Development of a Novel in Silico Model to Investigate the Influence of Radial Clearance on the Acetabular Cup Contact Pressure in Hip Implants

Abstract

1. Introduction

2. Materials and Methods

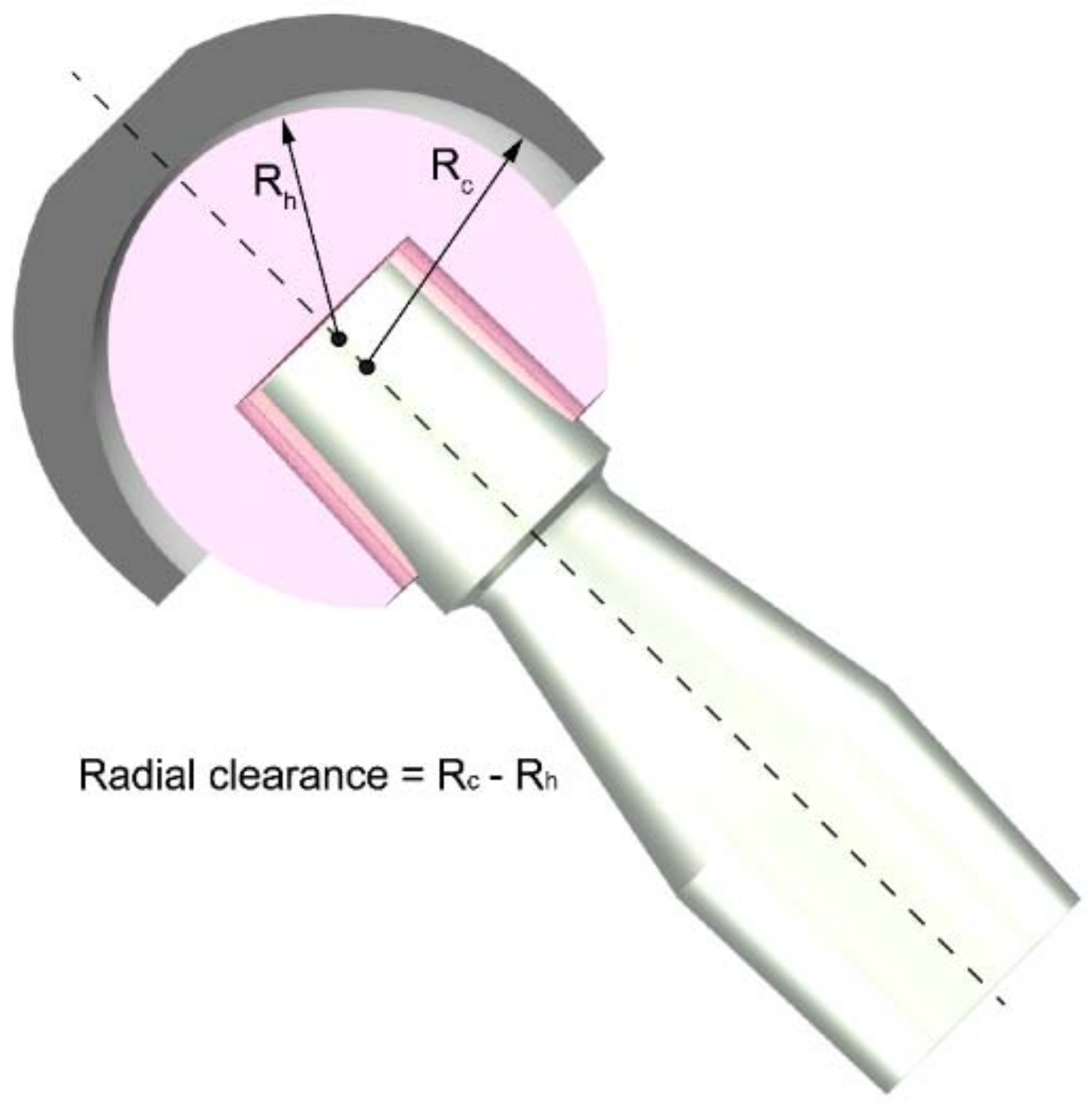

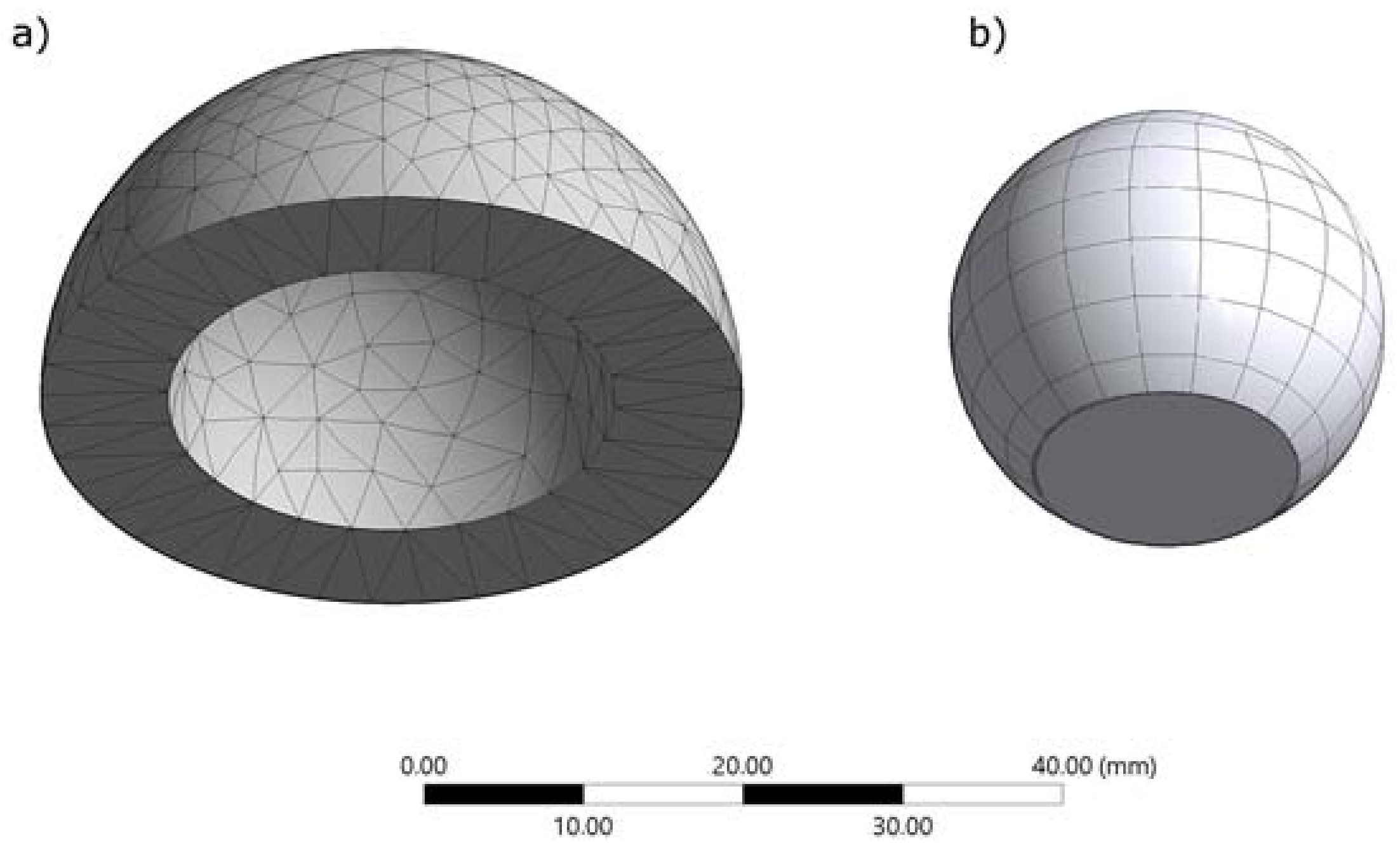

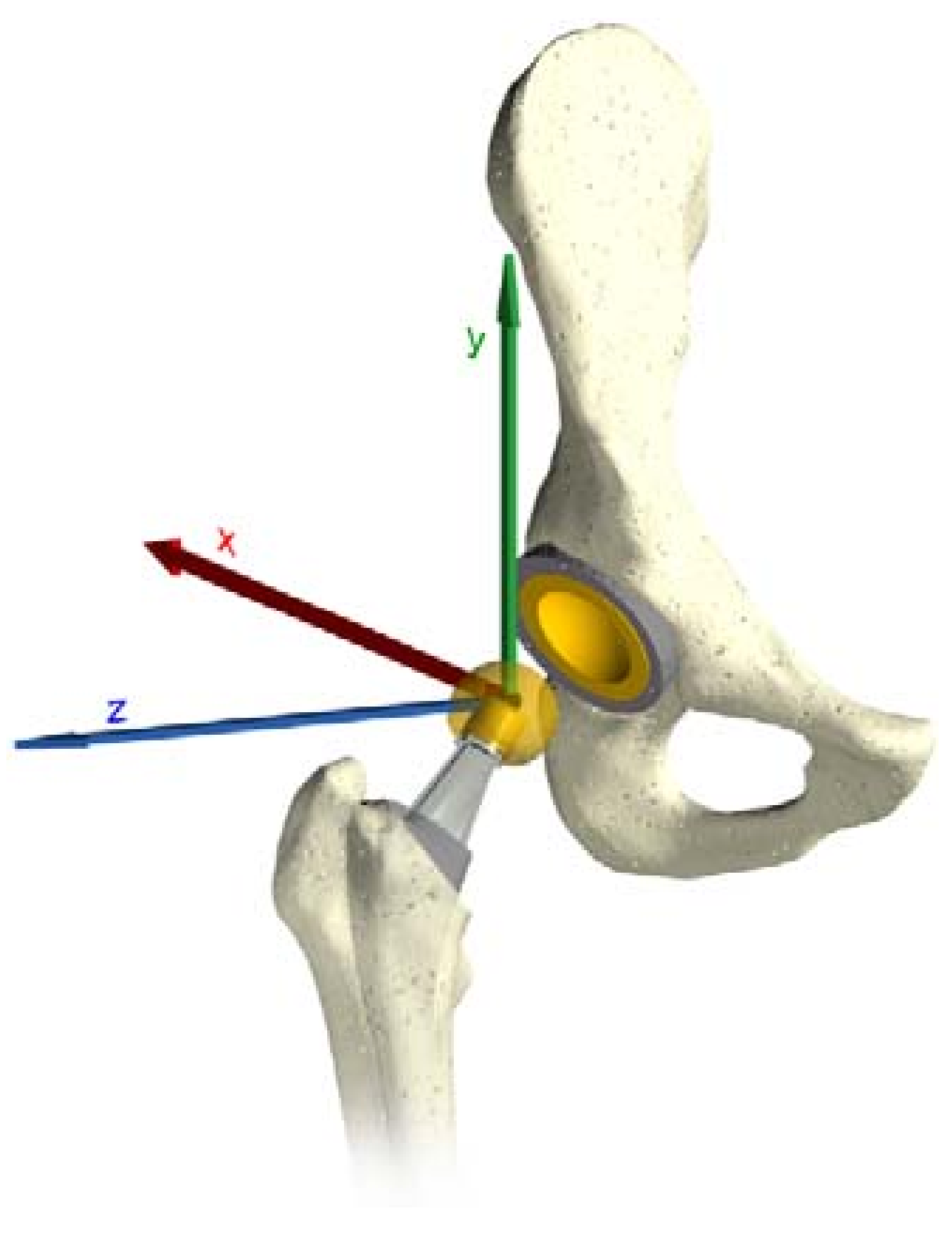

2.1. Finite Element Analysis (FEA) Model

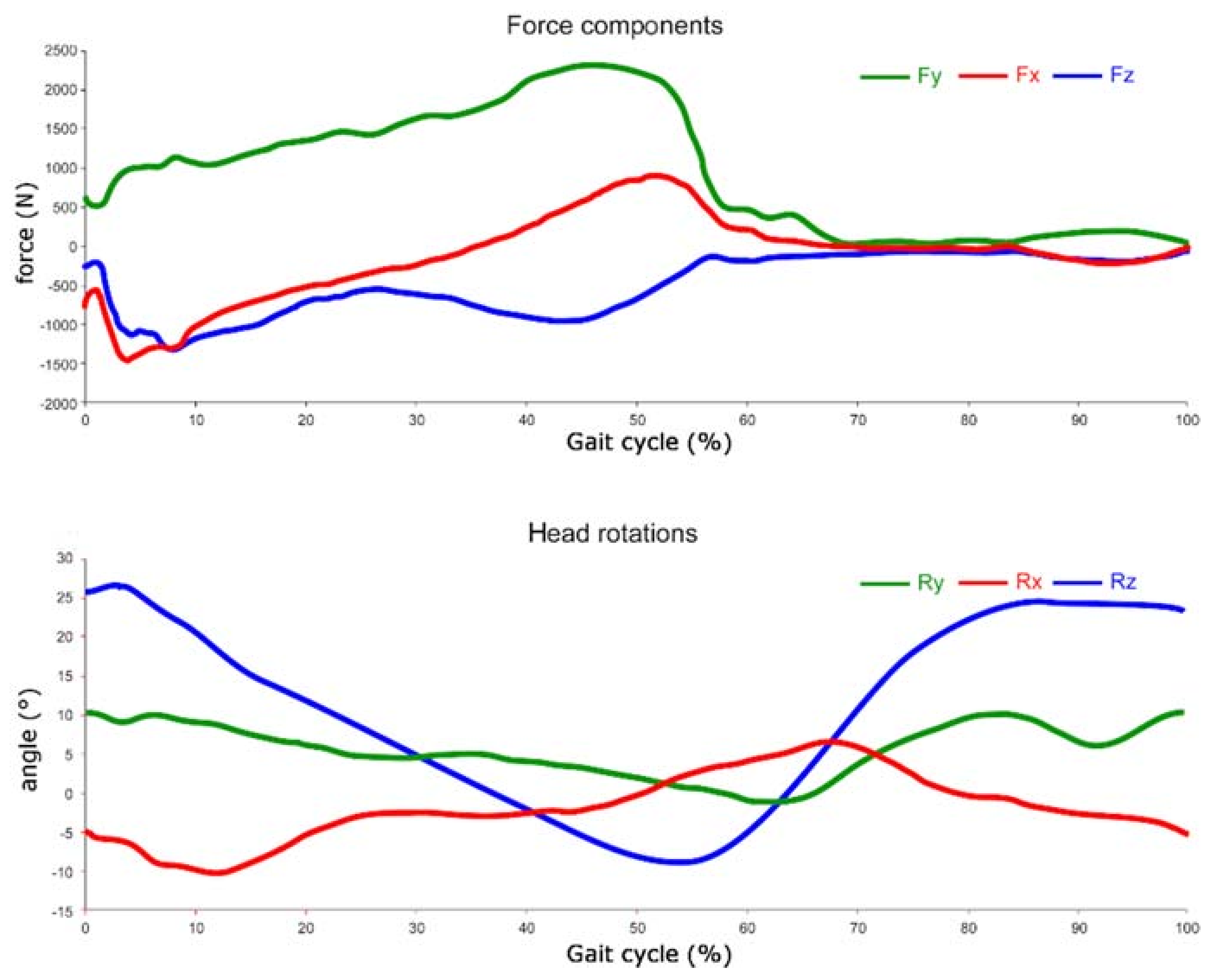

2.2. Gait Cycles and Loads

