On the Filler Materials of Metal Matrix Syntactic Foams

Abstract

:1. Introduction

2. Materials and Methods

3. Results and Discussion

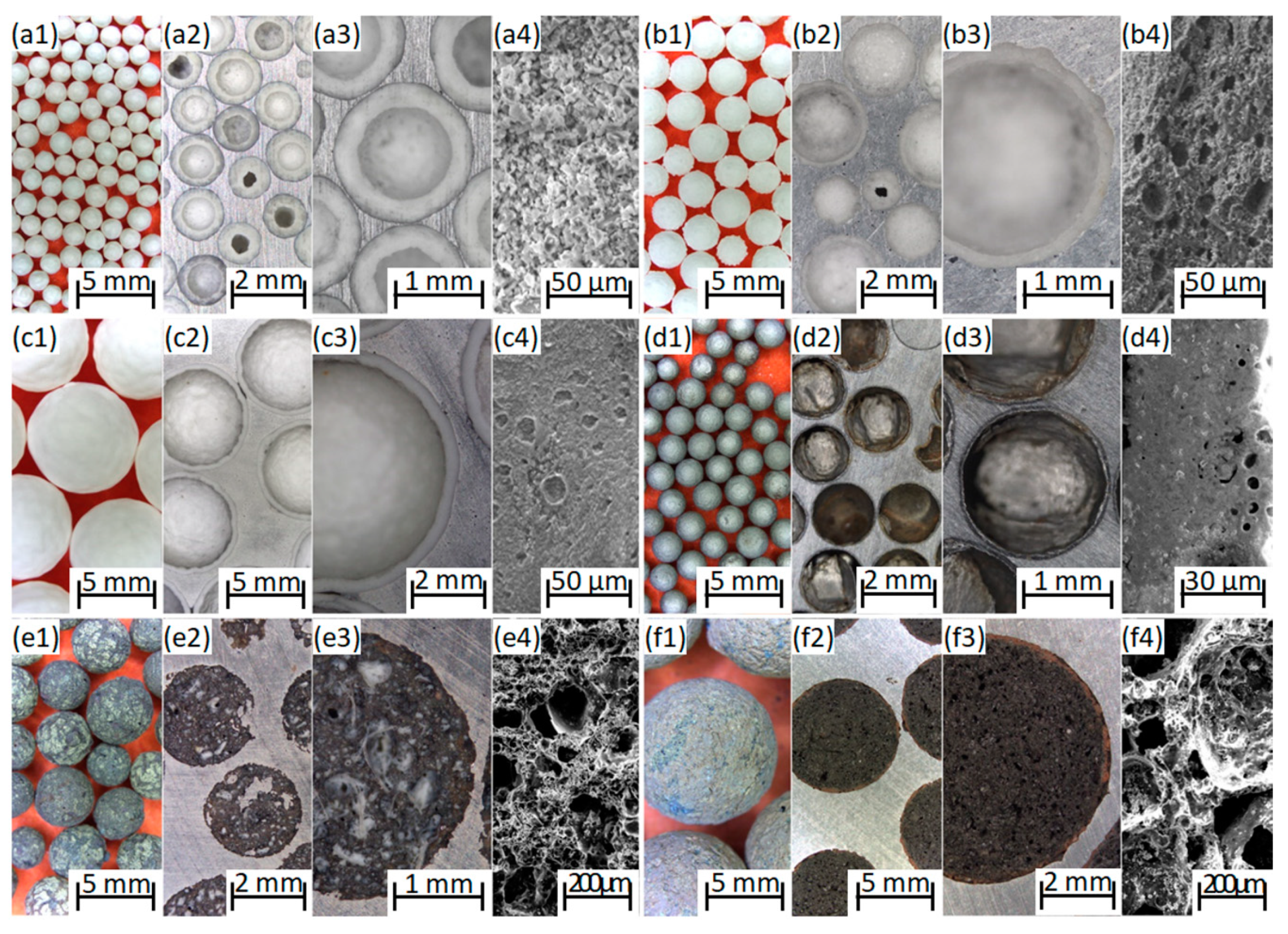

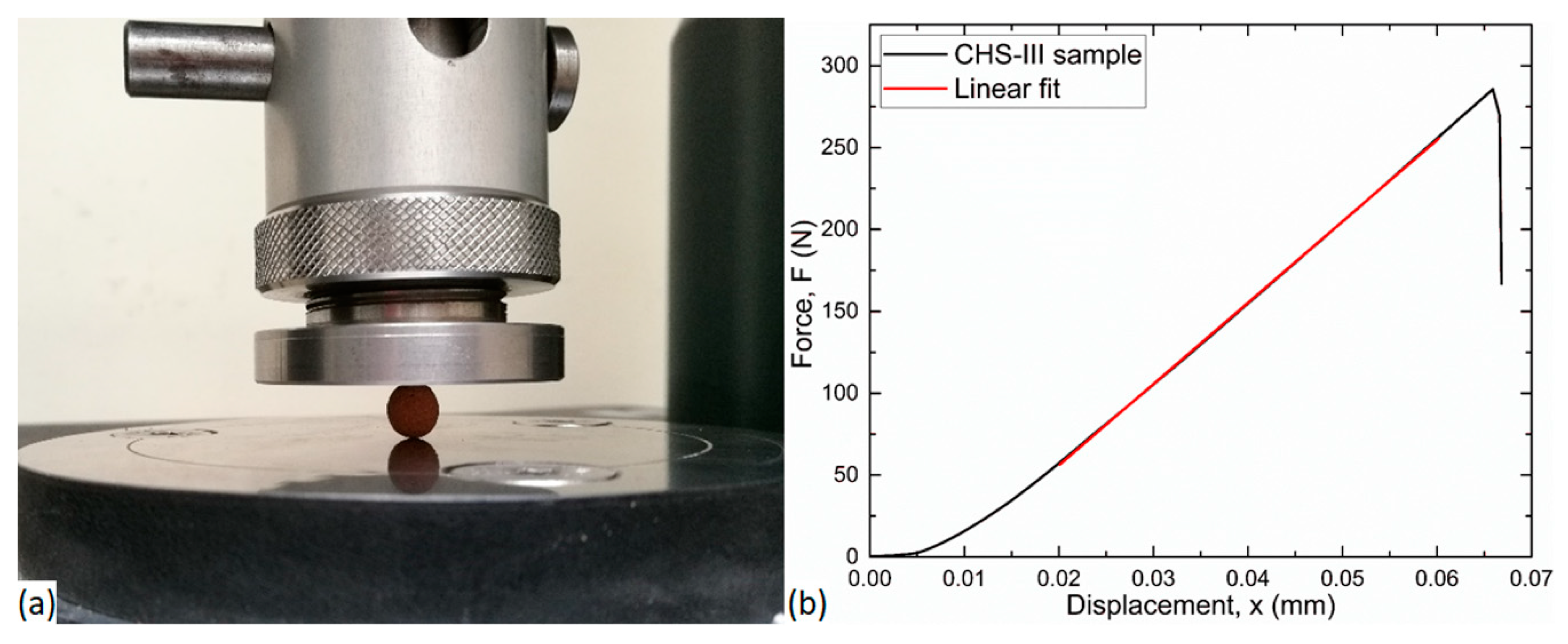

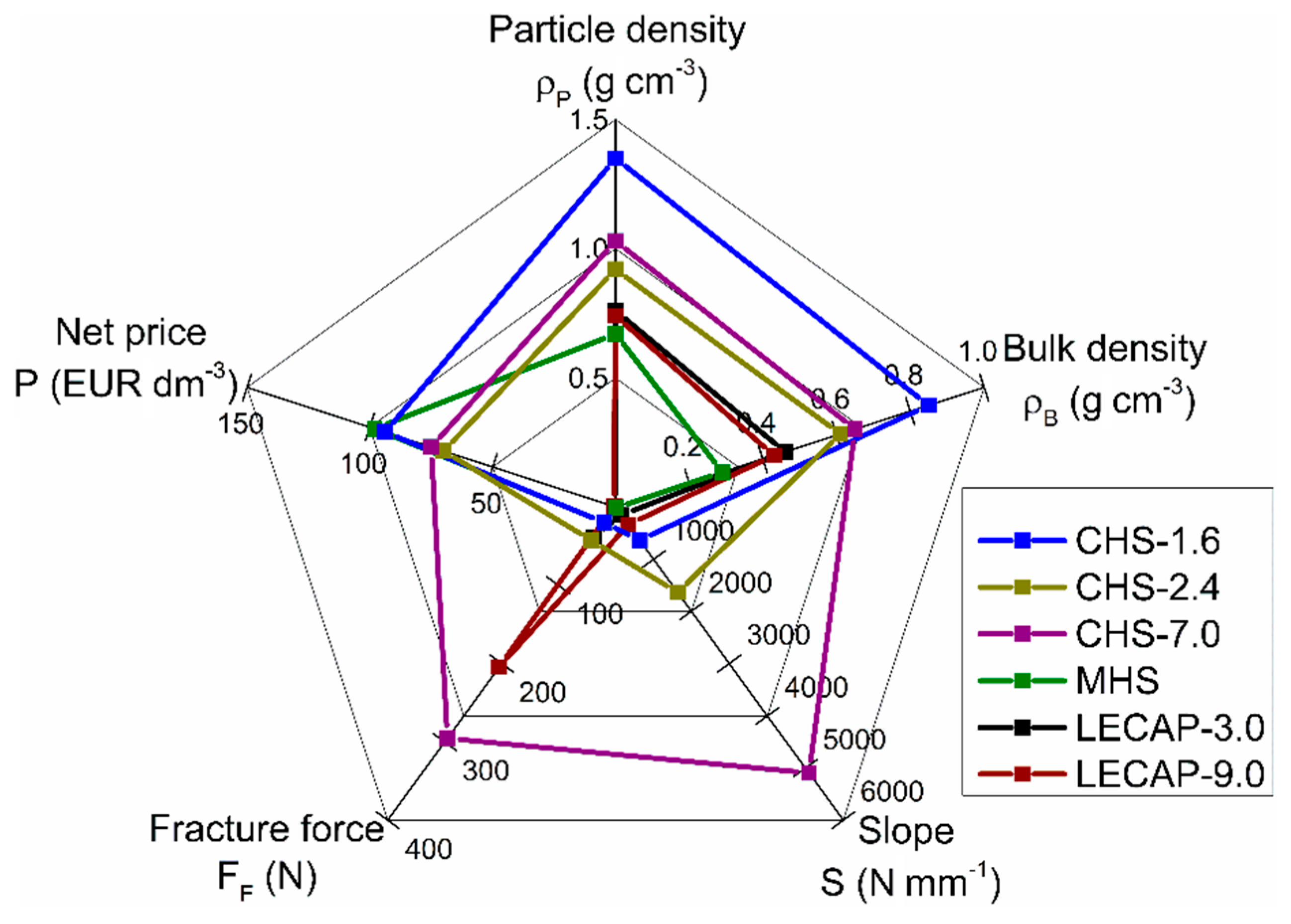

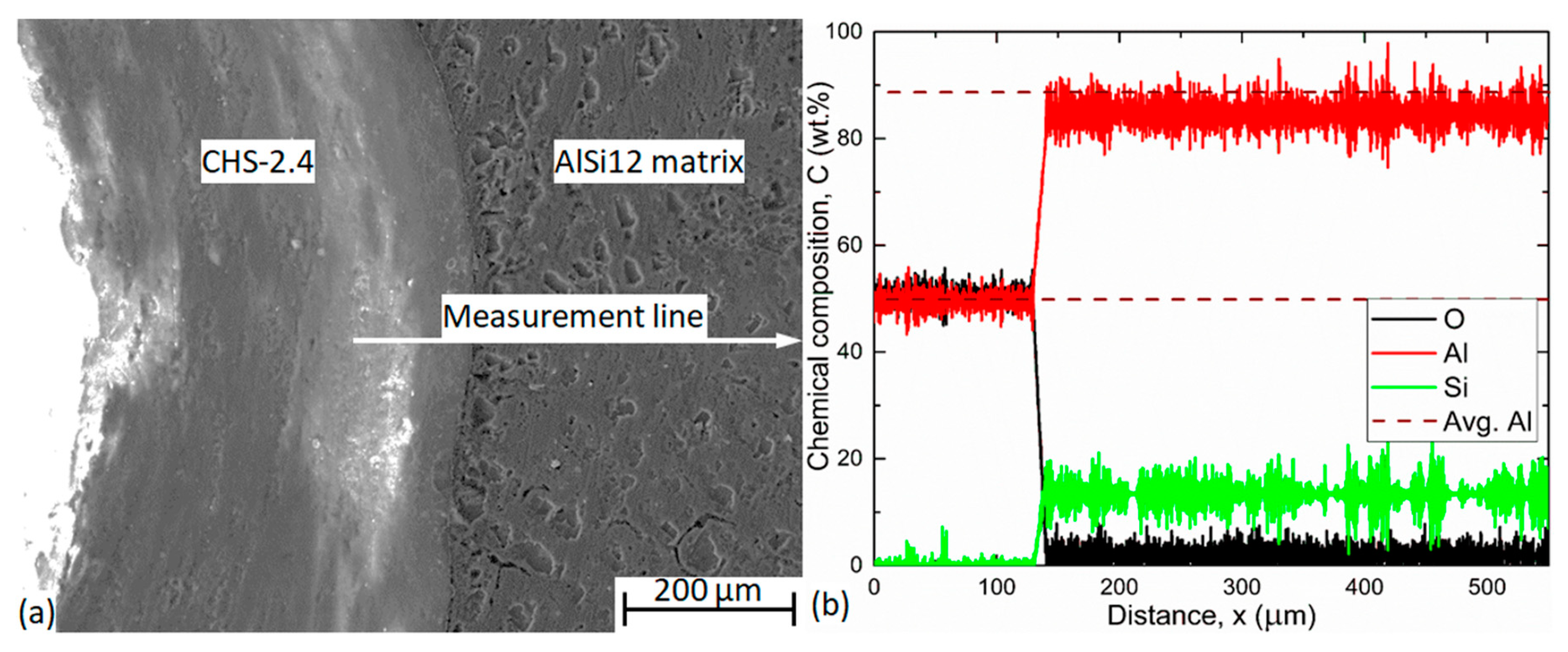

