Machinability of Rene 65 Superalloy

Abstract

:1. Introduction

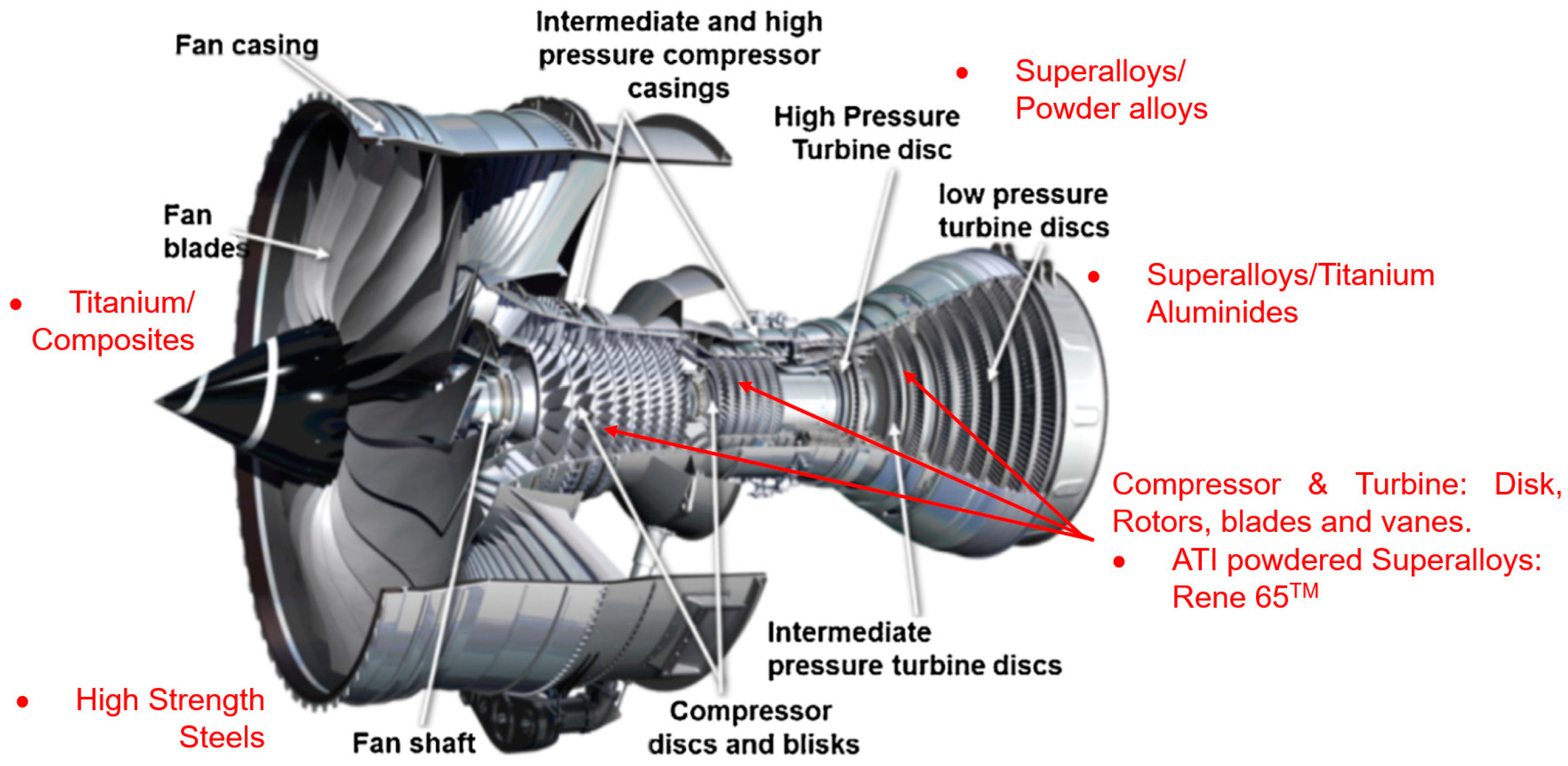

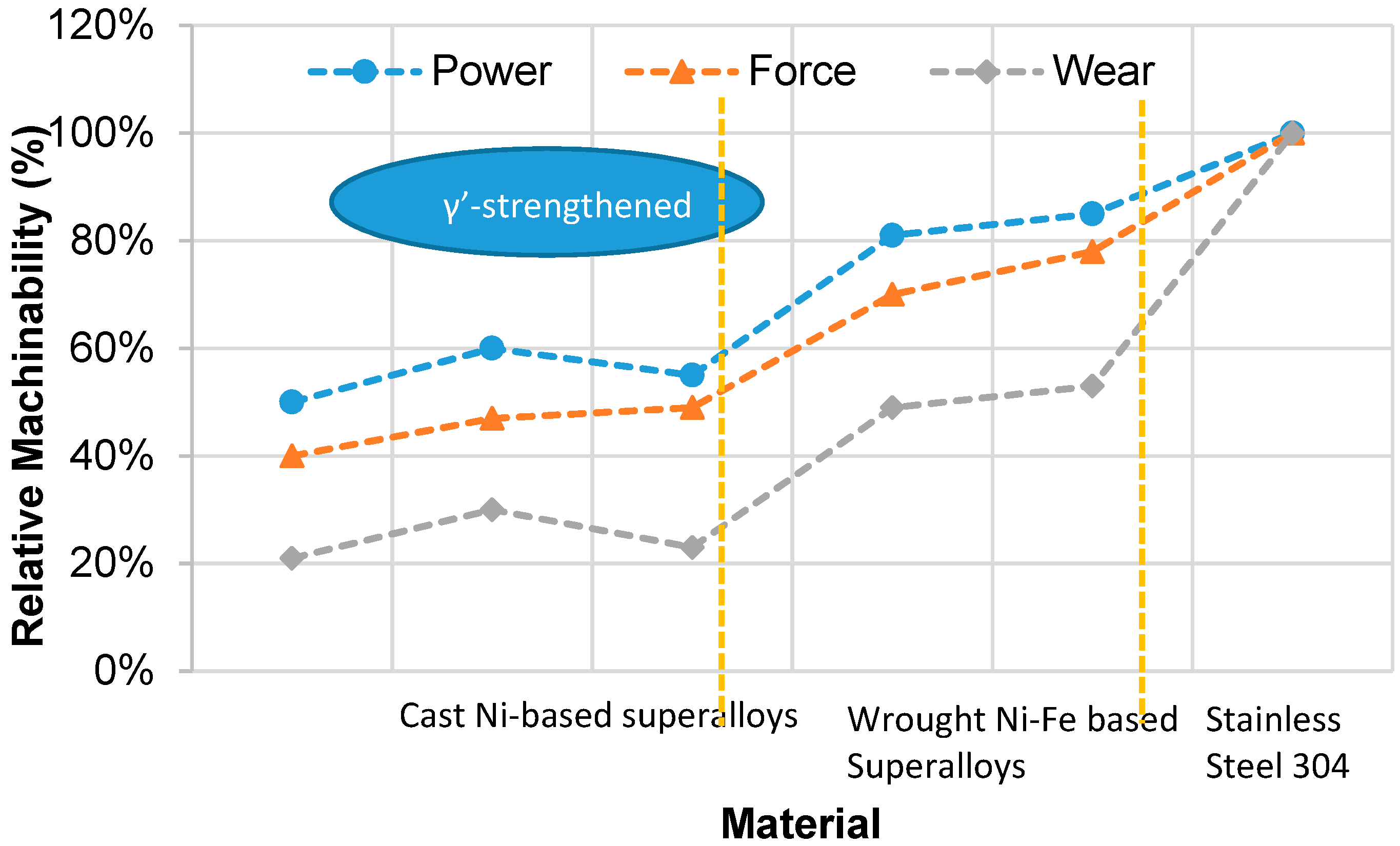

1.1. Rene 65 and Other Ni-Base Superalloys

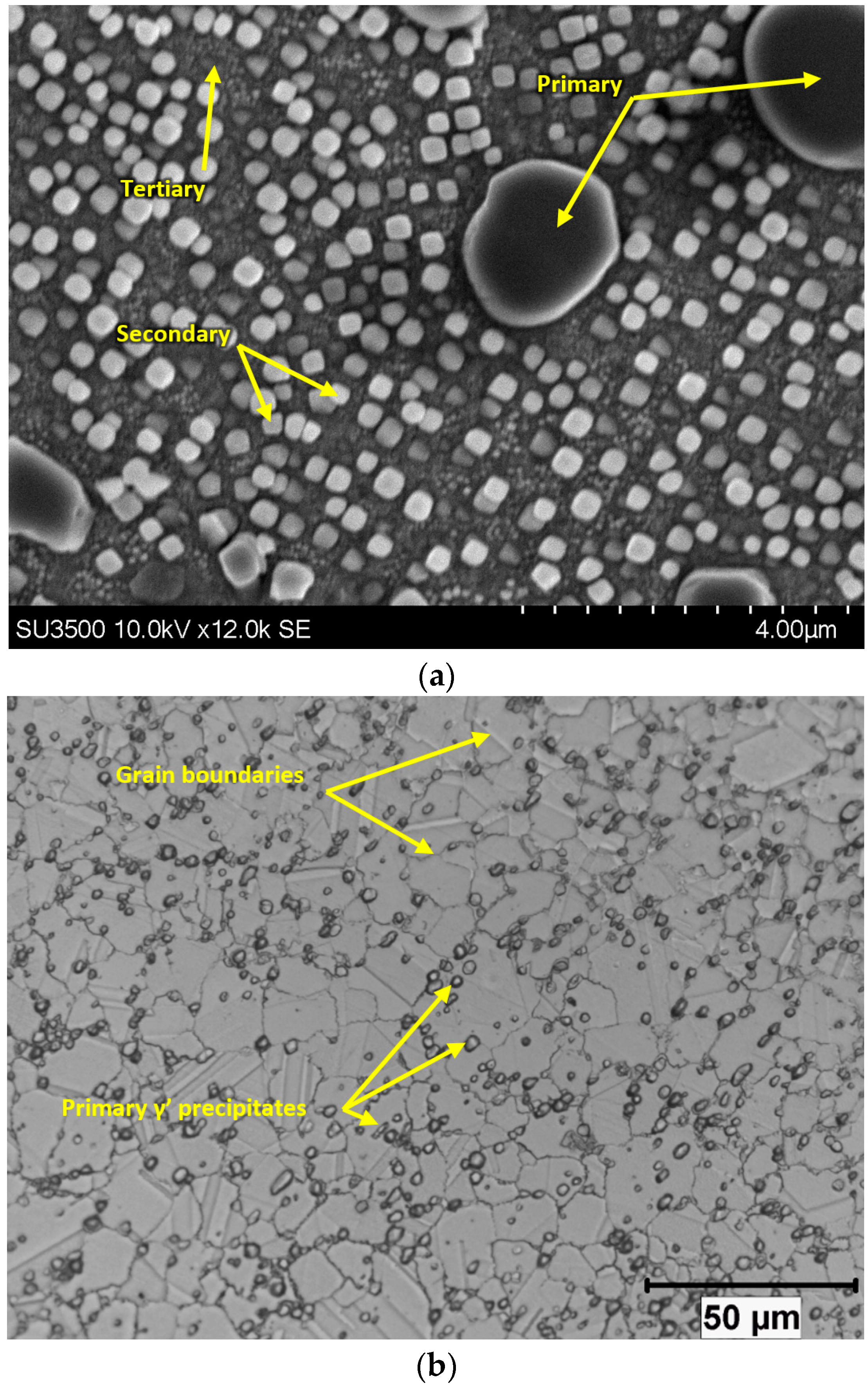

1.2. Microstructure of Rene 65

1.3. Strengthening of Ni Superalloys

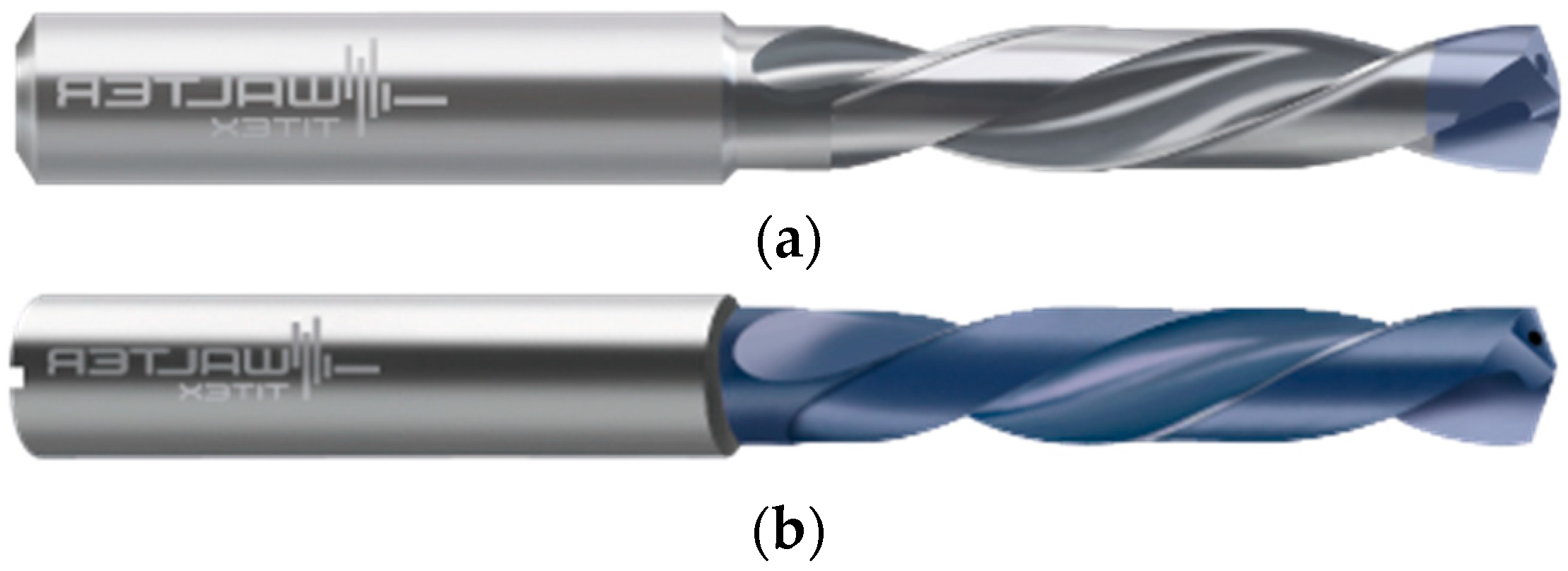

1.4. Cutting Drill Materials

2. Experimental Setup

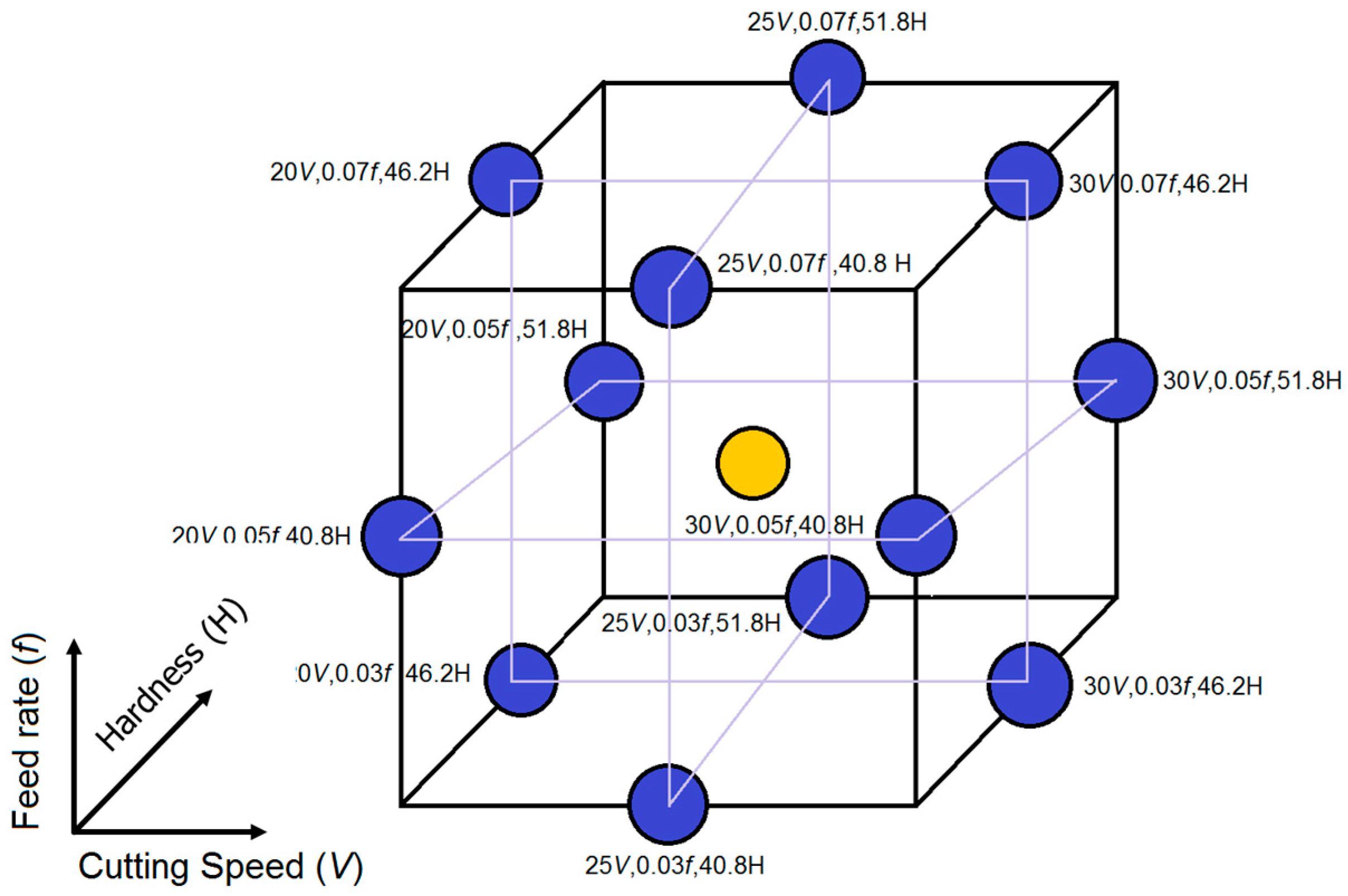

2.1. Experimental Design Plan

2.2. Heat Treatment

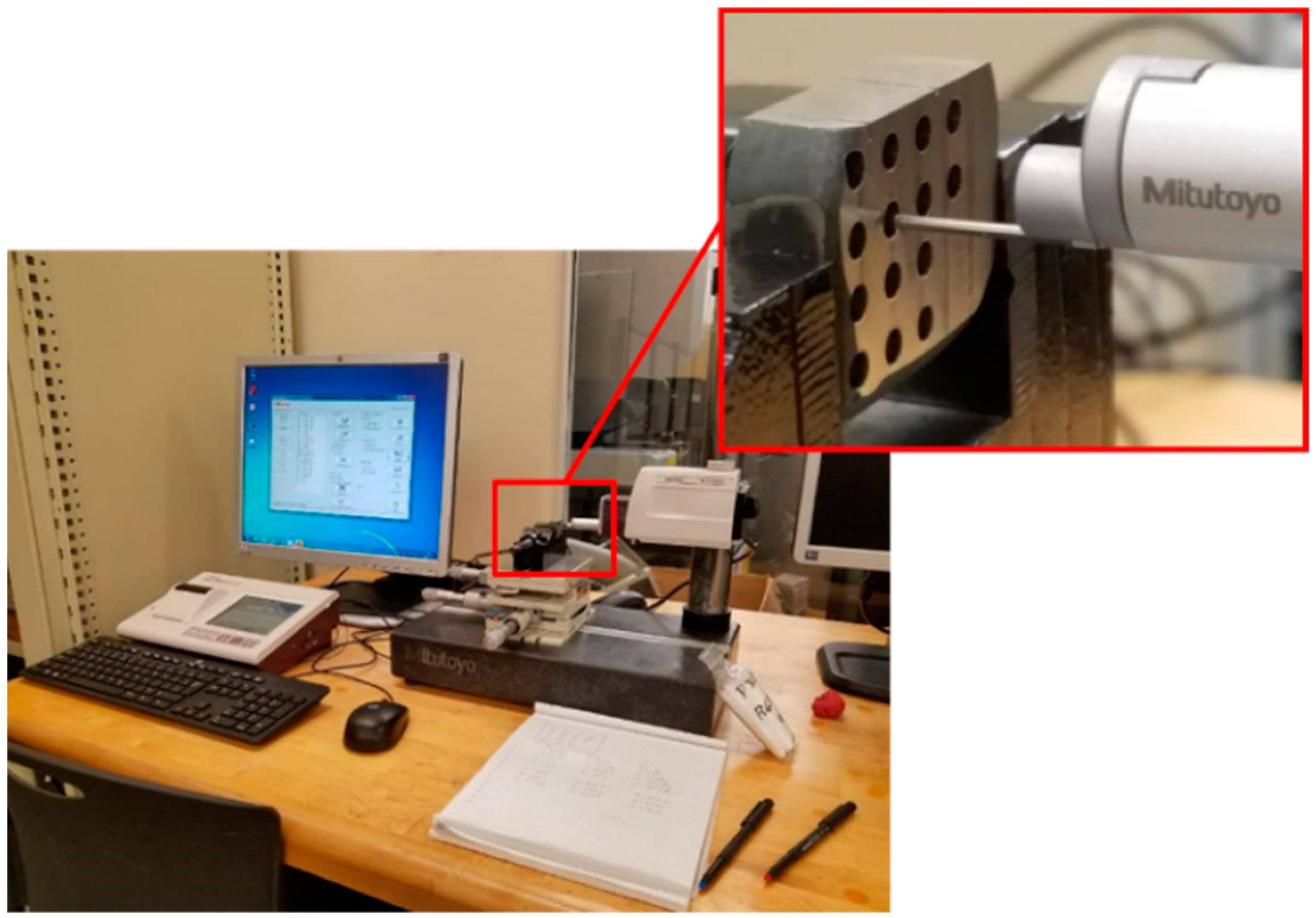

2.3. Measurement of Response Factors

3. Results and Discussions

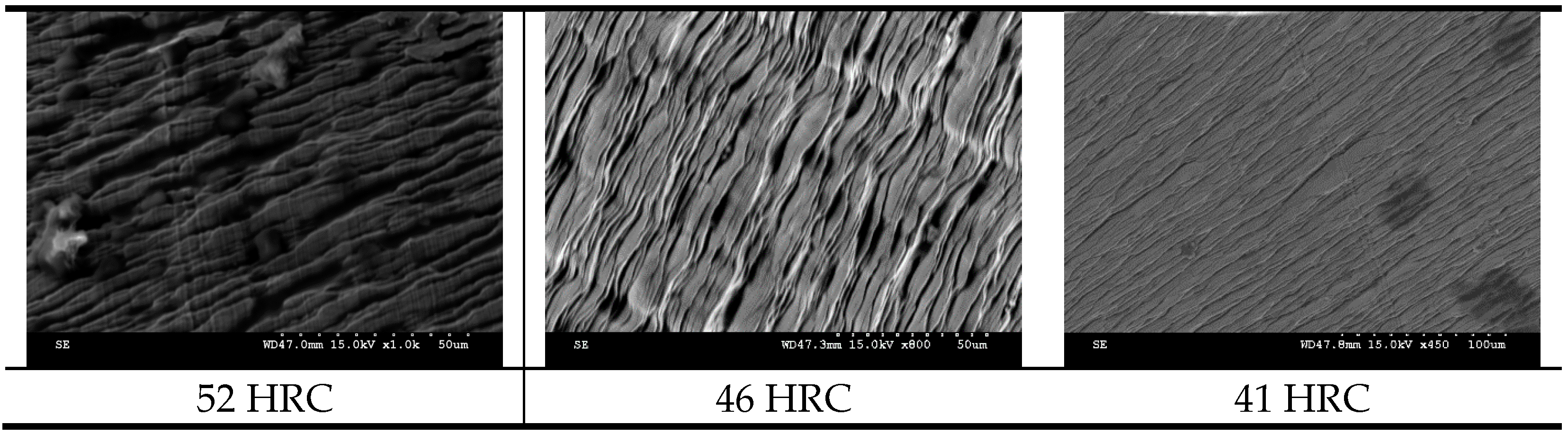

3.1. Impact of Heat Treatment on Rene 65 Microstructures

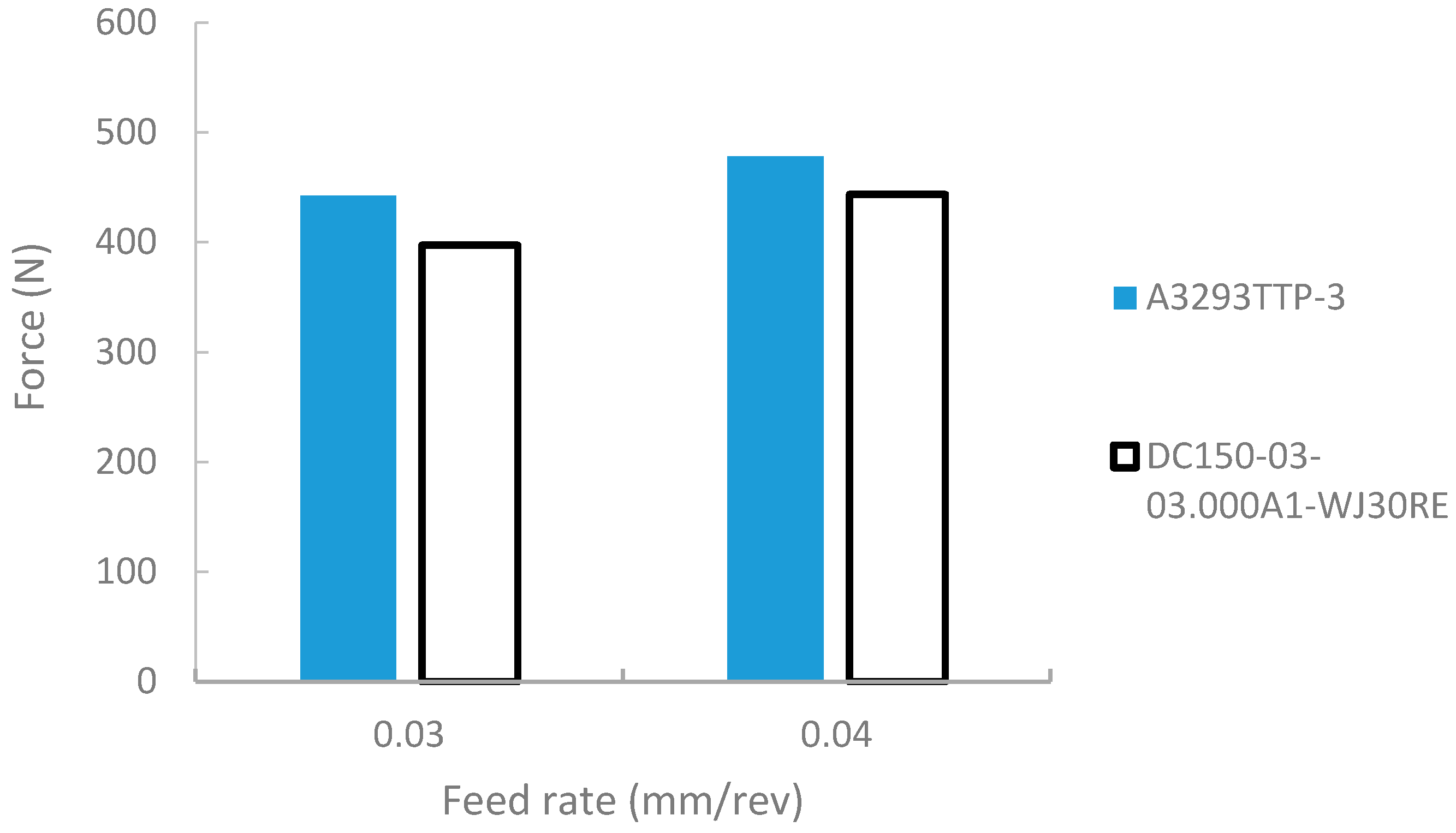

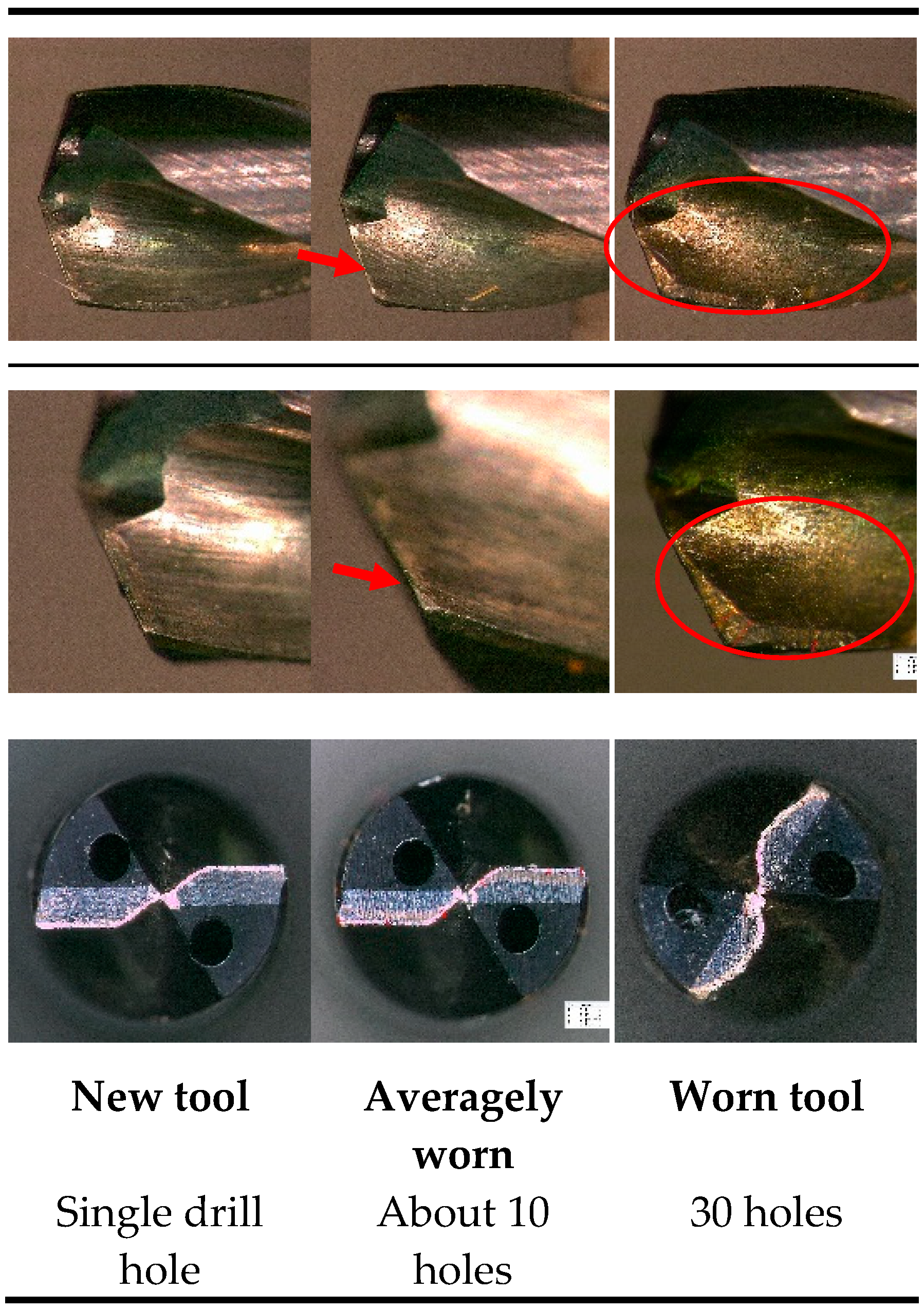

3.2. Effect of Drilling Tools

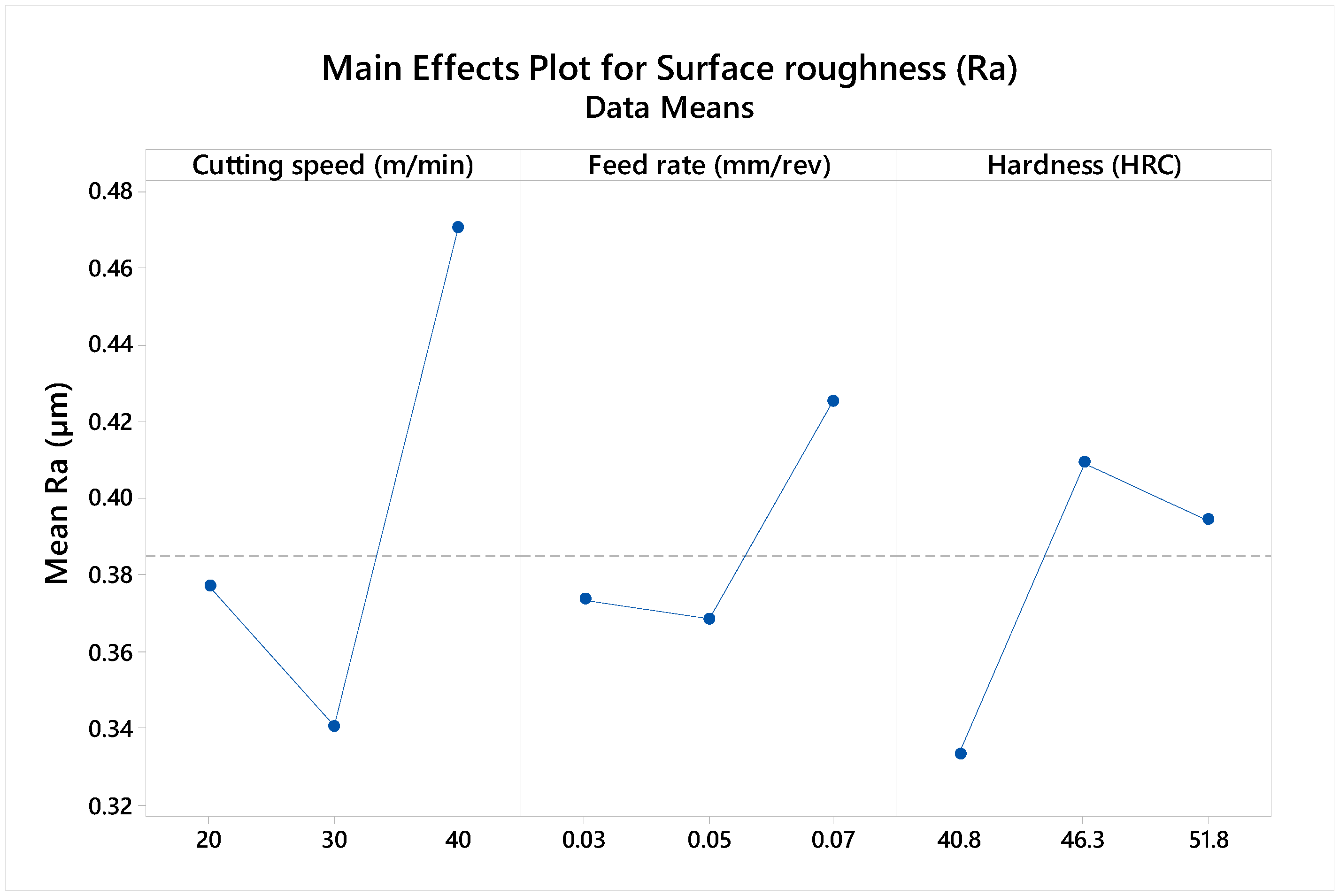

