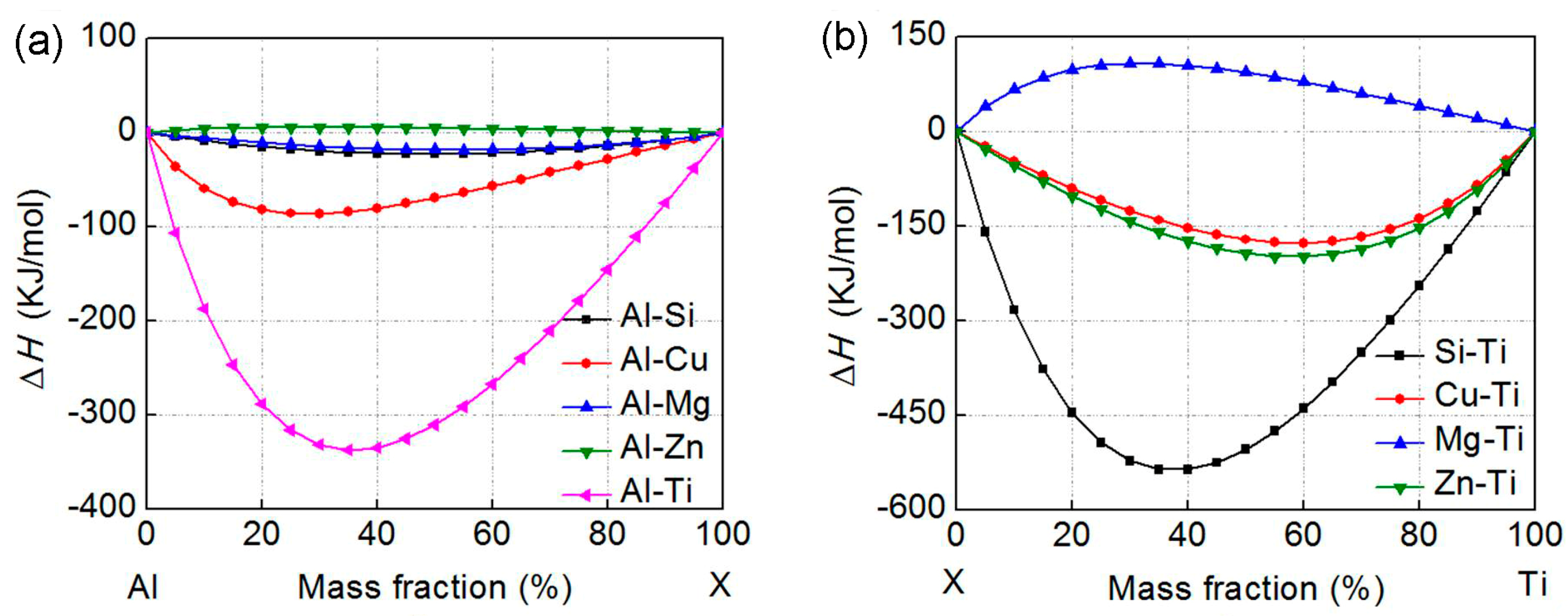

4.1. Effects of Alloying Elements on the Phase Constituents of Reaction Products

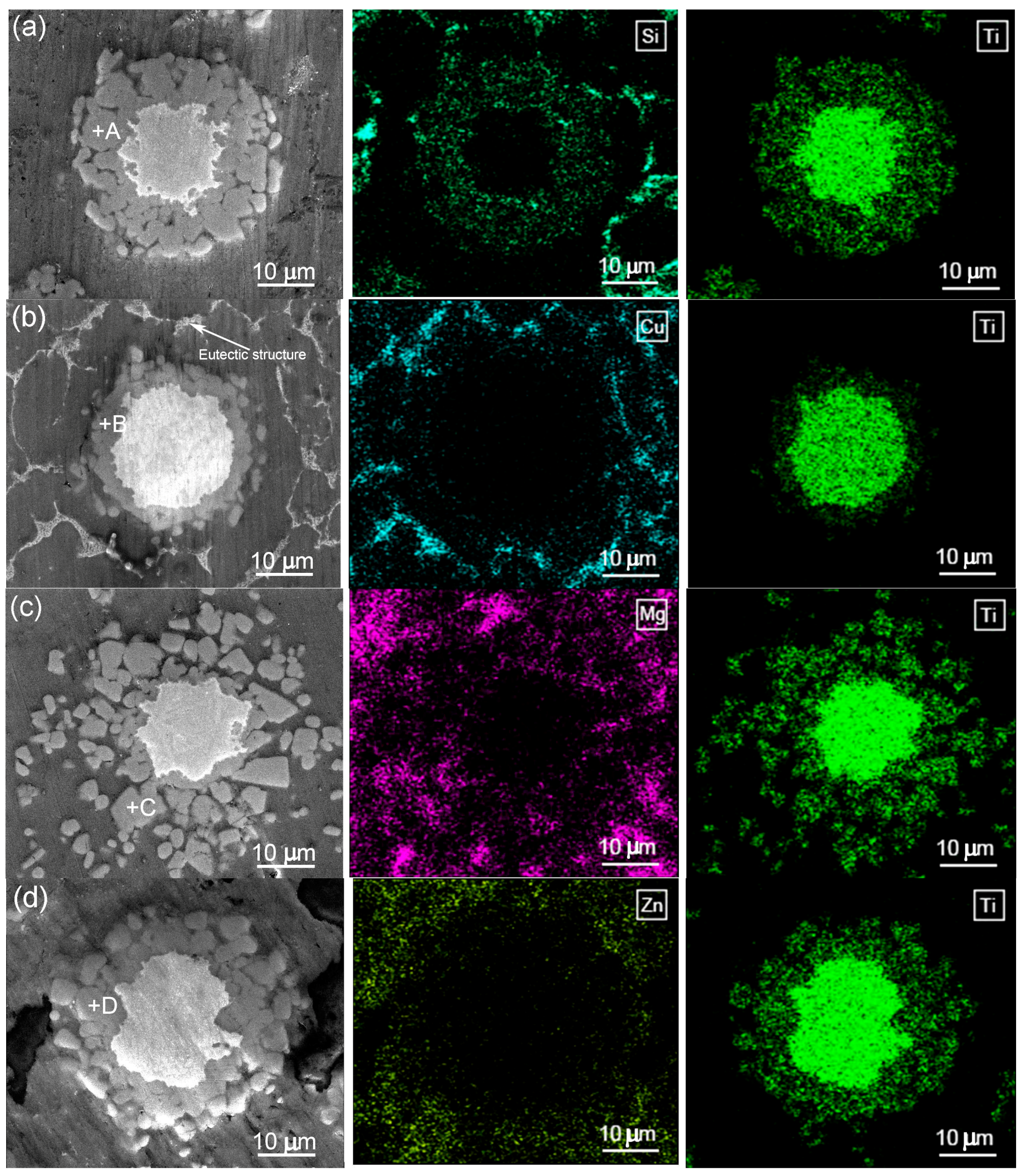

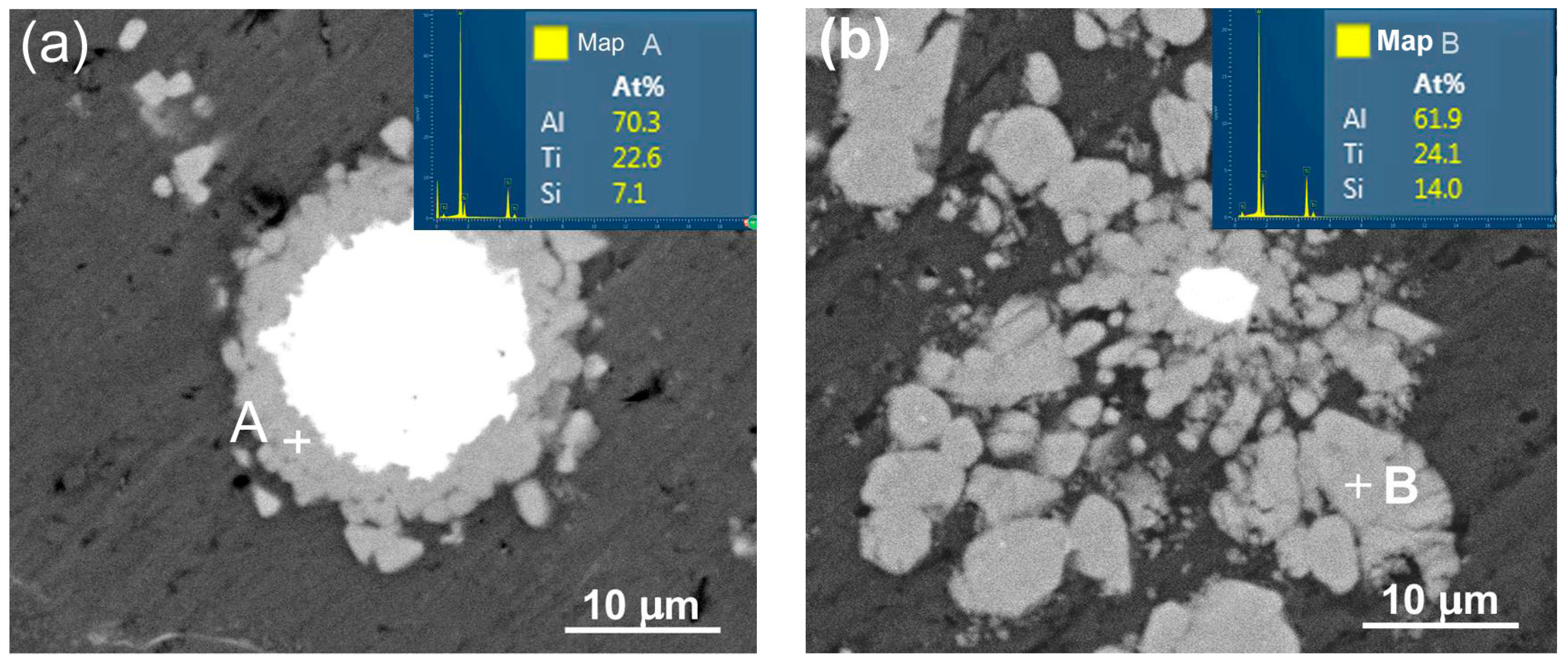

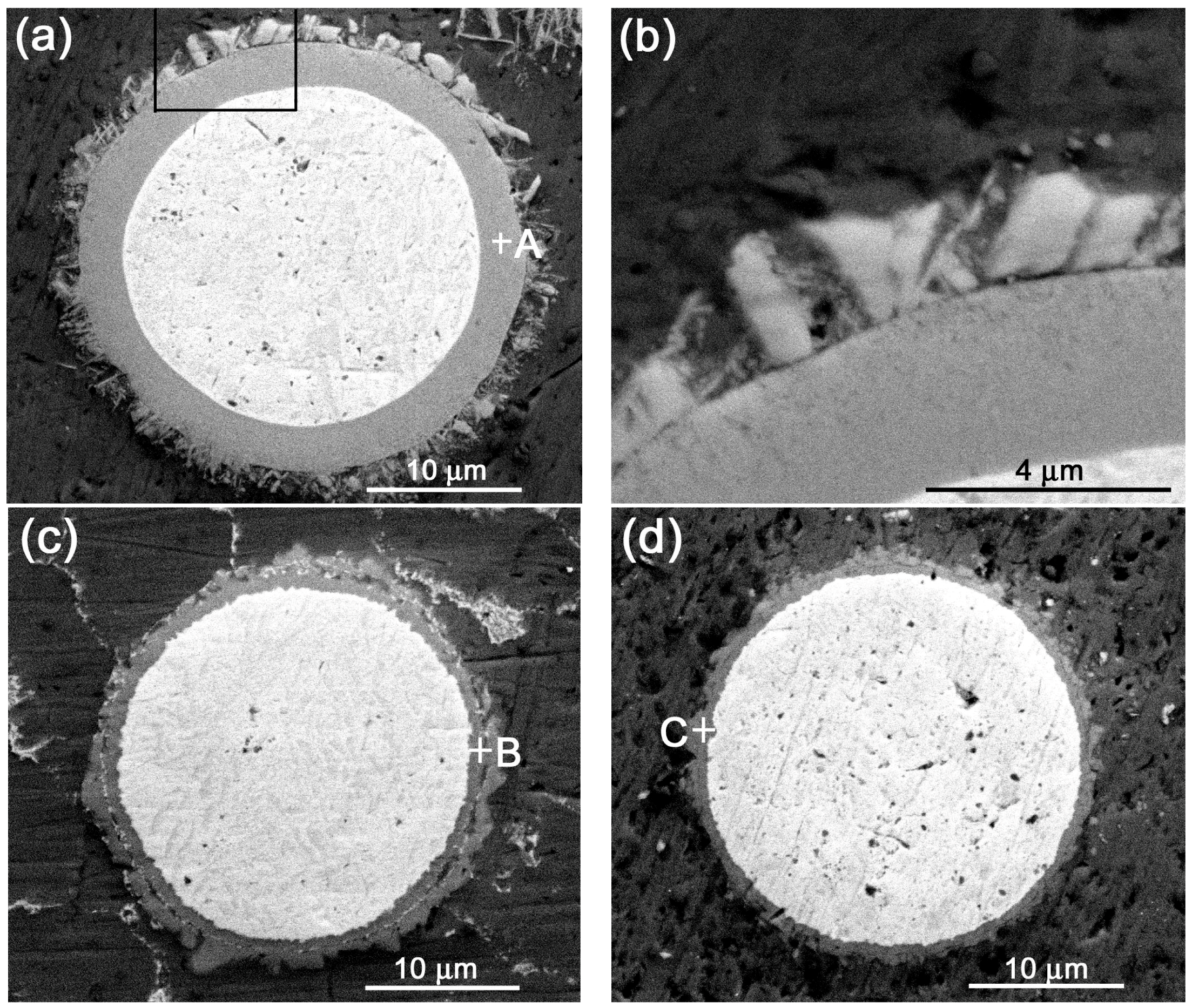

Figure 4 shows the SEM micrographs and EDS maps of the in situ formed reinforcing particles in the Al–5Ti–5.5X (X = Si, Cu, Mg and Zn) compacts heated at 993 K (720 °C) for 30 min. It reveals that Si uniformly distributed in the reaction layer besides in the eutectic structures of the Al matrix (

Figure 4a), which demonstrates that Si actually participated in the reaction between Ti powders and Al melt and the reaction product contained Si element. The EDS quantitative analysis for point A marked in

Figure 4a indicates that (Al + Si)/Ti atomic ratio is close to 3:1 (

Table 5), being just consistent to the composition of (Al,Si)

3Ti phase. This implies that the reaction product for the Si-containing system is the (Al,Si)

3Ti phase. Cu element all basically segregated in the eutectic structures of the Al matrix, and there was no Cu element in the reaction product (

Figure 4b). Mg and Zn distributed in both the primary Al grains and eutectic structures, and the reaction products also did not contain the corresponding alloying elements (

Figure 4c,d). These results are consistent to the fact that the solubilities of Si and Cu in Al phase are smaller than those of Mg and Zn [

27]. More importantly, the results indicate that Cu, Mg, and Zn did not actually participate in the reaction. In the all cases, Ti element was distributed in the reaction products besides in the residual unreacted Ti phase (the Ti maps in

Figure 4). The EDS results for the reaction products (marked by B, C and D in

Figure 4b–d respectively) in the Cu, Mg, and Zn-containing systems show that Al/Ti atomic ratios were all close to 3:1 (

Table 5), which means that all of the reaction products in these three systems were Al

