1. Introduction

Because of the high temperature resistance and corrosion resistance of 304 stainless steel, and high strength and high thermal conductivity of Q235 carbon steel [

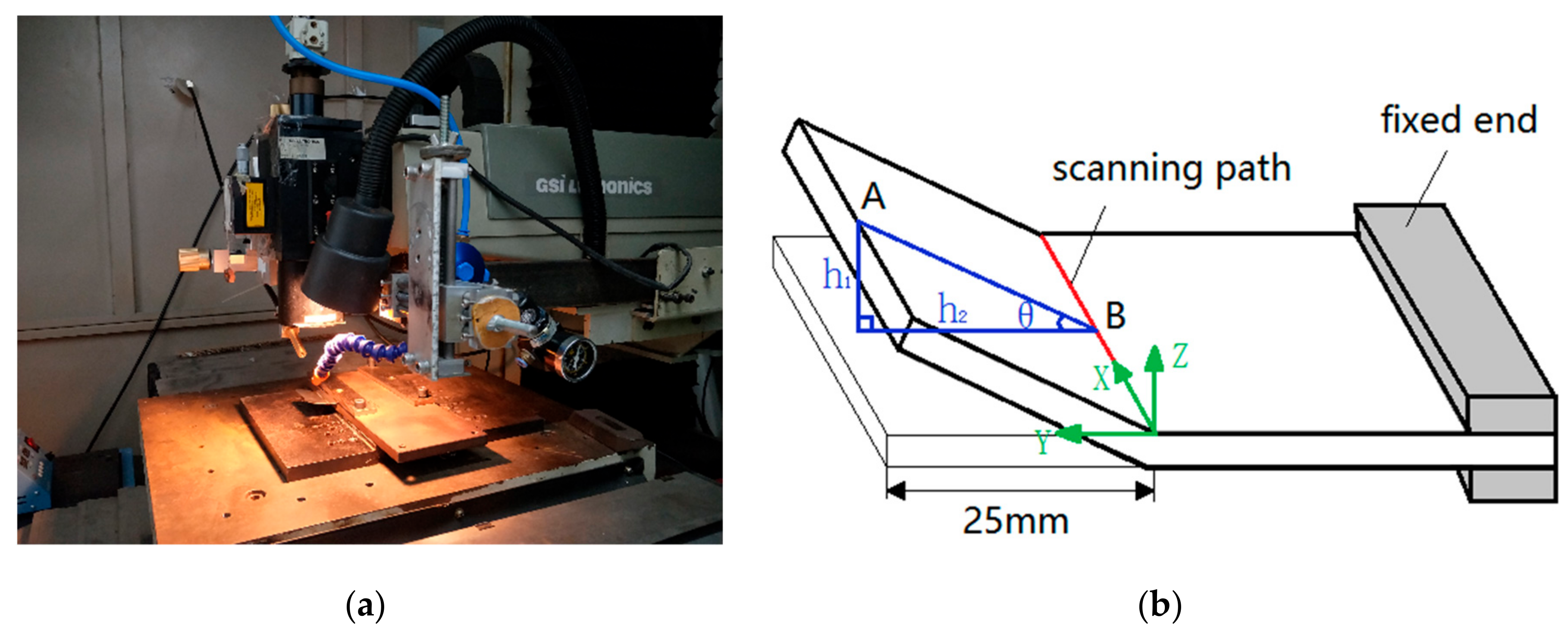

1], SCLP has broad application prospects in corrugated bulkhead of flying machine and deep-sea scuba machine, as shown in

Figure 1. As a new kind of composite material, SCLP has a transition layer between the matrix (carbon steel) and cladding (stainless steel), formed by physical contact, chemical reaction and element diffusion. Shen et al. [

2] prepared the composite material of 304 stainless steel-reinforced Q235 carbon steel by a modified hot-rolling process. It was found that a metallurgical bonding was formed between the stainless steel layer and the carbon steel substrate. Dhib et al. [

3] pointed out that the hot-roll bonding process caused the formation of a thin diffusion layer with decarburized ferrite zone of the parent metal and carburized austenite zone of the clad layer. Zhang et al. [

4] investigated the behaviors and mechanisms of diffusion welding between 304 stainless steel and pure Ni based on molecular dynamics simulation, and found that atoms diffused into the opposite side and diffusion distance increased with rise in temperature.