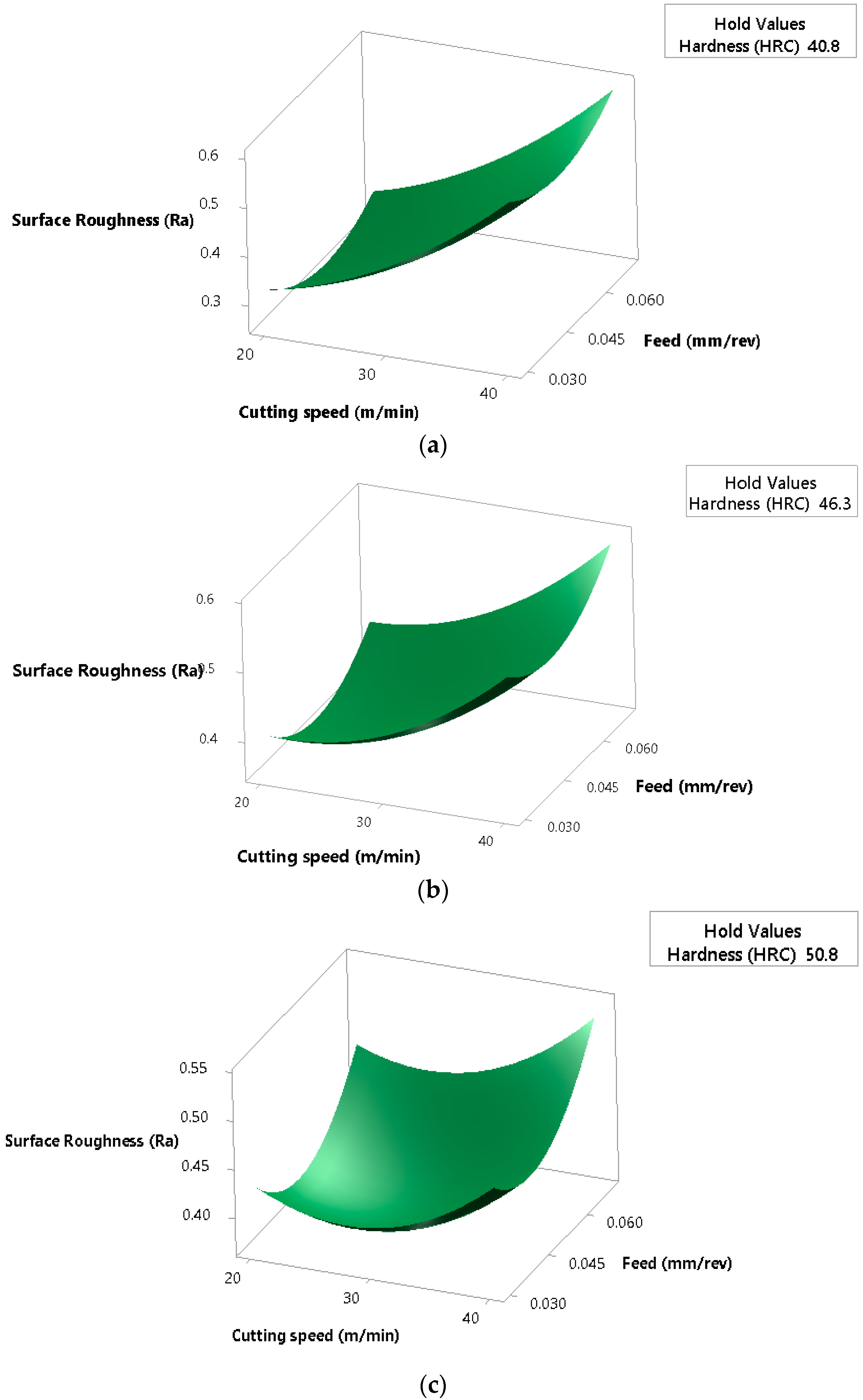

3.3. Surface Roughness

3.4. Cutting Force Analysis

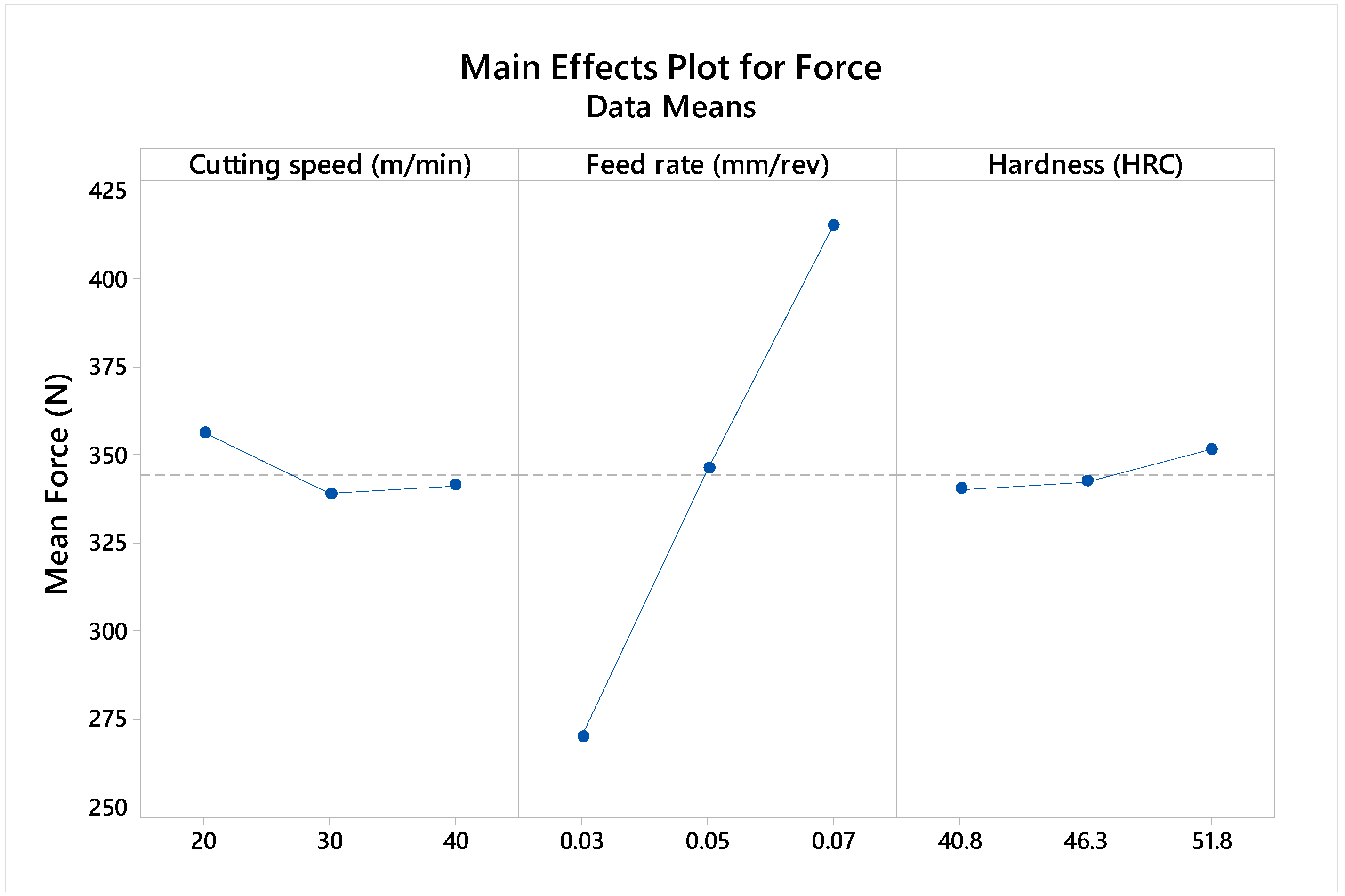

3.4.1. Main Effect Plots of Cutting Forces

3.4.2. Analysis of Cutting Force Prediction Models

- (a)

- Linear model: Table 6 shows the ANOVA table for the linear solution. From the table, the model developed recognized as significant to the data, also indicating the significance of the feed with a Pearson test value of 0.000. The model summary indicates a 96.17% r-square and 92.13% r-square predicted value. From the lack of fit test for the model, we cannot conclude that there is a lack of fit for the model with a 0.069 P-value. The model equation is shown in Equation (1).

- (b)

- Full quadratic equation with interactions: The ANOVA of the quadratic solution is shown in Table 7. The quadratic expression also shows high