Grain-Size Distribution Effects on the Attenuation of Laser-Generated Ultrasound in α-Titanium Alloy

Abstract

1. Introduction

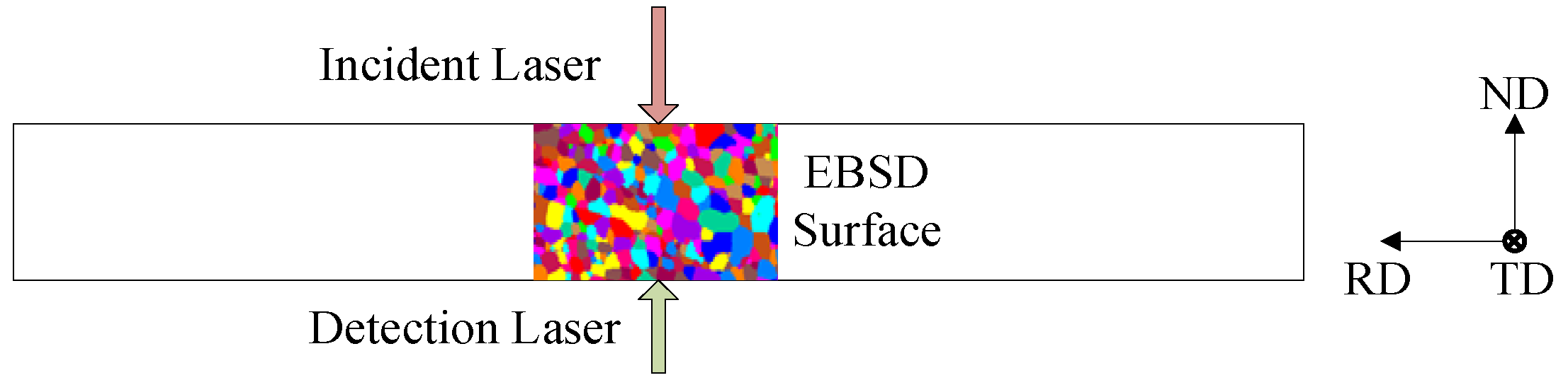

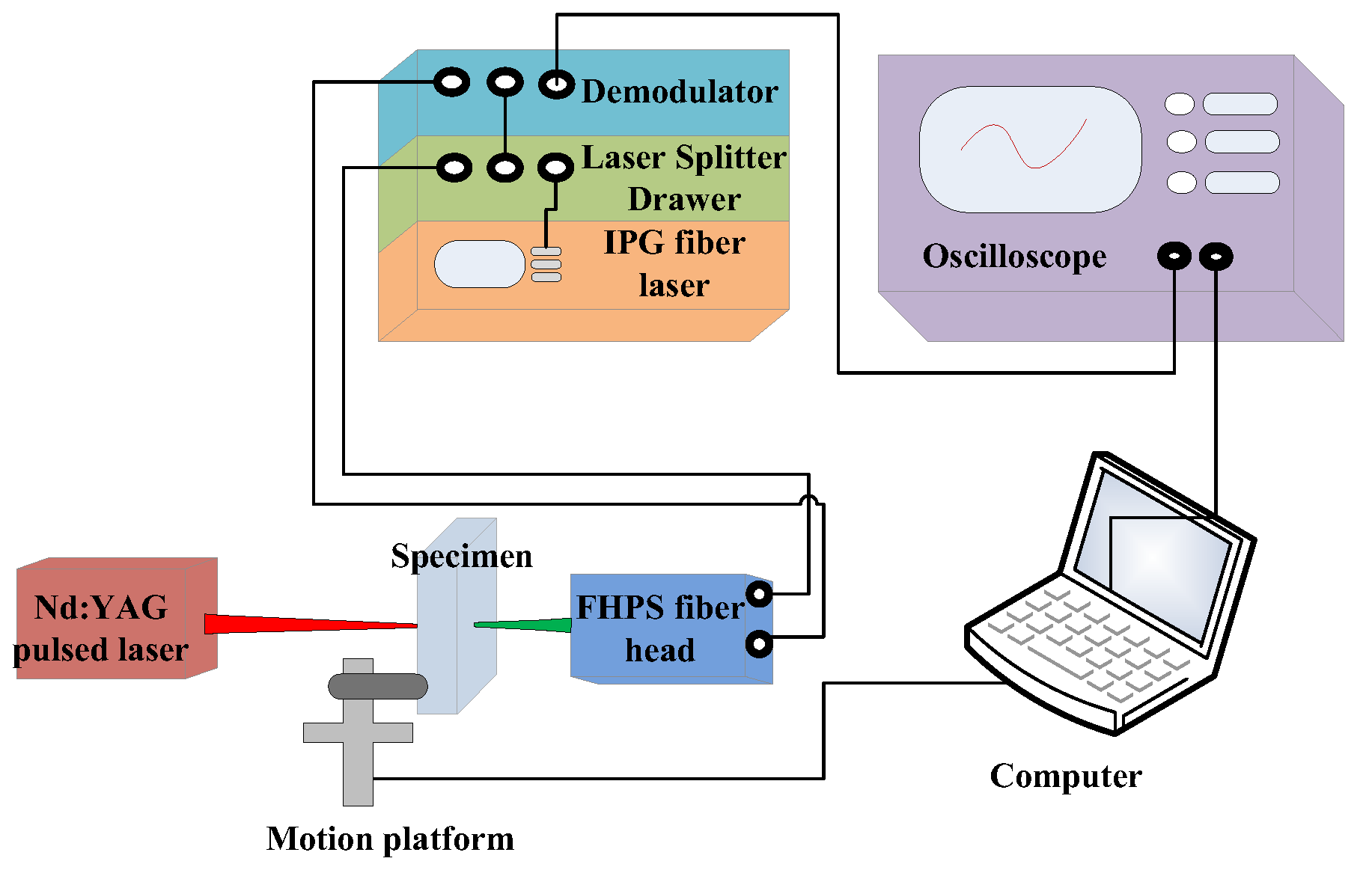

2. Materials and Methods

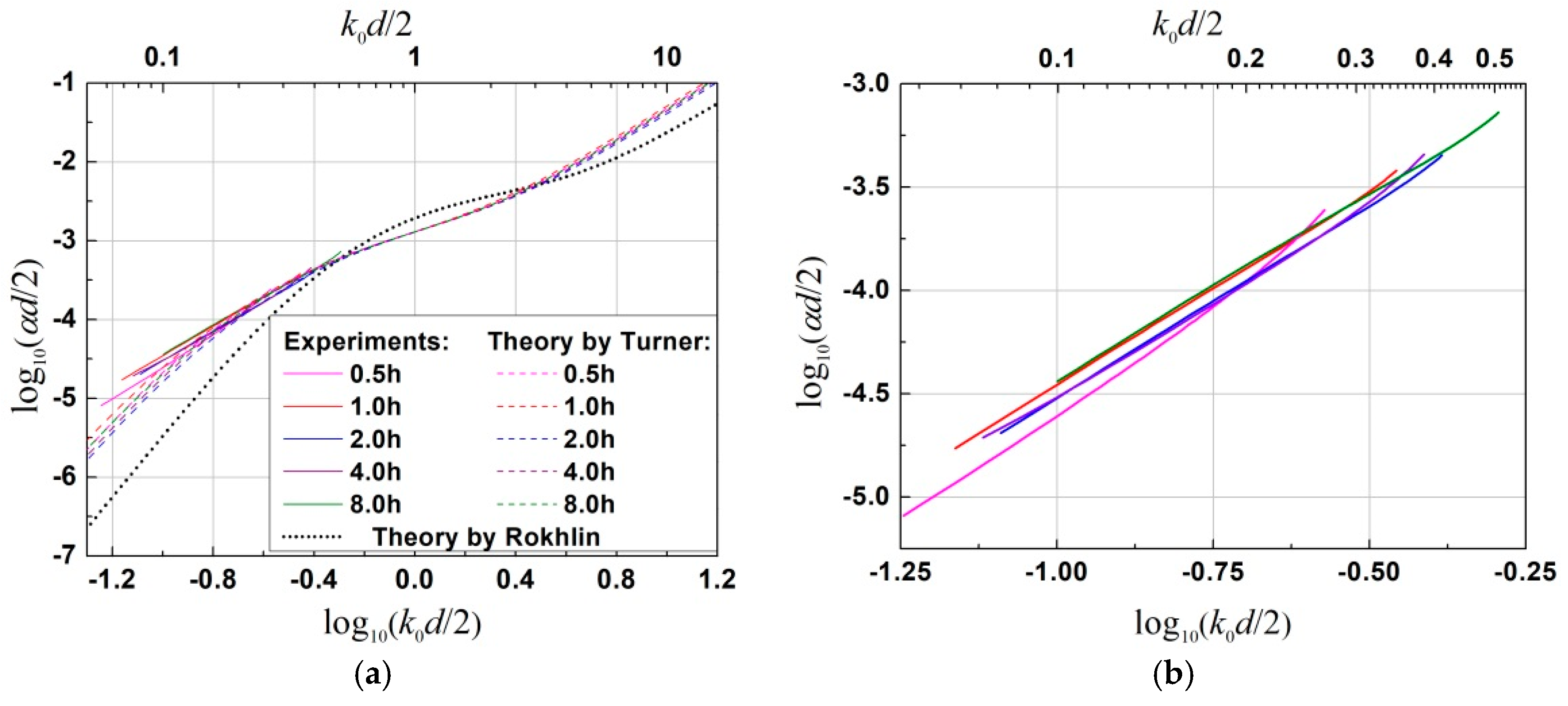

3. Results

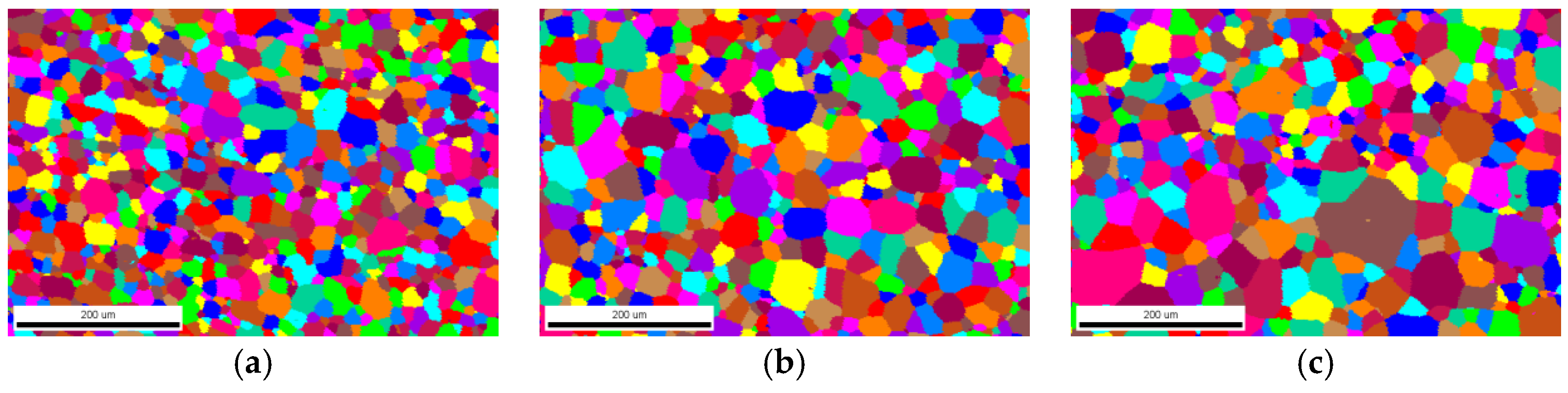

3.1. Metallographical Observations

