Behavior of Cross Arms Inserted in Concrete-Filled Circular GFRP Tubular Columns

Abstract

1. Introduction

2. Experimental Program

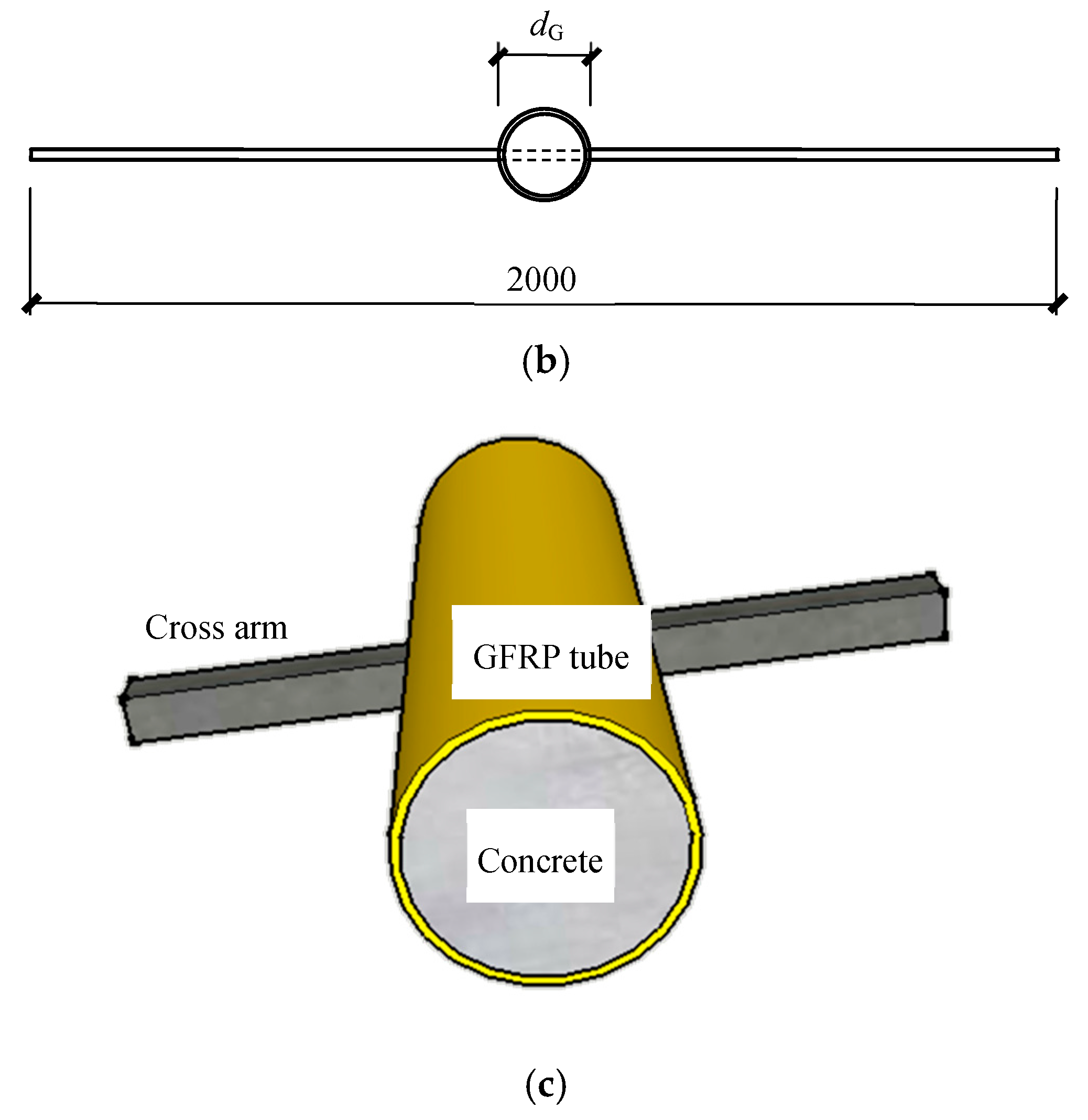

2.1. Specimen Geometry and Dimensions

2.2. Material Properties

2.3. Specimen Preparation

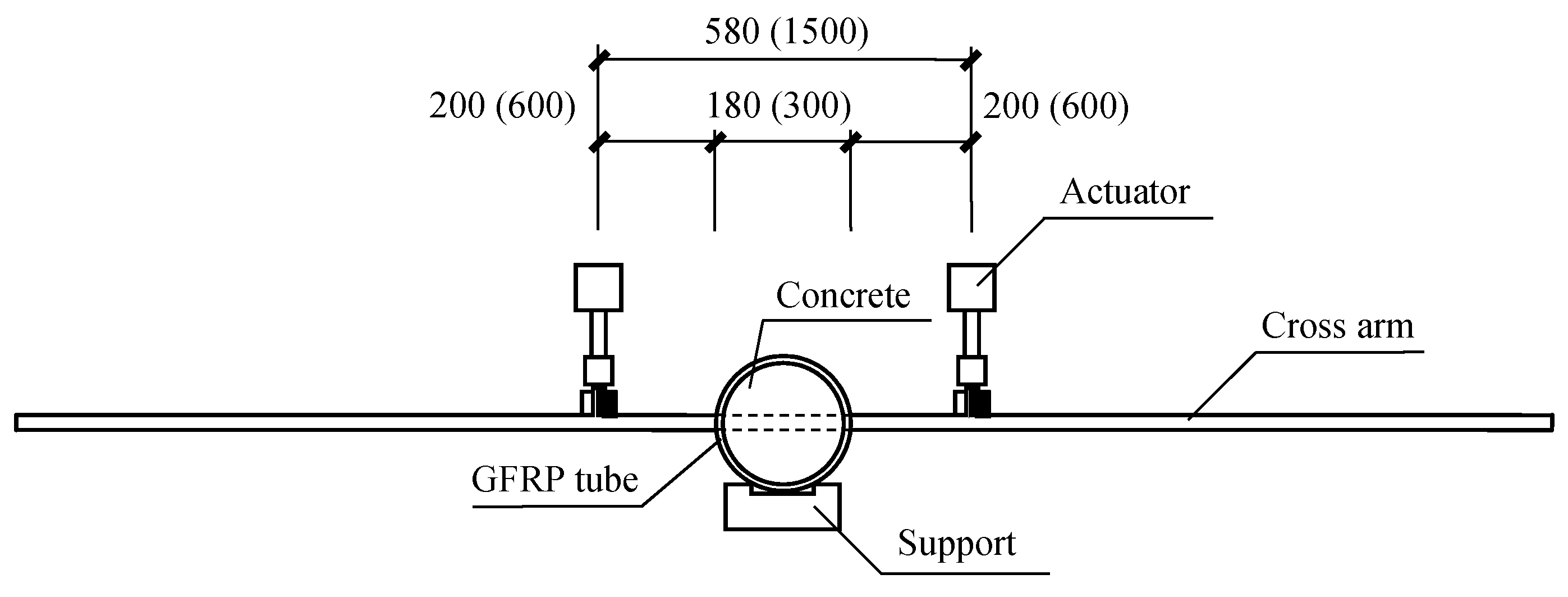

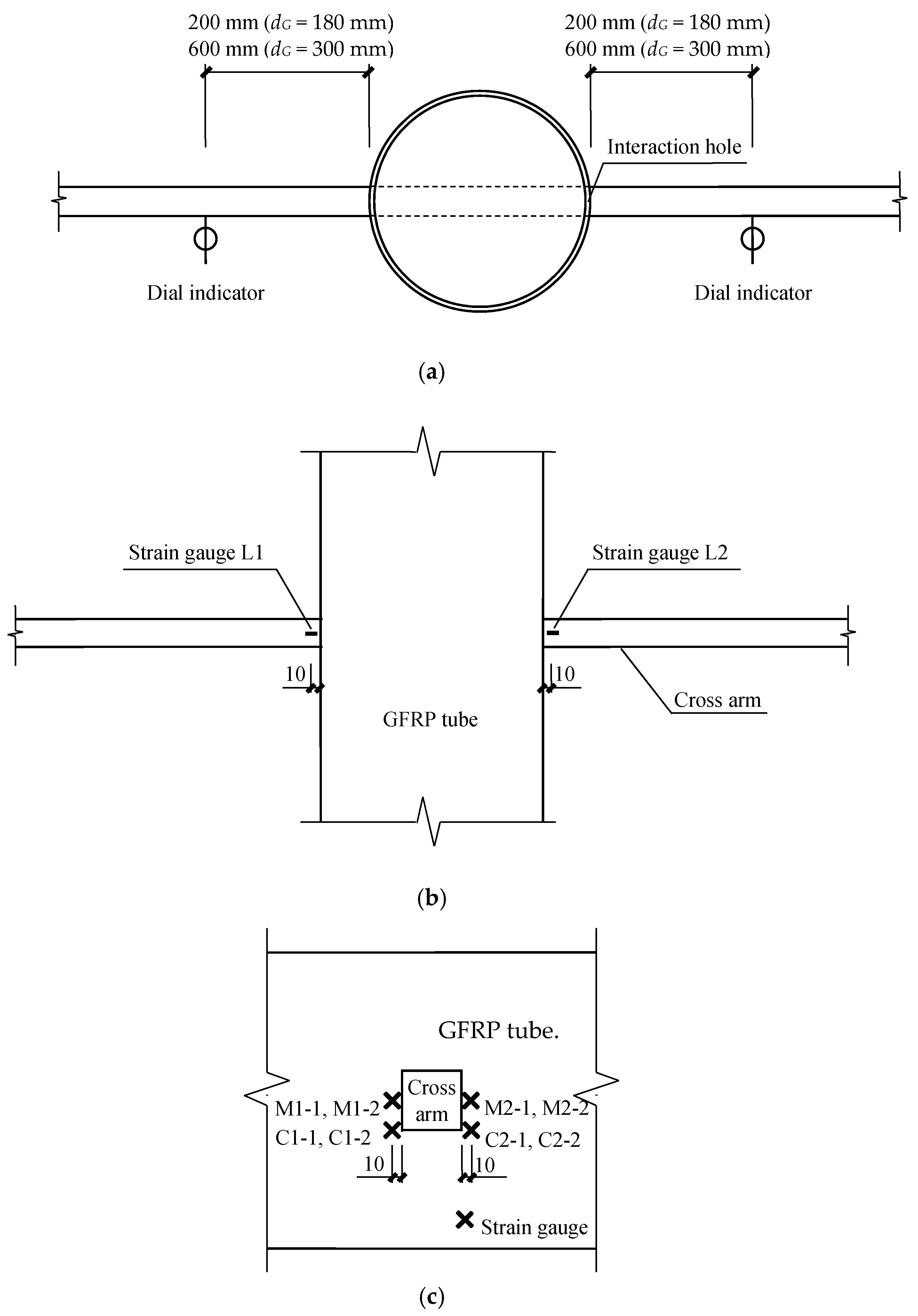

2.4. Test Set-Up and Data Acquisition

3. Results and Discussions

3.1. Failure Mode

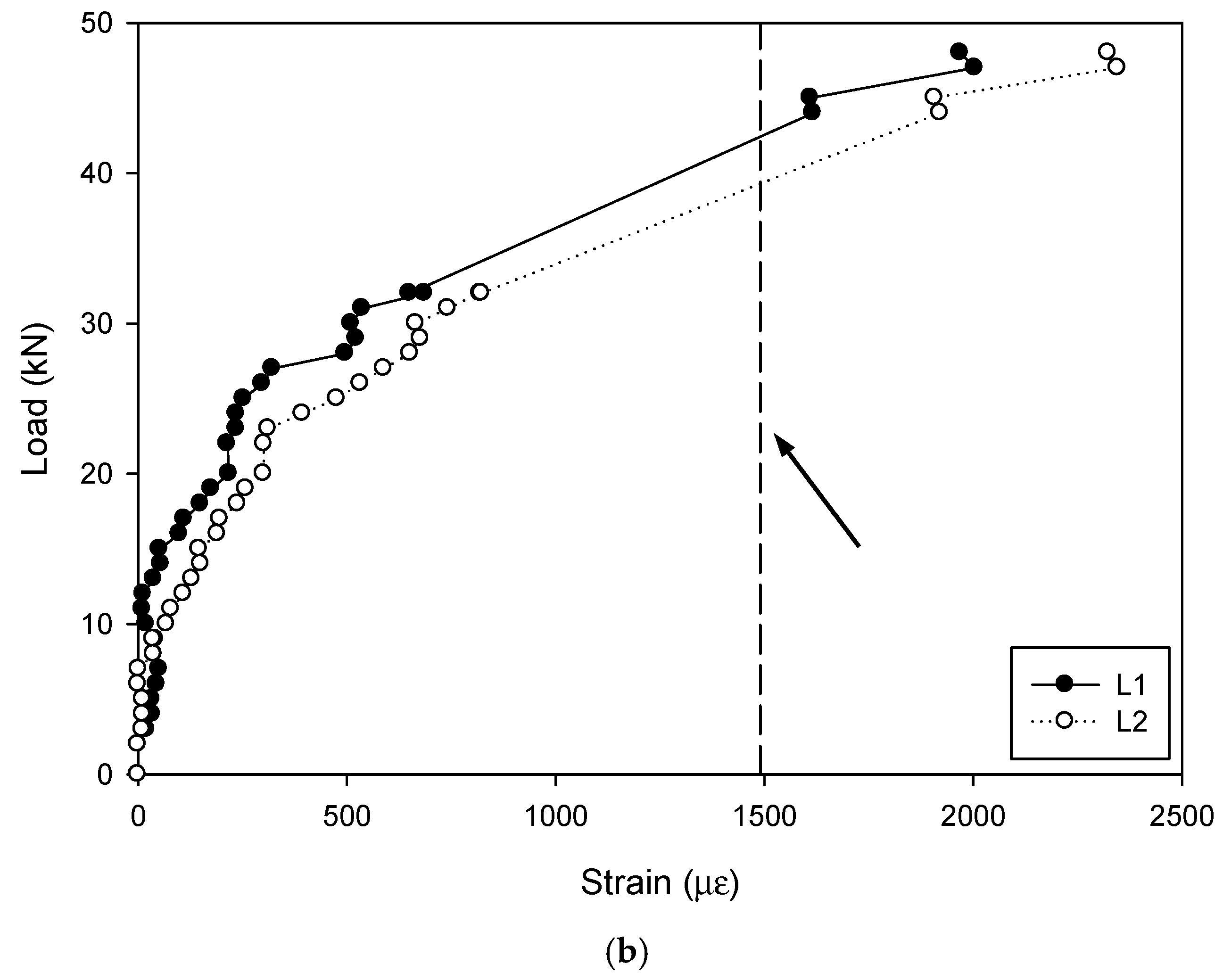

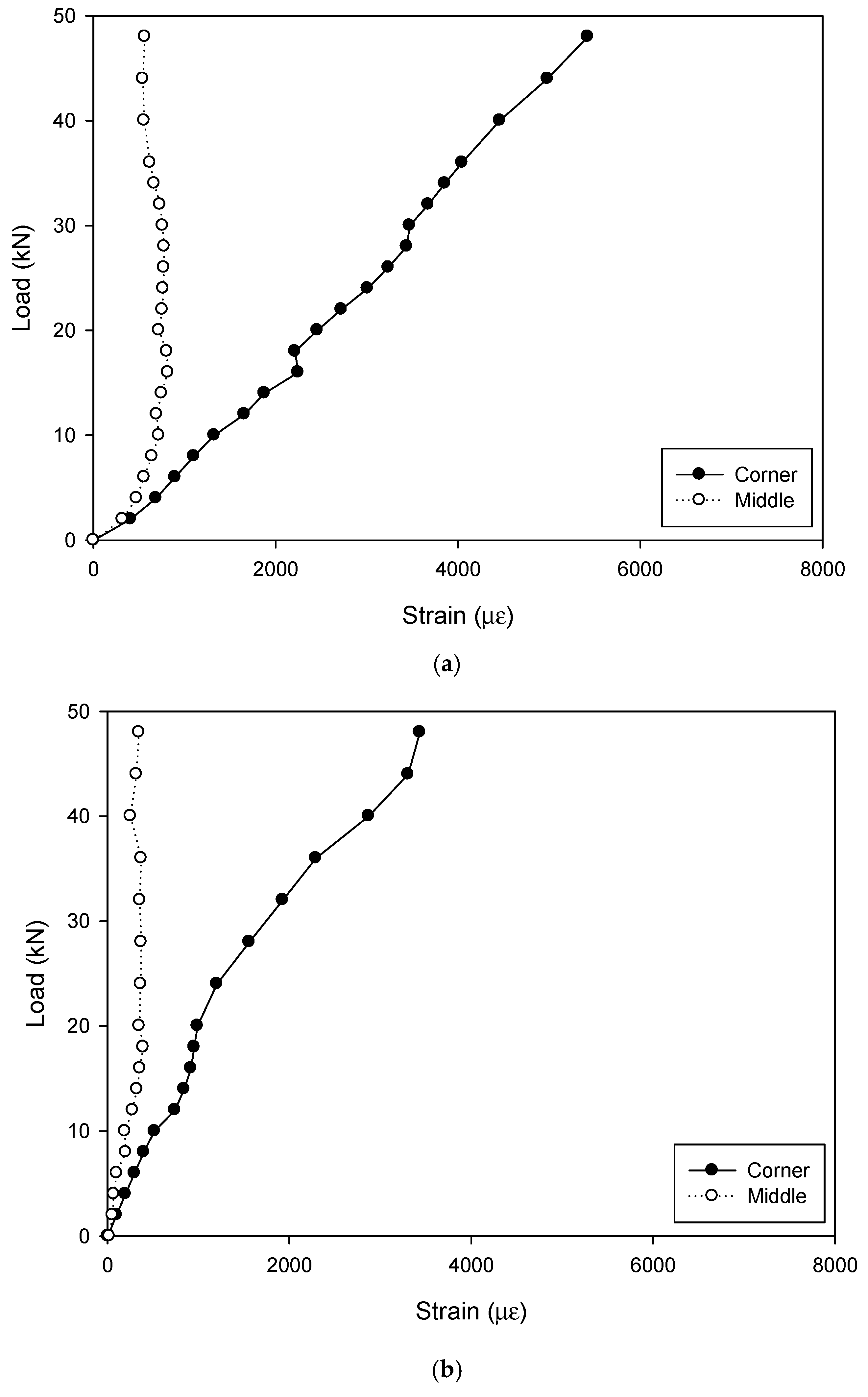

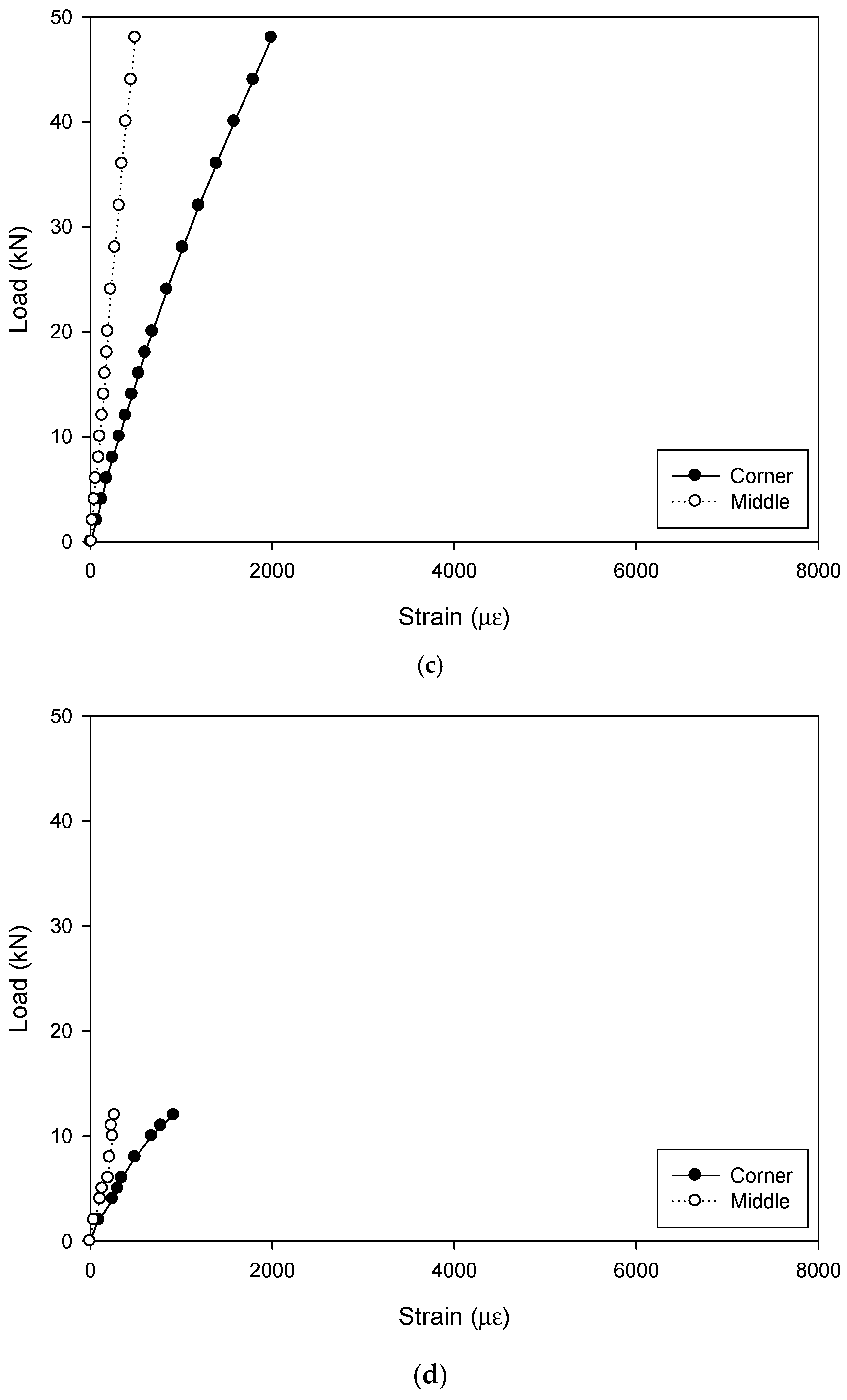

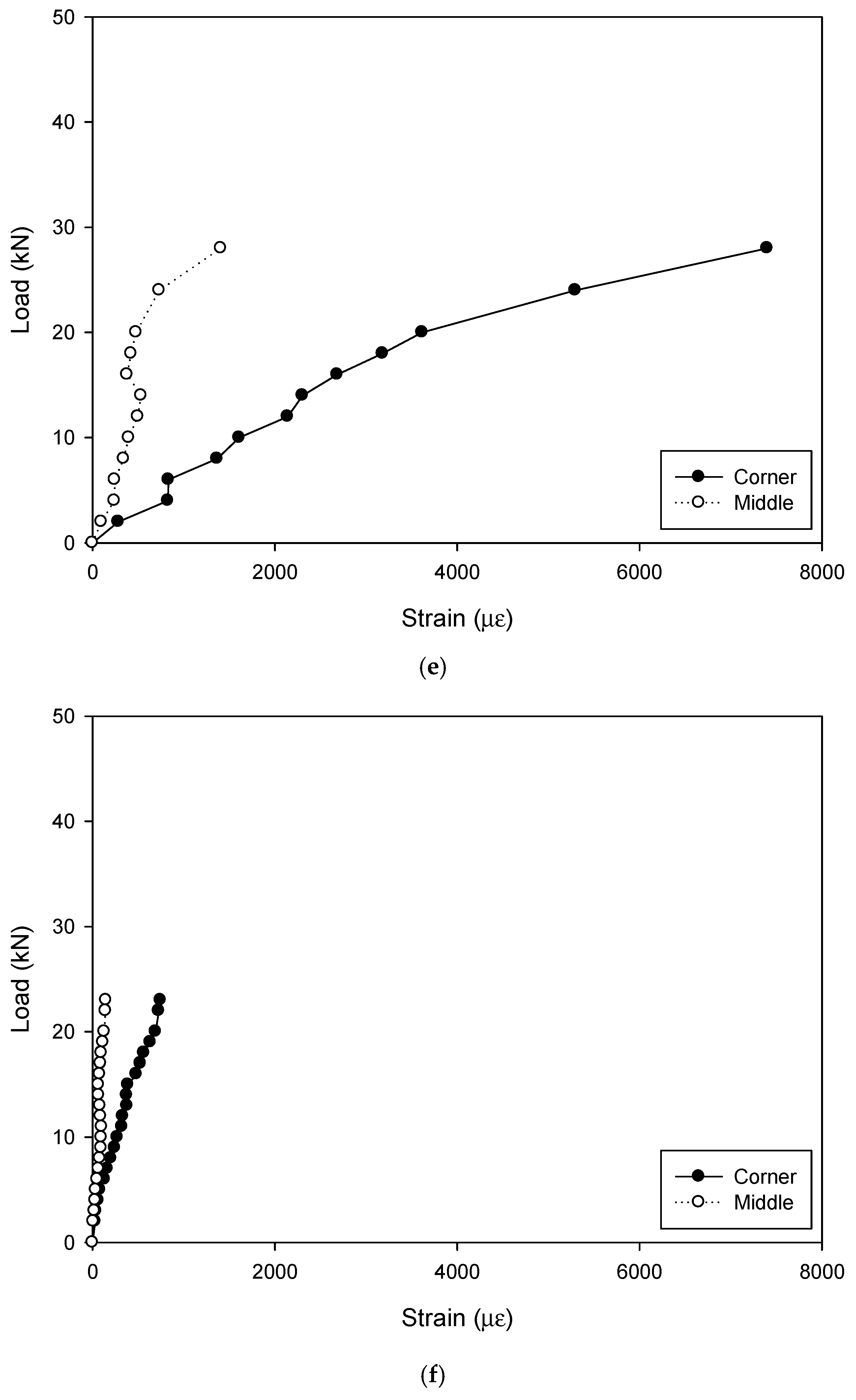

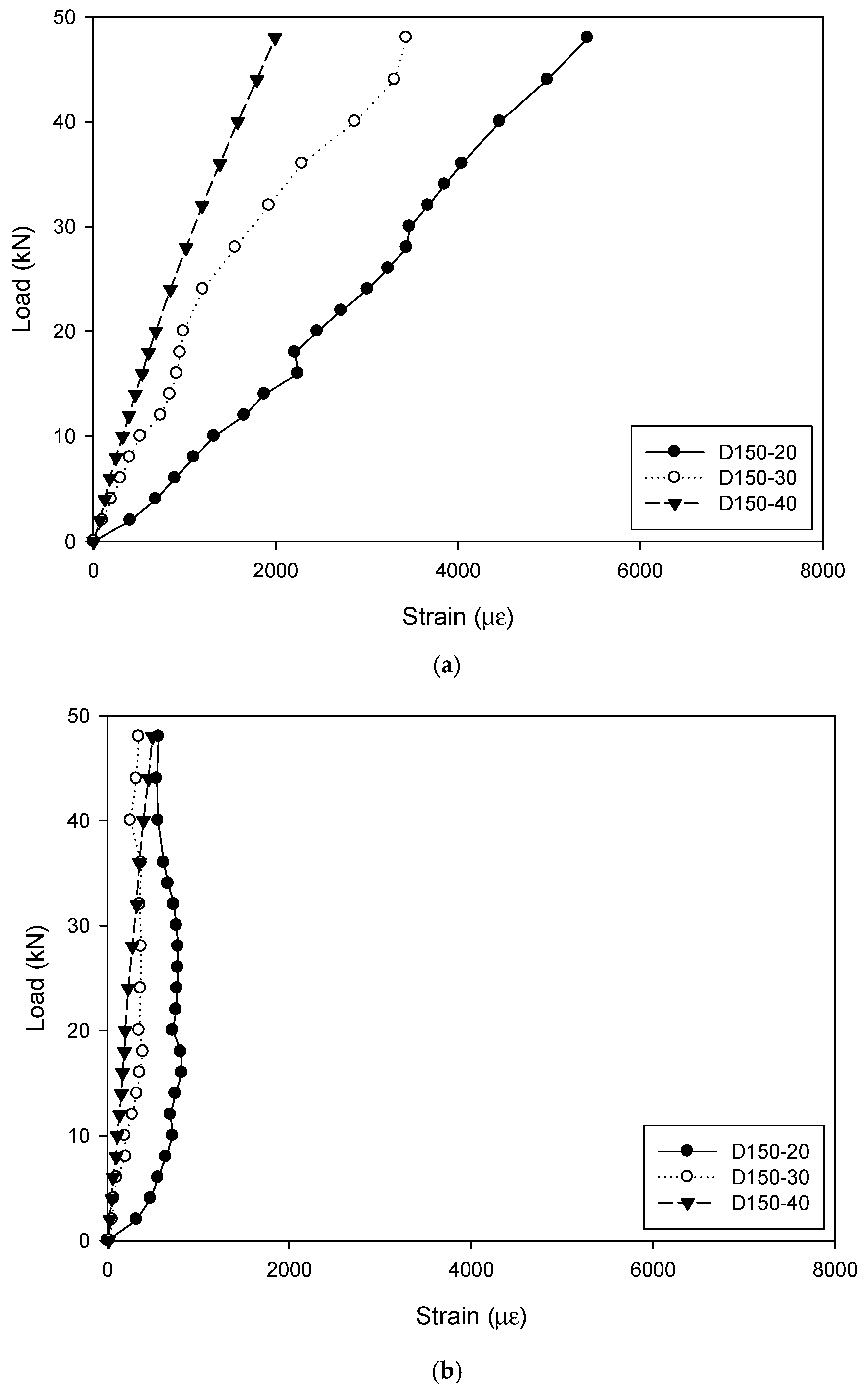

3.2. Stain on the GFRP Tube

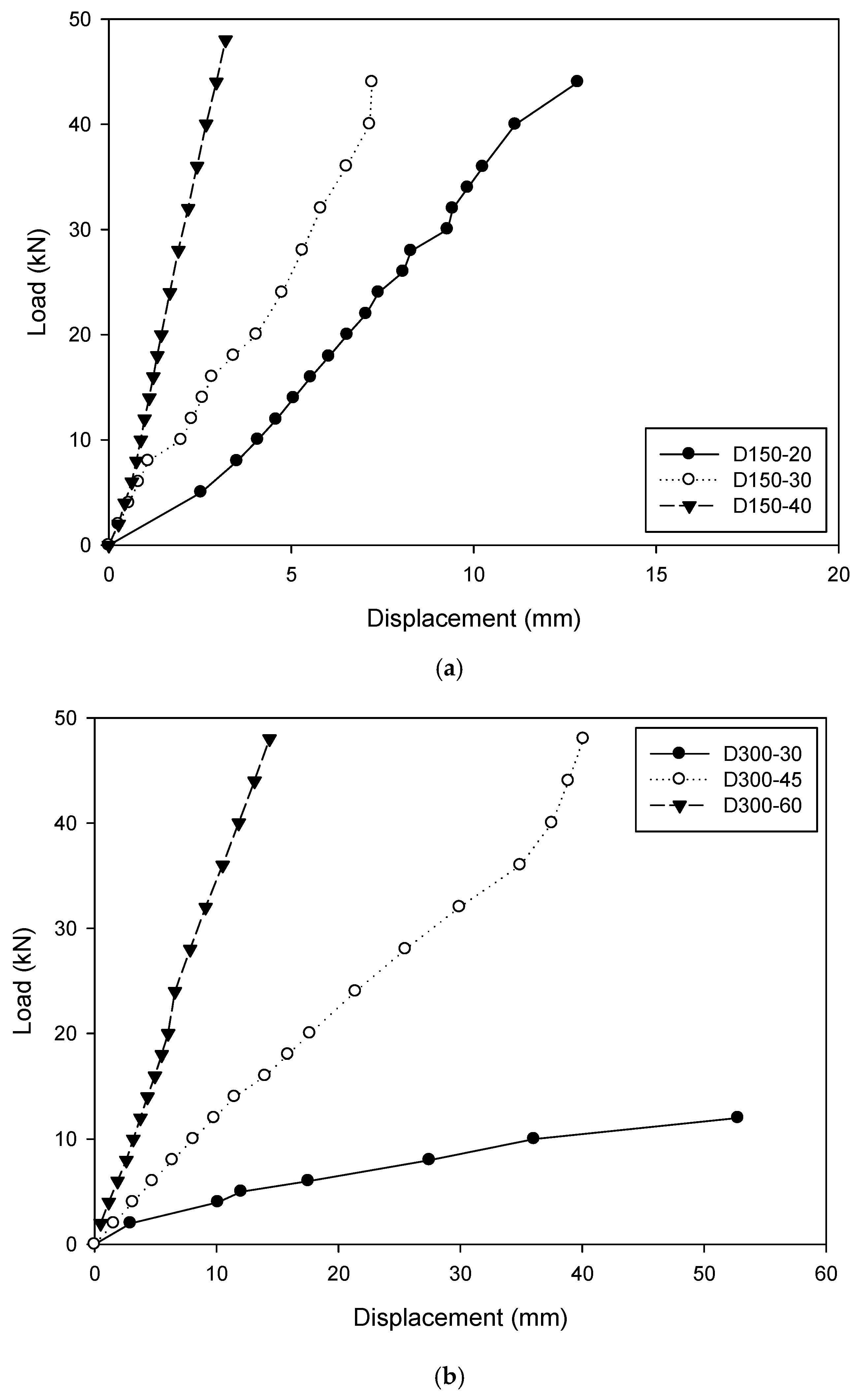

3.3. Displacement of the Cross Arm

