A Novel, Multifunctional, Floatable, Lightweight Cement Composite: Development and Properties

Abstract

1. Introduction

2. Materials and Mixing Methodology

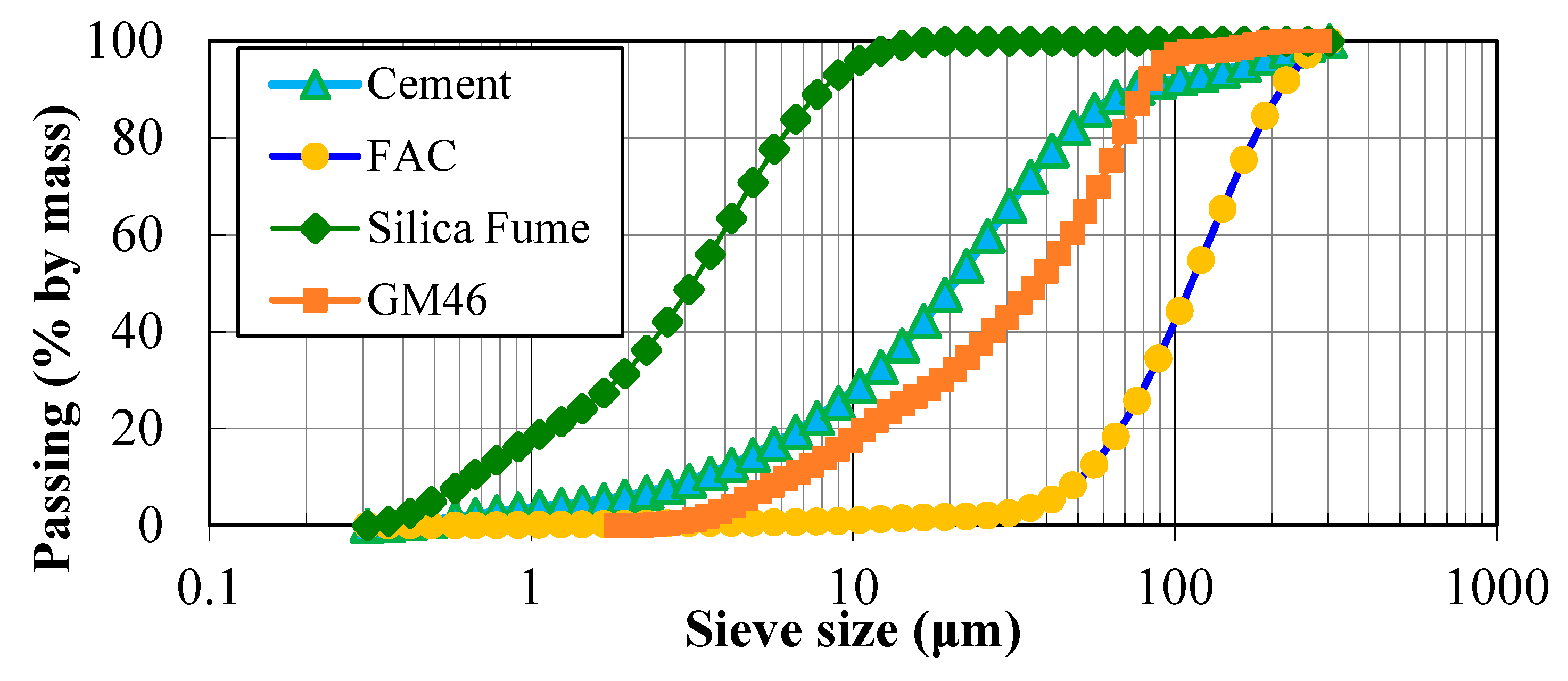

2.1. Materials

2.2. Mix Proportion

2.3. Mixing Procedures

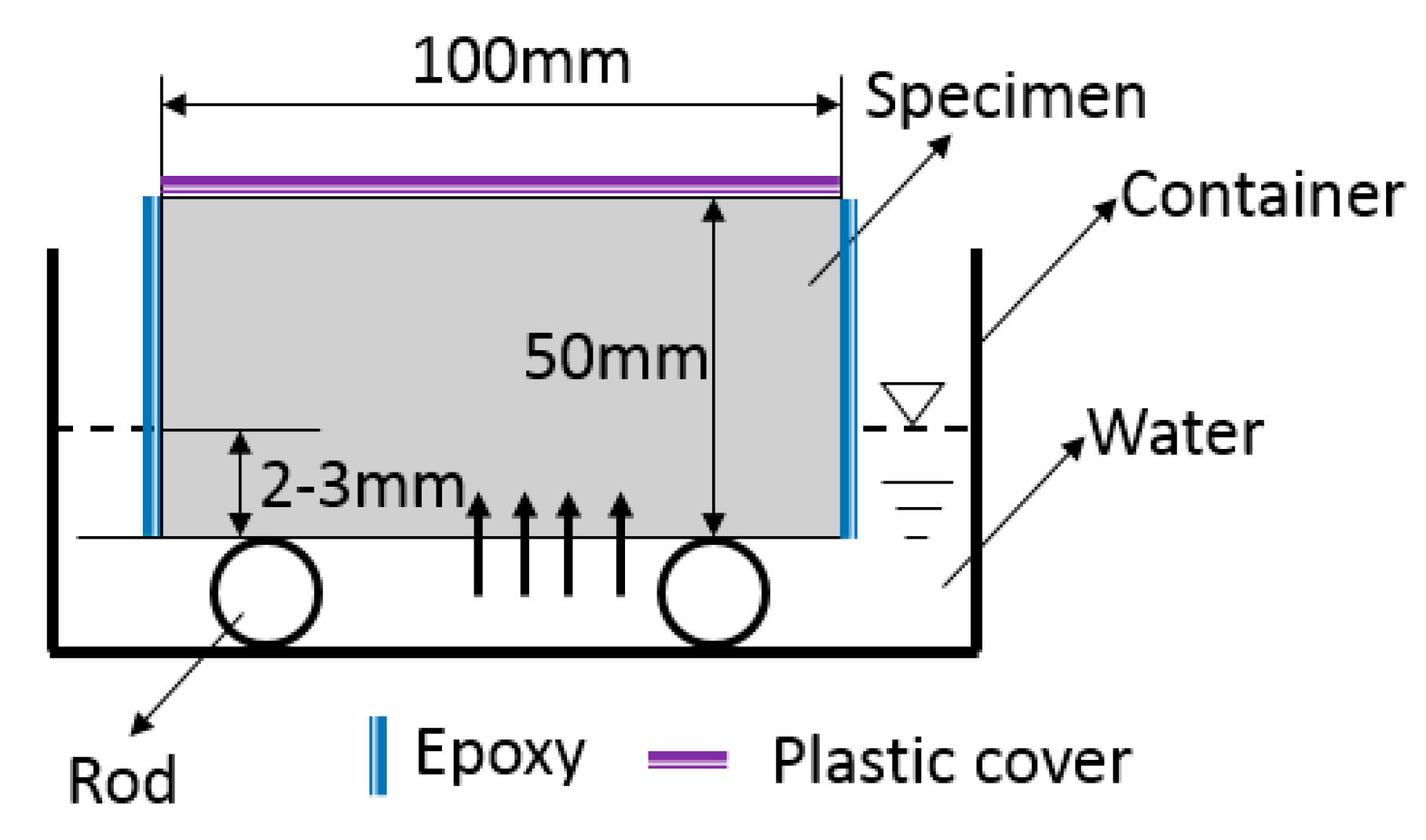

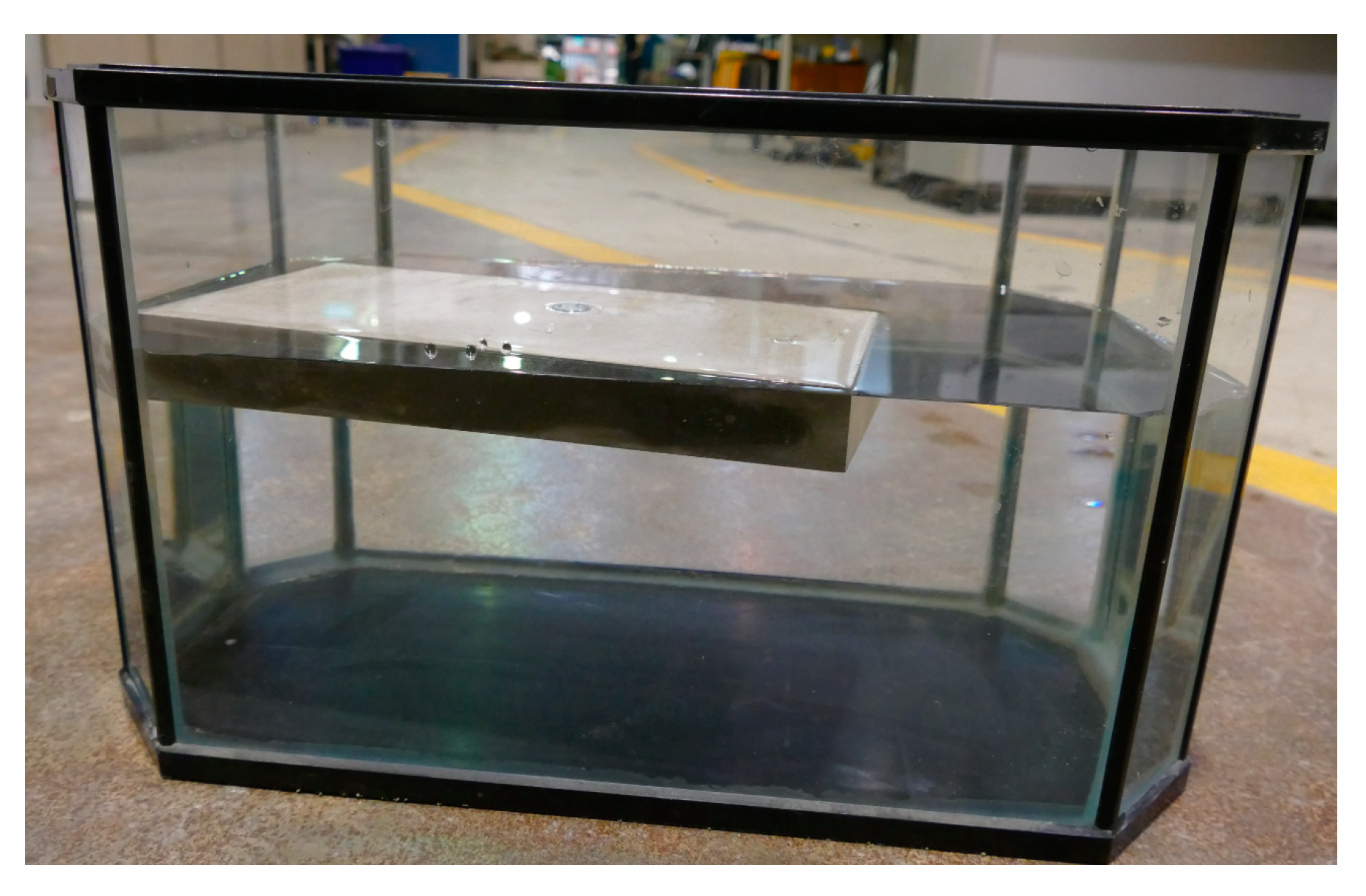

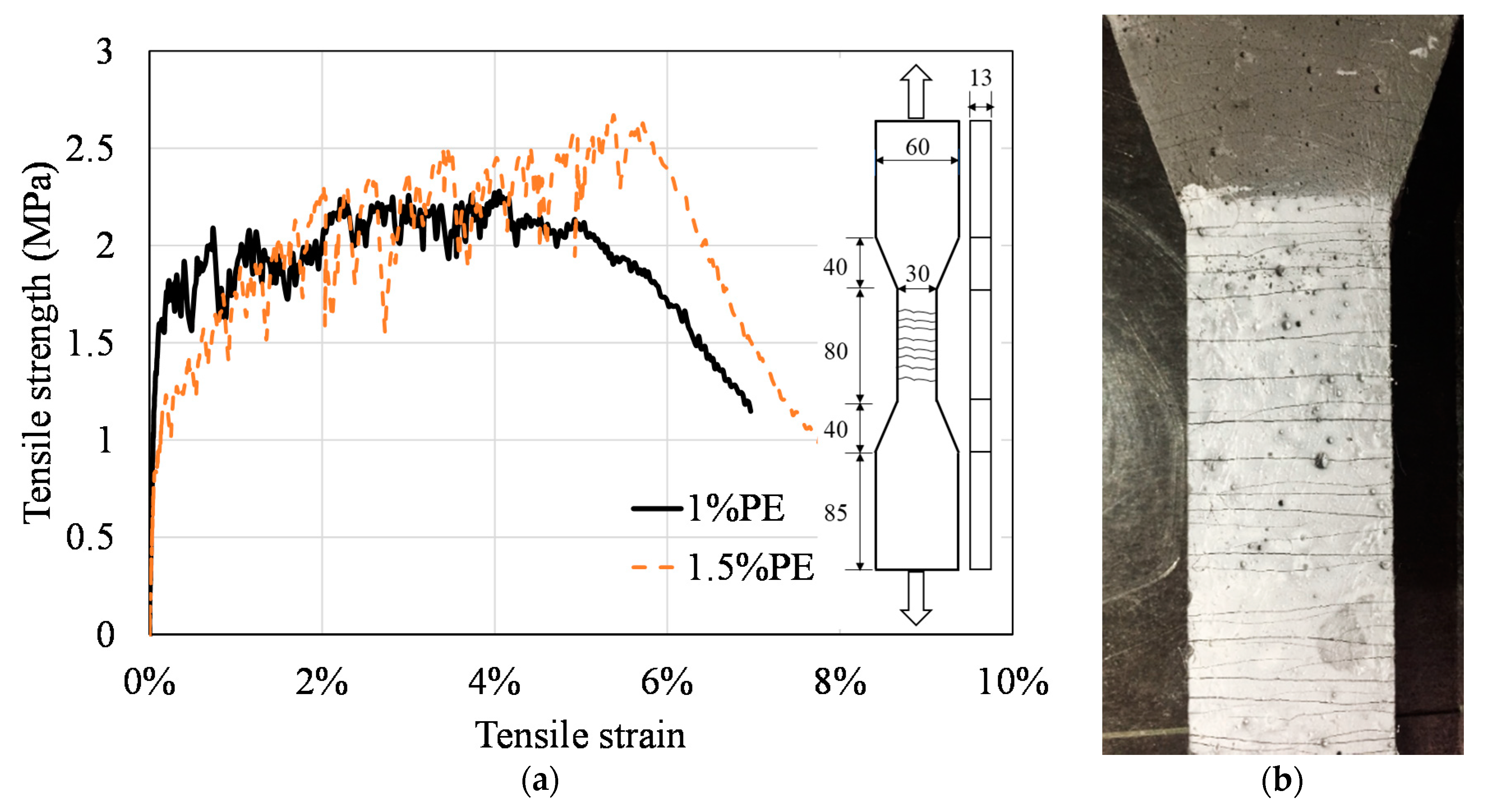

2.4. Test Methods

3. Experimental Results