A corrugated bulkhead contains a large number of bending structures. In a bending process, laser bending does not require molds, contacts, or external forces. As a newly developed flexible forming technology, it is suitable for forming plates. Because of the complexity of material properties and the interaction between laser and material, domestic and foreign scholars focus on accurate modeling in laser bending simulation. For this reason, many scholars have devoted a lot of work to calculate composite material properties. Liu et al. [

5] predicted the bending angle of SiC reinforced aluminum matrix composite based on the Vollertsen’s model in laser forming by calculating equivalent properties. Gou et al. [

6] calculated thermal expansion properties of textile-reinforced composites with certain structure symmetries by a unit cell model. Mishurova et al. [

7] calculated equivalent elastic properties of polymer-fiber reinforced concrete in the framework of the non-interaction approximation, the Mori-Tanaka-Benveniste scheme, and the Maxwell scheme. During the laser bending process, the transition layer is an extremely important component of composite plate and its properties are key factors affecting load transfer, stress distribution and deformation; the transition layer of laminated composite plate should be fully considered in terms of modeling. Because there are no specific properties of the transition layer in existing manuals, scholars use a variety of methods to unify the calculation of material properties for the transition layer. For a bilayer material system including an Al 6061 metal layer and a SiC ceramic layer, Shen et al. [

8] analyzed the temperature and stress fields during the laser-forming process, but did not consider the combination mechanisms of the joint surface and introduction into the model. Song et al. [

9] calculated the physical properties of the transition layer by mean value method, and simulated deformation behaviors of the SCLP model. At present, material properties of the transition layer are mainly calculated by the mean value method. However, the mean value method cannot reflect the heterogeneity of material distribution in the transition layer, which is a key factor affecting the angle of laser bending. Therefore, it is particularly important to accurately describe the dimensions and material properties of the transition layer by an equivalent method considering the admixture of 304 stainless steel and Q235 carbon steel.