3.1. Properties of the Filler Particles

3.2. Properties of Metal Matrix Syntactic Foams (MMSFs)

4. Conclusions

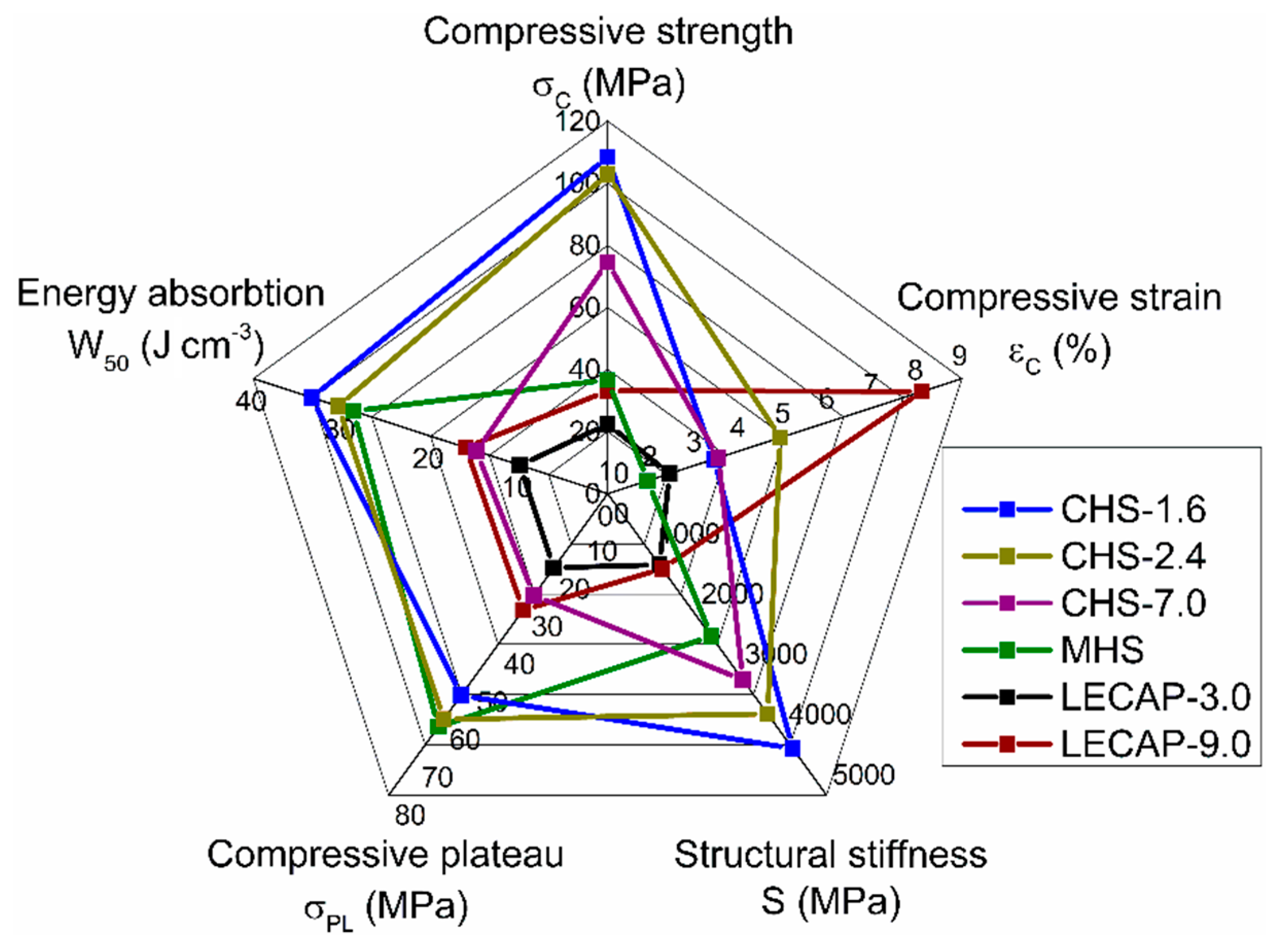

- From the mechanical properties point of few, the individual CHS-7.0 particles proved to have the highest performance, but in MMSFs, these fillers showed lower mechanical strength values compared to the smaller CHSs. CHS-filled MMSFs can be applied as high-performance, lightweight structural parts.

- Metallic hollow spheres (MHSs) showed as high plateau strength and energy absorption capability as the high-performance CHSs, but without compressive strength and structural stiffness that was too high. All of these features are connected to low compressive strains; therefore, MHSs-filled MMSFs are excellent candidates for energy-absorbing applications, such as protective devices and collision dampers.

