Influence of Defects on Bending Properties of 2D-T700/E44 Composites Prepared by Improved Compression Molding Process

Abstract

:1. Introduction

2. Experimental Materials and Methods

2.1. Experimental Materials

2.2. Experimental Methods

2.3. Testing and Characterization Methods

3. Experimental Results and Analysis

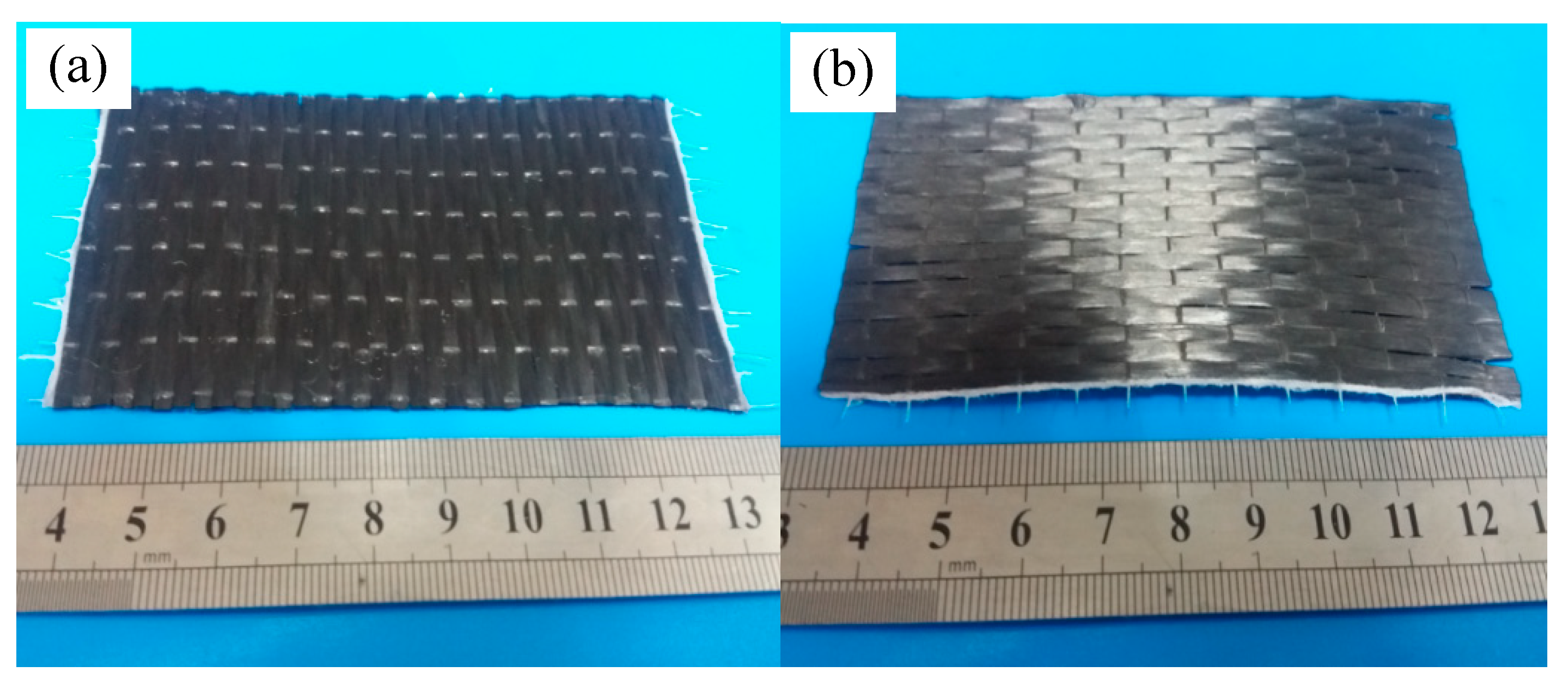

3.1. Insufficient Resin Impregnation

3.2. Weak Interlaminar Binding Force

3.3. Fiber Displacement Warping

3.4. Hole

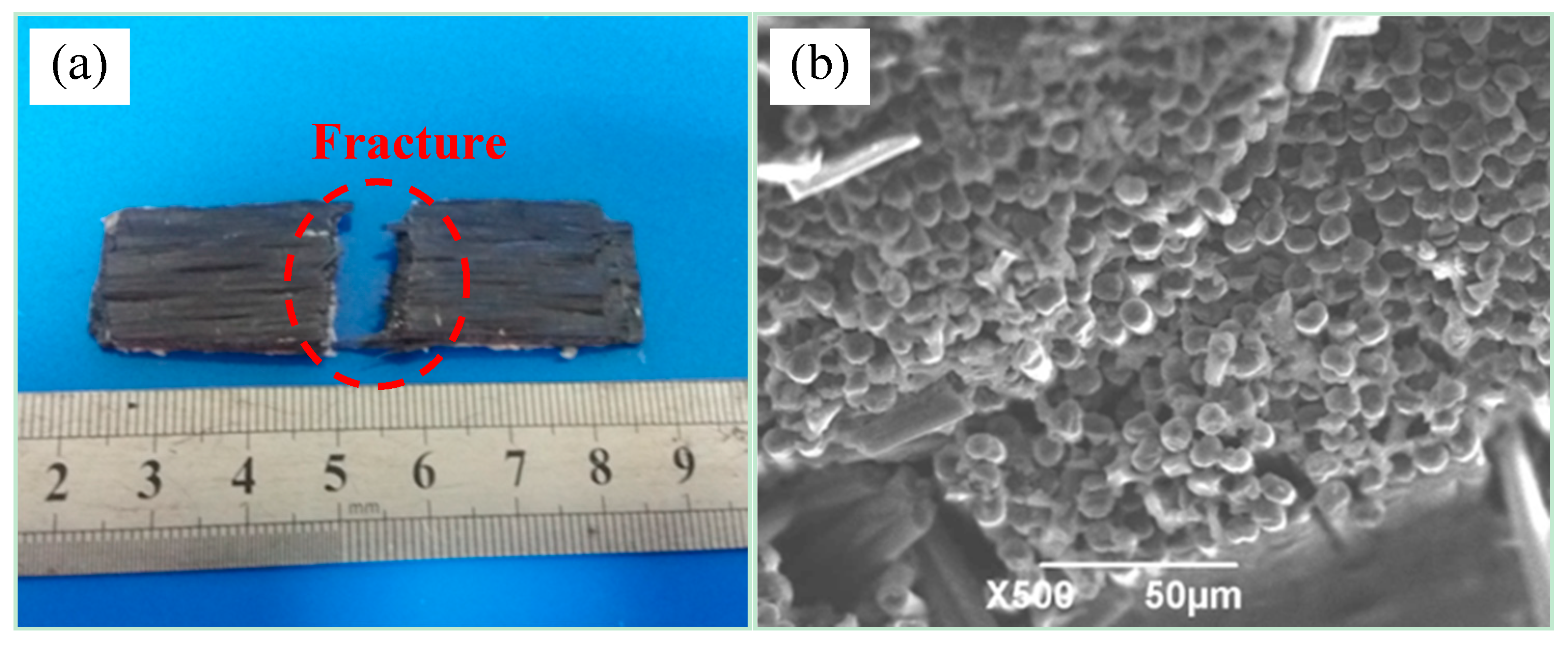

3.5. Brittle Fracture of Composite Materials