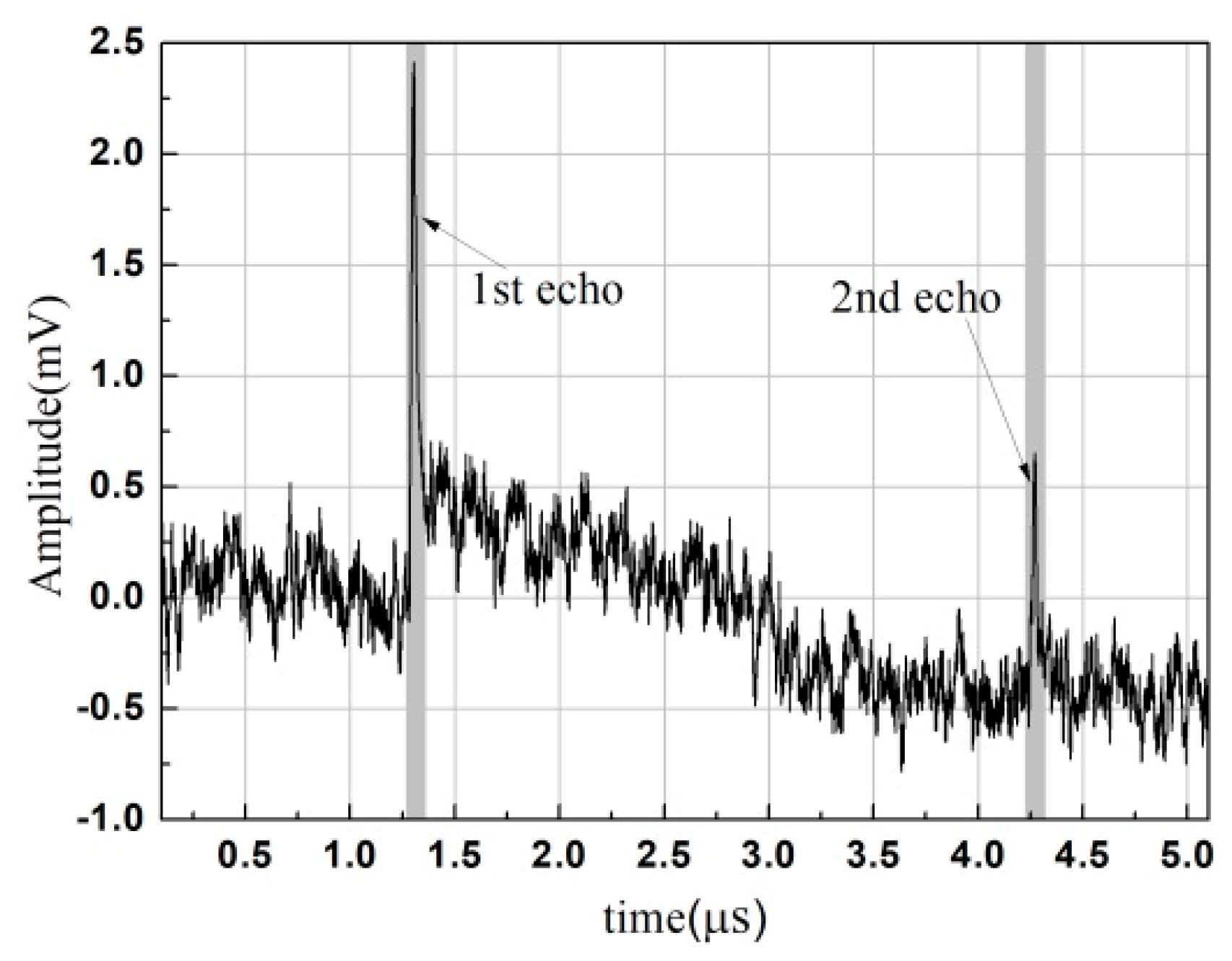

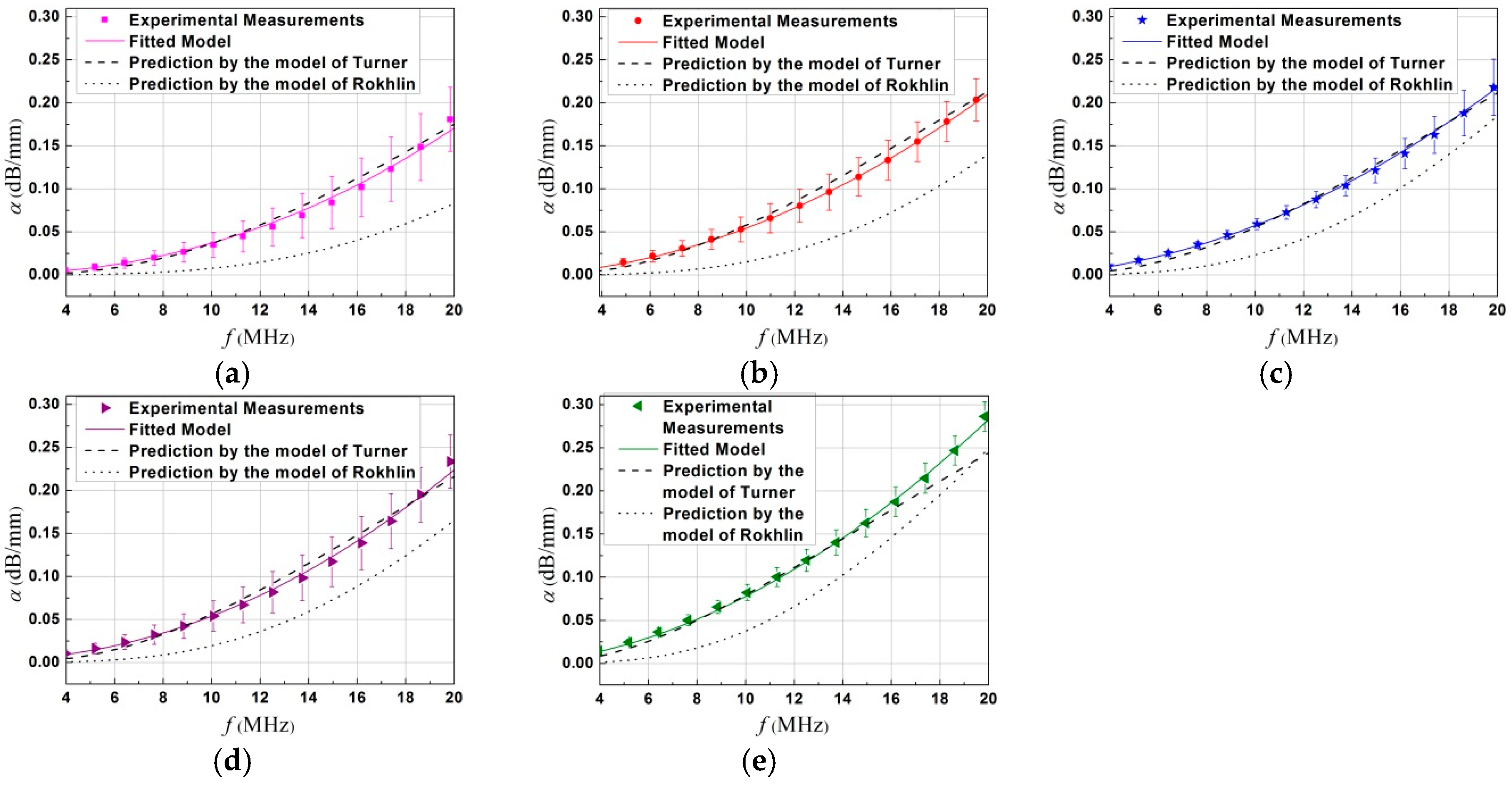

3.2. Ultrasonic Attenuation Measurements

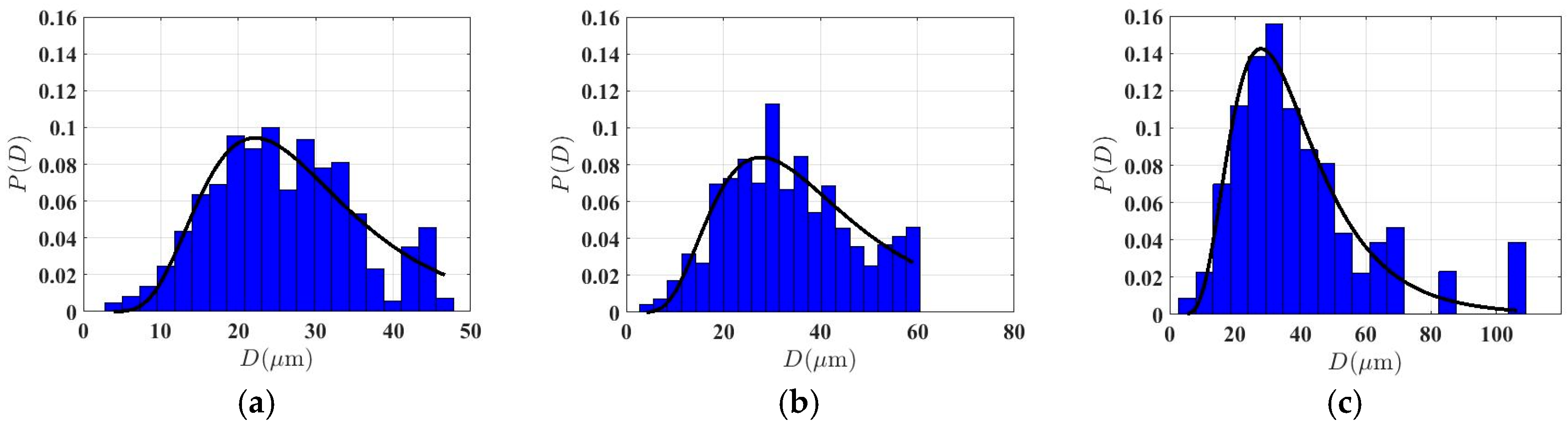

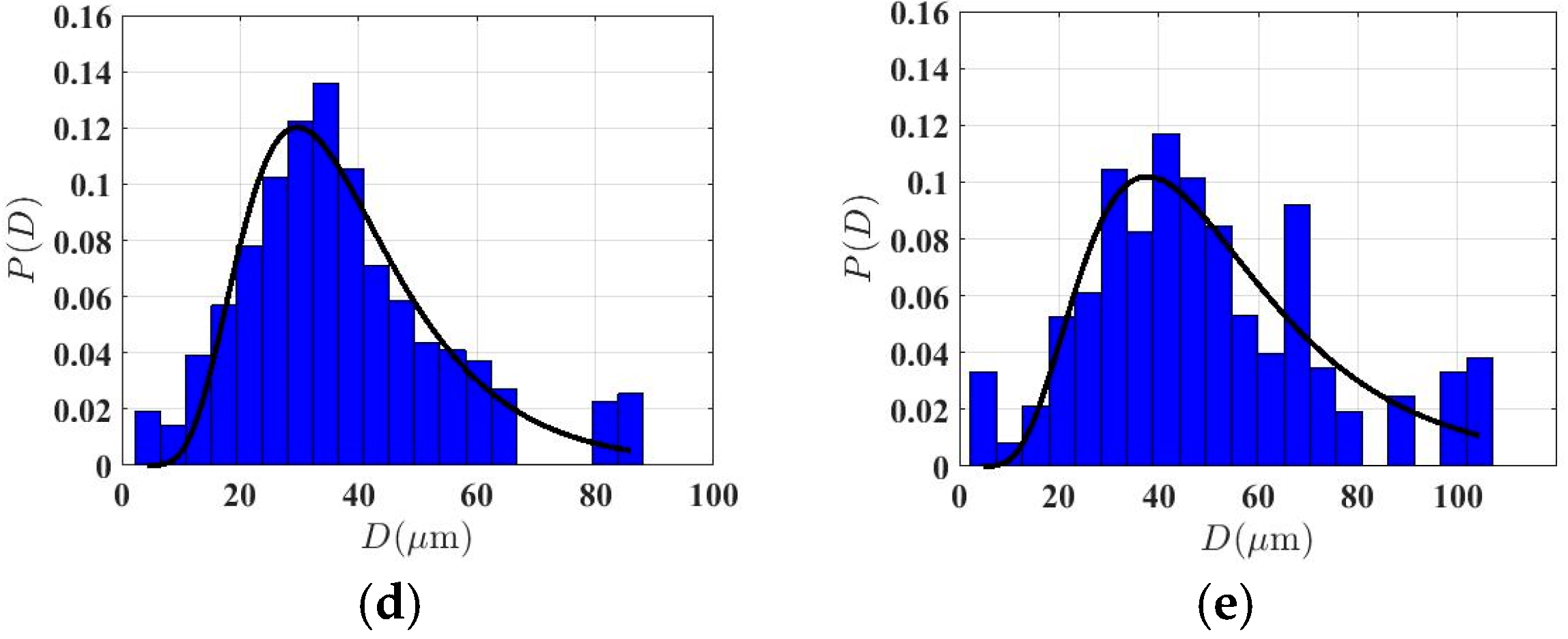

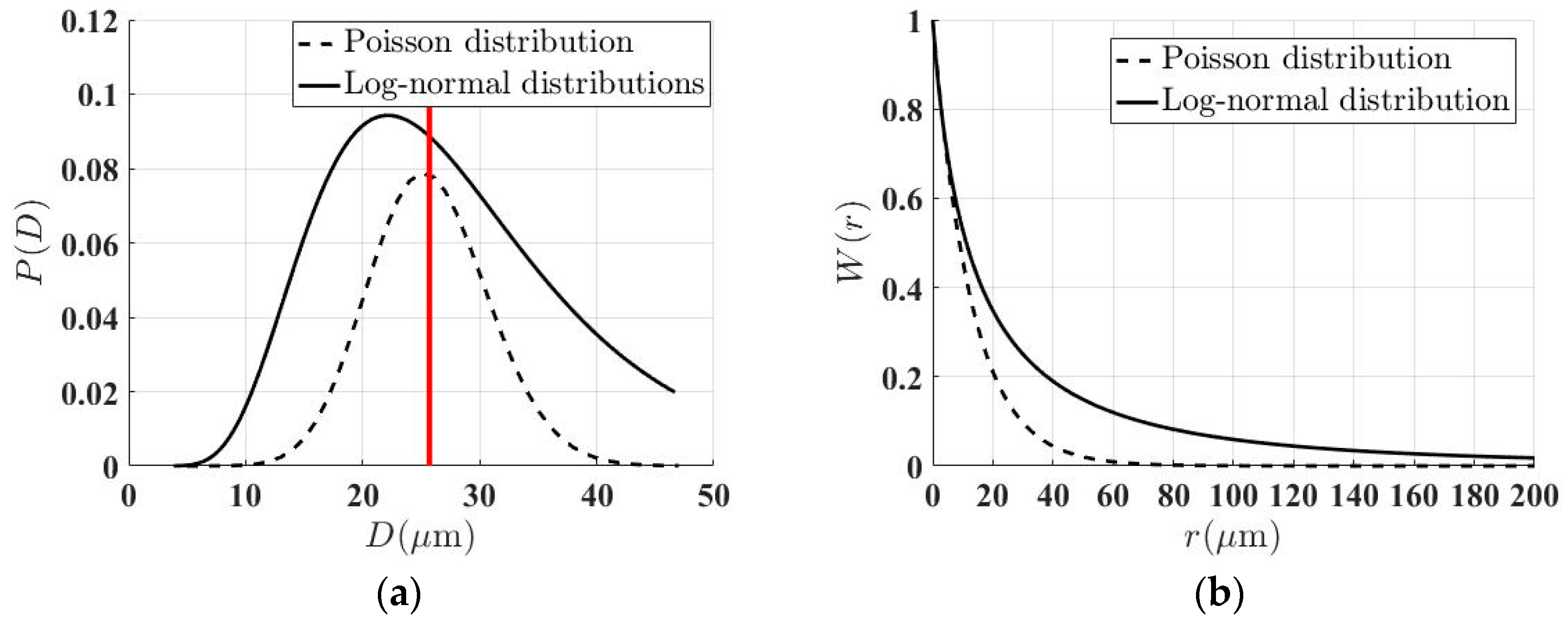

3.3. Grain Size Characterization

4. Discussions

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Richeton, T.; Wagner, F.; Chen, C.; Toth, L. Combined