Abstract

The gelcasting method is usually employed to fabricate relatively dense ceramics. In this work, however, porous Al2O3 ceramics with submicron-sized pores were fabricated using the water-based gelcasting method by keeping the Al2O3 content at low levels. By controlling the water content in the ceramic slurries and the sintering temperature of the green samples, the volume fractions and the size characteristics of the pores in the porous Al2O3 can be readily obtained. For the porous Al2O3 ceramics prepared with 30 vol.% Al2O3 content in the slurries, their open porosities were from 38.3% to 47.2%, while their median pore sizes varied from 299.8 nm to 371.9 nm. When there was more Al2O3 content in the slurries (40 vol.% Al2O3), the porous Al2O3 ceramics had open porosities from 37.0% to 46.5%, and median pore sizes from 355.4 nm to 363.1 nm. It was found that a higher sintering temperature and Al2O3 content in the slurries increased the mechanical strength of the porous Al2O3 ceramics.

1. Introduction

Porous materials (including ceramic, metallic and polymeric types) are being developed and employed in different fields [1,2,3,4,5,6,7,8,9,10,11,12,13,14]. Among these types of porous materials, many researchers are investigating porous ceramics [1,2,3,4,5,6,7,8,9]. To date, many methods have been developed to prepare porous ceramics. Although the partial sintering of green bodies can result in porous ceramics, their properties are not usually desirable. In general, there are three types of processing techniques [15] that have been employed to fabricate porous ceramics: replica, sacrificial template, and direct foaming.

One of the most important methods for the replica technique is the freeze-casting method [16], in which ice crystals grow in a ceramic slurry to occupy spaces inside the ceramic body. During the freeze-drying process, these ice crystals are directly vaporized by vacuum sublimation and leave pores inside the ceramic green body. The freeze-casting technique is widely used to fabricate different types of porous ceramics [17,18,19,20,21,22,23,24,25,26,27]. However, the freeze-casting process, especially the freeze-drying stage, typically takes quite a long time and consumes much more electrical power. In addition, ice crystals usually grow into dendrites, which make the pore surfaces rough, and the porous ceramics often exhibit anisotropic properties.

Herein, a water-based gelcasting route is presented for fabricating porous Al2O3 ceramics with submicron pores, which could be used for filtration and other purposes. One of the advantages of the gelcasting method is that ceramics with complicated shapes can be readily fabricated [28,29]. In this method, high solid content in the ceramic slurries, or low water content, is usually needed to obtain relatively dense ceramics [28,29]. The purpose of this work, however, is to prepare porous ceramics, rather than dense ceramics. Hence, in this work, the Al2O3 solid content is maintained at a relatively lower level, while the water content is kept at a relatively higher level in the ceramic slurries. Instead of freezing the water in the ceramic slurries into ice crystals, as in the freeze casting method [16], it is evaporated during the drying stage, and pores are retained in the green body. This allows porous Al2O3 ceramics with submicron pores to be successfully fabricated. It is noted that fabrication of porous ceramics with submicron pores using the gelcasting method has scarcely been reported in the literature.

2. Experimental

2.1. Material Preparation

Alpha Al2O3 powders (99.9% purity, grain size about 1 μm on average, Jiyuan Brother Materials Co. Ltd., Henan, China) were used in this study. The chemicals and fabrication method can be referred to in our previous work [30]. For the fabrication of porous ceramics in the present work, the Al2O3 content in the slurries was kept relatively low, at about 30–40 vol.%. In our previous work [30], however, the Al2O3 content in the slurries was about 55 vol.%, which is much higher than in the present work.

