Deformation of Single Crystals, Polycrystalline Materials, and Thin Films: A Review

Abstract

1. Introduction

2. Deformation of Materials

2.1. Deformation of Single Crystals

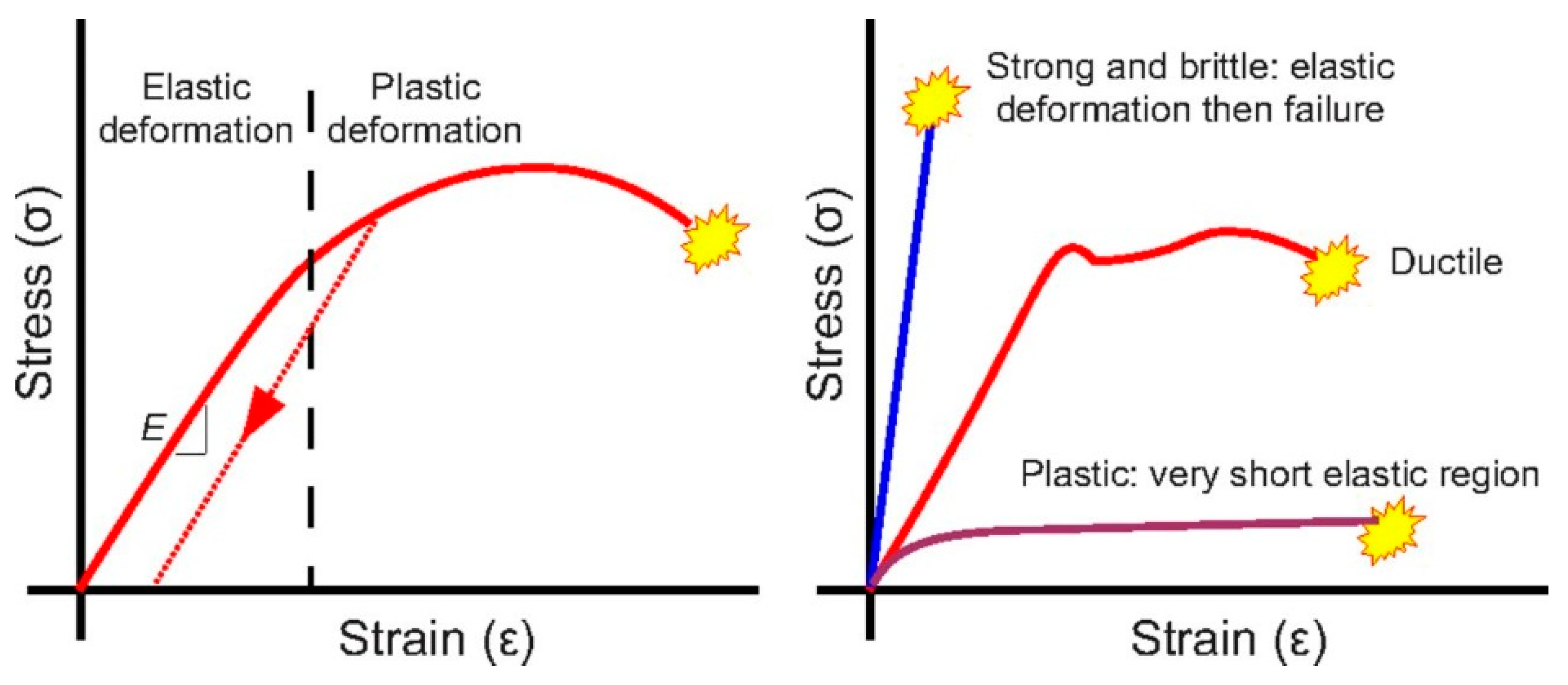

