Increase in Strength and Fretting Resistance of Alloy 718 Using the Surface Modification Process

Abstract

:1. Introduction

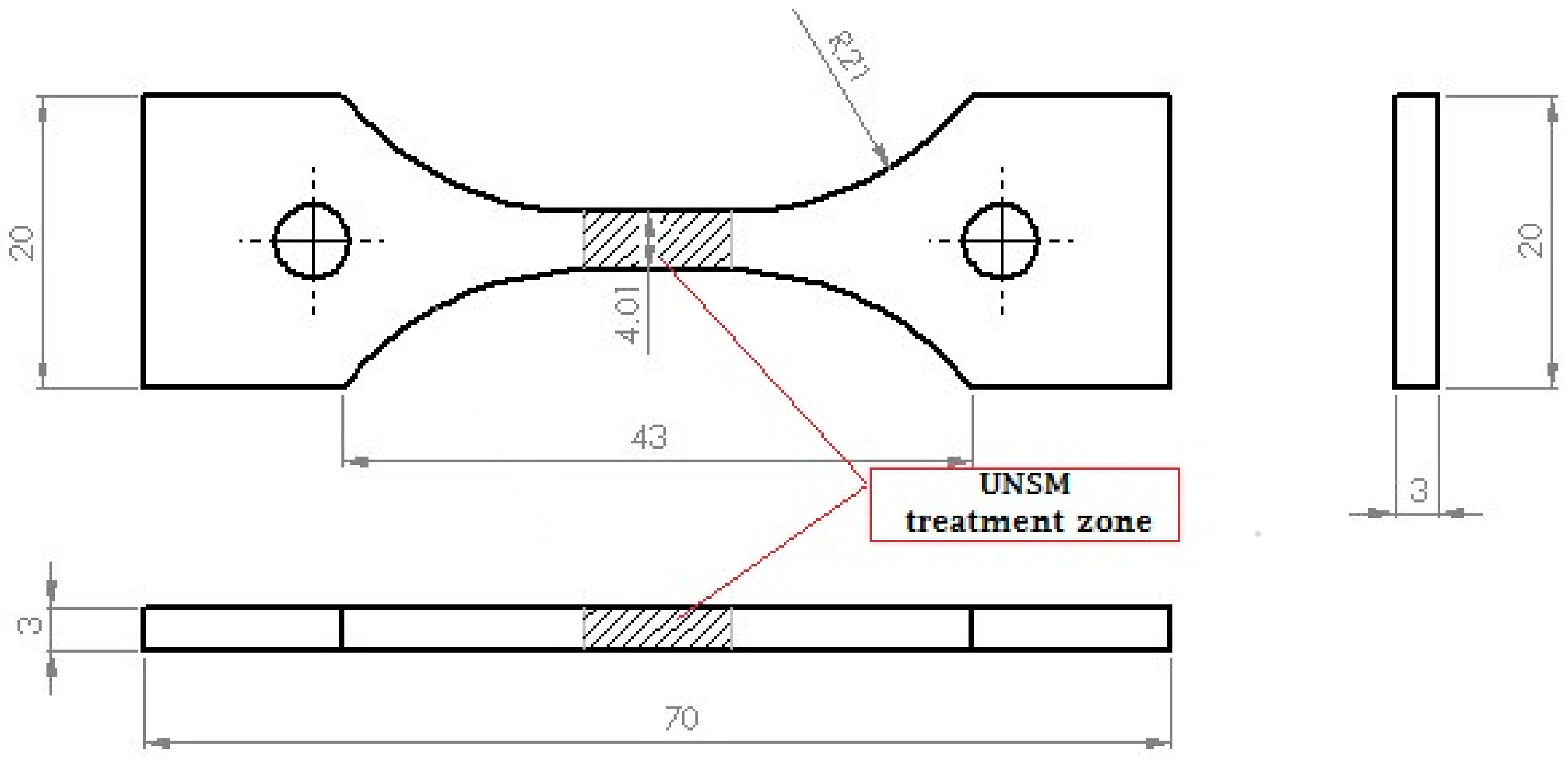

2. Materials and Methods

2.1. Material

2.2. Characterization

3. Results and Discussion

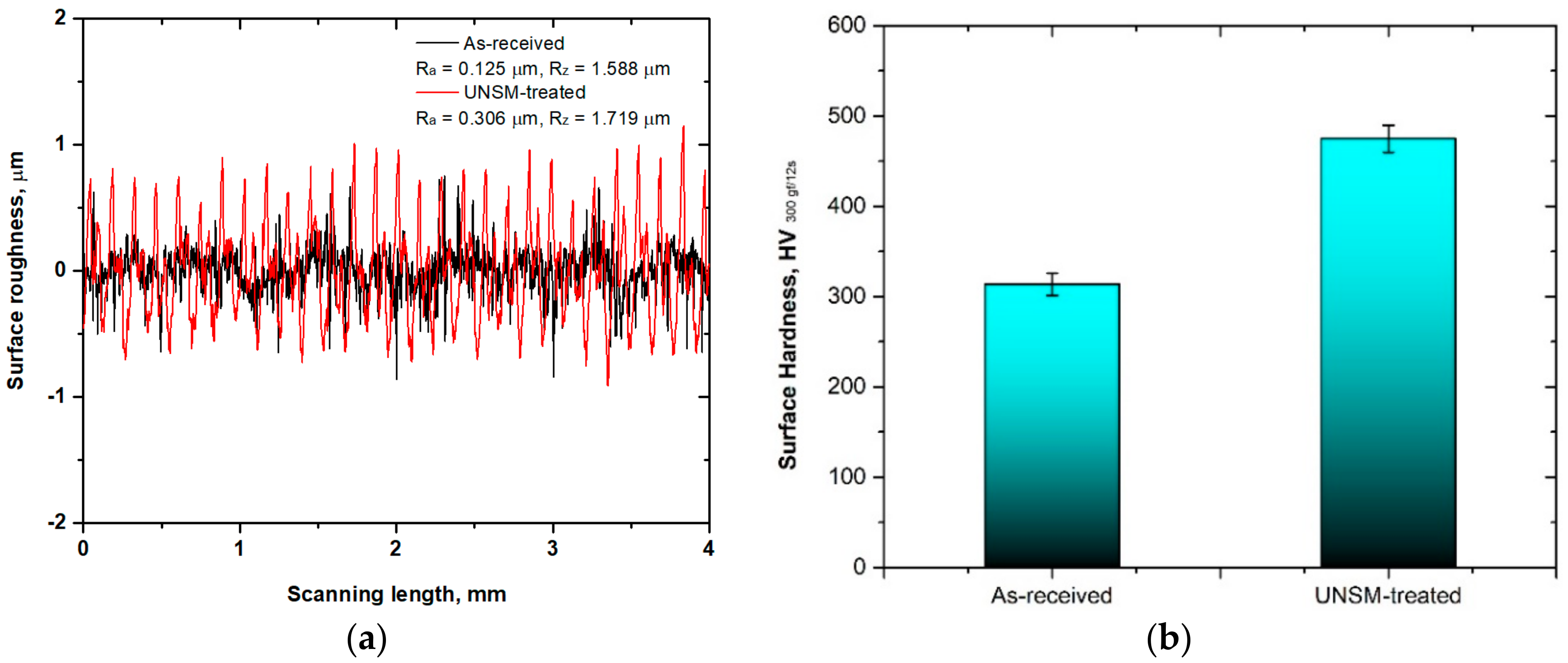

3.1. Surface Roughness and Hardness

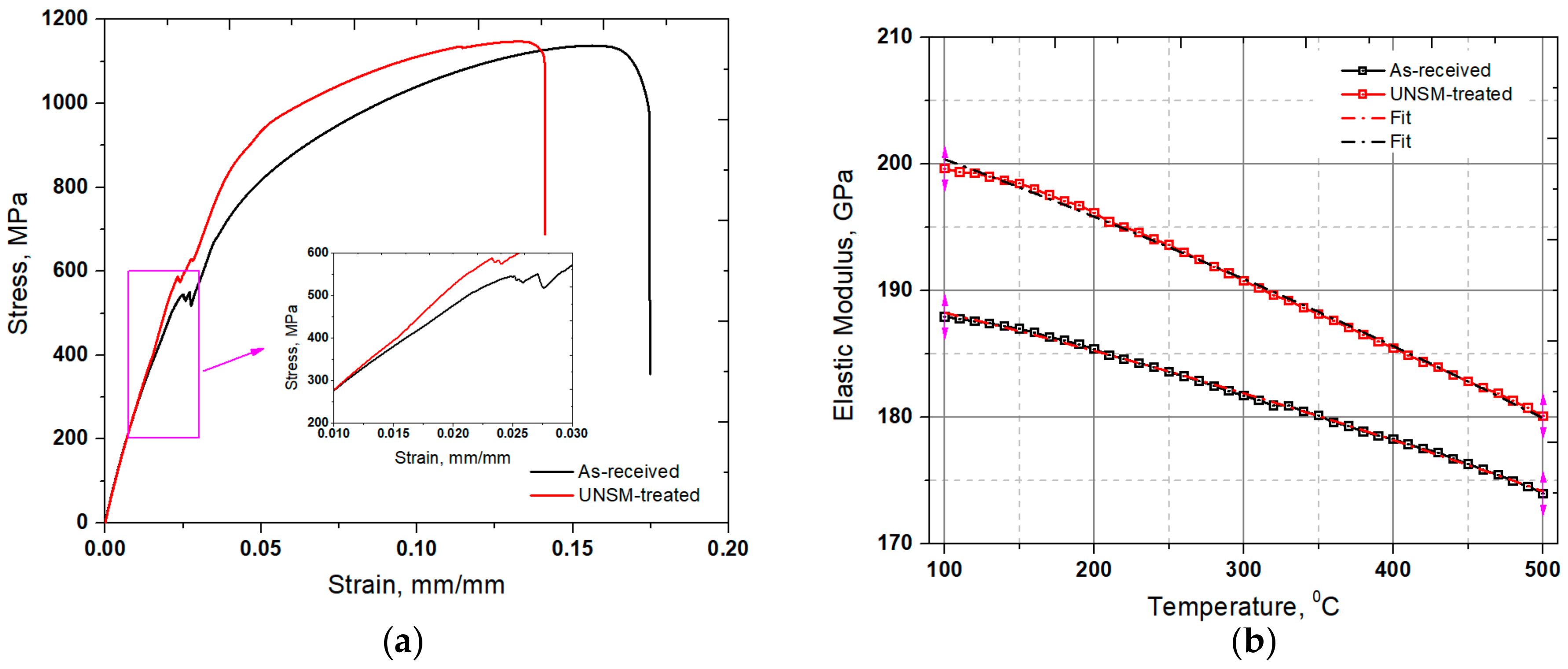

3.2. Tensile and Dynamic Elastic Modulus

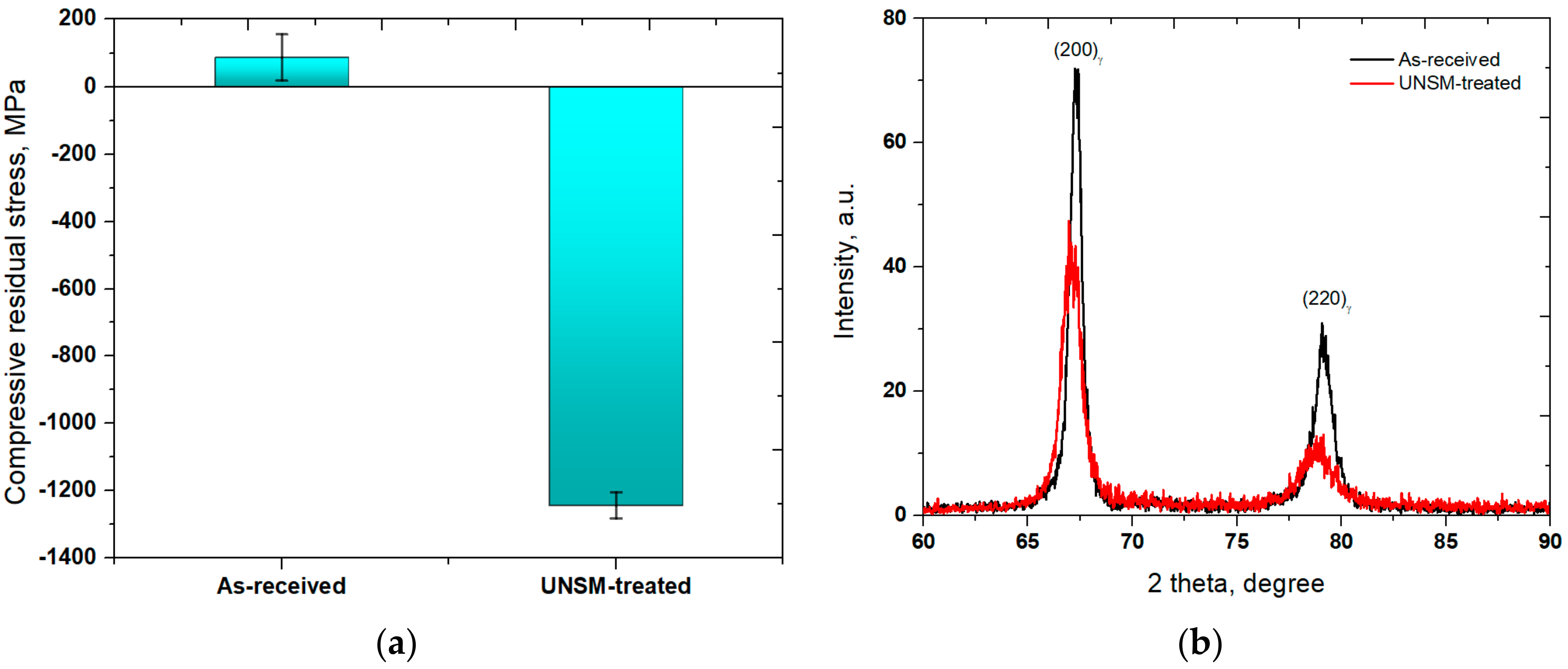

3.3. Surface Residual Stress and XRD Pattern

3.4. Cross-Sectional Observation by SEM

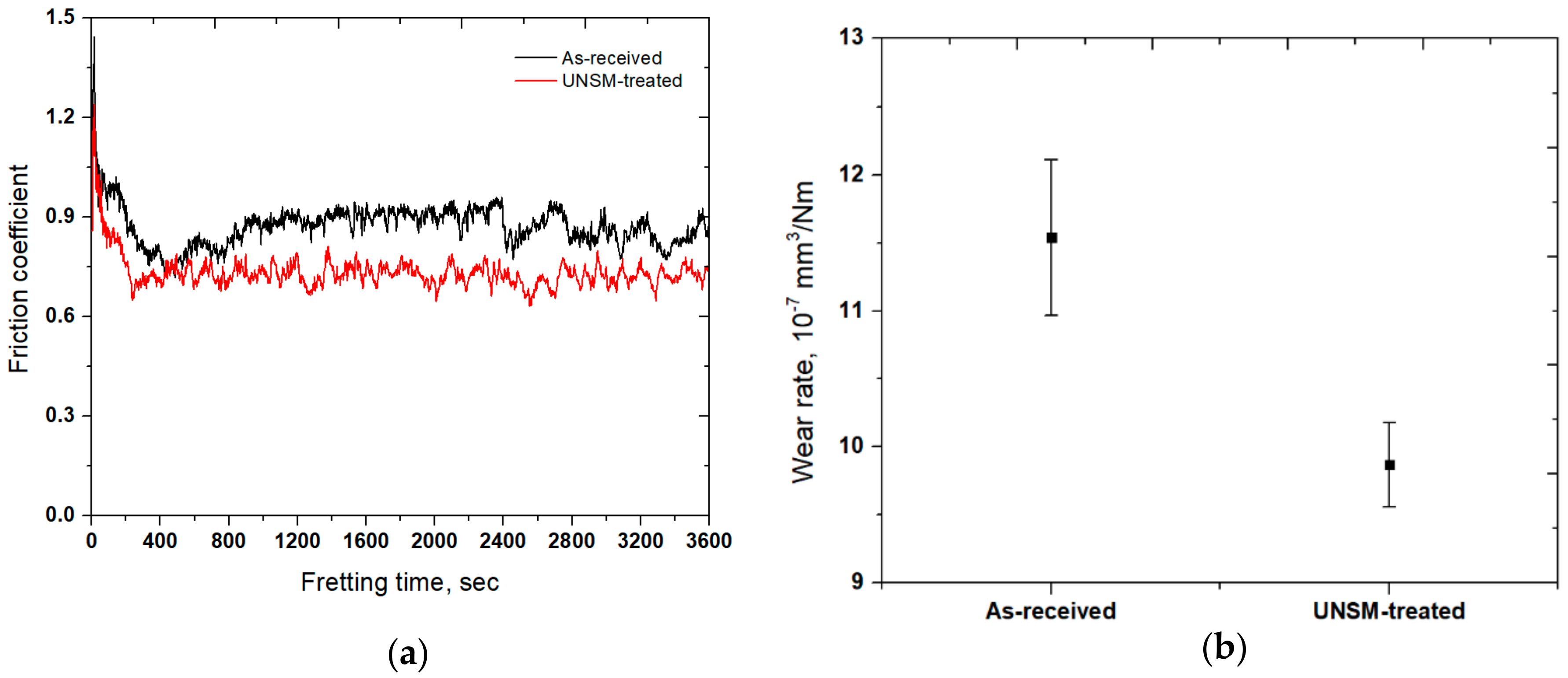

