The Effect of Varying Almond Shell Flour (ASF) Loading in Composites with Poly(Butylene Succinate (PBS) Matrix Compatibilized with Maleinized Linseed Oil (MLO)

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Manufacturing of PBS/ASF/MLO Composites

2.3. Mechanical Characterization

2.4. Thermal and Thermomechanical Characterization

2.5. Morphology Characterization

3. Results and Discussion

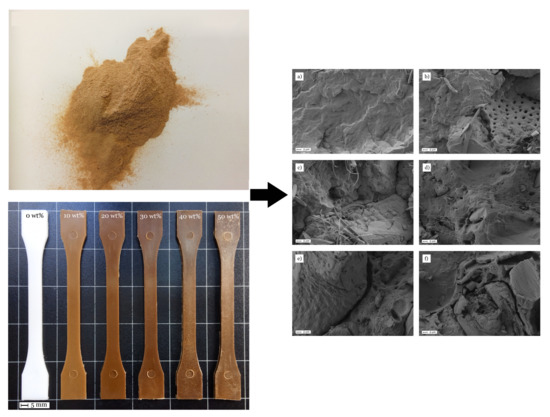

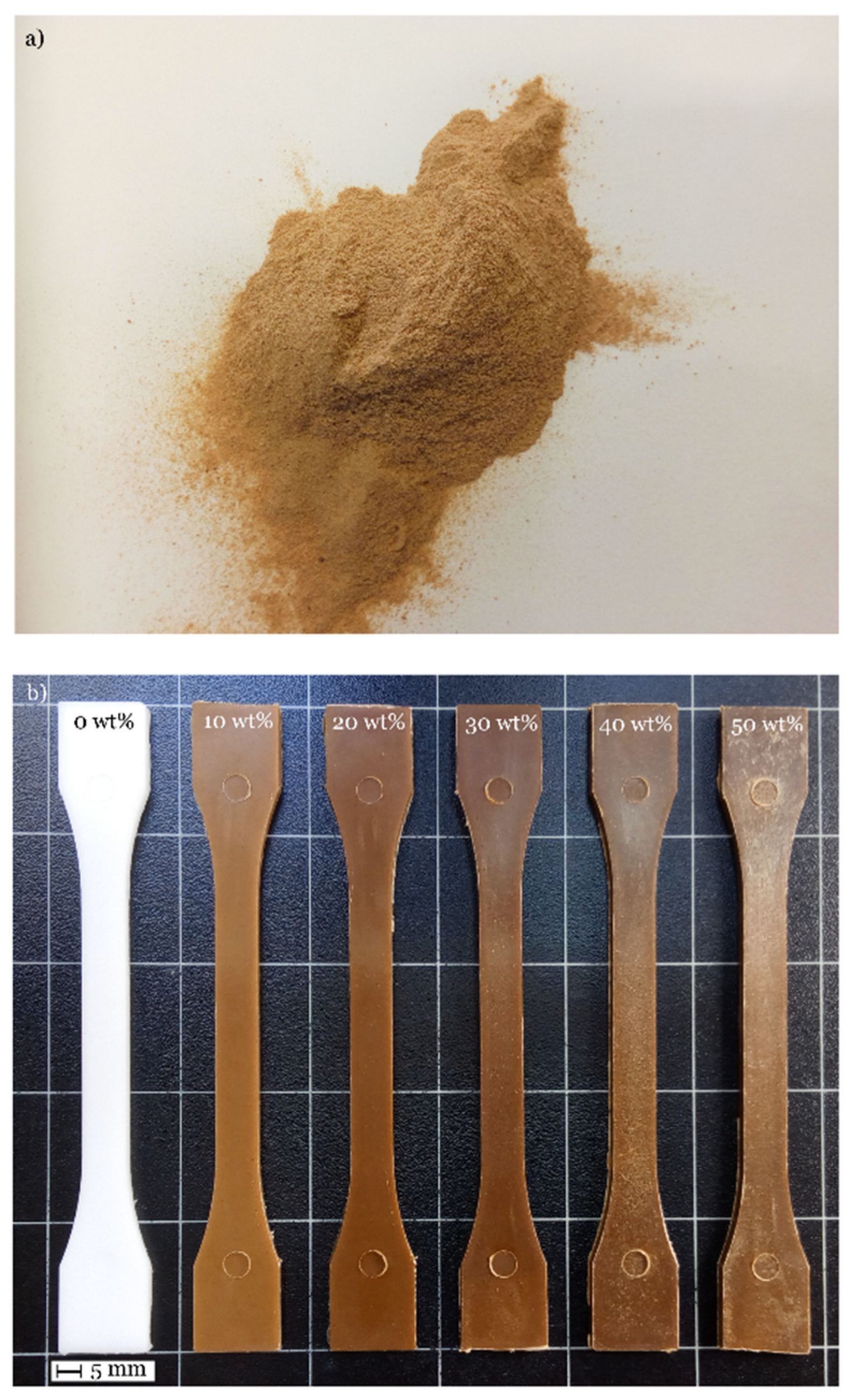

3.1. Appearance and Mechanical Properties of PBS/ASF/MLO Composites.

3.2. Thermal Properties of PBS/ASF/MLO Composites

3.3. Thermomechanical Properties of PBS/ASF/MLO Composites.

4. Conclusions

Supplementary Materials

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Hottle, T.A.; Bilec, M.M.; Landis, A.E. Biopolymer production and end of life comparisons using life cycle assessment. Resour. Conserv. Recyc. 2017, 122, 295–306. [Google Scholar] [CrossRef]

- Niaounakis, M. Biopolymers: Reuse, Recycling, and Disposal; Elsevier: Amsterdam, The Netherlands, 2013; pp. 1–413. [Google Scholar]

- Zhu, Y.; Romain, C.; Williams, C.K. Sustainable polymers from renewable resources. Nature 2016, 540, 354–362. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Gandini, A.; Lacerda, T.M. From monomers to polymers from renewable resources: Recent advances. Prog. Polym. Sci. 2015, 48, 1–39. [Google Scholar] [CrossRef]

- Eichhorn, S.J.; Gandini, A. Materials from Renewable Resources. MRS Bull. 2010, 35, 187–190. [Google Scholar] [CrossRef]

- Fombuena, V.; Sanchez-Nacher, L.; Samper, M.D.; Juarez, D.; Balart, R. Study of the Properties of Thermoset Materials Derived from Epoxidized Soybean Oil and Protein Fillers. J. Am. Oil Chem. Soc. 2013, 90, 449–457. [Google Scholar] [CrossRef]

