Microstructure and Solidification Crack Susceptibility of Al 6014 Molten Alloy Subjected to a Spatially Oscillated Laser Beam

Abstract

:1. Introduction

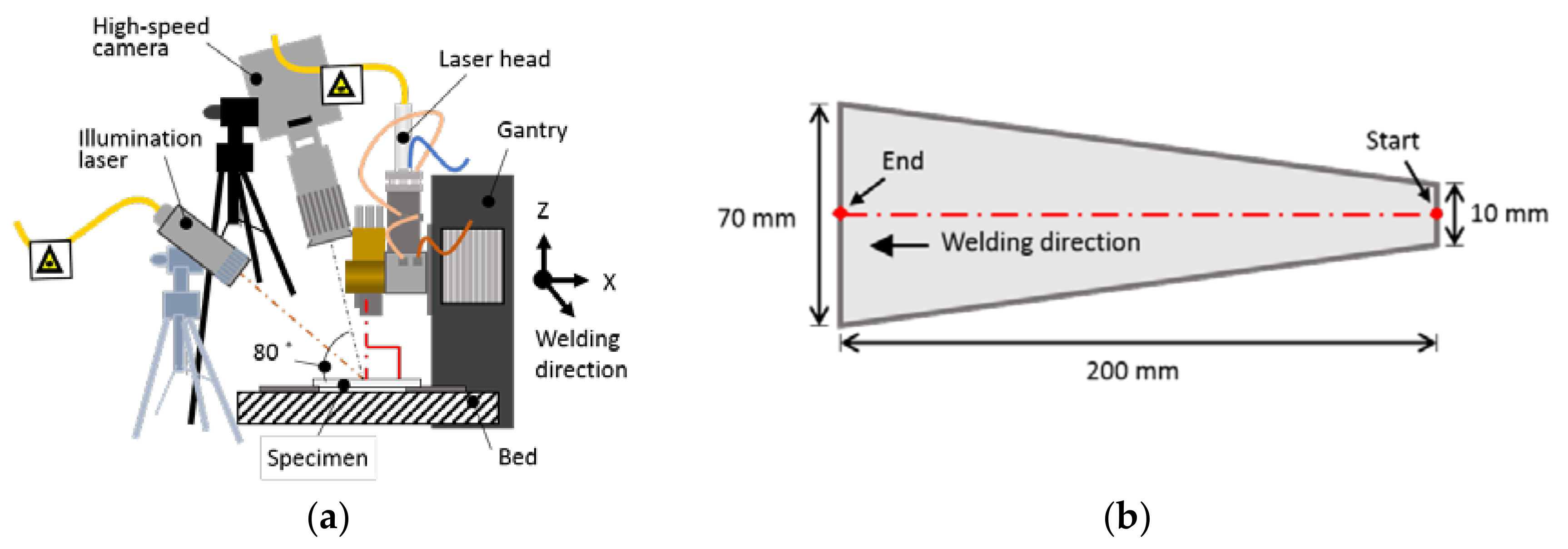

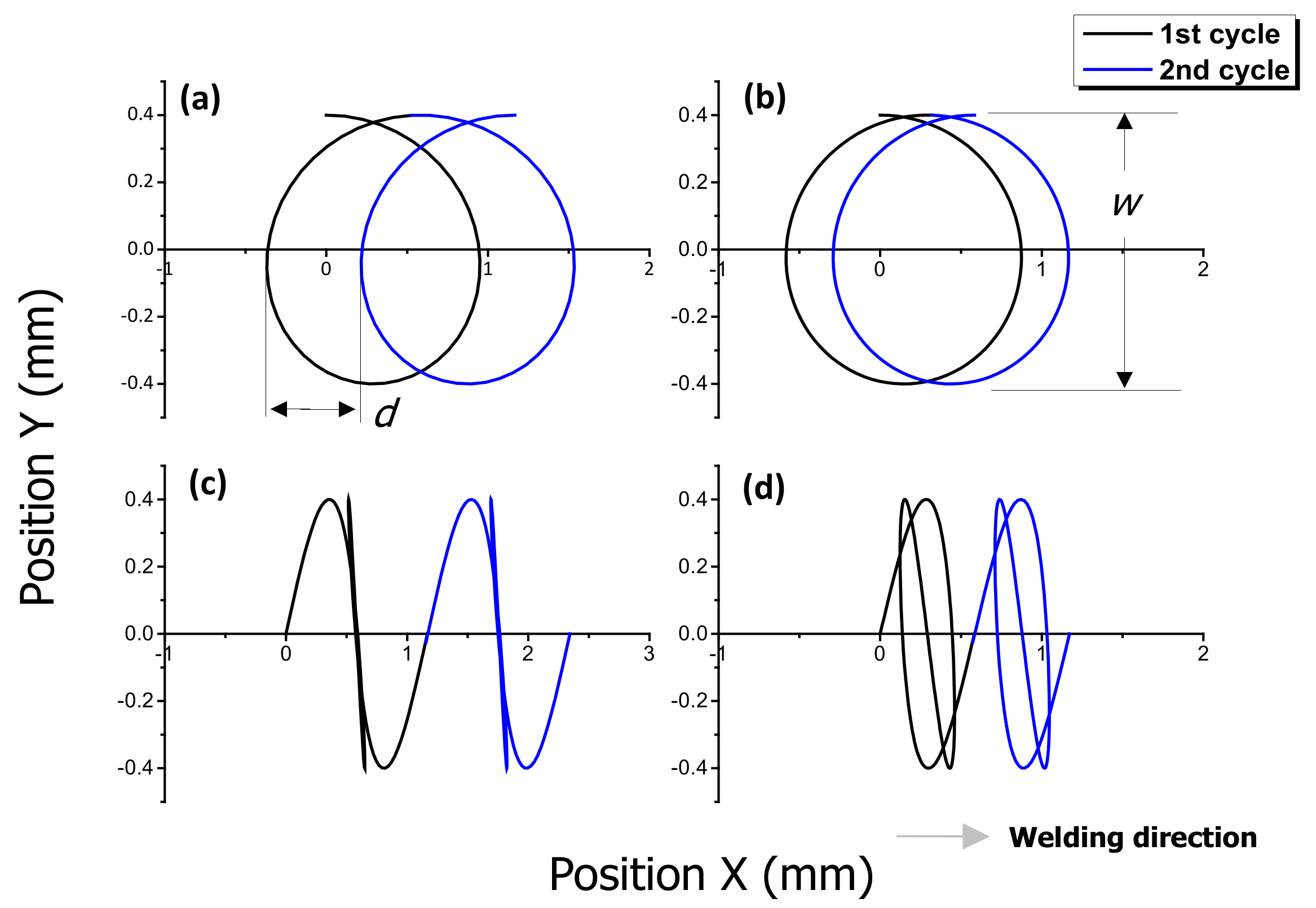

2. Experimental Procedure

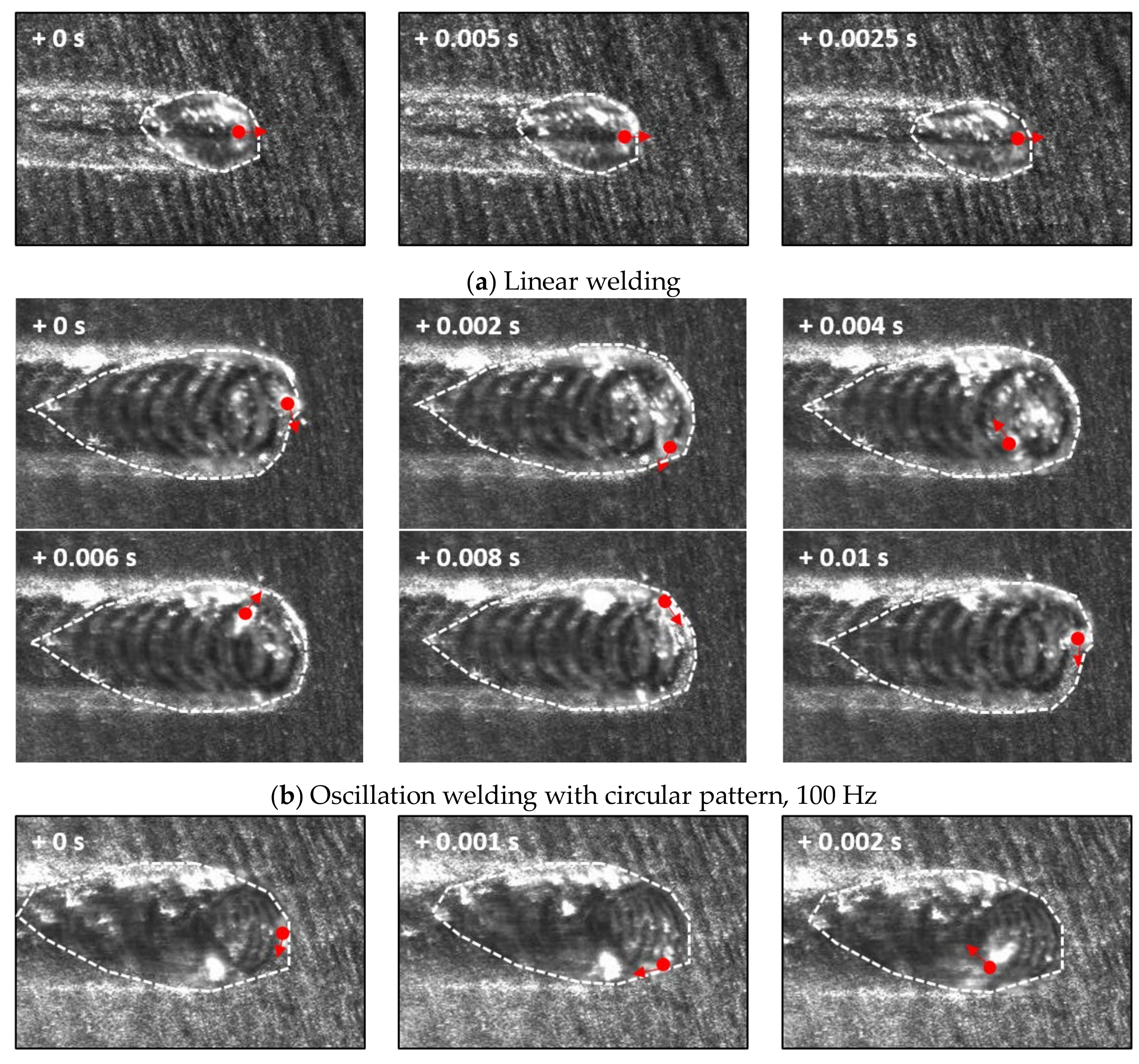

3. Results and Discussion

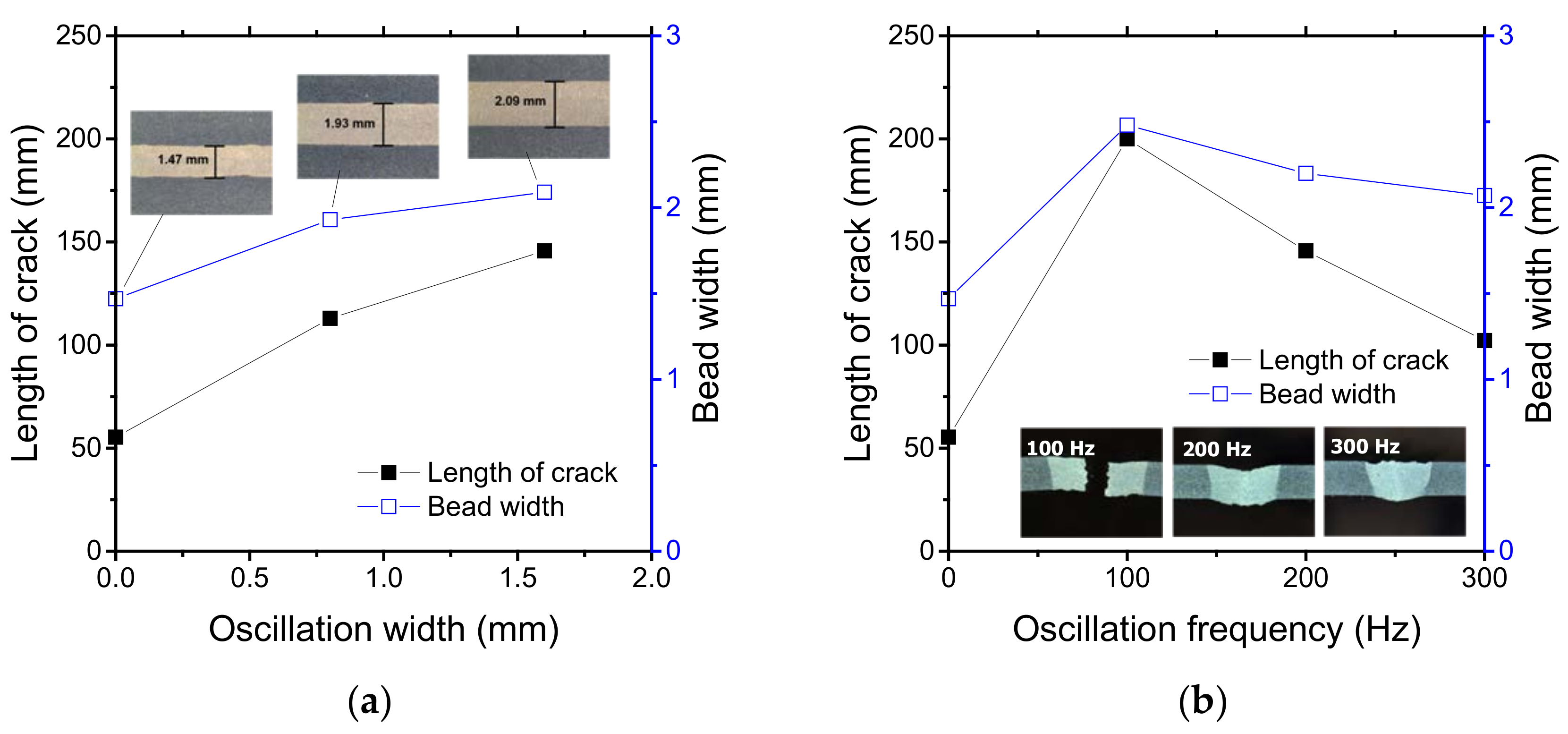

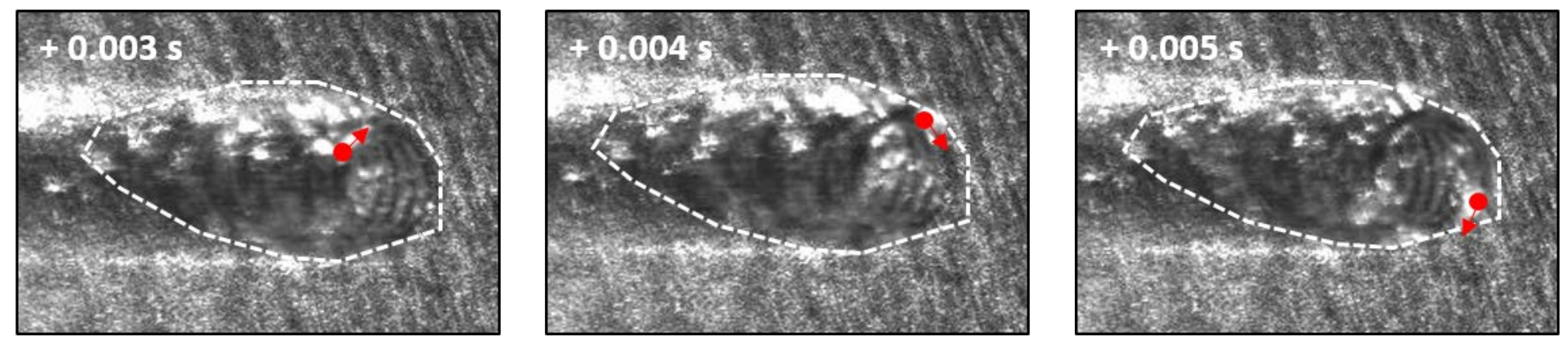

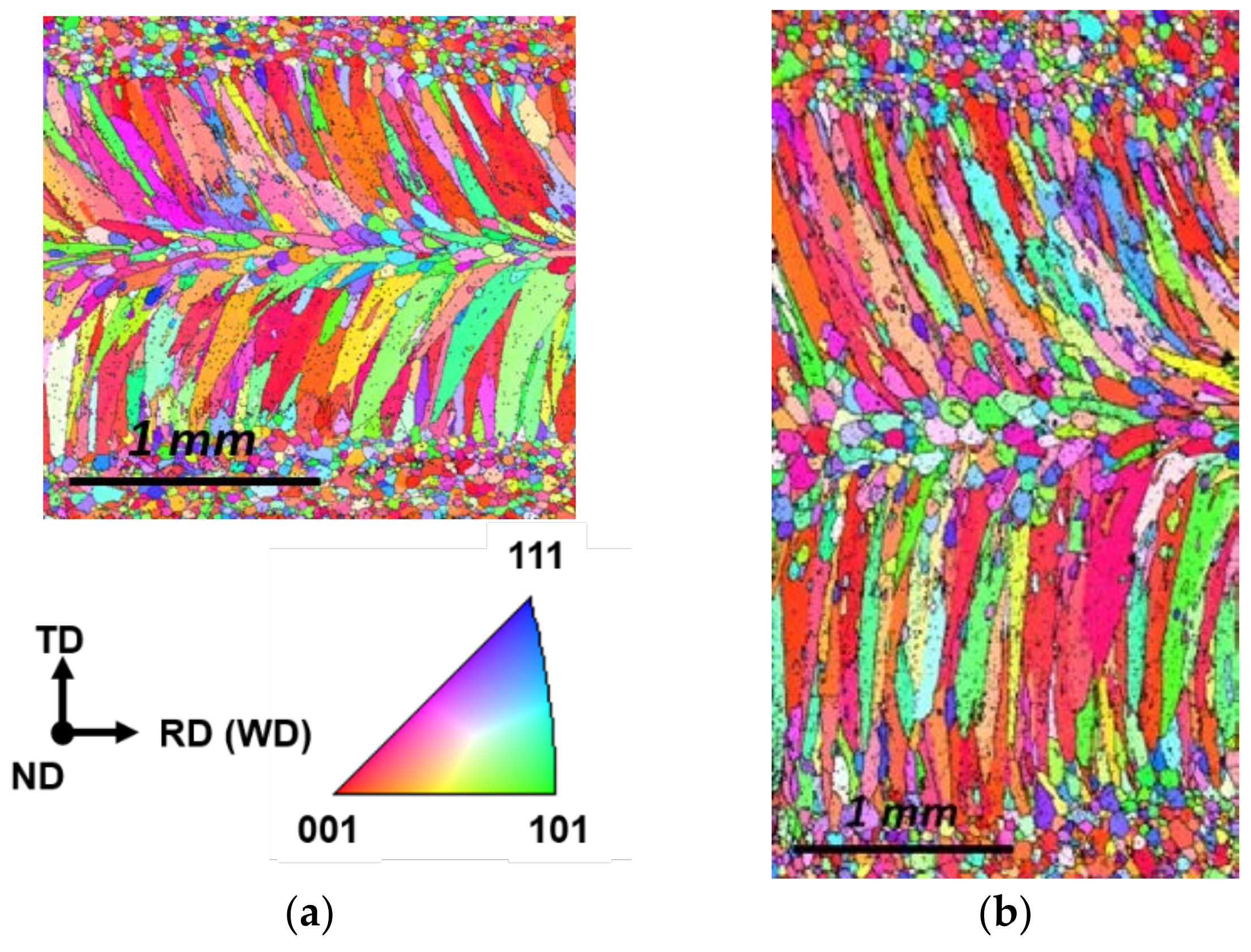

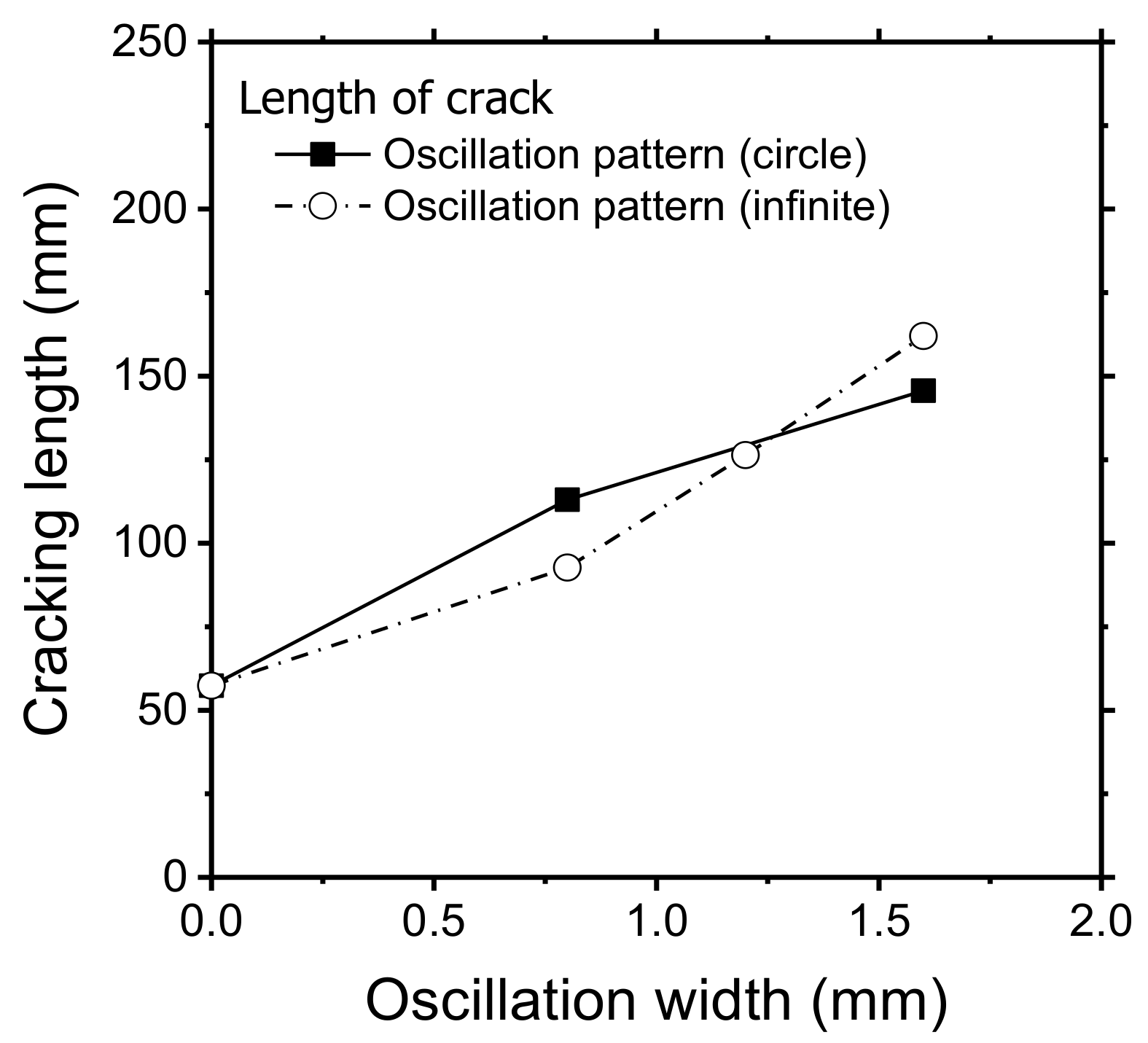

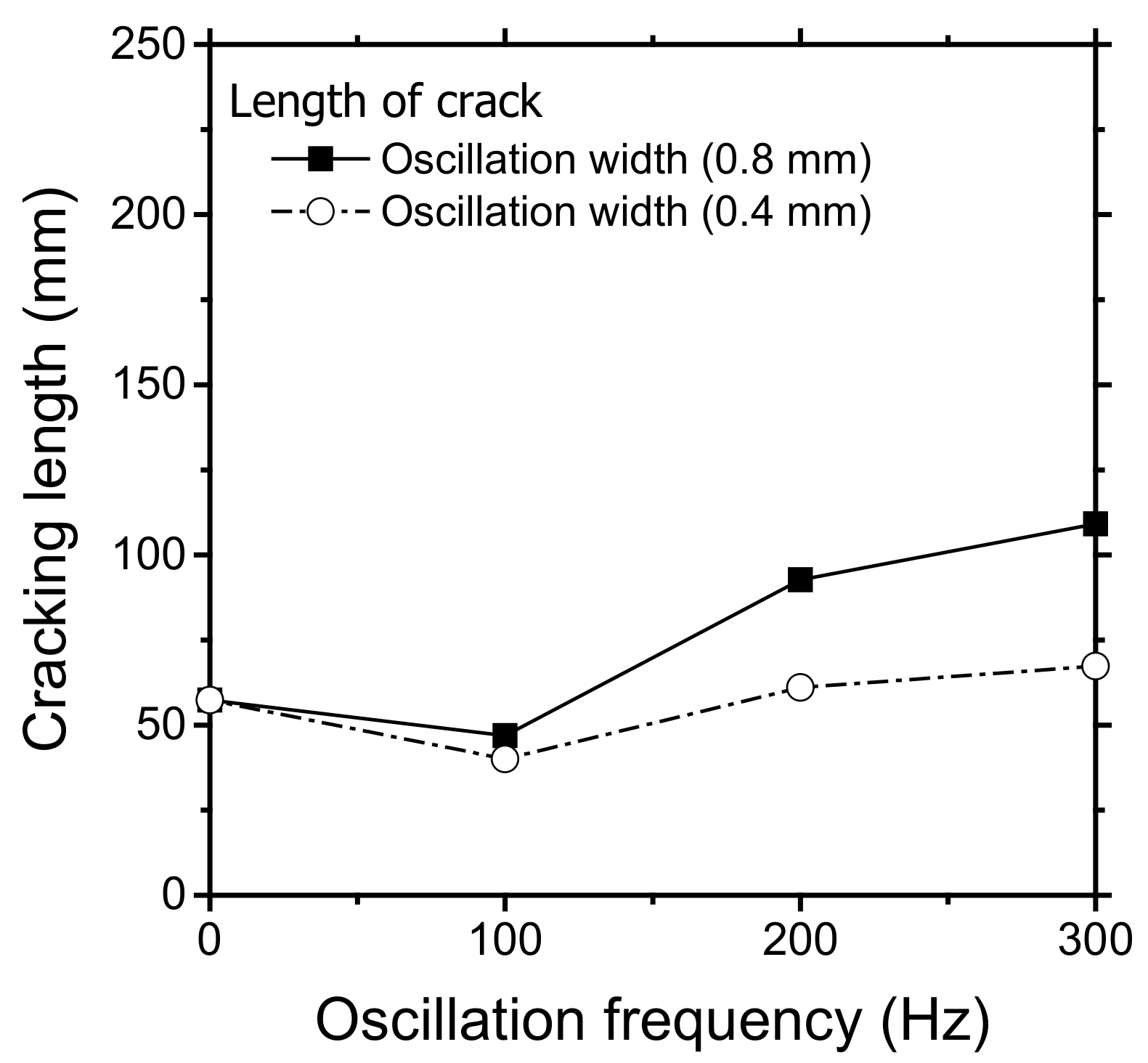

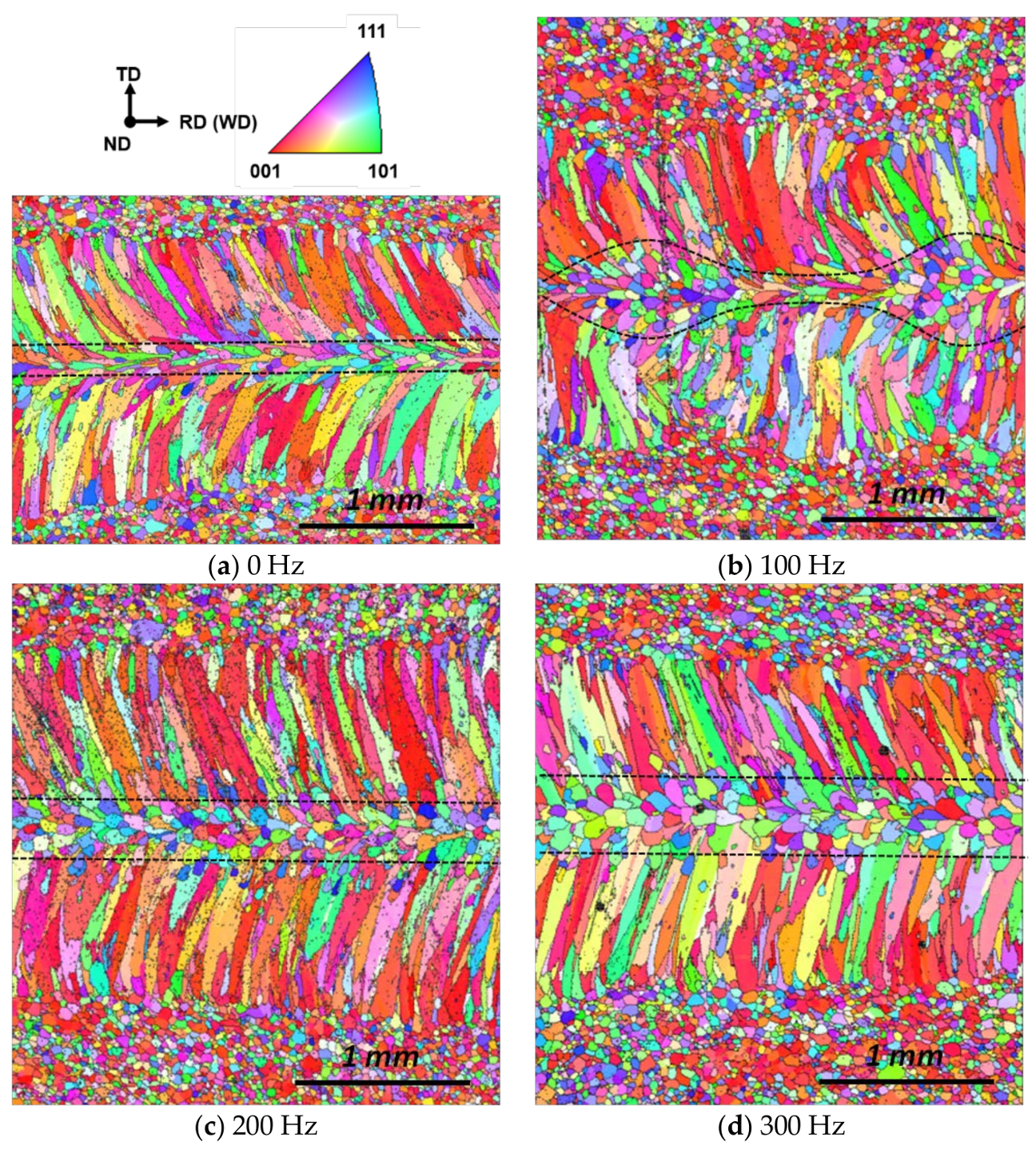

