Magnetoresistance and Thermal Transformation Arrest in Pd2Mn1.4Sn0.6 Heusler Alloys

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussions

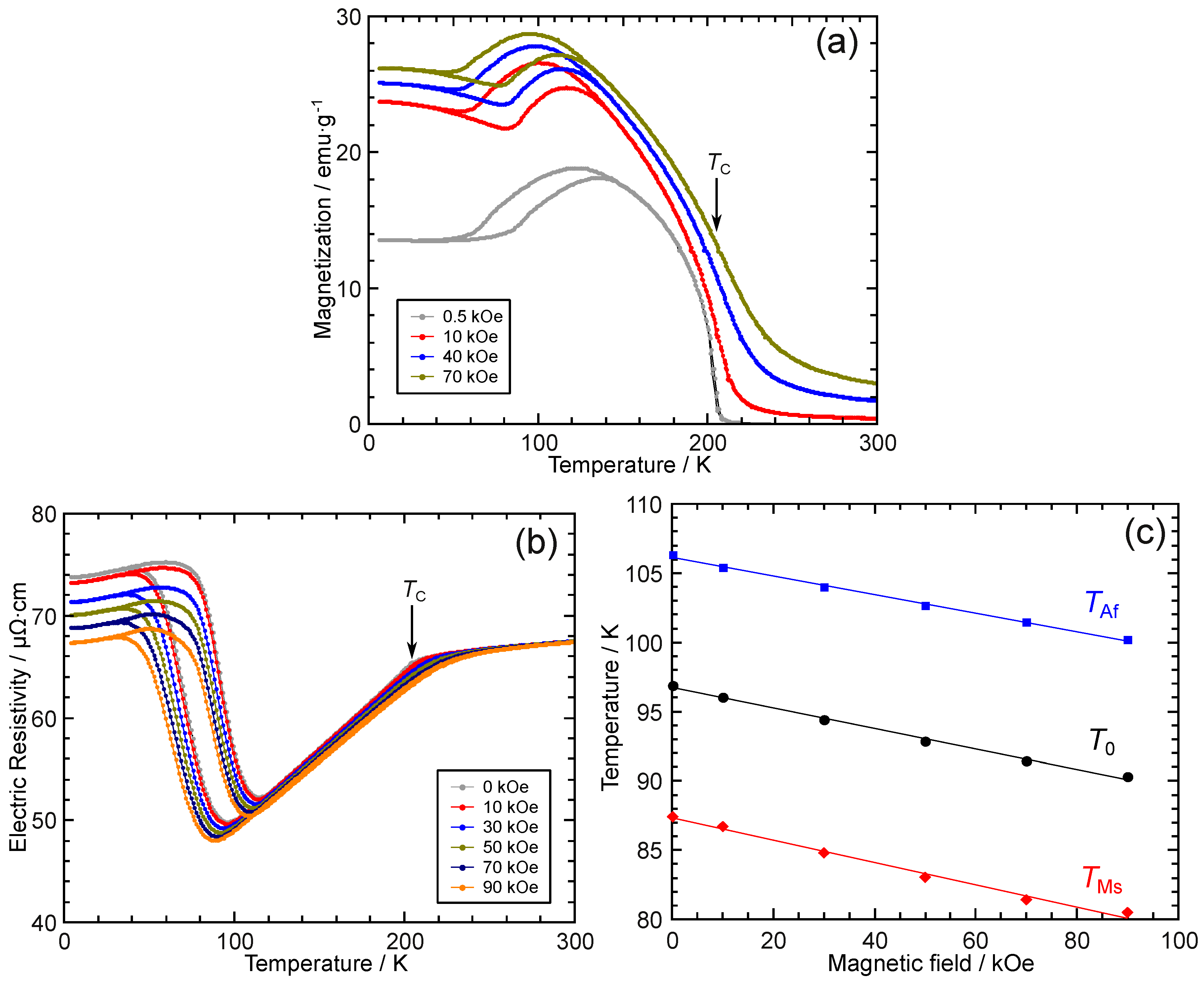

3.1. Martensitic Transformation Behaviors

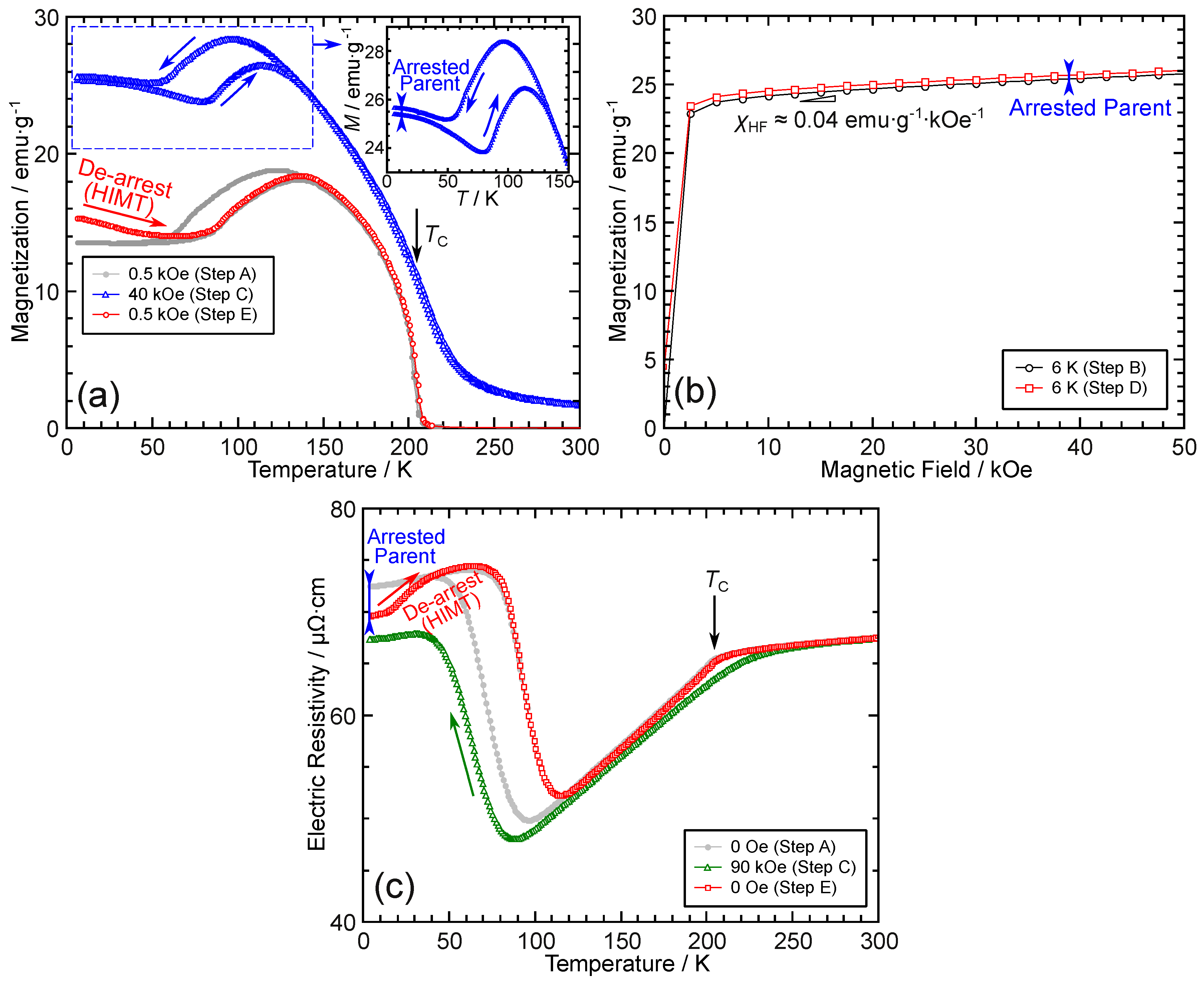

3.2. Thermal Transformation Arrest and Heating-Induced Martensitic Transformation

- Step A.

- Under 0.5 kOe, a thermomagnetization measurement was conducted starting from 300 K to 6 K and back to 300 K. The magnetic field was turned off, and the temperature was set to 6 K.

- Step B.

- At 6 K, a magnetization measurement up to 50 kOe was conducted.

- Step C.

- Under 40 kOe, a magnetization measurement was conducted starting from 6 K to 300 K and back to 6 K. The magnetic field was then turned off; the temperature was maintained at 6 K.

- Step D.

- The same as Step B.

- Step E.

- Under 0.5 kOe, a thermomagnetization measurement was conducted starting from 6 K to 300 K.

- Step A.

- Under no magnetic field, the electric resistivity was measured starting from 300 K to 4 K and back to 300 K.

- Step B.

- The value of the electric resistivity was recorded at 4 K under no magnetic field.

- Step C.

- Under 90 kOe, the electric resistivity was measured starting from 300 K to 4 K.

- Step D.

- The value of the electric resistivity was recorded at 4 K under no magnetic field.

- Step E.

- Under no magnetic field, the electric resistivity was measured by heating from 4 K to 300 K.