- Ferrero, B.; Boronat, T.; Moriana, R.; Fenollar, O.; Balart, R. Green Composites Based on Wheat Gluten Matrix and Posidonia Oceanica Waste Fibers as Reinforcements. Polym. Compos. 2013, 34, 1663–1669. [Google Scholar] [CrossRef]

- Kondratowicz, F.; Ukielski, R. Synthesis and hydrolytic degradation of poly (ethylene succinate) and poly (ethylene terephthalate) copolymers. Polym. Degrad. Stab. 2009, 94, 375–382. [Google Scholar] [CrossRef]

- Mochizuki, M.; Hirami, M. Structural effects on the biodegradation of aliphatic polyesters. Polym. Adv. Technol. 1997, 8, 203–209. [Google Scholar] [CrossRef]

- Debuissy, T.; Pollet, E.; Averous, L. Synthesis of potentially biobased copolyesters based on adipic acid and butanediols: Kinetic study between 1,4-and 2,3-butanediol and their influence on crystallization and thermal properties. Polymer 2016, 99, 204–213. [Google Scholar] [CrossRef]

- Patel, M.K.; Bechu, A.; Villegas, J.D.; Bergez-Lacoste, M.; Yeung, K.; Murphy, R.; Woods, J.; Mwabonje, O.N.; Ni, Y.Z.; Patel, A.D.; Gallagher, J.; Bryant, D. Second-generation bio-based plastics are becoming a reality—Non-renewable energy and greenhouse gas (GHG) balance of succinic acid-based plastic end products made from lignocellulosic biomass. Biofuels Bioprod. Biorefin. Biofpr. 2018, 12, 426–441. [Google Scholar] [CrossRef]

- Huang, Z.; Qian, L.; Yin, Q.; Yu, N.; Liu, T.; Tian, D. Biodegradability studies of poly(butylene succinate) composites filled with sugarcane rind fiber. Polym. Test. 2018, 66, 319–326. [Google Scholar] [CrossRef]