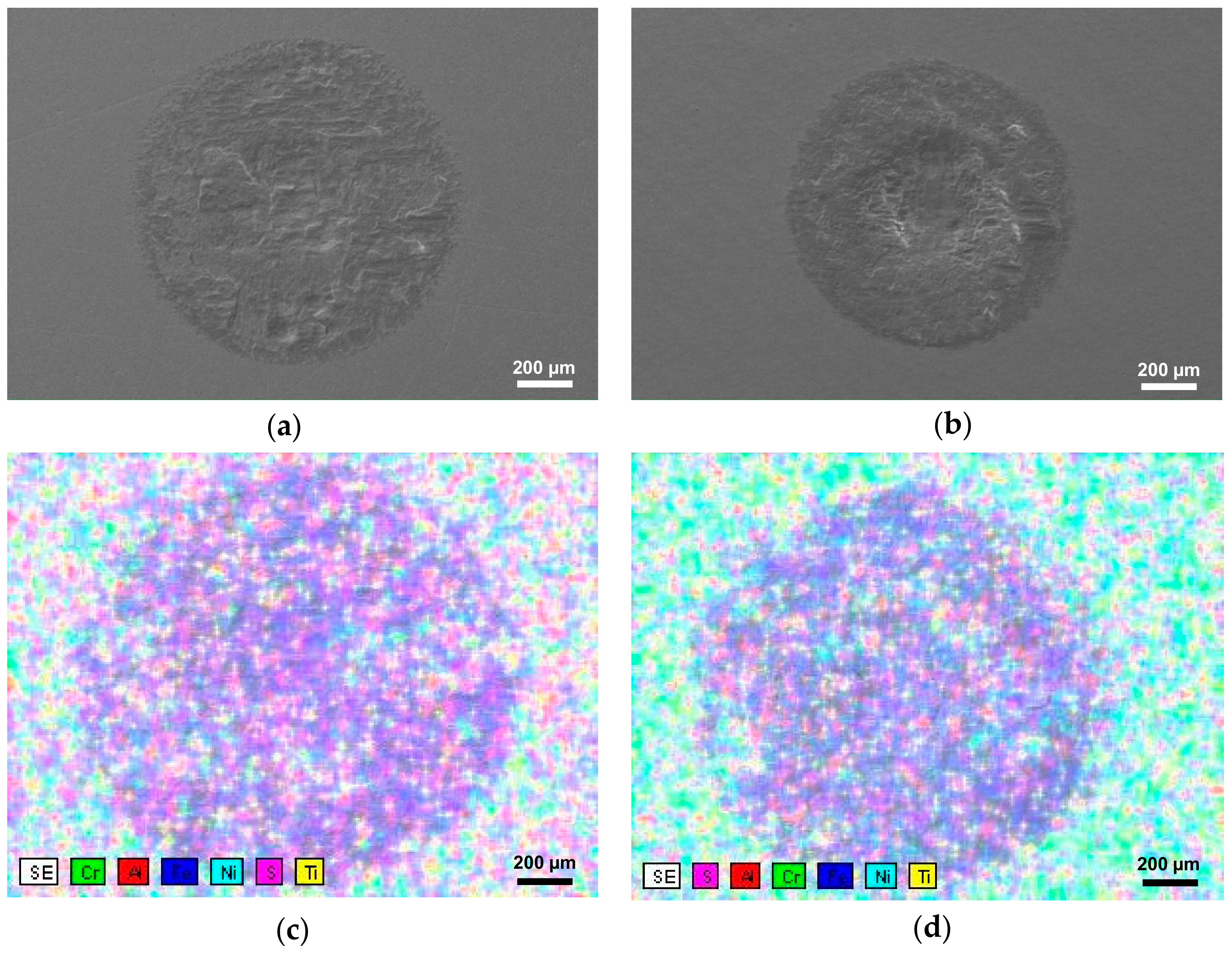

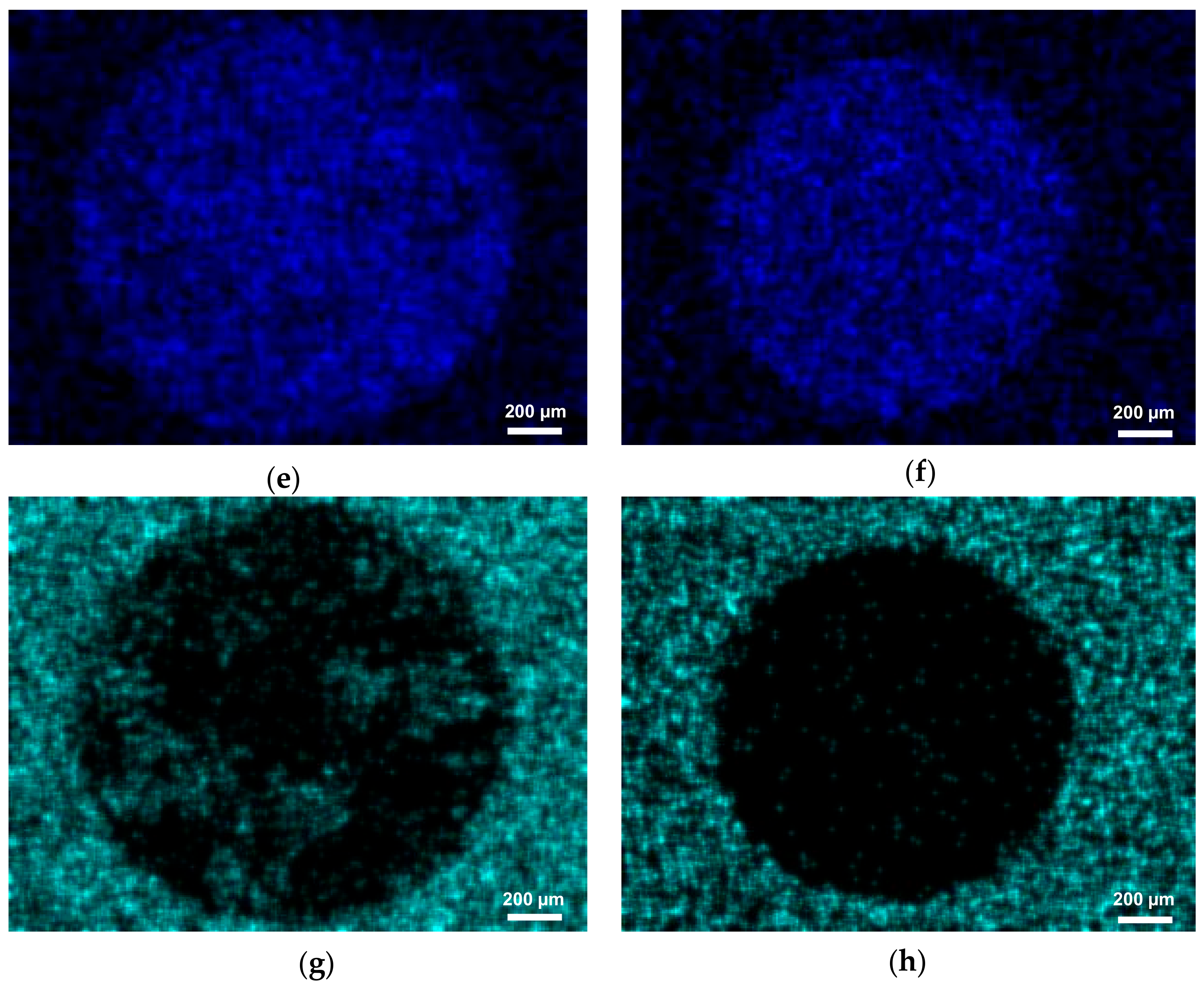

3.5. Friction Coefficient and Fretting Wear Resistance

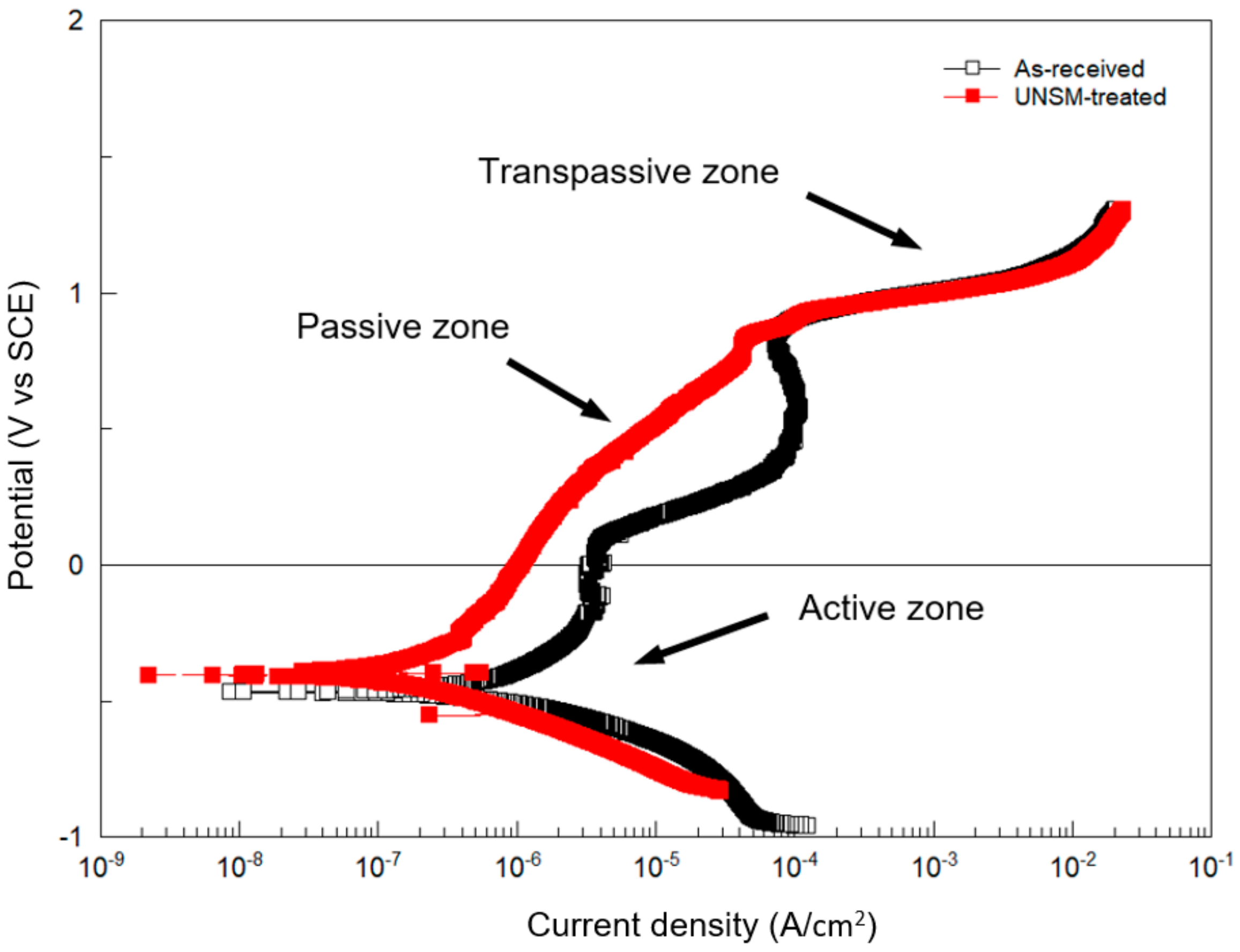

3.6. Corrosion Resistance

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Zhu, L.; Xu, Z.; Gu, Y. Effect of laser power on the microstructure and mechanical properties of heat treated Inconel 718 superalloy by laser solid forming. J. Alloys Compd. 2018, 746, 159–167. [Google Scholar] [CrossRef]

