Assumption of Constraining Force to Explain Distortion in Laser Additive Manufacturing

Abstract

:1. Introduction

2. Materials and Methodology

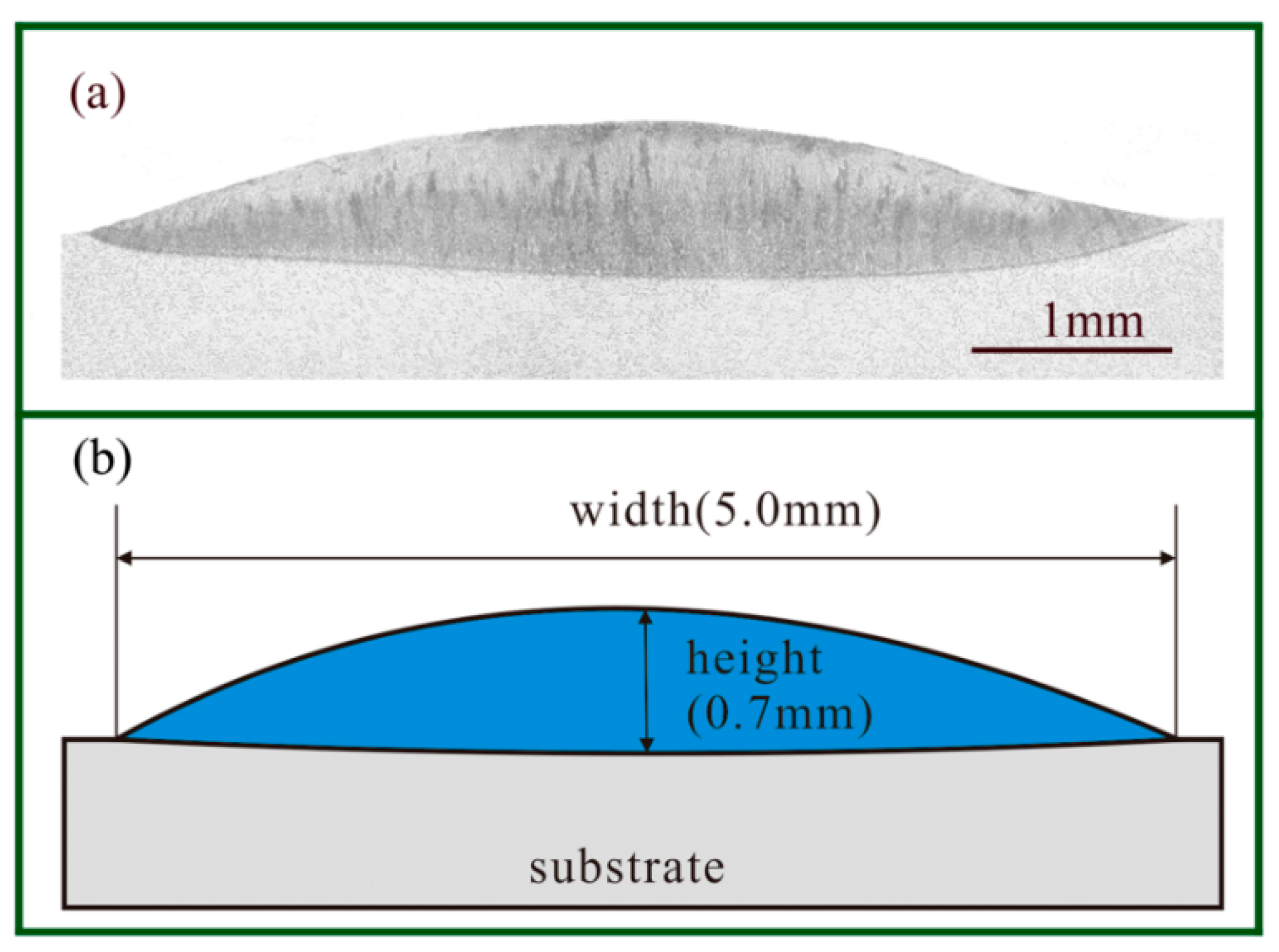

2.1. LMD and AISI 316L

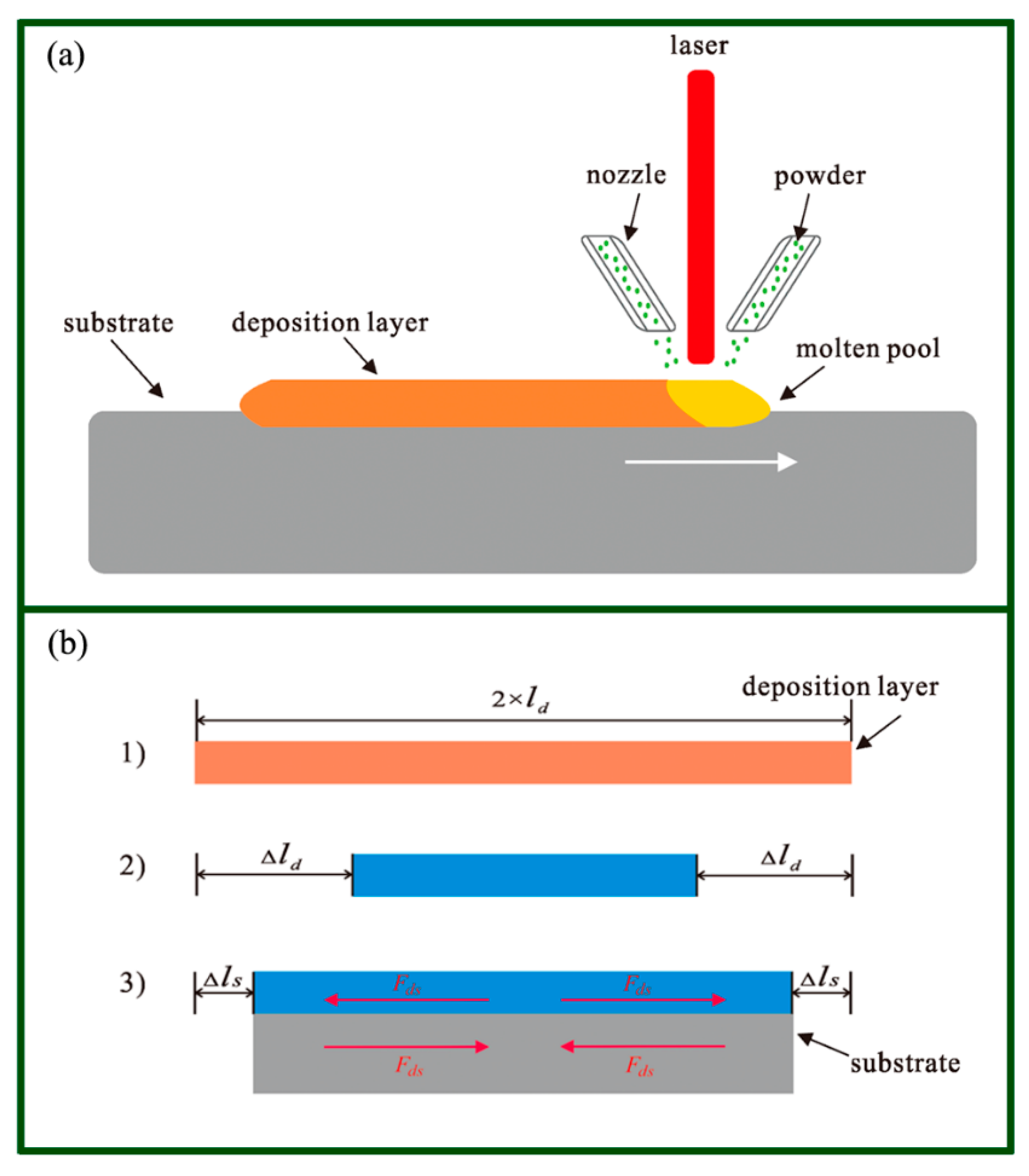

2.2. Assumption of Constraining Force