- Puchalski, M.; Szparaga, G.; Biela, T.; Gutowska, A.; Sztajnowski, S.; Krucinska, I. Molecular and Supramolecular Changes in Polybutylene Succinate (PBS) and Polybutylene Succinate Adipate (PBSA) Copolymer during Degradation in Various Environmental Conditions. Polymers 2018, 10, 251. [Google Scholar] [CrossRef]

- Fujimaki, T. Processability and properties of aliphatic polyesters, ‘BIONOLLE’, synthesized by polycondensation reaction. Polym. Degrad. Stab. 1998, 59, 209–214. [Google Scholar] [CrossRef]

- Cihal, P.; Vopicka, O.; Pilnacek, K.; Poustka, J.; Friess, K.; Hajslova, J.; Dobias, J.; Dole, P. Aroma scalping characteristics of polybutylene succinate based films. Polym. Test. 2015, 46, 108–115. [Google Scholar] [CrossRef]

- Siracusa, V.; Lotti, N.; Munari, A.; Rosa, M.D. Poly(butylene succinate) and poly(butylene succinate-co-adipate) for food packaging applications: Gas barrier properties after stressed treatments. Polym. Degrad. Stab. 2015, 119, 35–45. [Google Scholar] [CrossRef]

- Gigli, M.; Fabbri, M.; Lotti, N.; Gamberini, R.; Rimini, B.; Munari, A. Poly(butylene succinate)-based polyesters for biomedical applications: A review. Eur. Polym. J. 2016, 75, 431–460. [Google Scholar] [CrossRef]

- Cheng, H.H.; Xiong, J.; Xie, Z.N.; Zhu, Y.T.; Liu, Y.M.; Wu, Z.Y.; Yu, J.; Guo, Z.X. Thrombin-Loaded Poly (butylene succinate)-Based Electrospun Membranes for Rapid Hemostatic Application. Macromol. Mater. Eng. 2018, 303, 1700395. [Google Scholar] [CrossRef]

- Costa-Pinto, A.R.; Martins, A.M.; Castelhano-Carlos, M.J.; Correlo, V.M.; Sol, P.C.; Longatto-Filho, A.; Battacharya, M.; Reis, R.L.; Neves, N.M. In vitro degradation and in vivo biocompatibility of chitosan–poly (butylene succinate) fiber mesh scaffolds. J. Bioact. Compat. Polym. 2014, 29, 137–151. [Google Scholar] [CrossRef] [Green Version]

- Wu, D.; Lin, D.; Zhang, J.; Zhou, W.; Zhang, M.; Zhang, Y.; Wang, D.; Lin, B. Selective localization of nanofillers: effect on morphology and crystallization of PLA/PCL blends. Macromol. Chem. Phys. 2011, 212, 613–626. [Google Scholar] [CrossRef]

- Peponi, L.; Sessini, V.; Arrieta, M.P.; Navarro-Baena, I.; Sonseca, A.; Dominici, F.; Gimenez, E.; Torre, L.; Tercjak, A.; López, D. Thermally-activated shape memory effect on biodegradable nanocomposites based on PLA/PCL blend reinforced with hydroxyapatite. Polym. Degrad. Stab. 2018, 151, 36–51. [Google Scholar] [CrossRef] [Green Version]

- Dicker, M.P.M.; Duckworth, P.F.; Baker, A.B.; Francois, G.; Hazzard, M.K.; Weaver, P.M. Green composites: A review of material attributes and complementary applications. Compos. Part A Appl. Sci. Manuf. 2014, 56, 280–289. [Google Scholar] [CrossRef]

- Gurunathan, T.; Mohanty, S.; Nayak, S.K. A review of the recent developments in biocomposites based on natural fibres and their application perspectives. Compos. Part A Appl. Sci. Manuf. 2015, 77, 1–25. [Google Scholar] [CrossRef]

- Lau, K.T.; Hung, P.Y.; Zhu, M.H.; Hui, D. Properties of natural fibre composites for structural engineering applications. Compos. Part B Eng. 2018, 136, 222–233. [Google Scholar] [CrossRef]

- Chun, K.S.; Yeng, C.M.; Hussiensyah, S. Green Coupling Agent for Agro-Waste Based Thermoplastic Composites. Polym. Compos. 2018, 39, 2441–2450. [Google Scholar] [CrossRef]