significance of the quadratic model to the captured problem with no improved significance from interactions and squares. The feed rate also possesses a 100 percent significance in p-test estimation. However, the summary of this model indicates a higher R-square value of 98.74% and 80.68% R-square predicted. The regression equation of the quadratic representation is seen in Equation (2).

- (c)

- Significant factor equation: The ANOVA table, which only includes significant factors, is shown in Table 8. This table indicates the feed rate as being the only significant factor to force prediction. Through a stepwise regression with an alpha value of 0.1 all non-significant factors have been removed during model formulation. A slightly lower R-square value of 94.56% is obtained with 94.15% improved adjusted and 92.80% predicted r-square values. The regression equation based only on the feed rate is shown in Equation (3).

- (d)

- Power form equation: In power or exponential regression, the function is a polynomial equation of the form y = axb. This form of equation allows us to model a problem whose factors do not increases in a non-linear fashion. Power regression is one in which the response directly relates to the input factor raised to a given power. It can be obtained by first taking the log of both factors and response values and then performing a least square regression on the transformed data and finally, an inverse transformation to ascertain that the resulting power function captures the trend of the data. A lower but still acceptable, R-square value of 93.86% with a 91.81% r-square predicted value is obtained. The inverse transformation of the regression function of Equation (4) is shown in Equation (5).