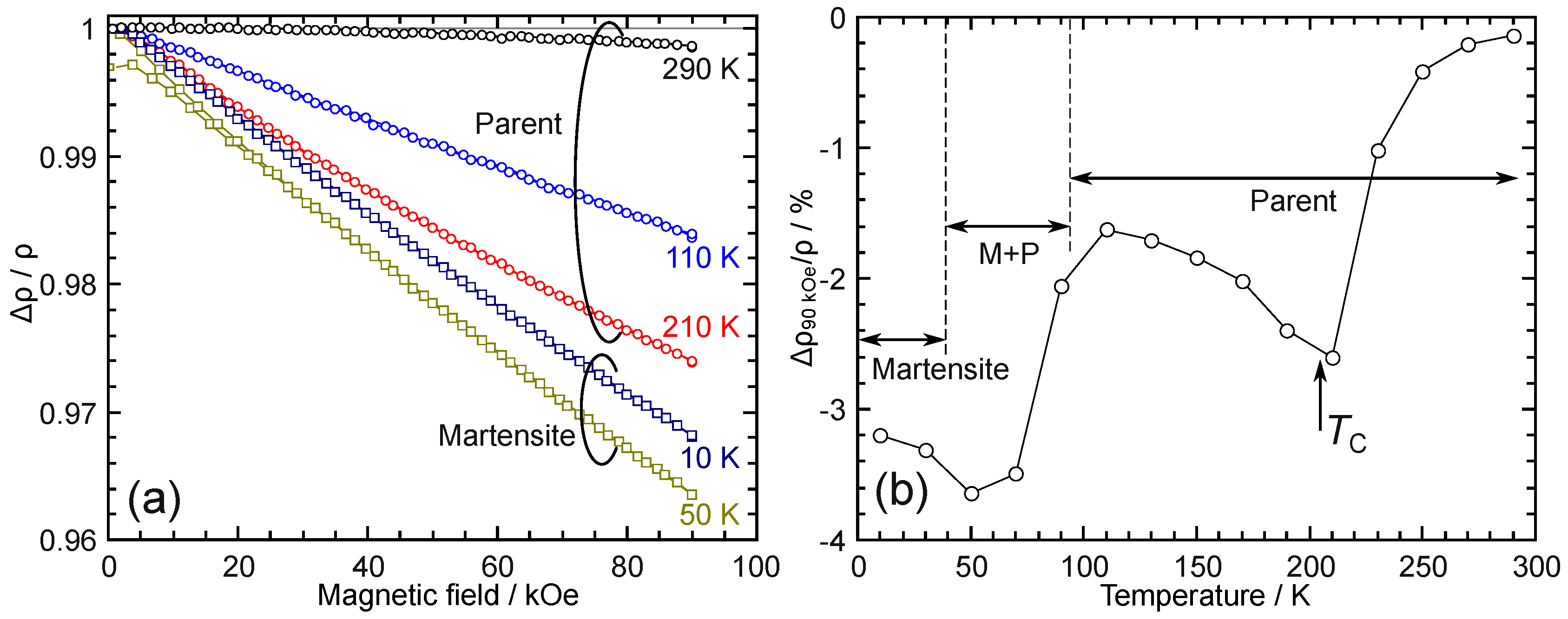

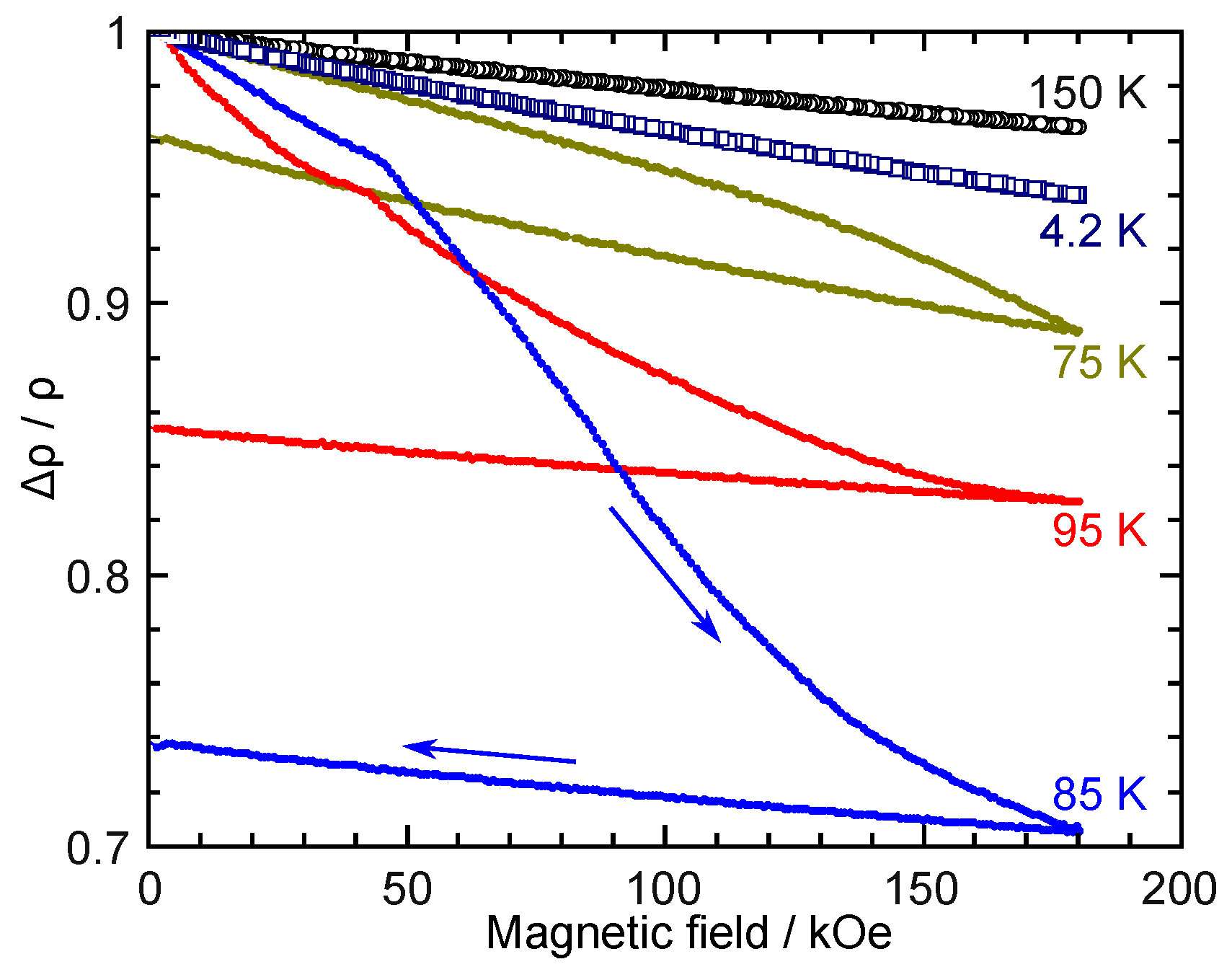

3.3. Intrinsic and Extrinsic Magnetoresistance

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Chang, L.C.; Read, T.A. Plastic deformation and diffusionless phase changes in metals—The gold-cadmium beta-phase. Trans. AIME 1951, 191, 47–52. [Google Scholar] [CrossRef]

- Buehler, W.J.; Gilfrich, J.V.; Wiley, R.C. Effect of low-temperature phase changes on the mechanical properties of alloys near composition TiNi. J. Appl. Phys. 1963, 34, 1475–1477. [Google Scholar] [CrossRef]

- Lagoudas, D. (Ed.) Shape Memory Alloys: Modeling and Engineering Applications; Springer: Berlin/Heidelberg, Germany, 2008. [Google Scholar]

- Donkersloot, H.C.; Van Vucht, J.H.N. Martensitic transformations in gold-titanium, palladium-titanium and platinum-titanium alloys near the equiatomic composition. J. Less Common Met. 1970, 20, 83–91. [Google Scholar] [CrossRef]

- Hornbogen, E.; Wassermann, G. Über den einfluß von spannungen und das auftreten von umwandlungsplastizität bei der beta1–beta′′-umwandlung des messings. Zeitschrift Fur Metallkunde 1956, 47, 427–433. [Google Scholar]