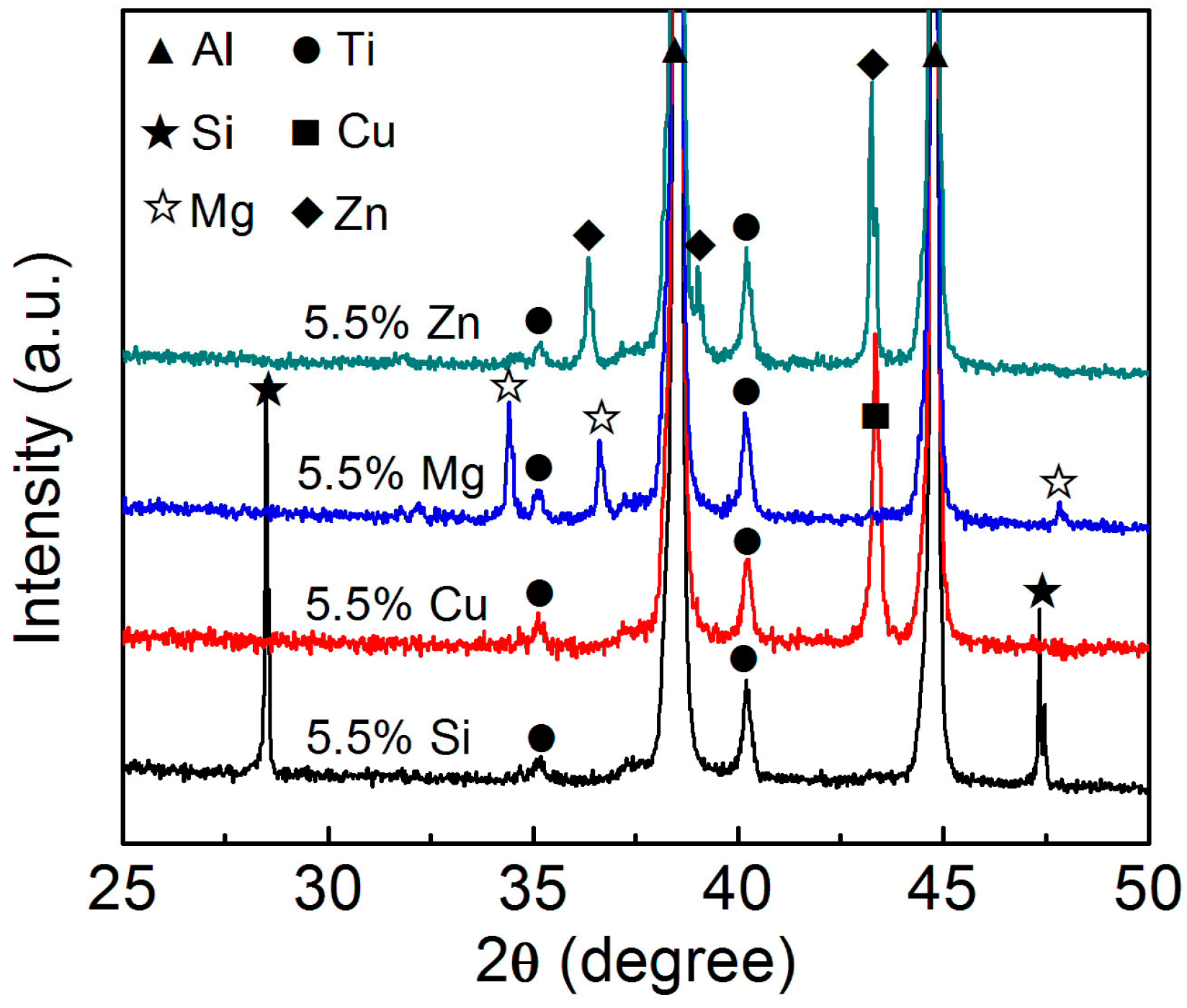

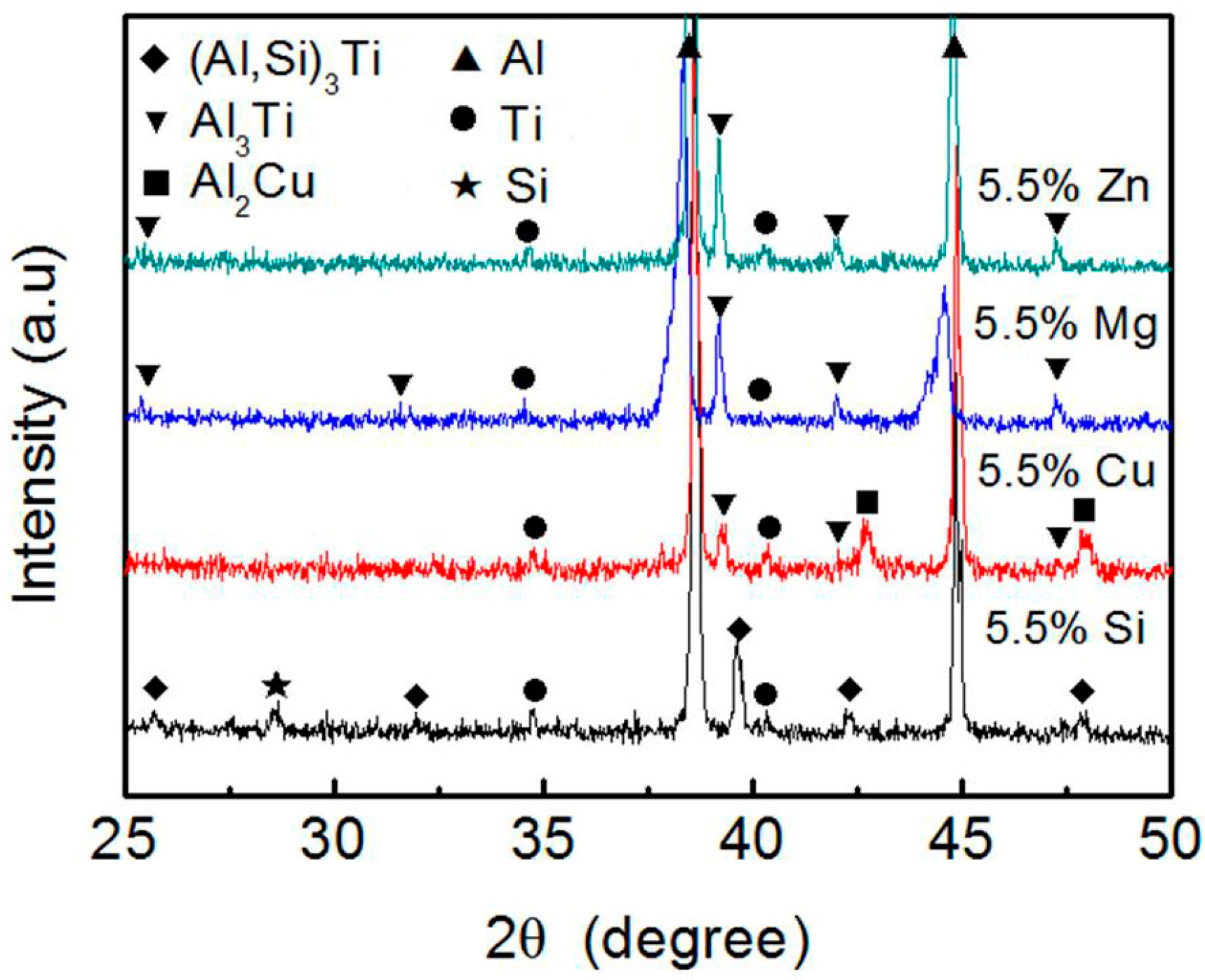

3Ti phase, being exclusive of the other compounds. The results from XRD further confirm this conclusion, the Ti-having compound is Al

3Ti phase for the Al–5Ti–5.5X (X = Cu, Mg, Zn) systems, while that is (Al,Si)

3Ti phase for the Al–5Ti–5.5Si alloy (

Figure 5). That is, Si element participated in the reaction between Ti powders and Al melt and a Al–Ti–Si ternary phase of (Al,Si)

3Ti formed after the compact was heated for 30 min at 993 K (720 °C), while Cu, Mg, and Zn did not take part in the reaction and only one binary phase of Al

3Ti generated.

