Effects of Different Hot Working Techniques on Inclusions in GH4738 Superalloy Produced by VIM and VAR

Abstract

1. Introduction

2. Experimental

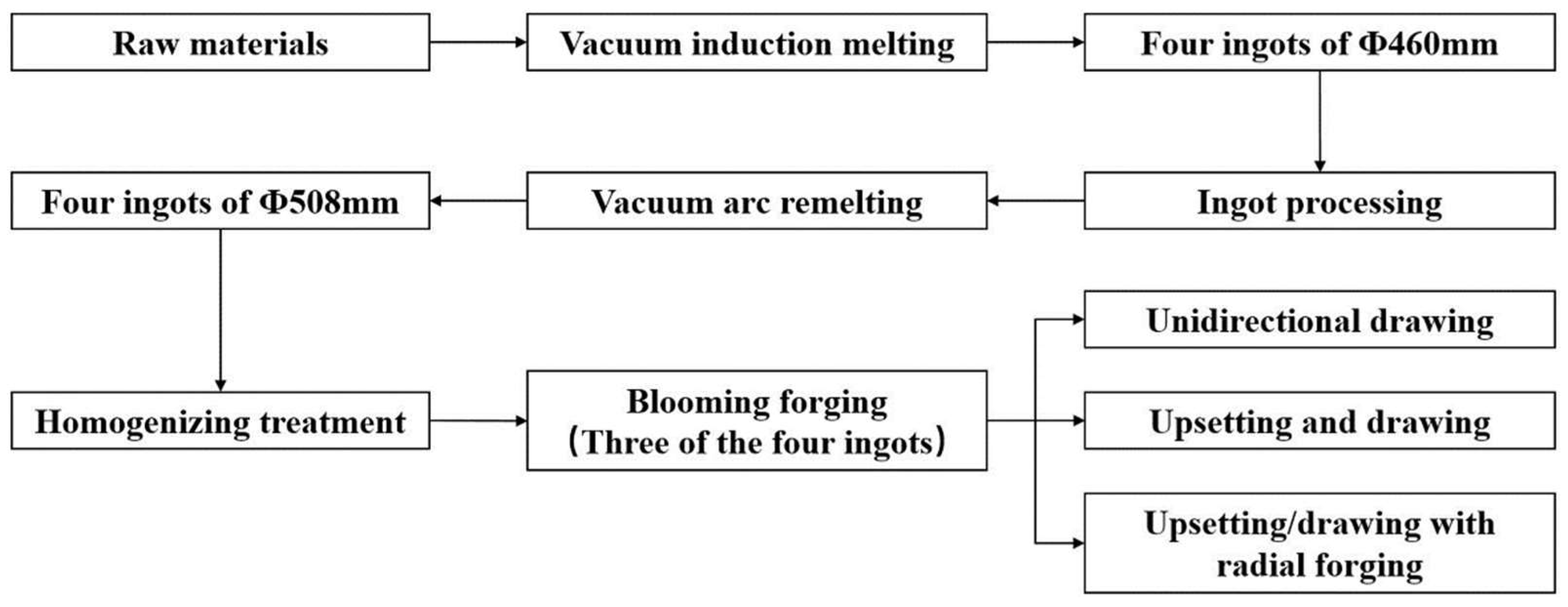

2.1. Melting and Hot Working

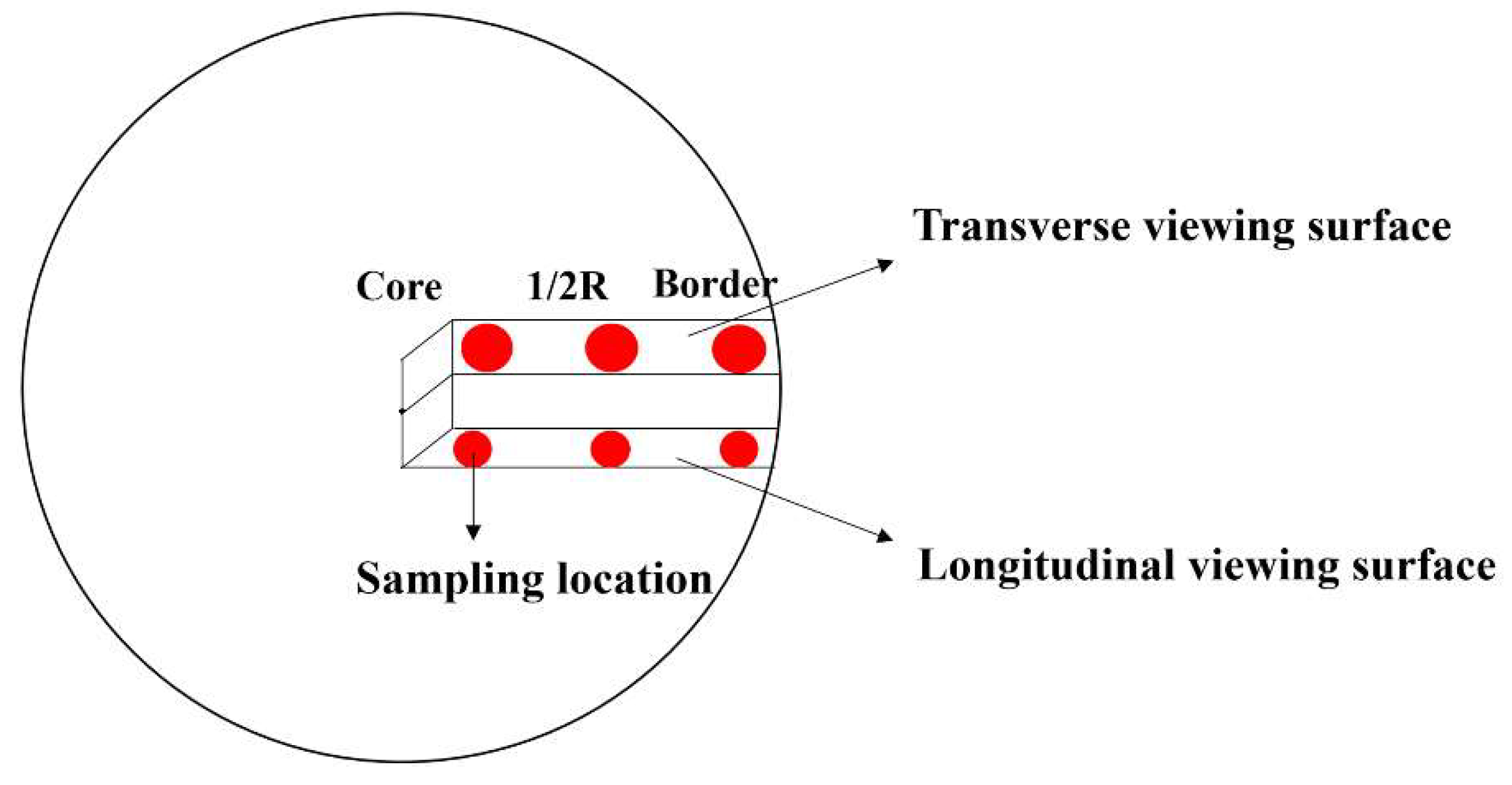

