Fabrication and Application of Carboxymethyl Cellulose-Carbon Nanotube Aerogels

Abstract

1. Introduction

2. Materials and Methods

2.1. Chemicals and Reagents

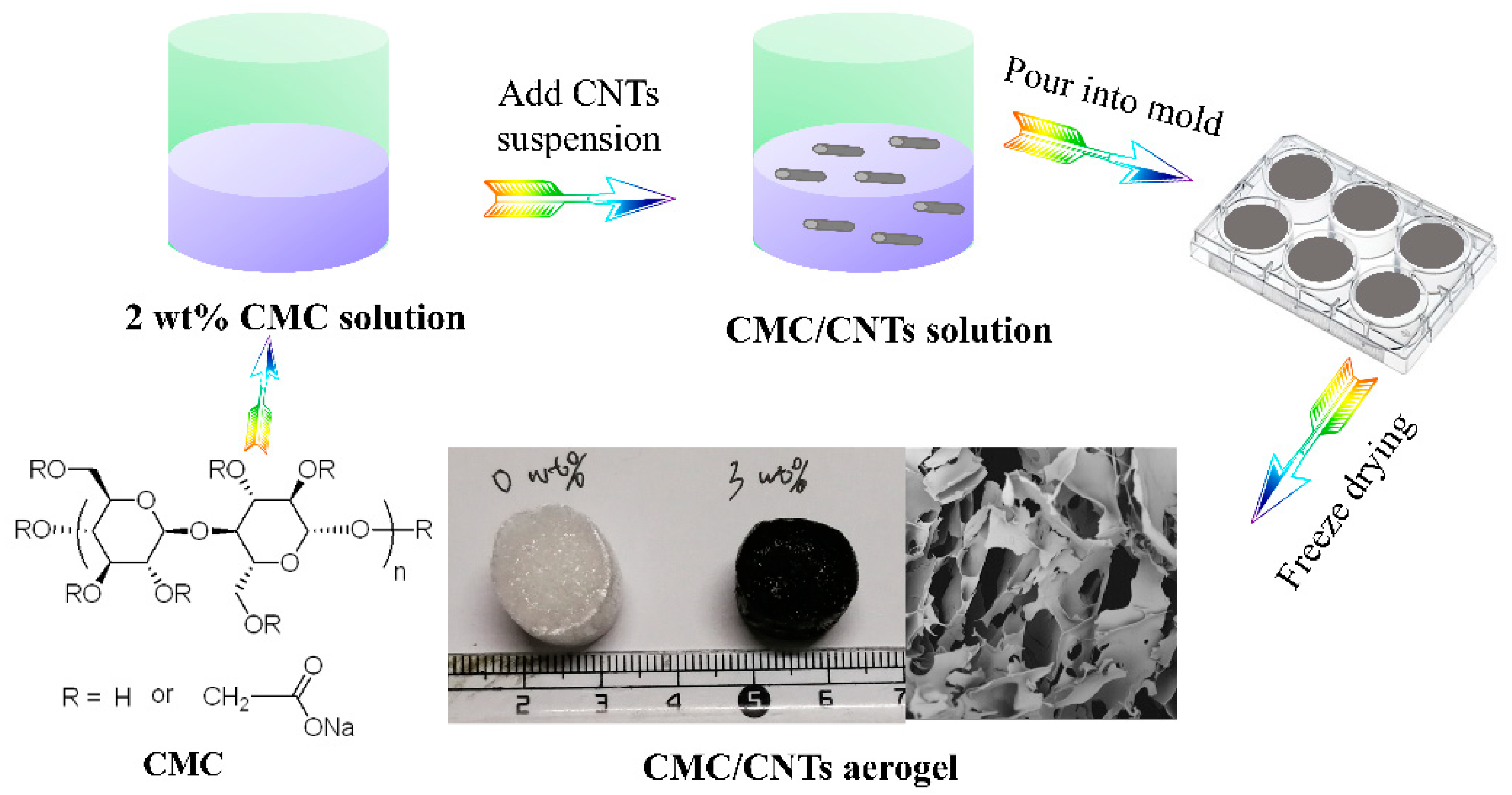