- Panthapulakkal, S.; Sain, M. Agro-residue reinforced high-density polyethylene composites: Fiber characterization and analysis of composite properties. Compos. Part A Appl. Sci. Manuf. 2007, 38, 1445–1454. [Google Scholar] [CrossRef]

- Vaisanen, T.; Haapala, A.; Lappalainen, R.; Tomppo, L. Utilization of agricultural and forest industry waste and residues in natural fiber-polymer composites: A review. Waste Manag. 2016, 54, 62–73. [Google Scholar] [CrossRef] [PubMed]

- Feng, Y.H.; Li, Y.J.; Xu, B.P.; Zhang, D.W.; Qu, J.P.; He, H.Z. Effect of fiber morphology on rheological properties of plant fiber reinforced poly(butylene succinate) composites. Compos. Part B Eng. 2013, 44, 193–199. [Google Scholar] [CrossRef]

- Terzopoulou, Z.N.; Papageorgiou, G.Z.; Papadopoulou, E.; Athanassiadou, E.; Reinders, M.; Bikiaris, D.N. Development and Study of Fully Biodegradable Composite Materials Based on Poly(butylene succinate) and Hemp Fibers or Hemp Shives. Polym. Compos. 2016, 37, 407–421. [Google Scholar] [CrossRef]

- Lee, J.M.; Ishak, Z.A.M.; Taib, R.M.; Law, T.T.; Thirmizir, M.Z.A. Mechanical, Thermal and Water Absorption Properties of Kenaf-Fiber-Based Polypropylene and Poly(Butylene Succinate) Composites. J. Polym. Environ. 2013, 21, 293–302. [Google Scholar] [CrossRef]

- Tserki, V.; Matzinos, P.; Panayiotou, C. Novel biodegradable composites based on treated lignocellulosic waste flour as filler Part II. Development of biodegradable composites using treated and compatibilized waste flour. Compos. Part A Appl. Sci. Manuf. 2006, 37, 1231–1238. [Google Scholar] [CrossRef]

- Yen, F.S.; Liao, H.T.; Wu, C.S. Characterization and biodegradability of agricultural residue-filled polyester ecocomposites. Polym. Bull. 2013, 70, 1613–1629. [Google Scholar] [CrossRef]

- El Mechtali, F.Z.; Essabir, H.; Nekhlaoui, S.; Bensalah, M.; Jawaid, M.; Bouhfid, R.; Qaiss, A. Mechanical and Thermal Properties of Polypropylene Reinforced with Almond Shells Particles: Impact of Chemical Treatments. J. Bionic Eng. 2015, 12, 483–494. [Google Scholar] [CrossRef]

- Essabir, H.; Nekhlaoui, S.; Malha, M.; Bensalah, M.O.; Arrakhiz, F.Z.; Qaiss, A.; Bouhfid, R. Bio-composites based on polypropylene reinforced with Almond Shells particles: Mechanical and thermal properties. Mater. Des. 2013, 51, 225–230. [Google Scholar] [CrossRef]

- Garcia, A.M.; Garcia, A.I.; Cabezas, M.L.; Reche, A.S. Study of the Influence of the Almond Variety in the Properties of Injected Parts with Biodegradable Almond Shell Based Masterbatches. Waste Biomass Valoriz. 2015, 6, 363–370. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Sammon, C.; Balart, R.; Torres-Giner, S. Compatibilization of highly sustainable polylactide/almond shell flour composites by reactive extrusion with maleinized linseed oil. Ind. Crops Prod. 2018, 111, 878–888. [Google Scholar] [CrossRef]

- Garcia, A.V.; Santonja, M.R.; Sanahuja, A.B.; Selva, M.D.G. Characterization and degradation characteristics of poly (epsilon-caprolactone)-based composites reinforced with almond skin residues. Polym. Degrad. Stab. 2014, 108, 269–279. [Google Scholar] [CrossRef] [Green Version]

- Liminana, P.; Garcia-Sanoguera, D.; Quiles-Carrillo, L.; Balart, R.; Montanes, N. Development and characterization of environmentally friendly composites from poly(butylene succinate) (PBS) and almond shell flour with different compatibilizers. Compos. Part B Eng. 2018, 144, 153–162. [Google Scholar] [CrossRef]

- Fu, S.Y.; Feng, X.Q.; Lauke, B.; Mai, Y.W. Effects of particle size, particle/matrix interface adhesion and particle loading on mechanical properties of particulate-polymer composites. Compos. Part B Eng. 2008, 39, 933–961. [Google Scholar] [CrossRef]