4. Theoretical Analysis on the Vertical Displacement of the Cross Arm

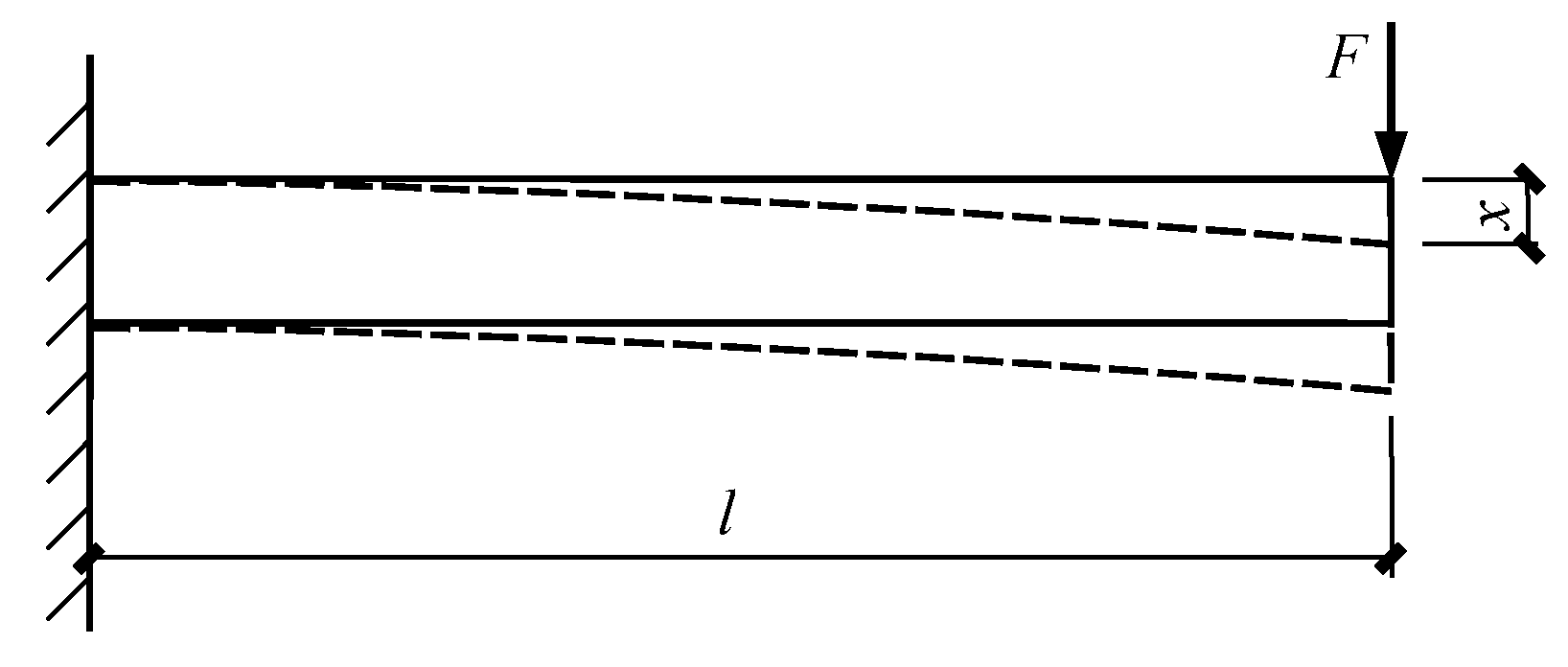

4.1. Theoretical Solution Based on the Mechanics of Materials

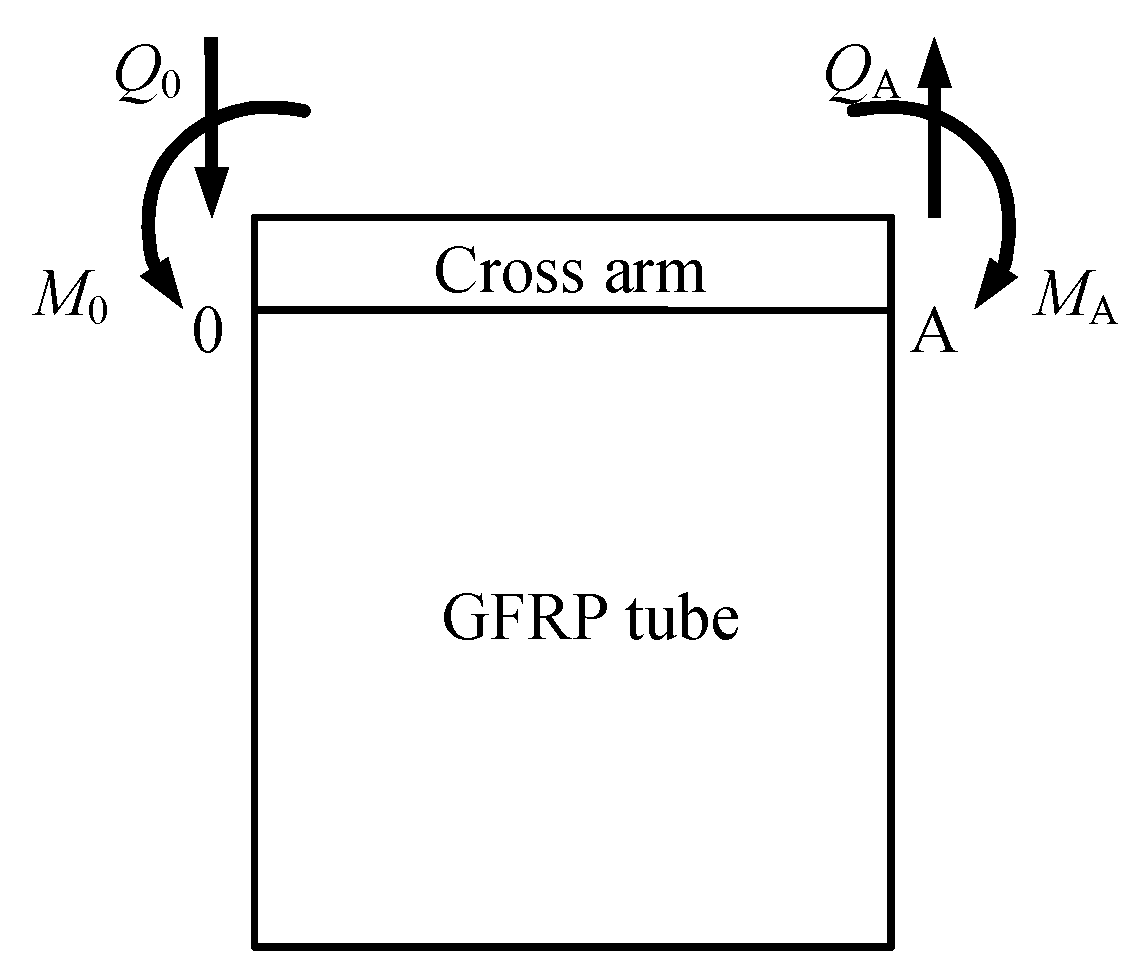

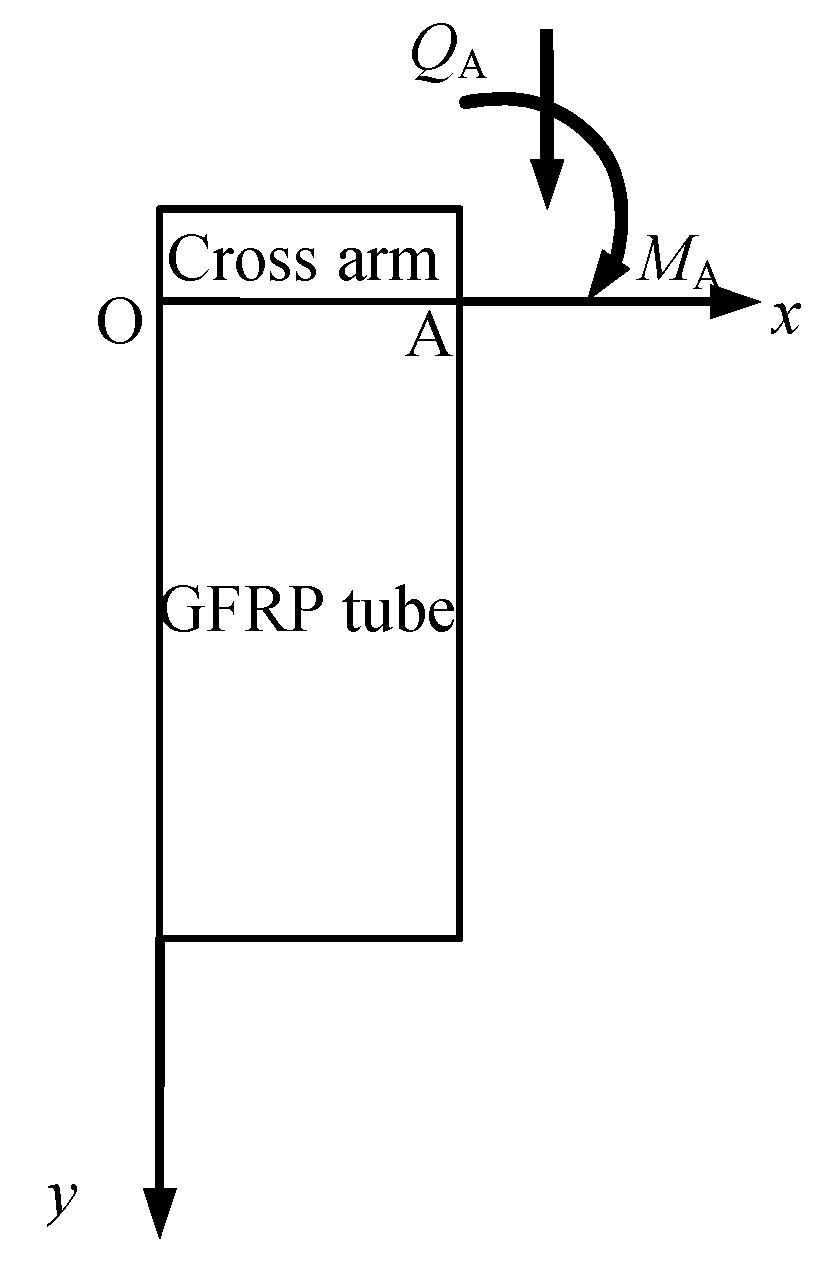

4.2. Theoretical Solution Based on the Elastic Foundation Beam Theory

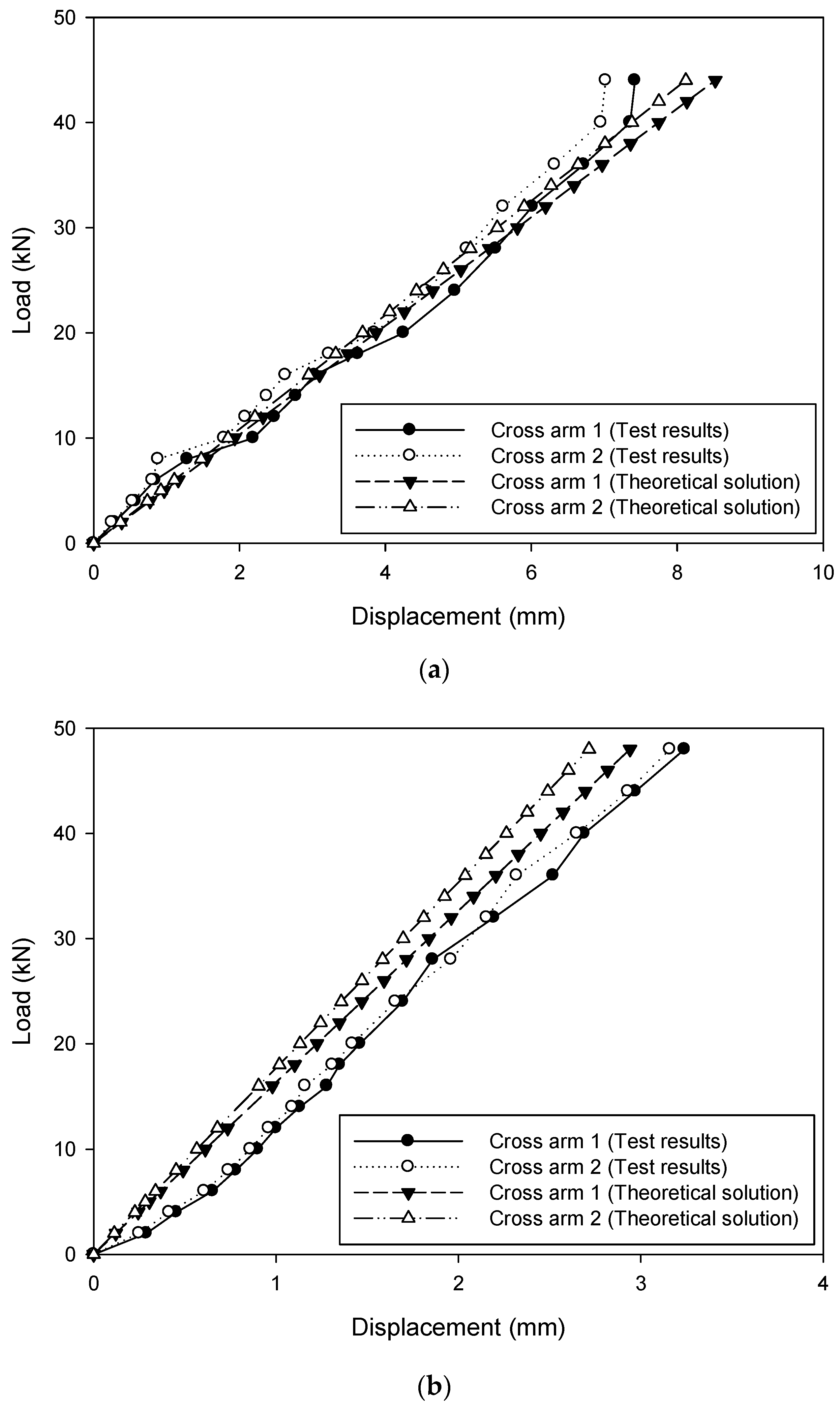

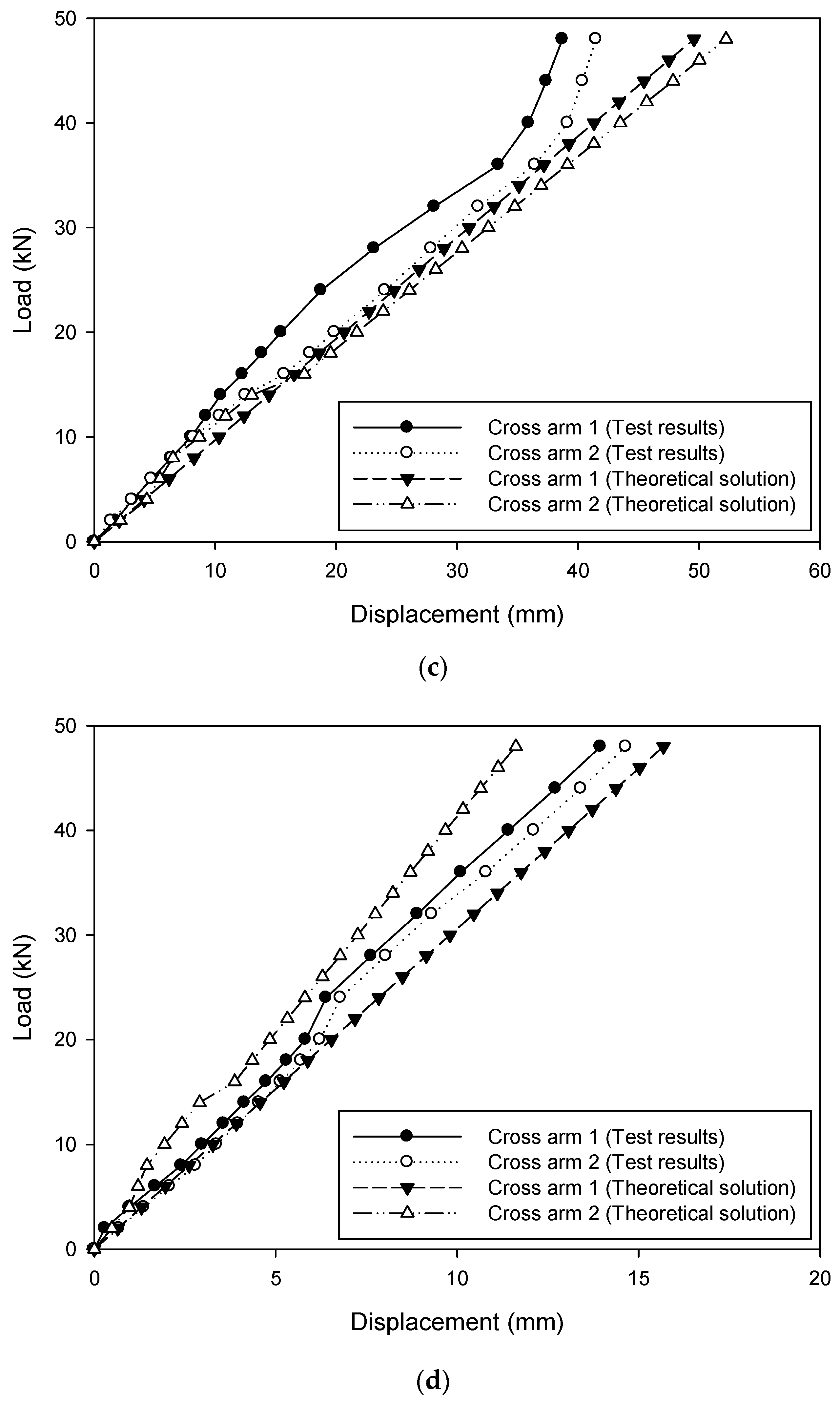

4.3. Comparison of the Cross Arm Displacement between Theoretical Solution and Experimental Findings

5. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Wu, Y.F.; Jiang, C. Effect of load eccentricity on the stress–strain relationship of FRP-confined concrete columns. Compos. Struct. 2013, 98, 228–241. [Google Scholar] [CrossRef]

