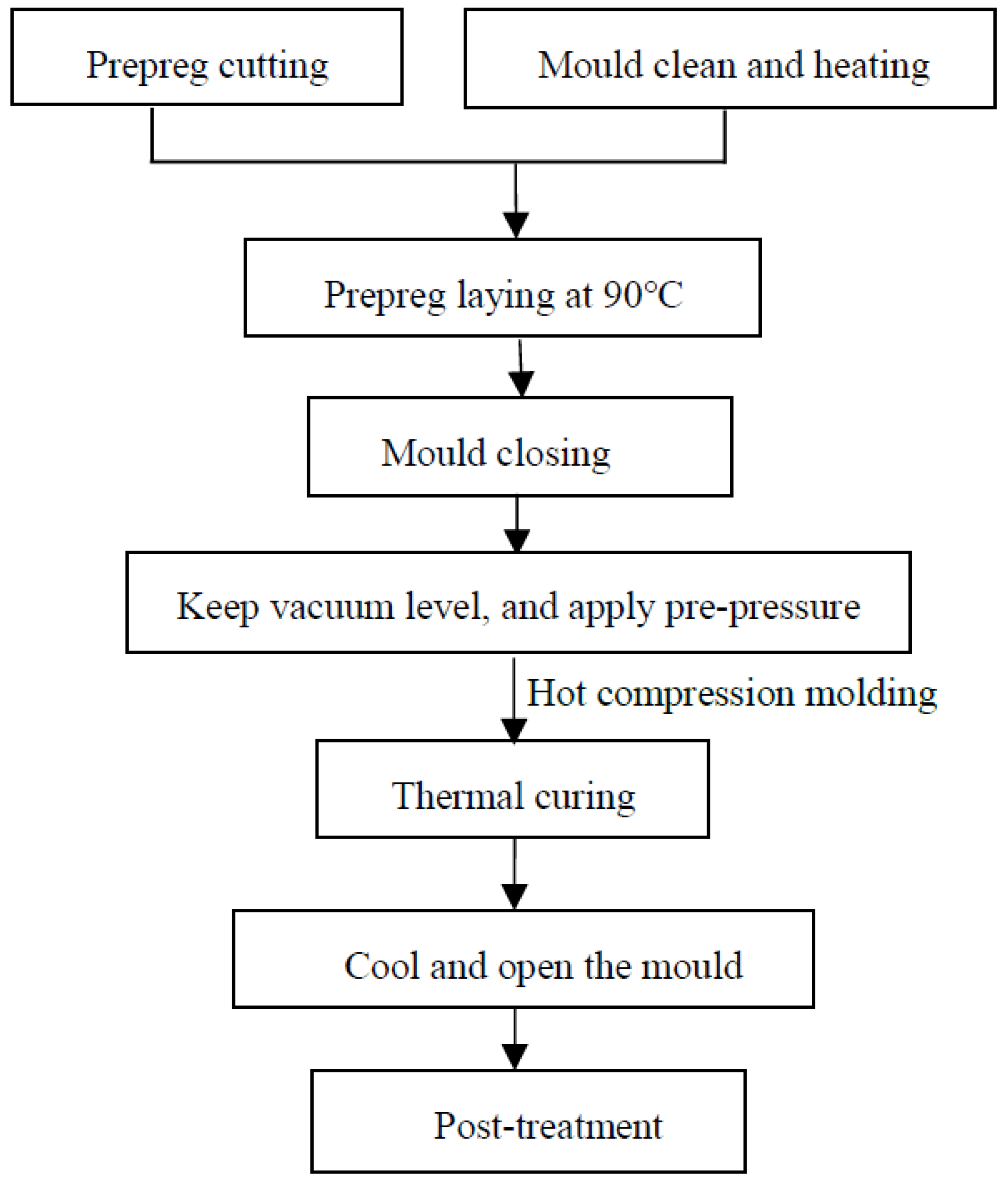

3.1.1. Specimen Preparations

- (1)

- Cut and lay the carbon fiber prepreg according to the desired sequences of composite laminates.

- (2)

- Clean mold and apply the release agent uniformly on it. In this procedure, we should try to keep the mold surface as smooth as possible.

- (3)

- Raise the ambient temperature in the mold to 90 °C, and then open the mold. Transfer the layered prepreg to the mold cavity.

- (4)

- Close the mold and start to vacuum. To acquire composite structures with a high quality, the inner vacuum degree should be kept at around −97 KPa. Moreover, a pre-pressure of 0.5 MPa is applied and kept for 5 to 15 s before the thermal curing process.

- (5)

- The inner pressure is raised to 8 to 10 MPa, and the inner temperature remains at 200 ± 3 °C. This thermal curing process lasts about 30 to 90 s.

- (6)

- Turn off the vacuum apparatus and heat source. When the temperature drops down to 80 °C, the product can be easily demolded and taken out. To acquire standard specimens of composites, the Delong DX25S machine tool (Delong CNC equipment Co. LDT, Taizhou, China) with emery wire was employed.