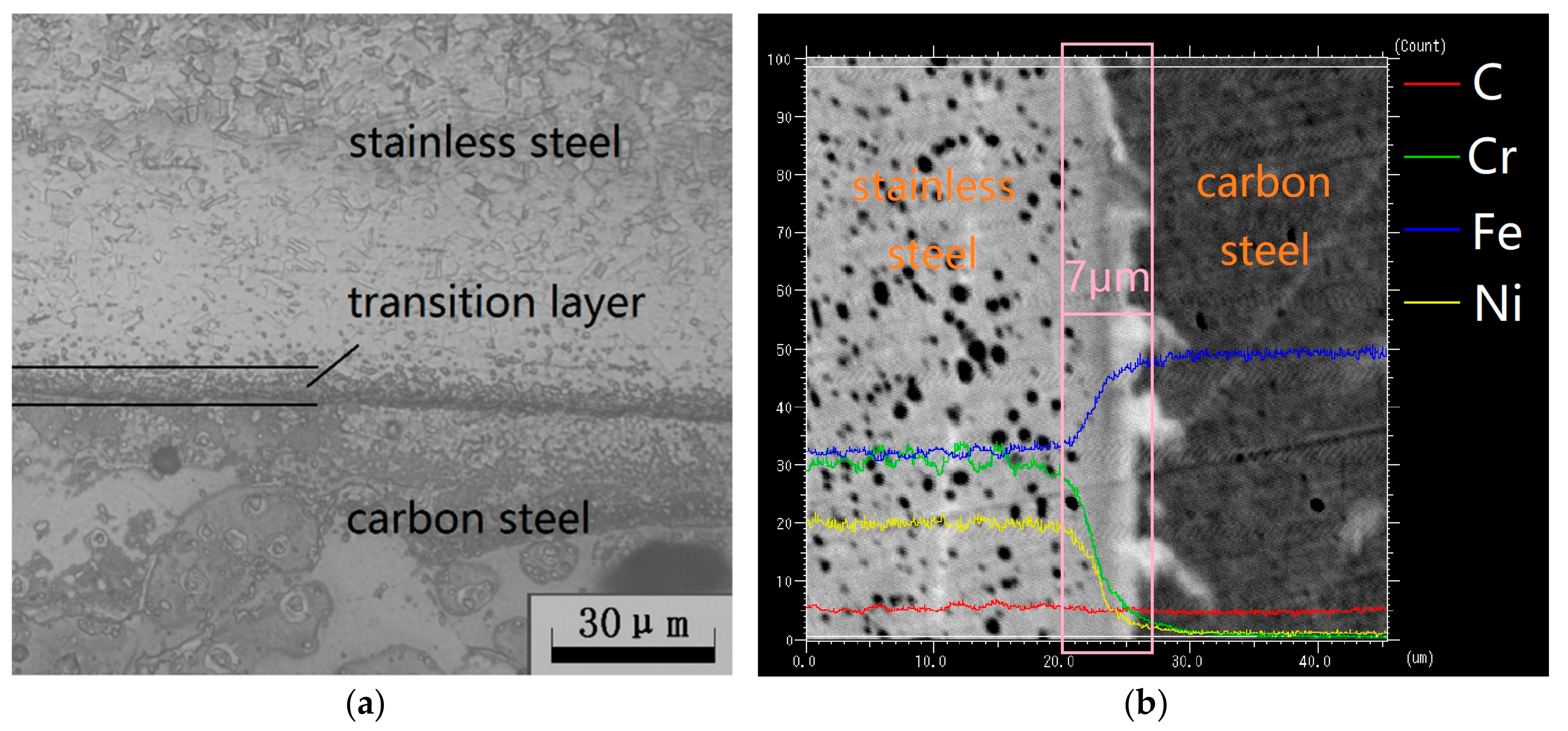

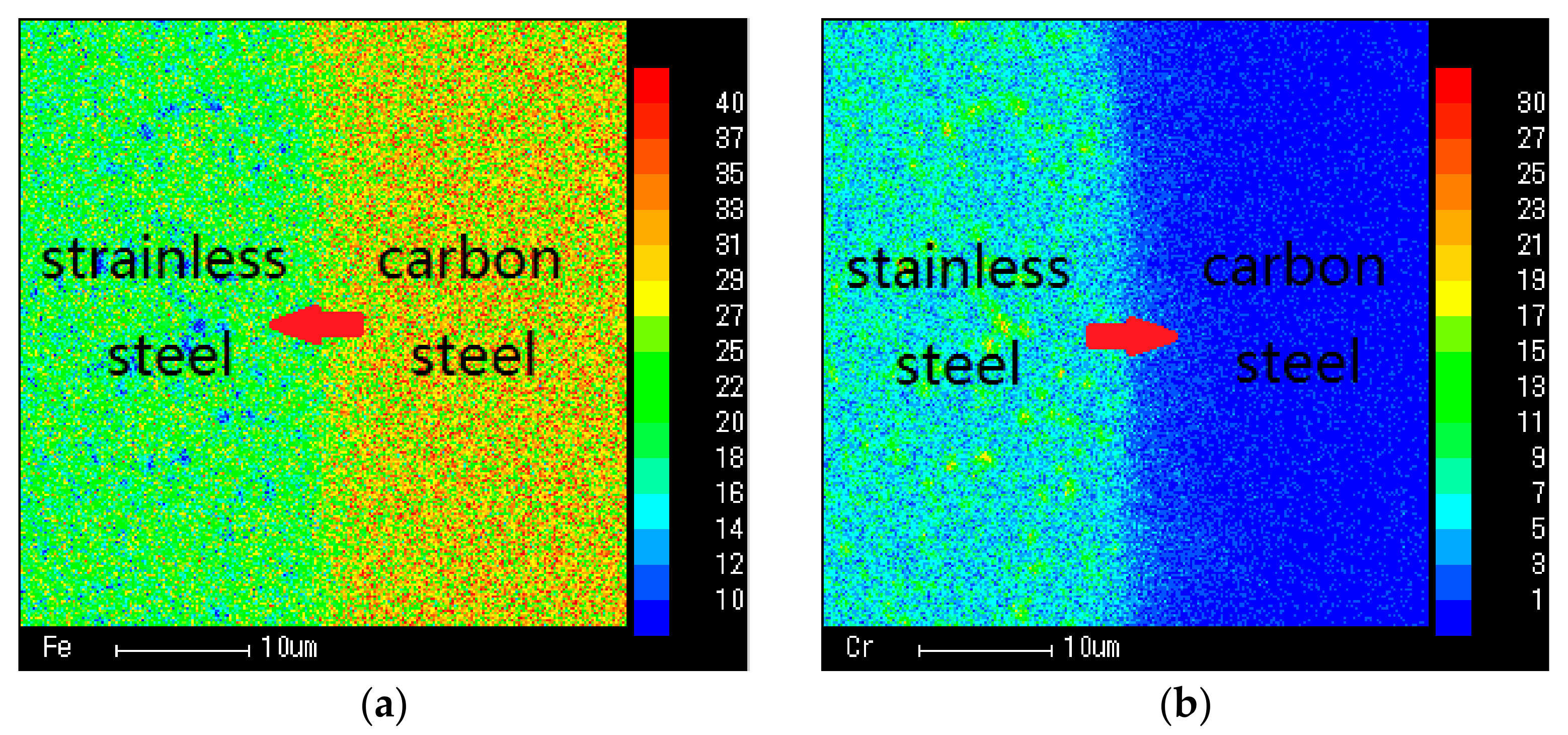

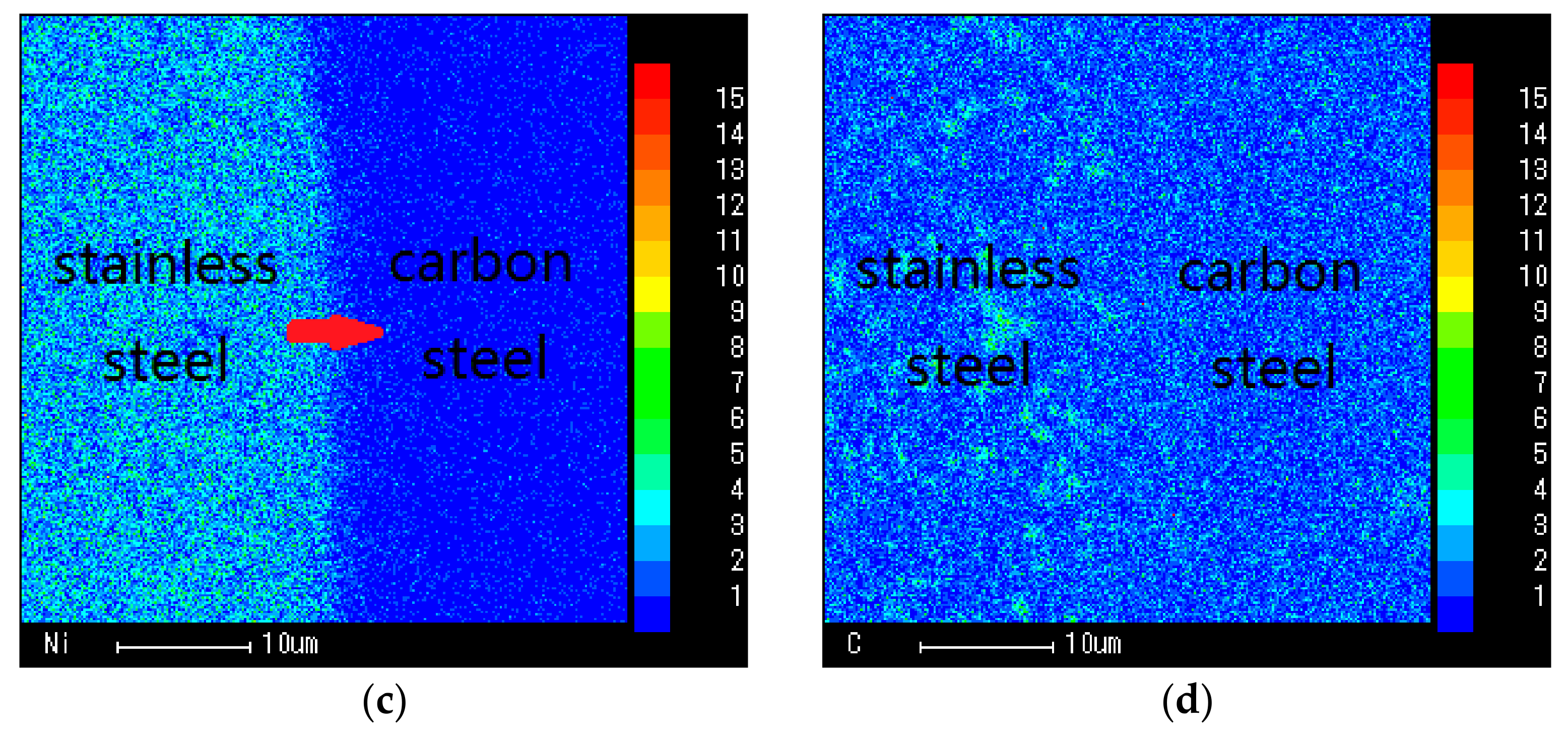

In this work, the element distribution in the SCLP and the transition layer thickness are obtained by electron probe experiments and the element content in the SCLP is measured by energy dispersive spectrometer. Then, the volume fraction of stainless steel and carbon steel in the transition layer are calculated combining the element content in the SCLP. On account of the volume fraction and the element distribution of the transition layer, the calculation of the equivalent properties of the transition layer (including thermal conductivity, thermal expansion coefficient, elastic modulus, density, Poisson’s ratio and specific heat capacity) is carried out by the effective medium theory, Turner formula, Mori-Tanaka method and mixture law. Furthermore, a finite element model of laser bending is developed based on the equivalent properties of the transition layer. The bending angle of laser processing is predicted by the simulation of laser loading and material deformation, which provides a theoretical and experimental basis for laser bending of SCLP.

3. Simulations and Analysis

Because the transition layer is a region formed by inter-diffusion of elements in stainless steel and carbon steel, its properties and constituent elements are different from those of both sides. There are no specific transition layer properties in the existing manuals, so the transition layer needs to be theoretically calculated to improve modeling accuracy using the finite element method. According to the assumptions, the transition layer is considered to consist of stainless steel with volume fraction of V1 and carbon steel with volume fraction of V2. According to the transition layer bonding mechanism, the corresponding theoretical formula is selected to calculate the equivalent properties, that is, the material properties of the transition layer.