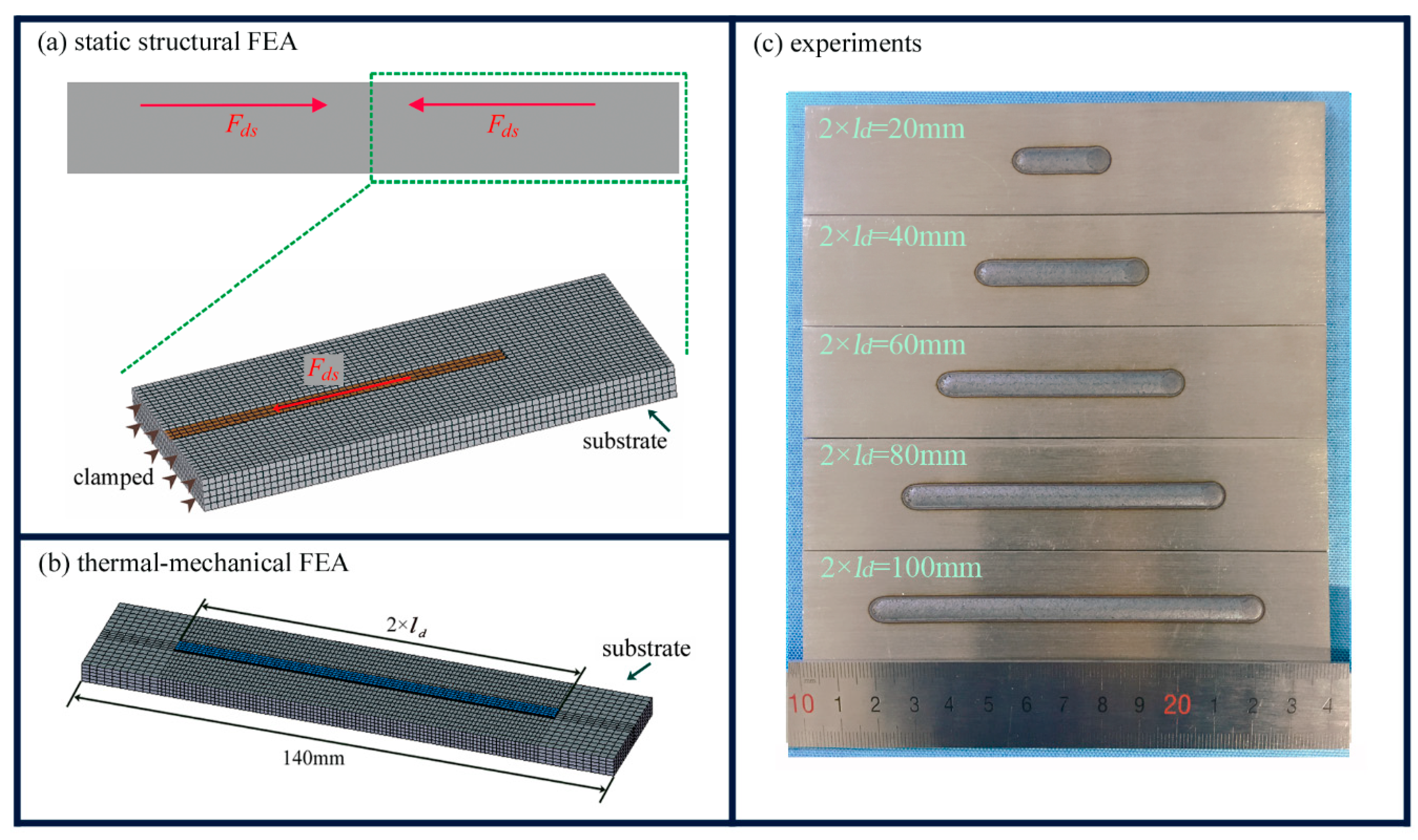

2.3. Static Structural FEA Model

2.4. Thermal-Mechanical FEA Model

2.5. LMD Experiments and Measurements

3. Results and Discussion

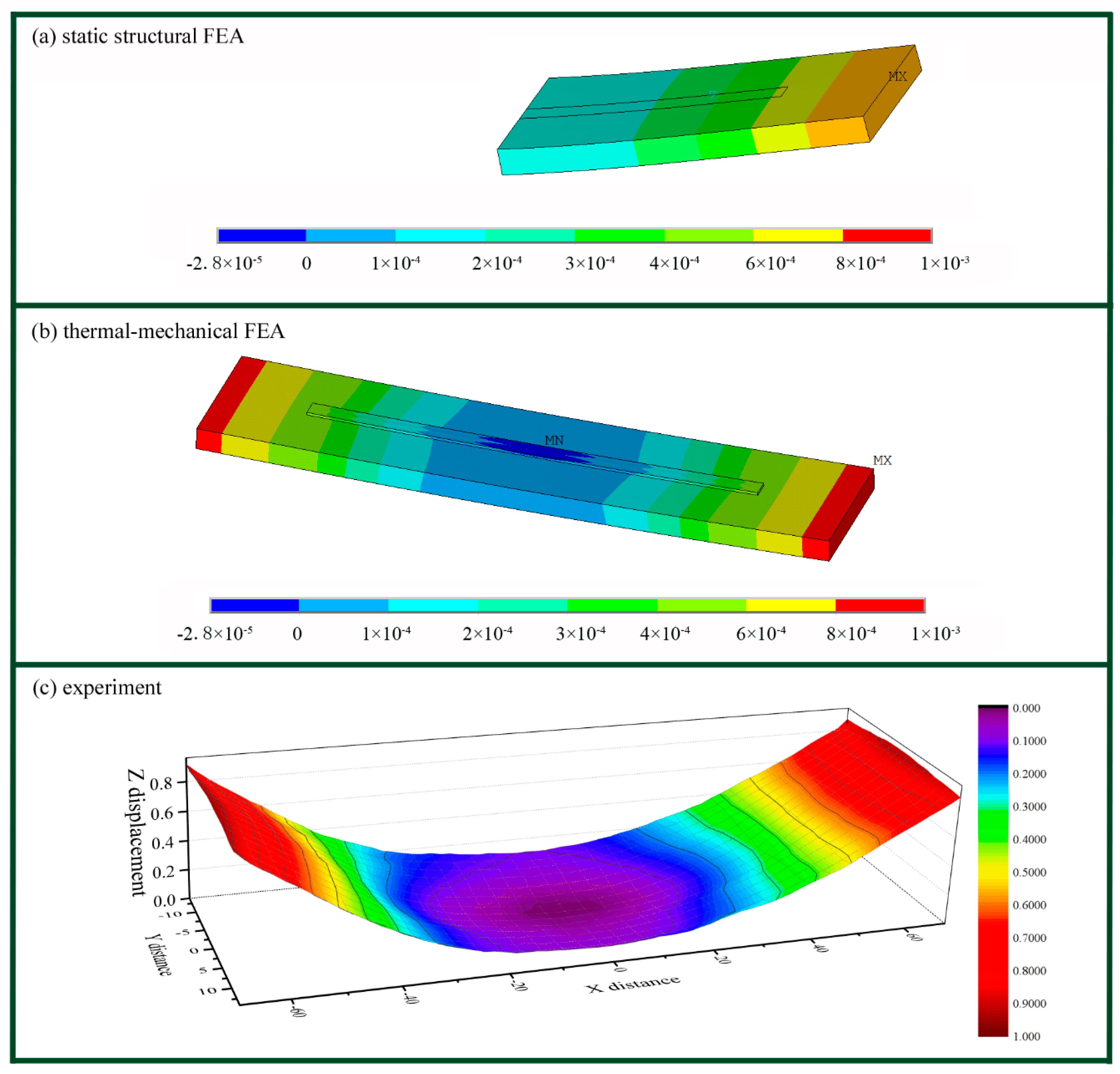

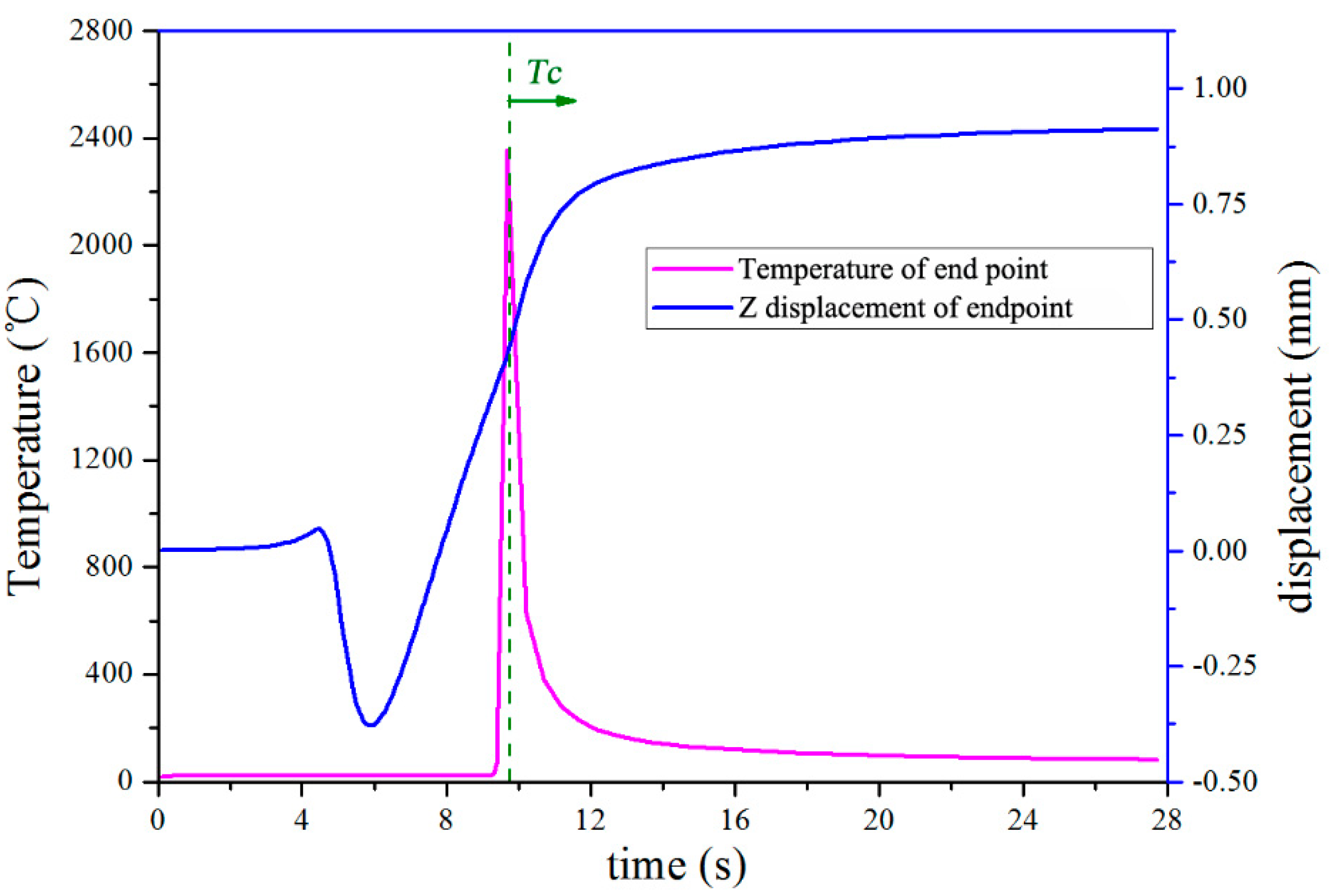

3.1. Distortion via Three Methods

3.2. Distribution of Stresses