- Kim, H.S.; Lee, B.H.; Lee, S.; Kim, H.J.; Dorgan, J. Enhanced interfacial adhesion, mechanical, and thermal properties of natural flour-filled biodegradable polymer bio-composites. J. Therm. Anal. Calorim. 2011, 104, 331–338. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, J.; Cheng, P.J.; Shi, J.J.; Yao, L.; Qiu, Y.P. Helium plasma treatment voltage effect on adhesion of ramie fibers to polybutylene succinate. Ind. Crops Prod. 2014, 61, 16–22. [Google Scholar] [CrossRef]

- Sepe, R.; Bollino, F.; Boccarusso, L.; Caputo, F. Influence of chemical treatments on mechanical properties of hemp fiber reinforced composites. Compos. Part B Eng. 2018, 133, 210–217. [Google Scholar] [CrossRef]

- Shaniba, V.; Sreejith, M.P.; Aparna, K.B.; Jinitha, T.V.; Purushothaman, E. Mechanical and thermal behavior of styrene butadiene rubber composites reinforced with silane-treated peanut shell powder. Polym. Bull. 2017, 74, 3977–3994. [Google Scholar] [CrossRef]

- Phua, Y.J.; Chow, W.S.; Ishak, Z.A.M. Reactive processing of maleic anhydride-grafted poly(butylene succinate) and the compatibilizing effect on poly(butylene succinate) nanocomposites. Express Polym. Lett. 2013, 7, 340–354. [Google Scholar] [CrossRef] [Green Version]

- Zhu, N.Q.; Ye, M.; Shi, D.J.; Chen, M.Q. Reactive compatibilization of biodegradable poly(butylene succinate)/Spirulina microalgae composites. Macromol. Res. 2017, 25, 165–171. [Google Scholar] [CrossRef]

- Chieng, B.W.; Ibrahim, N.A.; Then, Y.Y.; Loo, Y.Y. Epoxidized Vegetable Oils Plasticized Poly(lactic acid) Biocomposites: Mechanical, Thermal and Morphology Properties. Molecules 2014, 19, 16024–16038. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Orue, A.; Eceiza, A.; Arbelaiz, A. Preparation and characterization of poly(lactic acid) plasticized with vegetable oils and reinforced with sisal fibers. Ind. Crop. Prod. 2018, 112, 170–180. [Google Scholar] [CrossRef]

- Balart, J.F.; Fombuena, V.; Fenollar, O.; Boronat, T.; Sanchez-Nacher, L. Processing and characterization of high environmental efficiency composites based on PLA and hazelnut shell flour (HSF) with biobased plasticizers derived from epoxidized linseed oil (ELO). Compos. Part B Eng. 2016, 86, 168–177. [Google Scholar] [CrossRef] [Green Version]

- Garcia-Garcia, D.; Ferri, J.M.; Montanes, N.; Lopez-Martinez, J.; Balart, R. Plasticization effects of epoxidized vegetable oils on mechanical properties of poly(3-hydroxybutyrate). Polym. Int. 2016, 65, 1157–1164. [Google Scholar] [CrossRef] [Green Version]

- Sarwono, A.; Man, Z.; Bustam, M.A. Blending of Epoxidised Palm Oil with Epoxy Resin: The Effect on Morphology, Thermal and Mechanical Properties. J. Polym. Environ. 2012, 20, 540–549. [Google Scholar] [CrossRef]

- Carbonell-Verdu, A.; Garcia-Garcia, D.; Dominici, F.; Torre, L.; Sanchez-Nacher, L.; Balart, R. PLA films with improved flexibility properties by using maleinized cottonseed oil. Eur. Polym. J. 2017, 91, 248–259. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Fenollar, O.; Fombuena, V.; Lopez-Martinez, J.; Balart, R. Improvement of Mechanical Ductile Properties of Poly(3-hydroxybutyrate) by Using Vegetable Oil Derivatives. Macromol. Mater. Eng. 2017, 302, 1600330. [Google Scholar] [CrossRef]