2.2. Preparation and Testing

3. Results and Discussions

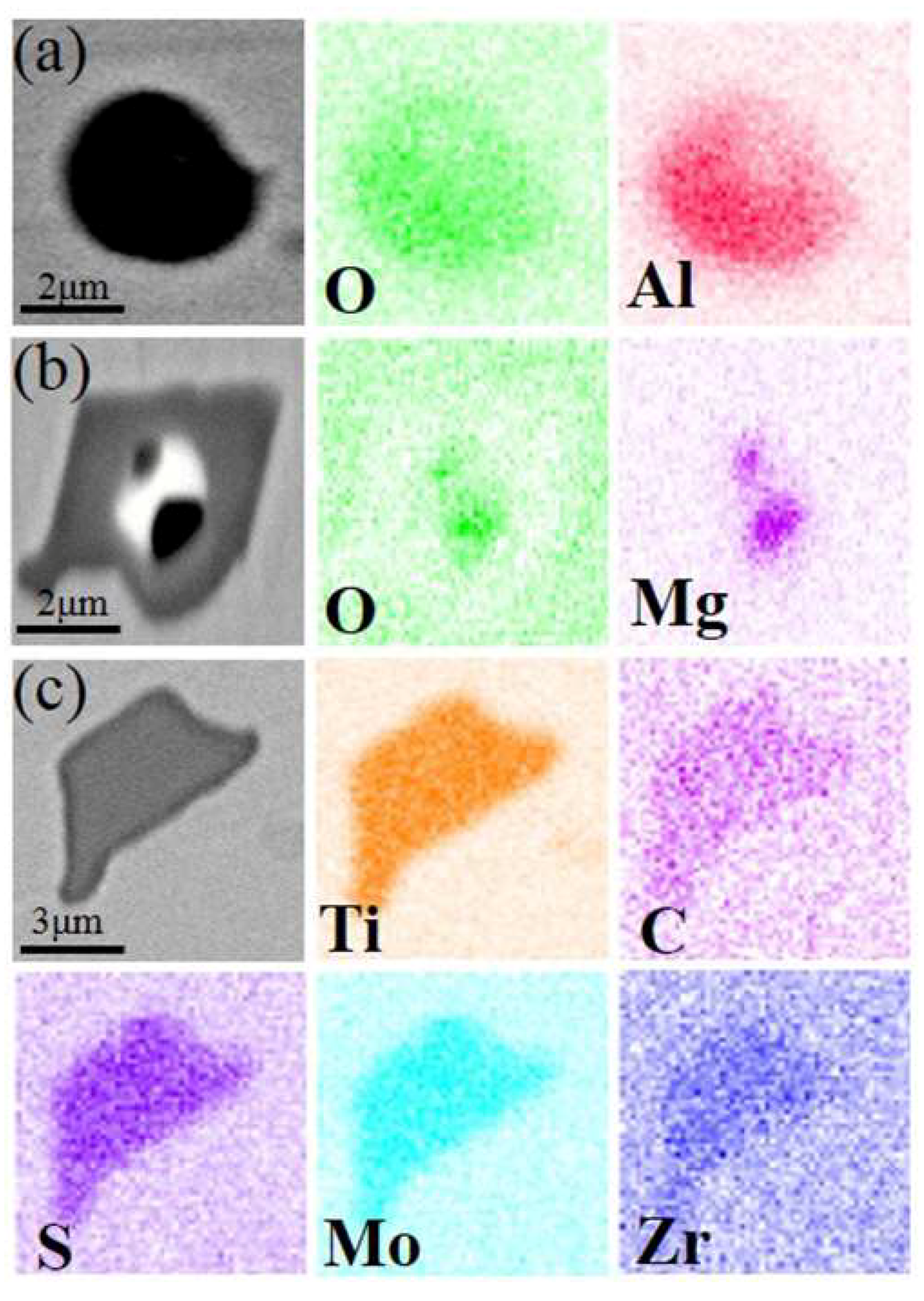

3.1. Inclusion Type and Percentage Contribution

3.2. Distribution of Inclusions in Transverse and Longitudinal Directions

4. Conclusions

- The three hot working methods have minimal impact on the inclusion type and percentage in GH4738. The melting technology plays a determining role. Four types of inclusions were found in the superalloy during this experiment: TiC–TiN–Mo–S composite, TiC–TiN composite, Ce–Mo–S composite, and SiC inclusions.