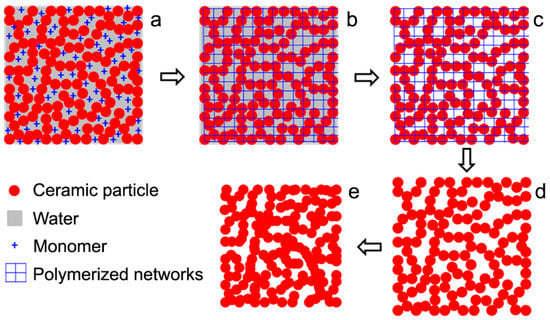

Figure 1 illustrates the processing steps for fabricating porous Al2O3 ceramics in this work. Ball-milled Al2O3 suspensions were poured into a metal mold (Figure 1a), and monomers were then polymerized to form crosslinked networks (Figure 1b) at 60 °C, for about 15 min. Then, the wet green bodies were dried at 70–110 °C and pores were retained (Figure 1c). The polymers within the dried green bodies were burnt out at 600 °C in air for 2 h. This process is called “degreasing” (Figure 1d). These samples were then sintered in air at 1300 °C, 1350 °C and 1400 °C for 2 h to obtain porous Al2O3 ceramics (Figure 1e).

Figure 1.

Fabrication steps of porous Al2O3 ceramics by gelcasting, (a) Al2O3 suspension; (b) polymerization of monomers; (c) drying; (d) burning out of polymers; and (e) sintering.

2.2. Material Characterization

The Archimedes method was used to measure the bulk densities of the porous Al2O3 ceramics, and their flexural strength was measured with an electronic universal testing machine (Sans Materials Testing Co. Ltd., Shanghai, China) under a three-point bending setup with a span length of 30 mm and a crosshead speed of 0.5 mm/min. The size of the sample was 3 mm × 4 mm × 36 mm. For the compressive strength test, the sample size was 5 mm in diameter and 10 mm in height, and it was measured with the same instrument and the same crosshead speed. The porosities and pore sizes of the Al2O3 porous ceramics were measured using the mercury porosimetry analysis method (AutoPore IV 9500, Micromeritics, Norcross, GA, USA).

A field emission scanning electron microscope (FESEM, Hitachi S4800, Tokyo, Japan) was used to investigate the microstructural characteristics of the porous Al2O3 ceramics. The Al2O3 particle size was analyzed using an image analysis software system (ImageJ, National Institutes of Health, Bethesda, MD, USA).