effects of texture and grain size distribution on the tensile behavior of α-titanium. Materials 2018, 11, 1088. [Google Scholar] [CrossRef] [PubMed]

- Berbenni, S.; Favier, V.; Berveiller, M. Micro-macro modelling of the effects of the grain size distribution on the plastic flow stress of heterogeneous materials. Comput. Mater. Sci. 2007, 39, 96–105. [Google Scholar] [CrossRef]

- Berbenni, S.; Favier, V.; Berveiller, M. Impact of the grain size distribution on the yield stress of heterogeneous materials. Int. J. Plast. 2007, 23, 114–142. [Google Scholar] [CrossRef]

- Bucki, J.J.; Kurzydłowski, K.J. Analysis of the effect of grain size uniformity on the flow stress of polycrystals: Part I: Studies of the relationship between the variance of grain volume and the variance of the grain area on polycrystal cross section. Mater. Charact. 1992, 29, 365–374. [Google Scholar] [CrossRef]

- Smith, C.J.; Stephens, J.D.; Hancock, B.C.; Vahdat, A.S.; Cetinkaya, C. Acoustic assessment of mean grain size in pharmaceutical compacts. Int. J. Pharm. 2011, 419, 137–146. [Google Scholar] [CrossRef] [PubMed]

- Gil, F.J.; Planell, J.A. Behaviour of normal grain growth kinetics in single phase titanium and titanium alloys. Mater. Sci. Eng. A-Struct. 2000, 283, 17–24. [Google Scholar] [CrossRef]

- Zeng, F.; Agnew, S.R.; Raeisinia, B.; Myneni, G.R. Ultrasonic attenuation due to grain boundary scattering in pure niobium. J. Nondestruct. Eval. 2010, 29, 93–103. [Google Scholar] [CrossRef]