3.4.3. Graphical Comparison of Model Predictions

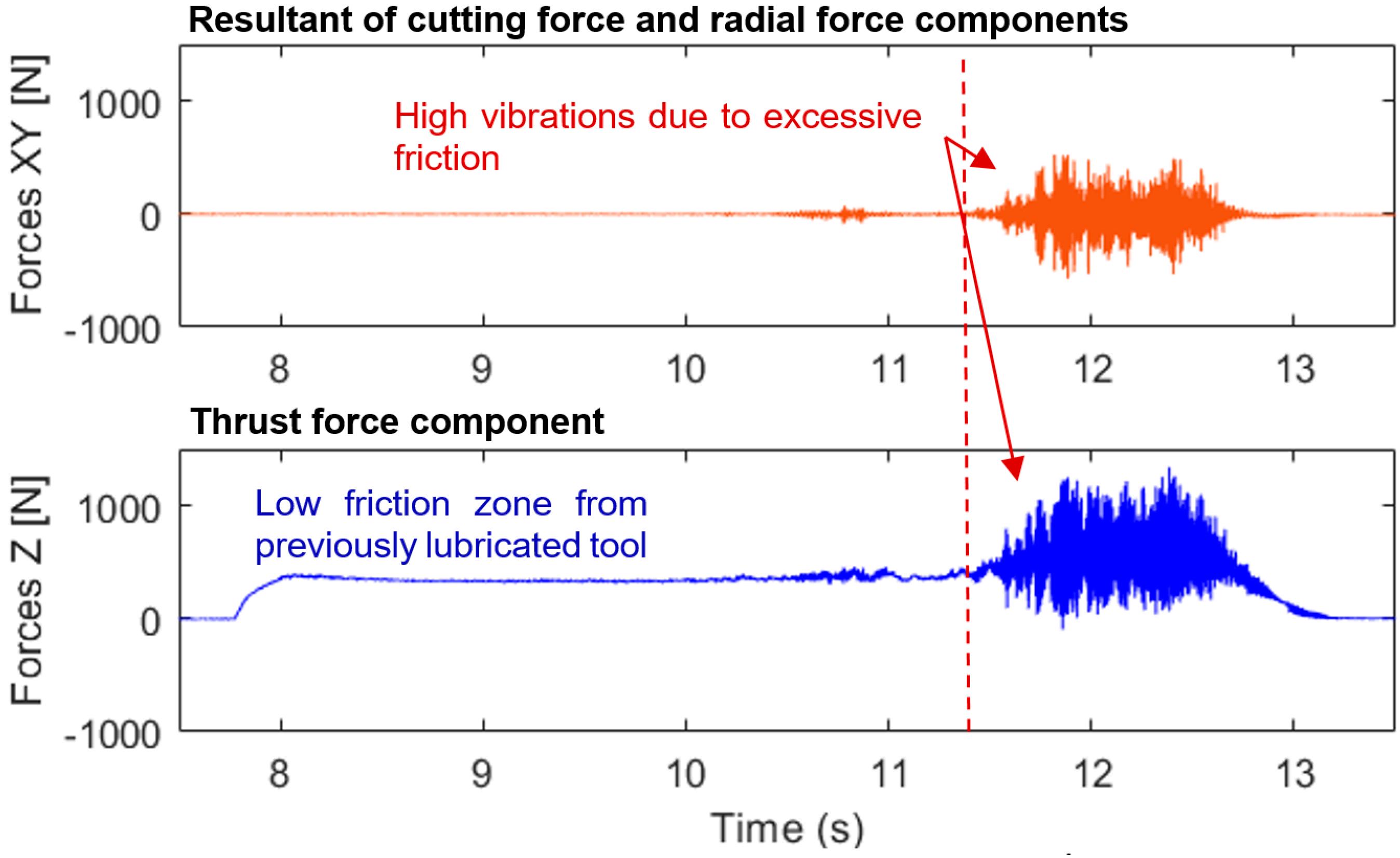

3.5. Wear and Lubrication in Machining Rene 65

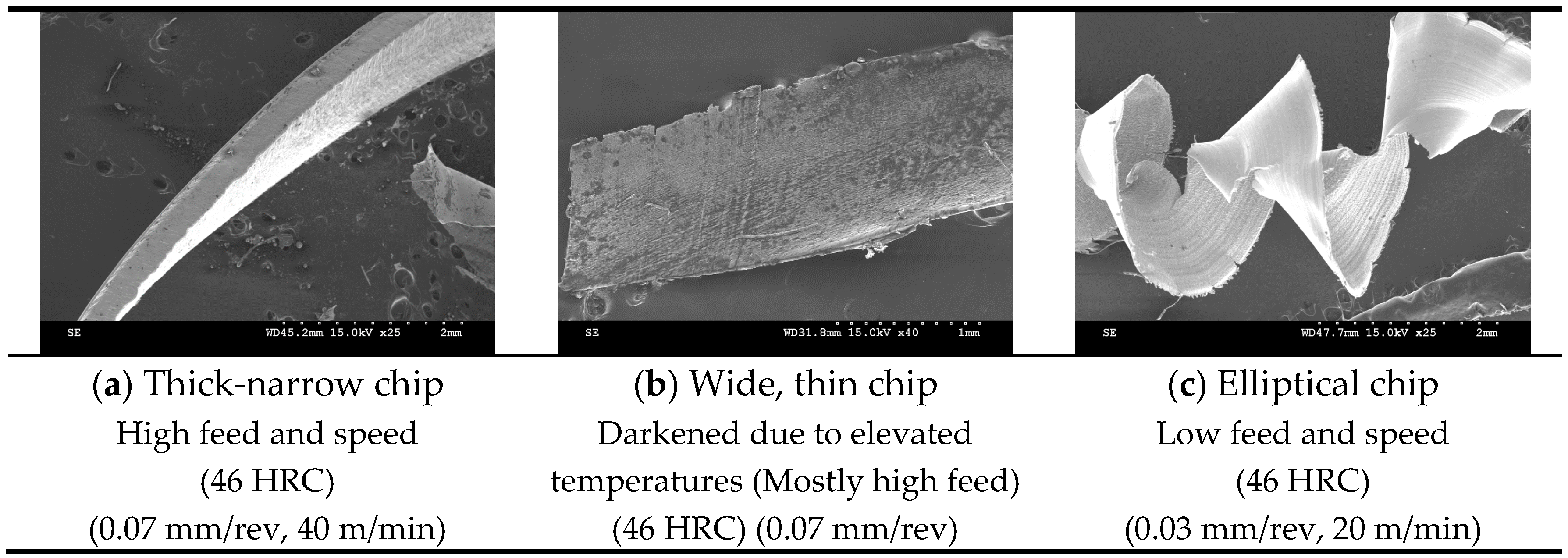

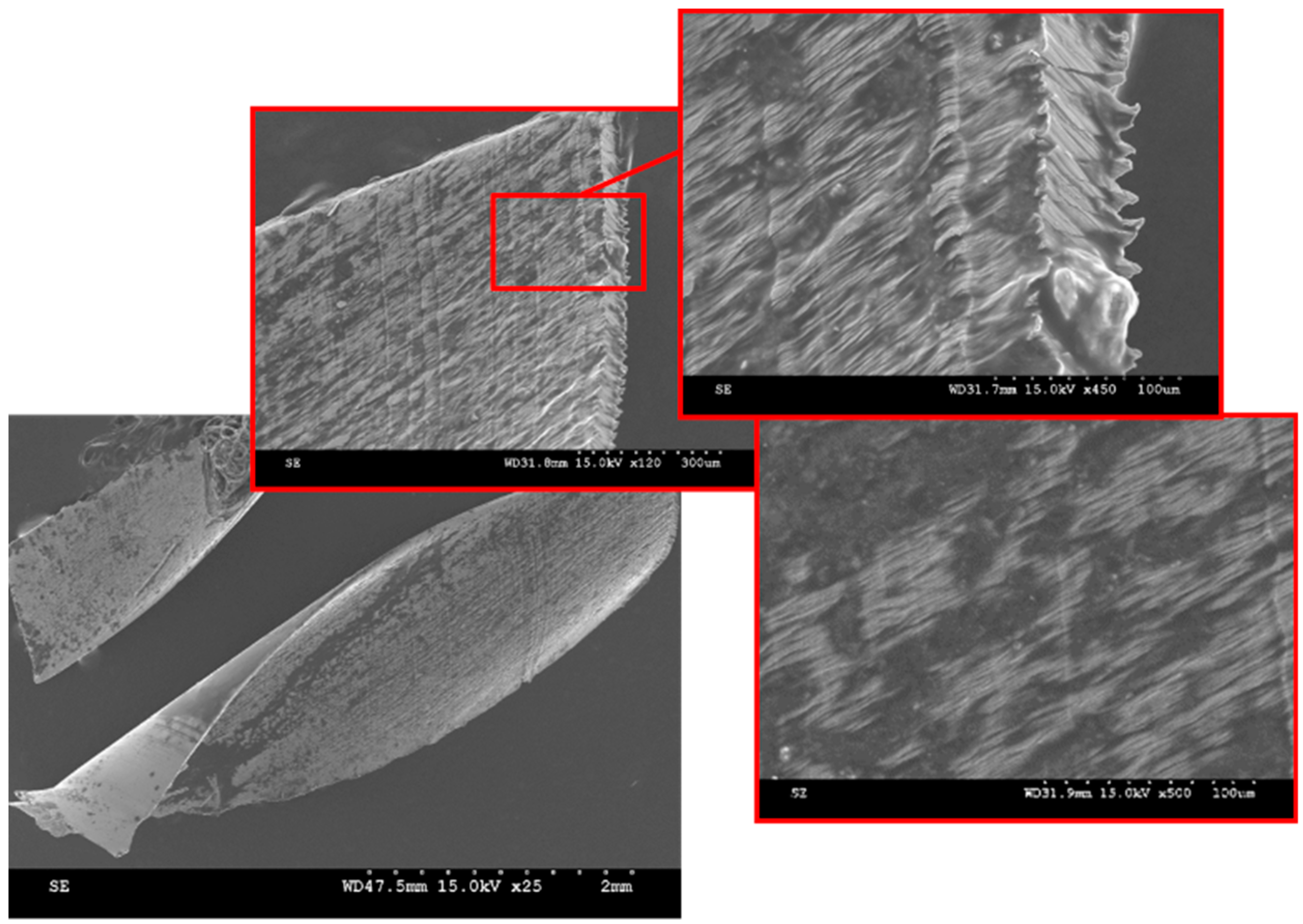

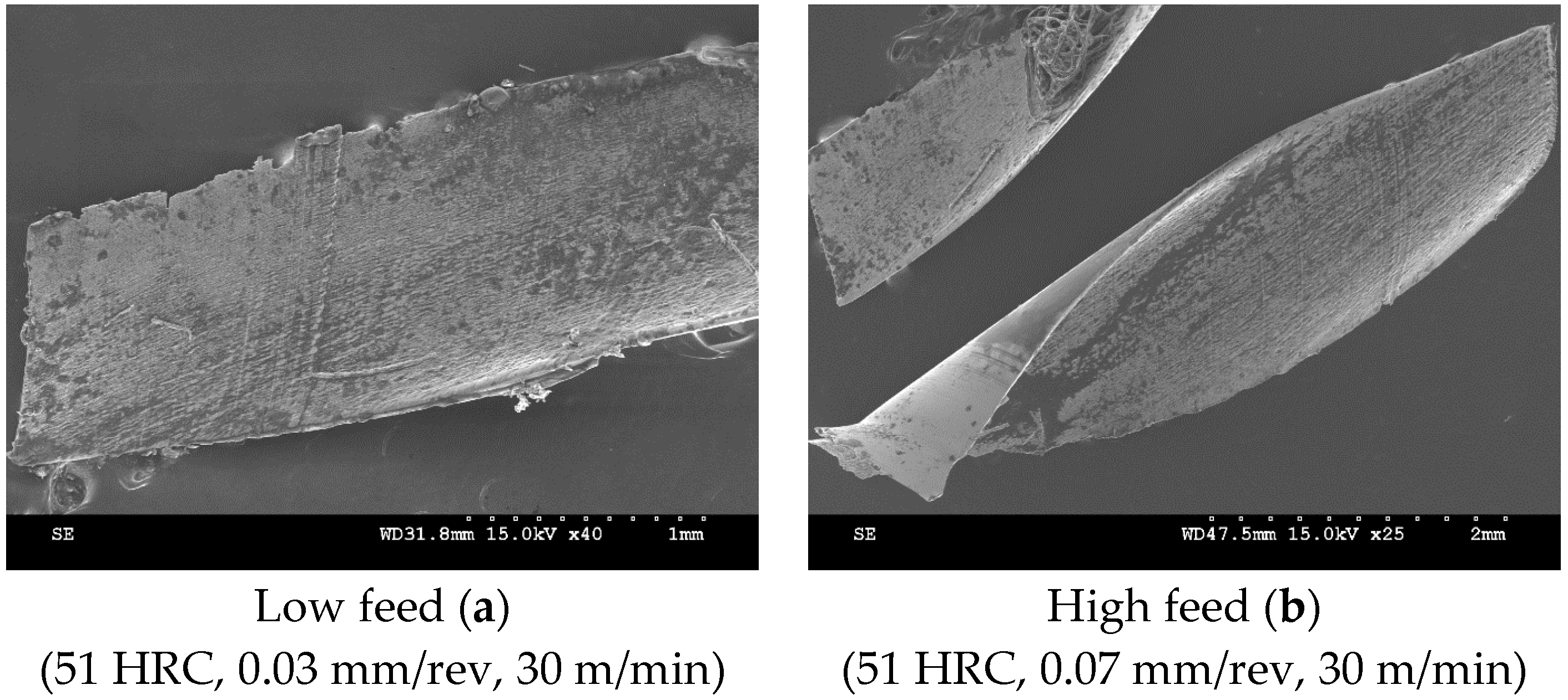

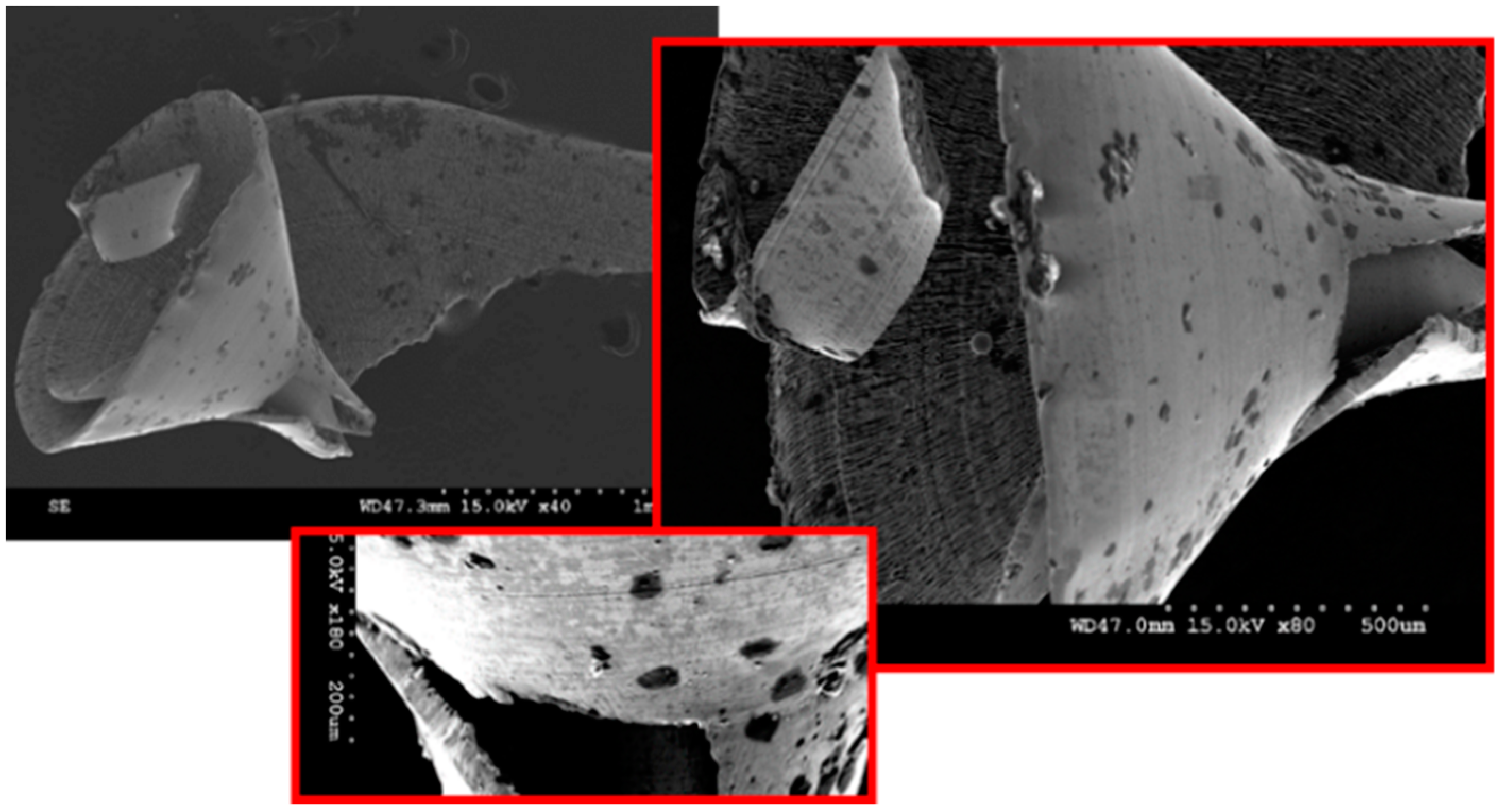

3.6. Cutting Chip Analysis

4. Conclusions

- In general, the 41 HRC samples presented an improved machinability with reduced cutting forces and surface roughness. However, the range of hardnesses tested did not demonstrate a significant influence on the generation of cutting forces in drilling operations.

- The machinability of nickel-based alloys can be affected by the grade of the coating applied on the tool.

- The cutting feed rate was identified as the most significant parameter in the generation of cutting forces, while the cutting speed was more significant in the generation of surface roughness.

- The cutting parameters had a significant effect on the morphology of the chip and on the segmentation observed in harder samples.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Devaux, A.; Georges, E.; Héritier, P. Development of New C&W Superalloys for High Temperature Disk Applications. Adv. Mater. Res. 2011, 278, 405–410. [Google Scholar] [CrossRef] [Green Version]

- Heaney, J.A.; Lasonde, M.L.; Powell, A.M.; Bond, B.J.; O’Brien, C.M. Development of a New Cast and Wrought Alloy (Rene 65) for High Temperature Disk Applications. In Proceedings of the 8th International Symposium on Superalloy 718 and Derivatives, Pittsburgh, PA, USA, 28 September–1 October 2014. [Google Scholar]

- Wessman, A.; Laurence, A.; Laurence, A.; Cormier, J.; Villechaise, P.; Billot, T.; Franchet, J.-M. Thermal Stability of Cast and Wrought Alloy Rene 65. In Proceedings of the 13th International Symposium of Superalloys, Seven Springs, PA, USA, 11–15 September 2016. [Google Scholar]

- M’Saoubi, R.; Axinte, D.; Soo, S.L.; Nobel, C.; Attia, H.; Kappmeyer, G.; Engin, S.; Sim, W.-M. High performance cutting of advanced aerospace alloys and composite materials. CIRP Annals 2015, 64, 557–580. [Google Scholar] [CrossRef]