3. Results and Discussion

3.1. Microstructural Characteristics

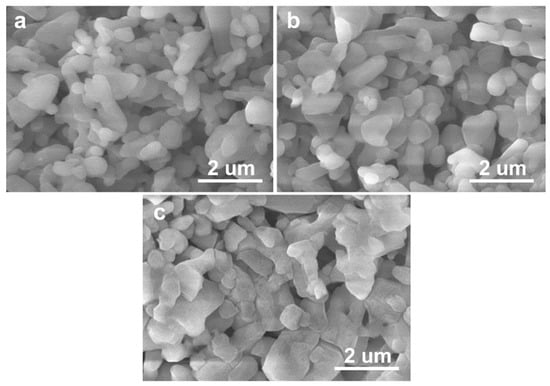

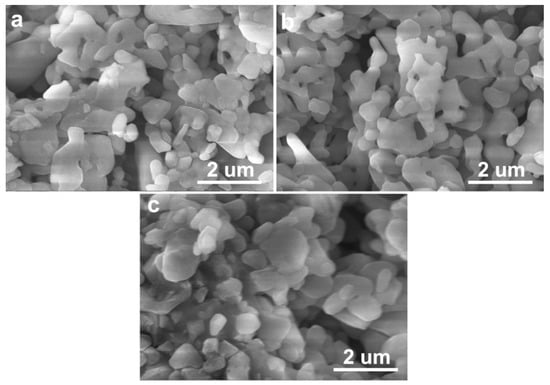

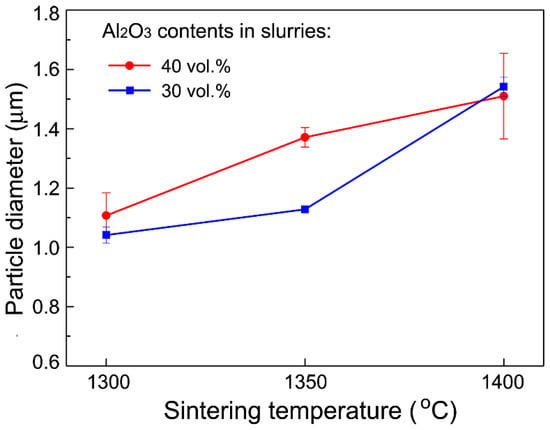

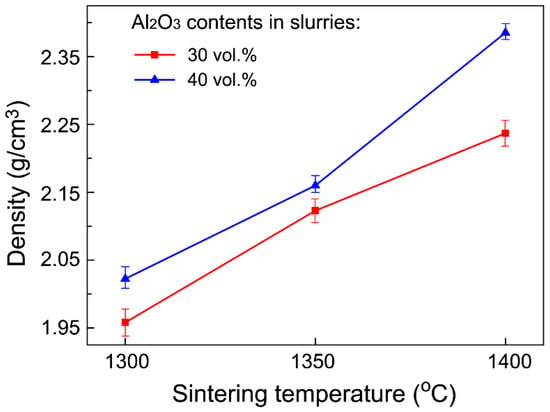

Figure 2 and Figure 3 show the microstructural morphologies of the porous Al2O3 ceramics, which were prepared with the Al2O3 content in the ceramic slurries with 30 vol.% (Figure 2) and 40 vol.% (Figure 3), respectively. The pore structures can be readily seen in Figure 2 and Figure 3, and the Al2O3 particles can also be clearly identified. As shown in Figure 4 and Figure 5, the Al2O3 particle size and the density of the porous Al2O3 ceramics steadily increased with the sintering temperature. This is generally expected for ceramics [31]. For the porous Al2O3 ceramics prepared with an Al2O3 content of 30 vol.% in the slurries, the particle size and density increased from about 1.03 μm and 1.96 g/cm3 for sintering at 1300 °C, to 1.52 μm and 2.24 g/cm3 for sintering at 1400 °C, respectively. For the porous Al2O3 ceramics prepared with Al2O3 content at 40 vol.% in the slurries, the particle size and the density increased from about 1.10 μm and 2.02 g/cm3 for sintering at 1300 °C, to 1.49 μm and 2.38 g/cm3 for sintering at 1400 °C, respectively.

Figure 2.

FESEM images of porous Al2O3 ceramics sintered at 1300 °C (a); 1350 °C (b) and 1400 °C (c), with the Al2O3 content at 30 vol.% in the ceramic slurries.

Figure 3.

FESEM images of porous Al2O3 ceramics sintered at 1300 °C (a); 1350 °C (b) and 1400 °C (c), with the Al2O3 content at 40 vol.% in the ceramic slurries.

Figure 4.

Variation of the particle diameter of porous Al2O3 ceramics with sintering temperature.

Figure 5.

Variation of density of porous Al2O3 ceramics with sintering temperature.

