Cellulose-Silica Nanocomposites of High Reinforcing Content with Fungi Decay Resistance by One-Pot Synthesis

Abstract

1. Introduction

2. Materials and Methods

3. Results and Discussion

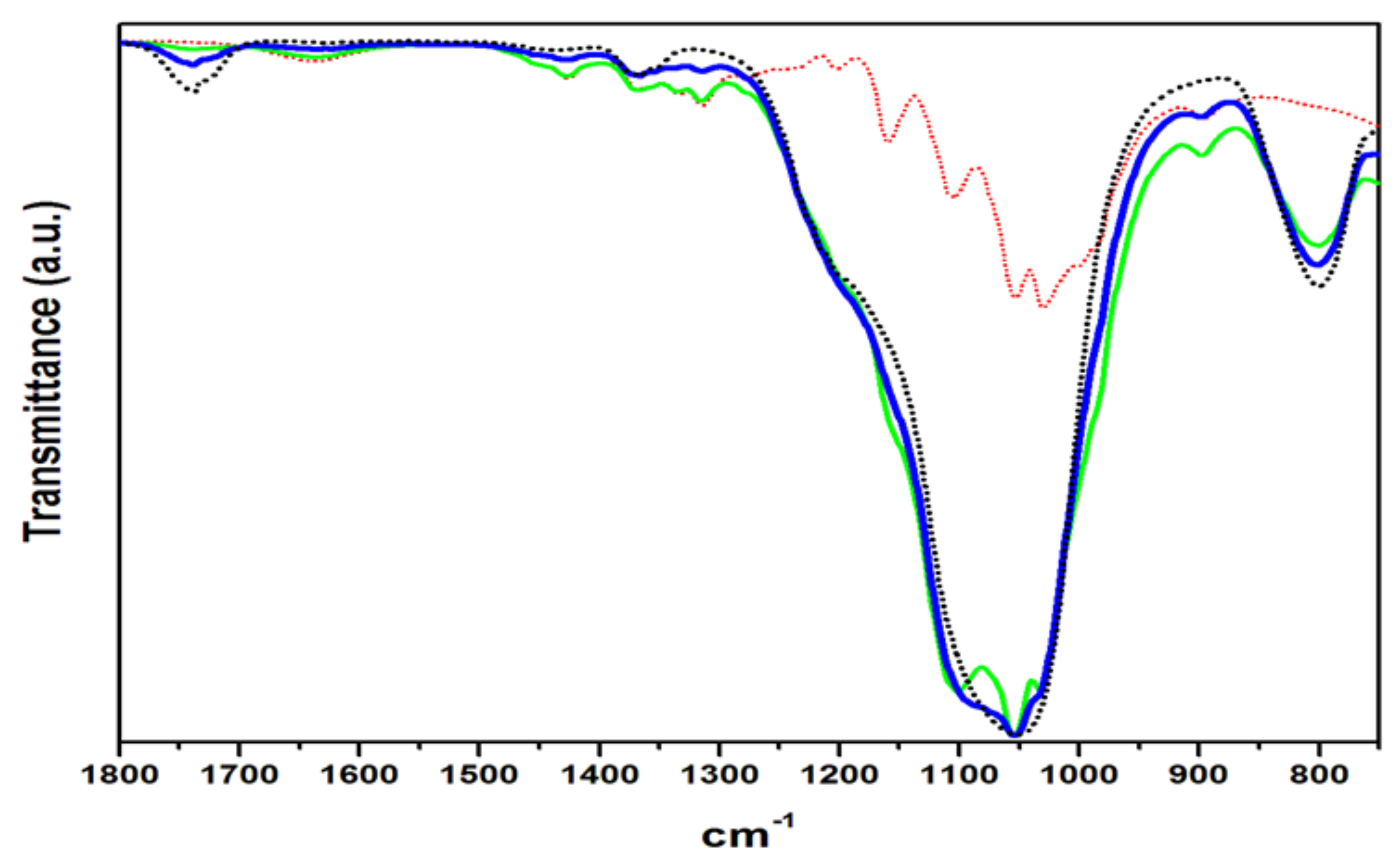

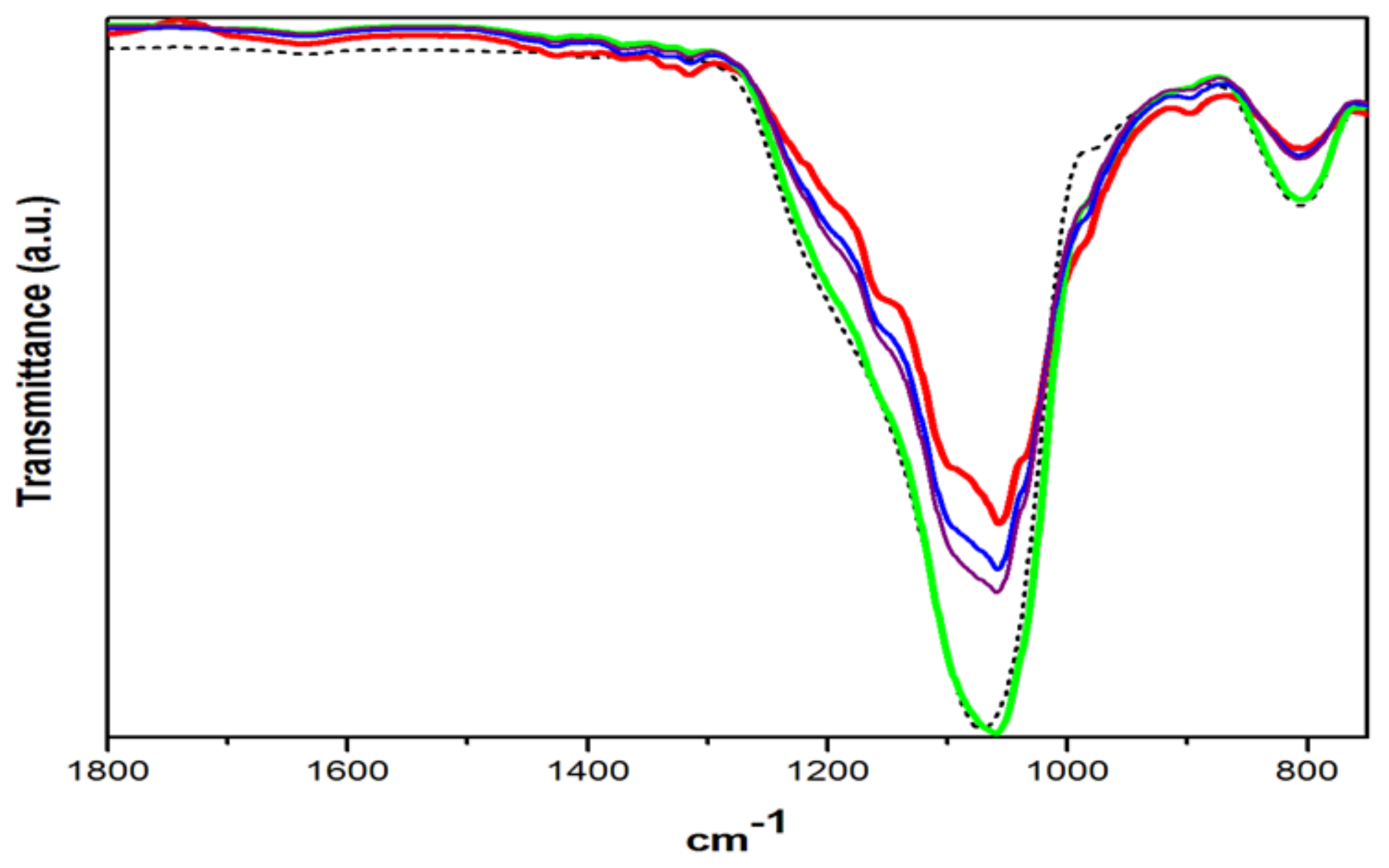