3.6. Composite Materials without Defects

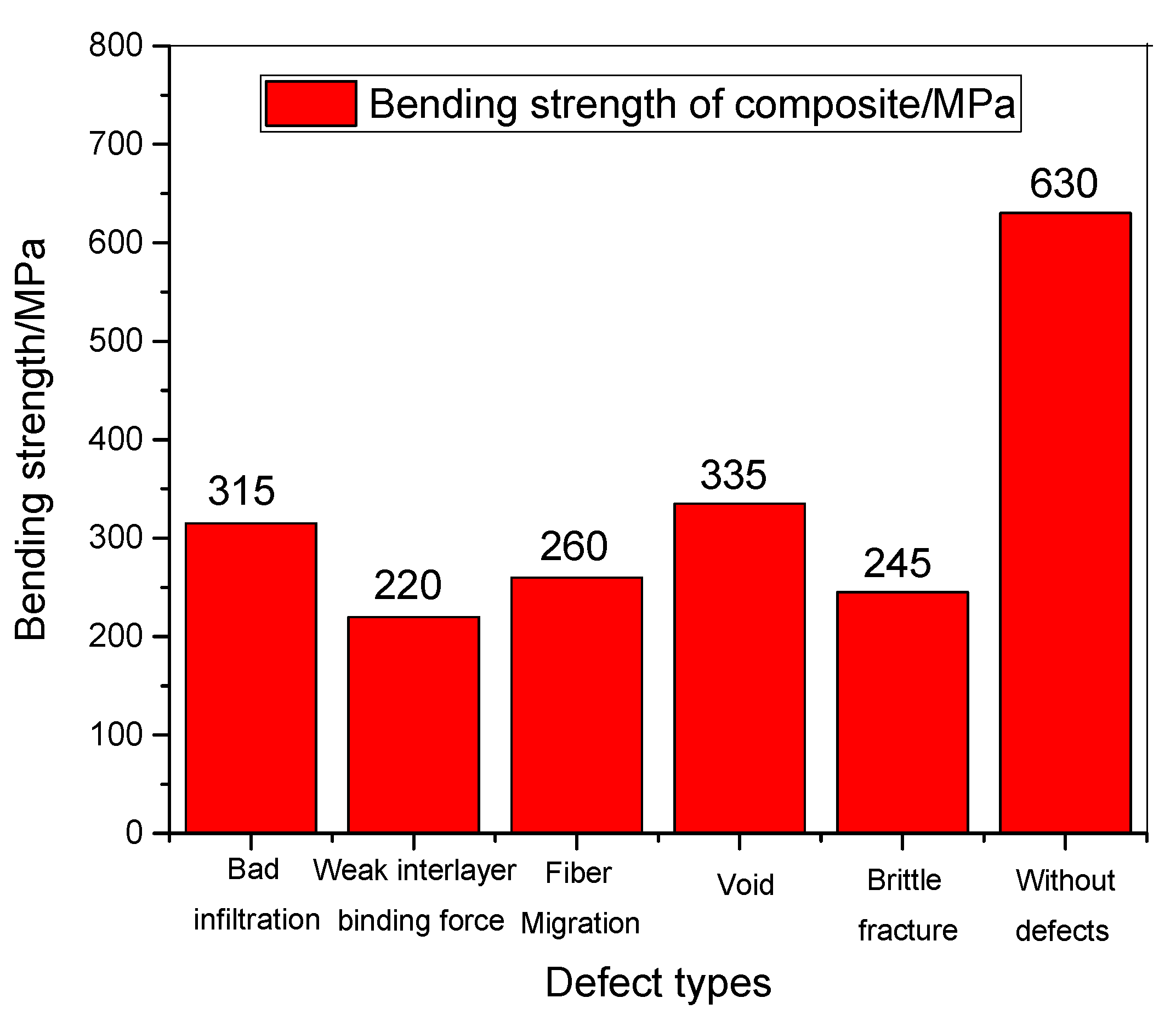

3.7. Property Comparison of Composites under Different Defects

4. Conclusions

- (1)

- 2D-T700/E44 composite materials can be prepared by using ICM. When the process parameters of curing mixed ratio, curing temperature, pressure, and time are not controlled properly, the preparation defects such as insufficient impregnation, weak interlaminar binding force, fiber displacement and warping, holes, and brittle fracture of the composite material occur easily.

- (2)

- The effects of different defect forms on the bending properties of CFRP composites are obviously different. Bending strength values of composites under the defects such as weak interlaminar binding force, brittle fracture of composite material and fiber displacement, and warping are only 34.9%, 41.3%, and 38.9%ofthe bending strength of 2D-T700/E44 composite without defects. Bending strength values of the composites under the defects such as insufficient resin impregnation and hole only reach 50% and 53.2% of the bending strength of 2D-T700/E44 composite without defects, respectively.