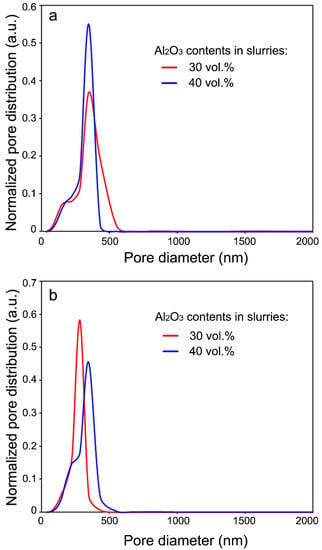

Table 1 and Table 2 list the porosities and median pore diameters of the porous Al2O3 ceramics prepared with the Al2O3 contents in the ceramic slurries at 30 vol.% (Table 1) and 40 vol.% (Table 2), respectively. Figure 6 shows the pore size distribution functions of the porous Al2O3 ceramics sintered at 1300 °C (Figure 6a) and 1400 °C (Figure 6b). It can be seen from Table 1 and Table 2 that the porosity decreased with the sintering temperature. The closed porosities of the porous Al2O3 ceramics prepared with 40 vol.% Al2O3 content in the slurries were generally smaller than the samples prepared with 30 vol.% Al2O3 content in the slurries. In both of the two series of porous Al2O3 ceramics, the closed porosities were much smaller than the open porosities. This suggests that most of the pores in these samples were open pores [27]. This will be beneficial for filtration applications [1]. For the porous Al2O3 ceramics prepared with 30 vol.% Al2O3 content in the slurries, the median pore diameter decreased quickly from about 371.9 nm for sintering at 1300 °C, to about 299.8 nm for sintering at 1400 °C (Table 1). For the porous Al2O3 ceramics prepared with 40 vol.% Al2O3 content in the slurries, however, the pore diameter only slightly decreased (Table 2). The median pore diameter decreased from about 363.1 nm for sintering at 1300 °C, to about 355.4 nm for sintering at 1400 °C (Table 2). In fact, these results are in good agreement with the microstructural morphologies shown in Figure 2c and Figure 3c. It can be noted that the pore size in Figure 3c of the 1400 °C-sintered porous Al2O3 ceramics prepared with 40 vol.% Al2O3 content in the slurries was larger than that in Figure 2c of the 1400 °C-sintered porous Al2O3 ceramics prepared with 30 vol.% Al2O3 content in the slurries.

Table 1.

Porosities and median pore diameters of porous Al2O3 ceramics (30 vol.% Al2O3 in the slurries).

Table 2.

Porosities and median pore diameters of porous Al2O3 ceramics (40 vol.% Al2O3 in the slurries).

Figure 6.

Normalized pore size distribution of porous Al2O3 ceramics for the sintering temperatures of 1300 °C (a) and 1400 °C (b).

3.2. Mechanical Properties

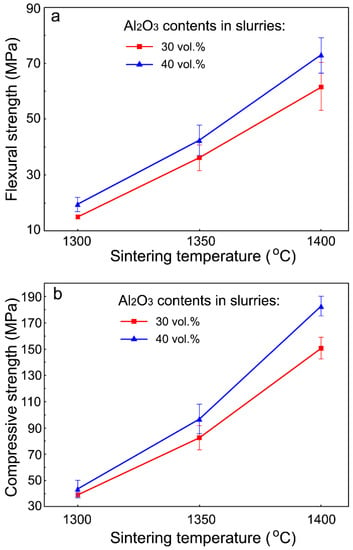

The flexural and compressive strength of the porous Al2O3 ceramics are shown in Figure 7. Figure 7a shows the dependence of the flexural strength of the porous Al2O3 ceramics on the sintering temperature. The flexural strength increased with the increasing sintering temperature. For the porous Al2O3 ceramics prepared with Al2O3 content at 30 vol.% in the slurries, their flexural strength increased from 15.0 MPa when sintered at 1300 °C, to 36.2 MPa and 61.5 MPa when sintered at 1350 °C and 1400 °C, respectively. For the porous Al2O3 ceramics prepared with Al2O3 content at 40 vol.% in the slurries, their flexural strength increased from 19.6 MPa when sintered at 1300 °C, to 42.5 MPa and 73.1 MPa when sintered at 1350 °C and 1400 °C, respectively. Compared with our previous work on gelcasted Al2O3 ceramics [30], in which 55 vol.% Al2O3 content was used in the slurries, the porous Al2O3 ceramics of the present work had smaller flexural strength.

Figure 7.

Variation of the flexural strength (a) and compressive strength (b) of porous Al2O3 ceramics with sintering temperature.