2.2. Preparation of CMC Aerogel

2.3. Preparation of CMC/CNTs Aerogel

2.4. Characterization

3. Results and Discussion

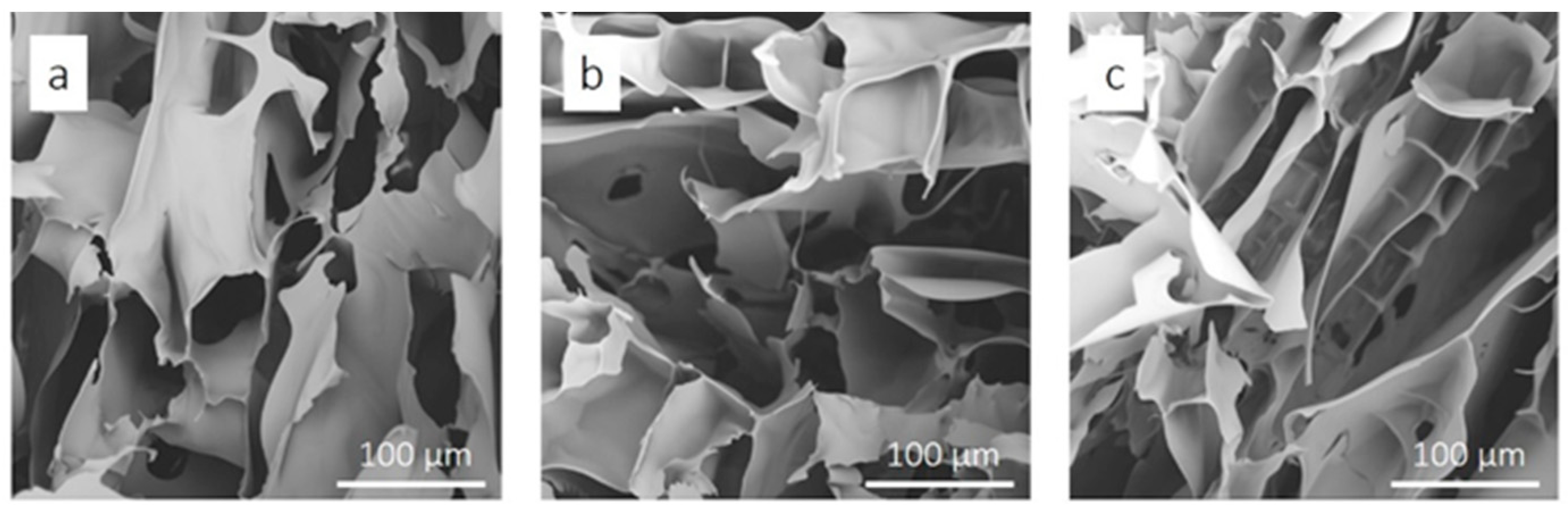