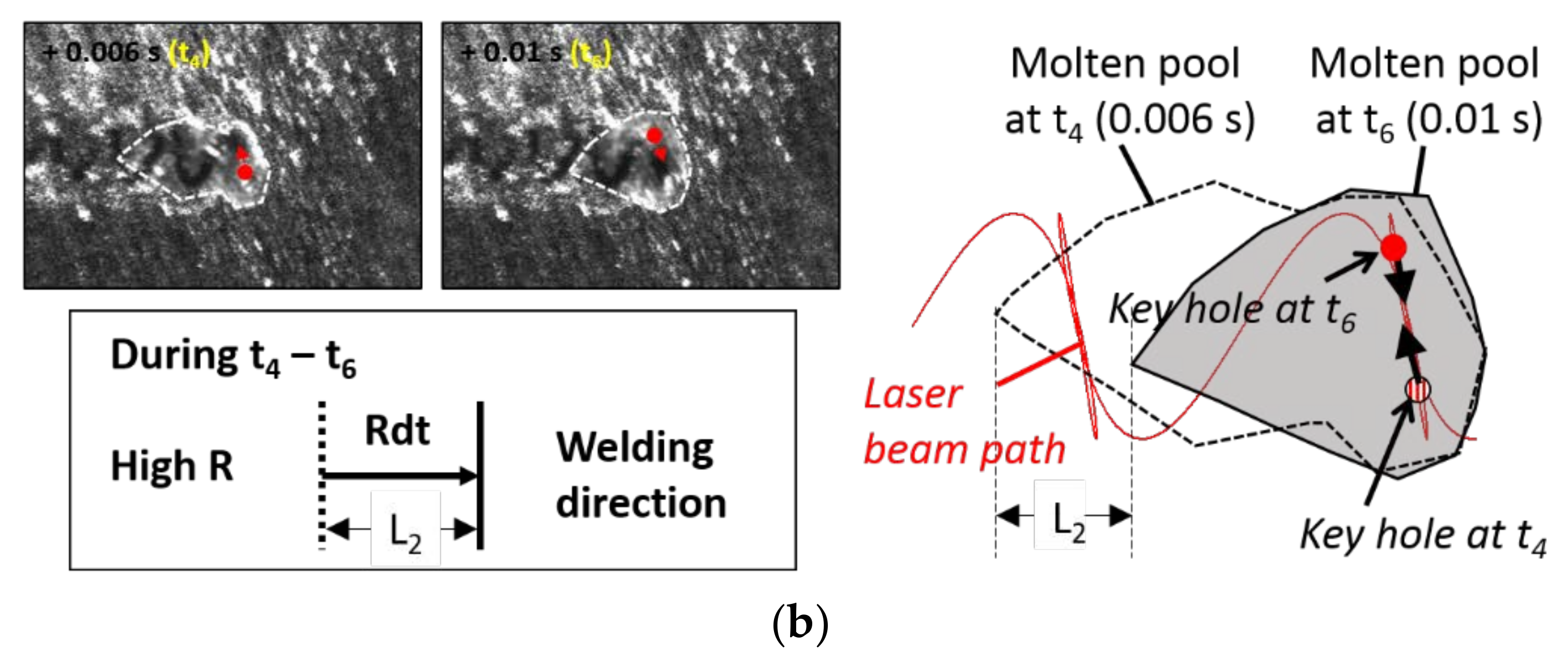

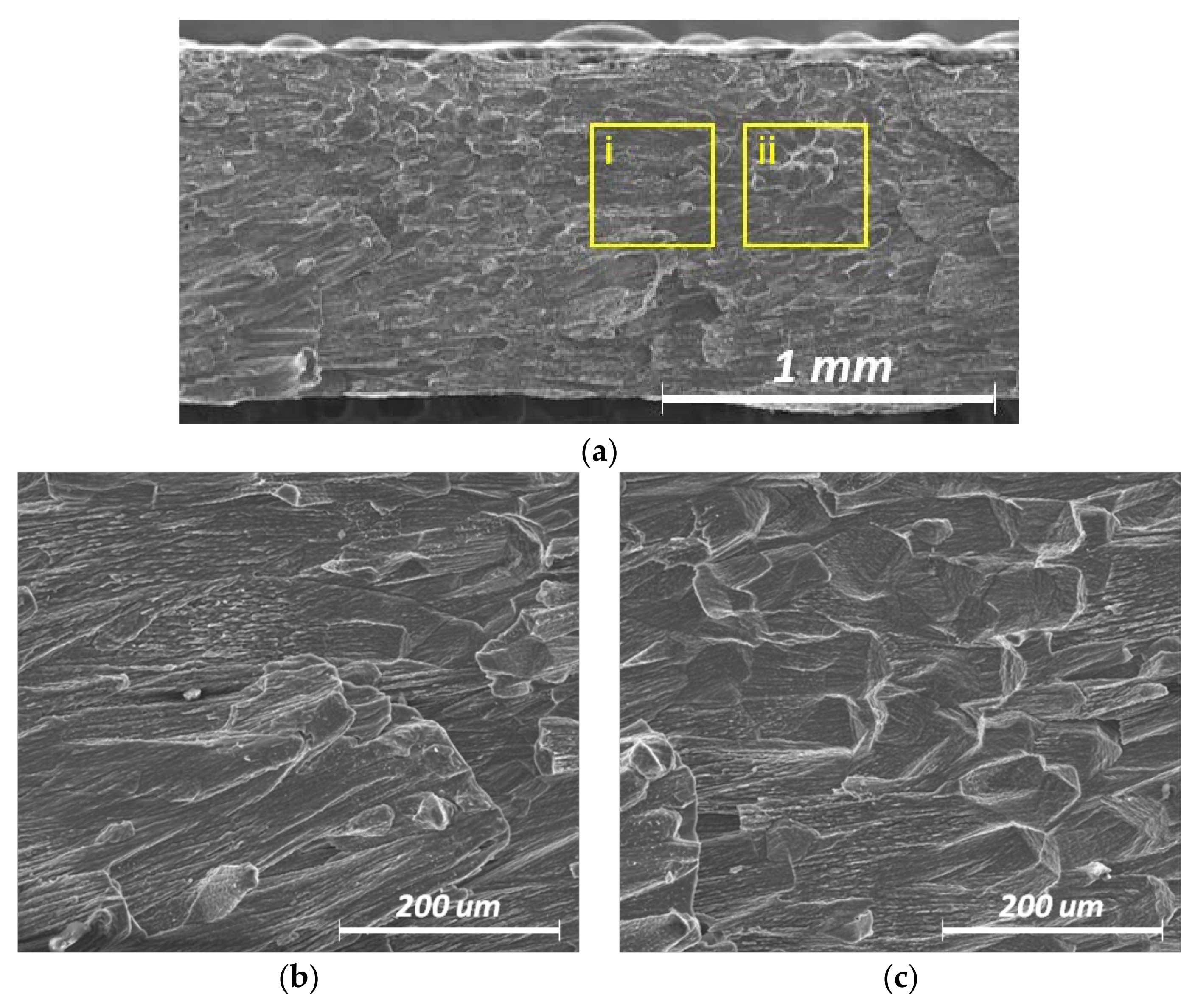

3.1. Effects of Circular Beam Pattern on Hot Crack Susceptibility

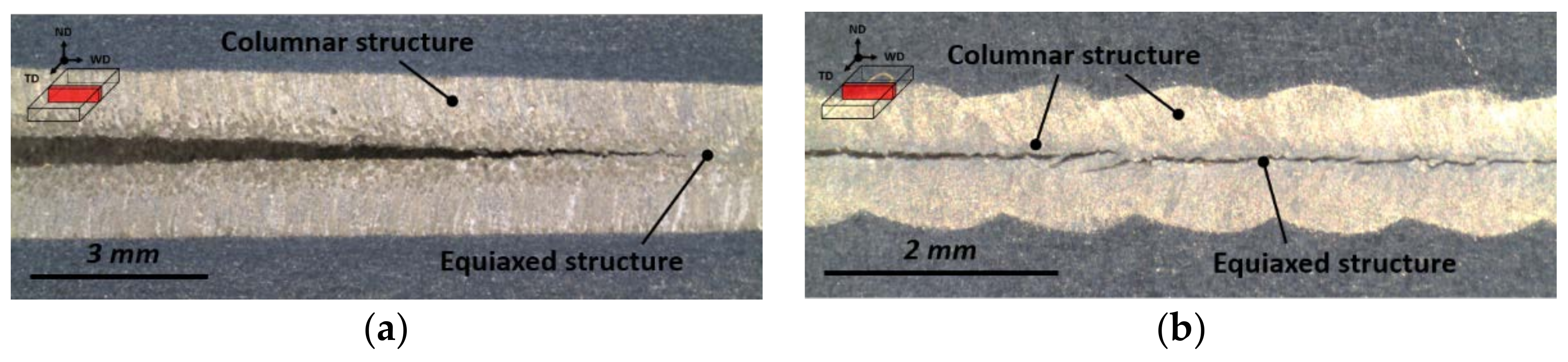

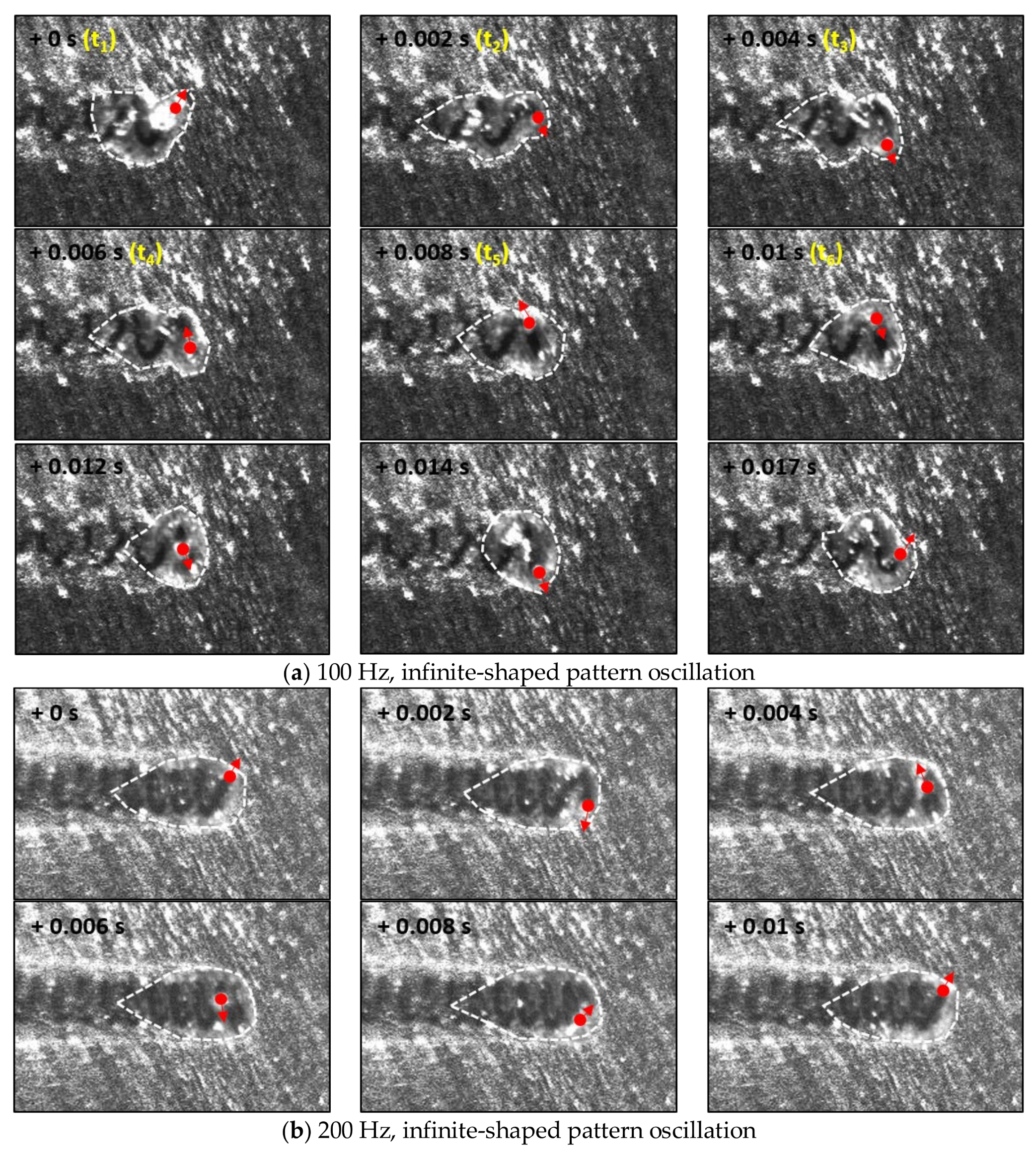

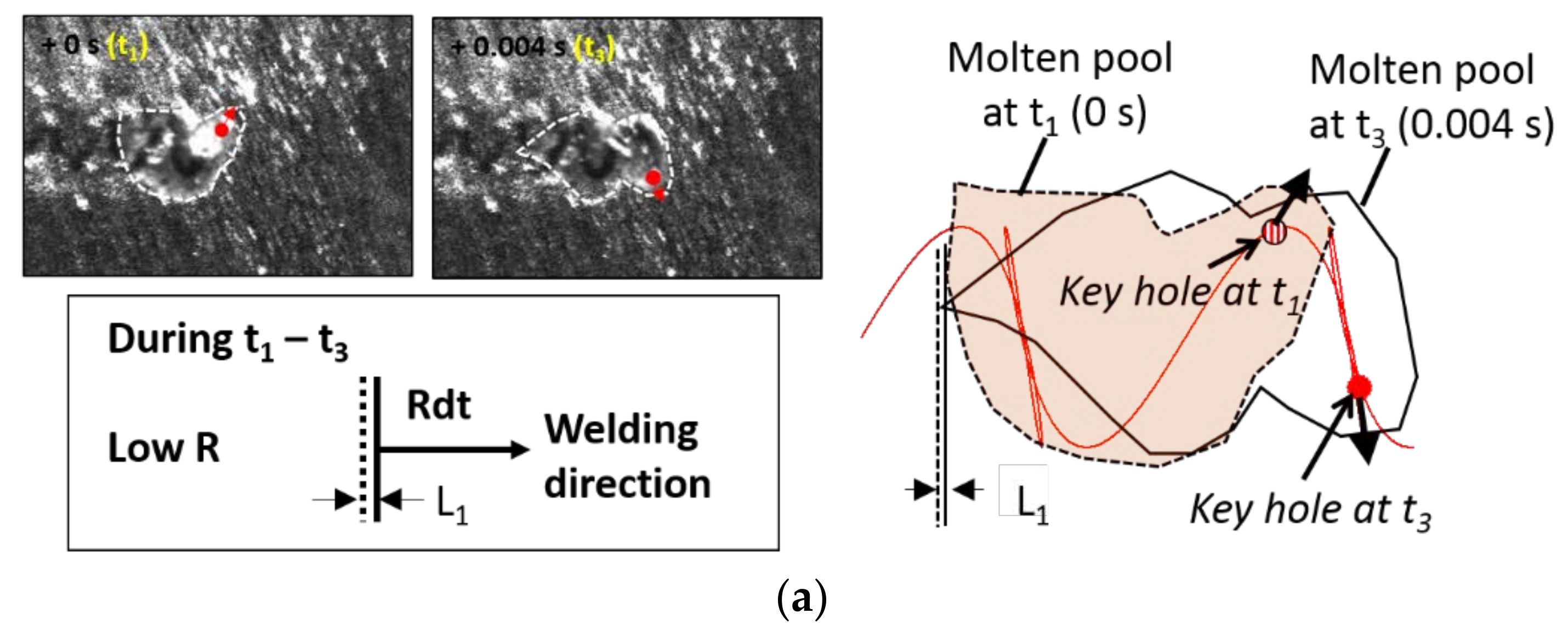

3.2. Effects of Infinite-Shaped Beam Pattern on Hot Crack Susceptibility

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Nakata, K.; Matsuda, F. Ductility characteristics of commercial aluminium alloys between liquidus and solidus temperatures during welding and evaluation of weld solidification cracking susceptibility. Weld. Int. 1995, 9, 706–716. [Google Scholar] [CrossRef]