3.1. Density, Workability, Air Content, and Compressive Strength

3.2. Flexural and Tensile Strength

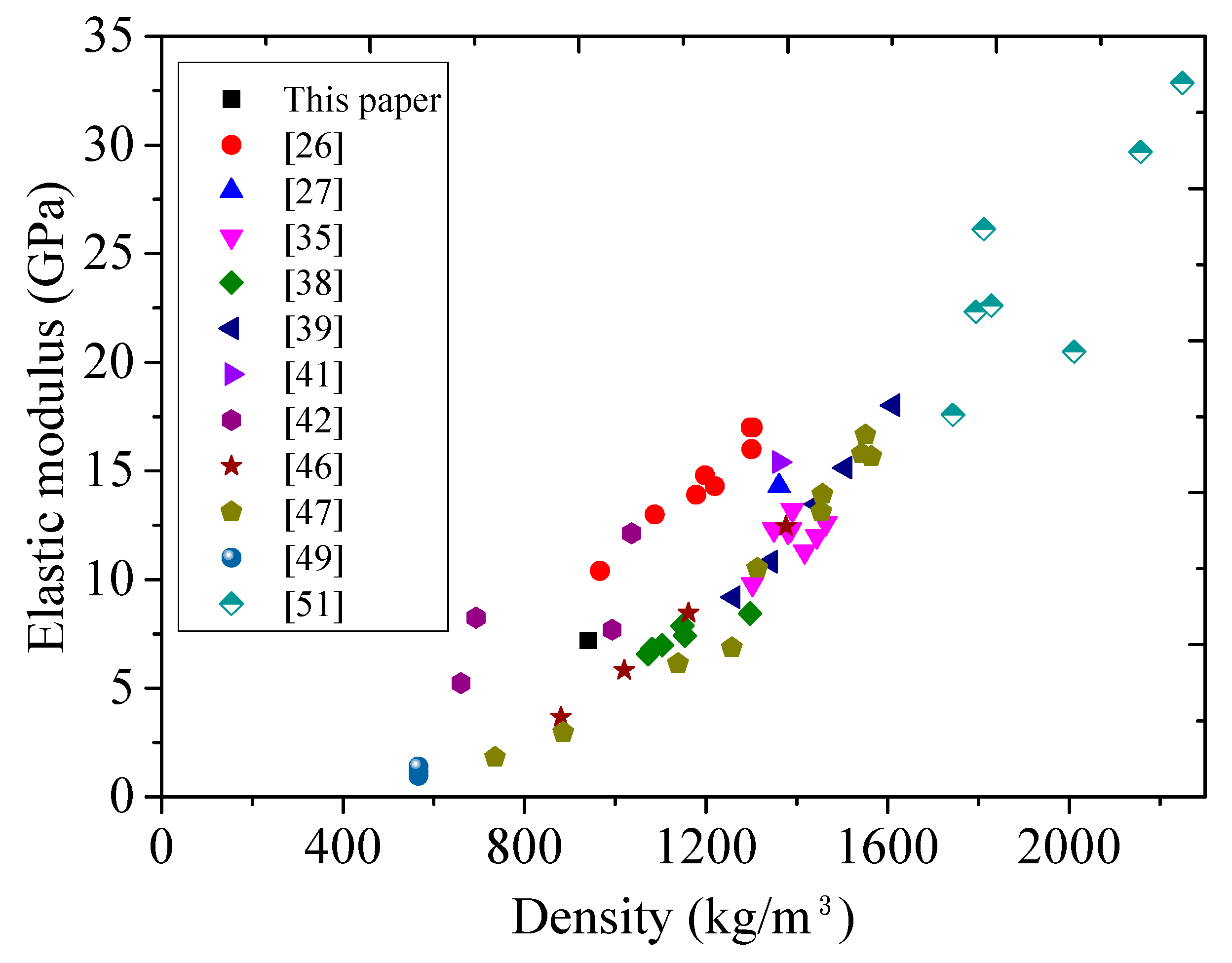

3.3. Elastic Modulus

3.4. Sorptivity

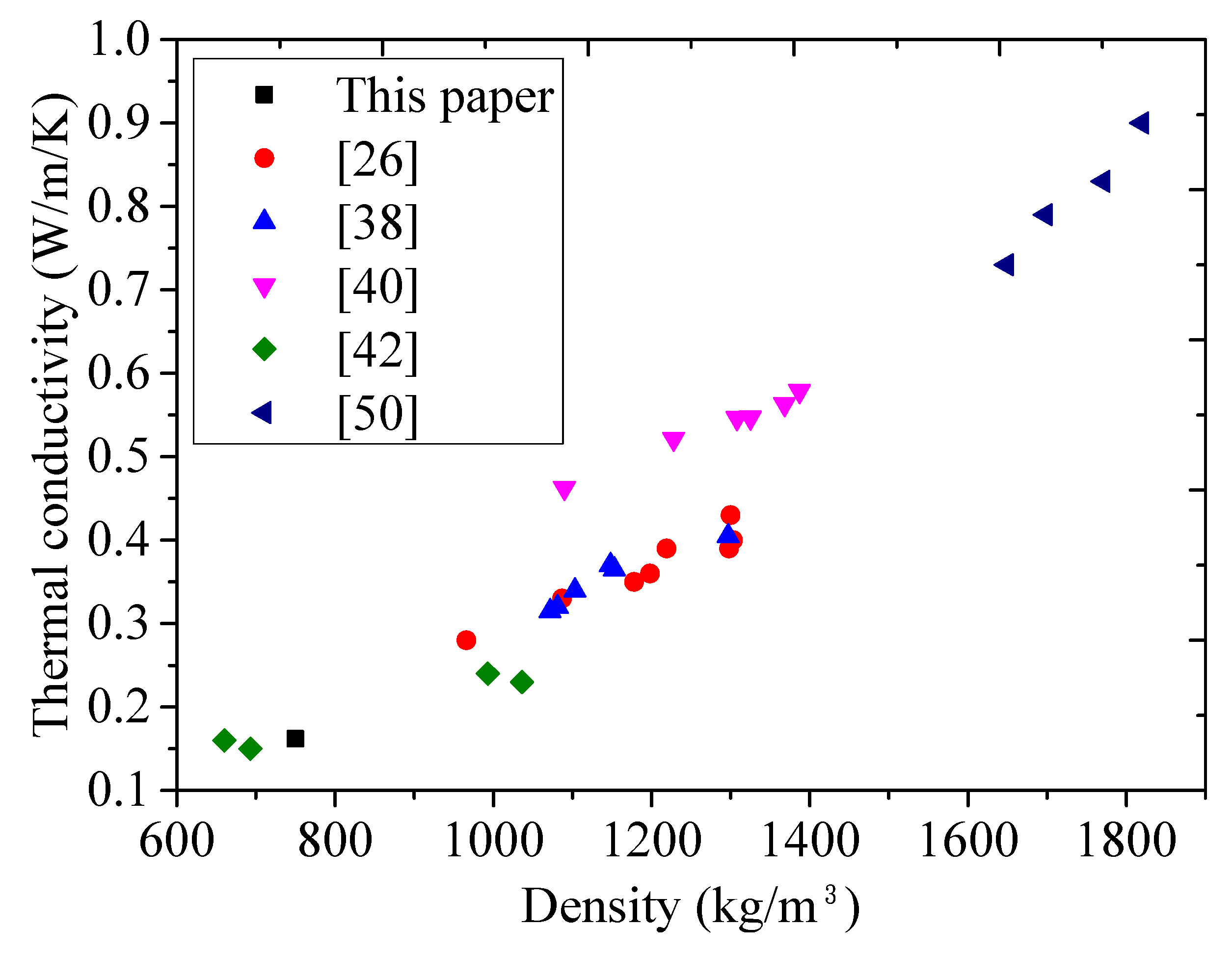

3.5. Thermal Conductivity

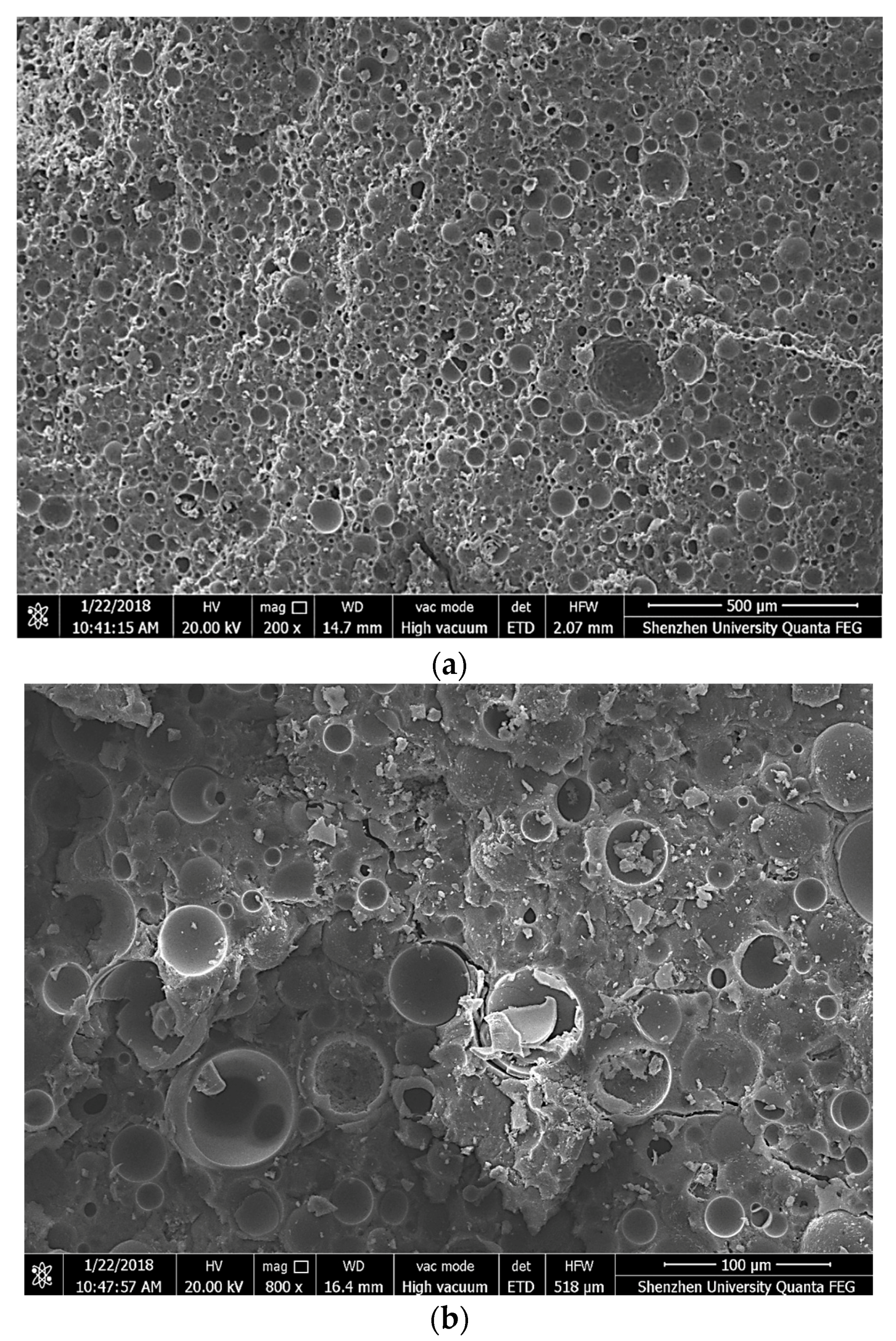

3.6. Microstructural Characterization

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Liew, J.Y.R.; Huang, Z.Y. Lightweight Steel-Concrete Composite Flooring—Recent Innovation. In Proceedings of the 9th International Symposium on Steel Structures, Jeju, Korea, 1–4 November 2017; pp. 655–658. [Google Scholar]

- Huang, Z.Y.; Liew, J.Y.R. Lightweight Composite Flooring for PPVC—Residual Mechanical Behaviour of ULCC after Exposing to Elevated Temperature. In Proceedings of the 9th International Symposium on Steel Structures, Jeju, Korea, 1–4 November 2017; pp. 659–662. [Google Scholar]

- Huang, Z.Y.; Liew, J.Y.R. Compressive resistance of steel-concrete-steel sandwich composite walls with J-hook connectors. J. Constr. Steel Res. 2016, 124, 142–162. [Google Scholar] [CrossRef]

- Deep Water—The Next Step for Offshore Wind Energy. Available online: http://www.ewea.org/fileadmin/files/library/publications/reports/DeepWater.pdf (accessed on 31 July 2013).