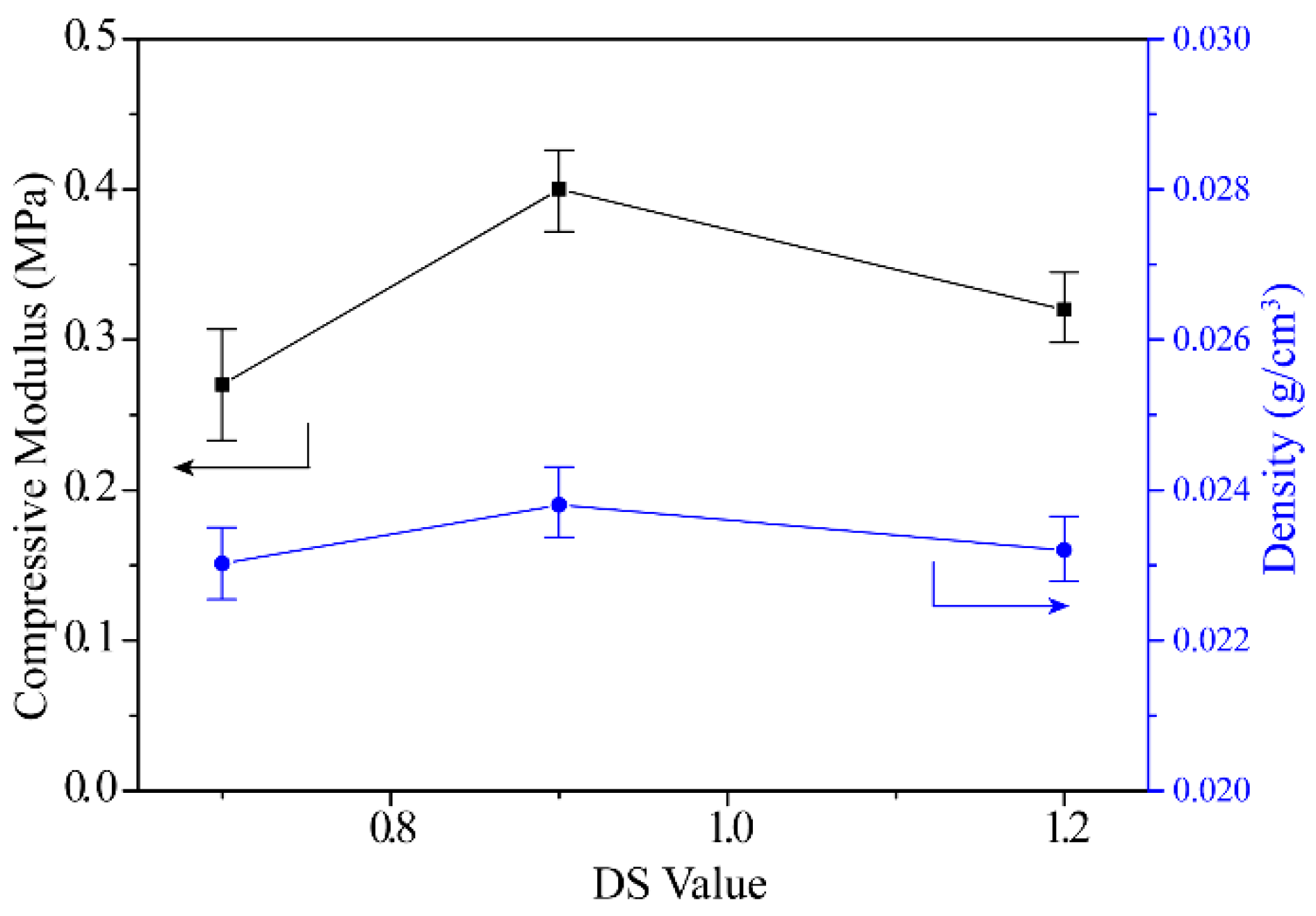

3.1. The Influence of the Degree of Substitution (DS) Value on the Properties of CMC Aerogel

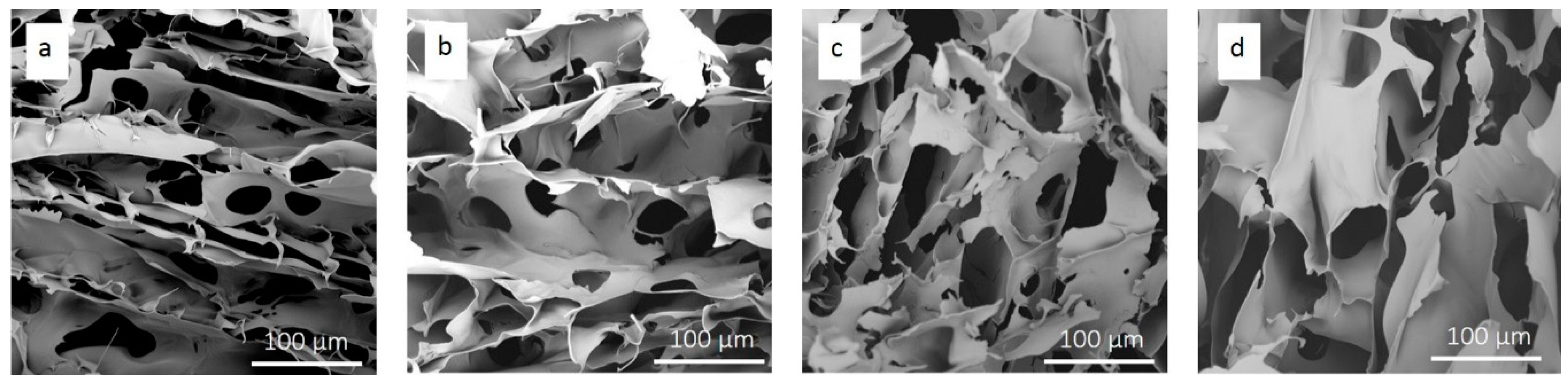