- Eskin, D.; Katgerman, L. Mechanical properties in the semi-solid state and hot tearing of aluminium alloys. Prog. Mater. Sci. 2004, 49, 629–711. [Google Scholar] [CrossRef]

- Cross, C. On the origin of weld solidification cracking. In Hot Cracking Phenomena in Welds; Springer: Berlin, Germany, 2005; pp. 3–18. [Google Scholar]

- Zhao, H.; White, D.; DebRoy, T. Current issues and problems in laser welding of automotive aluminium alloys. Int. Mater. Rev. 1999, 44, 238–266. [Google Scholar] [CrossRef]

- Dowd, J. Weld cracking of aluminum alloys. Weld. J. 1952, 31, 448–456. [Google Scholar]

- Dudas, J.H. Preventing weld cracks in high strength aluminum alloys. Weld. J. 1966, 45, 241s–249s. [Google Scholar]

- Savage, W.; Nippes, E.; Varsik, J. Hot-Cracking Susceptibility of 3004 Aluminum. Weld. J. 1979, 58, 45–53. [Google Scholar]

- Matsuda, F.; Nakata, K. A New Test Specimen for Self-Restraint Solidification Crack Susceptibility Test of Electron-Beam Welding Bead: Fan-Shaped Cracking Test. Trans. JWRI 1982, 11, 87–94. [Google Scholar]