As shown in Figure 7a, in general, the porous Al2O3 ceramics prepared with 40 vol.% Al2O3 content in the slurries exhibited higher flexural strength than those prepared with 30 vol.% Al2O3 content in the slurries for all three sintering temperatures. Furthermore, the difference in their flexural strength became larger at the higher sintering temperature of 1400 °C (Figure 7a). This can be attributed to the larger total porosity of the porous Al2O3 ceramics prepared with 30 vol.% Al2O3 content in the slurries than those with 40 vol.% Al2O3 content in the slurries (Table 1 and Table 2).

The compressive strength of the porous Al2O3 ceramics increased with the increasing sintering temperature (Figure 7b). This variation in behavior is similar to the flexural strength as shown in Figure 7a. For the porous Al2O3 ceramics prepared with Al2O3 content at 30 vol.% in the slurries, their compressive strength increased from 39.1 MPa when sintered at 1300 °C, to 82.6 MPa and 150.6 MPa when sintered at 1350 °C and 1400 °C, respectively. For the porous Al2O3 ceramics prepared with Al2O3 content at 40 vol.% in the slurries, their compressive strength increased from 43.6 MPa when sintered at 1300 °C, to 96.9 MPa and 182.8 MPa when sintered at 1350 °C and 1400 °C, respectively. Therefore, these porous Al2O3 ceramics are mechanically strong enough for practical applications. The dependence of their compressive strength on the sintering temperature (Figure 7b) is in agreement with the results of the Al2O3/mullite composite porous ceramics reported by others [32]. However, the compressive strength of the porous Al2O3 ceramics of this work was consistently higher than the Al2O3/mullite composite porous ceramics [32] and the porous Al2O3 ceramics prepared using carbon black as a pore former [33].

4. Conclusions

Porous Al2O3 ceramics with submicron pores were fabricated using the water-based gelcasting method. The open porosities and median pore sizes of the porous Al2O3 ceramics with 30 vol.% Al2O3 content in the slurries were 47.2% and 371.9 nm when sintered at 1300 °C, 42.5% and 330.6 nm when sintered at 1350 °C, and 38.3% and 299.8 nm when sintered at 1400 °C. The open porosities and median pore sizes of the porous Al2O3 ceramics with 40 vol.% Al2O3 content in the slurries were 46.5% and 363.1 nm when sintered at 1300 °C, 41.7% and 358.5 nm when sintered at 1350 °C, and 37.0% and 355.4 nm when sintered at 1400 °C. The porous Al2O3 ceramics exhibited high mechanical strength, which increased with both increasing sintering temperature and increasing Al2O3 content in the slurries.

Author Contributions

Conceptualization, N.C. and X.Q.; Methodology, X.Q.; Software, Z.Y.; Validation, Z.Y., N.C. and X.Q.; Formal Analysis, Z.Y., N.C. and X.Q.; Investigation, Z.Y.; Resources, N.C. and X.Q.; Data Curation, Z.Y.; Writing-Original Draft Preparation, Z.Y.; Writing-Review & Editing, N.C. and X.Q.; Visualization, Z.Y.; Supervision, N.C. and X.Q.; Project Administration, N.C.; Funding Acquisition, N.C. and X.Q.

Funding

This research was funded by the National Natural Science Foundation of China (grant numbers: 51362020, 11674231).

Acknowledgments

The authors are grateful to Wang and Hu for their assistance in the measurements of pore characteristics and mechanical properties of the samples.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Hammel, E.C.; Ighodaro, O.L.-R.; Okoli, O.I. Processing and properties of advanced porous ceramics: An application based review. Ceram. Int. 2014, 40, 15351–15370. [Google Scholar]

- Li, D.; Li, M. Porous Y2SiO5 Ceramic with low thermal conductivity. J. Mater. Sci. Technol. 2012, 28, 799–802. [Google Scholar] [CrossRef]

- Sobsey, M.D.; Stauber, C.E.; Casanova, L.M.; Brown, J.M.; Elliott, M.A. Point of use household drinking water filtration: A practical, effective solution for providing sustained access to safe drinking water in the developing world. Environ. Sci. Technol. 2008, 42, 4261–4267. [Google Scholar] [CrossRef] [PubMed]