- Nagasawa, A.; Gyobu, A.; Enami, K.; Nenno, S.; Nakanishi, N. Structural phenomena preceding martensitic phase transformation in Cu–Al–Zn alloy. Scr. Metall. 1976, 10, 895–899. [Google Scholar] [CrossRef]

- Chen, C.W. Some characteristics of the martensite transformation of Cu-Al-Ni alloys. Trans. AIME 1957, 209, 1202–1203. [Google Scholar] [CrossRef]

- Higuchi, A.; Suzuki, K.; Matsumoto, Y.; Sugimoto, K.; Komatsu, S.; Nakamura, Y. Shape memory effect in Cu-Al-Be ternary alloys. J. Phys. Colloq. 1982, 43, C4-767–C4-772. [Google Scholar] [CrossRef]

- Morawiec, H.; Lel’tko, J.; Koval, Y.; Kolomytzev, V. High-temperature Cu-Al-Nb shape memory alloys. Mater. Sci. Forum 2000, 327, 291–294. [Google Scholar] [CrossRef]

- Dunne, D.P.; Wayman, C.M. Effect of austenite ordering on martensite transformation in Fe-Pt alloys near composition Fe3Pt: 1. Morphology and transformation characteristics. Metall. Trans. 1973, 4, 137–145. [Google Scholar] [CrossRef]

- Oshima, R. Successive martensitic transformations in Fe–Pd alloys. Scr. Metall. 1981, 15, 829–833. [Google Scholar] [CrossRef]

- Maki, T.; Kobayashi, K.; Minato, M.; Tamura, I. Thermoelastic martensite in an ausaged Fe-Ni-Ti-Co alloy. Scr. Metall. 1984, 18, 1105–1109. [Google Scholar] [CrossRef]

- Sato, A.; Yamaji, Y.; Mori, T. Physical properties controlling shape memory effect in Fe–Mn–Si alloys. Acta Metall. 1986, 34, 287–294. [Google Scholar] [CrossRef]

- Tanaka, Y.; Himuro, Y.; Kainuma, R.; Sutou, Y.; Omori, T.; Ishida, K. Ferrous polycrystalline shape-memory alloy showing huge superelasticity. Science 2010, 327, 1488–1490. [Google Scholar] [CrossRef]

- Omori, T.; Ando, K.; Okano, M.; Xu, X.; Tanaka, Y.; Ohnuma, I.; Kainuma, R.; Ishida, K. Superelastic effect in polycrystalline ferrous alloys. Science 2011, 333, 68–71. [Google Scholar] [CrossRef]

- Kainuma, R.; Takahashi, S.; Ishida, K. Thermoelastic martensite and shape memory effect in ductile Cu-Al-Mn alloys. Metall. Mater. Trans. A 1996, 27, 2187–2195. [Google Scholar] [CrossRef]

- Omori, T.; Kusama, T.; Kawata, S.; Ohnuma, I.; Sutou, Y.; Araki, Y.; Ishida, K.; Kainuma, R. Abnormal grain growth induced by cyclic heat treatment. Science 2013, 341, 1500–1502. [Google Scholar] [CrossRef]

- Omori, T.; Iwaizako, H.; Kainuma, R. Abnormal grain growth induced by cyclic heat treatment in Fe–Mn–Al–Ni superelastic alloy. Mater. Des. 2016, 101, 263–269. [Google Scholar] [CrossRef]

- Xu, X.; Omori, T.; Nagasako, M.; Okubo, A.; Umetsu, R.Y.; Kanomata, T.; Ishida, K.; Kainuma, R. Cooling-induced shape memory effect and inverse temperature dependence of superelastic stress in Co2Cr(Ga,Si) ferromagnetic Heusler alloys. Appl. Phys. Lett. 2013, 103, 164104. [Google Scholar] [CrossRef]

- Ogawa, Y.; Ando, D.; Sutou, Y.; Koike, J. A lightweight shape-memory magnesium alloy. Science 2016, 353, 368–370. [Google Scholar] [CrossRef]

- Hames, F.A. Ferromagnetic-alloy phases near the compositions Ni2MnIn, Ni2MnGa, Co2MnGa, Pd2MnSb, and PdMnSb. J. Appl. Phys. 1960, 31, S370–S371. [Google Scholar] [CrossRef]

- Webster, P.J.; Tebble, R.S. The magnetic and chemical ordering of the Heusler alloys Pd2MnIn, Pd2MnSn and Pd2MnSb. Philos. Mag. 1967, 16, 347–361. [Google Scholar] [CrossRef]

- Webster, P.J.; Ziebeck, K.R.A.; Town, S.L.; Peak, M.S. Magnetic order and phase-transformation in Ni2MnGa. Philos. Mag. B 1984, 49, 295–310. [Google Scholar] [CrossRef]

- Ullakko, K.; Huang, J.K.; Kantner, C.; O’Handley, R.C.; Kokorin, V.V. Large magnetic-field-induced strains in NiMnGa single crystals. Appl. Phys. Lett. 1996, 69, 1966–1968. [Google Scholar] [CrossRef]

- James, R.D.; Wuttig, A. Magnetostriction of martensite. Philos. Mag. A 1998, 77, 1273–1299. [Google Scholar] [CrossRef]

- Kakeshita, T.; Takeuchi, T.; Fukuda, T.; Tsujiguchi, M.; Saburi, T.; Oshima, R.; Muto, S. Giant magnetostriction in an ordered Fe3Pt single crystal exhibiting a martensitic transformation. Appl. Phys. Lett. 2000, 77, 1502–1504. [Google Scholar] [CrossRef]

- Fujita, A.; Fukamichi, K.; Gejima, F.; Kainuma, R.; Ishida, K. Magnetic properties and large magnetic-field-induced strains in off-stoichiometric Ni–Mn-Al Heusler alloys. Appl. Phys. Lett. 2000, 77, 3054–3056. [Google Scholar] [CrossRef]