- The mechanical properties of LECAP0filled MMSFs can be considered low, but still higher compared to ‘conventional’ closed cell metallic foams. Considering the low price of LECAPs, these MMSFs can be considered for cheap high energy-absorbing capability applications in large volumes, such as in the case of building protection.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Manonukul, A.; Muenya, N.; Léaux, F.; Amaranan, S. Effects of replacing metal powder with powder space holder on metal foam produced by metal injection moulding. J. Mater. Process. Technol. 2010, 210, 529–535. [Google Scholar] [CrossRef]

- Mondal, D.P.; Jha, N.; Gull, B.; Das, S.; Badkul, A. Microarchitecture and compressive deformation behaviour of Al-alloy (LM13)-cenosphere hybrid Al-foam prepared using CaCO3 as foaming agent. Mater. Sci. Eng. A 2013, 560, 601–610. [Google Scholar] [CrossRef]

- Smith, B.H.; Szyniszewski, S.; Hajjar, J.F.; Schafer, B.W.; Arwade, S.R. Steel foam for structures: A review of applications, manufacturing and material properties. J. Constr. Steel Res. 2012, 71, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Linul, E.; Movahedi, N.; Marsavina, L. On the Lateral Compressive Behavior of Empty and Ex-Situ Aluminum Foam-Filled Tubes at High Temperature. Materials 2018, 11, 554. [Google Scholar] [CrossRef] [PubMed]

- Kováčik, J.; Marsavina, L.; Linul, E. Poisson’s Ratio of Closed-Cell Aluminium Foams. Materials 2018, 11, 1904. [Google Scholar] [CrossRef]

- Motz, C.; Friedl, O.; Pippan, R. Fatigue crack propagation in cellular metals. Int. J. Fatigue 2005, 27, 1571–1581. [Google Scholar] [CrossRef]

- Yang, X.; Hu, Q.; Du, J.; Zou, T.; Sha, J.; He, C.; Zhao, N. Compression fatigue properties of open-cell aluminum foams fabricated by space-holder method. Int. J. Fatigue 2018, 121, 272–280. [Google Scholar] [CrossRef]

- Braszczyńska-Malik, K.N.; Kamieniak, J. AZ91 magnesium matrix foam composites with fly ash cenospheres fabricated by negative pressure infiltration technique. Mater. Charact. 2017, 128, 209–216. [Google Scholar] [CrossRef]

- Luong, D.; Lehmhus, D.; Gupta, N.; Weise, J.; Bayoumi, M. Structure and Compressive Properties of Invar-Cenosphere Syntactic Foams. Materials 2016, 9, 115. [Google Scholar] [CrossRef]

- Jha, N.; Mondal, D.P.; Goel, M.D.; Majumdar, J.D.; Das, S.; Modi, O.P. Titanium cenosphere syntactic foam with coarser cenosphere fabricated by powder metallurgy at lower compaction load. Trans. Nonferrous Met. Soc. China 2014, 24, 89–99. [Google Scholar] [CrossRef]

- Movahedi, N.; Murch, E.G.; Belova, V.I.; Fiedler, T. Effect of Heat Treatment on the Compressive Behavior of Zinc Alloy ZA27 Syntactic Foam. Materials 2019, 12, 792. [Google Scholar] [CrossRef] [PubMed]

- Movahedi, N.; Taherishargh, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. Mechanical and Microstructural Characterization of an AZ91-Activated Carbon Syntactic Foam. Materials 2018, 12, 3. [Google Scholar] [CrossRef] [PubMed]

- Huang, Z.; Yu, S.; Li, M. Microstructures and compressive properties of AZ91D/fly-ash cenospheres composites. Trans. Nonferrous Met. Soc. China 2010, 20, s458–s462. [Google Scholar] [CrossRef]

- Rajan, T.P.D.; Pillai, R.M.; Pai, B.C.; Satyanarayana, K.G.; Rohatgi, P.K. Fabrication and characterisation of Al-7Si-0.35Mg/fly ash metal matrix composites processed by different stir casting routes. Compos. Sci. Technol. 2007, 67, 3369–3377. [Google Scholar] [CrossRef]

- Santa Maria, J.A.; Schultz, B.F.; Ferguson, J.B.; Rohatgi, P.K. Al-Al2O3 syntactic foams—Part I: Effect of matrix strength and hollow sphere size on the quasi-static properties of Al-A206/Al2O3 syntactic foams. Mater. Sci. Eng. A 2013, 582, 415–422. [Google Scholar] [CrossRef]

- Ferguson, J.B.; Santa Maria, J.A.; Schultz, B.F.; Rohatgi, P.K. Al-Al2O3 syntactic foams—Part II: Predicting mechanical properties of metal matrix syntactic foams reinforced with ceramic spheres. Mater. Sci. Eng. A 2013, 582, 423–432. [Google Scholar] [CrossRef]

- Májlinger, K. Wear properties of hybrid AlSi12 matrix syntactic foams. Int. J. Mater. Res. 2015, 106, 1165–1173. [Google Scholar] [CrossRef]