3.1. Fourier Transform Infrared Spectroscopy

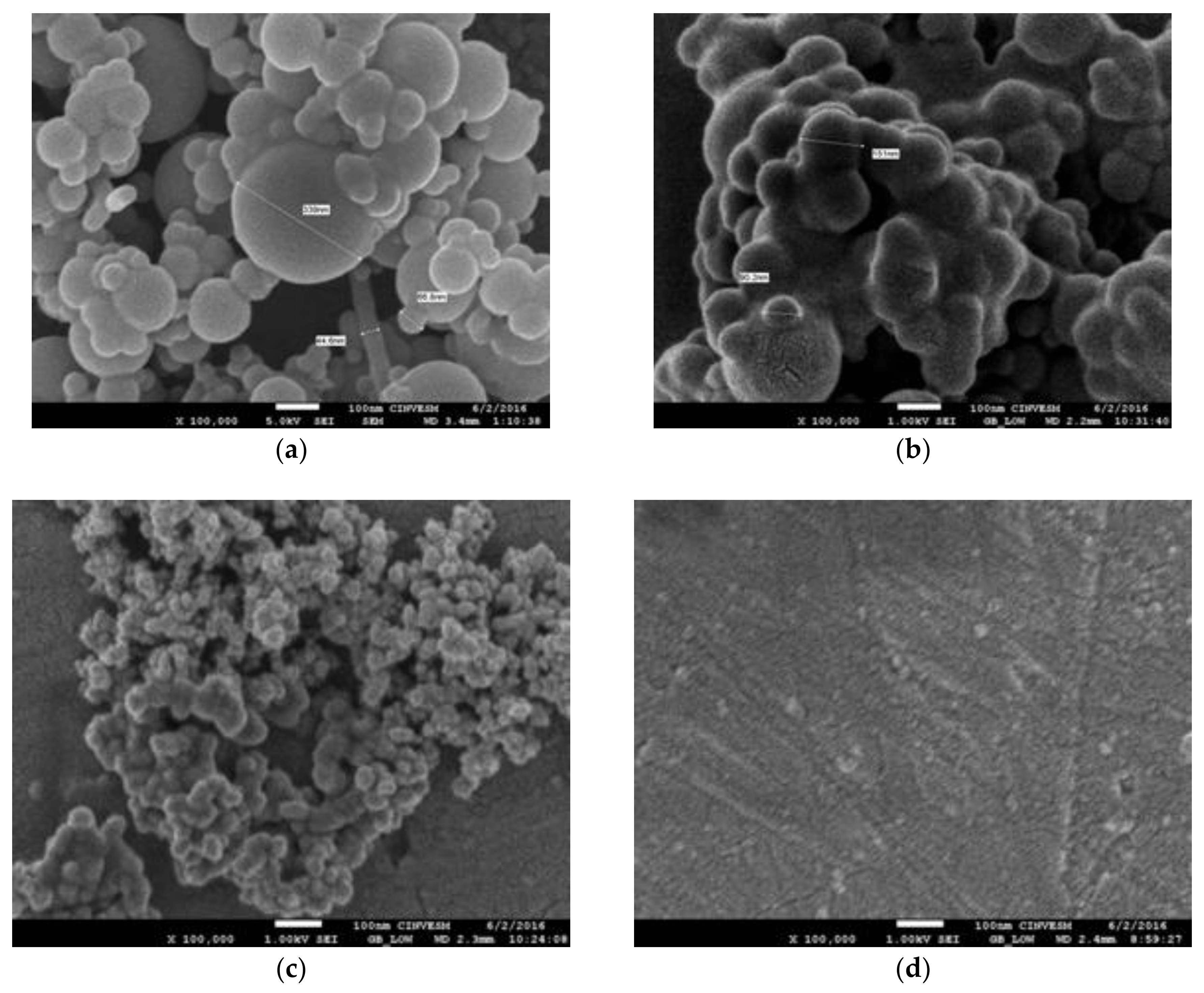

3.2. Scanning Electron Microscopy

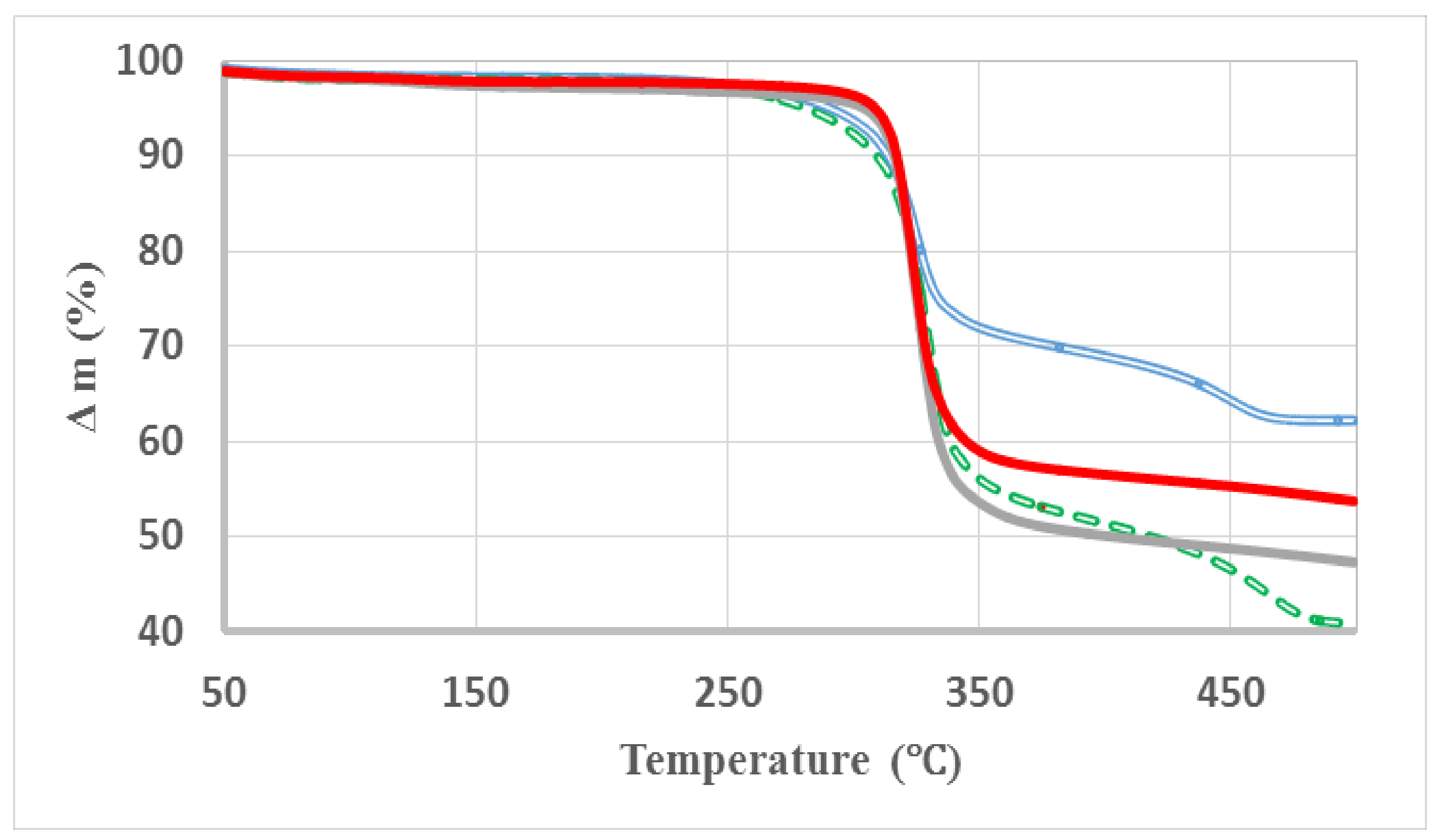

3.3. Thermogravimetric Analysis

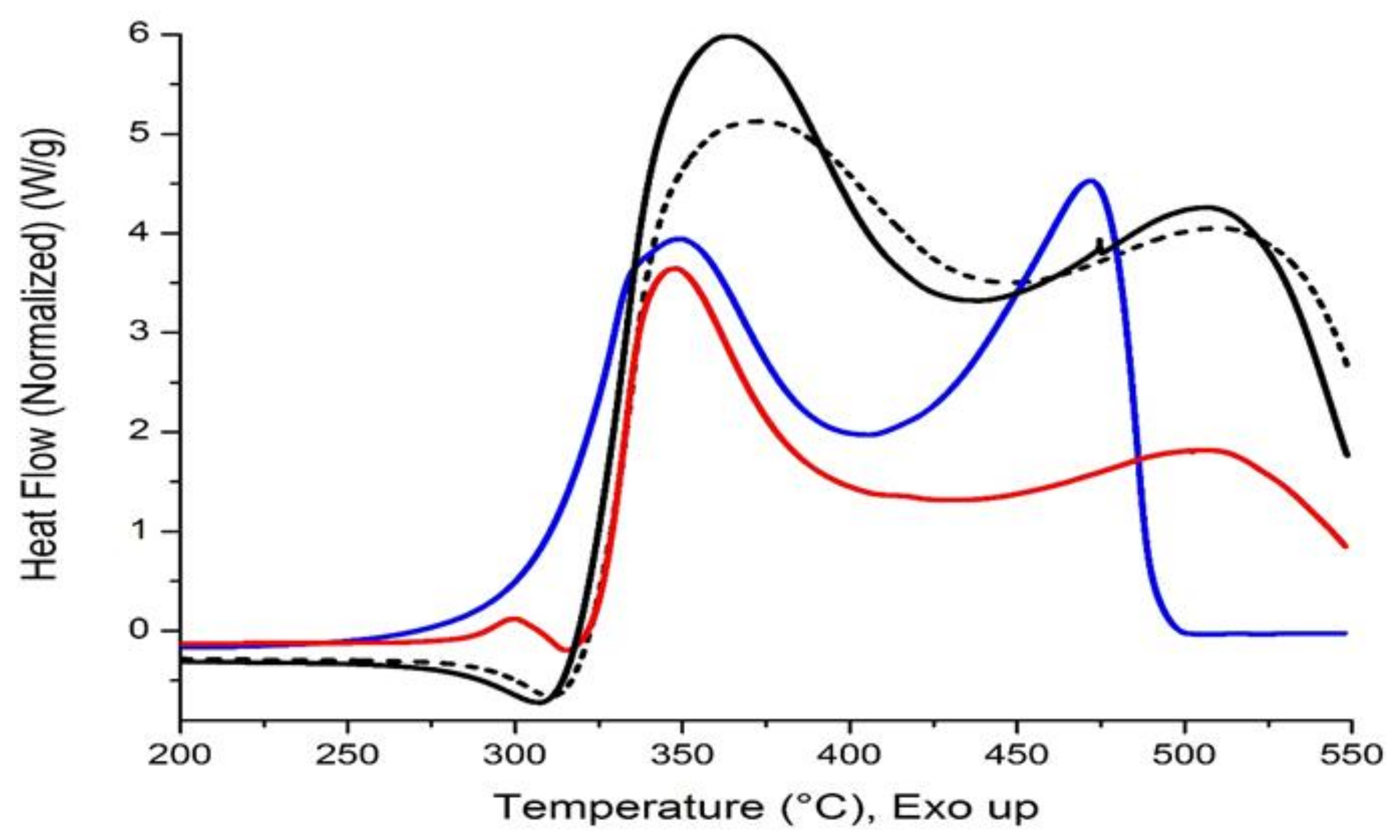

3.4. Differential Scanning Calorimetry

