1. Introduction

In recent years, the road construction industry has made great progress with the development of technologies, but the qualities of existing roads are mixed. The asphalt concrete pavement, as the surface course of the road structure, is subjected to repeated actions of vehicle loads and the environmental influence of seasonal changes. Under cyclic loading, the stresses and strains in the material change continuously, which results in the reduction of the strength. Pavement under cyclic loading is prone to fatigue failure. The fatigue life of pavement material has become the focus of research for an increasing number of researchers [

1,

2,

3,

4,

5,

6,

7,

8]. Three approaches are usually used to study fatigue life: the phenomenological approach, the fracture-mechanics-based approach, and the energy (damage) approach [

9,

10,

11,

12,

13,

14,

15].

The fracture mechanics approach was used to study fatigue by monitoring crack development in its early stages. Researchers carried out many studies on the fatigue properties of asphalt concrete with rubber grains based on fracture mechanics [

16,

17]. Principles of fracture mechanics were applied to data obtained by monitoring the size and the length of the crack opening to discover the stress intensity factors at the crack tip [

18,

19]. The Paris equation can describe the relation of the stress intensity factors to the crack propagation and was used to describe the growth process of fatigue cracks and predict the fatigue life of the asphalt mixture [

20,

21,

22]. Limitations of this approach include the need for a large amount of experimental data, considering only the crack propagation, and the stress intensity factor

KI being not a material constant at higher temperatures [

23,

24]. Also, fracture mechanics cannot accurately describe the viscoelastic plastic mechanical properties of the asphalt mixture.

Researchers carried out many studies on the fatigue properties of bitumen and the asphalt mixture based on the dissipated energy concept. These studies assumed that fatigue life depends on the accumulation of dissipated energy in each loading cycle. The fatigue equation established based on this assumption was used to predict fatigue life [

25,

26,

27,

28]. Later studies demonstrated that the damage was related to the rate of change in dissipated energy from one loading cycle to the next and only part of the dissipated energy can cause damage to the material. Therefore, it is inaccurate to use the total dissipated energy to predict the fatigue life [

29,

30,

31].

The phenomenological approach provides an important idea for the early study of fatigue properties. This approach assumes that the stress or the strain in the asphalt layer is related to the number of load repetitions to failure. Some fatigue equations established based on this assumption were used to predict fatigue life [

32,

33]. There was a large discreteness in the fatigue life predicted by these equations. Also, the phenomenological approach cannot reveal the mechanism of damage evolution [

34,

35,

36,

37].

The fatigue equations in the above studies, established from different perspectives, were used to predict the fatigue life of the asphalt mixture. These equations, established after processing a large amount of experimental data, were complex and inconvenient to use. Permanent deformation (PD) is accumulated during the damage evolution process of the asphalt mixture, and since the PD is easy to obtain and deal with, establishing the fatigue equation based on the analysis of the PD has important implications for researchers in predicting the fatigue life of the asphalt mixture.