- Wu, G.H.; Dou, Z.Y.; Sun, D.L.; Jiang, L.T.; Ding, B.S.; He, B.F. Compression behaviors of cenosphere–pure aluminum syntactic foams. Scr. Mater. 2007, 56, 221–224. [Google Scholar] [CrossRef]

- Goel, M.D.; Peroni, M.; Solomos, G.; Mondal, D.P.; Matsagar, V.A.; Gupta, A.K.; Larcher, M.; Marburg, S. Dynamic compression behavior of cenosphere aluminum alloy syntactic foam. Mater. & Des. 2012, 42, 418–423. [Google Scholar]

- Yu, M.; Zhu, P.; Ma, Y. Experimental study and numerical prediction of tensile strength properties and failure modes of hollow spheres filled syntactic foams. Comput. Mater. Sci. 2012, 63, 232–243. [Google Scholar] [CrossRef]

- Orbulov, I.N.; Májlinger, K. On the microstructure of ceramic hollow microspheres. Period. Polytech. Mech. Eng. 2010, 54, 89–94. [Google Scholar] [CrossRef]

- Orbulov, I.N.; Szlancsik, A. On the Mechanical Properties of Aluminum Matrix Syntactic Foams. Adv. Eng. Mater. 2018, 20, 1–12. [Google Scholar] [CrossRef]

- Orbulov, I.N. Metal matrix syntactic foams produced by pressure infiltration—The effect of infiltration parameters. Mater. Sci. Eng. A 2013, 583, 11–19. [Google Scholar] [CrossRef]

- Orbulov, I.N.; Dobránszky, J. Producing metal matrix syntactic foams by pressure infiltration. Period. Polytech. Mech. Eng. 2008, 52, 35–42. [Google Scholar] [CrossRef]

- Orbulov, I.N. Compressive properties of aluminium matrix syntactic foams. Mater. Sci. Eng. A 2012, 555, 52–56. [Google Scholar] [CrossRef]

- Orbulov, I.N.; Ginsztler, J. Compressive characteristics of metal matrix syntactic foams. Compos. Part A Appl. Sci. Manuf. 2012, 43, 553–561. [Google Scholar] [CrossRef] [Green Version]

- Kádár, C.; Máthis, K.; Orbulov, I.N.; Chmelík, F. Monitoring the failure mechanisms in metal matrix syntactic foams during compression by acoustic emission. Mater. Lett. 2016, 173, 31–34. [Google Scholar] [CrossRef] [Green Version]

- Katona, B.; Orbulov, I.N. Structural Damages in Syntactic Metal Foams Caused by Monotone or Cyclic Compression. Period. Polytech. Mech. Eng. 2017, 61, 146–152. [Google Scholar] [CrossRef]

- Szlancsik, A.; Katona, B.; Dombóvári, Z.; Orbulov, I.N. On the effective Young’s modulus of metal matrix syntactic foams. Mater. Sci. Technol. 2017, 33, 2283–2289. [Google Scholar] [CrossRef]

- Katona, B.; Szlancsik, A.; Tábi, T.; Orbulov, I.N. Compressive characteristics and low frequency damping of aluminium matrix syntactic foams. Mater. Sci. Eng. A 2019, 739, 140–148. [Google Scholar] [CrossRef]

- Lin, Y.; Zhang, Q.; Ma, X.; Wu, G. Mechanical behavior of pure Al and Al–Mg syntactic foam composites containing glass cenospheres. Compos. Part A Appl. Sci. Manuf. 2016, 87, 194–202. [Google Scholar] [CrossRef]

- Luong, D.D.; Strbik, O.M.; Hammond, V.H.; Gupta, N.; Cho, K. Development of high performance lightweight aluminum alloy/SiC hollow sphere syntactic foams and compressive characterization at quasi-static and high strain rates. J. Alloys Compd. 2013, 550, 412–422. [Google Scholar] [CrossRef]

- Szlancsik, A.; Katona, B.; Bobor, K.; Májlinger, K.; Orbulov, I.N. Compressive behaviour of aluminium matrix syntactic foams reinforced by iron hollow spheres. Mater. Des. 2015, 83, 230–237. [Google Scholar] [CrossRef] [Green Version]

- Szlancsik, A.; Katona, B.; Májlinger, K.; Orbulov, I.N. Compressive behavior and microstructural characteristics of iron hollow sphere filled aluminum matrix syntactic foams. Materials 2015, 8, 7926–7937. [Google Scholar] [CrossRef] [PubMed]

- Bálint, A.; Szlancsik, A. Mechanical Properties of Iron Hollow Sphere Reinforced Metal Matrix Syntactic Foams. Mater. Sci. Forum 2015, 812, 3–8. [Google Scholar] [CrossRef]

- Rabiei, A.; O’Neill, A.T. A study on processing of a composite metal foam via casting. Mater. Sci. Eng. A 2005, 404, 159–164. [Google Scholar] [CrossRef]