3.1.2. Matrix Material Properties

3.2. Work Method

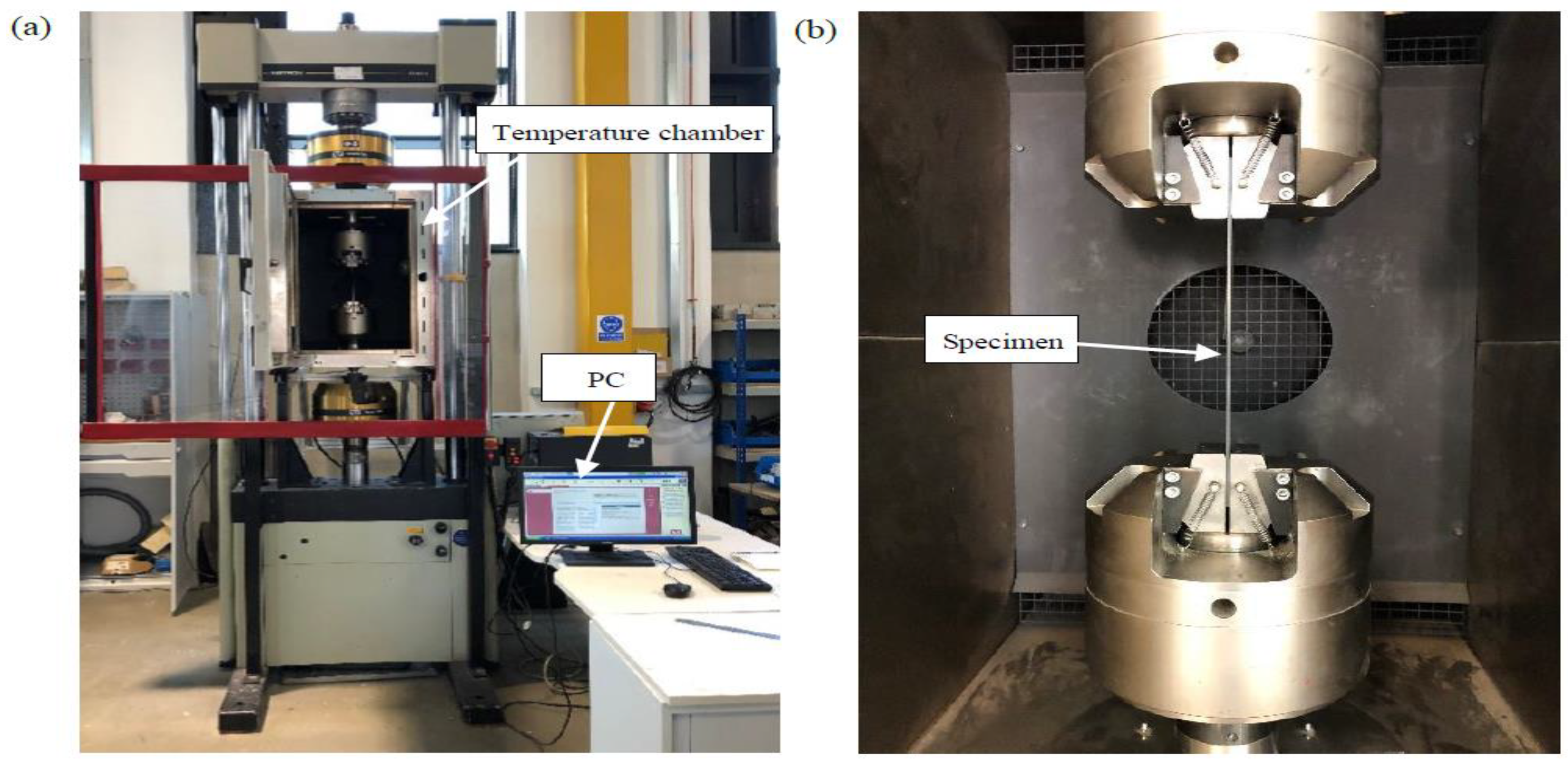

3.2.1. Tensile Test

3.2.2. Proposed Fatigue Damage Model

4. Discussions

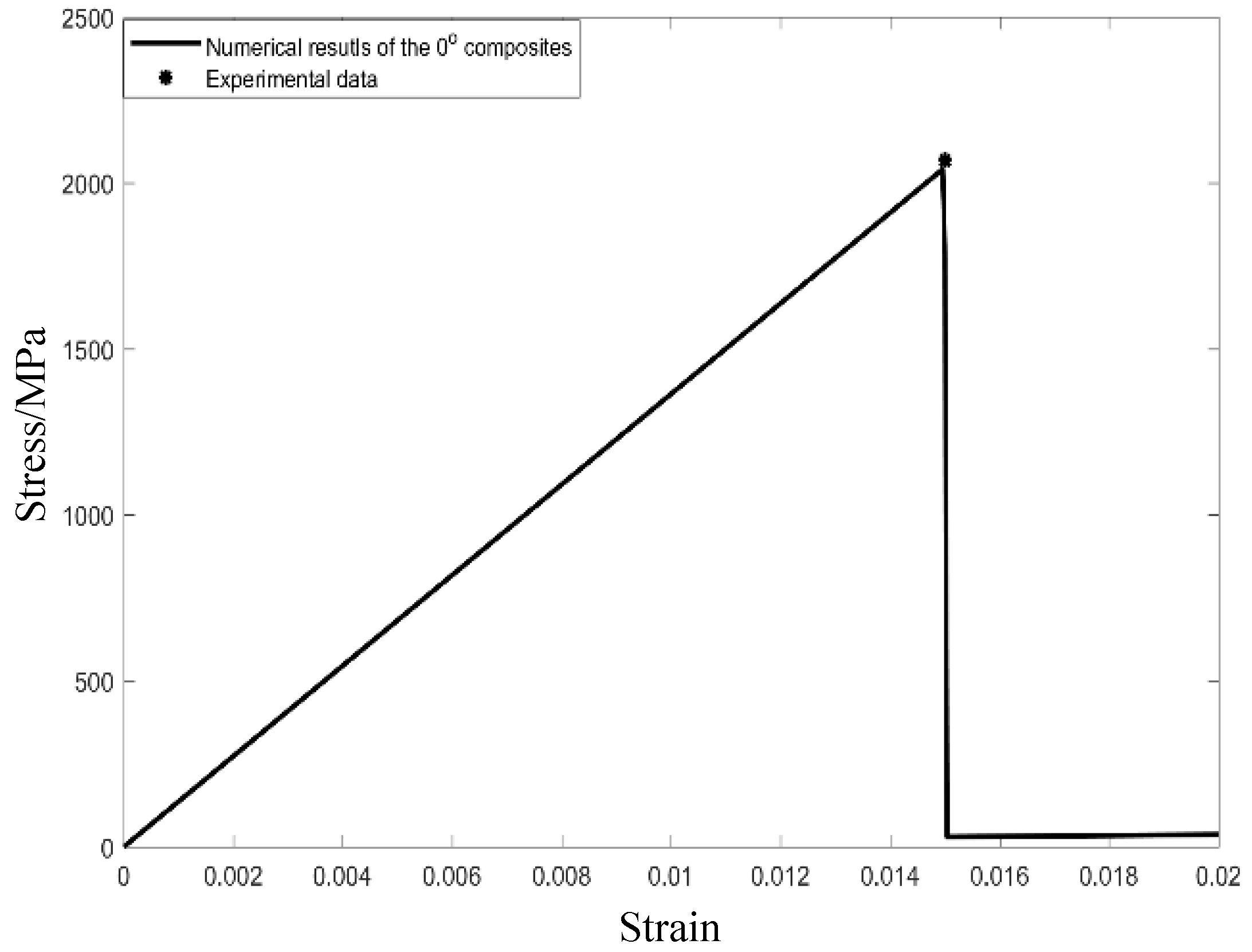

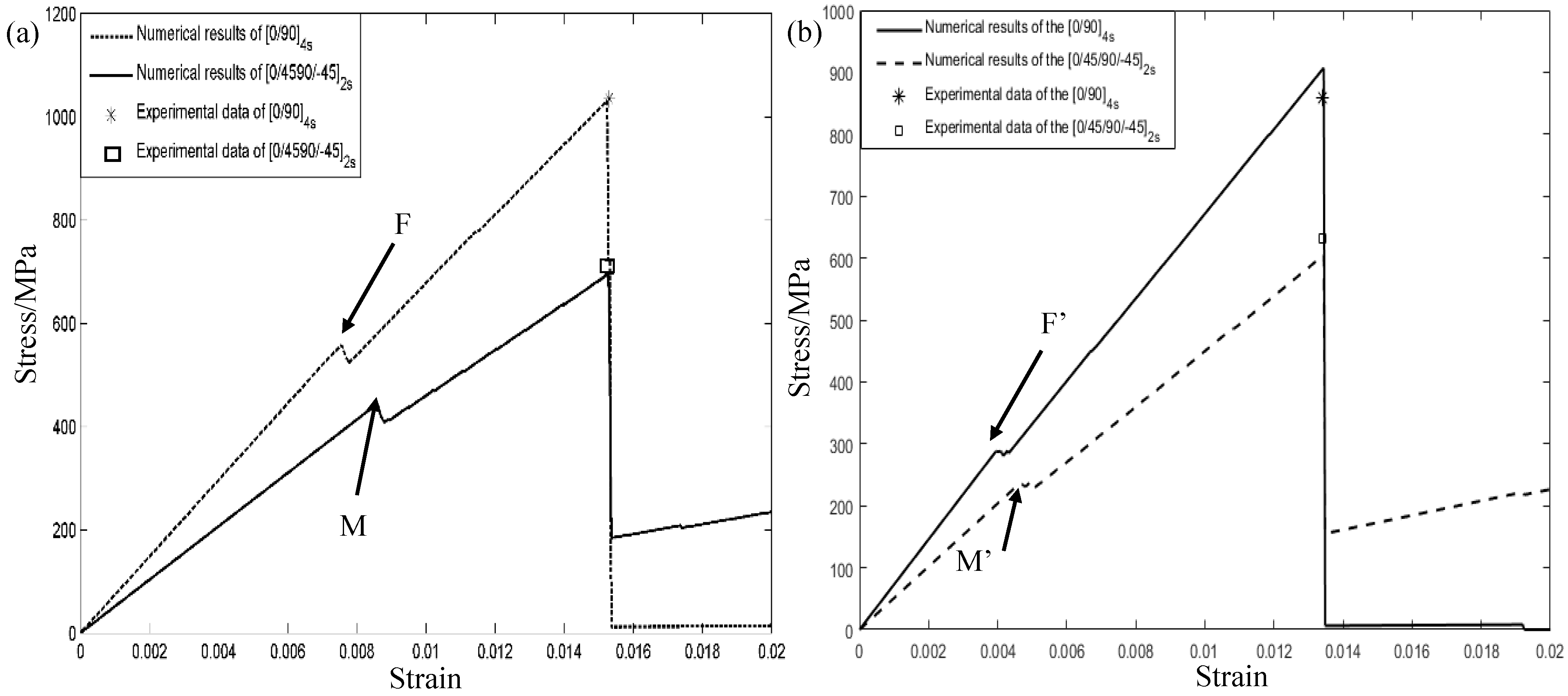

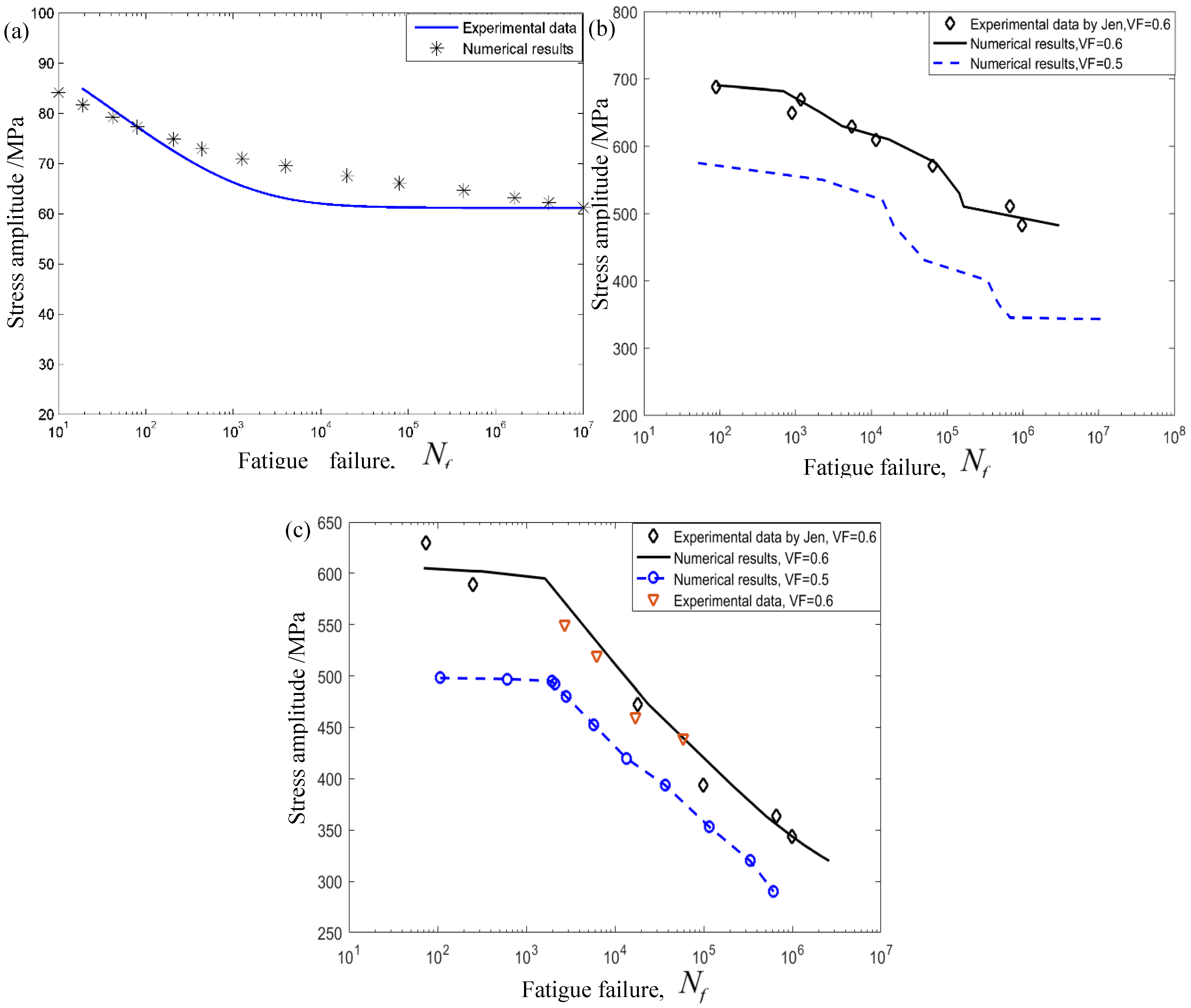

4.1. Fatigue Model Validation

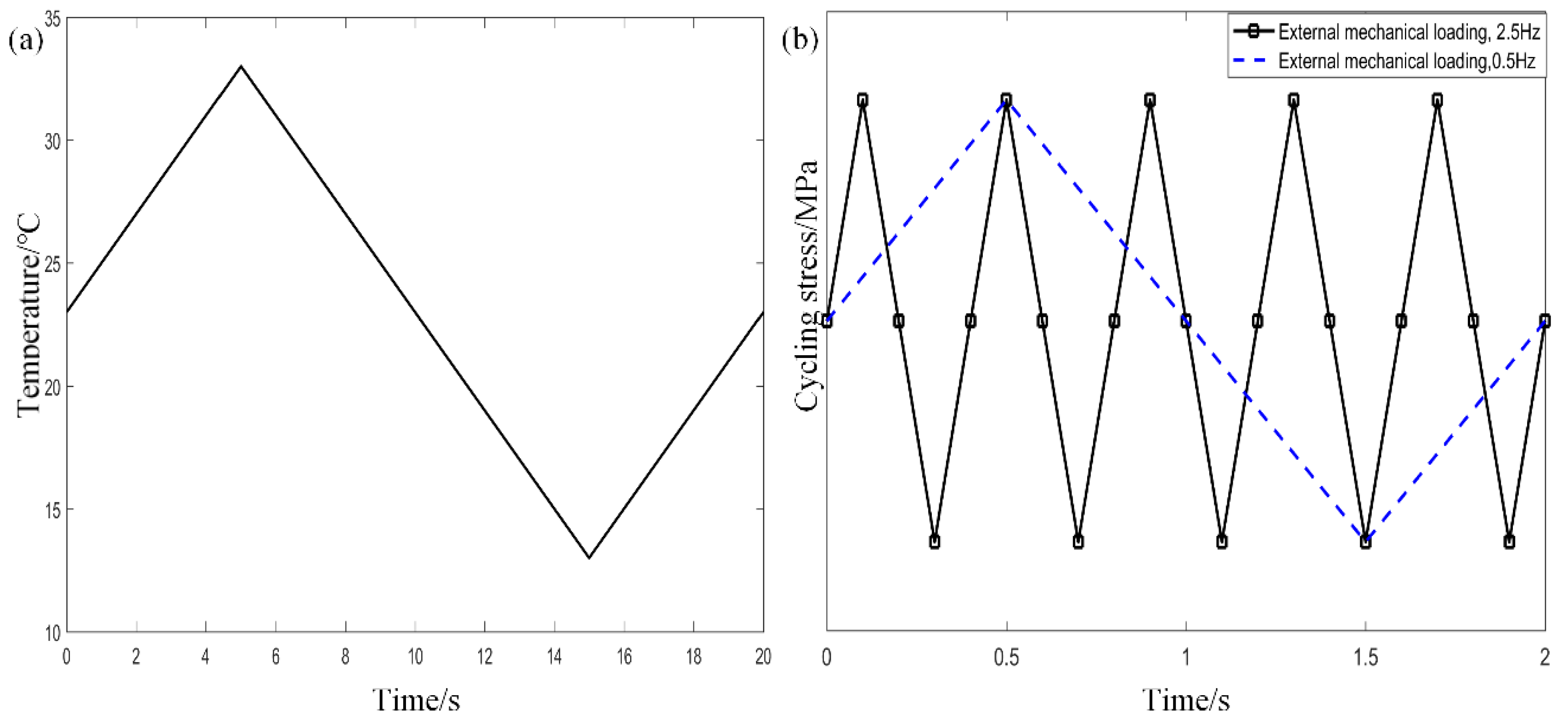