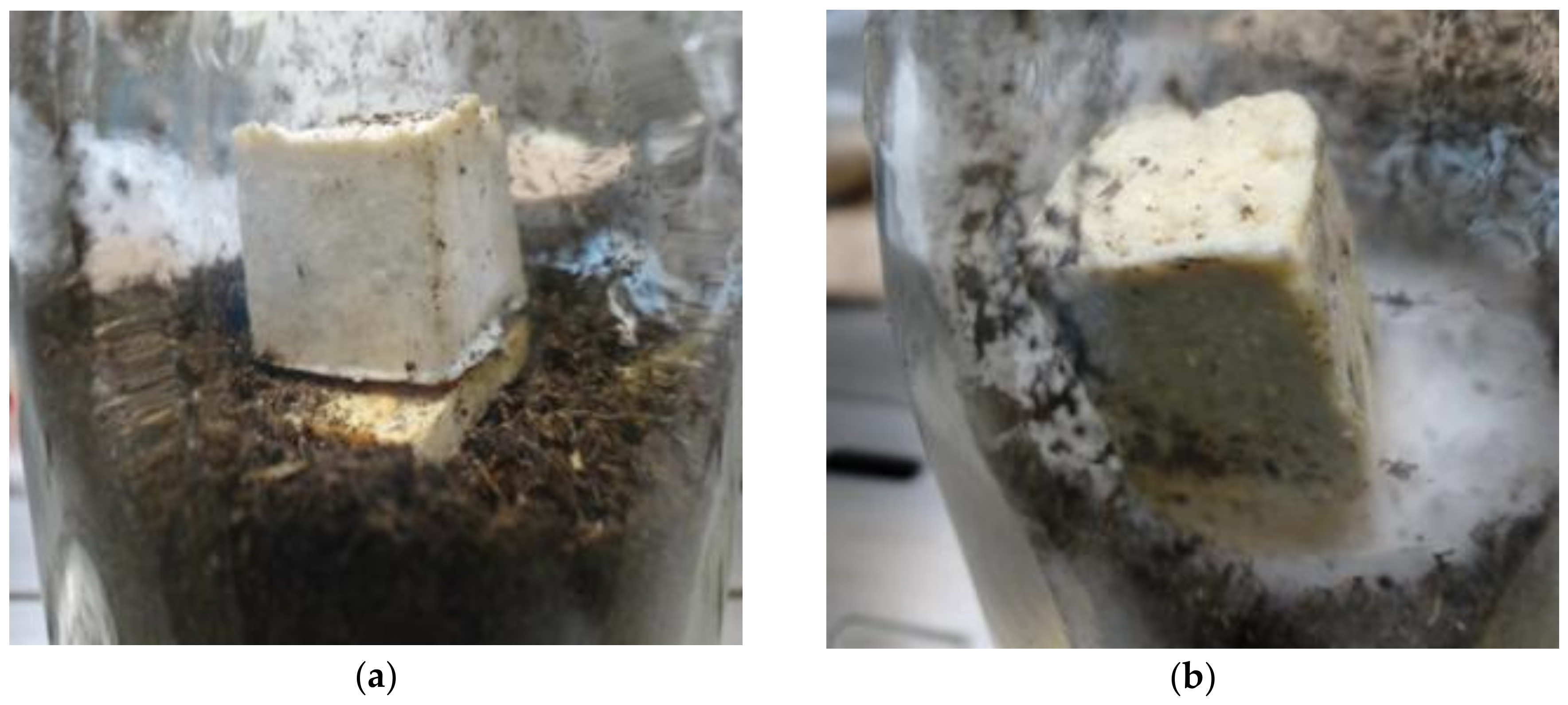

3.5. Trametes Versicolor Resistance

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kakani, S.L.; Kakani, A. Material Science; New Age International Publishers: New Delhi, India, 2006; ISBN 8122415288. [Google Scholar]

- Miao, C.; Wadood, Y.; Hamad, W.Y. Cellulose reinforced polymer composites and nanocomposites: A critical review. Cellulose 2013, 20, 2221–2262. [Google Scholar] [CrossRef]

- Mansor, M.R.; Sapuan, S.M. Concurrent Conceptual Design and Materials Selection of Natural Fiber Composite Products; Springer Briefs in Materials; Springer: Singapore, 2018; ISBN 978-981-10-6589-7. [Google Scholar]

- Saba, N.; Md Tahir, P.; Jawaid, M. A Review on potentiality of nano filler/natural fiber filled polymer hybrid composites. Polymers 2014, 6, 2247–2273. [Google Scholar] [CrossRef]