- Ferri, J.M.; Garcia-Garcia, D.; Sanchez-Nacher, L.; Fenollar, O.; Balart, R. The effect of maleinized linseed oil (MLO) on mechanical performance of poly(lactic acid)-thermoplastic starch (PLA-TPS) blends. Carbohydr. Polym. 2016, 147, 60–68. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Ren, M.; Song, J.; Song, C.; Zhang, H.; Sun, X.; Chen, Q.; Zhang, H.; Mo, Z. Crystallization kinetics and morphology of poly (butylene succinate-co-adipate). J. Polym. Sci. Part B Polym. Phys. 2005, 43, 323–3241. [Google Scholar] [CrossRef]

- Ye, H.-M.; Chen, X.-T.; Liu, P.; Wu, S.-Y.; Jiang, Z.; Xiong, B.; Xu, J. Preparation of Poly(butylene succinate) Crystals with Exceptionally High Melting Point and Crystallinity from Its Inclusion Complex. Macromolecules 2017, 50, 5425–5433. [Google Scholar] [CrossRef]

- Barcík, Š.; Gašparík, M.; Razumov, E.Y. Effect of temperature on the color changes of wood during thermal modification. Cellul. Chem. Technol. 2015, 49, 789–798. [Google Scholar]

- Ostafi, M.-F.; Dinulică, F.; Nicolescu, V.-N. Physical properties and structural features of common walnut (Juglans regia L.) wood: A case-study/Physikalische Eigenschaften und strukturelle Charakteristika des Holzes der Walnuß (Juglans regia L.): Eine Fallstudie. Die Bodenkultur J. Land Manag. Food Environ. 2016, 67, 105–120. [Google Scholar] [CrossRef]

- Luís, R.C.G.; Nisgoski, S.; Klitzke, R.J. Effect of Steaming on the Colorimetric Properties of Eucalyptus saligna Wood. Floresta e Ambiente 2018. [Google Scholar] [CrossRef]

- Lopes, J.d.O.; Garcia, R.A.; Latorraca, J.V.d.F.; Nascimento, A.M.d. Color change of teak wood by heat treatment. Floresta e Ambiente 2014, 21, 521–534. [Google Scholar] [CrossRef]

- Yang, H.-S.; Kim, H.-J.; Park, H.-J.; Lee, B.-J.; Hwang, T.-S. Water absorption behavior and mechanical properties of lignocellulosic filler–polyolefin bio-composites. Compos. Struct. 2006, 72, 429–437. [Google Scholar] [CrossRef]

- Xu, X.-L.; Zhang, M.; Qiang, Q.; Song, J.-Q.; He, W.-Q. Study on the performance of the acetylated bamboo fiber/PBS composites by molecular dynamics simulation. J. Compos. Mater. 2016, 50, 995–1003. [Google Scholar] [CrossRef]

- Wu, C.-S.; Hsu, Y.-C.; Liao, H.-T.; Yen, F.-S.; Wang, C.-Y.; Hsu, C.-T. Characterization and Biocompatibility of Chestnut Shell Fiber-Based Composites with Polyester. J. Appl. Polym. Sci. 2014, 131. [Google Scholar] [CrossRef]

- Saeed, U.; Nawaz, M.A.; Al-Turaif, H.A. Wood flour reinforced biodegradable PBS/PLA composites. J. Compos. Mater. 2018, 52, 2641–2650. [Google Scholar] [CrossRef]

- Luo, X.; Li, J.; Feng, J.; Yang, T.; Lin, X. Mechanical and thermal performance of distillers grains filled poly(butylene succinate) composites. Mater. Des. 2014, 57, 195–200. [Google Scholar] [CrossRef]

- Ljungberg, N.; Wesslen, B. The effects of plasticizers on the dynamic mechanical and thermal properties of poly (lactic acid). J. Appl. Polym. Sci. 2002, 86, 1227–1234. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Blanes-Martínez, M.; Montanes, N.; Fenollar, O.; Torres-Giner, S.; Balart, R. Reactive toughening of injection-molded polylactide pieces using maleinized hemp seed oil. Eur. Polym. J. 2018, 98, 402–410. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Garcia-Garcia, D.; Carbonell-Verdu, A.; Balart, R.; Torres-Giner, S. Effect of different compatibilizers on injection-molded green composite pieces based on polylactide filled with almond shell flour. Compos. Part B Eng. 2018, 147, 76–85. [Google Scholar] [CrossRef]

- Calabia, B.P.; Ninomiya, F.; Yagi, H.; Oishi, A.; Taguchi, K.; Kunioka, M.; Funabashi, M. Biodegradable poly (butylene succinate) composites reinforced by cotton fiber with silane coupling agent. Polymers 2013, 5, 128–141. [Google Scholar] [CrossRef]