3.3. Comparison of Displacement Curves

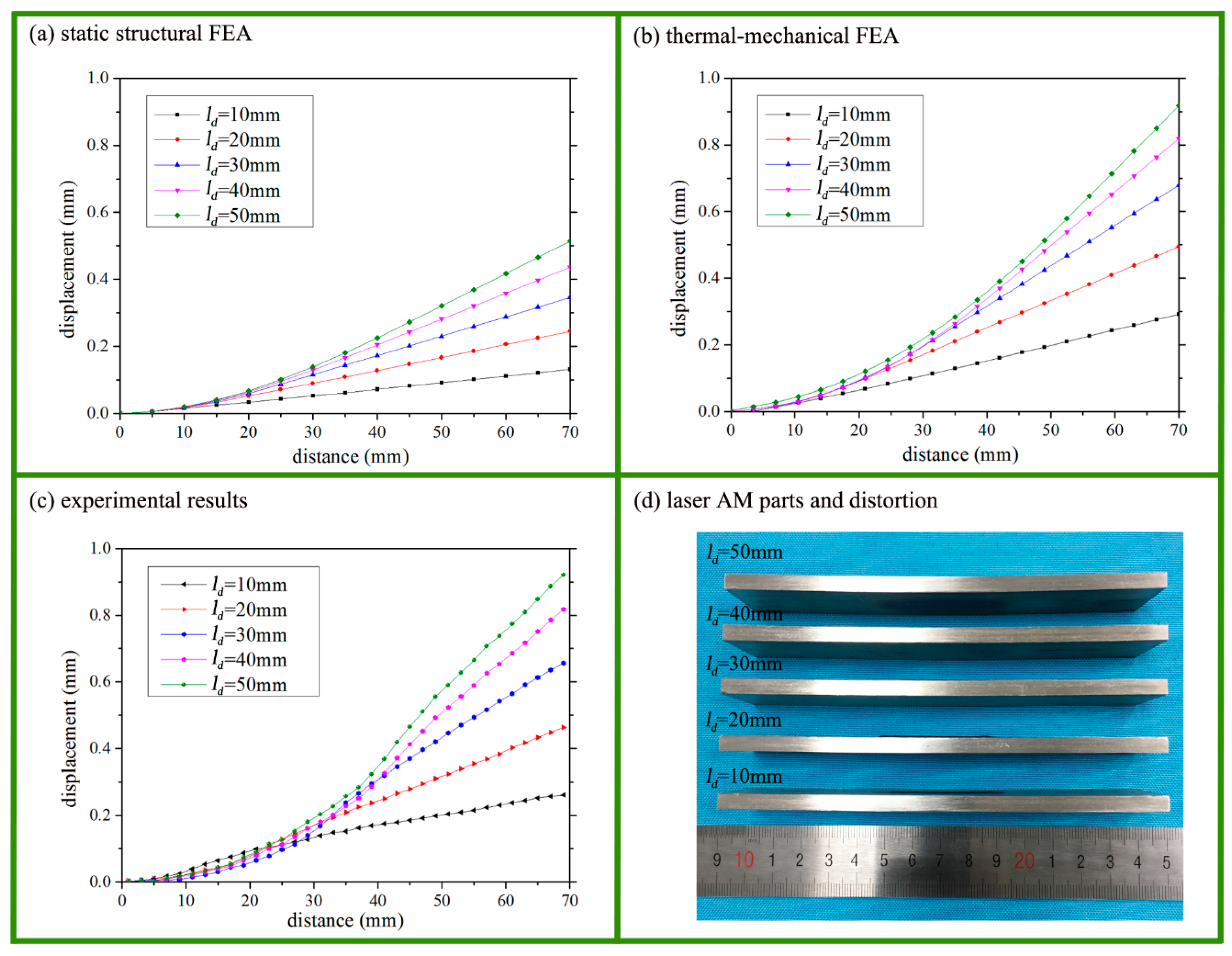

4. Calculation of the Constraining Force

4.1. Expression of the Constraining Force

4.2. Calculation of the Constraining Force

5. Validation of Relationships between Distortion and Temperature and Cross-Sectional Area