- Cicală, E.; Duffet, G.; Andrzejewski, H.; Grevey, D.; Ignat, S. Hot cracking in Al–Mg–Si alloy laser welding–operating parameters and their effects. Mater. Sci. Eng. A 2005, 395, 1–9. [Google Scholar] [CrossRef]

- Ploshikhin, V.; Prikhodovsky, A.; Ilin, A.; Makhutin, M.; Heimerdinger, C.; Palm, F. Influence of the weld metal chemical composition on the solidification cracking susceptibility of AA6056-T4 alloy. Weld. World 2006, 50, 46–50. [Google Scholar] [CrossRef]

- Ahn, Y.N.; Kim, C.H. Evaluation of crack sensitivity and gap bridging ability during laser butt welding of aluminum 5J32 and 6K21 alloys. Mater. Sci. Forum 2011, 695, 247–250. [Google Scholar] [CrossRef]

- Langrieger, H.; Krafft, F.; Mensinger, M.; Oefele, F. Thermomechanical analysis of the formation of hot cracks in remote laser welded aluminium fillet welds. J. Laser Appl. 2016, 28, 022414. [Google Scholar] [CrossRef]

- Kuryntsev, S.V.; Gilmutdinov, A.K. The effect of laser beam wobbling mode in welding process for structural steels. Int. J. Adv. Manuf. Technol. 2015, 81, 1683–1691. [Google Scholar] [CrossRef]

- Hao, K.; Li, G.; Gao, M.; Zeng, X. Weld formation mechanism of fiber laser oscillating welding of austenitic stainless steel. J. Mater. Process. Technol. 2015, 225, 77–83. [Google Scholar] [CrossRef]

- Schmitt, F.; Mehlmann, B.; Gedicke, J.; Olowinsky, A.; Gillner, A.; Poprawe, R. Laser beam micro welding with high brilliant fiber lasers. J. Laser Micro/Nanoeng. 2010, 5, 197–203. [Google Scholar] [CrossRef]

- Sommer, M.; Weberpals, J.-P.; Müller, S.; Berger, P.; Graf, T. Advantages of laser beam oscillation for remote welding of aluminum closely above the deep-penetration welding threshold. J. Laser Appl. 2017, 29, 012001. [Google Scholar] [CrossRef]