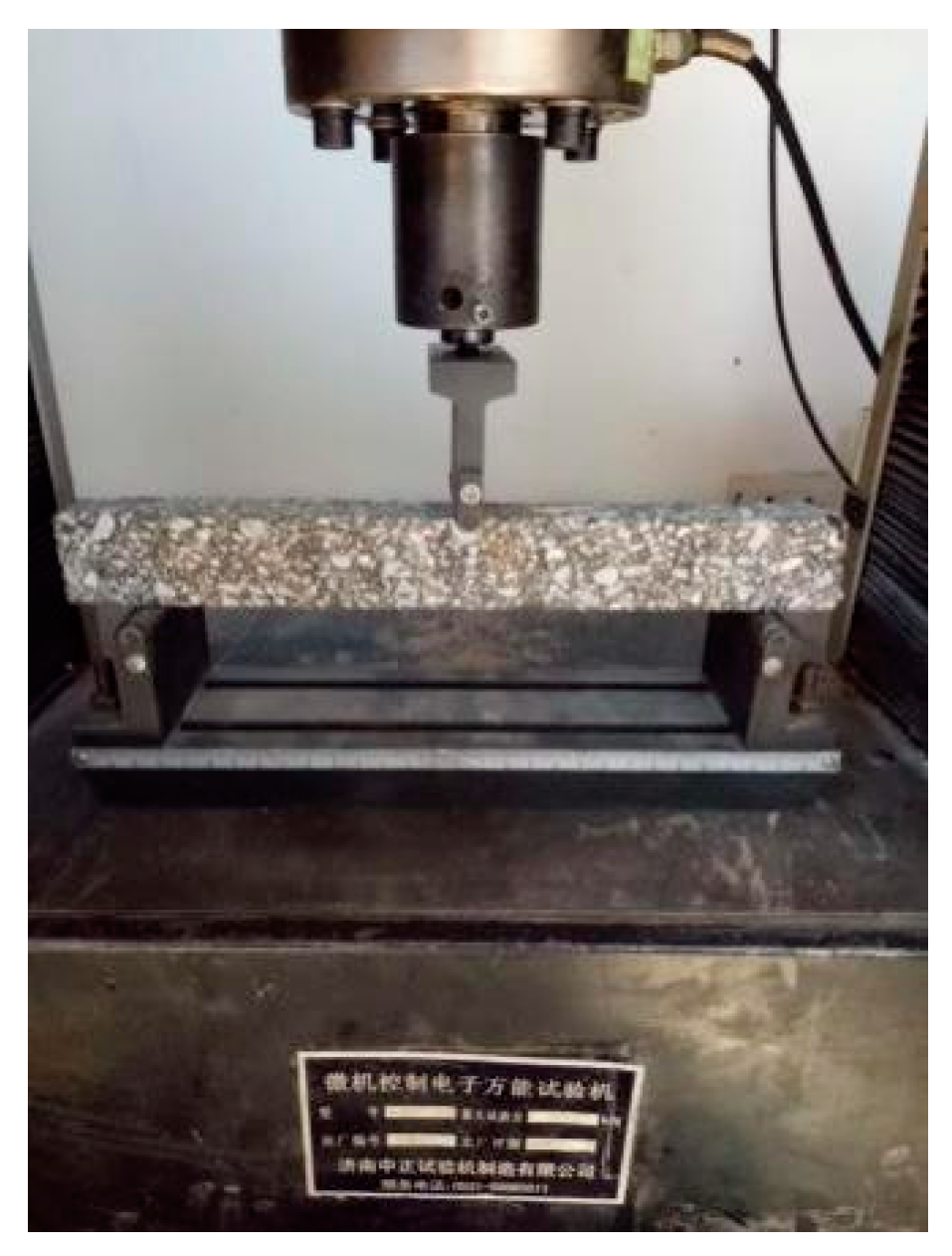

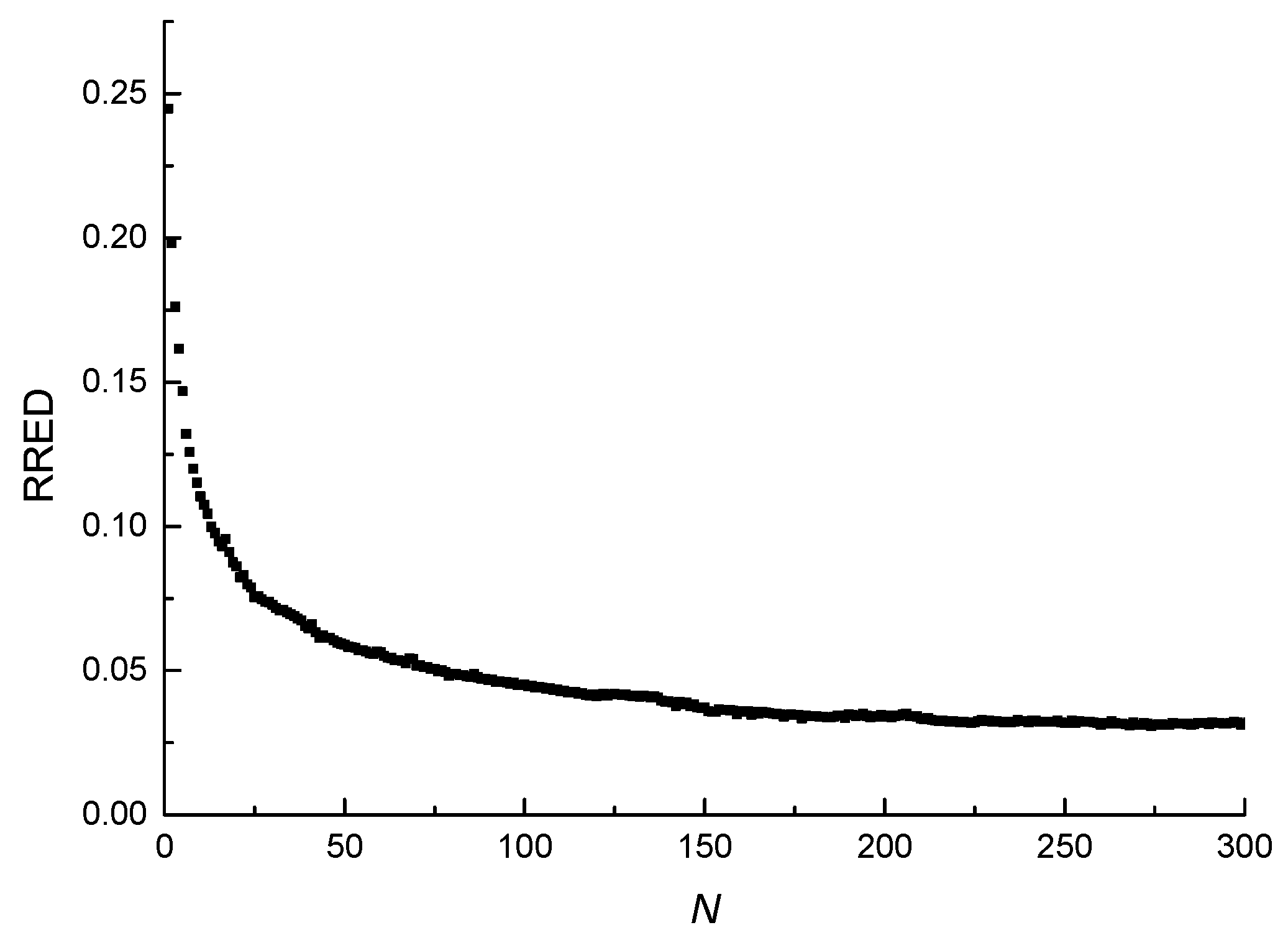

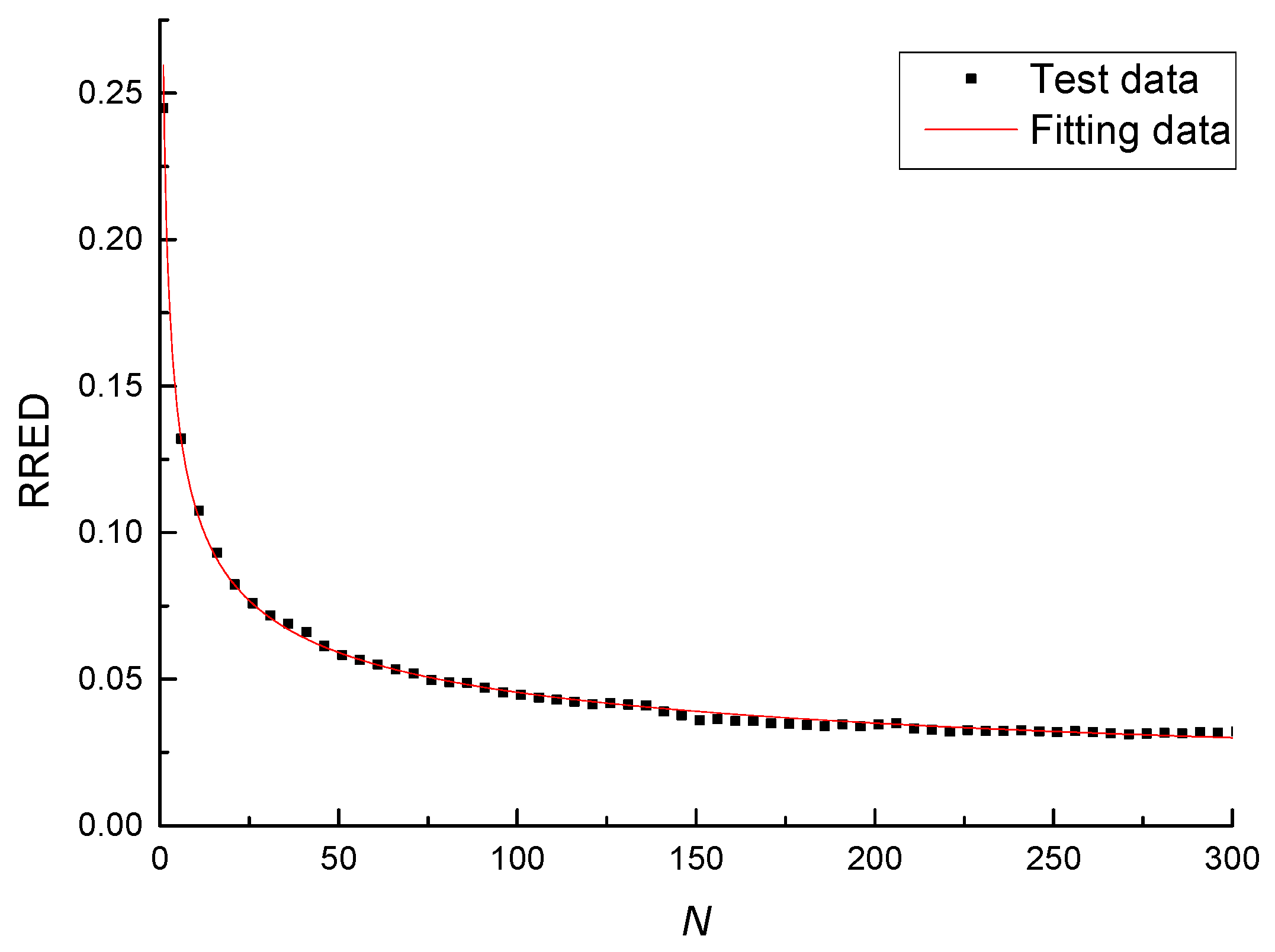

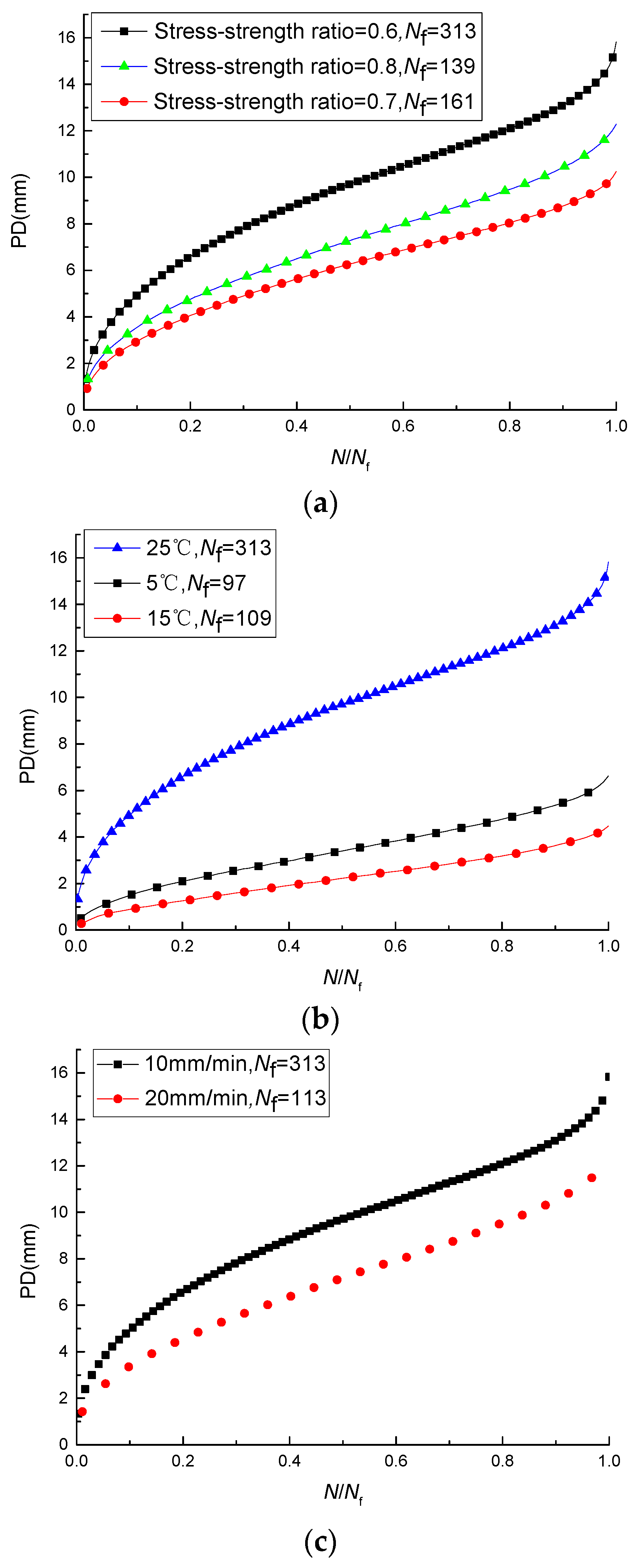

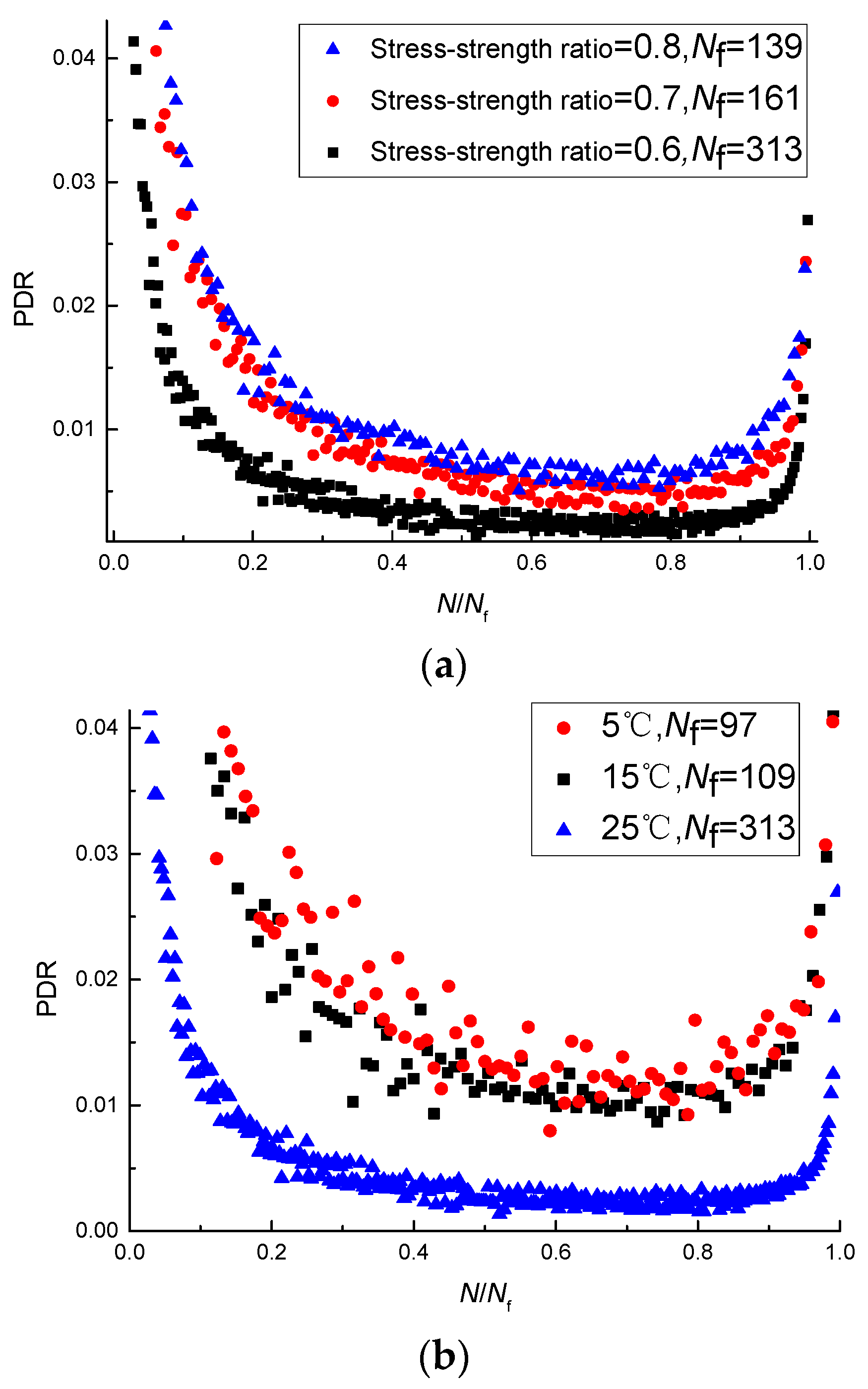

To address the shortcomings of the above studies, understand the change law of deformation of the asphalt mixture under cyclic loading, and predict the fatigue life from the perspective of deformation, the AC-13I asphalt mixture was used under different experimental conditions to carry out the three-point bending fatigue tests in this paper. By analyzing the change laws of the recovery ratio of elastic deformation (RRED), the conclusions drawn from this are that the elastic recovery ability of the asphalt mixture under cyclic loading gradually decreases, and two mathematical models describing the change laws of the RRED and the PD are proposed. By analyzing the influence of experimental factors on the RRED and the PD, the conclusions also drawn are that the RRED or the PD does not change monotonously with fatigue life, and the RRED or