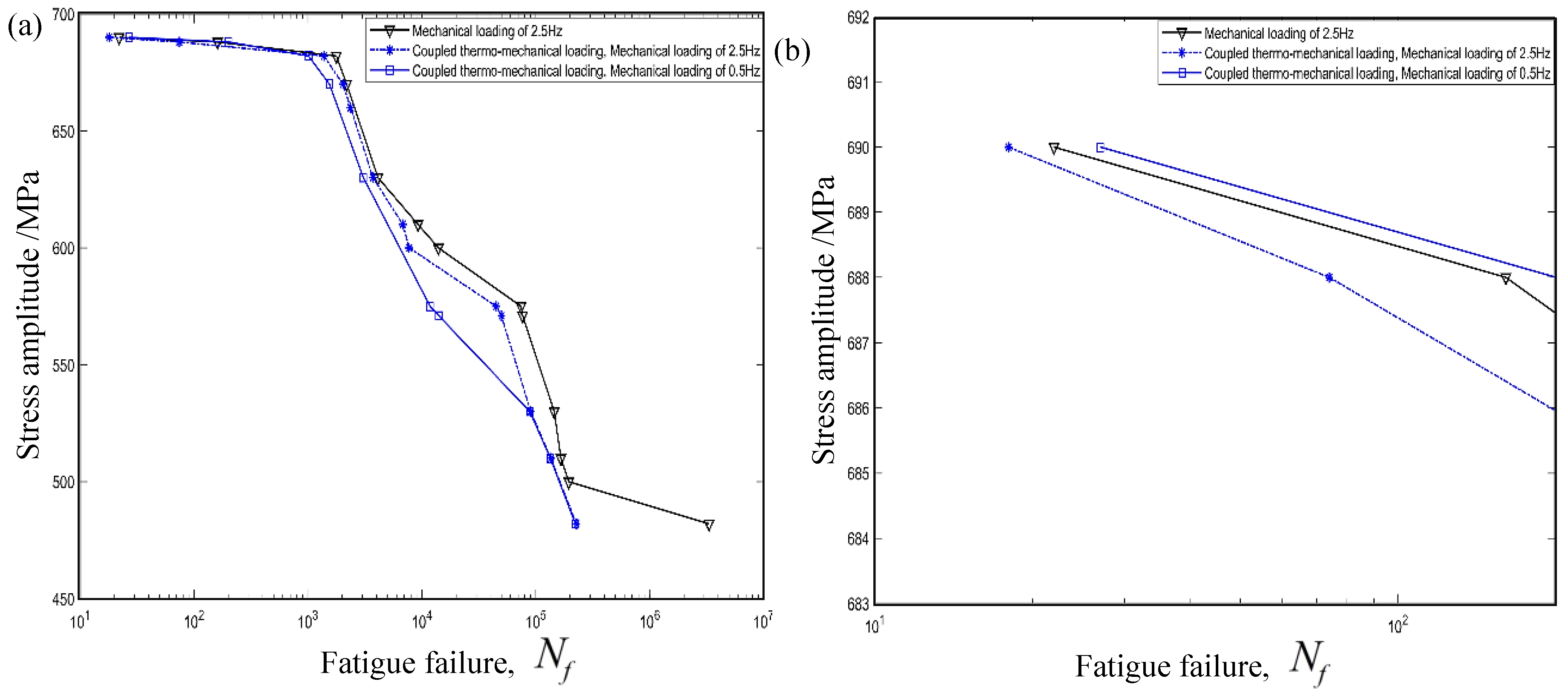

4.2. Evaluations of Fatigue Life under Coupled Thermo–Mechanical Loading

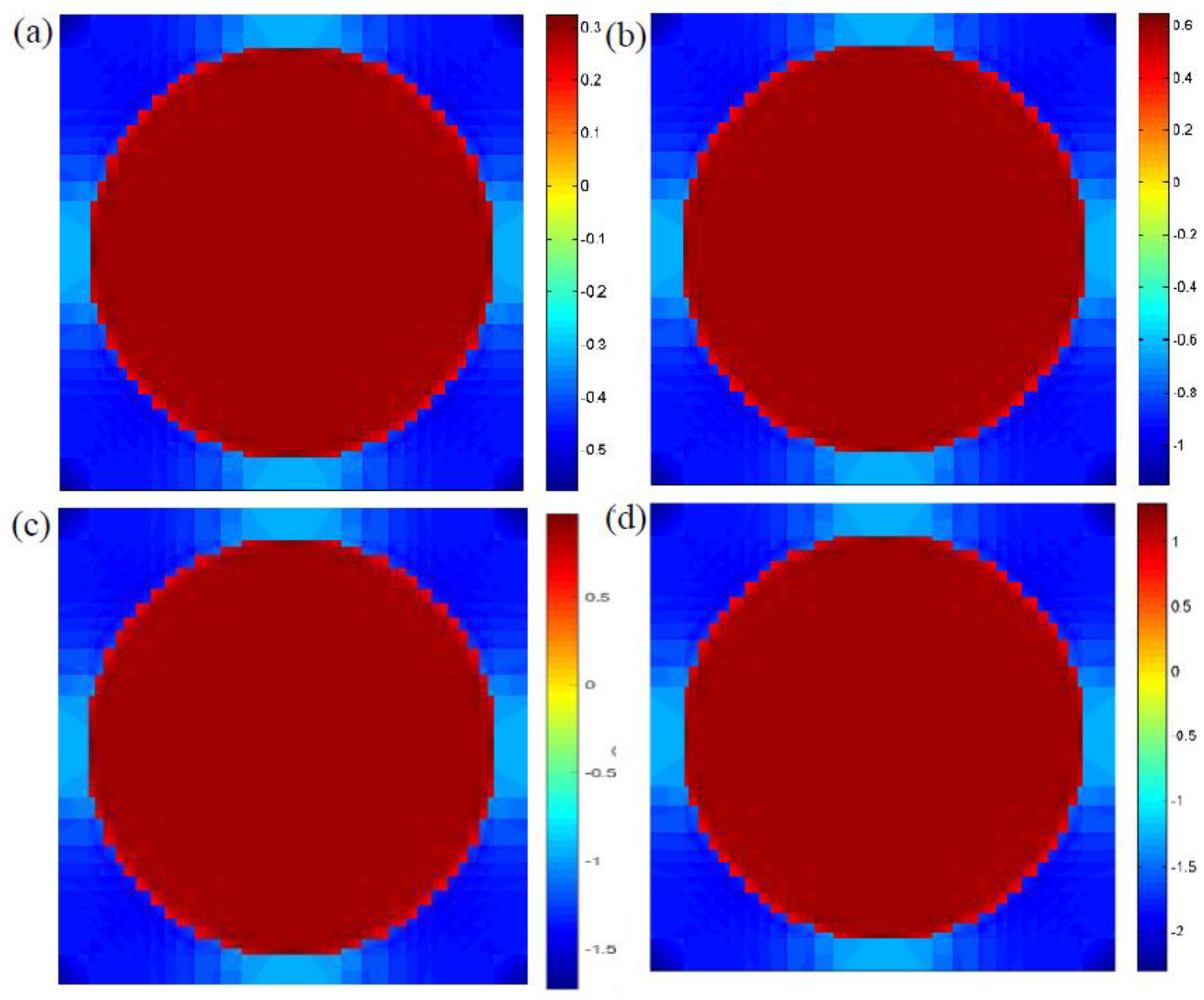

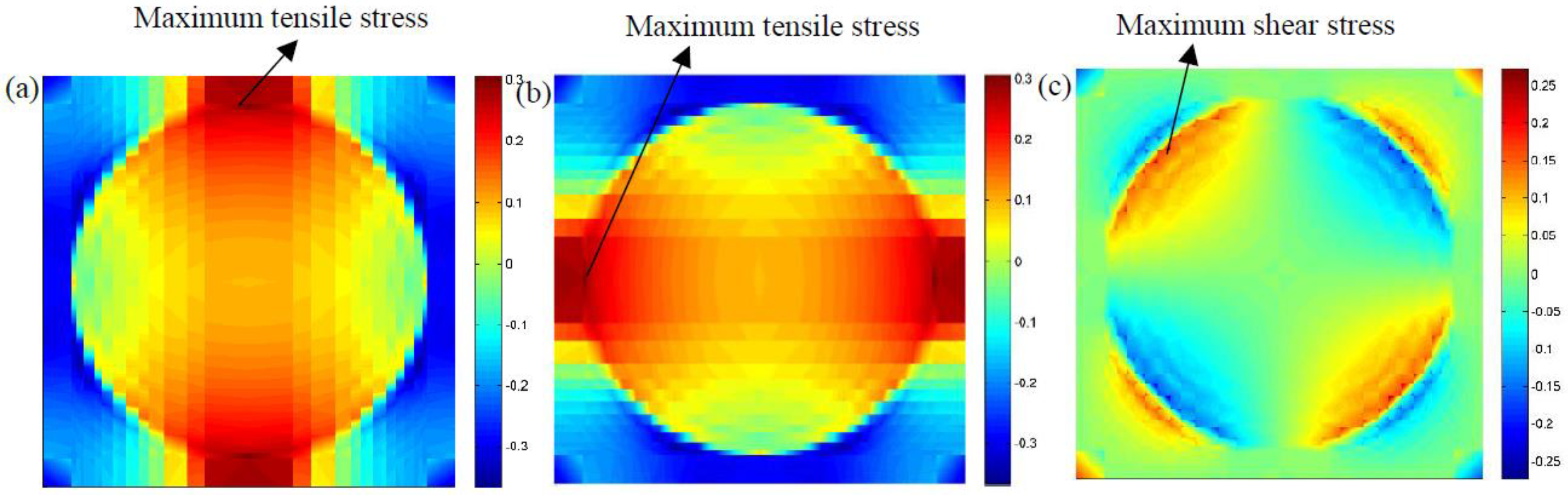

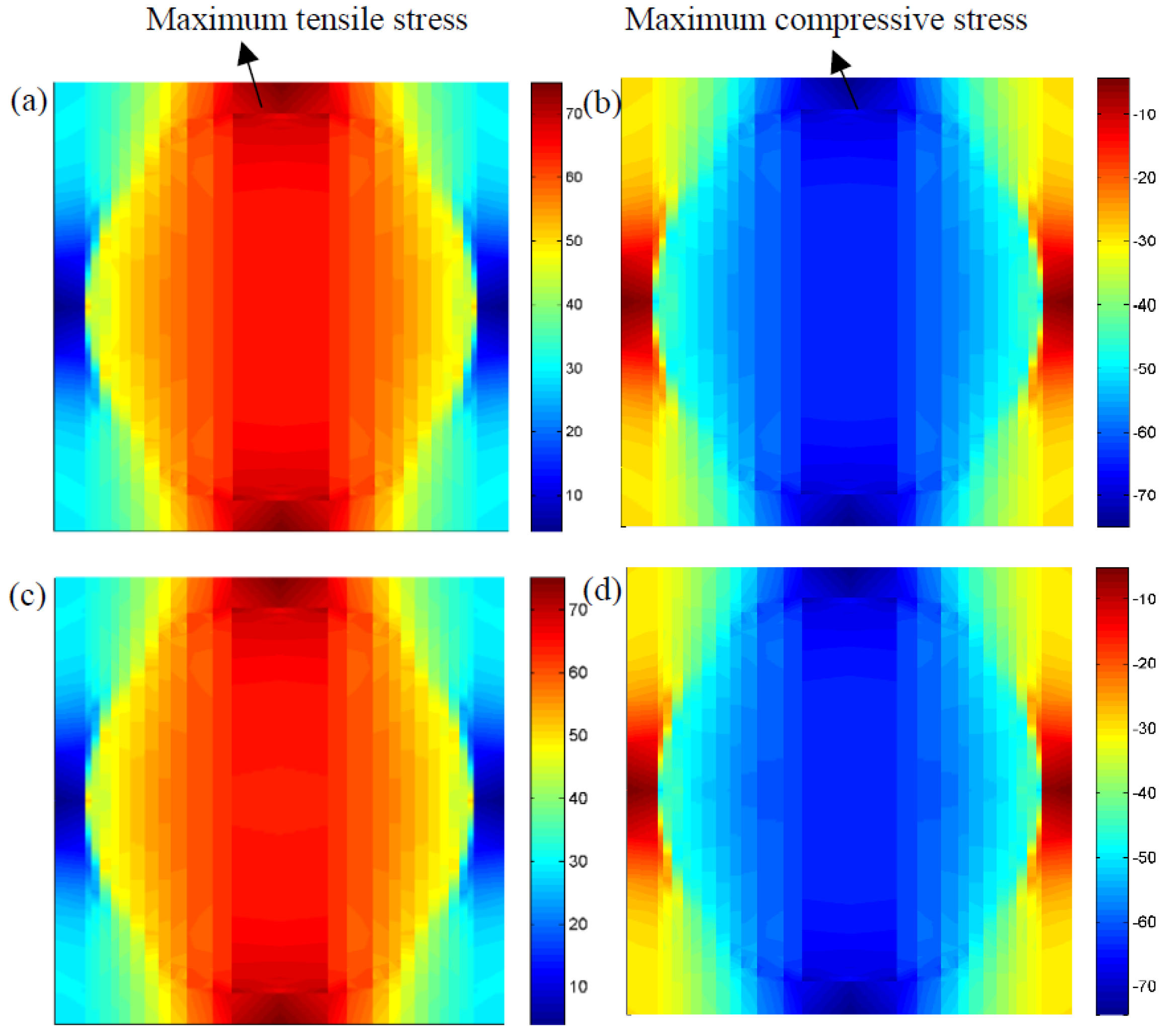

4.3. Local Stress Distribution under Coupled Thermo–Mechanical Loading

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Lee, J.S.; Kim, J. Effect