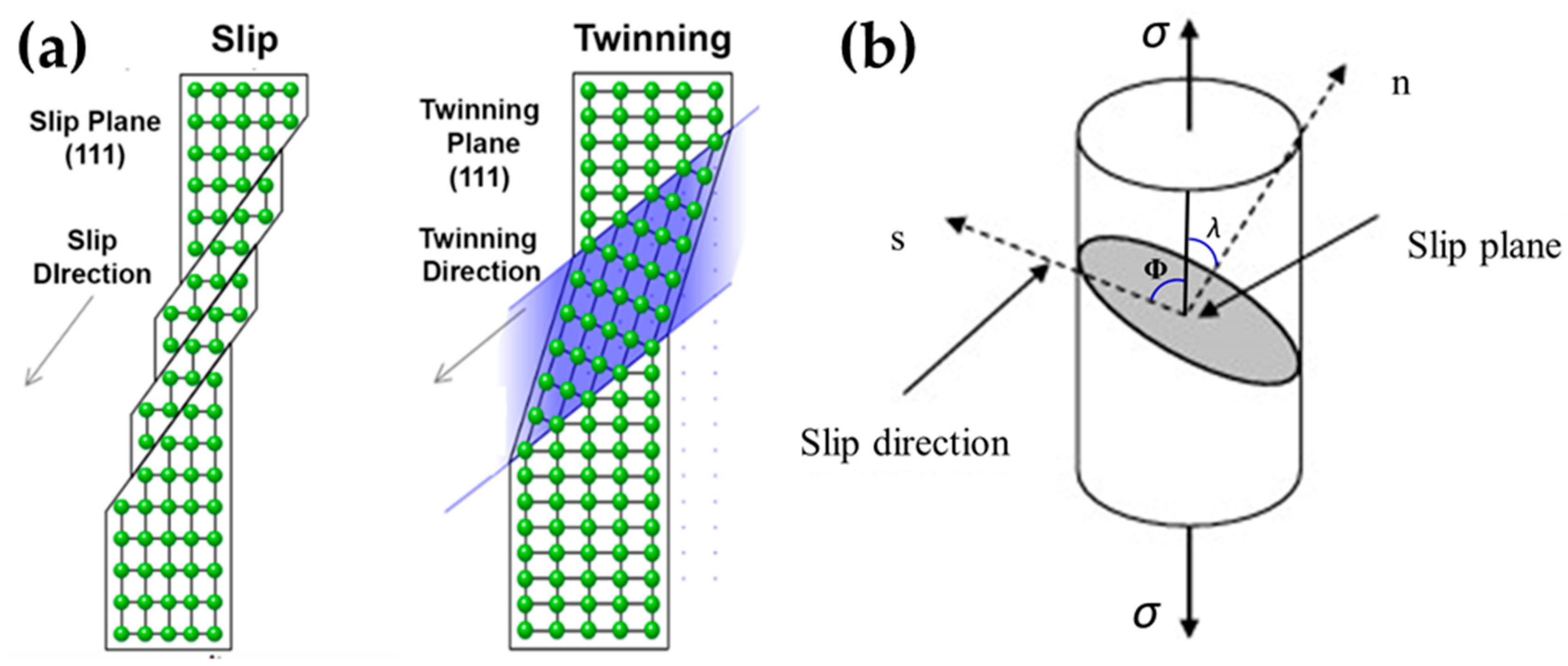

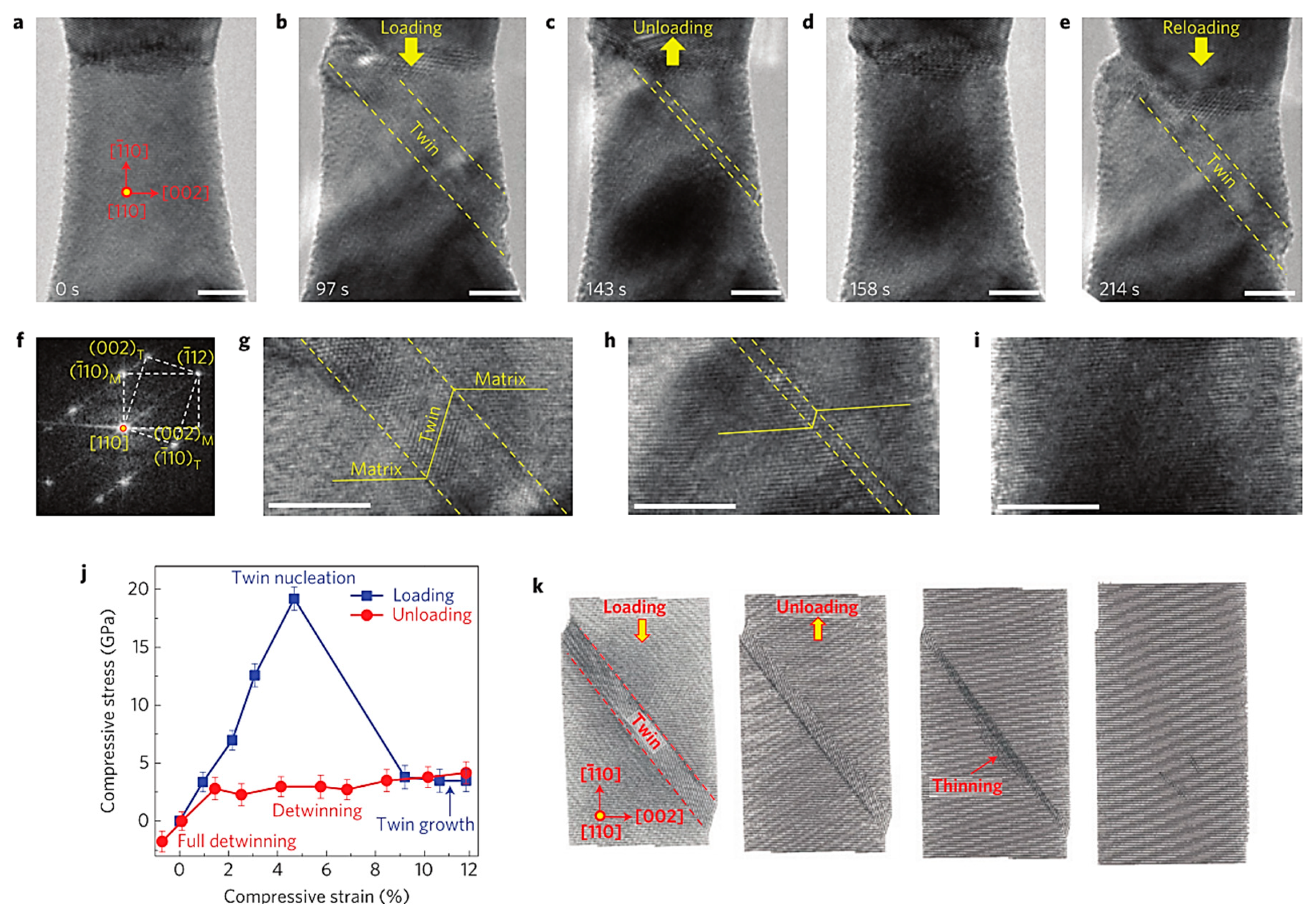

2.1.1. Deformation Types in Single Crystals

2.1.2. Deformation Mechanism in Single Crystals

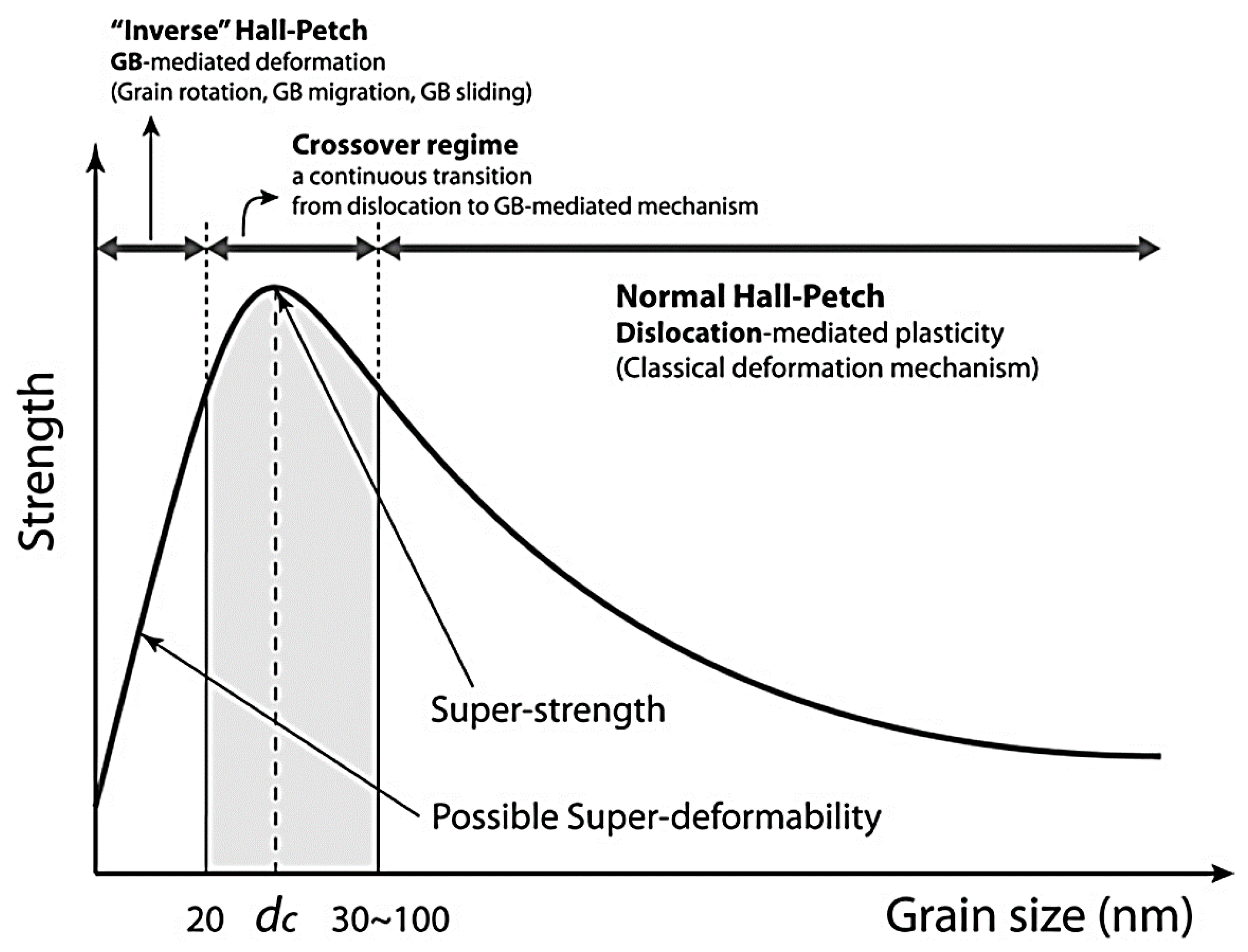