the PD cannot be directly used to predict the fatigue life of the asphalt mixture under cyclic loading. The PD of the asphalt mixture does not change monotonously with fatigue life, indicating that only part of the PD causes the damage of the asphalt mixture, and that the other part causes the viscoelastic deformation. By analyzing the relationship between the damage evolution speed and the value of the permanent deformation ratio (PDR), it was found that the faster the damage evolution speed of the asphalt mixture under cyclic loading was, the earlier the damage was close to the threshold of failure, and the fatigue life of the asphalt mixture under cyclic loading decreased with the increase of the damage evolution speed. It was also found that the power function could be used to describe the mathematical relationship between fatigue life and the plateau value of the PDR of the asphalt mixture. The fatigue equation was established based on the power-function relationship between the plateau value of the PDR and the fatigue life. The predicted fatigue life of the asphalt mixture under different test conditions was calculated by the fatigue equation and compared with the test fatigue life. The relative error between the fatigue life predicted by the fatigue equation and the test fatigue life was small, which indicates that the proposed equation can be used to accurately predict the fatigue life of an asphalt mixture.

5. Analysis of PDR

The PD is related to damage evolution and fatigue life, but the PD cannot be directly used to predict the fatigue life of the asphalt mixture. To reveal the relationship between the PD and the fatigue life, the definition of PDR is proposed in this paper as

where PD

N+1 and PD

N are the PDs of the loading cycle (

N+1) and the loading cycle

N. Under certain conditions, the PD of the viscoelastic deformation part of each loading cycle is a fixed value [

41]. The PDR reflects the proportion of the PD that produces the viscoelastic deformation to the total PD of each loading cycle. The value of PDR is only related to the damage deformation.