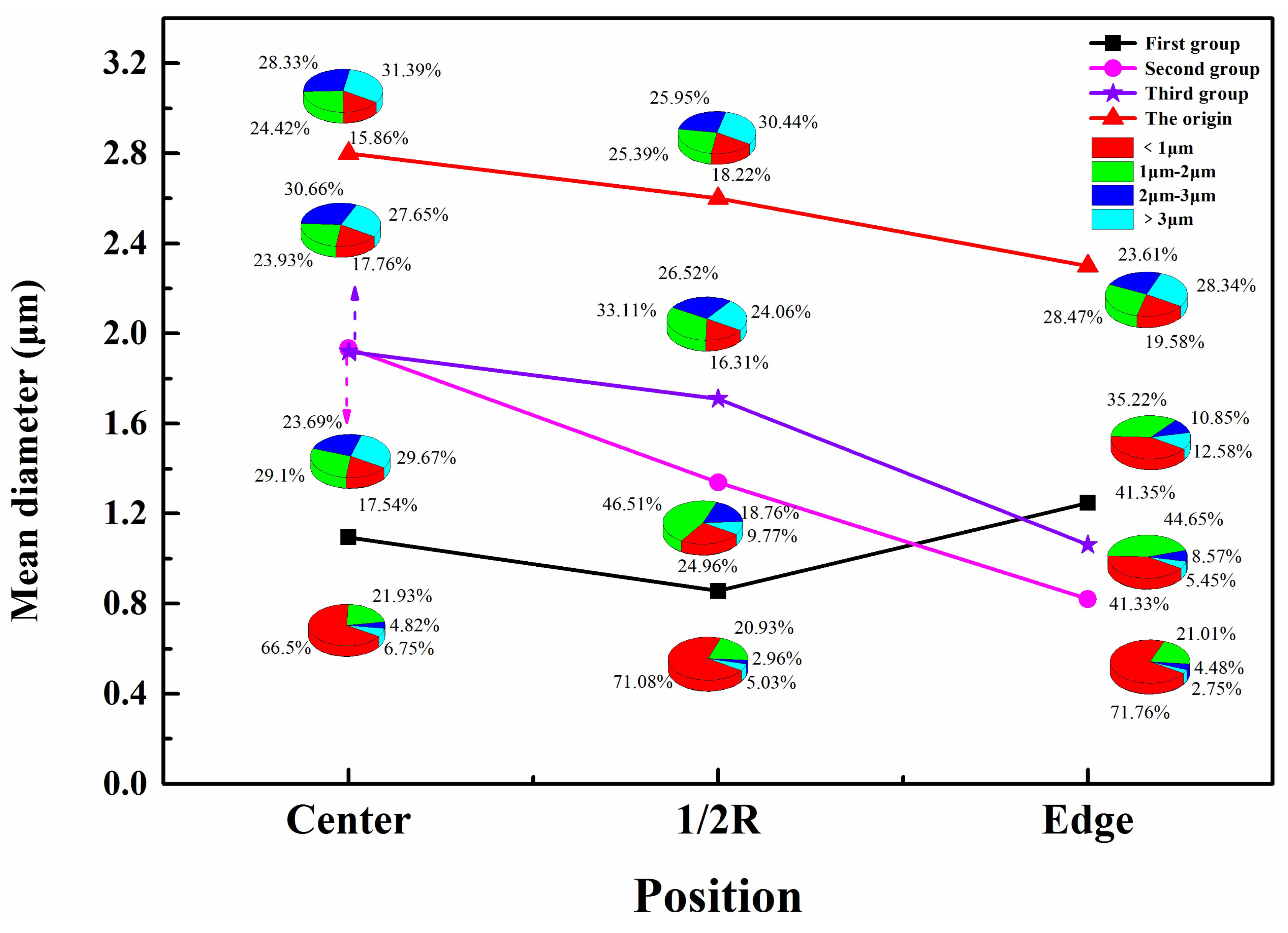

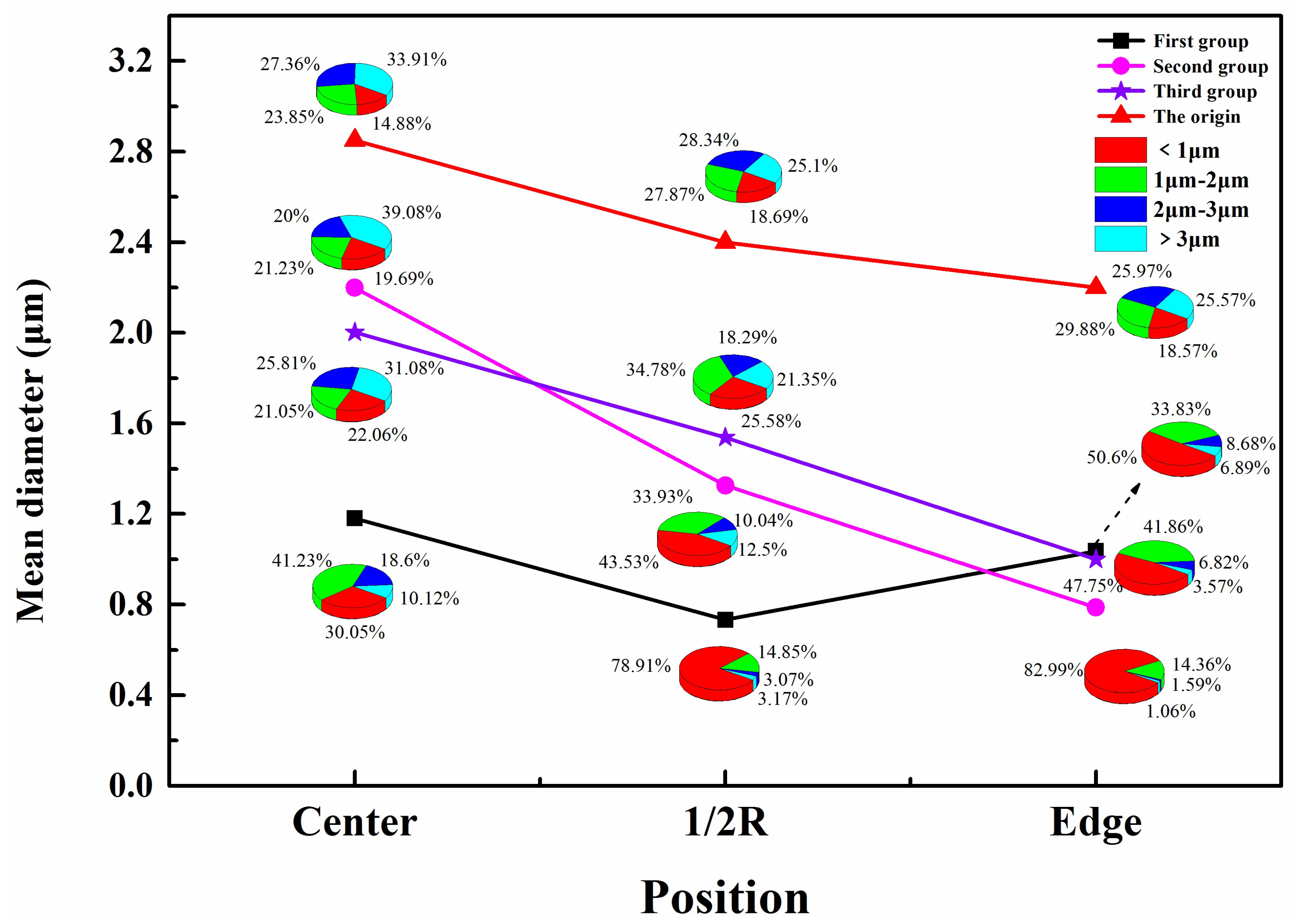

- For GH4738 subjected to hot working by unidirectional drawing, the average inclusion size first decreased, and then increased from the center to the edge. This technique primarily affected the inclusion size at the 1/2R point of the superalloy.

- For GH4738 subjected to hot working by upsetting and drawing, and upsetting/drawing with radial forging, the average inclusion size decreased from the center to the edge. These two techniques primarily affected the inclusion size at the edge of the superalloy.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Williams, J.C.; Starke, E.A., Jr. Progress in structural materials for aerospace systems. Acta Mater. 2003, 51, 5775–5799. [Google Scholar] [CrossRef]

- Decker, R.F. The evolution of wrought age-hardenable superalloys. JOM 2006, 58, 32–36. [Google Scholar] [CrossRef]

- Zhang, B.J.; Zhao, G.P.; Zhang, W.Y.; Huang, S.; Chen, S.F. Investigation of high performance disc alloy GH4065 and associated advanced processing techniques. Acta Metall. Sin. 2015, 51, 1227–1234. [Google Scholar]

- Shi, C.X.; Zhong, Z.Y. Development and innovation of superalloy in China. Acta Metall. Sin. 2010, 46, 1281–1288. [Google Scholar] [CrossRef]

- Hegde, S.R.; Kearsey, R.M.; Beddoes, J.C. Designing homogenization-solution heat treatments for single crystal supperalloys. Mater. Sci. Eng. A 2010, 527, 5528–5538. [Google Scholar] [CrossRef]

- Furuya, Y.; Matsuoka, S.; Kimura, T.; Hayaishi, M. Effects of inclusion and ODA sizes on gigacycle fatigue properties of high-strength steels. Tetsu Hagane 2005, 91, 630–638. [Google Scholar] [CrossRef]