- Ota, A.; Ueshima, N.; Oikawa, K.; Imano, S. Microstructure Controlling of U720-Typed Superalloys to Improve a Hot and Cold Workability by Using Incoherent Gamma Prime. In Proceedings of the 9th International Symposium on Superalloy 718 & Derivatives: Energy, Aerospace and Industrial Applications; Springer: Cham, Switzerland, 2018; pp. 987–999. [Google Scholar]

- Kaya, E.; Akyuz, B. Effects of cutting parameters on machinability characteristics of Ni-based superalloys: A review. Open Eng. 2017, 7, 330–342. [Google Scholar] [CrossRef]

- Donachie, M.J.; Donachie, S.J. Superalloys: A Technical Guide; ASM International: Materials Park, OH, USA, 2002. [Google Scholar]

- Podziewski, P.; Gorski, J.; Czarniak, P.; Wilkowski, J.; Szymanowski, K.; Cyrankowski, M. MDF-machinability during drilling. Ann. Warsaw Univ. Life Sci.-SGGW For. Wood Technol. 2014, 87, 167–171. [Google Scholar]

- Henderson, A. Updated Force Model for Milling Nickel-Based Superalloys. Ph.D. Thesis, Clemson University, Clemson, SC, USA, 2012. [Google Scholar]

- Henderson, A.; Bunget, C.; Kurfess, T. Integration of On-Machine Measurements in the Force Modeling for Machining of Advanced Nickel-Based Superalloys. In Proceedings of the ASME/ISCIE 2012 International Symposium on Flexible Automation, St. Louis, MO, USA, 18–20 June 2012; pp. 561–567. [Google Scholar]

- Mellinger, J.C.; Ozdoganlar, O.B.; DeVor, R.E.; Kapoor, S.G. Modeling chip-evacuation forces and prediction of chip-clogging in drilling. J. Manuf. Sci. Eng. 2002, 124, 605–614. [Google Scholar] [CrossRef]

- Choudhury, I.A.; El-Baradie, M.A. Machinability of nickel-base super alloys: A general review. J. Mater. Process. Technol. 1998, 77, 278–284. [Google Scholar] [CrossRef]

- Vernier, S.; Franchet, J.M.; Dumont, C.; Bozzolo, N. A Mechanism Leading to gamma‘ Precipitates with {111} Facets and Unusual Orientation Relationships to the Matrix in gamma-gamma‘ Nickel-Based Superalloys. Metall. Mater. Trans. A 2018, 49a, 4308–4323. [Google Scholar] [CrossRef]

- Ezugwu, E.O.; Wang, Z.M.; Machado, A.R. The machinability of nickel-based alloys: A review. J. Mater. Process. Technol. 1999, 86, 1–16. [Google Scholar] [CrossRef]

- Mouritz, A.P. Chapter 4—Strengthening of metal alloys. In Introduction to Aerospace Materials; Woodhead Publishing: Sawston, UK, 2012; pp. 57–90. [Google Scholar] [CrossRef]