- Oksman, K.; Mathew, A.P.; Bondeson, D.; Kvien, I. Manufacturing process of cellulose whiskers/polylactic acid nanocomposites. Compos. Sci. Technol. 2006, 66, 2776–2784. [Google Scholar] [CrossRef]

- Pickering, K.L.; Aruan Efendy, M.G.; Le, T.M. A review of recent developments in natural fibre composites and their mechanical performance. Compos. Part A 2016, 83, 98–112. [Google Scholar] [CrossRef]

- Matthews, F.L.; Rawlings, R.D. Composite Materials: Engineering and Science; CRC Press/Woodhead Publishing: Cambridge, UK, 1999; ISBN 978-1-85573-473-9. [Google Scholar]

- Missoum, K.; Belgacem, M.N.; Bras, J. Nanofibrillated cellulose surface modification: A review. Materials 2013, 6, 1745–1766. [Google Scholar] [CrossRef] [PubMed]

- Faruk, O.; Bledzki, A.K.; Fink, H.P.; Sain, M. Progress report on natural fiber reinforced composites. Macromol. Mater. Eng. 2014, 299, 9–26. [Google Scholar] [CrossRef]

- Singh, B.; Gupta, M.; Verma, A. Influence of fiber surface treatment on the properties of sisal-polyester composites. Polym. Compos. 1996, 17, 910–918. [Google Scholar] [CrossRef]

- Cai, J.; Liu, S.; Feng, J.; Kimura, S.; Wada, M.; Kuga, S.; Zhang, L. Cellulose–Silica nanocomposite aerogels by in Situ formation of silica in cellulose gel. Angew. Chem. Int. Ed. 2012, 51, 2076–2079. [Google Scholar] [CrossRef] [PubMed]

- Feng, J.; Le, D.; Nguyen, S.T.; Chin Nien, V.T.; Jewell, D.; Duong, H.M. Silica-Cellulose hybrid aerogels for thermal and acoustic insulation applications. Colloids Surf. A 2016, 506, 298–305. [Google Scholar] [CrossRef]

- Ramesh, S.; Kim, J.; Kim, J.-H. Characteristic of Hybrid Cellulose-Amino functionalized POSS-Silica nanocomposite and antimicrobial activity. J. Nanomater. 2015, 2015, 936590. [Google Scholar] [CrossRef]

- Capadona, J.R.; Van Den Berg, O.; Capadona, L.A.; Schroeter, M.; Rowan, S.J.; Tyler, D.J.; Weder, C. A versatile approach for the processing of polymer nanocomposites with self-assambled nanofibre templates. Nat. Nanotechnol. 2007, 2, 765–769. [Google Scholar] [CrossRef] [PubMed]

- Eichhorn, S.J.; Dufresne, A.; Aranguren, M.; Marcovich, N.E.; Capadona, J.R.; Rowan, S.J.; Weder, C.; Thielemans, W.; Roman, M.; Renneckar, S.; et al. Current international research into cellulose nanofibres and nanocomposites. J. Mater. Sci. 2010, 45, 1–33. [Google Scholar] [CrossRef]

- ASTM D1413-07. Standard Test Method for Wood Preservatives by Laboratory Soil-Block Cultures; American Society for Testing and Materials: West Conshohoken, PA, USA, 1999. [Google Scholar]

- Marechal, Y.; Chanzy, H. The hydrogen bond network in Ibeta cellulose as observed by infrared spectrometry. J. Mol. Struct. 2000, 523, 183–196. [Google Scholar] [CrossRef]

- Kondo, T.; Sawatari, C. A Fourier transform infra-red spectroscopic analysis of the character of hydrogen bonds in amorphous cellulose. Polymer 1996, 37, 393–399. [Google Scholar] [CrossRef]

- Rodríguez-Díaz, J.M.; Prieto García, J.O.; Bravo Sánchez, L.R.; da Silva, M.G.C.; da Silva, V.L.; Arteaga-Pérez, L.E. Comprehensive characterization of sugarcane bagasse ash for its use as an adsorbent. BioEnergy Res. 2015, 8, 1885–1895. [Google Scholar] [CrossRef]

- Criado, M.; Aperador, W.; Sobrados, I. Microstructured and mechanical properties of alkali activated Colombian raw materials. Materials 2016, 9, 158. [Google Scholar] [CrossRef] [PubMed]

- Rodríguez-Robledo, M.C. Compositos Híbridos de Matriz Celulósica y Reforzantes Inorgánicos. Master’s Thesis, Universidad del Papaloapan, San Juan Bautista Tuxtepec, Mexico, 1 June 2017. [Google Scholar]

- Vásquez-Zacarías, L. Estudio del Desempeño de Compositos Híbridos de Matriz Celulósica. Master’s Thesis, Universidad del Papaloapan, San Juan Bautista Tuxtepec, Mexico, 15 March 2017. [Google Scholar]