- Taghipour, R.; Moan, T. Efficient frequency-domain analysis of dynamic response for the multi-body wave energy converter in multi-directional wave. In Proceedings of the Eighteenth International Offshore and Polar Engineering Conference. Vancouver, BC, Canada, 6–11 July 2008. [Google Scholar]

- CEB-FIP. FIP Model Code for Concrete Structures; Comité Euro-International du Béton: Lausanne, Switzerland, 2013. [Google Scholar]

- ASTM 213R-14 Guide for Structural Lightweight-Aggregate Concrete; American Society of Testing and Materials: West Conshohocken, PA, USA, 2014.

- ASTM C330/C330M-14 Standard Specification for Lightweight Aggregates for Structural Concrete; American Society of Testing and Materials: West Conshohocken, PA, USA, 2014.

- BS EN 13055. Lightweight Aggregates. Part 1 Lightweight Aggregates. Lightweight Aggregates for Concrete, Mortar and Grout; British Standards Institution: London, UK, 2016. [Google Scholar]

- JGJ 51-02, Technical Specification for Lightweight Aggregate Concrete; Chinese Code: Beijing, China, 2002.

- Lotfy, A.; Hossain, K.M.A.; Lachemi, M. Mix design and properties of lightweight self-consolidating concretes developed with furnace slag, expanded clay and expanded shale aggregates. J. Sustain. Cem. Based Mater. 2015, 5, 297–323. [Google Scholar] [CrossRef]

- Kramar, D.; Bindiganavile, V. Impact response of lightweight mortars containing expanded perlite. Cem. Concr. Compos. 2013, 37, 205–214. [Google Scholar] [CrossRef]

- Yu, R.; Onna, D.V.V.; Spiesz, P.; Yu, Q.L.; Brouwersa, H.J.H. Development of Ultra-Lightweight Fibre Reinforced Concrete applying expanded waste glass. J. Clean. Prod. 2016, 112, 690–701. [Google Scholar] [CrossRef]

- Liu, X.M.; Chia, K.S.; Zhang, M.H. Development of lightweight concrete with high resistance to water and chloride-ion penetration. Cem. Concr. Compos. 2010, 32, 757–766. [Google Scholar] [CrossRef]

- Babu, D.S.; Babu, K.G.; Wee, T.H. Properties of lightweight expanded polystyrene aggregate concretes containing fly ash. Cem. Concr. Res. 2005, 35, 1218–1223. [Google Scholar] [CrossRef]

- Işıkdağ, B. Characterization of lightweight ferrocement panels containing expanded perlite-based mortar. Constr. Build. Mater. 2015, 81, 15–23. [Google Scholar] [CrossRef]

- Amran, Y.H.M.; Farzadnia, N.; Ali, A.A.A. Properties and applications of foamed concrete: A review. Constr. Build. Mater. 2015, 101, 990–1005. [Google Scholar] [CrossRef]

- Lim, S.K.; Tan, C.S.; Lim, O.Y.; Lee, Y.L. Fresh and hardened properties of lightweight foamed concrete with palm oil fuel ash as filler. Constr. Build. Mater. 2013, 46, 39–47. [Google Scholar] [CrossRef]

- Putman, B.J.; Neptune, A.I. Comparison of test specimen preparation techniques for pervious concrete pavements. Constr. Build. Mater. 2011, 25, 3480–3485. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete, 5th ed.; Pearson: London, UK, 2011. [Google Scholar]

- Chandra, S.; Berntsson, L. Lightweight Aggregate Concrete Science, Technology and Applications; Standard Publishers Distributors: Delhi, India, 2003; ISBN 81-8014-052-0. [Google Scholar]

- Mydin, M.A.O.; Wang, Y.C. Structural performance of lightweight steel-foamed concrete-steel composite walling system under compression. Thin-Walled Struct. 2011, 49, 66–76. [Google Scholar] [CrossRef]

- Prabha, P.; Marimuthu, V.; Saravanan, M.; Palani, G.S.; Lakshmanan, N.; Senthil, R. Effect of confinement on steel-concrete composite light-weight load-bearing wall panels under compression. J. Constr. Steel Res. 2013, 81, 11–19. [Google Scholar] [CrossRef]

- He, Y.; Zhang, X.; Zhang, Y.; Zhou, Y. Effects of particle characteristics of lightweight aggregate on mechanical properties of lightweight aggregate concrete. Constr. Build. Mater. 2014, 72, 270–282. [Google Scholar] [CrossRef]

- Hassanpour, M.; Shafigh, P.; Mahmud, H.B. Lightweight aggregate concrete fiber reinforcement—A review. Constr. Build. Mater. 2012, 37, 452–461. [Google Scholar] [CrossRef]

- Wu, Y.P.; Wang, J.Y.; Monteiro, P.J.M.; Zhang, M.H. Development of ultra-lightweight cement composites with low thermal conductivity and high specific strength for energy efficient buildings. Constr. Build. Mater. 2015, 87, 100–112. [Google Scholar] [CrossRef]

- Huang, Z.Y.; Liew, J.Y.R.; Xiong, M.X.; Wang, J.Y. Structural behaviour of double skin composite system using ultra-lightweight cement composite. Constr. Build. Mater. 2015, 86, 51–63. [Google Scholar] [CrossRef]

- Huang, Z.Y.; Wang, J.Y.; Liew, J.Y.R.; Marshall, P.W. Lightweight steel–concrete–steel sandwich composite shell subject to punching shear. Ocean Eng. 2015, 102, 146–161. [Google Scholar] [CrossRef]

- Huang, Z.Y.; Liew, J.Y.R. Numerical studies of steel-concrete-steel sandwich wall subjected to axial loads. Steel Compos. Struct. 2016, 21, 461–477. [Google Scholar] [CrossRef]

- Huang, Z.Y.; Liew, J.Y.R. Nonlinear finite element modelling and parametric study of curved steel-concrete-steel double skin composite panel filled with ultra-lightweight cement composite. Constr. Build. Mater. 2015, 95, 922–938. [Google Scholar] [CrossRef]

- Huang, Z.Y.; Liew, J.Y.R. Structural behaviour of steel-concrete-steel sandwich composite wall subjected compression and end moment. Thin-Walled Struct. 2016, 98, 592–606. [Google Scholar] [CrossRef]

- Huang, Z.Y.; Liew, J.Y.R. Experimental and analytical studies of curved steel–concrete–steel sandwich panels under patch loads. Mater. Des. 2016, 93, 104–117. [Google Scholar] [CrossRef]