- Tancret, F.; Galindo-Nava, E.; Rivera Díaz-del-Castillo, P.E.J. Dynamic recrystallisation model in precipitation-hardened superalloys as a tool for the joint design of alloys and forming processes. Mater. Des. 2016, 103, 293–299. [Google Scholar] [CrossRef]

- Locq, D.; Caron, P.; Raujol, S.; Pettinari-Sturmel, F.; Coujou, A.; Clément, N. On the Role of Tertiary γ′ Precipitates in the Creep Behaviour at 700 C of a PM Disk Superalloy. In Superalloys 2004; Green, K.A., Pollock, T.M., Harada, H., Eds.; TMS: Warrendale, PA, USA, 2004; pp. 179–187. [Google Scholar]

- Reed, R.C. The Superalloys: Fundamentals and Applications; Cambridge University Press: Cambridge, UK, 2008. [Google Scholar]

- Uddin, M.S.; Pham, B.; Sarhan, A.; Basak, A.; Pramanik, A. Comparative study between wear of uncoated and TiAlN-coated carbide tools in milling of Ti6Al4V. Adv. Manuf. 2017, 5, 83–91. [Google Scholar] [CrossRef] [Green Version]

- Rosnan, R.; Azmi, A.I.; Murad, M.N. Effects of Cutting Parameters on Tool Wear and Thrust Force in Drilling Nickel-Titanium (NiTi) Alloys Using Coated and Uncoated Carbide Tools. Key Eng. Mater. 2018, 791, 111–115. [Google Scholar] [CrossRef]

- Olufayo, O.A. Ultra-high Precision Machining of Contact Lens Polymers. Ph.D. Thesis, Nelson Mandela Metropolitan University, Port-Elizabeth, South Africa, 2015. [Google Scholar]

- Kasim, M.S.; Che Haron, C.H.; Ghani, J.A.; Mohamad, E.; Izamshah, R.; Mohd, A.A.; Saedon, J.B. Multi-Objective Optimization Using Box-Behken of Response Surface Methodology for High-Speed Machining of Inconel 718. Appl. Mech. Mater. 2014, 629, 487–492. [Google Scholar] [CrossRef]

- Stephenson, D.A.; Agapiou, J.S. Metal Cutting Theory and Practice; CRC Press: Boca Raton, FL, USA, 2016. [Google Scholar]

- Thakur, D.G.; Ramamoorthy, B.; Vijayaraghavan, L. Effect of cutting parameters on the degree of work hardening and tool life during high-speed machining of Inconel 718. Int. J. Adv. Manuf. Technol. 2012, 59, 483–489. [Google Scholar] [CrossRef]

- Bhoyar, Y.R.; Kamble, P.D. Finite Element Analysis on Temperature Distribution of Turning Process. Int. J. Mod. Eng. Res. 2013, 3, 541–546. [Google Scholar]

- Bono, M.; Ni, J. The location of the maximum temperature on the cutting edges of a drill. Int. J. Mach. Tools Manuf. 2006, 46, 901–907. [Google Scholar] [CrossRef] [Green Version]