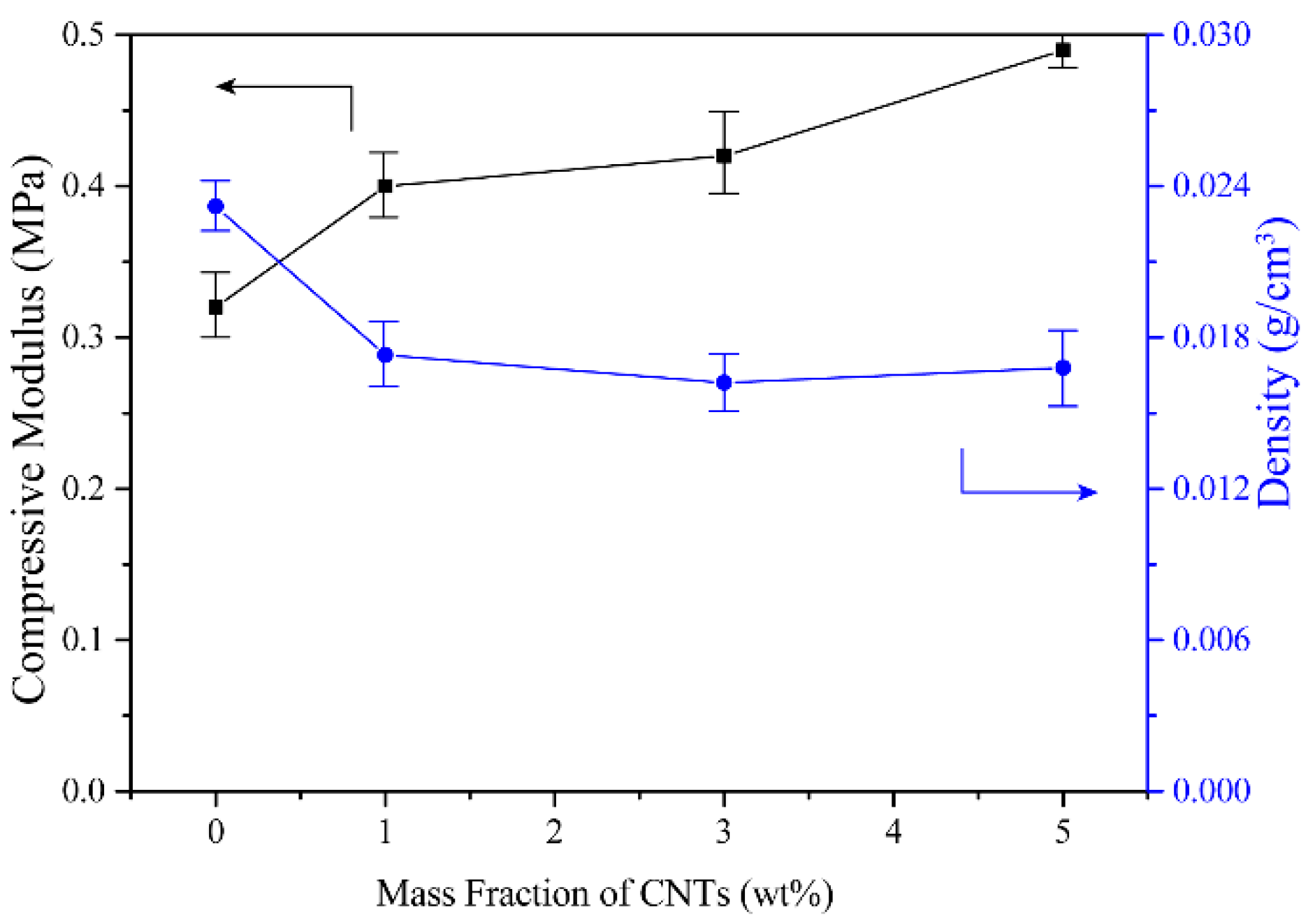

3.2. The Influence of the CNTs on the Properties of CMC Aerogel

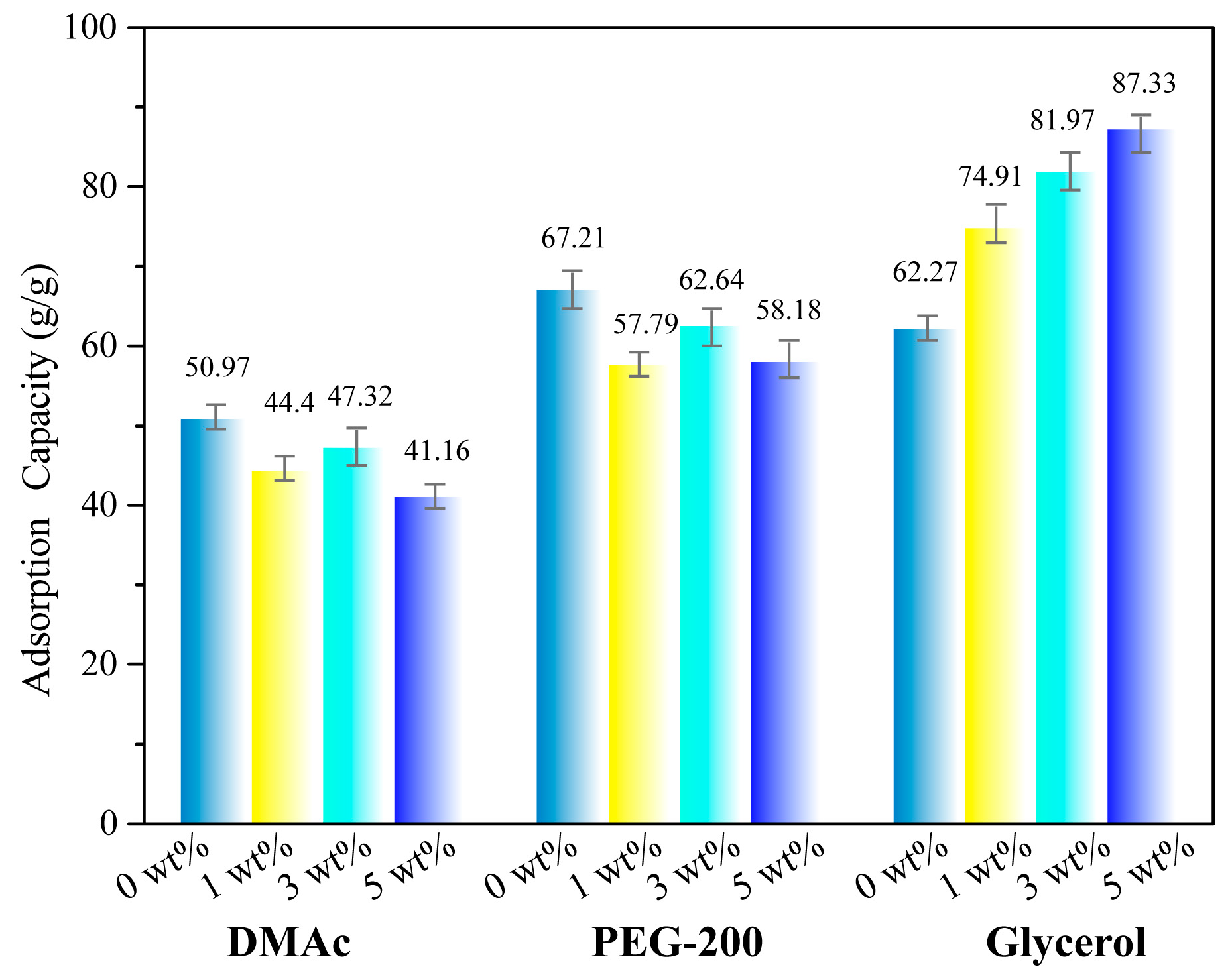

3.3. The Adsorption Performance of Cellulose Aerogels

4. Conclusions

- (1)

- The DS value has little effect on the surface structure, mechanical properties and density of the CMC aerogels due to the uneven distribution of the substituents.