- Frollini, E.; Bartolucci, N.; Sisti, L.; Celli, A. Poly (butylene succinate) reinforced with different lignocellulosic fibers. Ind. Crop. Prod. 2013, 45, 160–169. [Google Scholar] [CrossRef]

- Faulstich de Paiva, J.M.; Frollini, E. Unmodified and modified surface sisal fibers as reinforcement of phenolic and lignophenolic matrices composites: thermal analyses of fibers and composites. Macromol. Mater. Eng. 2006, 291, 405–417. [Google Scholar] [CrossRef]

- Wang, G.; Guo, B.; Xu, J.; Li, R. Rheology, Crystallization Behaviors, and Thermal Stabilities of Poly(butylene succinate)/Pristine Multiwalled Carbon Nanotube Composites Obtained by Melt Compounding. J. Appl. Polym. Sci. 2011, 121, 59–67. [Google Scholar] [CrossRef]

- Dumazert, L.; Rasselet, D.; Pang, B.; Gallard, B.; Kennouche, S.; Lopez-Cuesta, J.-M. Thermal stability and fire reaction of poly(butylene succinate) nanocomposites using natural clays and FR additives. Polym. Adv. Technol. 2018, 29, 69–83. [Google Scholar] [CrossRef]

- Chen, G.X.; Yoon, J.S. Thermal stability of poly(L-lactide)/poly(butylene succinate)/clay nanocomposites. Polym. Degrad. Stab. 2005, 88, 206–212. [Google Scholar] [CrossRef]

- Ferrero, B.; Fombuena, V.; Fenollar, O.; Boronat, T.; Balart, R. Development of natural fiber-reinforced plastics (NFRP) based on biobased polyethylene and waste fibers from Posidonia oceanica seaweed. Polym. Compos. 2015, 36, 1378–1385. [Google Scholar] [CrossRef]

- Fuqua, M.A.; Chevali, V.S.; Ulven, C.A. Lignocellulosic byproducts as filler in polypropylene: Comprehensive study on the effects of compatibilization and loading. J. Appl. Polym. Sci. 2013, 127, 862–868. [Google Scholar] [CrossRef]

| Sample Code | PBS (wt %) | ASF (wt %) | MLO (wt %) |

|---|---|---|---|

| PBS | 100 | 0 | 0 |

| PBS + 10 ASF + 1.5 MLO | 88.5 | 10 | 1.5 |

| PBS + 20 ASF + 3 MLO | 77 | 20 | 3 |

| PBS + 30 ASF + 4.5 MLO | 65.5 | 30 | 4.5 |

| PBS + 40 ASF + 6 MLO | 54 | 40 | 6 |

| PBS + 50 ASF + 7.5 MLO | 42.5 | 50 | 7.5 |

| Sample Code | Maximum Tensile Strength, σt (MPa) | Tensile Modulus, Et (MPa) | Elongation at Break, εb (%) | Shore D Hardness | Impact Strength (J m−2) |

|---|---|---|---|---|---|

| PBS | 31.5 ± 0.9 | 417 ± 21 | 215.6 ± 16.5 | 60.1 ± 0.5 | 16.5 ± 0.8 |

| PBS + 30 ASF [38] | 14.8 ± 0.5 | 790 ± 56 | 6.3 ± 0.9 | 71.2 ± 0.3 | 1.8 ± 0.3 |

| PBS + 10 ASF + 1.5 MLO | 24.6 ± 0.2 | 561 ± 29 | 17.0 ± 0.6 | 66.7 ± 0.7 | 5.4 ± 0.4 |

| PBS + 20 ASF + 3 MLO | 18.6 ± 0.4 | 601 ± 63 | 20.7 ± 1.3 | 66.9 ± 0.9 | 3.9 ± 0.9 |

| PBS + 30 ASF + 4.5 MLO | 13.8 ± 0.3 | 535 ± 51 | 25.8 ± 1.0 | 67.2 ± 0.2 | 3.8 ± 0.5 |

| PBS + 40 ASF + 6 MLO | 9.3 ± 0.4 | 465 ± 76 | 16.3 ± 0.7 | 65.3 ± 0.5 | 2.6 ± 0.2 |

| PBS + 50 ASF + 7.5 MLO | 7.1 ± 0.2 | 364 ± 47 | 16.4 ± 1.0 | 63.3 ± 0.5 | 2.6 ± 0.1 |

| Sample Code | Melt Enthalpy, ΔHm (J g−1) | Melt Peak Temperature, Tm (°C) | χc (%) |