- Heidenreich, S. Hot gas filtration—A review. Fuel 2013, 104, 83–94. [Google Scholar] [CrossRef]

- Sundaram, S.; Colombo, P.; Katoh, Y. Selected emerging opportunities for ceramics in energy, environment, and transportation. Int. J. Appl. Ceram. Technol. 2013, 10, 731–739. [Google Scholar] [CrossRef]

- Zhou, M.; Shu, D.; Li, K.; Zhang, W.Y.; Ni, H.J.; Sun, B.D.; Wang, J. Deep filtration of molten aluminum using ceramic foam filters and ceramic particles with active coatings. Metall. Mater. Trans. A 2003, 34, 1183–1191. [Google Scholar] [CrossRef]

- Olson, R.A.; Martins, L.C.B. Cellular ceramics in metal filtration. Adv. Eng. Mater. 2005, 7, 187–192. [Google Scholar] [CrossRef]

- Deville, S.; Saiz, E.; Tomsia, A.P. Freeze casting of hydroxyapatite scaffolds for bone tissue engineering. Biomaterials 2006, 27, 5480–5489. [Google Scholar] [CrossRef] [PubMed]

- Moene, R.; Makkee, M.; Moulijn, J.A. High surface area silicon carbide as catalyst support characterization and stability. Appl. Catal. A Gen. 1998, 167, 321–330. [Google Scholar] [CrossRef]

- Linul, E.; Movahedi, N.; Marsavina, L. On the lateral compressive behavior of empty and ex-situ Aluminum foam-filled tubes at high temperature. Materials 2018, 11, 554. [Google Scholar] [CrossRef] [PubMed]

- Linul, E.; Movahedi, N.; Marsavina, L. The temperature and anisotropy effect on compressive behavior of cylindrical closed-cell aluminum-alloy foams. J. Alloy. Compd. 2018, 740, 1172–1179. [Google Scholar] [CrossRef]

- Chang, S.; Li, L.; Lu, L.; Fuh, J.Y.H. Selective laser sintering of porous silica enabled by carbon additive. Materials 2017, 10, 1313. [Google Scholar] [CrossRef] [PubMed]

- Tanaka, M.; Haniu, H.; Kamanaka, T.; Takizawa, T.; Sobajima, A.; Yoshida, K.; Aoki, K.; Okamoto, M.; Kato, H.; Saito, N. Physico-chemical, in vitro, and in vivo evaluation of a 3D unidirectional porous hydroxyapatite scaffold for bone regeneration. Materials 2017, 10, 33. [Google Scholar] [CrossRef] [PubMed]

- Lee, H.-P.; Lin, D.-J.; Yeh, M.-L. Phenolic modified ceramic coating on biodegradable Mg alloy: The improved corrosion resistance and osteoblast-like cell activity. Materials 2017, 10, 696. [Google Scholar] [CrossRef] [PubMed]

- Studart, A.R.; Gonzenbach, U.T.; Tervoort, E.; Gauckler, L.J. Processing routes to macroporous ceramics: A review. J. Am. Ceram. Soc. 2006, 89, 1771–1789. [Google Scholar] [CrossRef]

- Liu, R.; Xu, T.; Wang, C.-A. A review of fabrication strategies and applications of porous ceramics prepared by freeze-casting method. Ceram. Int. 2016, 42, 2907–2925. [Google Scholar] [CrossRef]

- Sofie, S.W.; Dogan, F. Freeze casting of aqueous alumina slurries with glycerol. J. Am. Ceram. Soc. 2001, 84, 1459–1464. [Google Scholar] [CrossRef]

- Fukasawa, T.; Deng, Z.-Y.; Ando, M.; Ohji, T.; Goto, Y. Pore structure of porous ceramics synthesized from water-based slurry by freeze-dry process. J. Mater. Sci. 2001, 36, 2523–2527. [Google Scholar] [CrossRef]