5.1. Relationships between Distortion and Temperature

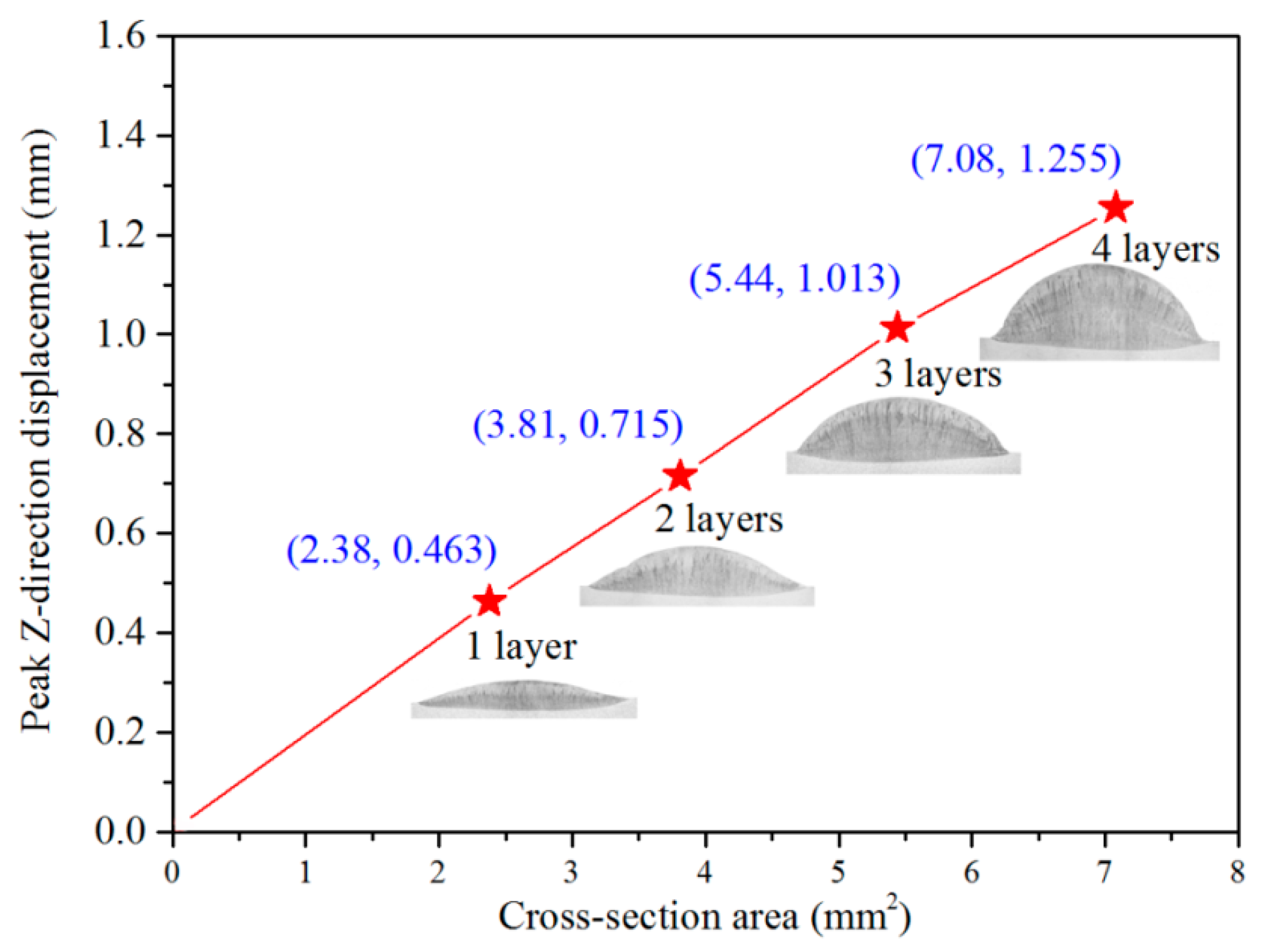

5.2. Relationships between Distortion and Cross-Sectional Area

6. Conclusions

- (i)

- The assumption of constraining force can be used to explain and better understand the distortion that occurs in metal AM.

- (ii)

- Both the temperature and cross-sectional area play a critical role in determining the constraining force. In particular, the cross-sectional area accumulates during metal AM, causing almost linear increments in the constraining force and peak Z-directional displacement.