|---|---|---|---|

| PBS | 65.1 ± 1.7 | 119.6 ± 0.9 | 57.7 ± 1.7 |

| PBS + 10 ASF + 1.5 MLO | 61.0 ± 2.4 | 113.8 ± 1.2 | 62.4 ± 2.5 |

| PBS + 20 ASF + 3 MLO | 52.5 ± 1.2 | 113.8 ± 2.1 | 61.8 ± 1.4 |

| PBS + 30 ASF + 4.5 MLO | 47.8 ± 2.8 | 113.9 ± 1.9 | 66.2 ± 3.9 |

| PBS + 40 ASF + 6 MLO | 37.2 ± 0.9 | 113.8 ± 0.9 | 62.5 ± 1.5 |

| PBS + 50 ASF + 7.5 MLO | 31.0 ± 1.6 | 114.1 ± 1.7 | 66.1 ± 3.4 |

| Sample Code | T5% (°C) | Tmax (°C) | Residual Weight (%) |

|---|---|---|---|

| PBS | 338.1 | 414.7 | 0.39 |

| PBS + 10 ASF + 1.5 MLO | 338.0 | 414.9 | 1.14 |

| PBS + 20 ASF + 3 MLO | 305.3 | 414.2 | 1.58 |

| PBS + 30 ASF + 4.5 MLO | 295.8 | 407.6 | 0.68 |

| PBS + 40 ASF + 6 MLO | 272.7 | 395. 7 | 1.39 |

| PBS + 50 ASF + 7.5 MLO | 256.3 | 378.7 | 1.86 |

| Sample Code | CLTE (μm m−1 °C−1) Obtained by TMA | Thermal Parameters Obtained by DTMA | ||

|---|---|---|---|---|

| Below Tg | Above Tg | Tg (°C) | tanδ | |

| PBS | 84.4 | 222.3 | −22.9 | 0.094 |

| PBS + 10 ASF + 1.5 MLO | 85.11 | 193.6 | −22.8 | 0.090 |

| PBS + 20 ASF + 3 MLO | 81.8 | 166.9 | −23.0 | 0.085 |

| PBS + 30 ASF + 4.5 MLO | 74.9 | 167.1 | −21.6 | 0.077 |

| PBS + 40 ASF + 6 MLO | 83.5 | 168.0 | −18.2 | 0.077 |

| PBS + 50 ASF + 7.5 MLO | 81.7 | 149.8 | −17.9 | 0.081 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liminana, P.; Quiles-Carrillo, L.; Boronat, T.; Balart, R.; Montanes, N. The Effect of Varying Almond Shell Flour (ASF) Loading in Composites with Poly(Butylene Succinate (PBS) Matrix Compatibilized with Maleinized Linseed Oil (MLO). Materials 2018, 11, 2179. https://doi.org/10.3390/ma11112179

Liminana P, Quiles-Carrillo L, Boronat T, Balart R, Montanes N. The Effect of Varying Almond Shell Flour (ASF) Loading in Composites with Poly(Butylene Succinate (PBS) Matrix Compatibilized with Maleinized Linseed Oil (MLO). Materials. 2018; 11(11):2179. https://doi.org/10.3390/ma11112179

Chicago/Turabian StyleLiminana, Patricia, Luis Quiles-Carrillo, Teodomiro Boronat, Rafael Balart, and Nestor Montanes. 2018. "The Effect of Varying Almond Shell Flour (ASF) Loading in Composites with Poly(Butylene Succinate (PBS) Matrix Compatibilized with Maleinized Linseed Oil (MLO)" Materials 11, no. 11: 2179. https://doi.org/10.3390/ma11112179

APA StyleLiminana, P., Quiles-Carrillo, L., Boronat, T., Balart, R., & Montanes, N. (2018). The Effect of Varying Almond Shell Flour (ASF) Loading in Composites with Poly(Butylene Succinate (PBS) Matrix Compatibilized with Maleinized Linseed Oil (MLO). Materials, 11(11), 2179. https://doi.org/10.3390/ma11112179