2.2. Deformation of Polycrystals

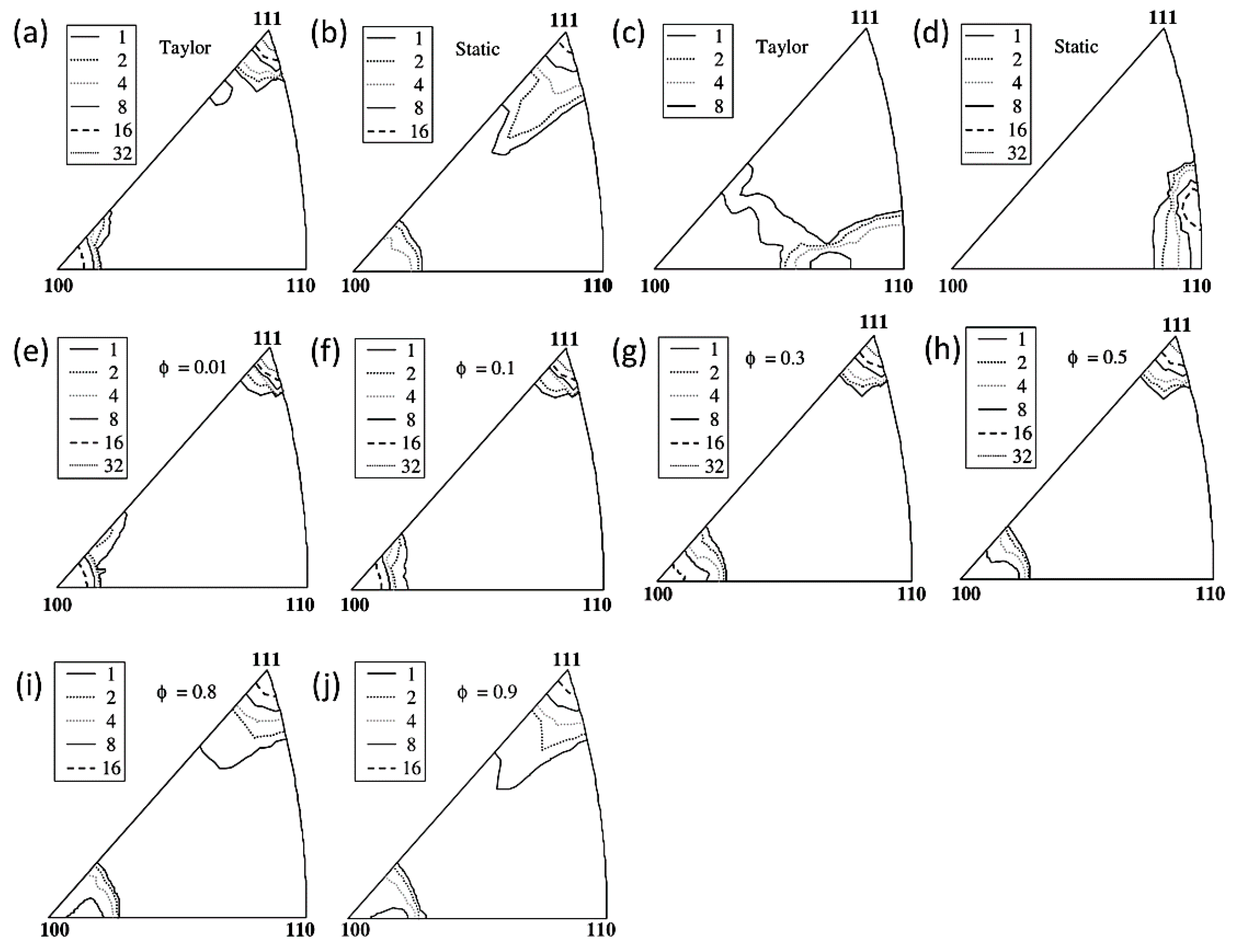

2.2.1. Deformation Models of Polycrystals

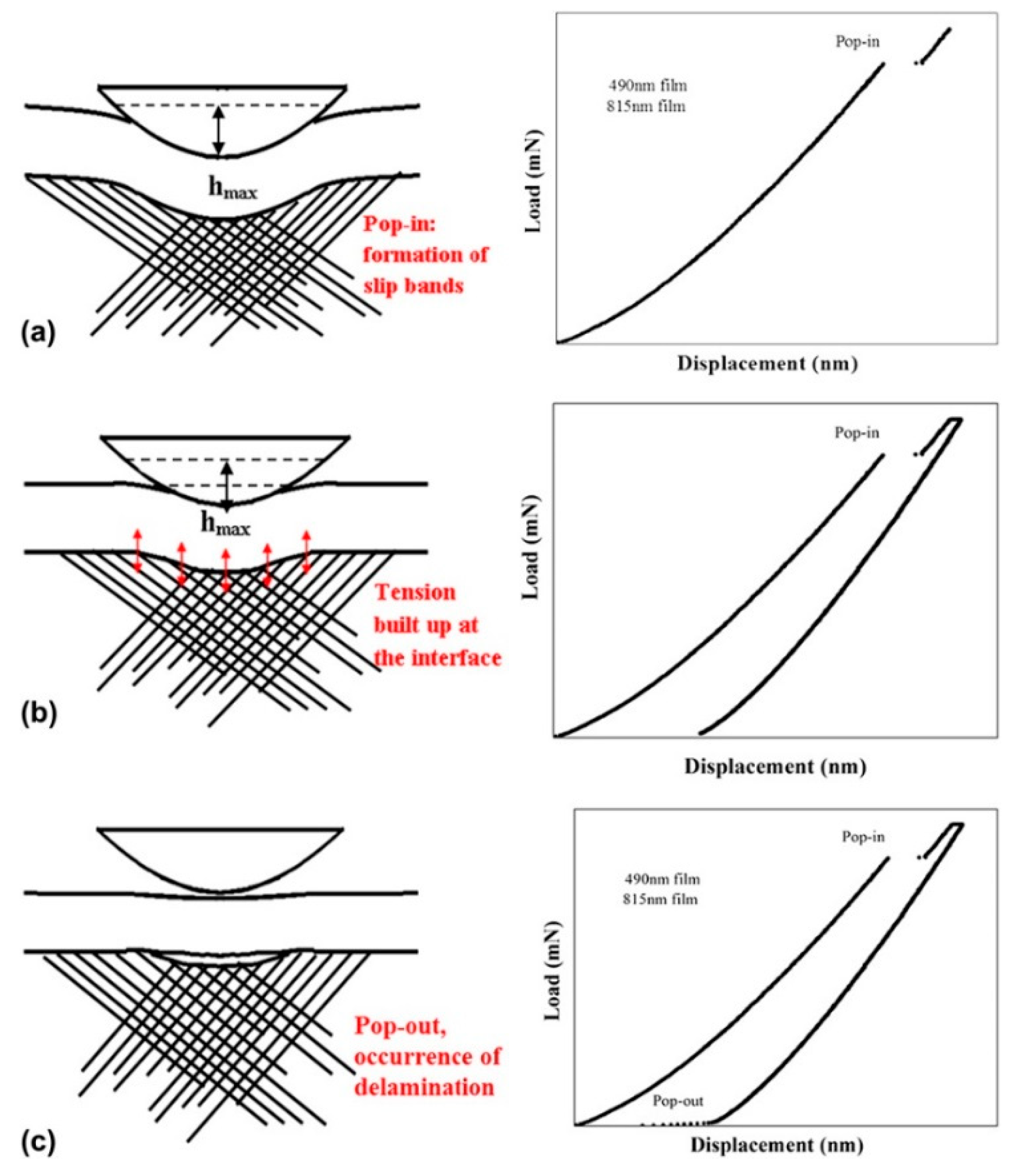

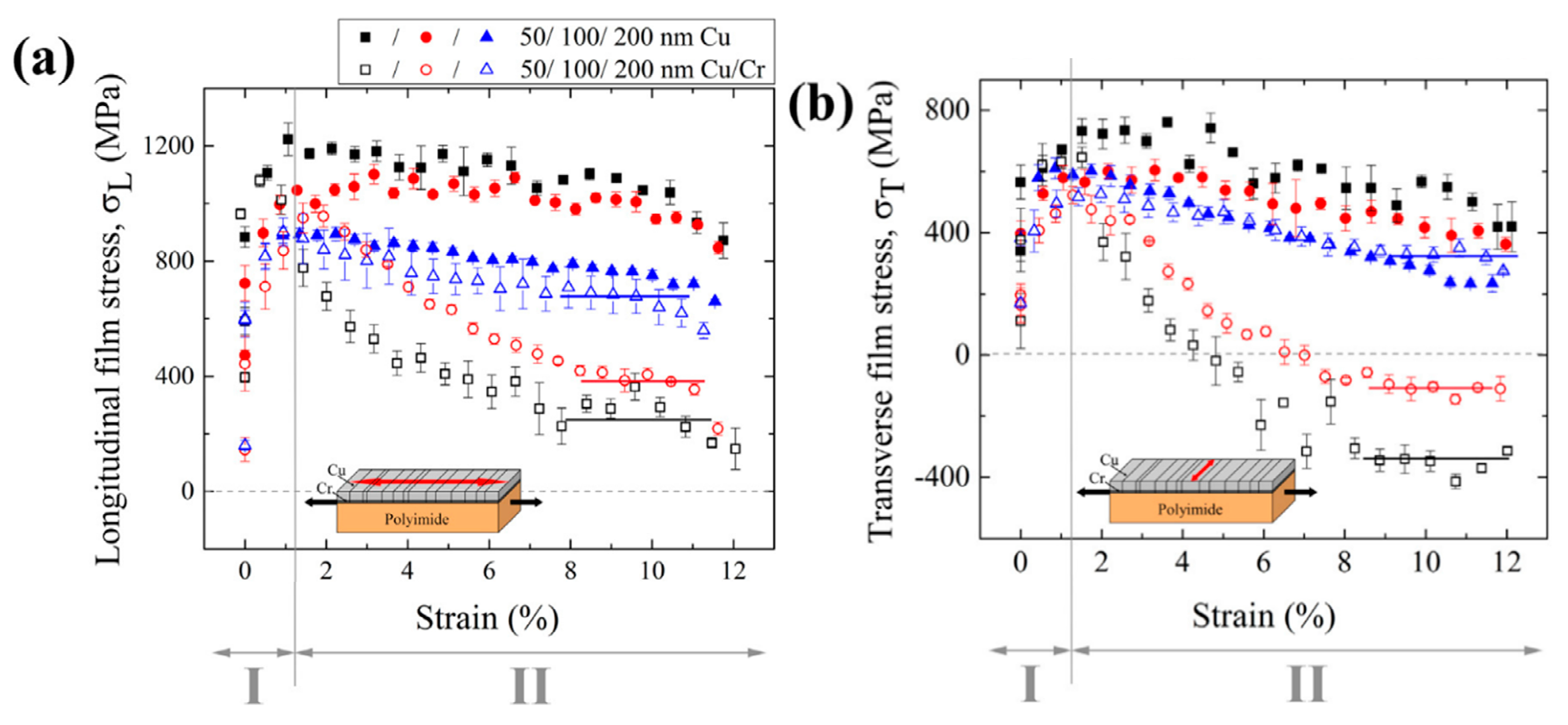

2.2.2. Deformation of Thin Films

3. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Gleiter, H. Nanocrystalline materials. In Advanced Structural and Functional Materials; Springer: Berlin/Heidelberg, Germany, 1991; pp. 1–37. [Google Scholar]