Author Contributions

Funding

Conflicts of Interest

References

- Yang, Y.; Guo, X.; He, C.; Gao, C.; Shuai, C. Regulating Degradation Behavior by Incorporating Mesoporous Silica for Mg Bone Implants. ACS Biomater. Sci. Eng. 2018, 4, 1046–1054. [Google Scholar] [CrossRef]

- Ahsan, M.N.; Pinkerton, A.J.; Moat, R.J.; Shackleton, J. A comparative study of laser direct metal deposition characteristics using gas and plasma-atomized Ti–6Al–4V powders. Mater. Sci. Eng. A 2011, 528, 7648–7657. [Google Scholar] [CrossRef]

- Yang, Y.; Wu, P.; Wang, Q.; Wu, H.; Liu, Y.; Deng, Y.; Zhou, Y.; Shuai, C. The enhancement of Mg corrosion resistance by alloying Mn and laser-melting. Materials 2016, 9, 216. [Google Scholar] [CrossRef] [PubMed]

- Coppola, B.; Cappetti, N.; Di Maio, L.; Scarfato, P.; Incarnato, L. 3D Printing of PLA/clay Nanocomposites: Influence of Printing Temperature on Printed Samples Properties. Materials 2018, 11, 1947. [Google Scholar] [CrossRef] [PubMed]

- Huang, B.; Bártolo, P.J. Rheological characterization of polymer/ceramic blends for 3D printing of bone scaffolds. Polym. Test. 2018, 68, 365–378. [Google Scholar] [CrossRef]

- Masoomi, M.; Thompson, S.M.; Shamsaei, N. Laser powder bed fusion of Ti-6Al-4V parts: Thermal modeling and mechanical implications. Int. J. Mach. Tools Manuf. 2017, 118–119, 73–90. [Google Scholar] [CrossRef]

- Nandwana, P.; Elliott, A.M.; Siddel, D.; Merriman, A.; Peter, W.H.; Babu, S.S. Powder bed binder jet 3D printing of Inconel 718: Densification, microstructural evolution and challenges. Curr. Opin. Solid State Mater. Sci. 2017, 21, 207–218. [Google Scholar] [CrossRef]

- Manvatkar, V.; De, A.; Debroy, T. Heat transfer and material flow during laser assisted multi-layer additive manufacturing. J. Appl. Phys. 2014, 116, 124905. [Google Scholar] [CrossRef]

- Roberts, I.A.; Wang, C.J.; Esterlein, R.; Stanford, M.; Mynors, D.J. A three-dimensional finite element analysis of the temperature field during laser melting of metal powders in additive layer manufacturing. Int. J. Mach. Tools Manuf. 2009, 49, 916–923. [Google Scholar] [CrossRef]

- Li, C.; Fu, C.H.; Guo, Y.B.; Fang, F.Z. A multiscale modeling approach for fast prediction of part distortion in selective laser melting. J. Mater. Process. Technol. 2016, 229, 703–712. [Google Scholar] [CrossRef]

- Tomus, D.; Rometsch, P.A.; Heilmaier, M.; Wu, X. Effect of minor alloying elements on crack-formation characteristics of Hastelloy-X manufactured by selective laser melting. Addit. Manuf. 2017, 16, 65–72. [Google Scholar] [CrossRef]

- Kruth, J.P.; Froyen, L.; Van Vaerenbergh, J.; Mercelis, P.; Rombouts, M.; Lauwers, B. Selective laser melting of iron-based powder. J. Mater. Process. Technol. 2004, 149, 616–622. [Google Scholar] [CrossRef]

- Biegler, M.; Graf, B.; Rethmeier, M. In-situ distortions in LMD additive manufacturing walls can be measured with digital image correlation and predicted using numerical simulations. Addit. Manuf. 2018, 20, 101–110. [Google Scholar] [CrossRef]

- Montevecchi, F.; Venturini, G.; Grossi, N.; Scippa, A.; Campatelli, G. Finite Element mesh coarsening for effective distortion prediction in Wire Arc Additive Manufacturing. Addit. Manuf. 2017, 18, 145–155. [Google Scholar] [CrossRef]

- Yu, J.; Lin, X.; Ma, L.; Wang, J.; Fu, X.; Chen, J.; Huang, W. Influence of laser deposition patterns on part distortion, interior quality and mechanical properties by laser solid forming (LSF). Mater. Sci. Eng. A 2011, 528, 1094–1104. [Google Scholar] [CrossRef]

- Gao, M.; Wang, Z.; Li, X.; Zeng, X. The Effect of Deposition Patterns on the Deformation of Substrates during Direct Laser Fabrication. J. Eng. Mater. Technol. 2013, 135, 034502. [Google Scholar] [CrossRef]

- Nickel, A.H.; Barnett, D.M.; Prinz, F.B. Thermal stresses and deposition patterns in layered manufacturing. Mater. Sci. Eng. A 2001, 317, 59–64. [Google Scholar] [CrossRef] [Green Version]

- Yan, H.; Shen, L.; Wang, X.; Tian, Z.; Xu, G.; Xie, D.; Liang, H. Stress and deformation evaluation of the subarea scanning effect in direct laser-deposited Ti-6Al-4V. Int. J. Adv. Manuf. Technol. 2018, 97, 915–926. [Google Scholar] [CrossRef]

- Cao, J.; Gharghouri, M.A.; Nash, P. Finite-element analysis and experimental validation of thermal residual stress and distortion in electron beam additive manufactured Ti-6Al-4V build plates. J. Mater. Process. Technol. 2016, 237, 409–419. [Google Scholar] [CrossRef]

- Mukherjee, T.; Zhang, W.; DebRoy, T. An improved prediction of residual stresses and distortion in additive manufacturing. Comput. Mater. Sci. 2017, 126, 360–372. [Google Scholar] [CrossRef]

- Denlinger, E.R.; Heigel, J.C.; Michaleris, P.; Palmer, T.A. Effect of inter-layer dwell time on distortion and residual stress in additive manufacturing of titanium and nickel alloys. J. Mater. Process. Technol. 2015, 215, 123–131. [Google Scholar] [CrossRef]

- Denlinger, E.R.; Heigel, J.C.; Michaleris, P. Residual stress and distortion modeling of electron beam direct manufacturing Ti-6Al-4V. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2015, 229, 1803–1813. [Google Scholar] [CrossRef]