- (3)

- When the process parameters are reasonable and the defects of composite materials are effectively eliminated, the bending strength can reach 630MPa. If defects occur, the bending property of the composite material will be greatly reduced. Too large or too small parameter values are unfavorable to the preparation of composite materials with ideal microstructure and properties. The defects of composite materials need to be reduced and avoided through process improvement and parameter control.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Guocheng, Q.; Boming, Z.; Yalin, Y. Research on carbon fiber/epoxy interfacial bonding characterization of transverse fiber bundle composites fabricated by different preparation processes: Effect of fiber volume fraction. Polym. Test. 2016, 52, 150–156. [Google Scholar]

- Gao, A.; Gu, Y.; Wu, Q.; Yuan, C.; Li, M.; Zhang, Z. Influence of processing temperature on interfacial behavior of HKT800 carbon fiber with BMI and epoxy matrices. Chin. J. Aeronaut. 2015, 28, 1255–1262. [Google Scholar] [CrossRef]

- Hosur, M.V.; Islam, M.M.; Jeelani, S. Processing and performance of nanophased braided carbon/epoxy composites. Mater. Sci. Eng. B Adv. 2010, 168, 22–29. [Google Scholar] [CrossRef]

- Roberto, M.; Gianluca, R.; Emanuela, S. Fibre bragg gratings for the monitoring of wooden structures. Materials 2018, 11, 7. [Google Scholar]

- Ramesh, M.; Palanikumar, K.; Reddy, K.H. Tensile properties of unidirectional carbon fiber-glass fiber hybrid reinforced epoxy composites in layer. Acta Mater. Compos. Sin. 2016, 33, 297–303. (In Chinese) [Google Scholar]

- Ekşı, S.; Genel, K. Comparison of mechanical properties of unidirectional and woven carbon, glass and aramid fiber reinforced epoxy composites. Composites 2017, 132, 879–882. [Google Scholar] [CrossRef]

- Maples, H.A.; Wakefield, S.; Robinson, P.; Bismarck, A. High performance carbon fibre reinforced epoxy composites with controllable stiffness. Compos. Sci. Technol. 2014, 105, 134–143. [Google Scholar] [CrossRef]

- Xiao, H.; Yan, Z.; Jianming, S.; Ye, L.; Jindong, Z.; Yue, H. Effect of graphene oxide addition on the interlaminar shear property of carbon fiber-reinforced epoxy composites. New Carbon Mater. 2017, 32, 48–55. [Google Scholar]

- Lee, S.K.; Kim, M.; Park, C.J.; Chol, M.J.; Cho, J.; Choi, C. Effect of fiber orientation on acoustic and vibration response of a carbon fiber/epoxy composite plate: Natural vibration mode and sound radiation. Int. J. Mech. Sci. 2016, 117, 162–173. [Google Scholar] [CrossRef]

- Xu, Y.; van Hoa, S. Mechanical properties of carbon fiber reinforced epoxy/clay nanocomposites. Compos. Sci. Technol. 2008, 68, 854–861. [Google Scholar] [CrossRef]

- Ma, Y.; Ueda, M.; Yokozeki, T.; Sugahara, T.; Yang, Y.; Hamada, H. A comparative study of the mechanical properties and failure behavior of carbon fiber/epoxy and carbon fiber/polyamide 6 unidirectional composites. Compos. Struct. 2017, 160, 89–99. [Google Scholar] [CrossRef]

- Baptista, R.; Mendão, A.; Rodrigues, F.; Figueiredo-Pina, C.G.; Guedes, M.; Marat-Mendes, R. Effect of high graphite filler contents on the mechanical and tribological failure behavior of epoxy matrix composites. Theor. Appl. Fract. Mech. 2016, 85, 113–124. [Google Scholar] [CrossRef]

- Chen, C.; Zhang, Y.T.; Gu, Y.Z. Study on Influencing factors of pore defects in carbon fiber/epoxy composites. Composites 2014, 5, 51–55. (In Chinese) [Google Scholar]