- Meyers, M.A.; Mishra, A.; Benson, D.J. Mechanical properties of nanocrystalline materials. Prog. Mater. Sci. 2006, 51, 427–556. [Google Scholar] [CrossRef]

- Schiøtz, J.; Di Tolla, F.D.; Jacobsen, K.W. Softening of nanocrystalline metals at very small grain sizes. Nature 1998, 391, 561–563. [Google Scholar] [CrossRef]

- Koch, C.C. Nanostructured Materials: Processing, Properties And Applications; William Andrew: Norwich, NY, USA, 2006. [Google Scholar]

- Pachla, W.; Kulczyk, M.; Sus-Ryszkowska, M.; Mazur, A.; Kurzydlowski, K.J. Nanocrystalline titanium produced by hydrostatic extrusion. J. Mater. Process. Technol. 2008, 205, 173–182. [Google Scholar] [CrossRef]

- Mo, Y.; Szlufarska, I. Simultaneous enhancement of toughness, ductility, and strength of nanocrystalline ceramics at high strain-rates. Appl. Phys. Lett. 2007, 90, 181926–181929. [Google Scholar] [CrossRef]

- Ritchie, R.O. The conflicts between strength and toughness. Nat. Mater. 2011, 10, 817–822. [Google Scholar] [CrossRef] [PubMed]

- Liu, C.; Lu, W.; Weng, G.J.; Li, J. A cooperative nano-grain rotation and grain-boundary migration mechanism for enhanced dislocation emission and tensile ductility in nanocrystalline materials. Mater. Sci. Eng. A 2019, 756, 284–290. [Google Scholar] [CrossRef]

- Ma, E.; Ding, J. Tailoring structural inhomogeneities in metallic glasses to enable tensile ductility at room temperature. Mater. Today 2016, 19, 568–579. [Google Scholar] [CrossRef]

- An, B.H.; Jeon, I.T.; Seo, J.H.; Ahn, J.-P.; Kraft, O.; Choi, I.S.; Kim, Y.K. Ultrahigh tensile strength nanowires with a Ni/Ni–Au multilayer nanocrystalline structure. Nano Lett. 2016, 16, 3500–3506. [Google Scholar] [CrossRef]

- Chen, G.; Peng, Y.; Zheng, G.; Qi, Z.; Wang, M.; Yu, H.; Dong, C.; Liu, C.T. Polysynthetic twinned TiAl single crystals for high-temperature applications. Nat. Mater. 2016, 15, 876–881. [Google Scholar] [CrossRef]

- Sherby, O.D.; Burke, P.M. Mechanical behavior of crystalline solids at elevated temperature. Prog. Mater. Sci. 1968, 13, 323–390. [Google Scholar] [CrossRef]

- Xu, S.; Xiong, L.; Chen, Y.; McDowell, D.L. Comparing EAM potentials to model slip transfer of sequential mixed character dislocations across two symmetric tilt grain boundaries in Ni. JOM 2017, 69, 814–821. [Google Scholar] [CrossRef]

- De Koning, M.; Kurtz, R.J.; Bulatov, V.; Henager, C.H.; Hoagland, R.G.; Cai, W.; Nomura, M. Modeling of dislocation–grain boundary interactions in FCC metals. J. Nucl. Mater. 2003, 323, 281–289. [Google Scholar] [CrossRef]

- Hussein, A.M.; Rao, S.I.; Uchic, M.D.; Dimiduk, D.M.; El-Awady, J.A. Microstructurally based cross-slip mechanisms and their effects on dislocation microstructure evolution in fcc crystals. Acta Mater. 2015, 85, 180–190. [Google Scholar] [CrossRef]

- Escaig, B. Cross-slipping process in the fcc structure. In Dislocation Dynamics; McGraw-Hill: New York, NY, USA, 1968. [Google Scholar]

- Li, Y.; Li, S.; Huang, M.; Li, Z. Analytical solution for Coble creep in polycrystalline materials under biaxial loading. Mech. Mater. 2015, 91, 290–294. [Google Scholar] [CrossRef]

- Sanders, P.; Rittner, M.; Kiedaisch, E.; Weertman, J.; Kung, H.; Lu, Y. Creep of nanocrystalline Cu, Pd, and al-Zr. Nanostruct. Mater. 1997, 9, 433–440. [Google Scholar] [CrossRef]

- Ovid’Ko, I. Deformation of nanostructures. Science 2002, 295, 2386. [Google Scholar] [CrossRef] [PubMed]

- Yu, M.; Fang, Q.; Feng, H.; Liu, Y. Effect of special rotational deformation on dislocation emission from interface collinear crack tip in nanocrystalline bi-materials. Acta Mech. 2016, 227, 2011–2024. [Google Scholar] [CrossRef]

- Ruano, O.A.; Wadsworth, J.; Sherby, O.D. Deformation of fine-grained alumina by grain boundary sliding accommodated by slip. Acta Mater. 2003, 51, 3617–3634. [Google Scholar] [CrossRef]

- Asaro, R.J.; Suresh, S. Mechanistic models for the activation volume and rate sensitivity in metals with nanocrystalline grains and nano-scale twins. Acta Mater. 2005, 53, 3369–3382. [Google Scholar] [CrossRef]

- Gottstein, G.; Shvindlerman, L.S. Grain Boundary Migration in Metals: Thermodynamics, Kinetics, Applications; CRC Press: Boca Raton, FL, USA, 2009. [Google Scholar]