3. Results

4. Discussion

5. Conclusions

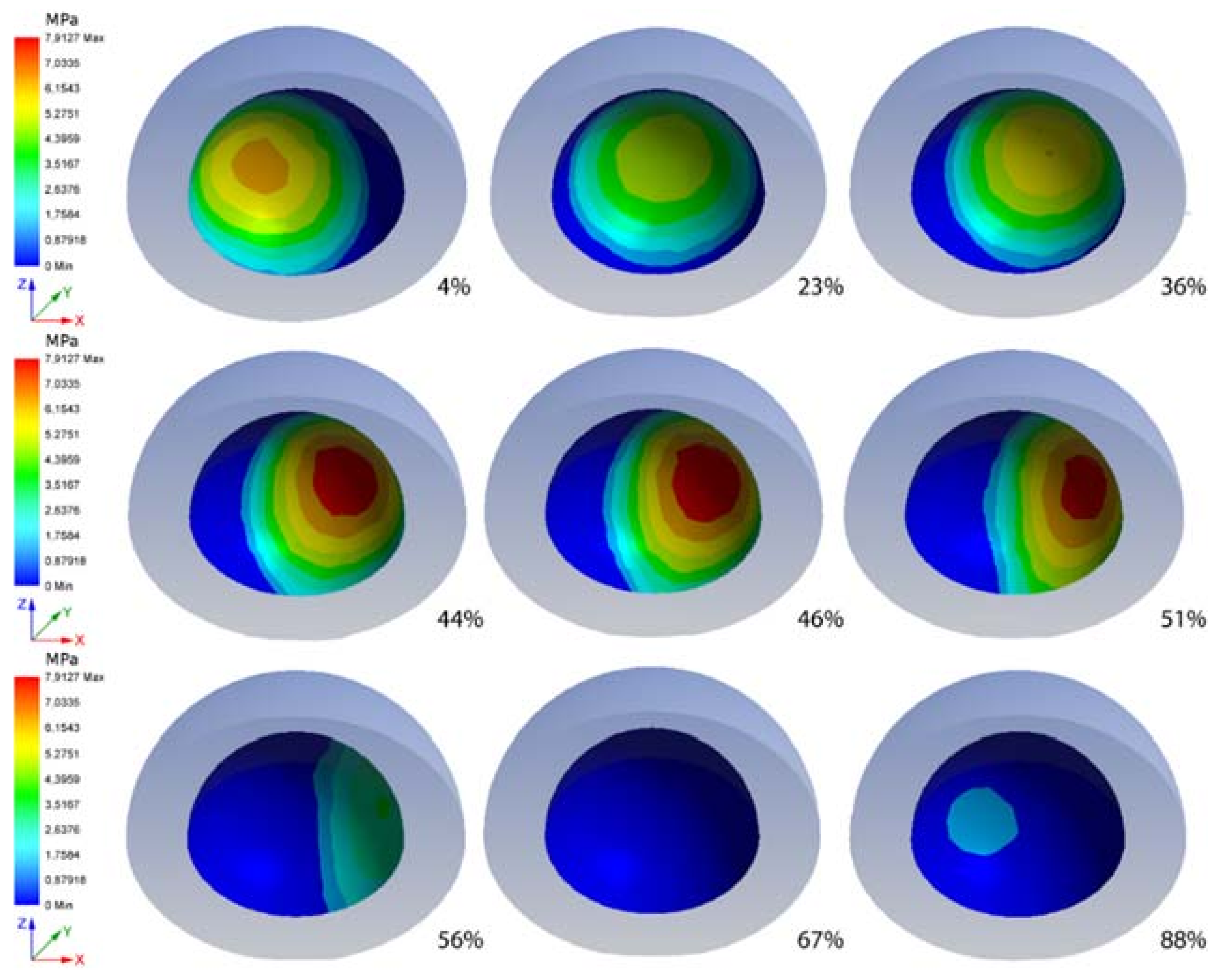

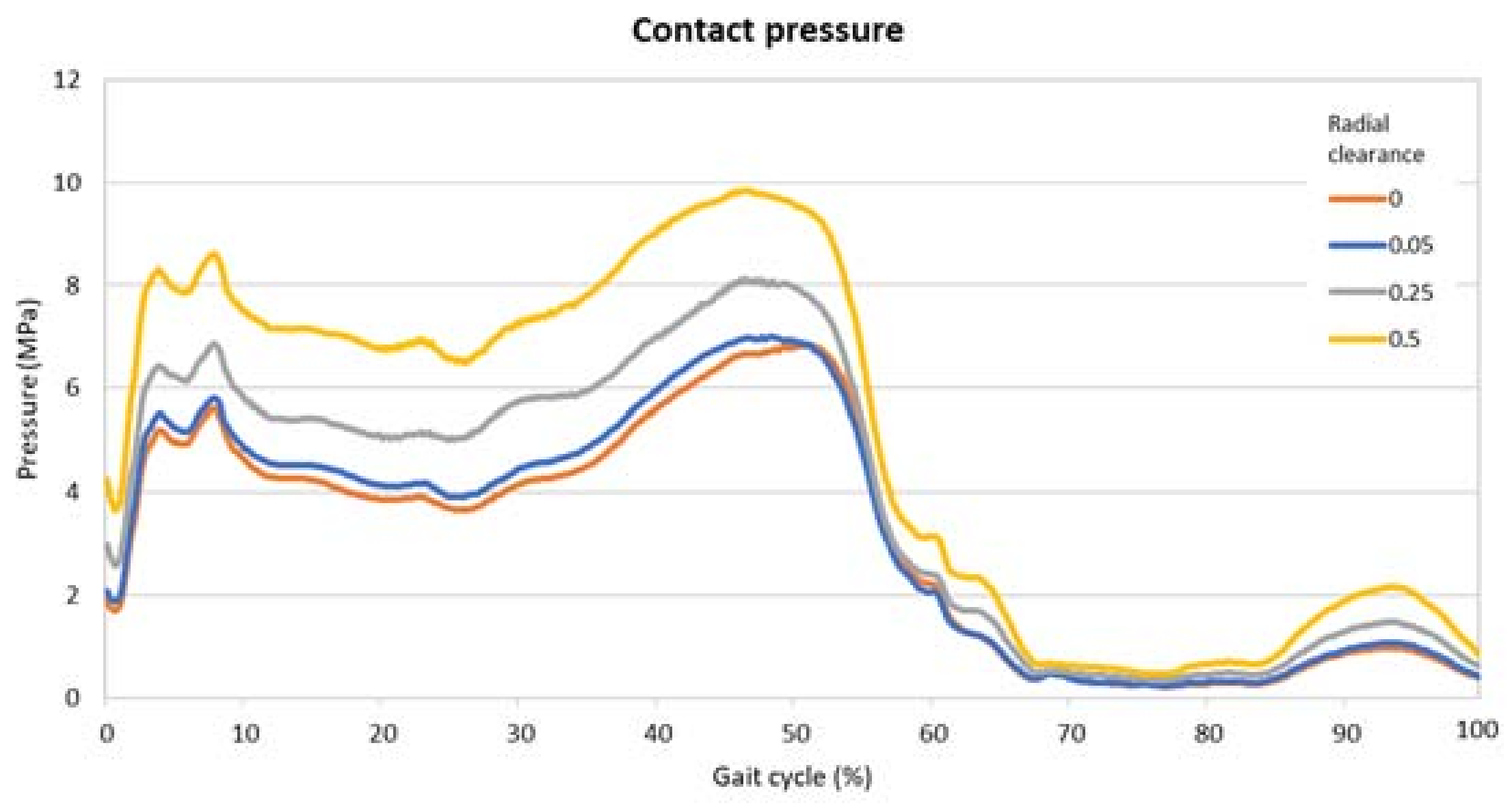

- along the walking cycle, the heel strike and the toe off are the instants