Previous investigation proposed that Al atoms in Al

3Ti phase could be partially substituted by Si atoms in Al–Si–Ti alloys, and Si content in the resulting (Al,Si)

3Ti varied in a wide range and its maximum content was up to 15.07 at % [

25]. In this work, the Si content is 9.9 at % and is within this range (

Table 5). In addition, the radius of Si atom is smaller than that of Al atom [

25], and thus the interplanar spacing and lattice constants of (Al,Si)

3Ti phase should be smaller than those of Al

3Ti phase and continuously decrease with the increase of Si content. According to Bragg diffraction formula [

28], the diffraction peak of (Al,Si)

3Ti phase will move towards the sites with a larger 2θ in XRD diffractogram. The XRD results demonstrate this deduction, the 2θ values corresponding to (Al,Si)

3Ti phase in the Al–5Ti–5.5Si alloy are larger than those of the Al

3Ti phase in the other systems (

Figure 5).

It is just due to the replacement of Al in the Al

3Ti phase by Si that there are several ternary compounds to possibly form in the Al–Ti–Si system, including AlTi

2Si

3 (τ2), AlTi

6Si

3, AlTi

4Si

7, Al

5Ti

7Si

12 (τ1), and Al

12Ti

5Si

3 [

29]. The most acceptable chemical formula of τ1 phase can be expressed as (Ti

1–xAl

x)(AlySi

1–y)

2, where x ≤ 0.12 and 0.06 ≤ y ≤ 0.25 [

30]. That is, the compositions of τ1 phase are estimated to be 8–20 at % Al, 29.3 at % Ti, and 62.6–50 at % Si. τ2 phase can be presented as Ti(Al

xSi

1–x)

2, with the x of 0.15–0.3. As indicated above, the maximum solubility of Si in Al

3Ti phase can be up to 15.07 at %. The crystal structure of this Si-containing Al

3Ti phase is still maintained the tetragonal crystal structure of Al

3Ti, so this phase is expressed as (Al,Si)

3Ti [

31]. But, it then transforms into τ1 phase when the Si content exceeds 15.07 at %. This is consistent with the above thermodynamic analysis, the stability of Al

3Ti then decreases when the Si content exceeds 7 wt % and Al

3Ti amount decreases as Si content in the Al–Ti–Si system increases. Another ternary phase, τ3, has been reported by Raman and Schubert, but its crystal structure and composition have not been identified [

21]. So, it can be found that the ternary phases in the Al–Ti–Si system are significantly depended on the Si concentration.