- Yu, Q.Q.; Chen, T.; Gu, X.L.; Zhao, X.L.; Xiao, Z.G. Fatigue behaviour of CFRP strengthened steel plates with different degrees of damage. Thin-Walled Struct. 2013, 69, 10–17. [Google Scholar] [CrossRef]

- Yu, Q.Q.; Chen, T.; Gu, X.L.; Zhao, X.L.; Xiao, Z.G. Boundary element analysis of fatigue crack growth for CFRP-strengthened steel plates with longitudinal weld attachments. J. Compos. Constr. 2015, 19, 04014044. [Google Scholar] [CrossRef]

- Yu, Q.Q.; Wu, Y.F. Fatigue strengthening of cracked steel beams with different configurations and materials. J. Compos. Constr. 2017, 21, 04016093. [Google Scholar] [CrossRef]

- Zhou, A.; Chow, C.L.; Lau, D. Structural behavior of GFRP reinforced concrete columns under the influence of chloride at casting and service stages. Compos. Part B Eng. 2018, 136, 1–9. [Google Scholar] [CrossRef]

- Yu, Q.Q.; Wu, Y.F. Fatigue retrofitting of cracked steel beams with CFRP laminates. Compos. Struct. 2018, 192, 232–244. [Google Scholar] [CrossRef]

- Wang, Y.L.; Wang, Y.S.; Wan, B.L.; Han, B.G.; Cai, G.C.; Chang, R.J. Strain and damage self-sensing of basalt fiber reinforced polymer laminates fabricated with carbon nanofibers/epoxy composites under tension. Compos. Part A Appl. Sci. Manuf. 2018, 113, 40–52. [Google Scholar] [CrossRef]

- Zhang, D.M.; Gu, X.L.; Yu, Q.Q.; Huang, H.W.; Wan, B.L.; Jiang, C. Fully probabilistic analysis of FRP-to-concrete bonded joints considering model uncertainty. Compos. Struct. 2018, 185, 786–806. [Google Scholar] [CrossRef]