- Ashori, A.; Sheykhnazari, S.; Tabarsa, T.; Shakeri, A.; Golalipour, M. Bacterial cellulose/silica nanocomposites: Preparation and characterization. Carbohydr. Polym. 2012, 90, 413–418. [Google Scholar] [CrossRef] [PubMed]

- Raabe, J.; de Souza Fonseca, A.; Bufalino, L.; Ribeiro, C.; Martins, M.A.; Marconcini, J.M.; Denzin, G.H. Evaluation of reaction factors for deposition of silica (SiO2) nanoparticles on cellulose fibers. Carbohydr. Polym. 2014, 114, 424–431. [Google Scholar] [CrossRef] [PubMed]

- Naghsh, M.; Sadeghi, M.; Moheb, A.; Chenar, M.P.; Mohagheghian, M. Separation of ethylene/ethane and propylene/propane by cellulose acetate–silica nanocomposite membranes. J. Membr. Sci. 2012, 423–424, 97–106. [Google Scholar] [CrossRef]

- Lu, T.; Jiang, M.; Jiang, Z.; Hui, D.; Wang, Z.; Zhou, Z. Effect of surface modification of bamboo cellulose fibers on mechanical properties of cellulose/epoxy composites. Compos. Part B Eng. 2013, 51, 28–34. [Google Scholar] [CrossRef]

- Siqueira, G.; Mathew, A.P.; Oksman, K. Processing of cellulose nanowhiskers/cellulose acetate butyrate nanocomposites using sol–gel process to facilitate dispersion. Compos. Sci. Technol. 2011, 71, 1886–1892. [Google Scholar] [CrossRef]

- Quiévy, N.; Jacquet, N.; Sclavons, M.; Deroanne, C.; Paquot, M.; Devaux, J. Influence of homogenization and drying on the thermal stability of microfibrillated cellulose. Polym. Degrad. Stab. 2010, 95, 306–314. [Google Scholar] [CrossRef]

- Soares, S.; Caminot, G.; Levchik, S. Comparative study of the thermal decomposition of pure cellulose and pulp paper. Polym. Degrad. Stab. 1995, 49, 275–283. [Google Scholar] [CrossRef]

- Sequeira, S.; Evtuguin, D.V.; Portugal, I. Preparation and properties of cellulose/silica hybrid composites. Polym. Compos. 2009, 30, 1275–1282. [Google Scholar] [CrossRef]

- Maeda, H.; Nakajima, M.; Hagiwara, T.; Sawaguchi, T.; Yano, S. Bacterial cellulose/silica hybrid fabricated by mimicking biocomposites. J. Mater. Sci. 2006, 41, 5646–5656. [Google Scholar] [CrossRef]

- Shi, J.; Lu, L.; Guo, W.; Zhang, J.; Cao, Y. Heat insulation performance, mechanics and hydrophobic modification of cellulose–SiO2 composite aerogels. Carbohyd. Polym. 2013, 98, 282–289. [Google Scholar] [CrossRef] [PubMed]

- Yang, H.; Yan, R.; Chen, H.; Lee, D.H.; Zheng, C. Characteristics of hemicellulose, cellulose and lignin pyrolysis. Fuel 2007, 86, 1781–1788. [Google Scholar] [CrossRef]

- Szczesniak, L.; Rachocki, A.; Tritt-Goc, J. Glass transition temperature and thermal decomposition of cellulose powder. Cellulose 2008, 15, 445–451. [Google Scholar] [CrossRef]

- Ciolacu, D.; Popa, V. On the thermal degradation of cellulose allomorphs. Cell Chem. Technol. 2006, 40, 445–449. [Google Scholar]

- Sequeira, S.; Evtuguin, D.V.; Portugal, I.; Esculcas, A.P. Synthesis and characterisation of cellulose/silica hybrids obtained by heteropoly acid catalysed sol–gel process. Mater. Sci. Eng. C 2007, 27, 172–179. [Google Scholar] [CrossRef]

- Ander, P.; Hatakka, A.; Eriksson, K.-E. Vanillic acid metabolism by the white-rot fungus Sporotrichum pulverulentum. Arch. Microbiol. 1980, 125, 189–202. [Google Scholar] [CrossRef]

- Kartal, S.N.; Clausen, C.A. Leachability and decay resistance of particleboard made from acid extracted and bioremediated CCA-treated wood. Int. Biodeterior. Biodegrad. 2001, 47, 183–191. [Google Scholar] [CrossRef]

- Lu, X.; Zhang, M.Q.; Rong, M.Z.; Yue, D.L.; Yang, G.C. Environmental degradability of self-reinforced composites made from sisal. Compos. Sci. Technol. 2004, 64, 1301–1310. [Google Scholar] [CrossRef]