3.1. Calculation of Equivalent Properties of Transition Layer

3.1.1. Equivalent Thermal Conductivity

Zhou et al. pointed out that due to the differing content of diffused materials, the calculation methods were diverse in the equivalent thermal conductivity calculation model. In this work, the content of stainless steel and carbon steel in the transition layer of the SCLP is almost equal. The heterogeneous continuous phase or dispersed phase can be calculated by the equivalent medium theory. The calculation process of the equivalent thermal conductivity of the transition layer can be expressed as follows [

10]:

where

kc is the thermal conductivity of transition layer,

k1 and

k2 are the thermal conductivity of stainless steel and carbon steel, respectively;

V1 and

V2 are the volume fraction of stainless steel and carbon steel, respectively.

3.1.2. Equivalent Thermal Expansion Coefficient

Makarian et al. [

11] developed a predictive model and verified the equivalent thermal expansion coefficient of particulate composites as a function of the thermo mechanical and geometrical properties of the individual constituents. Turner [

12] considered that an internal stress existed in a mixture such that the stresses were nowhere sufficient to disrupt the material; the sum of the internal forces could be equated to zero and an expression for thermal expansion coefficient of the mixture was obtained. According to the Turner model, thermal expansion coefficient of transition layer is given by:

where

αc is the thermal expansion coefficient of transition layer,

α1 and

α2 are the thermal expansion coefficient of stainless steel and carbon steel, respectively,

K1 and

K2 are the bulk modulus of stainless steel and carbon steel, respectively.

According to the formula of bulk modulus,

K1 and

K2 can be expressed as follows:

where

E1 and

E2 are the elasticity modulus of stainless steel and carbon steel, respectively; and

λ1 and

λ2 are the Poisson’s ratio of stainless steel and carbon steel, respectively. The Equations (4) and (5) are substituted into Equation (3) to obtain the equivalent thermal expansion coefficient as follows:

3.1.3. Equivalent Elasticity Modulus

Mori and Tanaka [

13] provided simple tools for the evaluation of the equivalent elasticity modulus of transition layer. The equivalent modulus method for non-homogeneous material assumed that average internal stress was uniform and took into account the effects of the interaction among the inclusions. The relationship about the equivalent elastic modulus of transition layer is given by using the mean field theory as follows:

where

Kc is the bulk modulus of transition layer,

α is the parameter that replaces variables. They are expressed as follows:

Therefore, the equivalent elasticity modulus for the transition layer can be obtained by the simultaneous formulas of Equations (7)–(9):

where

Ec is the equivalent elasticity modulus for the transition layer, and

λc is the Poisson’s ratio of the transition layer.

3.1.4. Other Equivalent Properties

In other aspects of the equivalent properties such as density, Poisson’s ratio and specific heat capacity are calculated by the law of mixing of composite materials:

where

ρc is the equivalent density of transition layer,

ρ1 and

ρ2 are the density of stainless steel and carbon steel, respectively. Similarly, the specific heat of transition layer is given by:

where

Cc is the equivalent specific heat capacity of the transition layer; and

C1 and

C2 are the specific heat capacity of stainless steel and carbon steel, respectively.