- Denlinger, E.R.; Gouge, M.; Irwin, J.; Michaleris, P. Michaleris, Thermomechanical model development and in situ experimental validation of the Laser Powder-Bed Fusion process. Addit. Manuf. 2017, 16, 73–80. [Google Scholar] [CrossRef]

- Heigel, J.C.; Michaleris, P.; Reutzel, E.W. Thermal-mechanical model development and validation of directed energy deposition additive manufacturing of Ti–6Al–4V. Addit. Manuf. 2015, 5, 9–19. [Google Scholar] [CrossRef]

- Denlinger, E.R.; Michaleris, P. Effect of stress relaxation on distortion in additive manufacturing process modeling. Addit. Manuf. 2016, 12, 51–59. [Google Scholar] [CrossRef] [Green Version]

- Hönnige, J.R.; Colegrove, P.A.; Ganguly, S.; Eimer, E.; Kabra, S.; Williams, S. Control of residual stress and distortion in aluminium wire + arc additive manufacture with rolling. Addit. Manuf. 2018, 22, 775–783. [Google Scholar] [CrossRef]

- Ghasri-Khouzani, M.; Peng, H.; Rogge, R.; Attardo, R.; Ostiguy, P.; Neidig, J.; Billo, R.; Hoelzle, D.; Shankar, M.R. Experimental measurement of residual stress and distortion in additively manufactured stainless steel components with various dimensions. Mater. Sci. Eng. A 2017, 707, 689–700. [Google Scholar] [CrossRef]

- Li, Y.; Zhou, K.; Tan, P.; Tor, S.B.; Chua, C.K.; Leong, K.F. Modeling temperature and residual stress fields in selective laser melting. Int. J. Mech. Sci. 2018, 136, 24–35. [Google Scholar] [CrossRef]

- Zielinski, J.; Mindt, H.W.; Düchting, J.; Schleifenbaum, J.H.; Megahed, M. Numerical and Experimental Study of Ti6Al4V Components Manufactured Using Powder Bed Fusion Additive Manufacturing. JOM 2017, 69, 2711–2718. [Google Scholar] [CrossRef] [Green Version]

- Li, C.; Liu, J.F.; Fang, X.Y.; Guo, Y.B. Efficient predictive model of part distortion and residual stress in selective laser melting. Addit. Manuf. 2017, 17, 157–168. [Google Scholar] [CrossRef]

- Afazov, S.; Denmark, W.A.; Toralles, B.L.; Holloway, A.; Yaghi, A. Distortion prediction and compensation in selective laser melting. Addit. Manuf. 2017, 17, 15–22. [Google Scholar] [CrossRef]

- Gray, G.T.; Livescu, V.; Rigg, P.A.; Trujillo, C.P.; Cady, C.M.; Chen, S.R.; Carpenter, J.S.; Lienert, T.J.; Fensin, S.J. Structure/property (constitutive and spallation response) of additively manufactured 316L stainless steel. Acta Mater. 2017, 138, 140–149. [Google Scholar] [CrossRef]

- Cherry, J.A.; Davies, H.M.; Mehmood, S.; Lavery, N.P.; Brown, S.G.R.; Sienz, J. Investigation in the effect of process parameters on microstructural and physical properties of 316L stainless steel parts by selective laser melting. Int. J. Adv. Manuf. Technol. 2015, 76, 869–879. [Google Scholar] [CrossRef]

- Wang, D.; Wu, S.; Yang, Y.; Dou, W.; Deng, S.; Wang, Z.; Li, S. The Effect of a Scanning Strategy on the Residual Stress of 316L Steel Parts Fabricated by Selective Laser Melting (SLM). Materials 2018, 11, 1821. [Google Scholar] [CrossRef] [PubMed]

- Carlton, H.D.; Haboub, A.; Gallegos, G.F.; Parkinson, D.Y.; MacDowell, A.A. Damage evolution and failure mechanisms in additively manufactured stainless steel. Mater. Sci. Eng. A 2016, 651, 406–414. [Google Scholar] [CrossRef] [Green Version]

- Paul, R.; Anand, S. Optimal part orientation in Rapid Manufacturing process for achieving geometric tolerances. J. Manuf. Syst. 2011, 30, 214–222. [Google Scholar] [CrossRef]

- Almeida, D.F.; Martins, R.F.; Cardoso, J.B. Numerical simulation of residual stresses induced by TIG butt-welding of thin plates made of AISI 316L stainless steel. Procedia Struct. Integr. 2017, 5, 633–639. [Google Scholar] [CrossRef]

- Chukkan, J.R.; Vasudevan, M.; Muthukumaran, S.; Kumar, R.R.; Chandrasekhar, N. Chandrasekhar, Simulation of laser butt welding of AISI 316L stainless steel sheet using various heat sources and experimental validation. J. Mater. Process. Technol. 2015, 219, 48–59. [Google Scholar] [CrossRef]

- Yin, J.; Zhu, H.; Ke, L.; Lei, W.; Dai, C.; Zuo, D. Simulation of temperature distribution in single metallic powder layer for laser micro-sintering. Comput. Mater. Sci. 2012, 53, 333–339. [Google Scholar] [CrossRef]

- Mukherjee, T.; Wei, H.L.; De, A.; DebRoy, T. Heat and fluid flow in additive manufacturing—Part I: Modeling of powder bed fusion. Comput. Mater. Sci. 2018, 150, 304–313. [Google Scholar] [CrossRef]

- Wang, L.; Wang, Y.; Sun, X.G.; He, J.Q.; Pan, Z.Y.; Wang, C.H. Finite element simulation of residual stress of double-ceramic-layer La2Zr2O7/8YSZ thermal barrier coatings using birth and death element technique. Comput. Mater. Sci. 2012, 53, 117–127. [Google Scholar] [CrossRef]