- Wang, J.Y.; Chia, K.S.; Liew, J.Y.R.; Zhang, M.H. Flexural performance of fiber reinforced ultra-lightweight cement composites with low fiber content. Cem. Concr. Compos. 2013, 43, 39–47. [Google Scholar] [CrossRef]

- Huang, Z.Y.; Liew, J.Y.R.; Li, W. Evaluation of compressive behavior of ultra-lightweight cement composite after elevated temperature exposure. Constr. Build. Mater. 2017, 148, 579–589. [Google Scholar] [CrossRef]

- Huang, Z.; Padmaja, K.; Li, S.; Richard Liewc, J.Y. Mechanical properties and microstructure of ultra-lightweight cement composites with fly ash cenospheres after exposure to high temperatures. Constr. Build. Mater. 2018, 164, 760–774. [Google Scholar] [CrossRef]

- Lu, Z.; Hanif, A.; Lu, C.; Liu, K.; Sun, G.; Li, Z. A Novel Lightweight Cementitious Composites with Enhanced Thermal Insulation and Mechanical Properties by Extrusion Technique. Constr. Build. Mater. 2018, 163, 446–449. [Google Scholar] [CrossRef]

- Chia, K.S.; Liu, X.M.; Liew, J.Y.R.; Zhang, M.H. Creep and shrinkage of ultra lightweight cement composite. In Proceedings of the 2013 World Congress on Advances in Structural Engineering and Mechanics, Jeju, Korea, 8–12 September 2013; pp. 3283–3297. [Google Scholar]

- Hanif, A.; Diao, S.; Lu, Z.; Fan, T.; Li, Z. Green lightweight cementitious composite incorporating aerogels and fly ash cenospheres—Mechanical and thermal insulating properties. Constr. Build. Mater. 2016, 116, 422–430. [Google Scholar] [CrossRef]

- Hanif, A.; Lu, Z.; Diao, S.; Zeng, X.; Li, Z. Properties investigation of fiber reinforced cement-based composites incorporating cenosphere fillers. Constr. Build. Mater. 2017, 140, 139–149. [Google Scholar] [CrossRef]

- Blanco, F.; Garcı́a, P.; Mateos, P.; Ayala, J. Characteristics and properties of lightweight concrete manufactured with cenospheres. Cem. Concr. Res. 2000, 30, 1715–1722. [Google Scholar] [CrossRef]

- Huang, Z.; Liew, J.Y.R. Steel-concrete-steel sandwich composite structures subjected to extreme loads. Int. J. Steel Struct. 2016, 16, 1009–1028. [Google Scholar] [CrossRef]

- Oreshkin, D.; Semenov, V.; Rozovskaya, T. Properties of Light-weight Extruded Concrete with Hollow Glass Microspheres. Procedia Eng. 2016, 153, 638–643. [Google Scholar] [CrossRef]

- Perfilov, V.A.; Oreshkin, D.V.; Semenov, V.S. Environmentally Safe Mortar and Grouting Solutions with Hollow Glass Microspheres. Procedia Eng. 2016, 150, 1479–1484. [Google Scholar] [CrossRef]

- Korolev, E.V.; Inozemtcev, A.S. Preparation and Research of the High-Strength Lightweight Concrete Based on Hollow Microspheres. Adv. Mater. Res. 2013, 746, 285–288. [Google Scholar] [CrossRef]

- Semenov, V.; Rozovskaya, T. Light-weight Dry Masonry Mixes with Hollow Ceramic Microspheres for Winter Conditions. Procedia Eng. 2016, 153, 623–629. [Google Scholar] [CrossRef]

- Hanif, A.; Parthasarathy, P.; Lu, Z.; Sun, M.; Li, Z. Fiber—Reinforced Cementitious Composites Incorporating Glass Cenospheres—Mechanical properties and Microstructure. Constr. Build. Mater. 2017, 154, 529–538. [Google Scholar] [CrossRef]

- Hanif, A.; Lu, Z.; Cheng, Y.; Diao, S.; Li, Z. Effects of Different Lightweight Functional Fillers for Use in Cementitious Composites. Int. J. Concr. Struct. Mater. 2017, 11, 99–113. [Google Scholar] [CrossRef]

- Al-Gemeel, A.N.; Zhuge, Y.; Youssf, O. Use of hollow glass microspheres and hybrid fibres to improve the mechanical properties of engineered cementitious composite. Constr. Build. Mater. 2018, 171, 858–870. [Google Scholar] [CrossRef]

- Yang, G.; Li, Z.Y. Experimental Study on Ultra-lightweight Fire-resistive Engineered Cementitious Composite. In Proceedings of the International Conference on Advanced Material Engineering, Wuhan, China, 15–17 April 2016; pp. 146–153. [Google Scholar] [CrossRef]

- Huang, X.; Ranade, R.; Zhang, Q.; Ni, W.; Li, V.C. Mechanical and thermal properties of green lightweight engineered cementitious composites. Constr. Build. Mater. 2013, 48, 954–960. [Google Scholar] [CrossRef]

- Yun, T.S.; Jeong, Y.J.; Han, T.S.; Youm, K.S. Evaluation of thermal conductivity for thermally insulated concretes. Energy Build. 2013, 61, 125–132. [Google Scholar] [CrossRef]

- Golewski, G.L. Evaluation of morphology and size of cracks of the Interfacial Transition Zone (ITZ) in concrete containing fly ash (FA). J. Hazard. Mater. 2018, 357, 298–304. [Google Scholar] [CrossRef] [PubMed]

- Golewski, G.L. Generalized Fracture Toughness and Compressive Strength of Sustainable Concrete Including Low Calcium Fly Ash. Materials 2017, 10, 1393. [Google Scholar] [CrossRef] [PubMed]

- Mcbride, S.P.; Shukla, A.; Bose, A. Processing and characterization of a lightweight concrete using cenospheres. J. Mater. Sci. 2002, 37, 4217–4225. [Google Scholar] [CrossRef]

- BS EN 1015-3:1999, Methods of Test for Mortar for Masonry—Part 3: Determination of Consistence of Fresh Mortar (by Flow Table); British Standards Institution: London, UK, 1999.

- ASTM C 138/C 138M–01. Density (Unit Weight), Yield, and Air Content (Gravimetric) of Concrete; American Society of Testing and Materials: West Conshohocken, PA, USA, 2001.

- ASTM C39/C39M-09, Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; American Society of Testing and Materials: West Conshohocken, PA, USA, 2009.

- ASTM C109/C109M-16a. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens); American Society of Testing and Materials: West Conshohocken, PA, USA, 2016.

- ASTM C469/C469M–14. Standard Test Method for Static Modulus of Elasticity and Poisson’s Ratio of Concrete in Compression; American Society of Testing and Materials: West Conshohocken, PA, USA, 2014.

- ACI Committee 318. Building Code requirements for Structural Concrete (ACI 318–311) and Commentary (ACI 318R–11); American Concrete Institute: Farmington Hills, MI, USA, 2005.