3.2. Calculation Results of Materials Equivalent Properties

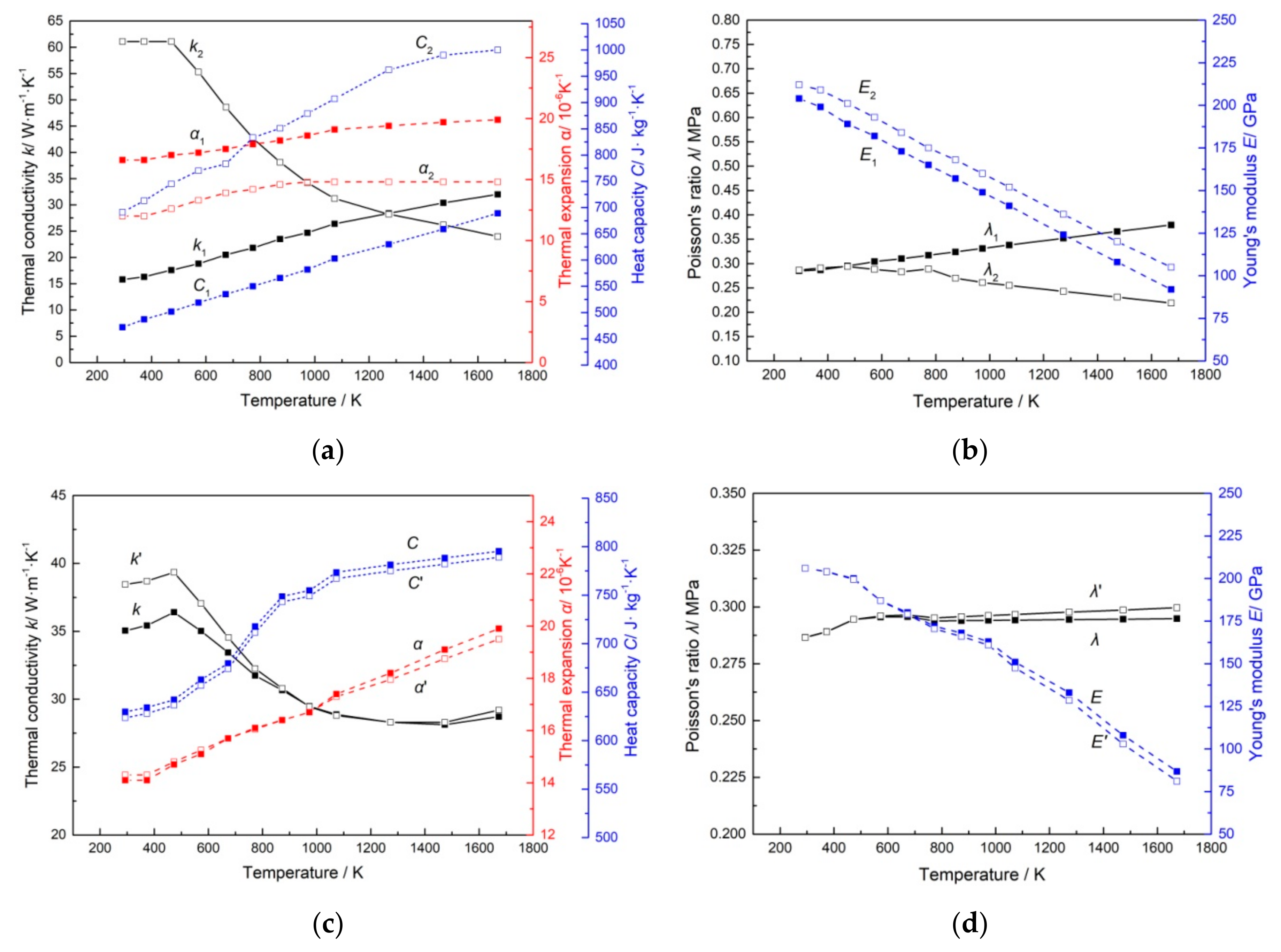

As shown in

Table 2, the composition and content of elements are detected by energy dispersive spectrometer of a scanning electron microscopic for each layer of SCLP.

According to calculations, the volume fraction of Fe, Cr, Ni and C diffused from the stainless steel layer are 46.06%, 48.55%, 53.35% and 40.00%, respectively, and from carbon steel are 53.94%, 51.45%, 46.65% and 60.00%, respectively. Because of the high content of Fe, the diffusion of Fe plays an important role in the formation of the transition layers. Therefore, the proportion of carbon steel in transition layer is slightly larger than that of stainless steel. Based on the weighted average method, the material of transition layer is composed of 46.63% stainless steel and 53.37% carbon steel. This volume fraction will be used to calculate the equivalent material properties in the transition layer.

According to the material volume fraction of the transition layer, the calculation results of equivalent properties are shown at room temperature in

Table 3. At the same time, temperature parameters are taken into consideration.

Figure 5a,b show thermodynamic and mechanical properties of stainless steel (X

1) and carbon steel (X

2) in the manual. Based on the calculation of MATLAB software,

Figure 5c,d show a comparison of the thermodynamic and mechanical properties between the equivalent method (X) and the mean value method (X’).

In the mean value method, the transition layer is regarded as a homogeneous mixture of stainless steel and carbon steel with equal proportion. However, according to the element distribution, it is known that there exists an inhomogeneous state in the transition layer. Parrott et al. [

14] pointed out that the mean value method of the thermal conductivities for two components was mathematically unsound and tended to overestimate the conductivity of the system. Therefore, the thermal conductivity calculated by the equivalent method is lower than the mean value method. For heterogeneous materials, the equivalent calculation of the transition layer takes into account the interaction between the internal particles, which is more suitable for predicting the thermal expansion coefficient of the composite than that of the mean value method. Moreover, the mean value method, without considering the proportions of the two materials in the transition layer, has a larger error in calculation of specific heat capacity due to the obvious difference between stainless steel and carbon steel. Other properties such as elastic modulus, density and Poisson’s ratio of stainless steel and carbon steel have relatively consistent tendency with temperature change. The approximation of the two materials makes the results of these properties obtained by the mean value method and the equivalent method basically the same.