- (2)

- Because of the agglomeration of CNTs, the specific surface area of the aerogels decreases with the increasing of CNTs amount. The aerogel densities were decreased after adding the CNTs suspension into the CMC matrix because of decreasing the solution concentration. The compressive modulus of aerogel was increased from 0.3 MPa of pure CMC aerogel to 0.5 MPa of 5 wt % CNTs/CMC aerogel.

- (3)

- Because the high viscosity liquid possesses strong adhesion to the pore wall, the adsorption capacity of the CMC aerogel to the liquid increases as the viscosity of the liquid increases.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Sun, P.; Yang, S.; Sun, X.; Wang, Y.; Pan, L.; Wang, H.; Wang, X. Functional Porous Carboxymethyl Cellulose/Cellulose Acetate Composite Microspheres: Preparation, Characterization, and Application in the Effective Removal of HCN from Cigarette Smoke. Polymers 2019, 11, 181. [Google Scholar] [CrossRef] [PubMed]

- Su, J.; Huang, Z.; Yuan, X.; Wang, X.; Li, M. Structure and properties of carboxymethyl cellulose/soy protein isolate blend edible films crosslinked by Maillard reactions. Carbohydr. Polym. 2010, 79, 145–153. [Google Scholar] [CrossRef]

- Ninan, N.; Muthiah, M.; Park, I.; Elain, A.; Thomas, S.; Grohens, Y. Pectin/carboxymethyl cellulose/microfibrillated cellulose composite scaffolds for tissue engineering. Carbohydr. Polym. 2013, 98, 877–885. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Liu, Y.; Wang, X.; Sun, Z.; Ma, J.; Wu, T. Porous graphene oxide/carboxymethyl cellulose monoliths, with high metal ion adsorption. Carbohydr. Polym. 2014, 101, 392–400. [Google Scholar] [CrossRef] [PubMed]

- Shen, J.; Cui, C.; Li, J.; Wang, L. In Situ Synthesis of a Silver-Containing Superabsorbent Polymer via a Greener Method Based on Carboxymethyl Celluloses. Molecules 2018, 23, 2483. [Google Scholar] [CrossRef]

- Velempini, T.; Pillay, K.; Mbianda, X.Y.; Arotiba, O.A. Carboxymethyl cellulose thiol-imprinted polymers: Synthesis, characterization and selective Hg (II) adsorption. J. Environ. Sci. 2018, 79, 280–296. [Google Scholar] [CrossRef]

- Wang, S.; Lu, A.; Zhang, L. Recent advances in regenerated cellulose materials. Prog. Polym. Sci. 2016, 53, 169–206. [Google Scholar] [CrossRef]

- Lopes, J.M.; Bermejo, M.D.; Mart, Á.; Cocero, M.J. Ionic Liquid as Reaction Media for the Production of Cellulose-Derived Polymers from Cellulosic Biomass. ChemEngineering 2017, 1, 10. [Google Scholar] [CrossRef]

- Long, L.; Weng, Y.; Wang, Y. Cellulose Aerogels: Synthesis, Applications, and Prospects. Polymers 2018, 10, 623. [Google Scholar] [CrossRef]

- Yu, M.; Han, Y.; Li, J.; Wang, L. One-step synthesis of sodium carboxymethyl cellulose-derived carbon aerogel/nickel oxide composites for energy storage. Chem. Eng. J. 2017, 324, 287–295. [Google Scholar] [CrossRef]

- Surapolchai, W.; Schiraldi, D.A. The effects of physical and chemical interactions in the formation of cellulose aerogels. Polym. Bull. 2010, 65, 951–960. [Google Scholar] [CrossRef]

- De France, K.J.; Hoare, T.; Cranston, E.D. Review of Hydrogels and Aerogels Containing Nanocellulose. Chem. Mater. 2017, 29, 4609–4631. [Google Scholar] [CrossRef]