of highest pressure, against these points the maximum pressure is located on the lateral side of the cup;

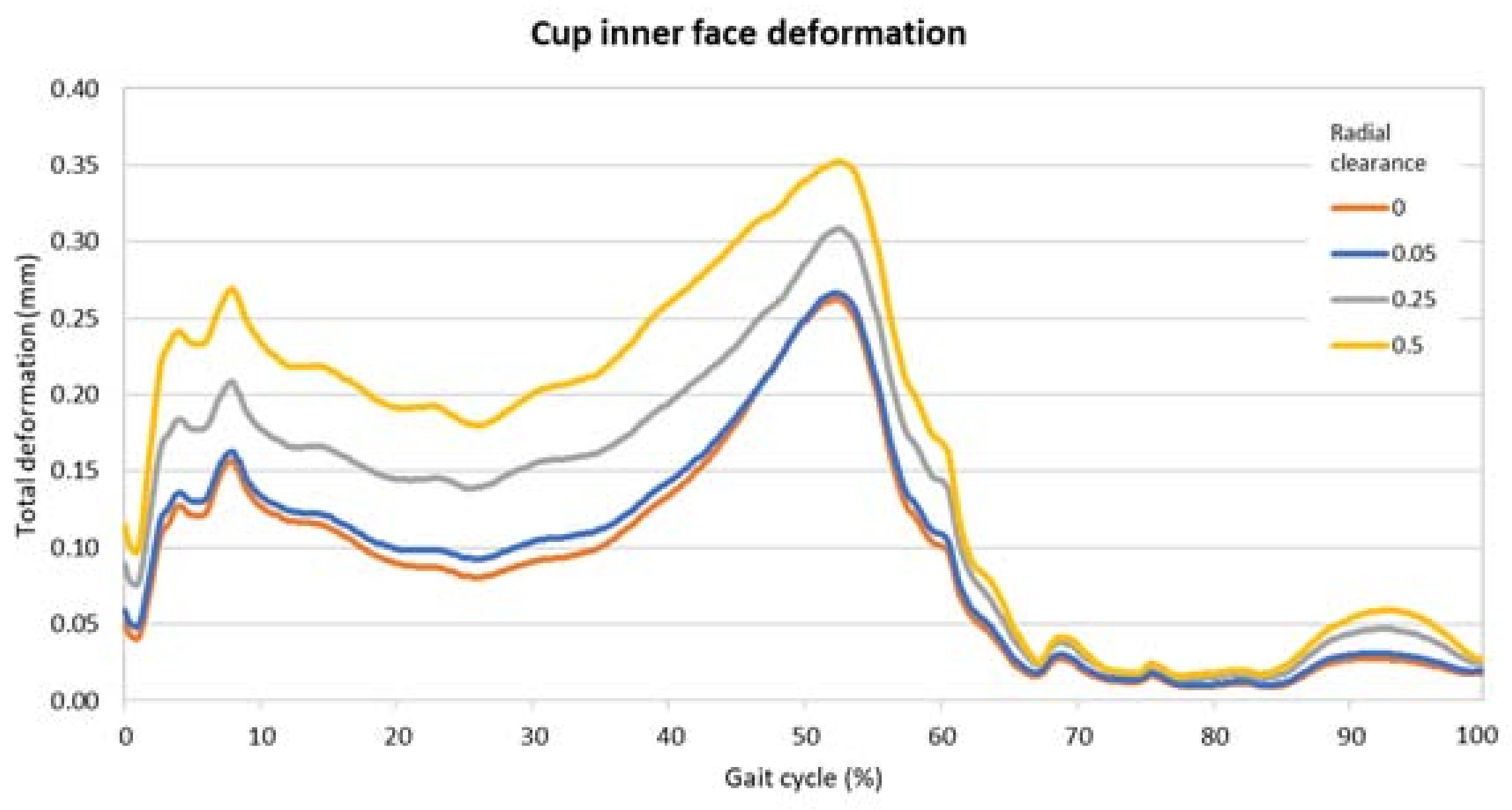

- radial clearance plays a substantial role on pressure and deformation magnitude across the gait cycle: the higher the clearance, the higher the pressure. Nevertheless, reducing the clearance to the smallest possible value is believed to affect the bearing lubrication;