5.1. Influence of Experimental Factors on PDR

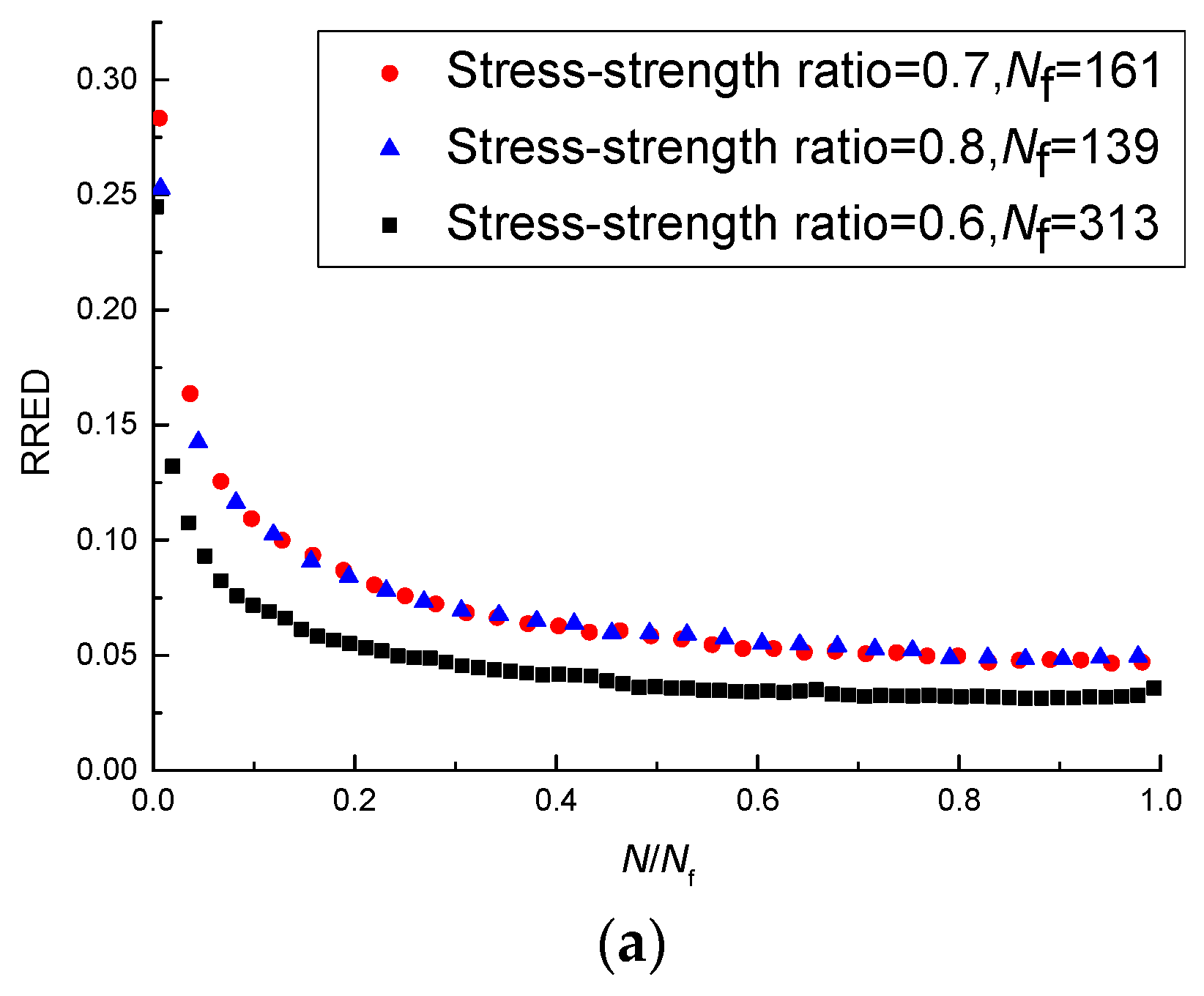

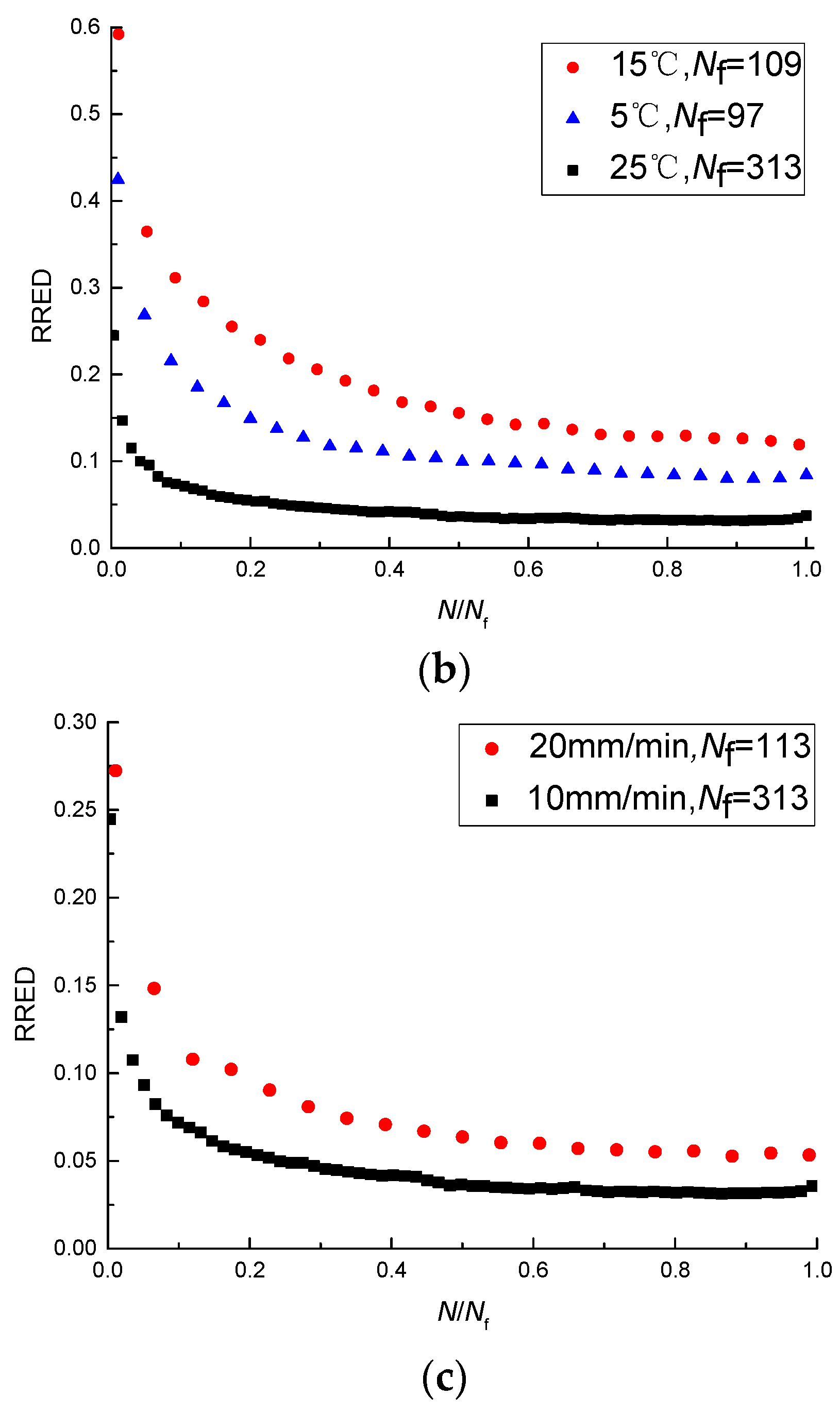

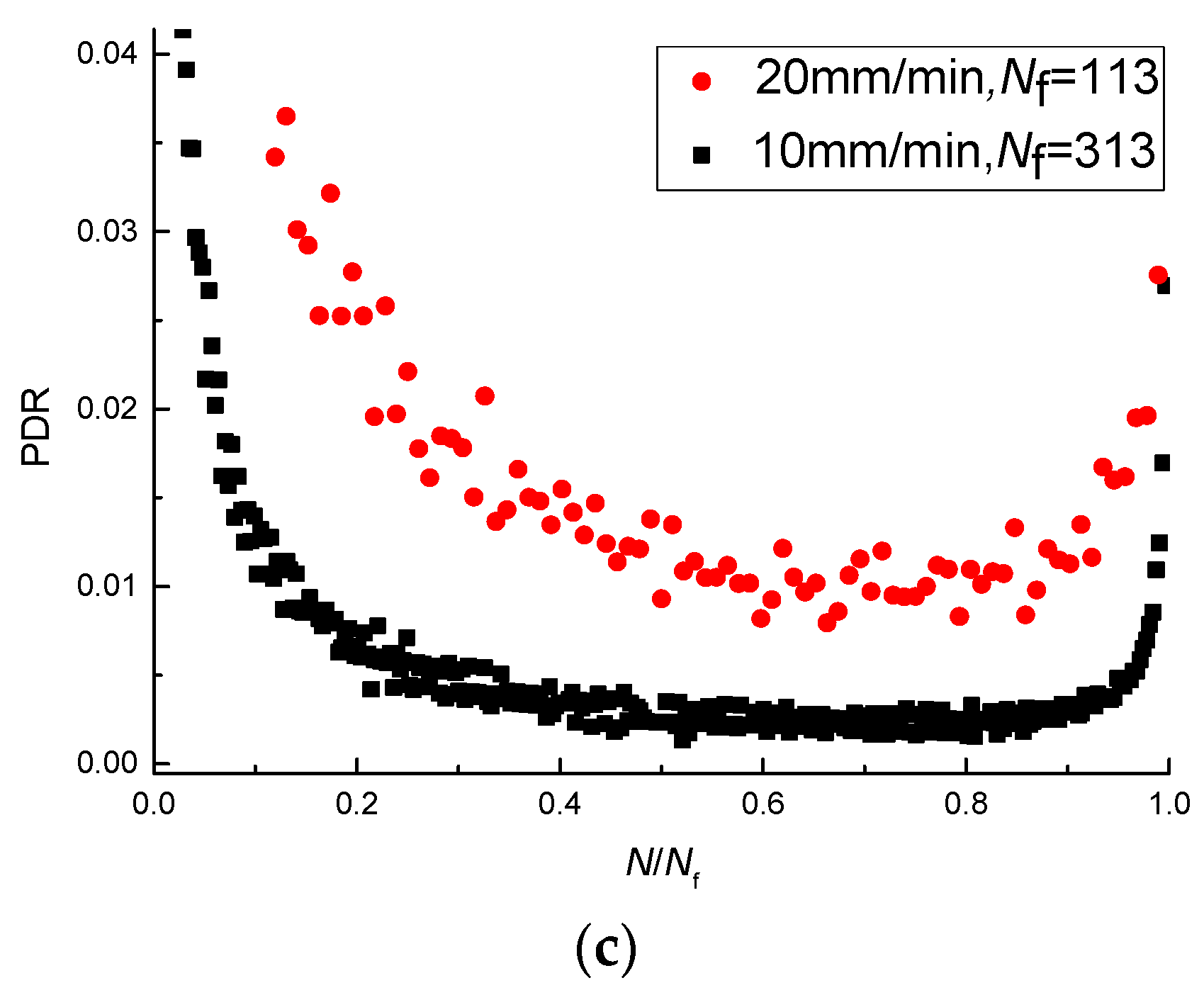

The PDRs at different loading cycles were calculated using Equation (4). To better analyze the PDR under different experimental factors, the number of loading cycles is converted into dimensionless quantities. As shown in