- Ott, E.A.; Groh, J.R.; Banik, A.; Dempster, I.; Gabb, T.P.; Helmink, R.; Liu, X.; Mitchell, A.; Sjoberg, G.P.; Wusatowska-Sarnek, A. Superalloy 718 and Derivatives; John Wiley & Sons, Inc.: New York, NY, USA, 2012. [Google Scholar]

- Kumar, S.A.; Raman, S.G.; Narayanan, T.S.; Gnanamoorthy, R. Fretting wear behavior of surface mechanical attrition treated alloy 718. Surf. Coat. Technol. 2012, 206, 4425–4432. [Google Scholar] [CrossRef]

- Lee, B.W.; Suh, J.J.H.; Lee, C.; Kim, T.G. Investigations on fretting fatigue in aircraft engine compressor blade. Eng. Fail. Anal. 2011, 18, 1900–1908. [Google Scholar] [CrossRef]

- Jouiad, M.; Marin, E.; Devarapalli, R.S.; Cornier, J.; Ravaux, F.; Le Gall, C.; Franchet, J.M. Microstructure and mechanical properties evolutions of alloy 718 during isothermal and thermal cycling over-aging. Mater. Des. 2016, 102, 284–296. [Google Scholar] [CrossRef]

- DuPont, J.N.; Lippold, J.C.; Kiser, S.D. Welding Metallurgy and Weldability of Nickel-Base Alloys; John Wiley & Sons, Inc.: New York, NY, USA, 2009. [Google Scholar]

- Lin, Y.C.; Deng, J.; Jiang, Y.Q.; Wen, D.X.; Liu, G. Effects of initial δ phase on hot tensile deformation behaviors and fracture characteristics of a typical Ni-based superalloy. Mater. Sci. Eng. A 2014, 598, 251–262. [Google Scholar] [CrossRef]