- Wang, L.; Xin, T.; Kong, D.; Shu, X.; Chen, Y.; Zhou, H.; Teng, J.; Zhang, Z.; Zou, J.; Han, X. In situ observation of stress induced grain boundary migration in nanocrystalline gold. Scr. Mater. 2017, 134, 95–99. [Google Scholar] [CrossRef]

- Skiba, N. Twin Deformation Mechanisms in Nanocrystalline and Ultrafine-Grained Materials. In Nanocrystals and Nanostructures; IntechOpen: London, UK, 2018. [Google Scholar]

- Kumar, M.A.; Kanjarla, A.; Niezgoda, S.; Lebensohn, R.; Tomé, C. Numerical study of the stress state of a deformation twin in magnesium. Acta Mater. 2015, 84, 349–358. [Google Scholar] [CrossRef]

- Hearn, E.J. Mechanics of Materials 2: The Mechanics of Elastic and Plastic Deformation of Solids and Structural Materials; Elsevier: Amsterdam, The Netherlands, 1997. [Google Scholar]

- Dow, J.A.T. Stress. J. Exp. Biol. 2014, 217, 5. [Google Scholar] [CrossRef] [PubMed][Green Version]

- Bourne, N.K. Unexpected twins. Physics 2016, 9, 19. [Google Scholar] [CrossRef]

- Wang, L.; Daniewicz, S.; Horstemeyer, M.; Sintay, S.; Rollett, A. Three-dimensional finite element analysis using crystal plasticity for a parameter study of microstructurally small fatigue crack growth in a AA7075 aluminum alloy. Int. J. Fatigue 2009, 31, 651–658. [Google Scholar] [CrossRef]

- Hull, D.; Bacon, D.J. Introduction to Dislocations; Elsevier: Amsterdam, The Netherlands, 2011; Volume 37. [Google Scholar]

- Niewczas, M. Dislocations and twinning in face centred cubic crystals. In Dislocations in Solids; Elsevier: Amsterdam, The Netherlands, 2007; Volume 13, pp. 263–364. [Google Scholar]

- Courtney, T.H. Mechanical Behavior of Materials; Waveland Press: Long Grove, IL, USA, 2005. [Google Scholar]

- Srinivasan, M.; Stoebe, T. Effect of Impurities on the Mechanical Behavior of MgO Single Crystals. J. Appl. Phys. 1970, 41, 3726–3730. [Google Scholar] [CrossRef]

- Spitzig, W.; Keh, A. The effect of orientation and temperature on the plastic flow properties of iron single crystals. Acta Metall. 1970, 18, 611–622. [Google Scholar] [CrossRef]

- Wu, J.; Tsai, W.; Huang, J.; Hsieh, C.; Huang, G.-R. Sample size and orientation effects of single crystal aluminum. Mater. Sci. Eng. A 2016, 662, 296–302. [Google Scholar] [CrossRef]

- Yu, Q.; Shan, Z.-W.; Li, J.; Huang, X.; Xiao, L.; Sun, J.; Ma, E. Strong crystal size effect on deformation twinning. Nature 2010, 463, 335–338. [Google Scholar] [CrossRef]

- Rawat, S.; Joshi, S.P. Effect of multiaxial loading on evolution of {101 2} twinning in magnesium single crystals. Mater. Sci. Eng. A 2016, 659, 256–269. [Google Scholar] [CrossRef]

- Narayanan, S.; Cheng, G.; Zeng, Z.; Zhu, Y.; Zhu, T. Strain hardening and size effect in five-fold twinned Ag nanowires. Nano Lett. 2015, 15, 4037–4044. [Google Scholar] [CrossRef]

- Chmielus, M.; Rolfs, K.; Wimpory, R.; Reimers, W.; Müllner, P.; Schneider, R. Effects of surface roughness and training on the twinning stress of Ni–Mn–Ga single crystals. Acta Mater. 2010, 58, 3952–3962. [Google Scholar] [CrossRef]

- Fitzner, A.; Prakash, D.L.; da Fonseca, J.Q.; Thomas, M.; Zhang, S.-Y.; Kelleher, J.; Manuel, P.; Preuss, M. The effect of aluminium on twinning in binary alpha-titanium. Acta Mater. 2016, 103, 341–351. [Google Scholar] [CrossRef]

- Yang, B.; Peng, X.; Huang, C.; Yin, D.; Zhao, Y.; Sun, S.; Yue, X.; Fu, T. Investigation of impurity induced twinning in MgO from first principles calculations. Comput. Mater. Sci. 2018, 150, 390–396. [Google Scholar] [CrossRef]

- Tseng, L.; Ma, J.; Wang, S.; Karaman, I.; Chumlyakov, Y.I. Effects of crystallographic orientation on the superelastic response of FeMnAlNi single crystals. Scr. Mater. 2016, 116, 147–151. [Google Scholar] [CrossRef]

- Cai, S.; Li, X.; Tao, N. Orientation dependence of deformation twinning in Cu single crystals. J. Mater. Sci. Technol. 2018, 34, 1364–1370. [Google Scholar] [CrossRef]

- Yoshinaga, H.; Horiuchi, R. Deformation mechanisms in magnesium single crystals compressed in the direction parallel to hexagonal axis. Trans. JIM 1963, 4, 1–8. [Google Scholar] [CrossRef]

- Kim, J.-K.; Kwon, M.-H.; De Cooman, B.C. On the deformation twinning mechanisms in twinning-induced plasticity steel. Acta Mater. 2017, 141, 444–455. [Google Scholar] [CrossRef]

- Karaman, I.; Sehitoglu, H.; Gall, K.; Chumlyakov, Y.I.; Maier, H. Deformation of single crystal Hadfield steel by twinning and slip. Acta Mater. 2000, 48, 1345–1359. [Google Scholar] [CrossRef]

- Wang, J.; Zeng, Z.; Weinberger, C.R.; Zhang, Z.; Zhu, T.; Mao, S.X. In situ atomic-scale observation of twinning-dominated deformation in nanoscale body-centred cubic tungsten. Nat. Mater. 2015, 14, 594–600. [Google Scholar] [CrossRef]

- Kocks, U. The relation between polycrystal deformation and single-crystal deformation. Metall. Trans. 1970, 1, 1121–1143. [Google Scholar] [CrossRef]

- Hall, E. The deformation and ageing of mild steel: III discussion of results. Proc. R. Soc. B 1951, 64, 747–753. [Google Scholar] [CrossRef]