- since radial clearance plays a key role in the lubricating phenomena, the proposed finite element model will be useful to exploit in the complete lubrication modelling of the joint toward a more and more realistic assessment of the in silico wear, accounting also for different radial clearances.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Affatato, S.; Freccero, N.; Taddei, P. The biomaterials challenge: A comparison of polyethylene wear using a hip joint simulator. J. Mech. Behav. Biomed. Mater. 2016, 53, 40–48. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Bersaglia, G.; Emiliani, D.; Foltran, I.; Taddei, P.; Reggiani, M.; Ferrieri, P.; Toni, A. The performance of gamma- and EtO-sterilised UHMWPE acetabular cups tested under severe simulator conditions. Part 2: Wear particle characteristics with isolation protocols. Biomaterials 2003, 24, 4045–4055. [Google Scholar] [CrossRef]

- Affatato, S.; Bersaglia, G.; Rocchi, M.; Taddei, P.; Fagnano, C.; Toni, A. Wear behaviour of cross-linked polyethylene assessed in vitro under severe conditions. Biomaterials 2005, 26, 3259–3267. [Google Scholar] [CrossRef] [PubMed]

- Grillini, L.; Affatato, S. How to measure wear following total hip arthroplasty. Hip Int. 2013, 23, 233–242. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Zavalloni, M.; Spinelli, M.; Costa, L.; Bracco, P.; Viceconti, M. Long-term in-vitro wear performance of an innovative thermo-compressed cross-linked polyethylene. Tribol. Int. 2010, 43, 22–28. [Google Scholar] [CrossRef]

- Affatato, S.; Testoni, M.; Cacciari, G.L.; Toni, A. Mixed oxides prosthetic ceramic ball heads. Part 2: Effect of the ZrO2 fraction on the wear of ceramic on ceramic joints. Biomaterials 1999, 20, 971–975. [Google Scholar] [CrossRef]

- Affatato, S.; Spinelli, M.; Zavalloni, M.; Mazzega-Fabbro, C.; Viceconti, M. Tribology and total hip joint replacement: Current concepts in mechanical simulation. Med. Eng. Phys. 2008, 30, 1305–1317. [Google Scholar] [CrossRef] [PubMed]

- Dumbleton, J.H. Tribology of Natural and Artificial Joints; Elsevier: New York, NY, USA, 1981. [Google Scholar]

- Petersen, D.; Link, R.; Wang, A.; Polineni, V.; Essner, A.; Sokol, M.; Sun, D.; Stark, C.; Dumbleton, J. The Significance of Nonlinear Motion in the Wear Screening of Orthopaedic Implant Materials. J. Test. Eval. 1997, 25, 239. [Google Scholar] [CrossRef]

- Affatato, S.; Bersaglia, G.; Foltran, I.; Emiliani, D.; Traina, F.; Toni, A. The influence of implant position on the wear of alumina-on-alumina studied in a hip simulator. Wear 2004, 256, 400–405. [Google Scholar] [CrossRef]

- Zanini, F.; Carmignato, S.; Savio, E.; Affatato, S. Uncertainty determination for X-ray computed tomography wear assessment of polyethylene hip joint prostheses. Precis. Eng. 2018, 52, 477–483. [Google Scholar] [CrossRef]

- Affatato, S.; Valigi, M.C.; Logozzo, S. Wear distribution detection of knee joint prostheses by means of 3D optical scanners. Materials (Basel) 2017, 10, 364. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Zanini, F.; Carmignato, S. Quantification of wear and deformation in different configurations of polyethylene acetabular cups using micro X-ray computed tomography. Materials (Basel) 2017, 10, 259. [Google Scholar] [CrossRef] [PubMed]

- ISO DIS 14242–1–Implants for Surgery–Wear of Total Hip-Joint Prostheses–Part 1: Loading and Displacement Paramenters for Wear–Testing Machines and Corresponding Environmental Conditions for Test; International Organization for Standardization: Geneva, Switzerland, 2012.

- Gao, L.; Dowson, D.; Hewson, R.W. Predictive wear modeling of the articulating metal-on-metal hip replacements. J. Biomed. Mater. Res. Part B Appl. Biomater. 2017, 105B, 497–506. [Google Scholar] [CrossRef] [PubMed]

- Liu, F.; Fisher, J.; Jin, Z. Computational modelling of polyethylene wear and creep in total hip joint replacements: Effect of the bearing clearance and diameter. Proc. Inst. Mech. Eng. Part J J. Eng. Tribol. 2012, 226, 552–563. [Google Scholar] [CrossRef]

- Suh, J.-K.; Bai, S. Finite Element Formulation of Biphasic Poroviscoelastic Model for Articular Cartilage. J. Biomech. Eng. 1998, 120, 195. [Google Scholar] [CrossRef] [PubMed]

- Töyräs, J.; Saarakkala, S.; Laasanen, M.S.; Töyräs, J.; Korhonen, R.K.; Rieppo, J.; Saarakkala, S.; Nieminen, M.T.; Hirvonen, J.; Jurvelin, J.S. Biomechanical properties of knee articular cartilage. Biorheology 2003, 40, 133–140. [Google Scholar]

- Li, G.; Gil, J.; Kanamori, A.; Woo, S.L.-Y. A Validated Three-Dimensional Computational Model of a Human Knee Joint. J. Biomech. Eng. 1999, 121, 657. [Google Scholar] [CrossRef] [PubMed]

- Amirouche, F.; Solitro, G.; Broviak, S.; Goldstein, W.; Gonzalez, M.; Barmada, R. Primary cup stability in THA with augmentation of acetabular defect. A comparison of healthy and osteoporotic bone. Orthop. Traumatol. Surg. Res. 2015, 101, 667–673. [Google Scholar] [CrossRef] [PubMed]

- Ghosh, R. Assessment of failure of cemented polyethylene acetabular component due to bone remodeling: A finite element study. J. Orthop. 2016, 13, 140–147. [Google Scholar] [CrossRef] [PubMed]