- Stanke, F.E.; Kino, G.S. A unified theory for elastic wave propagation in polycrystalline materials. J. Acoust. Soc. Am. 1984, 75, 665–681. [Google Scholar] [CrossRef]

- Karal, F.C., Jr.; Keller, J.B. Elastic, electromagnetic, and other waves in a random medium. J. Math. Phys. 1964, 5, 537–547. [Google Scholar] [CrossRef]

- Bhatia, A.B. Scattering of High-Frequency Sound Waves in Polycrystalline Materials. J. Acoust. Soc. Am. 1959, 31, 16–23. [Google Scholar] [CrossRef]

- Hirsekorn, S. The scattering of ultrasonic waves by polycrystals. J. Acoust. Soc. Am. 1982, 72, 1021–1031. [Google Scholar] [CrossRef]

- Weaver, R.L. Diffusivity of ultrasound in polycrystals. J. Mech. Phys. Solids 1990, 38, 55–86. [Google Scholar] [CrossRef]

- Kube, C.M. Iterative solution to bulk wave propagation in polycrystalline materials. J. Acoust. Soc. Am. 2017, 141, 1804–1811. [Google Scholar] [CrossRef] [PubMed]

- Turner, J.A. Elastic wave propagation and scattering in heterogeneous, anisotropic media: Textured polycrystalline materials. J. Acoust. Soc. Am. 1999, 106, 541–552. [Google Scholar] [CrossRef]

- Yang, L.; Lobkis, O.I.; Rokhlin, S.I. Shape effect of elongated grains on ultrasonic attenuation in polycrystalline materials. Ultrasonics 2011, 51, 697–708. [Google Scholar] [CrossRef] [PubMed]

- Yang, L.; Lobkis, O.I.; Rokhlin, S.I. Explicit model for ultrasonic attenuation in equiaxial hexagonal polycrystalline materials. Ultrasonics 2011, 51, 303–309. [Google Scholar] [CrossRef]

- Papadakis, E.P. Grain-Size Distribution in Metals and Its Influence on Ultrasonic Attenuation Measurements. J. Acoust. Soc. Am. 1961, 33, 1616–1621. [Google Scholar] [CrossRef]

- Papadakis, E.P. From micrograph to grain-size distribution with ultrasonic applications. J. Appl. Phys. 1964, 35, 1586–1594. [Google Scholar] [CrossRef]

- Nicoletti, D.; Kasper, D. Ultrasonic attenuation based on the roney generalized theory and multiple power-law grain-size distributions. IEEE Trans. Ultrason. Ferroelectr. Freq. Control 1994, 41, 144–149. [Google Scholar] [CrossRef]

- Anderson, A.; Nicoletti, D. Determination of Grain-Size Distributions from Ultrasonic Attenuation. In Review of Progress in QNDE; Springer: Boston, MA, USA, 1996; pp. 1503–1507. [Google Scholar]

- Smith, R.L. The effect of grain size distribution on the frequency dependence of the ultrasonic attenuation in polycrystalline materials. Ultrasonics 1982, 20, 211–214. [Google Scholar] [CrossRef]

- Arguelles, A.P.; Turner, J.A. Ultrasonic attenuation of polycrystalline materials with a distribution of grain sizes. J. Acoust. Soc. Am. 2017, 141, 4347–4353. [Google Scholar] [CrossRef] [PubMed]

- Rhines, F.N.; Patterson, B.R. Effect of the degree of prior cold work on the grain volume distribution and the rate of grain growth of recrystallized aluminum. Metall. Trans. A 1982, 13, 985–993. [Google Scholar] [CrossRef]

- Thompson, R.B.; Margetan, F.J.; Haldipur, P.; Yu, L.; Li, A.; Panetta, P.; Wasan, H. Scattering of elastic waves in simple and complex polycrystals. Wave Motion 2008, 45, 655–674. [Google Scholar] [CrossRef]

- Lindh-Ulmgren, E.; Ericsson, M.; Artymowicz, D.; Hutchinson, W.B. Laser-ultrasonics as a technique to study recrystallisation and grain growth. Mater. Sci. Forum 2004, 467, 1353–1362. [Google Scholar] [CrossRef]

- Kube, C.M. Attenuation of laser generated ultrasound in steel at high temperatures: Comparison of theory and experimental measurements. Ultrasonics 2016, 70, 238–240. [Google Scholar] [CrossRef] [PubMed]

- Zhang, X.G.; Simpson, W.A.; Vitek, J.M.; Barnard, D.J.; Tweed, L.J.; Foley, J. Ultrasonic attenuation due to grain boundary scattering in copper and copper-aluminum. J. Acoust. Soc. Am. 2004, 116, 109–116. [Google Scholar] [CrossRef]

- Garcin, T.; Schmitt, J.H.; Militzer, M. In-situ laser ultrasonic grain size measurement in superalloy INCONEL 718. J. Alloy. Compd. 2016, 670, 329–336. [Google Scholar] [CrossRef]