of cooling rate on mechanical properties of carbon fibre fabric and polypropylene composites. Mater. Res. Express 2017, 4, 1–8. [Google Scholar] [CrossRef][Green Version]

- Yang, Z.B.; Radzienski, M.; Kudela, P.; Ostachowicz, W. Damage detection in beam-like composite structures via Chebyshev pseudo spectral modal curvature. Compos. Struct. 2017, 168, 1–12. [Google Scholar] [CrossRef]

- Khan, M.A.; Kumar, S. Interfacial stresses in single-side composite patch-repairs with material tailored bondline. Mech. Adv. Mater. Struct. 2016, 25, 304–318. [Google Scholar] [CrossRef]

- Peng, C.; Li, X. The mechanical properties of PEEK/CF composites reinforced with ZrO2 nanoparticles. Mech. Compos. Mater. 2014, 49, 679–684. [Google Scholar] [CrossRef]

- Grenier, A.T.; Janssens, M.L.; Nash, L. Developing cone calorimeter acceptance criteria for materials used in high speed craft. Fire Mater 2000, 24, 29–35. [Google Scholar] [CrossRef]

- Gardiner, G. PEEK or PEKK in Future TPC Aerostructures? 2018. Available online: https://www.compositesworld.com/articles/peek-or-pekk-in-future-tpc-aerostructures (accessed on 4 March 2019).