- Wuttig, M.; Li, J.; Craciunescu, C. A new ferromagnetic shape memory alloy system. Scr. Mater. 2001, 44, 2393–2397. [Google Scholar] [CrossRef]

- Oikawa, K.; Wulff, L.; Iijima, T.; Gejima, F.; Ohmori, T.; Fujita, A.; Fukamichi, K.; Kainuma, R.; Ishida, K. Promising ferromagnetic Ni–Co–Al shape memory alloy system. Appl. Phys. Lett. 2001, 79, 3290–3292. [Google Scholar] [CrossRef]

- Oikawa, K.; Ota, T.; Ohmori, T.; Tanaka, Y.; Morito, H.; Fujita, A.; Kainuma, R.; Fukamichi, K.; Ishida, K. Magnetic and martensitic phase transitions in ferromagnetic Ni–Ga–Fe shape memory alloys. Appl. Phys. Lett. 2002, 81, 5201–5203. [Google Scholar] [CrossRef]

- Kainuma, R.; Imano, Y.; Ito, W.; Sutou, Y.; Morito, H.; Okamoto, S.; Kitakami, O.; Oikawa, K.; Fujita, A.; Kanomata, T.; et al. Magnetic-field-induced shape recovery by reverse phase transformation. Nature 2006, 439, 957–960. [Google Scholar] [CrossRef]

- Karaca, H.E.; Karaman, I.; Basaran, B.; Chumlyakov, Y.J.; Maier, H.J. Magnetic field and stress induced martensite reorientation in NiMnGa ferromagnetic shape memory alloy single crystals. Acta Mater. 2006, 54, 233–245. [Google Scholar] [CrossRef]

- Karaca, H.E.; Karaman, I.; Basaran, B.; Ren, Y.; Chumlyakov, Y.I.; Maier, H.J. Magnetic field-induced phase transformation in NiMnColn magnetic shape-memory alloys—A new actuation mechanism with large work output. Adv. Funct. Mater. 2009, 19, 983–998. [Google Scholar] [CrossRef]

- Koyama, K.; Watanabe, K.; Kanomata, T.; Kainuma, R.; Oikawa, K.; Ishida, K. Observation of field-induced reverse transformation in ferromagnetic shape memory alloy Ni50Mn36Sn14. Appl. Phys. Lett. 2006, 88, 132505. [Google Scholar] [CrossRef]

- Sakon, T.; Yamazaki, S.; Kodama, Y.; Motokawa, M.; Kanomata, T.; Oikawa, K.; Kainuma, R.; Ishida, K. Magnetic field-induced strain of Ni–Co–Mn–In alloy in pulsed magnetic field. Jpn. J. Appl. Phys. 2007, 46, 995–998. [Google Scholar] [CrossRef]

- Kainuma, R.; Oikawa, K.; Ito, W.; Sutou, Y.; Kanomata, T.; Ishida, K. Metamagnetic shape memory effect in NiMn-based Heusler-type alloys. J. Mater. Chem. 2008, 18, 1837–1842. [Google Scholar] [CrossRef]

- Yu, S.Y.; Liu, Z.H.; Liu, G.D.; Chen, J.L.; Cao, Z.X.; Wu, G.H.; Zhang, B.; Zhang, X.X. Large magnetoresistance in single-crystalline Ni50Mn50−xInx alloys (x=14–16) upon martensitic transformation. Appl. Phys. Lett. 2006, 89, 162503. [Google Scholar] [CrossRef]

- Koyama, K.; Okada, H.; Watanabe, K.; Kanomata, T.; Kainuma, R.; Ito, W.; Oikawa, K.; Ishida, K. Observation of large magnetoresistance of magnetic Heusler alloy Ni50Mn36Sn14 in high magnetic fields. Appl. Phys. Lett. 2006, 89, 182510. [Google Scholar] [CrossRef]

- Sharma, V.K.; Chattopadhyay, M.K.; Shaeb, K.H.B.; Chouhan, A.; Roy, S.B. Large magnetoresistance in Ni50Mn34In16 alloy. Appl. Phys. Lett. 2006, 89, 222509. [Google Scholar] [CrossRef]

- Yu, S.Y.; Ma, L.; Liu, G.D.; Liu, Z.H.; Chen, J.L.; Cao, Z.X.; Wu, G.H.; Zhang, B.; Zhang, X.X. Magnetic field-induced martensitic transformation and large magnetoresistance in NiCoMnSb alloys. Appl. Phys. Lett. 2007, 90, 242501. [Google Scholar] [CrossRef]

- Krenke, T.; Duman, E.; Acet, M.; Wassermann, E.; Moya, X.; Manosa, L.; Planes, A. Inverse magnetocaloric effect in ferromagnetic Ni–Mn–Sn alloys. Nat. Mater. 2005, 4, 450–454. [Google Scholar] [CrossRef]

- Planes, A.; Mañosa, L.; Acet, M. Magnetocaloric effect and its relation to shape-memory properties in ferromagnetic Heusler alloys. J. Phys. Condens. Matter 2009, 21, 233201. [Google Scholar] [CrossRef]

- Kihara, T.; Xu, X.; Ito, W.; Kainuma, R.; Tokunaga, M. Direct measurements of inverse magnetocaloric effects in metamagnetic shape-memory alloy NiCoMnIn. Phys. Rev. B 2014, 90, 214409. [Google Scholar] [CrossRef]

- Khovaylo, V.V.; Skokov, K.P.; Gutfleisch, O.; Miki, H.; Kainuma, R.; Kanomata, T. Reversibility and irreversibility of magnetocaloric effect in a metamagnetic shape memory alloy under cyclic action of a magnetic field. Appl. Phys. Lett. 2010, 97, 052503. [Google Scholar] [CrossRef]