- BS EN 196-1. Methods of Testing Cement—Part 1: Determination of Strength; British Standards Institution: London, UK, 2005.

- ASTM C349–14. Standard Test Method for Compressive Strength of Hydraulic-Cement Mortars (Using Portions of Prisms Broken in Flexure); American Society of Testing and Materials: West Conshohocken, PA, USA, 2014.

- JSCE, Recommendations for Design and Construction of High-Performance Fiber Reinforced Cement Composites with Multiple fine Cracks; Japan Society of Civil Engineers: Tokyo, Japan, 2008; pp. 1–16.

- ASTM C518-10. Standard Test Method for Steady-State Thermal Transmission Properties by Means of the Heat Flow Meter Apparatus; American Society of Testing and Materials: West Conshohocken, PA, USA, 2010.

- ASTM C177. Standard Test Method for Steady-State Heat Flux Measurements and Thermal Transmission Properties by Means of the Guarded-Hot-Plate Apparatus; American Society of Testing and Materials: West Conshohocken, PA, USA, 2013.

- ASTM, C1585. Standard Test Method for Measurement of Rate of Absorption of Water by Hydraulic-Cement Concretes; American Society of Testing and Materials: West Conshohocken, PA, USA, 2006.

- Yang, E.H.; Li, V.C. Strain-rate effects on the tensile behavior of strain-hardening cementitious composites. Constr. Build. Mater. 2014, 52, 96–104. [Google Scholar] [CrossRef]

- Kanda, T.; Li, V.C. Practical Design Criteria for Saturated Pseudo Strain Hardening Behavior in ECC. Adv. Concr. Technol. 2006, 4, 59–72. [Google Scholar] [CrossRef]

| Code Practice | Density of Lightweight Concrete ρ | 28-day Compressive Strength (fcm) |

|---|---|---|

| CEB-FIP 2010 [6] | Oven-dry: 800–2000 kg/m3 | LC8-LC80 (8–80 MPa) |

| ACI 213R-14 [7] | Air-dry: 1440–1850 kg/m3 | Common value: 21–35 MPa |

| ASTM C330 [8] | 1600–1840 kg/m3 | Common value: 17–28 MPa |

| BS EN 13055-2016 [9] | Not exceeding 2000 kg/m3 | N.A. |

| JGJ 51-2002 [10] | Oven-dry density ≤ 1950 kg/m3 | LC5.0-LC60 (10–38.5 MPa) |

| Literature | Lightweight Filler | Density ρ (kg/m3) | 28-day Compressive Strength fcm (MPa) | 28-day Flexural Strength fct (MPa) | Specific Strength (kPa/kgm−3) | Elastic Modulus Ec (GPa) | Thermal Conductivity λ (W/mK) |

|---|---|---|---|---|---|---|---|

| Oreshkin et al. [42] | 3MTM Glass Bubbles K25 | 660–993 693–1036 | 13.9–25.9 15.6–29.0 | 4.6–5.9 (non-extruded) 5.0–6.6 (extruded) | 21.1–26.1 22.5–28.0 | – | 0.16–0.24 0.15–0.23 |

| Blanco et al. [40] | Cenospheres from coal–burning power plant | 1090–1510 | 5.04–33.03 | 2.09–5.86 | 4.62–21.9 | – | 0.36–0.44 |

| Perfilov et al. [43] | Coated hollow glass microspheres (HGMS) | 750–1109 | 2.2–3.9 | 0.1–0.8 | 2.93–3.52 | – | – |

| Korolev et al. [44] | Hollow glass microspheres | 1252–1462 | 45.3–46.5 | – | 31.9–36.2 | – | – |

| Semenov et al. [45] | Hollow ceramic microspheres | 857–957 | 8.42–18.5 | 1.98–3.7 | 9.82–19.3 | – | – |

| Mcbride et al. [54] | Ceramic microspheres | 1810–2083 | 12.1–16.9 | 0.24–0.33 | 6.7–8.1 | – | – |

| Hanif et al. [38] | Fly ash cenospheres | 1187–1297 (dry:1003–1098) | 18.6–23.5 | 3.7–4.9 | 15.7–18.1 | 6.57–8.44 | 0.31–0.4 |

| Hanif et al. [39] | Fly ash cenospheres | 1260–1612 | 30.38–55.92 | 5.38–9.29 | 24.11–34.69 | 9.18–18.02 | – |

| Hanif et al. [46] | Glass cenospheres | 880.2–1375.7 | 14.3–43.0 | 4.75–7.89 | 16.2–31.3 | 3.68–12.5 | - |

| Hanif et al. [47] | Glass microspheres Fly ash cenospheres | 734.8–1564.1 1453.9–1551.3 | 6.23–47.9 40.4–53.6 | 0.78–6.7 6.96–11.3 | 8.48–30.6 27.8–34.6 | 1.82–15.7 13.1–16.7 | - |

| Al–Gemeel et al. [48] | Spherical 110P8 hollow glass microspheres | 2034–2158 | 55.5–65.0 | 5.6–14.0 | 27.3–30.1 | - | - |

| Yang and Li [49] | Hollow glass microspheres 3MTM K20 | 566.0–1001.0 | 3.4–5.5 | 1.06–1.69 (tensile) | 6.0–5.49 | 0.96–1.39 | - |

| Huang et al. [50] | Fly ash cenospheres | 1649–1820 | 25.0–47.6 | 4.8–5.9 (tensile) | 15.2–26.2 | - | 0.29–0.37 |

| Yun et al. [51] | Fly ash cenospheres | 2011–2370 | 24.6-43.9 | 1.52–3.16 | 12.2–18.5 | 17.6–39.1 | 1.41–2.21 |

| Wu et al. [26] | Fly ash cenospheres | 1154–1471 | 33.0–69.4 | 3.6–7.3 | 28.6–47.2 | 10.4–17.0 | 0.28–0.4 |

| Huang et al. [35] | Fly ash cenospheres | 1302–1464 | 46.9–65.8 | 7.06 | 36.0–44.9 | 9.8–13.2 | - |

| Huang et al. [41] | Fly ash cenospheres Hollow glass microspheres | 1361 946–969 | 64. 028.1–32.3 | 6.7–8. 0- | 47. 029.7–33.3 | 15.4 - | - |

| Composition | CaO | SiO2 | Al2O3 | Fe2O3 | MgO | K2O | Na2O | B2O3 | SO3 | C3S | C2S | C3A | C4AF |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Cement | 63.5 | 19.4 | 4.8 | 2.8 | 1.3 | 0.4 | 0.2 | - | 1.9 | 69.0 | 3.6 | 8.1 | 8.4 |

| Silica fume | 0.2 | 94.1 | 0.6 | 0.1 | 0.4 | 0.3 | 0.1 | - | N.A | N.A. | N.A. | N.A. | N.A. |

| FAC | - | 51.6 | 34.6 | - | 0.7 | - | - | - | - | - | - | - | - |

| GM | 13.4 | 72.7 | 1.0 | 0.0 | 0.0 | 0.0 | 6.2 | 6.4 | - | - | - | - | - |

| Type | Bulk Density (g/cm3) | Crushing Strength (MPa) | Moisture Content (%) | Flotation Ratio (%) |