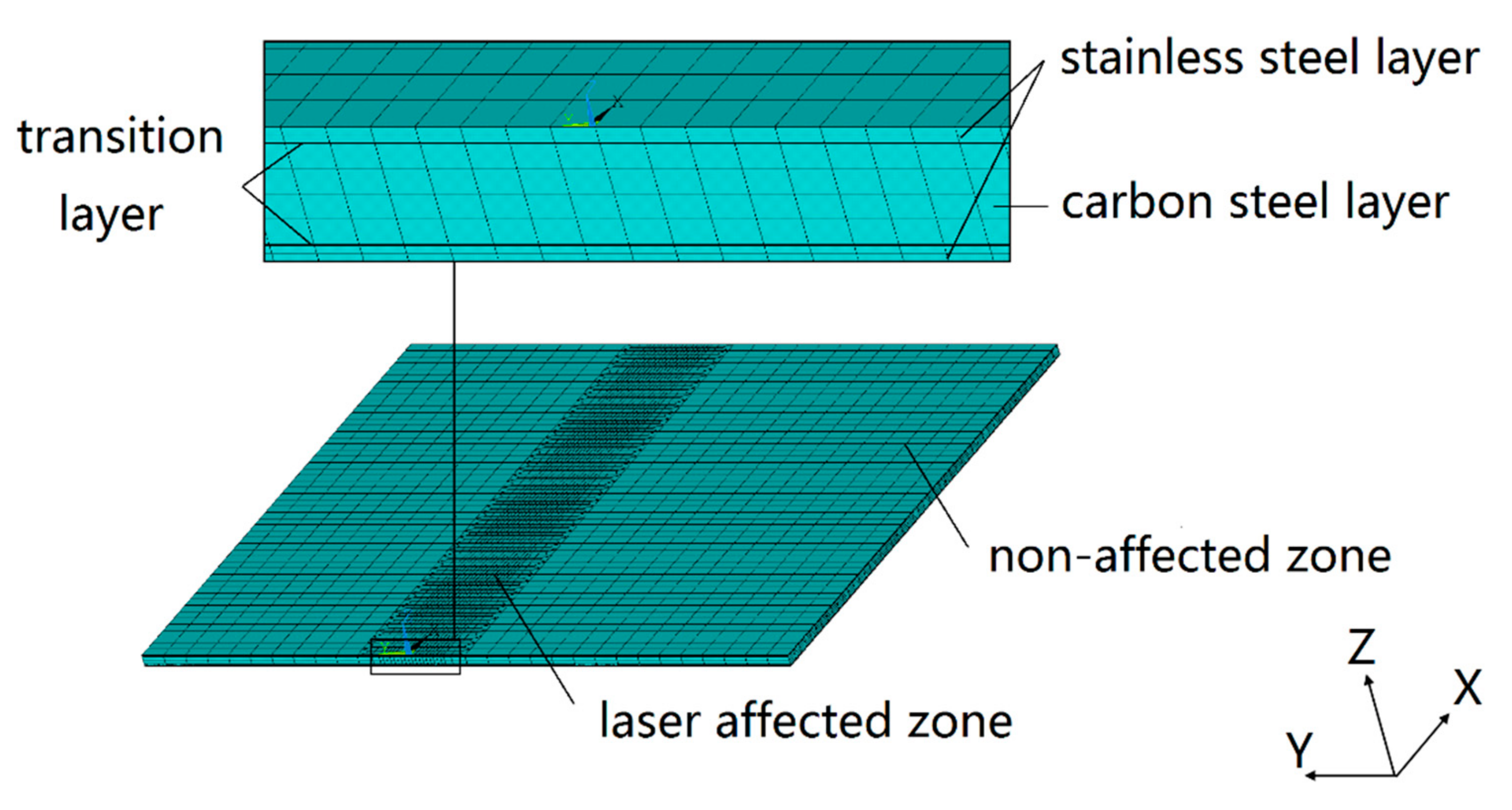

3.3. Finite Element Model of SCLP Considering Transition Layer

According to the transition layer properties obtained by the equivalent method, a 1:1 geometric model of the SCLP is established based on the actual work piece. In order to meet the requirements of manufacturing standards, the thickness of stainless steel, transition layer and carbon steel layer in the SCLP model with a size of 60 mm × 50 mm × 1 mm is 120 μm, 7 μm and 746 μm, respectively. In the ANSYS simulation of laser bending SCLP, mesh density has an important influence on the accuracy and efficiency of calculation.

Figure 6 shows the FEM grid partition profile of the SCLP in different directions. Due to the large temperature and stress gradient in a laser-affected zone with width of approximate 6 mm, the grid of the XOY plane is divided by the finer specification of 1/3 mm × 1/3 mm. In contrast, the temperature and stress field in the non-affected zone are relatively uniform, so the grid is chosen as the looser 1 × 1 mm specification. In the Z axis direction, the thickness of stainless steel, transition layer and carbon steel layer is 120 μm, 7 μm and 746 μm with different grid division, respectively (stainless steel 2 × 60 μm, transition layer 1 × 7 μm, and carbon layer 4 × 186.5 μm). The model consists of 60,450 elements and 61,724 modes. Eight-node three-dimensional element is used for both thermal and mechanical analyses.