- Albert, F.; Marben, P.; Graham, T. Remote laser welding of steel and aluminum alloys. Laser Tech. J. 2017, 14, 32–35. [Google Scholar] [CrossRef]

- Barbieri, G.; Cognini, F.; Moncada, M.; Rinaldi, A.; Lapi, G. Welding of automotive aluminum alloys by laser wobbling processing. Mater. Sci. Forum 2017, 879, 1057–1062. [Google Scholar] [CrossRef]

- Fetzer, F.; Jarwitz, M.; Stritt, P.; Weber, R.; Graf, T. Fine-tuned Remote Laser Welding of Aluminum to Copper with Local Beam Oscillation. Phys. Procedia 2016, 83, 455–462. [Google Scholar] [CrossRef]

- Wei, H.; Elmer, J.; DebRoy, T. Crystal growth during keyhole mode laser welding. Acta Mater. 2017, 133, 10–20. [Google Scholar] [CrossRef]

- Wang, L.; Gao, M.; Zhang, C.; Zeng, X. Effect of beam oscillating pattern on weld characterization of laser welding of AA6061-T6 aluminum alloy. Mater. Des. 2016, 108, 707–717. [Google Scholar] [CrossRef]

- Kraetzsch, M.; Standfuss, J.; Klotzbach, A.; Kaspar, J.; Brenner, B.; Beyer, E. Laser beam welding with high-frequency beam oscillation: Welding of dissimilar materials with brilliant fiber lasers. Phys. Procedia 2011, 12, 142–149. [Google Scholar] [CrossRef]

- Dittrich, D.; Jahn, A.; Standfuss, J.; Beyer, E. Laser beam welding of atmosphere aluminum die cast material using high frequency beam oscillation and brilliant beam sources. J. Laser Appl. 2017, 29, 022425. [Google Scholar] [CrossRef]

- Kou, S.; Le, Y. Grain structure and solidification cracking in oscillated arc welds of 5052 aluminum alloy. Metall. Trans. A 1985, 16, 1345–1352. [Google Scholar] [CrossRef]

- Gollnow, C.; Griesche, A.; Weidemann, J.; Kannengiesser, T. Influence of external loads on a characteristic angle between grains and solidus line as an indicator for hot cracking susceptibility during GTA welding. J. Mater. Process. Technol. 2017, 239, 172–177. [Google Scholar] [CrossRef]

- Shinozaki, K.; Wen, P.; Yamamoto, M.; Kadoi, K.; Kohno, Y.; Komori, T. Effect of grain size on solidification cracking susceptibility of type 347 stainless steel during laser welding. Trans. JWRI 2010, 39, 136–138. [Google Scholar] [CrossRef]

- Tang, Z.; Vollertsen, F. Influence of grain refinement on hot cracking in laser welding of aluminum. Weld. World 2014, 58, 355–366. [Google Scholar] [CrossRef]

- Von Witzendorff, P.; Kaierle, S.; Suttmann, O.; Overmeyer, L. Using pulse shaping to control temporal strain development and solidification cracking in pulsed laser welding of 6082 aluminum alloys. J. Mater. Process. Technol. 2015, 225, 162–169. [Google Scholar] [CrossRef]

- Von Witzendorff, P.; Kaierle, S.; Suttmann, O.; Overmeyer, L. In situ observation of solidification conditions in pulsed laser welding of AL6082 aluminum alloys to evaluate their impact on hot cracking susceptibility. Metall. Mater. Trans. A 2015, 46, 1678–1688. [Google Scholar] [CrossRef]

- Choi, K.-D.; Ahn, Y.-N.; Kim, C. Weld strength improvement for Al alloy by using laser weaving method. J. Laser Appl. 2010, 22, 116–119. [Google Scholar] [CrossRef]

- Kim, C.; Kang, M.; Kang, N. Solidification crack and morphology for laser weave welding of Al 5J32 alloy. Sci. Technol. Weld. Join. 2013, 18, 57–61. [Google Scholar] [CrossRef]

- Dan, W.; Shuntaro, S.; Kota, K.; Kenji, S.; Motomichi, Y. Investigation of evaluation method for hot cracking susceptibility of 310S stainless steel during laser welding using trans-varestraint test. Quart. J. Jpn. Weld. Soc. 2015, 33, 39–43. [Google Scholar]

- Kou, S. Welding Metallurgy, 2nd ed.; John Wiley & Sons: New York, NY, USA, 2002. [Google Scholar]

- David, S.; Vitek, J. Correlation between solidification parameters and weld microstructures. Int. Mater. Rev. 1989, 34, 213–245. [Google Scholar] [CrossRef]

- Wei, H.; Elmer, J.; DebRoy, T. Three-dimensional modeling of grain structure evolution during welding of an aluminum alloy. Acta Mater. 2017, 126, 413–425. [Google Scholar] [CrossRef]

| Chemical Element | Composition (wt. %) |

|---|---|

| Si | 0.09 |

| Fe | 0.16 |

| Cu | 1.42 |

| Mn | 0.04 |

| Mg | 2.45 |

| Cr | 0.21 |

| Zn | 5.61 |

| Ti | 0.03 |

| Al | Bal. |

| Welding Parameter | Experiment for Circular Pattern | Experiment for Infinite-Shaped Pattern | |

|---|---|---|---|

| Laser power (W) | 900 | ||

| Welding speed (m/min) | 3 | 3 | 3.5 |

| Oscillation width (mm) | 0, 0.8, 1.6 | 0, 0.8, 1.6 | 0, 0.4, 0.8 |

| Oscillation frequency (Hz) | 0, 100, 200, 300 | 200 | 0, 100, 200, 300 |

| Focal position (mm) | 0 | ||

| Beam tilting angle (°) | 0 | ||

| Beam pattern | Linear, Circle | Linear, infinite-shaped | |

| Shielding gas | Non-shielding | ||

| Equipment | Specification |

|---|---|

| Yb:YAG laser (YLR-1000-SM-WC) | Type: Single-mode laser |

| Maximum power: 1 kW | |

| Wavelength: 1060 nm | |

| Fiber diameter: 13 μm | |

| Laser optic (D50) | Focal length: 250 mm |

| Maximum wobble frequency: 300 Hz | |

| High speed camera (UX50) | Maximum frame rate: 5000 fps |

| Illumination laser (LIMO120-F400) | Maximum power: 120 W |

| Wavelength: 808 nm |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kang, M.; Han, H.N.; Kim, C. Microstructure and Solidification Crack Susceptibility of Al 6014 Molten Alloy Subjected to a Spatially Oscillated Laser Beam. Materials 2018, 11, 648. https://doi.org/10.3390/ma11040648

Kang M, Han HN, Kim C. Microstructure and Solidification Crack Susceptibility of Al 6014 Molten Alloy Subjected to a Spatially Oscillated Laser Beam. Materials. 2018; 11(4):648. https://doi.org/10.3390/ma11040648

Chicago/Turabian StyleKang, Minjung, Heung Nam Han, and Cheolhee Kim. 2018. "Microstructure and Solidification Crack Susceptibility of Al 6014 Molten Alloy Subjected to a Spatially Oscillated Laser Beam" Materials 11, no. 4: 648. https://doi.org/10.3390/ma11040648

APA StyleKang, M., Han, H. N., & Kim, C. (2018). Microstructure and Solidification Crack Susceptibility of Al 6014 Molten Alloy Subjected to a Spatially Oscillated Laser Beam. Materials, 11(4), 648. https://doi.org/10.3390/ma11040648