- Esposito, S. “Traditional” Sol-Gel Chemistry as a Powerful Tool for the Preparation of Supported Metal and Metal Oxide Catalysts. Materials 2019, 12, 668. [Google Scholar] [CrossRef] [PubMed]

- Fan, W.; Du, J.; Kou, J.; Zhang, Z.; Liu, F. Hierarchical porous cellulose/lanthanide hybrid materials as luminescent sensor. J. Rare Earths 2018, 36, 1036–1043. [Google Scholar] [CrossRef]

- Menshutina, N.; Tsygankov, P.; Ivanov, S. Synthesis and Properties of Silica and Alginate Hybrid Aerogel Particles with Embedded Carbon Nanotubes (CNTs) for Selective Sorption. Materials 2019, 12, 52. [Google Scholar] [CrossRef] [PubMed]

- Alam, A.; Zhang, Y.; Kuan, H.; Lee, S.; Ma, J. Polymer composite hydrogels containing carbon nanomaterials—Morphology and mechanical and functional performance. Prog. Polym. Sci. 2017, 77, 1–18. [Google Scholar] [CrossRef]

- Huang, T.; Shao, Y.; Zhang, Q.; Deng, Y.; Liang, Z.; Guo, F.; Li, P.; Wang, Y. Chitosan-Cross-Linked Graphene Oxide/Carboxymethyl Cellulose Aerogel Globules with High Structure Stability in Liquid and Extremely High Adsorption Ability. ACS Sustain. Chem. Eng. 2019, 7, 8775–8788. [Google Scholar] [CrossRef]

- Ge, X.; Shan, Y.; Wu, L.; Mu, X.; Peng, H.; Jiang, Y. High-strength and morphology-controlled aerogel based on carboxymethyl cellulose and graphene oxide. Carbohydr. Polym. 2018, 197, 277–283. [Google Scholar] [CrossRef]

- Huang, Z.; Liu, X.; Wu, W.; Li, Y.; Wang, H. Highly elastic and conductive graphene / carboxymethylcellulose aerogels for flexible strain-sensing materials. J. Mater. Sci. 2017, 52, 12540–12552. [Google Scholar] [CrossRef]

- Hajian, A.; Fu, Q.; Berglund, L.A. Recyclable and superelastic aerogels based on carbon nanotubes and carboxymethyl cellulose. Compos. Sci. Technol. 2018, 159, 1–10. [Google Scholar] [CrossRef]

- Marshall, M.W.; Popa-nita, S.; Shapter, J.G. Measurement of functionalised carbon nanotube carboxylic acid groups using a simple chemical process. Carbon 2006, 44, 1137–1141. [Google Scholar] [CrossRef]

- Atieh, M.A.; Bakather, O.Y.; Al-tawbini, B.; Bukhari, A.A.; Abuilaiwi, F.A.; Fettouhi, M.B. Effect of Carboxylic Functional Group Functionalized on Carbon Nanotubes Surface on the Removal of Lead from Water. Bioinorg. Chem. Appl. 2010, 2010. [Google Scholar] [CrossRef]

- Buchtová, N.; Budtova, T. Cellulose aero-, cryo- and xerogels: towards understanding of morphology control. Cellulose 2016, 23, 2585–2595. [Google Scholar] [CrossRef]

- García-González, C.A.; Alnaief, M.; Smirnova, I. Polysaccharide-based aerogels—Promising biodegradable carriers for drug delivery systems. Carbohydr. Polym. 2011, 86, 1425–1438. [Google Scholar] [CrossRef]

- Beaumont, M.; Kondor, A.; Plappert, S.; Mitterer, C.; Opietnik, M.; Potthast, A.; Rosenau, T. Surface properties and porosity of highly porous, nanostructured cellulose II particles. Cellulose 2016, 24, 1–6. [Google Scholar] [CrossRef]

- Long, L.; Li, F.; Weng, Y.; Wang, Y. Effects of Sodium Montmorillonite on the Preparation and Properties of Cellulose Aerogels. Polymers 2019, 11, 415. [Google Scholar] [CrossRef]