Figure 10, at first, the PDR decreases with the increase of the number of loading cycles, then the ratio increases, and the permanent-deformation-ratio plot can be divided into three stages. The trends of the PDRs (vs. the number of loading cycles) under different test conditions are the same. The PDR decreases with the increase of the stress-strength ratio and the loading rate and increases with the decrease of the temperature, so there is a negative correlation between fatigue life and the PDR.

5.2. Analysis of Damage Evolution

Under certain conditions, the PD of the viscoelastic deformation part of each loading cycle is a fixed value, and the value of the PDR is only related to the damage deformation. Therefore, the damage factor can be expressed based on the PDR as

where

D is the damage factor of the loading cycle

N and PDR

k is the PDR at the loading cycle

k.

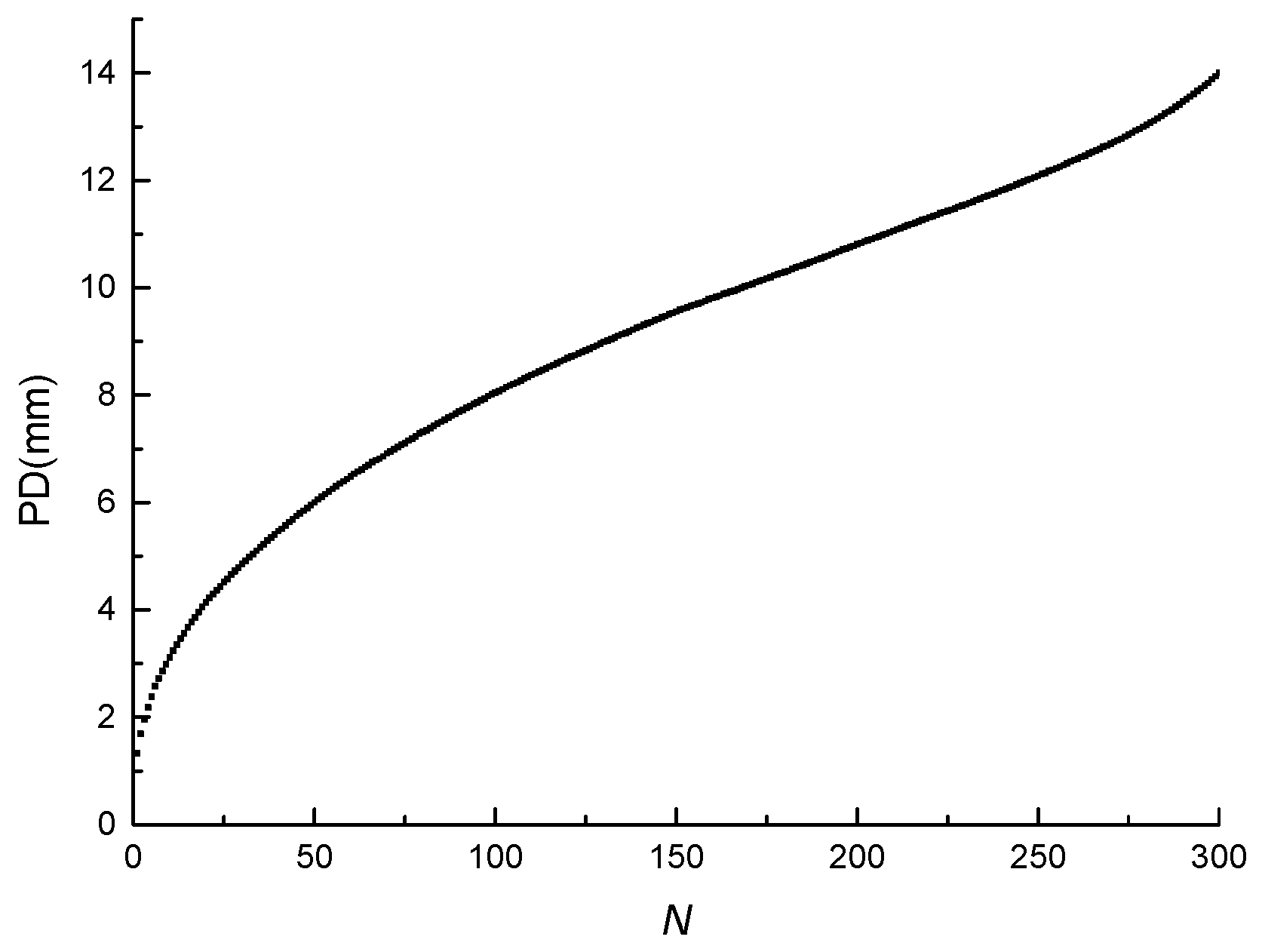

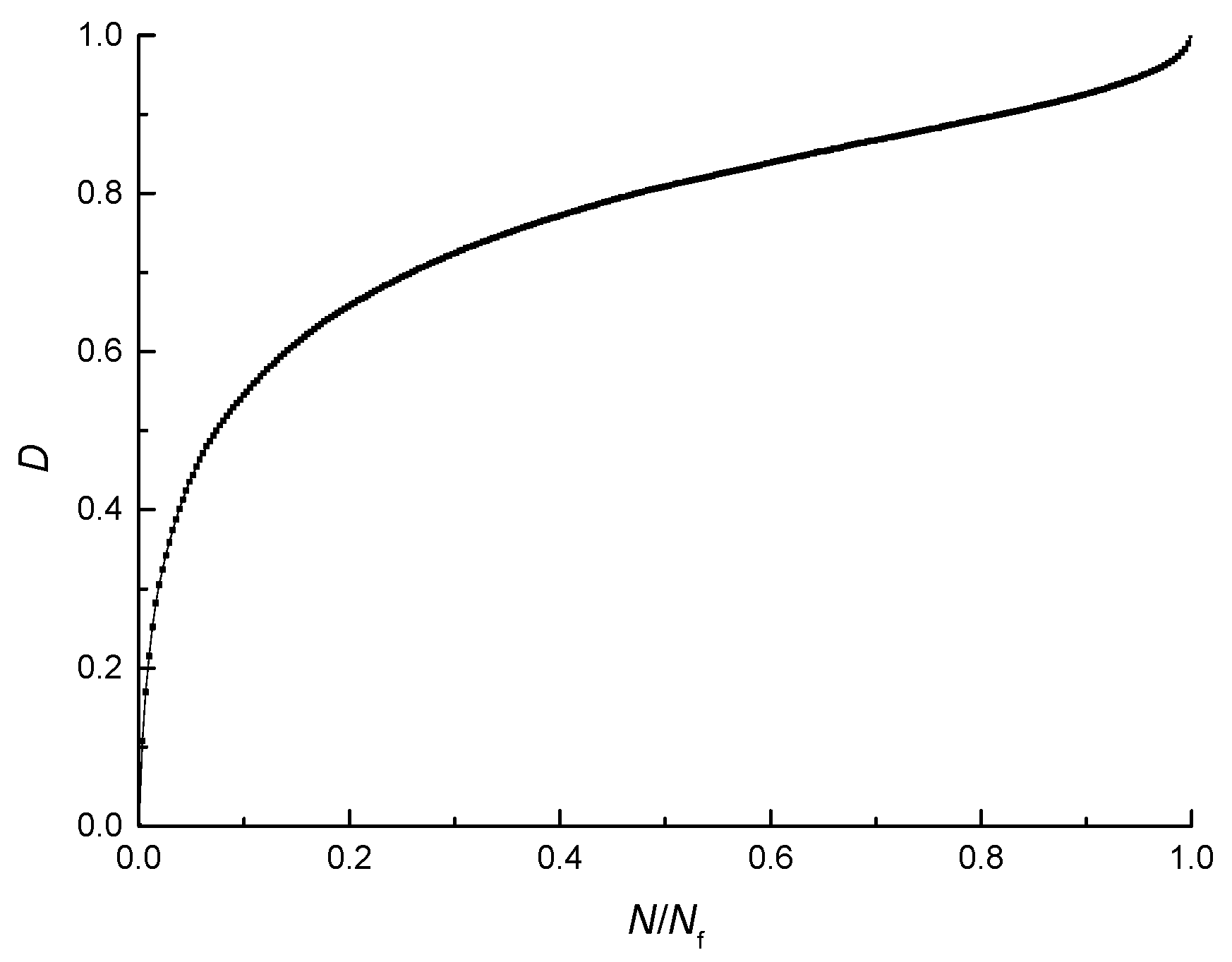