- Farber, B.; Small, K.A.; Allen, C.; Causton, R.J.; Nichols, A.; Simbolick, J.; Taheri, M.L. Correlation of mechanical properties to microstructure in Inconel 718 fabricated by direct metal laser sintering. Mater. Sci. Eng. A 2018, 712, 539–547. [Google Scholar] [CrossRef]

- Damodaram, R.; Raman, S.G.; Prasad Rao, K. Microstructure and mechanical properties of friction welded alloy 718. Mater. Sci. Eng. A 2013, 560, 781–786. [Google Scholar] [CrossRef]

- Mannan, S.; Pate, S.; deBarbadillo, J. Long term thermal stability of Inconel alloys 718, 706, 909, and Waspaloy at 593 °C and 704 °C. Superalloys 2000, 10, 449–458. [Google Scholar]

- Dehmas, M.; Lacaze, J.; Niang, A.; Viguier, B. TEM study of high-temperature precipitation of delta phase in Inconel 718 alloy. Adv. Mater. Sci. Eng. 2011, 2011, 940634. [Google Scholar] [CrossRef]

- Chlebus, E.; Gruber, K.; Kuznicka, B.; Kurzynowski, T. Effect of heat treatment on the microstructure and mechanical properties of Inconel 718 processed by selective laser melting. Mater. Sci. Eng. A 2015, 639, 647–655. [Google Scholar] [CrossRef]