- Yu, Q.Q.; Gao, R.X.; Gu, X.L.; Zhao, X.L.; Chen, T. Bond behavior of CFRP-steel double-lap joints exposed to marine atmosphere and fatigue loading. Eng. Struct. 2018, 175, 76–85. [Google Scholar] [CrossRef]

- Zhou, A.; Qin, R.Y.; Chow, C.L.; Lau, D. Structural performance of FRP confined seawater concrete columns under chloride environment. Compos. Struct. 2019, 216, 12–19. [Google Scholar] [CrossRef]

- Zhang, X.; Wang, Y.L.; Wan, B.L.; Cai, G.C.; Qu, Y. Effect of specimen thicknesses on water absorption and flexural strength of CFRP laminates subjected to water or alkaline solution immersion. Constr. Build. Mater. 2019, 208, 314–325. [Google Scholar] [CrossRef]

- Li, P.D.; Sui, L.L.; Xing, F.; Zhou, Y.W. Static and cyclic response of low-strength recycled aggregate concrete strengthened using fiber-reinforced polymer. Compos. Part B Eng. 2019, 160, 37–49. [Google Scholar] [CrossRef]

- Lozano, C.M.; Riveros, G.A. Effects of adhesive bond-slip behavior on the capacity of innovative FRP retrofits for fatigue and fracture repair of hydraulic steel structures. Materials 2019, 12, 1495. [Google Scholar] [CrossRef] [PubMed]

- Daugevičius, M.; Valivonis, J.; Skuturna, T. Prediction of deflection of reinforced concrete beams strengthened with fiber reinforced polymer. Materials 2019, 12, 1367. [Google Scholar] [CrossRef]

- Li, P.D.; Wu, Y.F.; Zhou, Y.W.; Xing, F. Stress-strain model for FRP-confined concrete subject to arbitrary load path. Compos. Part B Eng. 2019, 163, 9–25. [Google Scholar] [CrossRef]

- Jiang, C.; Wu, Y.F.; Jiang, J.F. Effect of aggregate size on stress-strain behavior of concrete confined by fiber composites. Compos. Struct. 2017, 168, 851–862. [Google Scholar] [CrossRef]

- Fam, A.Z.; Rizkalla, S.H. Flexural behavior of concrete-filled fiber-reinforced polymer circular tubes. J. Compos. Constr. 2002, 6, 123–132. [Google Scholar] [CrossRef]

- Cole, B.; Fam, A. Flexural load testing of concrete-filled FRP tubes with longitudinal steel and FRP rebar. J. Compos. Constr. 2006, 10, 161–171. [Google Scholar] [CrossRef]

- Wu, Z.S.; Li, W.X.; Sakuma, N. Innovative externally bonded FRP/concrete hybrid flexural members. Compos. Struct. 2006, 72, 289–300. [Google Scholar] [CrossRef]

- Hong, W.K.; Kim, H.C. Behavior of concrete columns confined by carbon composite tubes. Can. J. Civ. Eng. 2004, 31, 178–188. [Google Scholar] [CrossRef]