- Gottschall, T.; Skokov, K.P.; Frincu, B.; Gutfleisch, O. Large reversible magnetocaloric effect in Ni-Mn-In-Co. Appl. Phys. Lett. 2015, 106, 021901. [Google Scholar] [CrossRef]

- Lu, B.; Xiao, F.; Yan, A.; Liu, J. Elastocaloric effect in a textured polycrystalline Ni-Mn-In-Co metamagnetic shape memory alloy. Appl. Phys. Lett. 2014, 105, 161905. [Google Scholar] [CrossRef]

- Ahadi, A.; Kawasaki, T.; Harjo, S.; Ko, W.S.; Sun, Q.P.; Tsuchiya, K. Reversible elastocaloric effect at ultra-low temperatures in nanocrystalline shape memory alloys. Acta Mater. 2019, 165, 109–117. [Google Scholar] [CrossRef]

- Cong, D.; Xiong, W.; Planes, A.; Ren, Y.; Mañosa, L.; Cao, P.; Nie, Z.; Sun, X.; Yang, Z.; Hong, X.; et al. Colossal elastocaloric effect in ferroelastic Ni-Mn-Ti alloys. Phys. Rev. Lett. 2019, 122, 255703. [Google Scholar] [CrossRef]

- Sutou, Y.; Imano, Y.; Koeda, N.; Omori, T.; Kainuma, R.; Ishida, K.; Oikawa, K. Magnetic and martensitic transformations of NiMnX(X= In, Sn, Sb) ferromagnetic shape memory alloys. Appl. Phys. Lett. 2004, 85, 4358–4360. [Google Scholar] [CrossRef]

- Kanomata, T.; Fukushima, K.; Nishihara, H.; Kainuma, R.; Itoh, W.; Oikawa, K.; Ishida, K.; Neumann, K.; Ziebeck, K. Magnetic and crystallographic properties of shape memory alloys Ni2Mn1+xSn1−x. Mater. Sci. Forum 2008, 583, 119–129. [Google Scholar] [CrossRef]

- Brown, P.J.; Gandy, A.P.; Ishida, K.; Kainuma, R.; Kanomata, T.; Neumann, K.U.; Oikawa, K.; Ouladdiaf, B.; Ziebeck, K.R.A. The magnetic and structural properties of the magnetic shape memory compound Ni2Mn1.44Sn0.56. J. Phys. Condens. Matter 2006, 18, 2249–2259. [Google Scholar] [CrossRef]

- da Rocha, F.S.; Kakuno, E.M.; Kinast, E.J.; Mazzaro, I.; Fraga, G.L.F. Magnetic and structural properties of Pd–Mn–Sn intermetallics compounds. Eur. Phys. J. B 2011, 83, 167–172. [Google Scholar] [CrossRef]

- Kanomata, T.; Chieda, Y.; Okada, H.; Nishihara, H.; Kimura, A.; Nagasako, M.; Umetsu, R.Y.; Kainuma, R.; Ziebeck, K.R.A. Martensitic transition of Mn-rich Pd–Mn–Sn alloy. J. Alloys Compd. 2012, 541, 392–395. [Google Scholar] [CrossRef]

- Chieda, Y.; Kanomata, T.; Umetsu, R.Y.; Okada, H.; Nishihara, H.; Kimura, A.; Nagasako, M.; Kainuma, R.; Ziebeck, K.R.A. Magnetic phase diagram of Heuselr alloys Pd2Mn1+xSn1−x. J. Alloys Compd. 2013, 554, 335–339. [Google Scholar] [CrossRef]

- Barth, J.; Fecher, G.H.; Balke, B.; Ouardi, S.; Graf, T.; Felser, C.; Shkabko, A.; Weidenkaff, A.; Klaer, P.; Elmers, H.J.; et al. Itinerant half-metallic ferromagnets Co2TiZ (Z=Si, Ge, Sn): Ab initio calculations and measurement of the electronic structure and transport properties. Phys. Rev. B 2010, 81, 064404. [Google Scholar] [CrossRef]

- Kourov, N.I.; Marchenkov, V.V.; Pushin, V.G.; Belozerova, K.A. Electrical properties of ferromagnetic Ni2MnGa and Co2CrGa Heusler alloys. J. Exp. Theor. Phys. 2013, 117, 121–125. [Google Scholar] [CrossRef]

- Nishino, Y.; Kato, M.; Asano, S.; Soda, K.; Hayasaki, M.; Mizutani, U. Semiconductorlike behavior of electrical resistivity in Heusler-type Fe2VAl compound. Phys. Rev. Lett. 1997, 79, 1909–1912. [Google Scholar] [CrossRef]

- Xu, X.; Nagasako, M.; Kataoka, M.; Umetsu, R.Y.; Omori, T.; Kanomata, T.; Kainuma, R. Anomalous physical properties of Heusler-type Co2Cr(Ga,Si) alloys and thermodynamic study on reentrant martensitic transformation. Phys. Rev. B 2015, 91, 104434. [Google Scholar] [CrossRef]

- Craig, P.P.; Goldburg, W.I.; Kitchens, T.A.; Budnick, J.I. Transport properties at critical points: The resistivity of nickel. Phys. Rev. Lett. 1967, 19, 1334–1337. [Google Scholar] [CrossRef]

- Kasuya, T. Electrical resistance of ferromagnetic metals. Prog. Theor. Phys. 1956, 16, 58–63. [Google Scholar] [CrossRef]

- de Gennes, P.G.; Friedel, J. Anomalies de résistivité dans certains métaux magnétiques. J. Phys. Chem. Solids 1958, 4, 71–77. [Google Scholar] [CrossRef]