- Neville, B.P.; Rabiei, A. Composite metal foams processed through powder metallurgy. Mater. Des. 2008, 29, 388–396. [Google Scholar] [CrossRef]

- Fiedler, T.; Veyhl, C.; Belova, I.V.; Bernthaler, T.; Heine, B.; Murch, G.E. Mechanical properties and micro-deformation of sintered metallic hollow sphere structure. Comput. Mater. Sci. 2013, 74, 143–147. [Google Scholar] [CrossRef]

- Taherishargh, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. On the mechanical properties of heat-treated expanded perlite–aluminium syntactic foam. Mater. Des. 2014, 63, 375–383. [Google Scholar] [CrossRef]

- Szlancsik, A.; Katona, B.; Orbulov, I.N.; Taherishargh, M.; Fiedler, T. Fatigue properties of EP/A356 aluminium matrix syntactic foams with different densities. IOP Conf. Ser. Mater. Sci. Eng. 2018, 426, 012045. [Google Scholar] [CrossRef]

- Taherishargh, M.; Linul, E.; Broxtermann, S.; Fiedler, T. The mechanical properties of expanded perlite-aluminium syntactic foam at elevated temperatures. J. Alloys Compd. 2018, 737, 590–596. [Google Scholar] [CrossRef]

- Taherishargh, M.; Belova, I.V.; Murch, G.E.; Fiedler, T. Pumice/aluminium syntactic foam. Mater. Sci. Eng. A 2015, 635, 102–108. [Google Scholar] [CrossRef]

- Linul, E.; Lell, D.; Movahedi, N.; Codrean, C.; Fiedler, T. Compressive properties of zinc syntactic foams at elevated temperatures. Compos. Part B Eng. 2018, 167, 122–134. [Google Scholar] [CrossRef]

- Linul, E.; Marşavina, L.; Linul, P.-A.; Kovacik, J. Cryogenic and high temperature compressive properties of Metal Foam Matrix Composites. Compos. Struct. 2019, 209, 490–498. [Google Scholar] [CrossRef]

- Linul, E.; Movahedi, N.; Marsavina, L. The temperature and anisotropy effect on compressive behavior of cylindrical closed-cell aluminum-alloy foams. J. Alloys Compd. 2018, 740, 1172–1179. [Google Scholar] [CrossRef]

- Cochran, J.K. Ceramic hollow spheres and their applications. Curr. Opin. Solid State Mater. Sci. 1998, 3, 474–479. [Google Scholar] [CrossRef]

- Song, J.; Sun, Q.; Luo, S.; Arwade, S.R.; Gerasimidis, S.; Guo, Y.; Zhang, G. Compression behavior of individual thin-walled metallic hollow spheres with patterned distributions of microporosity. Mater. Sci. Eng. A 2018, 734, 453–475. [Google Scholar] [CrossRef]

- Yu, Q.; Zhao, Y.; Dong, A.; Li, Y. Preparation and Properties of C/C Hollow Spheres and the Energy Absorption Capacity of the Corresponding Aluminum Syntactic Foams. Materials 2018, 11, 997–1009. [Google Scholar] [CrossRef]

- Ranjbar, N.; Kuenzel, C. Cenospheres: A review. Fuel 2017, 207, 1–12. [Google Scholar] [CrossRef]

- Torquato, S.; Truskett, T.M.; Debenedetti, P.G. Is Random Close Packing of Spheres Well Defined? Phys. Rev. Lett. 2000, 84, 2064–2067. [Google Scholar] [CrossRef] [Green Version]

- Jaeger, H.M.; Nagel, S.R. Physics of the Granular State. Science 1992, 255, 1523–1531. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- ASM Handbook. Properties and Selection: Nonferrous Alloys and Special-Purpose Materials; ASM International: Materials Park, OH, USA, 1995; Volume 2.

- ISO13314:2011. Mechanical Testing of Metals—Ductility Testing—Compression Test for Porous and Cellular Metals 2011; IHS: Geneva, Switzerland, 2011.

| Filler | O | Al | Si | Fe | Other | Price |

|---|---|---|---|---|---|---|

| CHS-1.6 | 59.85 | 21.00 | 19.15 | - | - | 93.75 |

| CHS-2.4 | 49.19 | 46.82 | 0.94 | - | 3.05 | 70 |

| CHS-7.0 | 49.18 | 48.99 | 1.10 | - | 0.73 | 75 |

| MHS | 4.40 | - | - | 95.89 | 4.11 | 98 |

| LECAP-3.0 | 55.40 | 32.55 | 7.64 | 2.41 | 2.00 | 0.13 |

| LECAP-9.0 | 49.10 | 12.78 | 22.84 | 7.70 | 7.58 | 0.68 |

| Main Components (wt.%) | Al | Si | Fe | Other | Closest Standard Equivalent [52] |