- Seyfullayev, A.I.; Rustamova, M.A.; Kerimova, S.A.A. Problem of fatigue fracture mechanics of a two-layer material with edge cracks. Mech. Compos. Mater. 2017, 53, 415–424. [Google Scholar] [CrossRef]

- Li, W.N.; Cai, H.N.; Li, C.; Wang, K.; Fang, L. Micro-mechanics of failure for fatigue strength prediction of bolted joint structures of carbon fiber reinforced polymer composite. Compos. Struct. 2015, 124, 345–356. [Google Scholar] [CrossRef]

- Carvalho, O.; Buciumeanu, M.; Miranda, G. Mechanisms governing the tensile, fatigue, and wear behavior of carbon nanotube reinforced aluminum alloy. Mech. Adv. Mater. Struct. 2016, 23, 917–925. [Google Scholar] [CrossRef]

- Huang, T.; Zhang, Y.X.; Lo, S.R.; Lee, C.K. Experimental study on crack bridging in engineered cementitious composites under fatigue tensile loading. Constr. Build. Mater. 2017, 154, 167–175. [Google Scholar] [CrossRef]

- Huang, T.; Zhang, Y.X. Numerical modelling on degradation of mechanical behaviour for engineered cementitious composites under fatigue tensile loading. Eng. Fract. Mech. 2018, 188, 309–319. [Google Scholar] [CrossRef]

- Zhao, L.; Shan, M. A residual strain model for progressive fatigue damage analysis of composite structures. Compos. Struct. 2017, 169, 69–78. [Google Scholar] [CrossRef]

- Eftekhari, M.; Fatemi, A. On the strengthening effect of increasing cycling frequency on fatigue behavior of some polymers and their composites: Experiments and modeling. Int. J. Fatigue 2016, 87, 153–166. [Google Scholar] [CrossRef]

- Keulen, C.J.; Akay, E.; Melemez, F.F. Prediction of fatigue response of composite structures by monitoring the strain energy release rate with embedded fiber Bragg gratings. J. Intell. Mater. Syst. Struct. 2014, 27, 17–27. [Google Scholar] [CrossRef]

- Li, L.B. Damage monitor and life prediction of carbon fiber-reinforced ceramic-matrix composites at room and elevated temperatures using hysteresis dissipated energy-based damage parameter. Compos. Interfaces 2018, 25, 335–356. [Google Scholar]

- Zhu, Y.L. Research on Prediction of Damage Failure and Fatigue Life for C/C Composites; Nanjing University of Aeronautics and Astronautics: Nanjing, China, 2012. [Google Scholar]

- Garcea, S.C.; Sinclair, I.; Spearing, S.M. Fibre failure assessment in carbon fibre reinforced polymers under fatigue loading by synchrotron X-ray computed tomography. Compos. Sci. Technol. 2016, 133, 157–164. [Google Scholar] [CrossRef]

- Pakdel, H.; Mohammadi, B. Characteristic damage state of symmetric laminates subject to uniaxial monotonic-fatigue loading. Eng. Fract. Mech. 2018, 199, 86–100. [Google Scholar] [CrossRef]

- Alves, M.; Pimenta, S. A computationally-efficient micromechanical model for the fatigue life of unidirectional composites under tension-tension loading. Int. J. Fatigue 2018, 116, 677–690. [Google Scholar] [CrossRef]

- Hamidi, H.; Xiong, W.; Hoa, S.V. Fatigue behavior of thick composite laminates under flexural loading. Compos. Struct. 2018, 200, 277–289. [Google Scholar] [CrossRef]

- Pan, L.; Han, J.; Yang, Z. Temperature effects on the friction and wear behaviors of sicp/a356 composite against semimetallic materials. Adv. Mater. Sci. Eng. 2017, 2017, 1–12. [Google Scholar] [CrossRef]

- Yuan, M.; Yu, S.R.; Liu, E.Y. High-temperature damping capacity of fly ash cenosphere/AZ91D Mg alloy composites. Sci. Eng. Compos. Mater. 2018, 25, 197–204. [Google Scholar]

- Nguyen, D.D.; Nghiem, T.T.H. Determining the deflection of a thin composite plate in an unsteady temperature field. Mech. Compos. Mater. 2012, 48, 297–304. [Google Scholar]

- Campa, W.; Dhalle, M.M.J.; Wessel, W.A.J.; Warnet, L.; Atli-Veltin, B.; Putten, S.; Dam, J.A.M.; Brake, H.J.M. Cryogenic fatigue and stress-strain behavior of a fibre metal laminate. Phys. Procedia 2015, 67, 1043–1048. [Google Scholar] [CrossRef]

- Yang, G.X.; Yang, Y. Investigation on the thermal fatigue life evaluation method of railway brake disc with new material. Teh. Vjesn. 2018, 25, 1095–1102. [Google Scholar]

- Godin, N.; Reynaud, P.; RMili, M.; Fantozzi, G. Identification of a critical time with acoustic emission monitoring during static fatigue tests on ceramic matrix composites: Towards lifetime prediction. Appl. Sci. 2016, 6, 43. [Google Scholar] [CrossRef]

- Johnston, R. Mechanical characterisation of a fibre reinforced oxide/oxide ceramic matrix composite. J. Eur. Ceram. Soc. 2015, 35, 4513–4520. [Google Scholar]

- Pandey, A.; Arockiarajan, A. An experimental and theoretical fatigue study on macro fiber composite (MFC) under thermo-mechanical loadings. Eur. J. Mech.A/Solids 2017, 66, 26–44. [Google Scholar] [CrossRef]

- Eftekhari, M.; Fatemi, A. Creep-fatigue interaction and thermo-mechanical fatigue behaviors of thermoplastics and their composites. Int. J. Fatigue 2016, 91, 136–148. [Google Scholar] [CrossRef]

- Ye, J.J.; Chu, C.C.; Cai, H.; Wang, Y.K.; Qiao, X.J.; Zhai, Z.; Chen, X.F. A multi-scale modeling scheme for damage analysis of composite structures based on the high-fidelity generalized method of cells. Compos. Struct. 2018, 206, 42–53. [Google Scholar] [CrossRef]

- Cai, H.; Ye, J.J.; Wang, Y.K.; Jia, F.; Hong, Y.; Tian, S.H.; Chen, X.F. Matrix failures effect on damage evolution of particle reinforced composites. Mech. Adv. Mater. Struct. 2019. [Google Scholar] [CrossRef]

- Shi, P.P. Imperfect interface effect for nano-composites accounting for fiber section shape under antiplane shear. Appl. Math. Model. 2017, 43, 393–408. [Google Scholar] [CrossRef]

- Shi, P.P.; Zheng, X.J. The Yoffe-type moving tubular interface crack in a hollow composite cylinder with finite length. Int. J. Mech. Sci. 2015, 98, 29–38. [Google Scholar]