- Schreiner, W.H.; Brandao, D.E.; Ogiba, F.; Kunzler, J.V. Electrical resistivity of Heusler alloys. J. Phys. Chem. Solids 1982, 43, 777–780. [Google Scholar] [CrossRef]

- Fraga, G.L.F.; Kunzler, J.V.; Ogiba, F.; Brandão, D.E. Electrical resistivity of the Ni2MnIn Heusler alloy. Phys. Status Solidi A 1984, 83, K187–K190. [Google Scholar] [CrossRef]

- Dwevedi, S. Magnetic and transport properties of Mn-rich Ni35Mn50In15 alloy. J. Alloys Compd. 2013, 574, 188–190. [Google Scholar] [CrossRef]

- Adachi, Y.; Ogi, Y.; Kobayashi, N.; Hayasaka, Y.; Kanomata, T.; Umetsu, R.Y.; Xu, X.; Kainuma, R. Temperature dependences of the electrical resistivity on the Heusler alloy system Ni2MnGa1−xFex. Metals 2017, 7, 413. [Google Scholar] [CrossRef]

- Yakhmi, J.V.; Gopalakrishnan, I.K.; Grover, A.K. Electrical resistivity studies on the Heusler alloys Co2T1−xAl1+x(T = Ti or Zr). Phys. Status Solidi A 1984, 85, K89–K92. [Google Scholar] [CrossRef]

- Kainuma, R.; Imano, Y.; Ito, W.; Morito, H.; Sutou, Y.; Oikawa, K.; Fujita, A.; Ishida, K.; Okamoto, S.; Kitakami, O.; et al. Metamagnetic shape memory effect in a Heusler-type Ni43Co7Mn39Sn11 polycrystalline alloy. Appl. Phys. Lett. 2006, 88, 192513. [Google Scholar] [CrossRef]

- Yu, S.Y.; Cao, Z.X.; Ma, L.; Liu, G.D.; Chen, J.L.; Wu, G.H.; Zhang, B.; Zhang, X.X. Realization of magnetic field-induced reversible martensitic transformation in NiCoMnGa alloys. Appl. Phys. Lett. 2007, 91, 102507. [Google Scholar] [CrossRef]

- Xu, X.; Ito, W.; Tokunaga, M.; Kihara, T.; Oka, K.; Umetsu, R.Y.; Kanomata, T.; Kainuma, R. The thermal transformation arrest phenomenon in NiCoMnAl Heusler alloys. Metals 2013, 3, 298–311. [Google Scholar] [CrossRef]

- Sharma, V.K.; Chattopadhyay, M.K.; Roy, S.B. Kinetic arrest of the first order austenite to martensite phase transition in Ni50Mn34In16: dc magnetization studies. Phys. Rev. B 2007, 76, 140401(R). [Google Scholar] [CrossRef]

- Ito, W.; Ito, K.; Umetsu, R.Y.; Kainuma, R.; Koyama, K.; Watanabe, K.; Fujita, A.; Oikawa, K.; Ishida, K.; Kanomata, T. Kinetic arrest of martensitic transformation in the NiCoMnIn metamagnetic shape memory alloy. Appl. Phys. Lett. 2008, 92, 021908. [Google Scholar] [CrossRef]

- Xu, X.; Ito, W.; Umetsu, R.Y.; Koyama, K.; Kainuma, R.; Ishida, K. Kinetic arrest of martensitic transformation in Ni33.0Co13.4Mn39.7Ga13.9 metamagnetic shape memory alloys. Mater. Trans. 2010, 51, 469–471. [Google Scholar] [CrossRef]

- Xu, X.; Ito, W.; Tokunaga, M.; Umetsu, R.Y.; Kainuma, R.; Ishida, K. Kinetic arrest of martensitic transformation in NiCoMnAl metamagnetic shape memory alloy. Mater. Trans. 2010, 51, 1357–1360. [Google Scholar] [CrossRef]

- Cesari, E.; Kustov, S.; Salas, D. Entropy changes in ferromagnetic shape memory alloys. Mater. Sci. Forum 2011, 684, 49–60. [Google Scholar] [CrossRef]

- Ito, W.; Umetsu, R.Y.; Kainuma, R.; Kakeshita, T.; Ishida, K. Heat-induced and isothermal martensitic transformations from kinetically arrested parent phase in NiCoMnIn metamagnetic shape memory alloy. Scr. Mater. 2010, 63, 73–76. [Google Scholar] [CrossRef]

- Serrate, D.; De Teresa, J.M.; Córdoba, R.; Yusuf, S.M. Magnetoresistance and magnetostriction of Co2Cr0.6Fe0.4Al Heusler alloy. Solid State Commun. 2007, 142, 363–367. [Google Scholar] [CrossRef]

- Tolea, F.; Tolea, M.; Sofronie, M.; Popescu, B.; Crisan, A.; Leca, A.; Valeanu, M. Specific changes in the magnetoresistance of Ni–Fe–Ga Heusler alloys induced by Cu, Co, and Al substitutions. IEEE Trans. Magn. 2017, 53, 4400307. [Google Scholar] [CrossRef]

- Pal, D.; Mandal, K.; Gutfleisch, O. Large negative magnetoresistance in nickel-rich Ni–Mn–Ga Heusler alloys. J. Appl. Phys. 2010, 107, 09B103. [Google Scholar] [CrossRef]

- Liu, Z.H.; Liu, H.; Zhang, X.X.; Zhang, X.K.; Xiao, J.Q.; Zhu, Z.Y.; Dai, X.F.; Liu, G.D.; Chen, J.L.; Wu, G.H. Large negative magnetoresistance in quaternary Heusler alloy Ni50Mn8Fe17Ga25 melt-spun ribbons. Appl. Phys. Lett. 2005, 86, 182507. [Google Scholar] [CrossRef]