|---|---|---|---|---|---|

| AlSi12 | 86.0 | 12.8 | 0.1 | 1.1 | A413.0 |

| Filler | Diameter (mm) | Volume (mm3) | Mass (g) | Particle Density (g cm−3) | Loose Bulk Density (g cm−3) | Wall Thickness (μm) |

|---|---|---|---|---|---|---|

| CHS-1.6 | 1.41 ± 0.08 | 1.49 ± 0.26 | 0.0020 ± 0.0003 | 1.35 ± 0.17 | 0.85 ± 0.05 | 60 ± 1.7 |

| CHS-2.4 | 2.29 ± 0.16 | 6.41 ± 1.32 | 0.0068 ± 0.0013 | 0.92 ± 0.05 | 0.61 ± 0.04 | 24 ± 0.5 |

| CHS-7.0 | 6.97 ± 0.25 | 177.90 ± 18.54 | 0.1754 ± 0.0149 | 1.03 ± 0.05 | 0.65 ± 0.03 | 21 ± 1.1 |

| MHS | 1.45 ± 0.05 | 1.59 ± 0.19 | 0.0023 ± 0.0004 | 0.67 ± 0.09 | 0.29 ± 0.05 | 23 ± 0.6 |

| LECAP-3.0 | 3.24 ± 0.65 | 19.47 ± 10.73 | 0.0141 ± 0.0074 | 0.76 ± 0.20 | 0.46 ± 0.02 | - |

| LECAP-9.0 | 9.00 ± 0.45 | 384.89 ± 56.77 | 0.2862 ± 0.0469 | 0.74 ± 0.05 | 0.43 ± 0.02 | - |

| Filler | Fracture Force (N) | Slope (N mm−1) |

|---|---|---|

| CHS-1.6 | 19.8 ± 4.6 | 634 ± 170 |

| CHS-2.4 | 42.3 ± 24.6 | 1637 ± 717 |

| CHS-7.0 | 295.3 ± 39.0 | 5096 ± 459 |

| MHS | 19.6 ± 7.4 | 15 ± 7 |

| LECAP-3.0 | 38.1 ± 11.8 | 153 ± 142 |

| LECAP-9.0 | 204.5 ± 59.1 | 337 ± 163 |

| Filler | Boundary Layer Thickness (µm) |

|---|---|

| CHS-1.6 | 8.23 ± 1.79 |

| CHS-2.4 | 6.29 ± 3.07 |

| CHS-7.0 | 6.25 ± 1.75 |

| MHS | 6.26 ± 1.49 |

| LECAP-3.0 | 5.52 ± 1.24 |

| LECAP-9.0 | 6.15 ± 1.86 |

| Filler | ρrel (-) | σC (MPa) | εC (%) | S (MPa) | σPL (MPa) | W50, (J cm−3) |

|---|---|---|---|---|---|---|

| CHS-1.6 | 0.69 ± 0.01 | 108.4 ± 7.2 | 3.4 ± 0.3 | 4229 ± 191 | 53.3 ± 9.5 | 33.4 ± 1.7 |

| CHS-2.4 | 0.61± 0.01 | 102.9 ± 4.0 | 4.9 ± 0.2 | 3655 ± 220 | 59.9 ± 2.6 | 30.4 ± 0.9 |

| CHS-7.0 | 0.61± 0.01 | 74.6 ± 5.0 | 3.5 ± 0.5 | 3089 ± 252 | 27.0 ± 4.4 | 14.8 ± 1.2 |

| MHS | 0.52± 0.03 | 36.7 ± 4.8 | 1.9 ± 0.5 | 2369 ± 52 | 61.9 ± 5.2 | 28.7 ± 1.7 |

| LECAP-3.0 | 0.48± 0.01 | 22.4 ± 1.7 | 2.4 ± 0.3 | 1180 ± 123 | 19.7 ± 2.2 | 9.9 ± 0.9 |

| LECAP-9.0 | 0.57± 0.06 | 33.1 ± 3.7 | 8.1 ± 2.8 | 1249 ± 97 | 30.9 ± 5.8 | 16.0 ± 2.9 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Szlancsik, A.; Katona, B.; Kemény, A.; Károly, D. On the Filler Materials of Metal Matrix Syntactic Foams. Materials 2019, 12, 2023. https://doi.org/10.3390/ma12122023

Szlancsik A, Katona B, Kemény A, Károly D. On the Filler Materials of Metal Matrix Syntactic Foams. Materials. 2019; 12(12):2023. https://doi.org/10.3390/ma12122023

Chicago/Turabian StyleSzlancsik, Attila, Bálint Katona, Alexandra Kemény, and Dóra Károly. 2019. "On the Filler Materials of Metal Matrix Syntactic Foams" Materials 12, no. 12: 2023. https://doi.org/10.3390/ma12122023

APA StyleSzlancsik, A., Katona, B., Kemény, A., & Károly, D. (2019). On the Filler Materials of Metal Matrix Syntactic Foams. Materials, 12(12), 2023. https://doi.org/10.3390/ma12122023