- Aboudi, J.; Arnold, S.M.; Bednarcyk, B.A. Micromechanics of Composite Materials: A Generalized Multiscale Analysis Approach; Butterworth-Heinemann: Oxford, UK, 2012. [Google Scholar]

- Ye, J.J.; Hong, Y.; Wang, Y.K.; Shi, B.Q.; Zhai, Z.; Chen, X.F. Thermal cycling influences on compressive deformations of laminate composites. Polym. Compos. 2019, 40, 2908–2918. [Google Scholar] [CrossRef]

- ASTM International D3039/D3039M. Standard Test Method for Tensile Properties of Polymer Matrix Composite Materials; ASTM: West Conshohocken, PA, USA, 2000. [Google Scholar]

- ASTM International STP1330-98. Composite Materials: Fatigue and Fracture; ASTM: West Conshohocken, PA, USA, 1998. [Google Scholar]

- Kawai, M.; Yajima, S.; Hachinohe, A.; Kawase, Y. High-temperature off-axis fatigue behaviour of unidirectional carbon-fibre-reinforced composites with different resin matrices. Compos. Sci. Technol. 2001, 61, 1285–1302. [Google Scholar] [CrossRef]

- Soden, P.D.; Hinton, M.J.; Kaddour, A.S. Lamina properties, lay-up configurations and loading conditions for a range of fiber-reinforced composite laminates. Compos. Sci. Technol. 1998, 58, 1011–1022. [Google Scholar] [CrossRef]

- Ye, J.J.; Qiu, Y.Y.; Chen, X.F.; Ma, J. Initial and final failure strength analysis of composites based on a micromechanical method. Compos. Struct. 2015, 125, 328–335. [Google Scholar] [CrossRef]

- Victrex. Materials Properties Guide-Victrex. Available online: https://www.victrex.com/~/media/literature/en/material-properties-guide_us-4-20.pdf. 2002 (accessed on 4 March 2019).

- Xiao, X.R.; Hiel, C.C.; Cardon, A.H. Characterization and modeling of nonlinear viscoelastic response of peek resin and peek composites. Compos. Eng. 1994, 4, 681–702. [Google Scholar] [CrossRef]

- Ye, J.J.; Chu, C.C.; Cai, H.; Hou, X.N.; Shi, B.Q.; Tian, S.H.; Chen, X.F.; Ye, J.Q. A multi-scale model for studying failure mechanisms of composite wind turbine blades. Compos. Struct. 2019, 212, 220–229. [Google Scholar] [CrossRef]

- Wang, Y.X. Mechanics and Structural Design of Composite Materials; East China University of science and technology Press: Shanghai, China, 2012. [Google Scholar]

- Jen, M.H.; Tseng, Y.C.; Lin, W.H. Thermo-mechanical fatigue of centrally notched and unnotched AS-4/PEEK APC-2 composite laminates. Int. J. Fatigue 2006, 28, 901–909. [Google Scholar] [CrossRef]

- Chaboch, J.L.; Lesne, P.M. A non-linear continuous fatigue damage model. Fatigue Fract. Eng. Mater. Struct. 1988, 11, 1–17. [Google Scholar] [CrossRef]

- Arnold, S.M.; Murthy, P.; Bednarcyk, B.A.; Pineda, E.J. Microstructural influence on deformation and fatigue life of composites using the generalized method of cells. In Proceedings of the 56th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Kissimmee, FL, USA, 5–9 January 2015. [Google Scholar]

- Ye, J.J.; Wang, Y.W.; Wang, Y.K.; Shi, B.Q.; Li, Y.; Qiao, X.J. Microscopic modeling and effective properties evaluation of glass/epoxy plain woven composites. Mater. Res. Express 2018, 5, 1–9. [Google Scholar] [CrossRef]

- McKeen, L.W. Fatigue and Tribological Properties of Plastics and Elastomer, 3rd ed.; Elsevier: Oxford, UK, 2016. [Google Scholar]

| PEEK | Elastic Modulus (GPa) | Poisson’s Ratio | Tensile Strength XT (MPa) | Compressive Strength Xc (MPa) | Shear Strength Sm (MPa) | Thermal Coefficient α2 (10−6/Cº) | Thermal Conductivity (W/(m °L)) |

|---|---|---|---|---|---|---|---|

| 23 °C | 3.64 | 0.4 | 96.58 | 118 | 53.0 | 47.0 | 0.163 |

| 100 °C | 1.52 | 0.4 | 50.37 | - | 14.43 | 47.0 | 0.231 |

| Temperature | 23 °C (Room Temperature) | 100 °C | ||

|---|---|---|---|---|

| Layer Sequence | ||||

| Experimental Data (GPa) | 77.68 ± 2.94 | 55.01 ± 1.68 | 75.23 ± 2.71 | 52.09 ± 1.61 |

| Theoretical Results (GPa) | 74.33 | 51.81 | 72.87 | 50.92 |

| Temperature | 23 °C | 100 °C | ||

|---|---|---|---|---|

| Layer sequence | ||||

| Experimental data (MPa) | 1035.2 | 708.9 | 859.7 | 629.52 (100 °C) |

| Theoretical results (MPa) | 1031.5907 | 696.0 | 907.1 | 604.8 |

| Chaboch’s Equation | Proposed Fatigue Pertinent Equation |

|---|---|

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ye, J.; He, W.; Shi, Y.; Wang, Y.; Cai, G.; Zhai, Z.; Chen, X. Evaluate the Fatigue Life of CFRC Subjected to Coupled Thermo–Mechanical Loading. Materials 2019, 12, 2886. https://doi.org/10.3390/ma12182886

Ye J, He W, Shi Y, Wang Y, Cai G, Zhai Z, Chen X. Evaluate the Fatigue Life of CFRC Subjected to Coupled Thermo–Mechanical Loading. Materials. 2019; 12(18):2886. https://doi.org/10.3390/ma12182886

Chicago/Turabian StyleYe, Junjie, Wangpeng He, Yang Shi, Yiwei Wang, Gaigai Cai, Zhi Zhai, and Xuefeng Chen. 2019. "Evaluate the Fatigue Life of CFRC Subjected to Coupled Thermo–Mechanical Loading" Materials 12, no. 18: 2886. https://doi.org/10.3390/ma12182886

APA StyleYe, J., He, W., Shi, Y., Wang, Y., Cai, G., Zhai, Z., & Chen, X. (2019). Evaluate the Fatigue Life of CFRC Subjected to Coupled Thermo–Mechanical Loading. Materials, 12(18), 2886. https://doi.org/10.3390/ma12182886