- Okulov, I.V.; Volegov, A.S.; Attar, H.; Bönisch, M.; Ehtemam-Haghighi, S.; Calin, M.; Eckert, J. Composition optimization of low modulus and high-strength TiNb-based alloys for biomedical applications. J. Mech. Behav. Biomed. Mater. 2017, 65, 866–871. [Google Scholar] [CrossRef] [PubMed]

- Ehtemam-Haghighi, S.; Prashanth, K.G.; Attar, H.; Chaubey, A.K.; Cao, G.H.; Zhang, L.C. Evaluation of mechanical and wear properties of TixNb7Fe alloys designed for biomedical applications. Mater. Des. 2016, 111, 592–599. [Google Scholar] [CrossRef]

- Okazaki, K.; Conrad, H. Grain size distribution in recrystallized alpha-titanium. Trans. Jpn. Inst. Met. 1972, 13, 198–204. [Google Scholar] [CrossRef]

- Sarkar, S.; Moreau, A.; Militzer, M.; Poole, W.J. Evolution of austenite recrystallization and grain growth using laser ultrasonics. Metall. Mater. Trans. A 2008, 39, 897–907. [Google Scholar] [CrossRef]

- Du, H.; Turner, J.A. Ultrasonic attenuation in pearlitic steel. Ultrasonics 2014, 54, 882–887. [Google Scholar] [CrossRef] [PubMed]

- Krüger, S.; Lamouche, G.; Monchalin, J.P.; Kolarik, R.; Jeskey, G.; Choquet, M. On-line monitoring of wall thickness and austenite grain size on a seamless tubing production line at the timken company. Iron Steel Technol. 2005, 2, 1–44. [Google Scholar]

- Zhang, C.; Li, X.; Song, Y.; Han, X.; Han, J. Evaluating the grain size in curved components using the ultrasonic attenuation method with diffraction correction. NDT & E Int. 2016, 84, 20–26. [Google Scholar] [CrossRef]

- Margetan, F.J.; Yu, L.; Thompson, R.B. Computation of Grain-Noise Scattering Coefficients for Ultrasonic Pitch/Catch Inspections of Metals. AIP Conf. Proc. 2005, 760, 1300–1307. [Google Scholar]

| Annealed Temperature/Holding Time | Data Obtained by OIM Analysis | Best-fit Log-normal Distributions | ||||||

|---|---|---|---|---|---|---|---|---|

| Fraction of α-phase | (μm) | Distribution Width | Grain Sampled | (μm) | RMSE (10−2) | |||

| 800 °C/0.5 h | 1.000 | 26 | 9.3 | 1668 | 0.42 | −10.24 | 29 | 1.44 |

| 800 °C/1.0 h | 0.999 | 33 | 12.5 | 1050 | 0.50 | −10.54 | 40 | 1.34 |

| 800 °C/2.0 h | 0.999 | 39 | 14 | 1154 | 0.46 | −10.27 | 39 | 1.51 |

| 800 °C/4.0 h | 0.992 | 37 | 12.3 | 1150 | 0.43 | −10.25 | 39 | 1.40 |

| 800 °C/8.0 h | 0.987 | 49 | 10.7 | 916 | 0.48 | −9.95 | 53 | 2.04 |

| Samples | (μm) | a (10−3 dB/mm) | b* (10−15 dB·Sn/mm) | n | R-square | RMSE (10−2 dB/mm) |

|---|---|---|---|---|---|---|

| 0.5 h | 26 | 1.60 | 0.015 | 2.20 | 0.9932 | 0.44 |

| 1.0 h | 33 | 0.59 | 2.38 | 1.90 | 0.9996 | 0.14 |

| 2.0 h | 39 | 1.08 | 1.86 | 1.93 | 0.9992 | 0.18 |

| 4.0 h | 37 | 1.53 | 0.13 | 2.09 | 0.9964 | 0.41 |

| 8.0 h | 49 | 1.59 | 7.07 | 1.86 | 0.9991 | 0.27 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bai, X.; Zhao, Y.; Ma, J.; Liu, Y.; Wang, Q. Grain-Size Distribution Effects on the Attenuation of Laser-Generated Ultrasound in α-Titanium Alloy. Materials 2019, 12, 102. https://doi.org/10.3390/ma12010102

Bai X, Zhao Y, Ma J, Liu Y, Wang Q. Grain-Size Distribution Effects on the Attenuation of Laser-Generated Ultrasound in α-Titanium Alloy. Materials. 2019; 12(1):102. https://doi.org/10.3390/ma12010102

Chicago/Turabian StyleBai, Xue, Yang Zhao, Jian Ma, Yunxi Liu, and Qiwu Wang. 2019. "Grain-Size Distribution Effects on the Attenuation of Laser-Generated Ultrasound in α-Titanium Alloy" Materials 12, no. 1: 102. https://doi.org/10.3390/ma12010102

APA StyleBai, X., Zhao, Y., Ma, J., Liu, Y., & Wang, Q. (2019). Grain-Size Distribution Effects on the Attenuation of Laser-Generated Ultrasound in α-Titanium Alloy. Materials, 12(1), 102. https://doi.org/10.3390/ma12010102