- Popovich, V.A.; Borisov, E.V.; Popovich, A.A.; Sufiiarov, V.S.; Masaylo, D.V.; Alzina, L. Impact of heat treatment on mechanical behavior of Inconel 718 processed with tailored microstructure by selective laser melting. Mater. Des. 2017, 131, 12–22. [Google Scholar] [CrossRef]

- Raghavan, S.; Zhang, B.; Wang, P.; Sun, C.H.; Sharon Nai, M.L.; Li, T.; Wei, J. Effect of different heat treatments on the microstructure and mechanical properties in selective laser melted INCONEL 718 alloy. Mater. Manuf. Process. 2017, 32, 1588–1595. [Google Scholar] [CrossRef]

- Wang, Z.; Guan, K.; Gao, M.; Li, X.; Chen, X.; Zeng, X. The microstructure and mechanical properties of deposited-IN718 by selective laser melting. J. Alloys Compd. 2012, 513, 518–523. [Google Scholar] [CrossRef]

- Trosch, T.; Strosner, J.; Volkl, R.; Glatzel, U. Microstructure and mechanical properties of selective laser melted Inconel 718 compared to forging and casting. Mater. Lett. 2016, 164, 428–431. [Google Scholar] [CrossRef]

- Tucho, W.M.; Cuvillier, P.; Sjolyst-Kverneland, A.; Hansen, V. Microstructure and hardness studies of Inconel 718 manufactured by selective laser melting before and after solution heat treatment. Mater. Sci. Eng. A 2017, 689, 220–232. [Google Scholar] [CrossRef]

- Zheng, W.J.; Wei, X.P.; Song, Z.G.; Yong, Q.I.; Feng, H.; Xie, Q.C. Effects of carbon content on mechanical properties of Inconel 718 alloy. J. Iron Steel Res. 2015, 22, 78–83. [Google Scholar] [CrossRef]

- Liu, F.; Cheng, H.; Yu, X.; Yang, G.; Huang, C.; Lin, X.; Chen, J. Control of microstructure and mechanical properties of laser solid formed Inconel 718 superalloy by electromagnetic stirring. Opt. Laser Technol. 2018, 99, 342–350. [Google Scholar] [CrossRef]

- Chamanfar, A.; Monajati, H.; Rosenbaum, A.; Jahazi, M.; Bonakdar, A.; Morin, E. Microstructure and mechanical properties of surface and subsurface layers in broached and shot-peened Inconel-718 gas turbine disc fir-trees. Mater. Charact. 2017, 132, 53–68. [Google Scholar] [CrossRef]

- Gill, A.S.; Telang, A.; Vasudevan, V.K. Characteristics of surface layers formed on Inconel 718 by laser shock peening with and without a protective coating. J. Mater. Proc. Technol. 2015, 225, 463–472. [Google Scholar] [CrossRef]

- Standard Test Methods for Determining Average Grain Size; E112-13; ASTM International: West Conshohocken, PA, USA, 2014.

- Amanov, A.; Umarov, R. The effects of ultrasonic nanocrystal surface modification temperature on the mechanical properties and fretting wear resistance of Inconel 690 alloy. Appl. Surf. Sci. 2018, 441, 515–529. [Google Scholar] [CrossRef]

- Amanov, A.; Pyun, Y.S. Local heat treatment with and without ultrasonic nanocrystal surface modification of Ti-6AL-4V alloy: Mechanical and tribological properties. Surf. Coat. Technol. 2018, 326, 343–354. [Google Scholar] [CrossRef]

- Mbrosia Co., Ltd. Available online: http://www.mbrosia.co.kr/ (accessed on 6 August 2018.

- Anand Kumar, S.; Sundar, S.; Raman, S.G.S.; Kaul, R.; Ranganathan, K.; Bindra, K.S. Effects of laser peening on fretting wear behavior of alloy 718 fretted against two different counterbody materials. Proc. Inst. Mech. Eng. Part J. Eng. Tribol. 2017, 231, 1276–1288. [Google Scholar] [CrossRef]

- Amanov, A.; Cho, I.S.; Pyun, Y.S. Microstructural evolution and surface properties of nanostructured Cu-based alloy by ultrasonic nanocrystalline surface modification technique. Appl. Surf. Sci. 2016, 388, 185–195. [Google Scholar] [CrossRef]

- Cordero, Z.; Schuh, C.A.; Knight, B.E. Six decades of the Hall-Petch effect—A survey of grain size strengthening studies on pure metals. Int. Mater. Rev. 2016, 61, 495–512. [Google Scholar] [CrossRef]

- Gill, A.; Telang, A.; Mannava, S.R.; Qian, D.; Pyun, Y.S.; Vasudevan, V.K. Comparison of mechanisms of advanced mechanical surface treatments in nickel-based superalloy. Mater. Sci. Eng. A 2016, 576, 346–353. [Google Scholar] [CrossRef]

- Amanov, A.; Pyun, Y.S.; Kim, J.H.; Suh, C.M.; Cho, I.S.; Kim, H.D.; Wang, Q.; Khan, K. Ultrasonic fatigue performance of high temperature structural material Inconel 718 alloys at high temperature after UNSM treatment. Fatigue Fract. Eng. Mater. Struct. 2015, 38, 1266–1273. [Google Scholar] [CrossRef]