- Araki, K.; Halloran, J.W. Porous ceramic bodies with interconnected pore channels by a novel freeze casting technique. J. Am. Ceram. Soc. 2005, 88, 1108–1114. [Google Scholar] [CrossRef]

- Koh, Y.H.; Sun, J.J.; Kim, H.E. Freeze casting of porous Ni–YSZ cermets. Mater. Lett. 2007, 61, 1283–1287. [Google Scholar] [CrossRef]

- Chen, R.; Wang, C.-A.; Huang, Y.; Ma, L.; Lin, W. Ceramics with special porous structures fabricated by freeze-gelcasting: Using tert-butyl alcohol as a template. J. Am. Ceram. Soc. 2007, 90, 3478–3484. [Google Scholar] [CrossRef]

- Deville, S.; Saiz, E.; Nalla, R.K.; Tomsia, A.P. Freezing as a path to build complex composites. Science 2006, 311, 515–518. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Fidelis, C.L.; Serva, A.L.T.; Wilhelm, M.; Rezwan, K. Water-based freeze casting: Adjusting hydrophobic polymethylsiloxane for obtaining hierarchically ordered porous SiOC. J. Am. Ceram. Soc. 2017, 100, 1907–1918. [Google Scholar] [CrossRef]

- Fukushima, M.; Yoshizawa, Y.-I. Fabrication and morphology control of highly porous mullite thermal insulators prepared by gelation freezing route. J. Eur. Ceram. Soc. 2016, 36, 2947–2953. [Google Scholar] [CrossRef]

- Tang, Y.; Qiu, S.; Wu, C.; Miao, Q.; Zhao, K. Freeze cast fabrication of porous ceramics using tert-butyl alcohol–water crystals as template. J. Eur. Ceram. Soc. 2016, 36, 1513–1518. [Google Scholar] [CrossRef]

- Xu, T.; Wang, C.-A. Effect of two-step sintering on micro-honeycomb BaTiO3 ceramics prepared by freeze-casting process. J. Eur. Ceram. Soc. 2016, 36, 2647–2652. [Google Scholar] [CrossRef]

- Liu, X.; Xue, W.; Shi, C.; Sun, J. Fully interconnected porous Al2O3 scaffolds prepared by a fast cooling freeze casting method. Ceram. Int. 2015, 41, 11922–11926. [Google Scholar] [CrossRef]

- Franks, G.V.; Tallon, C.; Studart, A.R.; Sesso, M.L.; Leo, S. Colloidal processing: Enabling complex shaped ceramics with unique multiscale structures. J. Am. Ceram. Soc. 2017, 100, 458–490. [Google Scholar] [CrossRef]

- Leo, S.; Tallon, C.; Stone, N.; Franks, G.V. Near-net-shaping methods for ceramic elements of (body) armor systems. J. Am. Ceram. Soc. 2014, 97, 3013–3033. [Google Scholar] [CrossRef]

- Hu, Y.; Du, G.; Chen, N. A novel approach for Al2O3/epoxy composites with high strength and thermal conductivity, Compos. Sci. Technol. 2016, 124, 36–43. [Google Scholar]

- Barsoum, M.W. Fundamentals of Ceramics; McGraw Hill: New York, NY, USA, 1997. [Google Scholar]

- Sun, Z.; Fan, J.; Hu, P.; Ding, F.; Yang, J.; Yuan, F. A novel low-temperature strategy for synthesis of alumina ceramics with uniform and interconnected pores by silica coating. J. Mater. Sci. 2017, 52, 1603–1616. [Google Scholar] [CrossRef]

- Liu, J.; Li, Y.; Li, Y.; Sang, S.; Li, S. Effects of pore structure on thermal conductivity and strength of alumina porous ceramics using carbon black as pore-forming agent. Ceram. Int. 2016, 42, 8221–8228. [Google Scholar] [CrossRef]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).