- Li, M.H.; Sun, X.F.; Jin, T.; Guan, H.R.; Hu, Z.Q. Oxidation behavior of a single-crystal Ni-base superalloy in air—II: At 1000, 1100 and 1150 °C. Oxid. Met. 2003, 60, 195–210. [Google Scholar] [CrossRef]

- Kirka, M.M.; Brindley, K.A.; Neu, R.W.; Antolovich, S.D.; Shinde, S.R.; Gravett, P.W. Influence of coarsened and rafted microstructures on the thermomechanical fatigue of a Ni-base superalloy. Int. J. Fatigue 2015, 81, 191–201. [Google Scholar] [CrossRef]

- Mao, J.; Chang, K.M.; Yang, W.H.; Ray, K.; Vaze, S.P.; Ferrer, D.U. Cooling precipitation and strengthening study in powder metallurgy superalloy U720LI. Metall. Mater. Trans. A 2001, 32, 2441–2452. [Google Scholar] [CrossRef]

- Carter, J.L.W.; Kuper, M.W.; Uchic, M.D.; Mills, M.J. Characterization of localized deformation near grain boundaries of superalloy René-104 at elevated temperature. Mater. Sci. Eng. A 2014, 605, 127–136. [Google Scholar] [CrossRef]

- Radis, R.; Schaffer, M.; Albu, M.; Kothleitner, G.; Pölt, P.; Kozeschnik, E. Multimodal size distributions of γ′ precipitates during continuous cooling of UDIMET 720 Li. Acta Mater. 2009, 57, 5739–5747. [Google Scholar] [CrossRef]

- Degawa, T.; Ototani, T. Refining of high purity Ni-base superalloy using calcia refractory. Tetsu Hagane 1987, 73, 1691–1697. [Google Scholar] [CrossRef]

- Schneider, R.S.E.; Mülleder, M.; Zeller, P.; Würzinger, P.; Reiter, G.; Paul, S. Effects of low frequency alternating currents on the electro-slag remelting process. BHM 2016, 161, 20–26. [Google Scholar] [CrossRef]

- Shevchenko, D.M.; Ward, R.M. Liquid metal pool behavior during the vacuum arc remelting of INCONEL 718. Metall. Mater. Trans. B 2009, 40, 263–270. [Google Scholar] [CrossRef]

- Wang, X.H.; Jiang, M.; Chen, B.; Li, H.B. Study on formation of non-metallic inclusions with lower melting temperatures in extra low oxygen special steels. Sci. China Technol. Sci. 2012, 55, 1863–1872. [Google Scholar] [CrossRef]

- Ma, J.; Zhang, B.; Xu, D.K.; Han, E.H.; Ke, W. Effects of inclusion and loading direction on the fatigue behavior of hot rolled low carbon steel. Int. J. Fatigue 2010, 32, 1116–1125. [Google Scholar] [CrossRef]

- Furuya, Y.; Hirukawa, H.; Kimura, T.; Hayaishi, M. Gigacycle fatigue properties of high-strength steels according to inclusion and ODA sizes. Metall. Mater. Trans. A 2007, 38, 1722–1730. [Google Scholar] [CrossRef]

- Wang, X.C.; Wang, H.N.; Cheng, G.G.; Kou, Y.S.; Zuo, H.; Chen, L. Characteristics of inclusions in 20Cr13 stainless steel hot-rolled round bar. China Metall. 2014, 24, 17–21. [Google Scholar]

- Kawakami, K.; Taniguchi, T.; Nakashima, K. Generation mechanisms of non-metallic inclusions in high-cleanliness steel. Tetsu Hagane 2008, 93, 743–752. [Google Scholar] [CrossRef]

- Jiang, M.; Wang, X.H.; Chen, B.; Wang, W.J. Laboratory study on evolution mechanisms of non-metallic inclusions in high srength alloyed steel refined by high basicity slag. ISIJ Int. 2010, 50, 95–104. [Google Scholar] [CrossRef]

- Du, J.H.; Lu, X.D.; Deng, Q.; Bi, Z. Process in the research and manufacture of GH4169 alloy. J. Iron Steel Res. Int. 2015, 22, 657–663. [Google Scholar] [CrossRef]