- Deng, D. FEM prediction of welding residual stress and distortion in carbon steel considering phase transformation effects. Mater. Des. 2009, 30, 359–366. [Google Scholar] [CrossRef]

- Ghosh, S.; Choi, J. Three-dimensional transient finite element analysis for residual stresses in the laser aided direct metal/material deposition process. J. Laser Appl. 2005, 17, 144–158. [Google Scholar] [CrossRef]

- Simson, T.; Emmel, A.; Dwars, A.; Böhm, J. Residual stress measurements on AISI 316L samples manufactured by selective laser melting. Addit. Manuf. 2017, 17, 183–189. [Google Scholar] [CrossRef]

- Kruth, J.P.; Deckers, J.; Yasa, E.; Wauthlé, R. Assessing influencing factors of residual stresses in selective laser melting using a novel analysis method. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2012, 226, 980–991. [Google Scholar] [CrossRef]

- Bendeich, P.; Alam, N.; Brandt, M.; Carr, D.; Short, K.; Blevins, R.; Curfs, C.; Kirstein, O.; Atkinson, G.; Holden, T.; et al. Residual stress measurements in laser clad repaired low pressure turbine blades for the power industry. Mater. Sci. Eng. A 2006, 437, 70–74. [Google Scholar] [CrossRef]

- Sun, G.; Zhou, R.; Lu, J.; Mazumder, J. Evaluation of defect density, microstructure, residual stress, Young’s modulus, hardness and strength of laser-deposited AISI 4340 steel. Acta Mater. 2015, 84, 172–189. [Google Scholar] [CrossRef]

- Desai, P.D.; Ho, C.Y. Thermal Linear Expansion of Nine Selected AISI Stainless Steels; Defense Technical Information Center: Fort Belvoir, VA, USA, April 1978; Available online: http://www.dtic.mil/docs/citations/ADA129159 (accessed on 17 October 2018).

- Li, J.Y.; Sugiyama, S.; Yanagimoto, J. Microstructural evolution and flow stress of semi-solid type 304 stainless steel. J. Mater. Process. Technol. 2005, 61, 396–406. [Google Scholar] [CrossRef]

- Kelly, J.E.; Michalek, K.P.; O’connor, T.G.; Thomas, B.G.; Dantzig, J.A. Initial Development of thermal and stress fields in continuously cast steel billets. Metall. Trans. A 1988, 19, 2589–2602. [Google Scholar] [CrossRef]

- Haglund, P.; Frostevarg, J.; Powell, J.; Eriksson, I.; Kaplan, A.F. Holographic measurement of distortion during laser melting: Additive distortion from overlapping pulses. Opt. Laser Technol. 2018, 100, 1–6. [Google Scholar] [CrossRef]

- Williams, R.J.; Davies, C.M.; Hooper, P.A. A pragmatic part scale model for residual stress and distortion prediction in powder bed fusion. Addit. Manuf. 2018, 22, 416–425. [Google Scholar] [CrossRef]

| Temperature T/°C | Thermal Diffusivity λ/[W/(m·°C)] | Density ρ/(10−3 g/mm3) | Heat Capacity c/J/(kg·°C) | Linear Expansion Coefficient α/(10−6 °C−1) | Youngs Modulus E/(1011 Pa) |

|---|---|---|---|---|---|

| 0 | 13.5 | 7.88 | 498.6 | 15.1 | 1.98 |

| 200 | 16.7 | 7.63 | 525.4 | 17.8 | 1.82 |

| 400 | 19.8 | 7.29 | 552.2 | 19.6 | 1.70 |

| 600 | 22.9 | 6.86 | 579.0 | 20.6 | 1.56 |

| 800 | 26.1 | 6.35 | 605.8 | 21.0 | 1.34 |

| 1200 | 32.4 | 5.04 | 659.4 | 21.4 | 0.58 |

| 1450 | 36.3 | 4.04 | 692.9 | 21.6 | 0.05 |

| Deposition Length ld/mm | Peak Displacement by Static Structural-FEA dss/mm | Mean Peak Displacement of Experimental dex/mm | Constraining Coefficient kds | Constraining Force/kN |

|---|---|---|---|---|

| 10 | 0.13 | 0.261 | 0.79 | 20.1 |

| 20 | 0.24 | 0.463 | 0.76 | 19.3 |

| 30 | 0.35 | 0.656 | 0.74 | 18.8 |

| 40 | 0.44 | 0.817 | 0.73 | 18.5 |

| 50 | 0.51 | 0.921 | 0.71 | 18.0 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xie, D.; Zhao, J.; Liang, H.; Tian, Z.; Shen, L.; Xiao, M.; Ahsan, M.N.; Wang, C. Assumption of Constraining Force to Explain Distortion in Laser Additive Manufacturing. Materials 2018, 11, 2327. https://doi.org/10.3390/ma11112327

Xie D, Zhao J, Liang H, Tian Z, Shen L, Xiao M, Ahsan MN, Wang C. Assumption of Constraining Force to Explain Distortion in Laser Additive Manufacturing. Materials. 2018; 11(11):2327. https://doi.org/10.3390/ma11112327

Chicago/Turabian StyleXie, Deqiao, Jianfeng Zhao, Huixin Liang, Zongjun Tian, Lida Shen, Meng Xiao, Muhammad Naveed Ahsan, and Changjiang Wang. 2018. "Assumption of Constraining Force to Explain Distortion in Laser Additive Manufacturing" Materials 11, no. 11: 2327. https://doi.org/10.3390/ma11112327

APA StyleXie, D., Zhao, J., Liang, H., Tian, Z., Shen, L., Xiao, M., Ahsan, M. N., & Wang, C. (2018). Assumption of Constraining Force to Explain Distortion in Laser Additive Manufacturing. Materials, 11(11), 2327. https://doi.org/10.3390/ma11112327