- Lomeli-Ramirez, M.G.; Ochoa-Ruiz, H.G.; Fuentes-Talavera, F.J.; Garcia-Enriquez, S.; Cerpa-Gallegos, M.A.; Silva-Guzman, J.A. Evaluation of accelerated decay of wood plastic composites by Xylophagus fungi. Int. Biodeterior. Biodegrad. 2009, 63, 1030–1035. [Google Scholar] [CrossRef]

- Cerchiara, T.; Palermo, A.M.; Esposito, G.; Chidichimo, G. Effects of microwave heating for the conservation of paper artworks contaminated with Aspergillus versicolor. Cellulose 2018, in press. [Google Scholar] [CrossRef]

- Espino-Perez, E.; Domenek, S.; Belgacem, N.; Sillard, C.; Bras, J. Green process for chemical functionalization of nanocellulose with carboxylic acids. Biomacromolecules 2014, 15, 4551–4560. [Google Scholar] [CrossRef] [PubMed]

- Lee, K.-Y.; Aitomäki, Y.; Berglund, L.A.; Oksman, K.; Bismarck, A. On the use of nanocellulose as reinforcement in polymer matrix composites. Compos. Sci. Technol. 2014, 105, 15–27. [Google Scholar] [CrossRef]

- Wang, Y.; Chen, L. Impacts of nanowhisker on formation kinetics and properties of all-cellulose composite gels. Carbohydr. Polym. 2011, 83, 1937–1946. [Google Scholar] [CrossRef]

| Constituents wt % | C20 | AG20 | NSi | ASi |

|---|---|---|---|---|

| CP1 | 100 | 0 | 75 | 0 |

| CP2 | 100 | 0 | 100 | 0 |

| CP11 | 100 | 0 | 25 | 0 |

| CP12 | 100 | 0 | 50 | 0 |

| CP3 | 0 | 100 | 75 | 0 |

| CP4 | 0 | 100 | 100 | 0 |

| CP13 | 0 | 100 | 25 | 0 |

| CP14 | 0 | 100 | 50 | 0 |

| CP19 | 100 | 0 | 0 | 75 |

| CP20 | 100 | 0 | 0 | 100 |

| CP21 | 0 | 100 | 0 | 75 |

| CP22 | 0 | 100 | 0 | 100 |

| Sample | Tstart 1 (°C) | Tmax 1 (°C) | Tmax 2 (°C) | Tmax 2 (°C) | Mass Loss 3 (wt %) |

|---|---|---|---|---|---|

| CP2 | 225 | 324 | 350 | 485 | 59.1 |

| CP4 | 223 | 327 | 349 | 472 | 37.9 |

| CP20 | 280 | 325 | 350 | 505 | 52.7 |

| CP22 | 290 | 324 | 347 | 505 | 46.3 |

| AG20 | 250 | 325 | 373 | 511 | 97.0 |

| C20 | 225 | 323 | 363 | 507 | 97.0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Rodríguez-Robledo, M.C.; González-Lozano, M.A.; Ponce-Peña, P.; Quintana Owen, P.; Aguilar-González, M.A.; Nieto-Castañeda, G.; Bazán-Mora, E.; López-Martínez, R.; Ramírez-Galicia, G.; Poisot, M. Cellulose-Silica Nanocomposites of High Reinforcing Content with Fungi Decay Resistance by One-Pot Synthesis. Materials 2018, 11, 575. https://doi.org/10.3390/ma11040575

Rodríguez-Robledo MC, González-Lozano MA, Ponce-Peña P, Quintana Owen P, Aguilar-González MA, Nieto-Castañeda G, Bazán-Mora E, López-Martínez R, Ramírez-Galicia G, Poisot M. Cellulose-Silica Nanocomposites of High Reinforcing Content with Fungi Decay Resistance by One-Pot Synthesis. Materials. 2018; 11(4):575. https://doi.org/10.3390/ma11040575

Chicago/Turabian StyleRodríguez-Robledo, M. Concepción, M. Azucena González-Lozano, Patricia Ponce-Peña, Patricia Quintana Owen, Miguel Angel Aguilar-González, Georgina Nieto-Castañeda, Elva Bazán-Mora, Rubén López-Martínez, Guillermo Ramírez-Galicia, and Martha Poisot. 2018. "Cellulose-Silica Nanocomposites of High Reinforcing Content with Fungi Decay Resistance by One-Pot Synthesis" Materials 11, no. 4: 575. https://doi.org/10.3390/ma11040575

APA StyleRodríguez-Robledo, M. C., González-Lozano, M. A., Ponce-Peña, P., Quintana Owen, P., Aguilar-González, M. A., Nieto-Castañeda, G., Bazán-Mora, E., López-Martínez, R., Ramírez-Galicia, G., & Poisot, M. (2018). Cellulose-Silica Nanocomposites of High Reinforcing Content with Fungi Decay Resistance by One-Pot Synthesis. Materials, 11(4), 575. https://doi.org/10.3390/ma11040575