- Endo, K.; Matsuda, H.; Ooiwa, K.; Iijima, M.; Ito, K.; Goto, T.; Ono, A. Anomalous giant magnetoresistance in Heusler-type alloys Fe2+xV1−xGa. J. Phys. Soc. Jpn. 1997, 66, 1257–1260. [Google Scholar] [CrossRef]

- Kanomata, T.; Endo, K.; Chieda, Y.; Sugawara, T.; Obara, K.; Shishido, T.; Matsubayashi, K.; Uwatoko, Y.; Nishihara, H.; Umetsu, R.Y.; et al. Magnetic properties of Mn-rich Pd2MnSn Heusler alloys. J. Alloys Compd. 2010, 505, 29–33. [Google Scholar] [CrossRef]

- Pathak, A.K.; Gautam, B.R.; Dubenko, I.; Khan, M.; Stadler, S.; Ali, N. Phase transitions and magnetoresistance in Ni50Mn50−xInx Heusler alloys. J. Appl. Phys. 2008, 103, 07F315. [Google Scholar] [CrossRef]

- Umetsu, R.Y.; Endo, K.; Kondo, A.; Kindo, K.; Ito, W.; Xu, X.; Kanomata, T.; Kainuma, R. Magnetoresistance and transformation hysteresis in the Ni50Mn34.6In15.6 metamagnetic shape memory alloys. Mater. Trans. 2013, 54, 291–296. [Google Scholar] [CrossRef]

- Khan, M.; Pathak, A.K.; Paudel, M.R.; Dubenko, I.; Stadler, S.; Ali, N. Magnetoresistance and field-induced structural transitions in Ni50Mn50−xSnx Heusler alloys. J. Magn. Magn. Mater. 2008, 320, L21–L25. [Google Scholar] [CrossRef]

- Jing, C.; Yang, Y.J.; Li, Z.; Wang, X.L.; Kang, B.J.; Cao, S.X.; Zhang, J.C.; Zhu, J.; Lu, B. Tuning martensitic transformation and large magnetoresistance in Ni50−xCuxMn38Sn12 Heusler alloys. J. Appl. Phys. 2013, 113, 173902. [Google Scholar] [CrossRef]

- Xuan, H.C.; Shen, L.J.; Tang, T.; Cao, Q.Q.; Wang, D.H.; Du, Y.W. Magnetic-field-induced reverse martensitic transformation and large magnetoresistance in Ni50−xCoxMn32Al18 Heusler alloys. Appl. Phys. Lett. 2012, 100, 172410. [Google Scholar] [CrossRef]

| Alloy | (K) | Second-Order Polynomial Fit | Linear Fit | Reference | |||

|---|---|---|---|---|---|---|---|

| Range (K) | |||||||

| PdMnSn | 204 | 12.6 | 0.79 | 110–200 | 1.35 | This work | |

| PdMnIn | - | - | - | - | 2.0 | [62] | |

| PdMnSn | 189 | 9.2 | 6.1 | 105–180 | 7.1 | [62] | |

| PdMnSb | 247 | 11.4 | 5.3 | 105–240 | 10.8 | [62] | |

| NiMnIn | 323 | 2.71 | 4.23 | 150–300 | 3.3 | [62] | |

| 320–321 | 1.57–1.68 | 4.29–4.43 | 140–300 | - | [63] | ||

| NiMnSn | 344 | 4.46 | 3.94 | 150–300 | - | [62] | |

| NiMnSb | 334 | 10.4 | 2.73 | 150–300 | - | [62] | |

| NiMnIn | 325 | 33.4 | 3.19 | 220–280 | - | [38] | |

| NiMnIn | 333 | 25.4 | 1.34 | 100–300 | 2.68 | [64] | |

| NiMnGaFe | 377–431 | 3.34–9.18 | 0.26–6.37 | 100–390 | - | [65] | |

| CoTiAl | 126 | 70 | 11 | - | 42.7 | [66] | |

| CoTiAl | 155 | 70 | 10 | - | 39.4 | [66] | |

| CoZrAl | 194 | 60 | 17.6 | - | 42.2 | [66] | |

| CoZrAl | 196 | 140 | 39.5 | - | 64.7 | [66] | |

| CoZrAl | 188 | 80 | 0.5 | - | 44.8 | [66] | |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xu, X.; Okada, H.; Chieda, Y.; Aizawa, N.; Takase, D.; Nishihara, H.; Sakon, T.; Han, K.; Ito, T.; Adachi, Y.; et al. Magnetoresistance and Thermal Transformation Arrest in Pd2Mn1.4Sn0.6 Heusler Alloys. Materials 2019, 12, 2308. https://doi.org/10.3390/ma12142308

Xu X, Okada H, Chieda Y, Aizawa N, Takase D, Nishihara H, Sakon T, Han K, Ito T, Adachi Y, et al. Magnetoresistance and Thermal Transformation Arrest in Pd2Mn1.4Sn0.6 Heusler Alloys. Materials. 2019; 12(14):2308. https://doi.org/10.3390/ma12142308

Chicago/Turabian StyleXu, Xiao, Hironari Okada, Yusuke Chieda, Naoki Aizawa, Daiki Takase, Hironori Nishihara, Takuo Sakon, Kwangsik Han, Tatsuya Ito, Yoshiya Adachi, and et al. 2019. "Magnetoresistance and Thermal Transformation Arrest in Pd2Mn1.4Sn0.6 Heusler Alloys" Materials 12, no. 14: 2308. https://doi.org/10.3390/ma12142308

APA StyleXu, X., Okada, H., Chieda, Y., Aizawa, N., Takase, D., Nishihara, H., Sakon, T., Han, K., Ito, T., Adachi, Y., Kihara, T., Kainuma, R., & Kanomata, T. (2019). Magnetoresistance and Thermal Transformation Arrest in Pd2Mn1.4Sn0.6 Heusler Alloys. Materials, 12(14), 2308. https://doi.org/10.3390/ma12142308