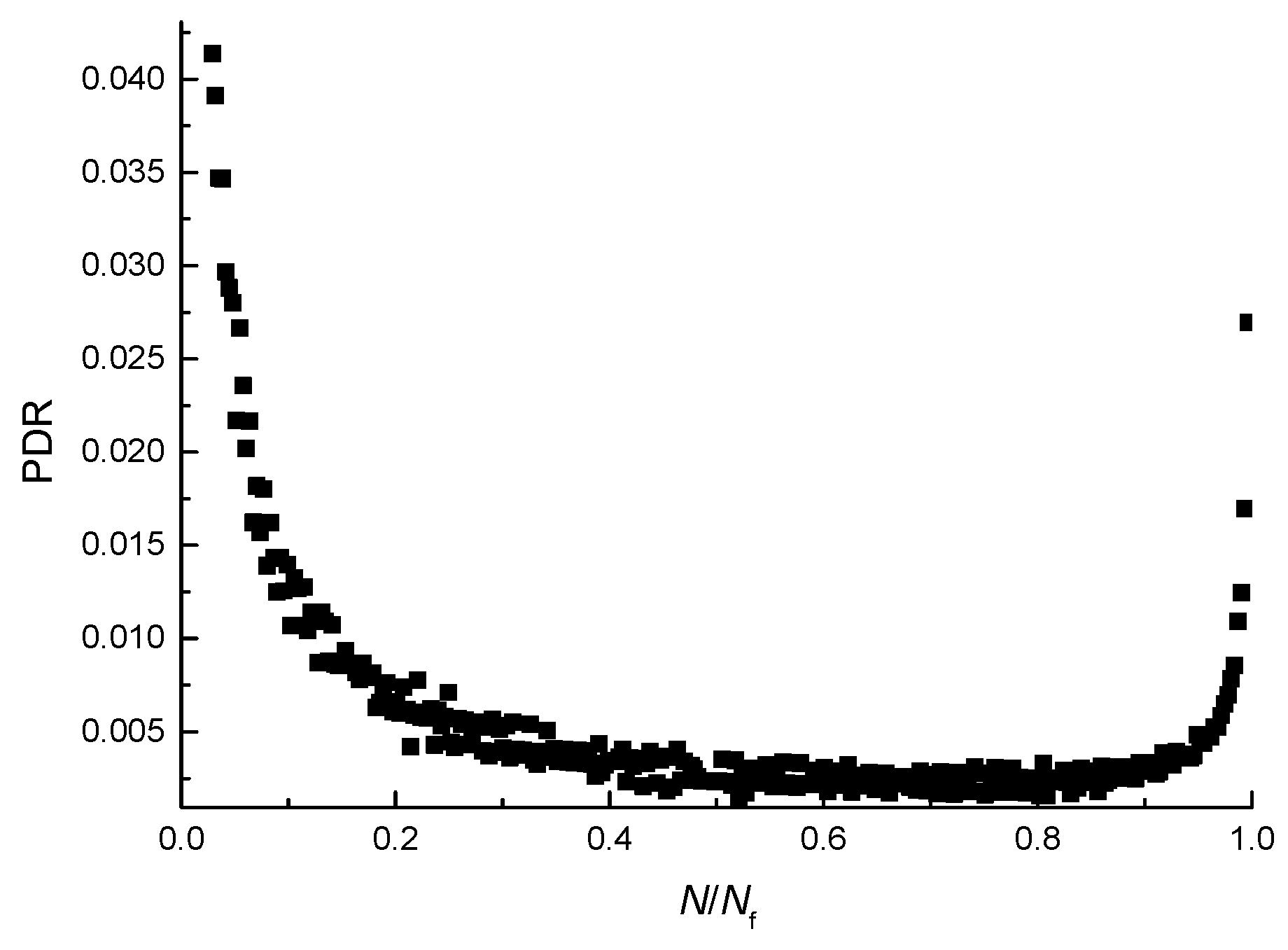

In order to study the damage evolution process of the asphalt mixture from the perspective of deformation, the damage evolution curve (the D-

N/

Nf curve) and the PDR evolution scatter plots (PDR-

N/

Nf scatter plot) for the fatigue test at the temperature of 25 °C, at the stress-strength ratio of 0.4, and at the loading rate of 10 mm/min are shown in

Figure 11 and

Figure 12. To better analyze the damage evolution process, the number of loading cycles is converted into dimensionless quantities.

As shown in

Figure 11, the damage increases nonlinearly during the fatigue test, and the process can be divided into three stages. In the first stage, the damage lasts a short time but increases rapidly, and at the end of this stage, it reaches a large value. In the second stage, the damage lasts a long time and increases stably. In the third stage, the damage increases sharply and the beam specimen fractures in the end [

42].