- Ozbakkaloglu, T.; Oehlers, D.J. Concrete-filled square and rectangular FRP tubes under axial compression. J. Compos. Constr. 2008, 12, 469–477. [Google Scholar] [CrossRef]

- Fam, A.; Rizkalla, S. Large scale testing and analysis of hybrid concrete/composite tubes for circular beam-column applications. Constr. Build. Mater. 2003, 17, 507–516. [Google Scholar] [CrossRef]

- Mirmiran, A.; Shahawy, M.; Beitleman, T. Slenderness limit for hybrid FRP-concrete columns. J. Compos. Constr. 2001, 5, 26–34. [Google Scholar] [CrossRef]

- Becque, J.; Patnaik, A.K.; Rizkalla, S.H. Analytical models for concrete confined with FRP tubes. J. Compos. Constr. 2003, 7, 31–38. [Google Scholar] [CrossRef]

- Wei, Y.; Wu, G.; Li, G.F. Performance of circular concrete-filled fiber-reinforced polymer-steel composite tube columns under axial compression. J. Reinf. Plast. Compos. 2014, 33, 1911–1928. [Google Scholar] [CrossRef]

- Mirmiran, A.; Zagers, K.; Yuan, W. Nonlinear finite element modeling of concrete confined by fiber composites. Finite Elem. Anal. Des. 2000, 35, 79–96. [Google Scholar] [CrossRef]

- Fam, A.; Son, J.K. Finite element modeling of hollow and concrete-filled fiber composite tubes in flexure: Optimization of partial filling and a design method for poles. Eng. Struct. 2008, 30, 2667–2676. [Google Scholar] [CrossRef]

- Abdelkarim, O.I.; ElGawady, M.A. Analytical and finite-element modeling of FRP-concrete-steel double-skin tubular columns. J. Bridge Eng. 2015, 20, B4014005. [Google Scholar] [CrossRef]

- Nguyen, T.T.; Waldmann, D.; Bui, T.Q. Computational chemo-thermo-mechanical coupling phase-field model for complex fracture induced by early-age shrinkage and hydration heat in cement-based materials. Comput. Methods Appl. Mech. Eng. 2019, 348, 1–28. [Google Scholar] [CrossRef]

- Thai, D.K.; Kim, S.E.; Bui, T.Q. Modified empirical formulas for predicting the thickness of RC panels under impact loading. Constr. Build. Mater. 2018, 169, 261–275. [Google Scholar] [CrossRef]

- Robert, M.; Fam, A. Long-term performance of GFRP tubes filled with concrete and subjected to salt solution. J. Compos. Constr. 2012, 16, 217–224. [Google Scholar] [CrossRef]

- Li, Y.L.; Zhao, X.L.; Singh Raman, R.K. Mechanical properties of seawater and sea sand concrete-filled FRP tubes in artificial seawater. Constr. Build. Mater. 2018, 191, 977–993. [Google Scholar] [CrossRef]

- Li, H.; Ma, M.L.; Xian, G.J.; Yan, X.; Ou, J.P. Performances of concrete-filled GFRP or GFRP-steel circular tubes subjected to freeze-thaw cycles. Int. J. Struct. Stab. Dyn. 2012, 12, 95–108. [Google Scholar] [CrossRef]

- Xu, F.; Chen, J.; Chan, T.M. Mechanical behaviour of concrete-filled CHS connections subjected to in-plane bending. Eng. Struct. 2017, 148, 101–112. [Google Scholar] [CrossRef]

- Xu, F.; Chen, J.; Jin, W.L. Experimental investigation of concrete-filled steel tubular longitudinal gusset plate connections. J. Constr. Steel Res. 2016, 124, 163–172. [Google Scholar] [CrossRef]

- Yeh, H.Y.; Yang, S.C. Building of composite transmission tower. J. Reinf. Plast. Compos. 1997, 16, 414–424. [Google Scholar] [CrossRef]

- Yeh, H.Y.; Yeh, H.L. A simple failure analysis of the composite transmission tower. J. Reinf. Plast. Compos. 2001, 20, 1054–1065. [Google Scholar] [CrossRef]

- Ibrahim, S.; Polyzois, D. Ovalization analysis of fiber-reinforced plastic poles. Compos. Struct. 1999, 45, 7–12. [Google Scholar] [CrossRef]

- Polyzois, D.; Raftoyiannis, I.G.; Ibrahim, S. Finite elements method for the dynamic analysis of tapered composite poles. Compos. Struct. 1998, 43, 25–34. [Google Scholar] [CrossRef]

- Marzuki, H.F.A.; Mariatti, J. Laminate design of lightweight glass fiber reinforced epoxy composite for electrical transmission structure. Procedia Chem. 2016, 19, 871–878. [Google Scholar] [CrossRef]

- American Society of Civil Engineering. ASCE Manuals and Reports on Engineering Practice No.104, Recommended Practice for Fiber-Reinforced Polymer Products for Overhead Utility Line Structures; Reston, VA, USA, 2003. [Google Scholar]

- Wang, Z.S.; Ma, X.M.; Liu, Y.H.; Ma, H.; Guo, H.C. The mechanical behaviour and failure mode of FRP composite steel casing joints. Polym. Polym. Compos. 2016, 24, 91–98. [Google Scholar] [CrossRef]

- Godat, A.; Légeron, F.; Gagné, V.; Marmion, B. Use of FRP pultruded members for electricity transmission towers. Compos. Struct. 2013, 105, 408–421. [Google Scholar] [CrossRef]

- Guades, E.; Aravinthan, T.; Islam, M.M. Characterisation of the mechanical properties of pultruded fibre-reinforced polymer tube. Mater. Des. 2014, 63, 305–315. [Google Scholar] [CrossRef]

- GB 50017-2003. Code for Design of Steel Structures; Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2003. (In Chinese)

- GB 50010-2010. Code for Design of Concrete Structures; Ministry of Housing and Urban-Rural Development of the People’s Republic of China: Beijing, China, 2010. (In Chinese)

- Li, J.; Jiang, X.G.; Wang, H.Z.; Luo, S.; Xia, W.Z.; Li, X. Analytical element for Timoshenko beam on elastic Foundation. Eng. Mech. 2018, 2, 221–229. (In Chinese) [Google Scholar]

| Specimen | Diameter of the GFRP Tube dG (mm) | Wall Thickness of the GFRP Tube (mm) | Cross-Sectional Dimension of the Cross Arm (mm) |

|---|---|---|---|

| D150-20 | 180 | 10 | 20 × 20 |

| D150-30 | 180 | 10 | 30 × 30 |

| D150-40 | 180 | 10 | 40 × 40 |

| D300-30 | 300 | 12 | 30 × 30 |

| D300-45 | 300 | 12 | 45 × 45 |

| D300-60 | 300 | 12 | 60 × 60 |

| GFRP Tube | Water-Absorption Rate (%) | Degree of Cure (%) | Density (kg/m3) | Ultimate Tensile Strength (MPa) | Elastic Modulus (GPa) |

|---|---|---|---|---|---|

| dG = 180 mm | 0.15 | 95.9 | 2066.5 | 342.6 | 36.8 |

| dG = 300 mm | 0.14 | 92.7 | 1987.1 | 371.9 | 39.2 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, F.; Chen, J.; Yu, Q.-Q.; Dong, X. Behavior of Cross Arms Inserted in Concrete-Filled Circular GFRP Tubular Columns. Materials 2019, 12, 2280. https://doi.org/10.3390/ma12142280

Xie F, Chen J, Yu Q-Q, Dong X. Behavior of Cross Arms Inserted in Concrete-Filled Circular GFRP Tubular Columns. Materials. 2019; 12(14):2280. https://doi.org/10.3390/ma12142280

Chicago/Turabian StyleXie, Fang, Ju Chen, Qian-Qian Yu, and Xinlong Dong. 2019. "Behavior of Cross Arms Inserted in Concrete-Filled Circular GFRP Tubular Columns" Materials 12, no. 14: 2280. https://doi.org/10.3390/ma12142280

APA StyleXie, F., Chen, J., Yu, Q.-Q., & Dong, X. (2019). Behavior of Cross Arms Inserted in Concrete-Filled Circular GFRP Tubular Columns. Materials, 12(14), 2280. https://doi.org/10.3390/ma12142280