The numerical simulation of laser bending SCLP is a nonlinear transient thermal elastoplastic deformation process by ANSYS software (ANSYS 14.5, ANSYS, Inc., Canonsburg, PA, USA). The Newton-Raphson method is used for iterative solution. In order to speed up the convergence, the large deformation option and the automatic step option are turned on. The algorithm used in the ANSYS software is an implicit algorithm in the direct integration.

The pulsed laser moves with uniform speed along the scanning line to heat the upper stainless steel surface. In this paper, assuming that the single-pulse laser energy is a dynamic heat source that obeys the Gaussian distribution, the power density distribution of pulsed laser can be expressed as:

where

A is the absorption coefficient (about 0.25),

I0 is the power density at the laser center,

f(

x,

y) is the spatial distribution of pulsed laser,

g(

t) is the time distribution of pulsed laser. For the fundamental mode Gauss beam,

f(

x,

y) and

g(

t) can be expressed as:

where

x0 and

y0 are the coordinates of laser spot center,

x and

y are the current coordinates within the laser spot area,

r0 is the spot radius when light intensity drops to 1/

e center intensity,

t is the time,

tp is the pulse width (2 ms), and

f is the laser frequency (40 Hz).

3.4. Finite Element Equations of Heat Conduction

Assuming that the material of each layer is uniform, continuous and isotropic, and the properties change with temperature, the transient temperature field variable

T(

x,

y,

z,

t) satisfies Fourier’s law and energy conservation law in a Cartesian coordinate system. When laser heats the plate, the three-dimensional transient heat conduction equation is:

where

Tj is the instantaneous temperature distribution function of the

j-th layer,

ρj,

cj,

λj are density, specific heat and thermal conductivity of the

j-th layer, respectively,

j = 1, 2, …,

n. Assuming that the temperature and heat flow of different materials at the junction are continuous, the equations can be written as:

There is radiation and convection between the SCLP and the ambient environment, and the boundary condition can be written as follows:

where

k is thermal conductivity, and

he is equivalent convective heat transfer coefficient.

where

hc is convection heat transfer coefficient,

hr is radiative heat transfer coefficient,

ε is emissivity coefficient,

σ is Stefan-Boltzmann constant, and

Tw is the boundary temperature of the workpiece. Refer to the range of equivalent convective heat transfer coefficient in different environments, the value is 30 W·m

−2·K

−1.

T is the temperature of the workpiece.

Initial condition:

where

T0 is the initial temperature considered as 293 K.

Since the temperature, heat flow rate, thermal boundary conditions and internal energy of the SCLP change significantly with time during the laser bending process, the Equation (17) is solved by the Galerkin method. The heat balance matrix equation of the SCLP is obtained in nonlinear thermal analysis as follows:

where [

C(

T)] is the matrix of special heat capacity, {

(

t)} is the derivative of the node temperature with respect to time, [

K(

T)] is the matrix of heat conduction, {

T(

t)} is the vector of node temperature, and {

Q(

t)} is the vector of the node’s heat flow rate.

Using the backward difference method to discretize Equation (24) in time, the differential equations are linearized to obtain the control equation of the transient temperature field as follows:

3.5. Finite Element Equations of Thermal Elastic-Plasticity

Incremental theory is used to establish the relationship between thermal elastoplastic stress increment and strain increment for the SCLP. In the laser bending process, the deformation zone includes two parts of elastic deformation zone and plastic deformation zone. In the elastic zone, the total strain increment can be expressed as:

where {

dε}

e is elastic strain increment, and {

dε}

T is thermal strain increment caused by temperature change.

In the plastic zone, the total strain increment can be expressed as:

where {

dε}

p is plastic strain increment. During hot deformation, the stress-strain relationship can be expressed as:

In the elastic zone, [D] = [D]e, [D]e is elastic matrix, [C] = [C]e. In the plastic zone, [D] = [D]ep, [D]ep is elastoplastic matrix, [C] = [C]ep. [C] is a temperature-dependent vector.

A unit in the SCLP is taken. At time

t and

t +

dt, the temperature are

T and

T +

dT, the external force of the node are {

Fe} and {

f +

dF}

e, the displacement of the node are {

u} and {

u +

du}, the strain are {

ε} and {

ε +

dε}, and the stress are {

σ} and {

σ +

dσ}, respectively. According to the principle of virtual work, the equation can be expressed as:

The equation of the SCLP at time t can be expressed as:

where {

dR}

e is the force of equivalent nodal, and [

K]

e is stiffness matrix of the unit. According to elastic or plastic state of the unit, the corresponding formula is chosen to bring it into Equation (30), and simplified equation can be expressed as:

Using the Newton-Raphson method to linearize equation, the finite element equation of laser bending the SCLP can be expressed as:

where [

K] is tangent stiffness matrix, {Δ

u} is displacement increment of the node, {

Fa} is the vector of external force, and [

Fnr] is the vector of restoring force.