|---|---|---|---|---|

| FAC | 0.45 | 15.0 | 0.2 | 95 |

| GM40 | 0.38–0.42 | 27.6 | 0.5 | 92 |

| GM46 | 0.44–0.48 | 41.3 | 0.5 | 92 |

| GM60 | 0.57–0.63 | 68.9 | 0.5 | 92 |

| Mix ID | Fillers | Mix Proportion of Matrix by Volume of Total Binder | |||||

|---|---|---|---|---|---|---|---|

| Water/Binder | B 1 | Fillers/B | SP 6/B | Fiber (V%) | |||

| C 2 | SF 3 | ||||||

| ULCC-1 [26] | FAC 4 | 0.35 | 0.92 | 0.08 | 0.38 | 0.01 | - |

| FL40 | GM40 5 | 0.60 | 0.85 | 0.15 | 0.56 | 0.02 | - |

| FL46 | GM46 | 0.60 | 0.85 | 0.15 | 0.59 | 0.02 | - |

| FL60 | GM60 | 0.60 | 0.85 | 0.15 | 0.66 | 0.02 | - |

| FL46-35 | GM46 | 0.35 | 0.85 | 0.15 | 0.59 | 0.05 | - |

| FL46PE05 | GM46 | 0.65 | 0.85 | 0.15 | 0.59 | 0.02 | 0.5 |

| FL46PE10 | GM46 | 0.65 | 0.85 | 0.15 | 0.59 | 0.04 | 1.0 |

| FL46PE15 | GM46 | 0.65 | 0.85 | 0.15 | 0.59 | 0.05 | 1.5 |

| LWC 7 | Expanded shale | 0.35 | 0.90 | 0.1 | 0.6 | 0.02 | - |

| NWC 8 | Granite | 0.45 | 1 | 0 | - | 0.01 | - |

| Property | Test Standard | Testing Age | Specimen Type and Size (mm) | No. of Tests |

|---|---|---|---|---|

| Workability (flow table) | BS EN 1015-3 [55] | Right after mixing | - | - |

| Estimated porosity | ASTM C 138 [56] | - | - | - |

| Density of hardened specimens after demold | ASTM C 138 [56] | 1–2 days | Cube:50 × 50 × 50 | 3 |

| Compressive strength | ASTM C109 [58] ASTM C349 [62] BS EN 196-1 [61] ASTM C39 [57] | 28 days | Cube:50 × 50 × 50 Cube:40 × 40 × 40 - Cylinder:100 × 200 | 3 2 - 3 |

| Flexural strength | BS EN 196-1 [61] | 28 days | Prism: 40 × 40 × 160 | 3 |

| Tensile strength | JSCE-2008 [63] | 28 days | Dog-bone specimens | 3 |

| Elastic modulus Poisson’s Ratio | ASTM C469 [59] | 28 days | Cylinder:100 × 200 | 3 |

| Thermal conductivity | ASTM C518 [64] | Around 100 days 1 | Slab: 300 × 300 × 30 | 2 |

| Water sorptivity test | ASTM C 1585 [66] | 28 days | Cylinder: 100 × 50 | 3 |

| Type | Flow/Sump (mm) | Fresh Density ρ (kg/m3) | 28-day Compressive Strength fcm (MPa) | 28-day Flexural Strength fct (MPa) | Ec (GPa) | vc | Estimated Porosity (%) | Specific Strength (kPa/kgm−3) |

|---|---|---|---|---|---|---|---|---|

| ULCC-1 [26] | 200 | 1471 | 69.4 | 7.3 | 17.0 | 0.25 | 6.6 | 47.2 |

| FL40 | 160 | 970 | 41.0 (2.8) | 3.5(0.4) | - | - | 1.2 | 42.3 |

| FL46 | 164 | 940 | 39.5 (1.9) | 3.2(0.4) | 7.2 | 0.25 | 1.4 | 42.0 |

| FL60 | 160 | 890 | 31.1 (0.5) | 2.2(0.9) | - | - | 6.4 | 34.9 |

| FL46-35 | 120 | 880 | 32.1 (1.7) | 2.7(0.2) | - | - | 7.5 | 36.5 |

| FL46PE05 | 155 | 940 | 26.9 (2.4) | 4.0(0.7) | - | - | 0.9 | 28.6 |

| FL46PE10 1 | 140 | 940 | 27.3 (1.9) | 7.2(0.4) | - | - | 1.2 | 29.0 |

| FL46PE15 | 134 | 930 | 31.0 (3.3) | 9.5(0.5) | - | - | 1.7 | 33.3 |

| LWC | 100 (slump) | 1850 | 53.2 | - | - | 0.25 | 2.4 | 28.7 |

| NWC | 105 (slump) | 2360 | 68.0 | - | - | - | 8.8 | 28.8 |

| Mix ID | w/b | Aggregate Type | 1-Day Density ρ1 (kg/m3) | Oven-Dry Density ρo (kg/m3) | 28-Day Compressive Strength fcm (MPa) | Thermal Conductivity λ (W/mK) |

|---|---|---|---|---|---|---|

| FL46 1 | 0.60 | GM | 940 | 750 | 39.5 | 0.154 (10 °C) 0.162 (30 °C) 0.180 (90 °C) |

| ULCC-1 [26] | 0.35 | FAC | 1471 | 1303 | 69.4 | 0.40 |

| ULCC-6 [26] | 0.56 | FAC | 1154 | 966 | 33.0 | 0.28 |

| Concrete [26] | 0.42 | Granite | 2341 | 2251 | 67.6 | 1.98 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Huang, Z.; Wang, F.; Zhou, Y.; Sui, L.; Krishnan, P.; Liew, J.-Y.R. A Novel, Multifunctional, Floatable, Lightweight Cement Composite: Development and Properties. Materials 2018, 11, 2043. https://doi.org/10.3390/ma11102043

Huang Z, Wang F, Zhou Y, Sui L, Krishnan P, Liew J-YR. A Novel, Multifunctional, Floatable, Lightweight Cement Composite: Development and Properties. Materials. 2018; 11(10):2043. https://doi.org/10.3390/ma11102043

Chicago/Turabian StyleHuang, Zhenyu, Fang Wang, Yingwu Zhou, Lili Sui, Padmaja Krishnan, and Jat-Yuen. Richard Liew. 2018. "A Novel, Multifunctional, Floatable, Lightweight Cement Composite: Development and Properties" Materials 11, no. 10: 2043. https://doi.org/10.3390/ma11102043

APA StyleHuang, Z., Wang, F., Zhou, Y., Sui, L., Krishnan, P., & Liew, J.-Y. R. (2018). A Novel, Multifunctional, Floatable, Lightweight Cement Composite: Development and Properties. Materials, 11(10), 2043. https://doi.org/10.3390/ma11102043