- Agena, A.S. A study of flow characteristics of nanostructured Al-6082 alloy produced by ECAP under upsetting test. J. Mater. Process. Technol. 2009, 209, 856–863. [Google Scholar] [CrossRef]

- Ke, M.; Hackney, S.; Milligan, W.; Aifantis, E. Observation and measurement of grain rotation and plastic strain in nanostructured metal thin films. Nanostruct. Mater. 1995, 5, 689–697. [Google Scholar] [CrossRef]

- Farkas, D.; Mohanty, S.; Monk, J. Strain-driven grain boundary motion in nanocrystalline materials. Mater. Sci. Eng. A 2008, 493, 33–40. [Google Scholar] [CrossRef]

- Yamakov, V.; Wolf, D.; Phillpot, S.R.; Mukherjee, A.K.; Gleiter, H. Dislocation processes in the deformation of nanocrystalline aluminium by molecular-dynamics simulation. Nat. Mater. 2002, 1, 45–49. [Google Scholar] [CrossRef] [PubMed]

- Sternlicht, H.; Rheinheimer, W.; Hoffmann, M.J.; Kaplan, W.D. The mechanism of grain boundary motion in SrTiO 3. J. Mater. Sci. 2016, 51, 467–475. [Google Scholar] [CrossRef]

- Gianola, D.; Warner, D.; Molinari, J.-F.; Hemker, K. Increased strain rate sensitivity due to stress-coupled grain growth in nanocrystalline Al. Scr. Mater. 2006, 55, 649–652. [Google Scholar] [CrossRef]

- Greer, J.R.; De Hosson, J.T.M. Plasticity in small-sized metallic systems: Intrinsic versus extrinsic size effect. Prog. Mater. Sci. 2011, 56, 654–724. [Google Scholar] [CrossRef]

- Leffers, T. A modified Sachs approach to the plastic deformation of polycrystals as a realistic alternative to the Taylor model. In Strength of Metals and Alloys; Elsevier: Amsterdam, The Netherlands, 1979; pp. 769–774. [Google Scholar]

- Mao, W. Intergranular mechanical equilibrium during the rolling deformation of polycrystalline metals based on Taylor principles. Mater. Sci. Eng. A 2016, 672, 129–134. [Google Scholar] [CrossRef]

- Lebensohn, R.A.; Zecevic, M.; Knezevic, M.; McCabe, R.J. Average intragranular misorientation trends in polycrystalline materials predicted by a viscoplastic self-consistent approach. Acta Mater. 2016, 104, 228–236. [Google Scholar] [CrossRef]

- Zeng, T.; Shao, J.F.; Xu, W. A self-consistent approach for micro–macro modeling of elastic–plastic deformation in polycrystalline geomaterials. Int. J. Numer. Anal. Methods 2015, 39, 1735–1752. [Google Scholar] [CrossRef]

- Sachs, G. The Slip Induced Rheologh. Zeitschrift des Vereines Deutscher Ingenieure 1928, 72, 734–736. [Google Scholar]

- Kröner, E. Berechnung der elastischen Konstanten des Vielkristalls aus den Konstanten des Einkristalls. Zeitschrift für Physik 1958, 151, 504–518. [Google Scholar] [CrossRef]

- Taylor, G.I. Plastic strain in metals. J. Inst. Met. 1938, 62, 307–324. [Google Scholar]

- Ahzi, S.; Asaro, R.J.; Parks, D.M. Application of crystal plasticity theory for mechanically processed BSCCO superconductors. Mech. Mater. 1993, 15, 201–222. [Google Scholar] [CrossRef]

- Lin, T. Analysis of elastic and plastic strains of a face-centred cubic crystal. J. Mech. Phys. Solids 1957, 5, 143–149. [Google Scholar] [CrossRef]

- McHugh, P.; Asaro, J.; Shih, C. Texture development and strain hardening in rate dependent polycrystals. Acta Metall. Mat. 1993, 41, 1461–1477. [Google Scholar] [CrossRef]

- Takajo, S.; Vogel, S.C.; Tome, C.N. Viscoplastic self-consistent polycrystal modeling of texture evolution of ultra-low carbon steel during cold rolling. Model. Simul. Mater. Sci. Eng. 2019, 27. [Google Scholar] [CrossRef]

- Garmestani, H.; Lin, S.; Adams, B.; Ahzi, S. Statistical continuum theory for large plastic deformation of polycrystalline materials. J. Mech. Phys. Solids 2001, 49, 589–607. [Google Scholar] [CrossRef]

- Ahzi, S.; M’Guil, S. A new intermediate model for polycrystalline viscoplastic deformation and texture evolution. Acta Mater. 2008, 56, 5359–5369. [Google Scholar] [CrossRef]

- Tang, Y.; Yang, B.; Yang, H.; Yang, P.; Yang, J.; Hu, Y. Numerical investigation on mechanical properties of graphene covering silicon nanofilms. Comput. Mater. Sci. 2017, 126, 321–325. [Google Scholar] [CrossRef]

- Wang, H.; Ren, F.; Tang, J.; Qin, W.; Hu, L.; Dong, L.; Yang, B.; Cai, G.; Jiang, C. Enhanced radiation tolerance of YSZ/Al2O3 multilayered nanofilms with pre-existing nanovoids. Acta Mater. 2018, 144, 691–699. [Google Scholar] [CrossRef]

- Si, S.; Li, W.; Zhao, X.; Han, M.; Yue, Y.; Wu, W.; Guo, S.; Zhang, X.; Dai, Z.; Wang, X. Significant radiation tolerance and moderate reduction in thermal transport of a tungsten nanofilm by inserting monolayer graphene. Adv. Mater. 2017, 29, 1604623. [Google Scholar] [CrossRef] [PubMed]

- Yao, M.S.; Lv, X.J.; Fu, Z.H.; Li, W.H.; Deng, W.H.; Wu, G.D.; Xu, G. Layer-by-Layer Assembled Conductive Metal–Organic Framework Nanofilms for Room-Temperature Chemiresistive Sensing. Angew. Chem. Int. Ed. 2017, 56, 16510–16514. [Google Scholar] [CrossRef] [PubMed]

- Karan, S.; Jiang, Z.; Livingston, A.G. Sub–10 nm polyamide nanofilms with ultrafast solvent transport for molecular separation. Science 2015, 348, 1347–1351. [Google Scholar] [CrossRef] [PubMed]