As shown in

Figure 12, at first, the PDR decreases with the increase of the number of loading cycles, then the ratio increases, and the permanent-deformation-ratio plot can be divided into three stages. The first stage lasts a short time and the PDR decreases rapidly, but the speed of decreasing gradually slows down. At the end of the first stage, the PDR drops to a small value. The second stage lasts a long time and the PDR decreases slowly. The third stage lasts a short time, but the PDR increases sharply and the growth rate of the PDR increases gradually. The rapid decline in the first stage of the PDR shows that a considerable portion of the PD contributes to material damage. After the material damages to a certain extent, the PDR moves into the second stage of the low stable value, indicating that the PD mainly contributes to the viscoelastic deformation in the material. The PD of this part tends to be stable, which is far greater than what the PD contributed to material damage, which makes up a large proportion of the total deformation. In the third stage, the PD reaches the failure threshold and the specimen breaks quickly because of the deformation in the material accumulated in the first and second stage.

As shown in

Figure 11 and

Figure 12, the three stages of the PDR and the three stages of the damage correspond to each other, which indicates that there exists a connection between the damage evolution and the value of PDR. It can be seen from the growth rate of the damage and the value of PDR that the damage of the asphalt mixture increases rapidly in the first and third stage and the growth rates of damage in the first and third stage are greater than that in the second stage. In the same way, the values of the PDR in the first and third stage are greater than that in the second stage. Therefore, the PDR is an energy parameter reflecting the speed of damage evolution of the asphalt mixture, and the speed of damage evolution increases with the PDR of the asphalt mixture.

The faster the damage evolution speed of the asphalt mixture under cyclic loading is, the earlier the damage is close to the threshold of failure and the shorter the corresponding fatigue life is. Therefore, the fatigue life decreases with the increase of the PDR.

5.3. Establishment of Fatigue Equation Based on Plateau Value (PV) of PDR

The damage evolution analysis in

Section 5.2 showed that fatigue life decreases with the increase of the PDR. At first, the PDR decreases with the increase in the number of loading cycles, then the ratio increases, and the process can be divided into three stages. Although the PDR in the first and third stages is greater than that in the second stage, the second stage accounts for the major portion of the entire PD in the loading process. Therefore, the PDR in the second stage reflects the overall PDR of the three stages. In this paper, the average PDR in the second stage is taken as the plateau value (PV), and the PDR of the three stages is represented by the PV.

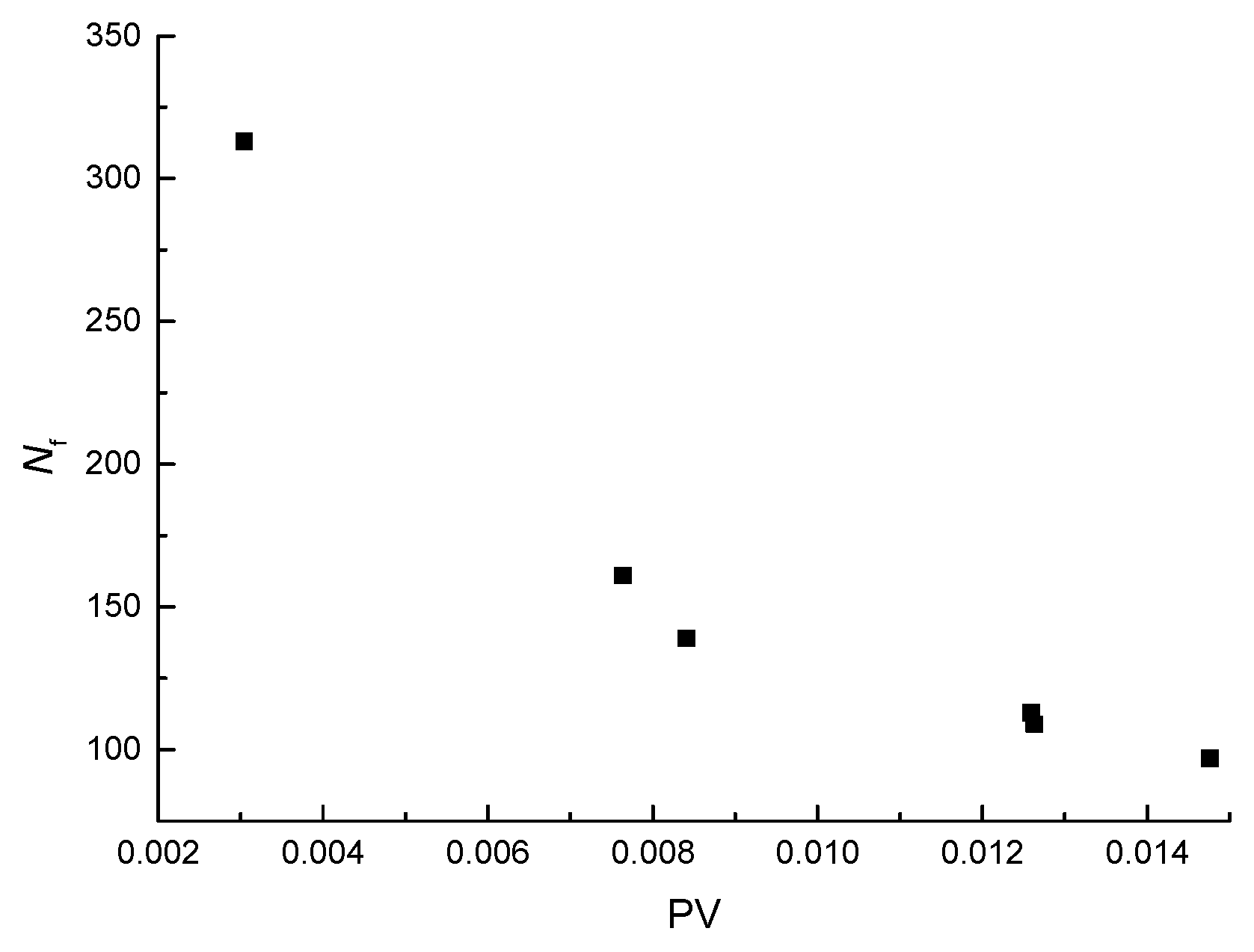

The results of the fatigue life (

Nf) and the PV of the three-point bending fatigue tests, as listed in

Table 6, indicate that fatigue life decreases with the increase of the plateau value (PV). The

Nf-PV scatter plot is shown in

Figure 13, which indicates that fatigue life can be expressed in a power function with the increase of PV. The power function, simple and easy to use, is established as

where

Nf is the fatigue life and

A and

B are fitting parameters. The fitting results are listed in

Table 7. The correlation coefficient is greater than 0.98, so the observed data are well represented by the equation.

According to the fatigue equation for the asphalt mixture, the predicted fatigue lives of the asphalt mixture under different test conditions were calculated and compared with the test fatigue lives, as listed in

Table 8. The average relative error of the fatigue life predicted by the fatigue equation to the test fatigue life is 11.03%. Therefore, the fatigue equation based on the plateau value of the PDR can well predict the fatigue life of the asphalt mixture under cyclic loading.