- Uddin, M.S.; Zhang, L.C. Predicting the wear of hard-on-hard hip joint prostheses. Wear 2013, 301, 192–200. [Google Scholar] [CrossRef]

- Huiskes, R.; Chao, E.Y.S.; Crippen, T.E. Parametric analyses of pin-bone stresses in external fracture fixation devices. J. Orthop. Res. 1985, 3, 341–349. [Google Scholar] [CrossRef] [PubMed]

- Smith, S.; Dowson, D.; Goldsmith, A. The effect of diametral clearance, motion and loading cycles upon lubrication of metal-on-metal total hip replacements. Proc. Inst. Mech. Eng. Part C 2001, 215, 1–5. [Google Scholar] [CrossRef]

- Felippa, C.A. Introduction to Finite Element Methods. 2004. Available online: https://www.colorado.edu/engineering/Aerospace/CAS/courses.d/IFEM.d/IFEM.Ch00.d/IFEM.Ch00.pdf (accessed on 19 July 2018).

- Herrera, A.; Ibarz, E.; Cegoñino, J.; Lobo-escolar, A.; Puértolas, S.; López, E.; Gracia, L.; Herrera, A.; Lobo-escolar, A.; Mateo, J. Applications of finite element simulation in orthopedic and trauma surgery. World J. Othop. 2012, 3, 25–41. [Google Scholar] [CrossRef] [PubMed]

- Maxian, T.A.; Brown, T.D.; Pedersen, D.R.; Callaghan, J.J. Adaptiive finite element modeling of long-term polyethylene wear in total hip arthroplasty. J. Orthop. Res. 1996, 14, 668–675. [Google Scholar] [CrossRef] [PubMed]

- Hu, C.; Liau, J.; Lung, C.; Huang, C.; Cheng, C. A two-dimensional finite element model for frictional heating analysis of total hip prosthesis. Mater. Sci. Eng. C 2001, 17, 11–18. [Google Scholar] [CrossRef]

- Sfantos, G.K.; Aliabadi, M.H.Ã. Total hip arthroplasty wear simulation using the boundary element method. J. Biomech. 2007, 40, 378–389. [Google Scholar] [CrossRef] [PubMed]

- Ruggiero, A.; Merola, M.; Affatato, S. Finite element simulations of hard-on-soft hip joint prosthesis accounting for dynamic loads calculated from a Musculoskeletal model during walking. Materials (Basel) 2018, 11, 574. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S.; Ruggiero, A.; Merola, M. Advanced biomaterials in hip joint arthroplasty. A review on polymer and ceramics composites as alternative bearings. Compos. Part B Eng. 2015, 83, 276–283. [Google Scholar] [CrossRef]

- Ruggiero, A.; D’Amato, R.; Gómez, E.; Merola, M. Experimental comparison on tribological pairs UHMWPE/TIAL6V4 alloy, UHMWPE/AISI316L austenitic stainless and UHMWPE/AL2O3 ceramic, under dry and lubricated conditions. Tribol. Int. 2016, 96, 349–360. [Google Scholar] [CrossRef]

- Ruggiero, A.; D’Amato, R.; Gómez, E. Experimental analysis of tribological behavior of UHMWPE against AISI420C and against TiAl6V4 alloy under dry and lubricated conditions. Tribol. Int. 2015, 92, 154–161. [Google Scholar] [CrossRef]

- Affatato, S.; Ruggiero, A.; De Mattia, J.S.; Taddei, P. Does metal transfer affect the tribological behaviour of femoral heads? Roughness and phase transformation analyses on retrieved zirconia and Biolox® Delta composites. Compos. Part B Eng. 2016, 92, 290–298. [Google Scholar] [CrossRef]

- Affatato, S.; Ruggiero, A.; Merola, M.; Logozzo, S. Does metal transfer differ on retrieved Biolox® Delta composites femoral heads? Surface investigation on three Biolox® generations from a biotribological point of view. Compos. Part B Eng. 2017, 113, 164–173. [Google Scholar] [CrossRef]

- Laurian, T.; Tudor, A. Some Aspects Regarding the Influence of the Clearance on the Pressure Distribution in Total Hip Joint Prostheses. In Proceeding of the National Tribology Conference RotTrib03, Annals, Galati, Romania, 24–26 September 2003. [Google Scholar]

- Barreto, S.; Folgado, J.; Fernandes, P.R.; Monteiro, J. The Influence of the Pelvic Bone on the Computational Results of the Acetabular Component of a Total Hip Prosthesis. J. Biomech. Eng. 2010, 132, 54503. [Google Scholar] [CrossRef] [PubMed]

- Damsgaard, M.; Rasmussen, J.; Christensen, S.T.; Surma, E.; de Zee, M. Analysis of musculoskeletal systems in the AnyBody Modeling System. Simul. Model. Pract. Theory 2006, 14, 1100–1111. [Google Scholar] [CrossRef]

- Vaughan, C.; Davis, B.L.; O’Connor, J.C. Dynamics of Human Gait. Available online: https://isbweb.org/data/ (accessed on 6 April 2018).