- Lu, Y.; Shu, X.; Liao, X. Size effect for achieving high mechanical performance body-centered cubic metals and alloys. Sci. China Mater. 2018, 61, 1495–1516. [Google Scholar] [CrossRef]

- Misra, A.; Hoagland, R. Plastic flow stability of metallic nanolaminate composites. J. Mater. Sci. 2007, 42, 1765–1771. [Google Scholar] [CrossRef]

- Sumitomo, T.; Huang, H.; Zhou, L. Deformation and material removal in a nanoscale multi-layer thin film solar panel using nanoscratch. Int. J. Mach. Tools Manuf. 2011, 51, 182–189. [Google Scholar] [CrossRef]

- Kim, K.-S.; Kim, J. Elasto-plastic analysis of the peel test for thin film adhesion. J. Eng. Mater. Technol. 1988, 110, 266–273. [Google Scholar] [CrossRef]

- Kohl, J.G.; Singer, I.L. Pull-off behavior of epoxy bonded to silicone duplex coatings. Prog. Org. Coat. 1999, 36, 15–20. [Google Scholar] [CrossRef]

- Ma, Q. A four-point bending technique for studying subcritical crack growth in thin films and at interfaces. J. Mater. Res. 1997, 12, 840–845. [Google Scholar] [CrossRef]

- Yang, B.; Sharp, J.S.; Smith, M.I. The interplay of crack hopping, delamination and interface failure in drying nanoparticle films. Sci. Rep.-UK 2016, 6, 32296. [Google Scholar] [CrossRef] [PubMed]

- Nolte, A.J.; Chung, J.Y.; Davis, C.S.; Stafford, C.M. Wrinkling-to-delamination transition in thin polymer films on compliant substrates. Soft Matter 2017, 13, 7930–7937. [Google Scholar] [CrossRef] [PubMed]

- Kusakabe, S.; Rawls, H.R.; Hotta, M. Relationship between thin-film bond strength as measured by a scratch test, and indentation hardness for bonding agents. Dent. Mater. 2016, 32, e55–e62. [Google Scholar] [CrossRef] [PubMed]

- Ginzburg, I.; Silva, G.; Talon, L. Analysis and improvement of Brinkman lattice Boltzmann schemes: Bulk, boundary, interface. Similarity and distinctness with finite elements in heterogeneous porous media. Phys. Rev. E 2015, 91, 023307. [Google Scholar] [CrossRef]

- Hosten, B.; Castaings, M. Finite elements methods for modeling the guided waves propagation in structures with weak interfaces. J. Acoust. Soc. Am. 2005, 117, 1108–1113. [Google Scholar] [CrossRef]

- Lu, M.; Xie, H.; Huang, H.; Zou, J.; He, Y. Indentation-induced delamination of plasma-enhanced chemical vapor deposition silicon nitride film on gallium arsenide substrate. J. Mater. Res. 2013, 28, 1047–1055. [Google Scholar] [CrossRef]

- Cordill, M.J.; Taylor, A.; Schalko, J.; Dehm, G. Microstructure and adhesion of as-deposited and annealed Cu/Ti films on polyimide. Int. J. Mater. Res. 2011, 102, 1–6. [Google Scholar] [CrossRef]

- Todeschini, M.; Bastos da Silva Fanta, A.; Jensen, F.; Wagner, J.B.; Han, A. Influence of Ti and Cr adhesion layers on ultrathin Au films. ACS Appl. Mater. Interfaces 2017, 9, 37374–37385. [Google Scholar] [CrossRef]

- Hee, A.C.; Jamali, S.S.; Bendavid, A.; Martin, P.J.; Kong, C.; Zhao, Y. Corrosion behaviour and adhesion properties of sputtered tantalum coating on Ti6Al4V substrate. Surf. Coat. Technol. 2016, 307, 666–675. [Google Scholar] [CrossRef]

- Marx, V.M.; Toth, F.; Wiesinger, A.; Berger, J.; Kirchlechner, C.; Cordill, M.J.; Fischer, F.D.; Rammerstorfer, F.G.; Dehm, G. The influence of a brittle Cr interlayer on the deformation behavior of thin Cu films on flexible substrates: Experiment and model. Acta Mater. 2015, 89, 278–289. [Google Scholar] [CrossRef] [PubMed]

| Metal | Crystal Structure | Purity (%) | Slip Plane | Slip Direction | CRSS (MPa) |

|---|---|---|---|---|---|

| Zn | HCP | 99.99 | (0001) | [1120] | 0.18 |

| Mg | HCP | 99.99 | (0001) | [1120] | 0.77 |

| Ag | FCC | 99.99 | (111) | [110] | 0.48 |

| 99.97 | (111) | [110] | 0.73 | ||

| 99.93 | (111) | [110] | 1.3 | ||

| Cu | FCC | 99.99 | (111) | [110] | 0.65 |

| 99.98 | (111) | [110] | 0.94 | ||

| Fe | BCC | 99.96 | (110) | [111] | 27.5 |

| (112) | |||||

| (123) |

| Loading Orientation | Dislocation | Twinning | Dominant Mechanism in Experiment | ||

|---|---|---|---|---|---|

| Slip System | Schmid Factor | Twin System | Schmid Factor | ||

| [10] | 1/2[11](01) | 0.41 | 1/6[11](12) | 0.47 | Twinning |

| [112] | 1/2[1](101) | 0.41 | 1/6[1](211) | 0.39 | Dislocation slip |

| [100] | 1/2[11](10) | 0.41 | 1/6 [11](21) | 0.47 | Twinning |

| [11] | 1/2[11](01) | 0.27 | 1/6[11](12) | 0.31 | Twinning |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, G.; Park, S.-J. Deformation of Single Crystals, Polycrystalline Materials, and Thin Films: A Review. Materials 2019, 12, 2003. https://doi.org/10.3390/ma12122003

Yang G, Park S-J. Deformation of Single Crystals, Polycrystalline Materials, and Thin Films: A Review. Materials. 2019; 12(12):2003. https://doi.org/10.3390/ma12122003

Chicago/Turabian StyleYang, Guijun, and Soo-Jin Park. 2019. "Deformation of Single Crystals, Polycrystalline Materials, and Thin Films: A Review" Materials 12, no. 12: 2003. https://doi.org/10.3390/ma12122003

APA StyleYang, G., & Park, S.-J. (2019). Deformation of Single Crystals, Polycrystalline Materials, and Thin Films: A Review. Materials, 12(12), 2003. https://doi.org/10.3390/ma12122003