- Pircher, N.; Carbajal, L.; Schimper, C.; Bacher, M.; Rennhofer, H.; Nedelec, J.M.; Lichtenegger, H.C.; Rosenau, T.; Liebner, F. Impact of selected solvent systems on the pore and solid structure of cellulose aerogels. Cellulose 2016, 23, 1949–1966. [Google Scholar] [CrossRef]

- Karadagli, I.; Schulz, B.; Schestakow, M.; Milow, B.; Gries, T.; Ratke, L. Production of porous cellulose aerogel fibers by an extrusion process. J. Supercrit. Fluids 2015, 106, 105–114. [Google Scholar] [CrossRef]

- Zhao, S.; Malfait, W.J.; Guerrero Alburquerque, N.; Koebel, M.M.; Nyström, G. Biopolymer Aerogels: Chemistry, Properties and Applications. Angew. Chem. Int. Ed. 2018, 130, 7704–7733. [Google Scholar] [CrossRef]

- Adebajo, M.O.; Frost, R.L.; Kloprogge, J.T.; Carmody, O.; Kokot, S. Porous Materials for Oil Spill Cleanup: A Review of Synthesis. J. Porous Mater. 2003, 10, 159–170. [Google Scholar] [CrossRef]

- Hasan, M.; Gopakumar, D.A.; Arumughan, V.; Pottathara, Y.B.; Seantier, B.; Nzihou, A.; Thomas, S.; Rizal, S.; Abdul Khalil, H.P.S. Robust Superhydrophobic Cellulose Nanofiber Aerogel for Multifunctional. Polymers 2019, 11, 495. [Google Scholar] [CrossRef]

- Nguyen, D.; Vu, C.; Vu, H.; Choi, H. Micron-Size White Bamboo Fibril-Based Silane Cellulose Aerogel: Fabrication and Oil Absorbent Characteristics. Materials 2019, 12, 1407. [Google Scholar] [CrossRef] [PubMed]

- Luo, Q.; Huang, X.; Gao, F.; Li, D.; Wu, M. Preparation and Characterization of High Amylose Corn Starch–Microcrystalline Cellulose Aerogel with High Absorption. Materials 2019, 12, 1420. [Google Scholar] [CrossRef]

- Xiang, C.; Wang, C.; Guo, R.; Lan, J. Synthesis of carboxymethyl cellulose-reduced graphene oxide aerogel for efficient removal of organic liquids and dyes. J. Mater. Sci. 2018, 54, 1872–1883. [Google Scholar] [CrossRef]

| DS Value | 0.7 | 0.9 | 1.2 |

|---|---|---|---|

| BET surface area (m2/g) | 109.94 | 106.78 | 111.26 |

| CNTs Amounts (wt %) | 0 | 1 | 3 | 5 |

|---|---|---|---|---|

| Pore size distribution (μm) | 30.6~152.5 | 9.71~128 | 8.7~118 | 16.6~132.4 |

| BET surface area (m2/g) | 111.26 | 100.56 | 70.21 | 66.81 |

© 2019 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Long, L.; Li, F.; Shu, M.; Zhang, C.; Weng, Y. Fabrication and Application of Carboxymethyl Cellulose-Carbon Nanotube Aerogels. Materials 2019, 12, 1867. https://doi.org/10.3390/ma12111867

Long L, Li F, Shu M, Zhang C, Weng Y. Fabrication and Application of Carboxymethyl Cellulose-Carbon Nanotube Aerogels. Materials. 2019; 12(11):1867. https://doi.org/10.3390/ma12111867

Chicago/Turabian StyleLong, Linyu, Fenfen Li, Mengying Shu, Caili Zhang, and Yunxuan Weng. 2019. "Fabrication and Application of Carboxymethyl Cellulose-Carbon Nanotube Aerogels" Materials 12, no. 11: 1867. https://doi.org/10.3390/ma12111867

APA StyleLong, L., Li, F., Shu, M., Zhang, C., & Weng, Y. (2019). Fabrication and Application of Carboxymethyl Cellulose-Carbon Nanotube Aerogels. Materials, 12(11), 1867. https://doi.org/10.3390/ma12111867