- Prati, E.; Freddi, A.; Ranieri, L.; Toni, A. Comparative fatigue damage analysis of hip-joint prostheses. J Biomech. 1982, 15, 808. [Google Scholar] [CrossRef]

- Huiskes, R.; Chao, E.Y.S. A survey of finite element analysis in orthopaedic biomechanics: The first decade. J. Biomech. 1983, 16, 385–409. [Google Scholar] [CrossRef]

- Abdel-Jaber, S.; Belvedere, C.; Leardini, Al.; Affatato, S.; Abdel Jaber, S.; Belvedere, C.; Leardini, Al.; Affatato, S. Wear simulation of total knee prostheses using load and kinematics waveforms from stair climbing. J. Biomech. 2015, 48, 3830–3836. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Jaber, S.; Belvedere, C.; De Mattia, J.S.; Leardini, A.; Affatato, S. A new protocol for wear testing of total knee prostheses from real joint kinematic data: Towards a scenario of realistic simulations of daily living activities. J. Biomech. 2016, 49, 2925–2931. [Google Scholar] [CrossRef] [PubMed]

- Battaglia, S.; Belvedere, C.; Jaber, S.A.; Affatato, S.; D’Angeli, V.; Leardini, A. A new protocol from real joint motion data for wear simulation in total knee arthroplasty: Stair climbing. Med. Eng. Phys. 2014, 36, 1605–1610. [Google Scholar] [CrossRef] [PubMed]

- Affatato, S. Towards wear testing of high demanding.pdf. J Brazilian Soc. Mech. Sci. Eng. 2018, 40, 260–266. [Google Scholar] [CrossRef]

- ISO-14243–2–Implants for Surgery–Wear of Total Knee-Joint Prostheses–Part 2: Methods of Measurement; International Organization for Standardization: Geneva, Switzerland, 2000.

- ISO DIS 14243–3–Implants for Surgery–Wear of Total Knee Joint Prostheses–Part 1: Loading and Displacement Paramenters for Wear-Testing Machines with Displacement Control and Corresponding Environmental Conditions for Test; International Organization for Standardization: Geneva, Switzerland, 2004.

- Mattei, L.; Di Puccio, F.; Ciulli, E. A comparative study of wear laws for soft-on-hard hip implants using a mathematical wear model. Tribol. Int. 2013, 63, 66–77. [Google Scholar] [CrossRef]

- Matsoukas, G.; Willing, R.; Kim, I.Y. Total Hip Wear Assessment: A Comparison Between Computational and In Vitro Wear Assessment Techniques Using ISO 14242 Loading and Kinematics. J. Biomech. Eng. 2009, 131, 41011. [Google Scholar] [CrossRef] [PubMed]

- Maxian, T.A.; Brown, T.D.; Pedersen, D.R.; Callaghan, J.J. A sliding-distance-coupled finite element formulation for polyethylene wear in total hip arthroplasty. J. Biomech. 1996, 29, 687–692. [Google Scholar] [CrossRef]

- Jin, Z.M.; Dowson, D. A full numerical analysis of hydrodynamic lubrication in artificial hip joint replacements constructed from hard materials. Proc. Inst. Mech. Eng. Part C J. Mech. Eng. Sci. 1999, 213, 355–370. [Google Scholar] [CrossRef]

- Jalali-Vahid, D.; Jagatia, M.; Jin, Z.M.; Dowson, D. Prediction of lubricating film thickness in UHMWPE hip joint replacements. J. Biomech. 2001, 34, 261–266. [Google Scholar] [CrossRef]

- Ruggiero, A.; Gòmez, E.; D’Amato, R. Approximate analytical model for the squeeze-film lubrication of the human ankle joint with synovial fluid filtrated by articular cartilage. Tribol. Lett. 2011, 41, 337–343. [Google Scholar] [CrossRef]

- Ruggiero, A.; Gómez, E.; D’Amato, R. Approximate closed-form solution of the synovial fluid film force in the human ankle joint with non-Newtonian lubricant. Tribol. Int. 2013, 57, 156–161. [Google Scholar] [CrossRef]

- Hua, X.; Li, J.; Wang, L.; Jin, Z.; Wilcox, R.; Fisher, J. Contact mechanics of modular metal-on-polyethylene total hip replacement under adverse edge loading conditions. J. Biomech. 2014, 47, 3303–3309. [Google Scholar] [CrossRef] [PubMed]

| Density | Young’s Modulus | Poisson’s Ratio | Bulk Modulus | Shear Modulus | Tensile Yield Strength | Tensile Ultimate Strength |

|---|---|---|---|---|---|---|

| (kg m−3) | (MPa) | (-) | (MPa) | (MPa) | (MPa) | (MPa) |

| 930 | 690 | 0.46 | 1640 | 241 | 21 | 40 |

| Radial clearance | 0 | 0.05 | 0.25 | 0.5 |

| Maximum pressure (MPa) | 6.82 | 7.00 | 8.12 | 9.84 |

| Maximum deformation (mm) | 0.26 | 0.27 | 0.31 | 0.35 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Affatato, S.; Merola, M.; Ruggiero, A. Development of a Novel in Silico Model to Investigate the Influence of Radial Clearance on the Acetabular Cup Contact Pressure in Hip Implants. Materials 2018, 11, 1282. https://doi.org/10.3390/ma11081282

Affatato S, Merola M, Ruggiero A. Development of a Novel in Silico Model to Investigate the Influence of Radial Clearance on the Acetabular Cup Contact Pressure in Hip Implants. Materials. 2018; 11(8):1282. https://doi.org/10.3390/ma11081282

Chicago/Turabian StyleAffatato, Saverio, Massimiliano Merola, and Alessandro Ruggiero. 2018. "Development of a Novel in Silico Model to Investigate the Influence of Radial Clearance on the Acetabular Cup Contact Pressure in Hip Implants" Materials 11, no. 8: 1282. https://doi.org/10.3390/ma11081282

APA StyleAffatato, S., Merola, M., & Ruggiero, A. (2018). Development of a Novel in Silico Model to Investigate the Influence of Radial Clearance on the Acetabular Cup Contact Pressure in Hip Implants. Materials, 11(8), 1282. https://doi.org/10.3390/ma11081282