- Lu, K. Making strong nanomaterials ductile with gradients. Science 2014, 345, 1455–1456. [Google Scholar] [CrossRef] [PubMed]

- Chae, J.M.; Lee, K.O.; Amanov, A. Gradient nanostructured tantalum by thermal-mechanical ultrasonic impact energy. Materials 2018, 11, 452. [Google Scholar] [CrossRef] [PubMed]

- Kattoura, M.; Telang, A.; Mannava, S.R.; Qian, D.; Vasudevan, V.K. Effect of ultrasonic nanocrystalline surface modification on residual stress, microstructure and fatigue behavior of ATI 718Plus alloy. Mater. Sci. Eng. A 2018, 711, 364–377. [Google Scholar] [CrossRef]

- Oikawa, K.; Su, Y.H.; Tomota, Y.; Kawasaki, T.; Shinohara, T.; Kai, T.; Hiroi, K.; Zhang, S.Y.; Parker, J.D.; Sato, H.; et al. A comparative study of the crystallite size and the dislocation density of bent steel plates using Bragg-edge transmission imaging, TOF neutron diffraction and EBSD. Phys. Procedia 2017, 88, 34–41. [Google Scholar] [CrossRef]

- Callister, W.D., Jr.; Rethwisch, D.G. Materials Science and Engineering: An Introduction, 9th ed.; Wiley & Sons, Inc.: Hoboken, NJ, USA, 2014. [Google Scholar]

- Suryanarayana, C. Mechanical behavior of emerging materials. Mater. Today 2012, 15, 486–498. [Google Scholar] [CrossRef]

- Cho, I.S.; Amanov, A.; Kim, J.D. The effects of AlCrN coating, surface modification and their combination on the tribological properties of high speed steel under dry conditions. Tribol. Int. 2015, 81, 61–72. [Google Scholar] [CrossRef]

- Frankel, G.S. Fundamentals of Corrosion Kinetics. In Active Protective Coatings New Generation Coatings for Metals; Springer: Dordrecht, The Netherlands, 2016; pp. 17–32. [Google Scholar]

- Lee, H.S.; Kim, D.S.; Jung, J.S.; Pyoun, Y.S.; Shin, K.S. Influence of peening on the corrosion properties of AISI304 stainless steel. Corros. Sci. 2009, 51, 2826–2830. [Google Scholar] [CrossRef]

- Hou, X.; Qin, H.; Gao, H.; Mankoci, S.; Zhang, R.; Zhou, X.; Ren, Z.; Doll, G.L.; Martini, A.; Sahai, N.; et al. A systematic study of mechanical properties, corrosion behavior and biocompatibility of AZ31B Mg alloy after ultrasonic nanocrystal surface modification. Mater. Sci. Eng. C 2017, 78, 1061–1071. [Google Scholar] [CrossRef] [PubMed]

- Moyomoto, H. Corrosion of ultrafine grained materials by severe plastic deformation, an overview. Mater. Trans. 2016, 57, 559–572. [Google Scholar] [CrossRef]

- Ralston, K.D.; Birbilis, N. Effect of grain size on corrosion. Corrosion 2010, 66, 075005. [Google Scholar] [CrossRef]

| Tensile Strength, MPa | Yield Strength, MPa | Elastic Modulus, GPa | Shear Modulus, GPa | Poisson’s Ratio | Elongation, % |

|---|---|---|---|---|---|

| 1150 | 950 | 211 | 77.2 | 0.294 | 25 |

| Fe | Cr | C | Ti | Mn | Si | Ni | S | P | Mo | Nb | Al |

|---|---|---|---|---|---|---|---|---|---|---|---|

| 17.62 | 18.84 | 0.024 | 0.95 | 0.02 | 0.06 | 53.64 | 0.002 | 0.003 | 3.08 | 5.23 | 0.53 |

| Frequency, kHz | Amplitude, µm | Speed, mm/min | Load, N | Feed-Rate, µm | Ball Diameter, mm | Ball Material |

|---|---|---|---|---|---|---|

| 20 | 50 | 2000 | 50 | 70 | 2.38 | WC |

| Frequency, Hz | Displacement Amplitude, µm | Normal Load, N | Test Duration, min | Hertzian Contact Stress, GPa |

|---|---|---|---|---|

| 30 | 50 | 50 | 60 | 1.06 |

| Specimens | Ecorr, V | Icorr, A/cm2 | χ2 |

|---|---|---|---|

| As-received | −0.48244 | 2.2734 × 10−6 | 8.439 |

| UNSM-treated | −0.40361 | 1.1227 × 10−6 | 9.864 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Amanov, A.; Umarov, R.; Amanov, T. Increase in Strength and Fretting Resistance of Alloy 718 Using the Surface Modification Process. Materials 2018, 11, 1366. https://doi.org/10.3390/ma11081366

Amanov A, Umarov R, Amanov T. Increase in Strength and Fretting Resistance of Alloy 718 Using the Surface Modification Process. Materials. 2018; 11(8):1366. https://doi.org/10.3390/ma11081366

Chicago/Turabian StyleAmanov, Auezhan, Rakhmatjon Umarov, and Tileubay Amanov. 2018. "Increase in Strength and Fretting Resistance of Alloy 718 Using the Surface Modification Process" Materials 11, no. 8: 1366. https://doi.org/10.3390/ma11081366

APA StyleAmanov, A., Umarov, R., & Amanov, T. (2018). Increase in Strength and Fretting Resistance of Alloy 718 Using the Surface Modification Process. Materials, 11(8), 1366. https://doi.org/10.3390/ma11081366