- Tang, Z.J.; Guo, T.M.; Kou, Z.S.; Fu, Y.; Jin, S. Feature and formation mechanism of inclusions in K4169 Ni-based superalloy. Chin. J. Nonferr. Met. 2015, 25, 2403–2413. [Google Scholar]

- Toro, A.; Zhou, F.; Wu, M.H.; Geertruyden, W.V.; Misiolek, W.Z. Characterization of non-metallic inclusions in superelastic NiTi tubes. J. Mater. Eng. Perform. 2009, 18, 448–458. [Google Scholar] [CrossRef]

- Shen, J.; Xia, T.D.; Wang, X.J.; Feng, X.C. Characterization and analysis of non-metallic inclusions in Ni42-Fe expansive alloy. Trans. Nonferr. Met. Soc. China 2007, 17, S1165–S1171. [Google Scholar]

- Podgornik, B.; Leskovšek, V.; Godec, M.; Senčič, B. Microstructure refinement and its effect on properties of spring steel. Mater. Sci. Eng. A 2014, 599, 81–86. [Google Scholar] [CrossRef]

- Wang, W.; Ma, R.; Zhao, J.; Zhai, R.X. Co-simulation technology of casting-forging combination forming process for grain distribution prediction. Mater. Rev. 2017, 31, 150–154. [Google Scholar]

- Chen, W.; Liu, J.S.; Dang, S.E. Uniformity control of deformation and microstructure in stretching process of large axial forging. J. Plast. Eng. 2015, 5, 13–17. [Google Scholar]

- Li, L.H.; Dong, J.X.; Zhang, M.C.; Yao, Z.H. Integrated simulation of the forging process for GH4738 alloy turbine disk and its application. Acta Metall. Sin. 2014, 50, 821–831. [Google Scholar]

- Du, J.H.; Zhao, G.P.; Deng, Q.; Lv, X.D.; Zhang, B.J. Development of wrought superalloy in China. J. Aeronaut. Mater. 2016, 3, 27–39. [Google Scholar]

- Kong, Y.H.; Li, L.; Zhu, S.G.; Chen, G.S. Study on microstructures and properties of different part in radial forged Gh4169 alloy. Rare Met. Mater. Eng. 2010, 39, 405–408. [Google Scholar]

| Cr | C | Co | Mo | Al | Ti | S | Ni |

|---|---|---|---|---|---|---|---|

| 18.92 | 0.07 | 13.13 | 3.96 | 1.47 | 2.97 | <0.15 | Balance |

| Method | TiC–TiN–Mo–S | TiC–TiN | Ce–Mo–S | SiC | Others |

|---|---|---|---|---|---|

| Unidirectional Drawing | 75.2 | 8.9 | 7 | 6.9 | 2 |

| Upsetting and Drawing | 75 | 9 | 7 | 7 | 2 |

| Upsetting/Drawing with Radial Forging | 75.4 | 9.2 | 6.8 | 6.7 | 1.9 |

| Origin | 74.6 | 9.1 | 7.1 | 6.9 | 2.3 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chen, Z.; Yang, S.; Li, J.; Guo, H.; Zheng, H. Effects of Different Hot Working Techniques on Inclusions in GH4738 Superalloy Produced by VIM and VAR. Materials 2018, 11, 1024. https://doi.org/10.3390/ma11061024

Chen Z, Yang S, Li J, Guo H, Zheng H. Effects of Different Hot Working Techniques on Inclusions in GH4738 Superalloy Produced by VIM and VAR. Materials. 2018; 11(6):1024. https://doi.org/10.3390/ma11061024

Chicago/Turabian StyleChen, Zhengyang, Shufeng Yang, Jingshe Li, Hao Guo, and Hongbo Zheng. 2018. "Effects of Different Hot Working Techniques on Inclusions in GH4738 Superalloy Produced by VIM and VAR" Materials 11, no. 6: 1024. https://doi.org/10.3390/ma11061024

APA StyleChen, Z., Yang, S., Li, J., Guo, H., & Zheng, H. (2018). Effects of Different Hot Working Techniques on Inclusions in GH4738 Superalloy Produced by VIM and VAR. Materials, 11(6), 1024. https://doi.org/10.3390/ma11061024