- Dong, C.; Davies, I.J. Flexural properties of E glass and TR50S carbon fiber reinforced epoxy hybrid composites. J. Mater. Eng. Perform. 2013, 22, 41–49. [Google Scholar] [CrossRef]

- Qi, L.H.; Zheng, W.Q.; Zhou, J.M.; Ju, L.Y. Effect of specific pressure on fabrication of 2D-Cf/Al composite by vacuum and pressure infiltration. Trans. Nonferr. Metal. Soc. 2013, 23, 1915–1921. [Google Scholar]

- Dong, C.; John, D.; Davies, I.J. Flexural properties of S-2 glass and TR30S carbon fiber-reinforced epoxy hybrid composites. Polym. Compos. 2012, 33, 773–781. [Google Scholar] [CrossRef]

- Amuthakkannan, P.; Manikandan, V.; Uthayakumar, M. Mechanical Properties of Basalt and Glass Fiber Reinforced Polymer Hybrid Composites. J. Adv. Microsc. Res. 2014, 9, 44–49. [Google Scholar] [CrossRef]

- Ma, Y.Q.; Qi, L.H.; Zhang, T.; Zhou, J.M.; Yao, G.Z. Study on defects of 2D-Cf/Al composite prepared by liquid-solid extrusion following vacuum infiltration technique. Int. J. Adv. Manuf. Technol. 2017, 88, 89–96. [Google Scholar] [CrossRef]

- Hu, Y.B.; Li, H.G.; Cai, L.; Zhu, J.P.; Pan, L.; Xu, J.; Tao, J. Preparation and properties of Fibre–Metal Laminates based on carbon fibre reinforced PMR polyimide. Compos. Part B Eng. 2015, 69, 587–591. [Google Scholar] [CrossRef]

- Arthanarieswaran, V.P.; Kumaravel, A.; Kathirselvam, M. Evaluation of mechanical properties of banana and sisal fiber reinforced epoxy composites: Influence of glass fiber hybridization. Mater. Des. 2014, 64, 194–202. [Google Scholar] [CrossRef]

- Campana, C.; Leger, R.; Sonnier, R.; Ferry, L.; Ienny, P. Effect of post curing temperature on mechanical properties of a flax fiber reinforced epoxy composite. Compos. Part A Appl. Sci. Manuf. 2018, 107, 171–179. [Google Scholar] [CrossRef]

| Curing Mixed Ratio/Mass Ratio | Natural Curing Time/h | Pressure-Free Heating Curing Temperature/°C | Pressure-Free Heating Curing Time/min | Pressure Heating Curing Temperature/°C | Pressure Heating Curing Pressure/MPa | Pressure Heating Curing Time/min |

|---|---|---|---|---|---|---|

| 5:1 | 6 | 115 | 110 | 50 | 10 | 25 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, Y.; Li, S.; Wang, J.; Ju, L.; Liu, X. Influence of Defects on Bending Properties of 2D-T700/E44 Composites Prepared by Improved Compression Molding Process. Materials 2018, 11, 2132. https://doi.org/10.3390/ma11112132

Ma Y, Li S, Wang J, Ju L, Liu X. Influence of Defects on Bending Properties of 2D-T700/E44 Composites Prepared by Improved Compression Molding Process. Materials. 2018; 11(11):2132. https://doi.org/10.3390/ma11112132

Chicago/Turabian StyleMa, Yuqin, Shuangshuang Li, Jie Wang, Luyan Ju, and Xinmei Liu. 2018. "Influence of Defects on Bending Properties of 2D-T700/E44 Composites Prepared by Improved Compression Molding Process" Materials 11, no. 11: 2132. https://doi.org/10.3390/ma11112132

APA StyleMa, Y., Li, S., Wang, J., Ju, L., & Liu, X. (2018). Influence of Defects on Bending Properties of 2D-T700/E44 Composites Prepared by Improved Compression Molding Process. Materials, 11(11), 2132. https://doi.org/10.3390/ma11112132