- Thellaputta, G.R.; Bose, P.S.C.; Rao, C.S.P. Machinability of Nickel Based Superalloys: A Review. Mater. Today-Proc. 2017, 4, 3712–3721. [Google Scholar] [CrossRef]

- Markopoulos, A.P.; Habrat, W.; Galanis, N.I.; Karkalos, N.E. Modelling and optimization of machining with the use of statistical methods and soft computing. In Design of Experiments in Production Engineering; Springer: New York, NY, USA, 2016; pp. 39–88. [Google Scholar]

- Beranoagirre, A.; Urbikain, G.; Calleja, A.; López de Lacalle, L.N. Drilling Process in γ-TiAl Intermetallic Alloys. Materials 2018, 11, 2379. [Google Scholar] [CrossRef] [PubMed]

- Luha, S.S. Study of Effect of Advanced PVD coating on Drilling of Nickel-Based Super Alloy Inconel 825. Master’s Thesis, National Institute of Technology Rourkela, Odisha, India, 2015. [Google Scholar]

- Elfizy, A. Enhanced Conditions for High Performance Machining of Hardened H13 Die Steel. Master’s Thesis, McMaster University, Hamilton, ON, Canada, 2008. [Google Scholar]

- Zhang, S.; Guo, Y. An experimental and analytical analysis on chip morphology, phase transformation, oxidation and their relationships in finish hard milling. Inter. J. Mach. Tools Manuf. 2009, 49, 805–813. [Google Scholar] [CrossRef]

- Yeo, S.; Ong, S. Assessment of the thermal effects on chip surfaces. J. Mater. Process. Technol. 2000, 98, 317–321. [Google Scholar] [CrossRef]

- Soković, M.; Mikuła, J.; Dobrzański, L.; Kopač, J.; Koseč, L.; Panjan, P.; Madejski, J.; Piech, A. Cutting properties of the Al2O3 + SiC (w) based tool ceramic reinforced with the PVD and CVD wear resistant coatings. J. Mater. Process. Technol. 2005, 164, 924–929. [Google Scholar] [CrossRef]

| Materials ID | Rene65 | AD730 | In.718 | Wasp | PER72 |

|---|---|---|---|---|---|

| Chemical Composition | |||||

| Nickel (Ni) | Bal. | Bal. | Bal. | Bal. | Bal. |

| Iron (Fe) | 1 | 4.00 | 18.00 | - | 0.138 |

| Cobalt (Co) | 13 | 8.50 | - | 13.25 | 14.5 |

| Chrome (Cr) | 16 | 15.70 | 18.1 | 19.4 | 16.06 |

| Molybdenum (Mo) | 4 | 3.1 | 2.9 | 4.25 | 2.88 |

| Tungsten (W) | 4 | 2.7 | - | - | 1.21 |

| Aluminum (Al) | 2.1 | 2.25 | 0.45 | 1.3 | 2.57 |

| Titanium (Ti) | 3.7 | 3.4 | 1.00 | 3 | 5.07 |

| Niobium (Nb) | 0.7 | 1.1 | 5.4 | - | - |

| Boron (B) | 0.016 | 0.01 | - | 0.006 | 0.016 |

| Carbon (C) | - | 0.015 | - | - | 0.017 |

| Zirconium | 0.05 | 0.03 | - | 0.05 | - |

| Drill Bit Material | Solid Carbide | Number of Flutes | 2 |

| Drill Bit Point Angle | 140 Degrees | Diameter Size | 3 mm |

| Drill Bit Finish | TiNAl | Coolant Through | Yes |

| A3293 | DC150 | ||

| Flute Length (A3293) | 26 mm | Flute Length (DC150) | 20 mm |

| Point Type (A3293) | Self-centering | Point Type (DC150) | Split point |

| Grade | K30F | Grade | WJ30RE |

| Extreme Inox—Extremely high performance in stainless steels | Walter Titex DC15—Versatile and highly wear resistant | ||

| Factor | Level 1 | Level 2 | Level 3 |

|---|---|---|---|

| Cutting Speed (m/min) | 20 | 30 | 40 |

| Feed Rate (mm/rev) | 0.03 | 0.05 | 0.07 |

| Hardness (HRC) | 41 | 46 | 52 |

| Hardness of Workpiece Material | Heat Treatment Process | ||

|---|---|---|---|

| Temperature | Time | Cooling | |

| 41 HRC | 1095 °C | 30 min | Water quench |

| 46 HRC | 1095 °C | 30 min | Air cool |

| 788 °C | 4 h | ||

| 788 °C | 2 h | ||

| 52 HRC | No treatment | ||

| Source | DF | ADJ SS | ADJ MS | F | P |

|---|---|---|---|---|---|

| Model | 9 | 0.085467 | 0.009496 | 5.93 | 0.032 |

| LINEAR | 3 | 0.048963 | 0.016321 | 10.20 | 0.014 |

| A: Speed (m/min) | 1 | 0.047278 | 0.047278 | 29.54 | 0.003 |

| B: Feed (mm/tooth) | 1 | 0.001485 | 0.001485 | 0.93 | 0.380 |

| C: Hardness (HRC) | 1 | 0.000200 | 0.000200 | 0.12 | 0.738 |

| Square | 3 | 0.020869 | 0.006956 | 4.35 | 0.074 |

| Speed × Speed | 1 | 0.006500 | 0.006500 | 4.06 | 0.100 |

| Feed × Feed | 1 | 0.010950 | 0.010950 | 6.84 | 0.047 |

| Hardness × Hardness | 1 | 0.002955 | 0.002955 | 1.85 | 0.232 |

| 2-way Interaction | 3 | 0.015635 | 0.005212 | 3.26 | 0.118 |

| Speed × Feed | 1 | 0.000210 | 0.000210 | 0.13 | 0.732 |

| Speed × Hardness | 1 | 0.014641 | 0.014641 | 9.15 | 0.029 |

| Feed × Hardness | 1 | 0.000784 | 0.000784 | 0.49 | 0.515 |

| Error | 5 | 0.008002 | 0.001600 | ||

| Lack-of-fit | 3 | 0.003081 | 0.001027 | 0.42 | 0.761 |

| Pure Error | 2 | 0.004921 | 0.002460 | ||

| Total | 14 | 0.093469 |

| Source | DF | ADJ SS | ADJ MS | F | P |

|---|---|---|---|---|---|

| Model | 3 | 43,011.6 | 14,337.2 | 92.17 | 0.000 |

| LINEAR | 3 | 43,011.6 | 14,337.2 | 92.17 | 0.000 |

| A: Speed (m/min) | 1 | 464.0 | 464.0 | 2.98 | 0.112 |

| B: Feed (mm/tooth) | 1 | 42,291.4 | 42,291.4 | 271.87 | 0.000 |

| C: Hardness (HRC) | 1 | 256.1 | 256.1 | 1.65 | 0.226 |

| Error | 11 | 1711.1 | 155.6 | ||

| Lack-of-Fit | 9 | 1684.0 | 187.1 | 13.80 | 0.069 |

| Pure Error | 2 | 27.1 | 13.6 | ||

| Total | 14 | 44,722.8 |

| Source | DF | ADJ SS | ADJ MS | F | P |

|---|---|---|---|---|---|

| Model | 9 | 44,159.3 | 4906.6 | 43.54 | 0.000 |

| LINEAR | 3 | 43,011.6 | 14,337.2 | 127.23 | 0.000 |

| A: Speed (m/min) | 1 | 464.0 | 464.6 | 4.12 | 0.098 |

| B: Feed (mm/tooth) | 1 | 42,291.4 | 42,294.4 | 375.30 | 0.000 |

| C: Hardness (HRC) | 1 | 256.1 | 256.1 | 2.27 | 0.192 |

| Square | 3 | 445.6 | 148.5 | 1.32 | 0.366 |

| Speed × Speed | 1 | 368.6 | 368.6 | 3.27 | 0.130 |

| Feed × Feed | 1 | 18.6 | 18.6 | 0.17 | 0.701 |

| Hardness × Hardness | 1 | 57.8 | 57.8 | 0.51 | 0.506 |

| 2-way Interaction | 3 | 702.2 | 234.1 | 2.08 | 0.222 |

| Speed × Feed | 1 | 7.1 | 7.1 | 0.06 | 0.812 |

| Speed × Hardness | 1 | 564.1 | 564.1 | 5.01 | 0.075 |

| Feed × Hardness | 1 | 131.0 | 131.0 | 1.16 | 0.330 |

| Error | 5 | 563.4 | 112.7 | ||

| Lack-of-Fit | 3 | 536.3 | 178.8 | 13.18 | 0.071 |

| Pure Error | 2 | 27.1 | 13.6 | ||

| Total | 14 | 44,722.8 |

| Source | DF | ADJ SS | ADJ MS | F | P |

|---|---|---|---|---|---|

| Regression | 1 | 42,291.4 | 42,291.4 | 226.13 | 0.000 |

| Feed (mm/rev) | 1 | 42,291.4 | 42,291.4 | 226.13 | 0.000 |

| Error | 13 | 2431.3 | 187.0 | ||

| Lack-of-Fit | 11 | 2404.2 | 218.6 | 16.12 | 0.060 |

| Pure Error | 2 | 27.1 | 13.6 | ||

| Total | 14 | 44,722.8 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Olufayo, O.A.; Che, H.; Songmene, V.; Katsari, C.; Yue, S. Machinability of Rene 65 Superalloy. Materials 2019, 12, 2034. https://doi.org/10.3390/ma12122034

Olufayo OA, Che H, Songmene V, Katsari C, Yue S. Machinability of Rene 65 Superalloy. Materials. 2019; 12(12):2034. https://doi.org/10.3390/ma12122034

Chicago/Turabian StyleOlufayo, Oluwole A., Hanqing Che, Victor Songmene, Christina Katsari, and Stephen Yue. 2019. "Machinability of Rene 65 Superalloy" Materials 12, no. 12: 2034. https://doi.org/10.3390/ma12122034

APA StyleOlufayo, O. A., Che, H., Songmene, V., Katsari, C., & Yue, S. (2019). Machinability of Rene 65 Superalloy. Materials, 12(12), 2034. https://doi.org/10.3390/ma12122034