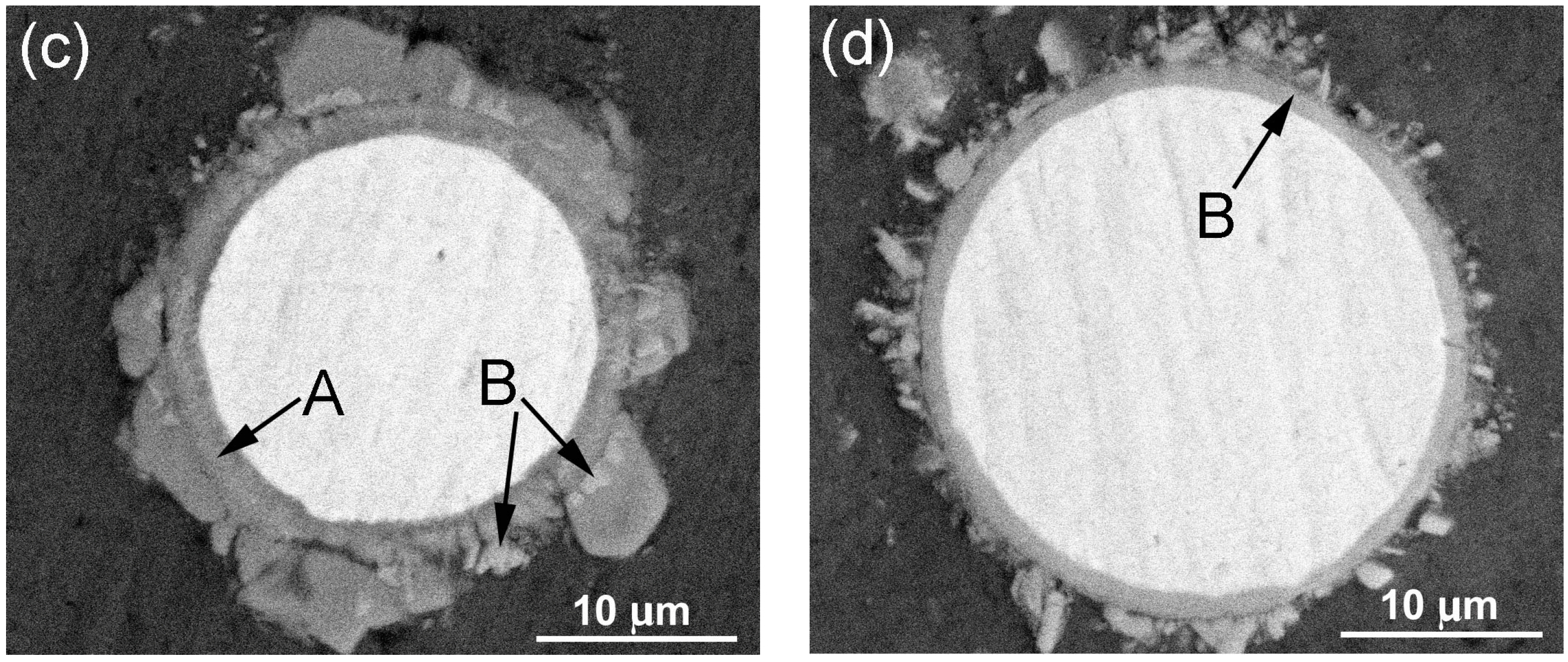

To further verify the effect of Si content on the ternary compounds, the experiment results from the Al–5Ti–2Si and Al–5Ti–9Si alloys heated for 30 min at 993 K are also presented. As shown by the inserts in

Figure 6, the reaction products (marked by A and B in

Figure 6a,b, respectively) in these two alloys were all (Al,Si)

3Ti phase. A previous investigation indicated that the (Al,Si)

3Ti compound was stable at 993K (720 °C) in Al–Ti–Si ternary system [

31].This result at least states that all of the reaction products for the Al–Ti–Si system with Si contents ranging of 2–9 wt % only contain one compound of (Al,Si)

3Ti at heating for 30 min.

Figure 7 shows the micrographs of the reinforcing particles in the Al–5Ti–XSi (X = 2, 5.5, 7, and 9) compacts heated for 10 min. It can be found that there were some white grey structures in the grey reaction products of the alloys with 5.5 and 9 wt % Si (marked by arrows B in

Figure 7b,c), while the products in the other two systems only had unique-color phase (

Figure 7a,d). In fact, the EDS results indicate that the products marked by arrows A in

Figure 7 all belong to a Al–Ti–Si ternary phase with low Si concentration, while those marked by arrows B are a Al–Ti–Si ternary phase with high Si content (

Table 6). When considering the errors of the EDS, it can be found that the (Al+Si)/Ti atomic ratios of all the A structures are close to 3:1, which implies that the A structures should be (Al,Si)

3Ti phase, while the compositions of the B structures are basically within the ranges of τ1 phase compositions, 8–20 at % Al, 29.3 at % Ti, and 62.6–50 at % Si [

30]. Namely, the product in the Al–5Ti–2Si alloy is the unique (Al,Si)

3Ti phase, while that in the Al–5Ti–9Si alloy is the unique τ1 phase and those in the other alloys are a mixture of (Al,Si)

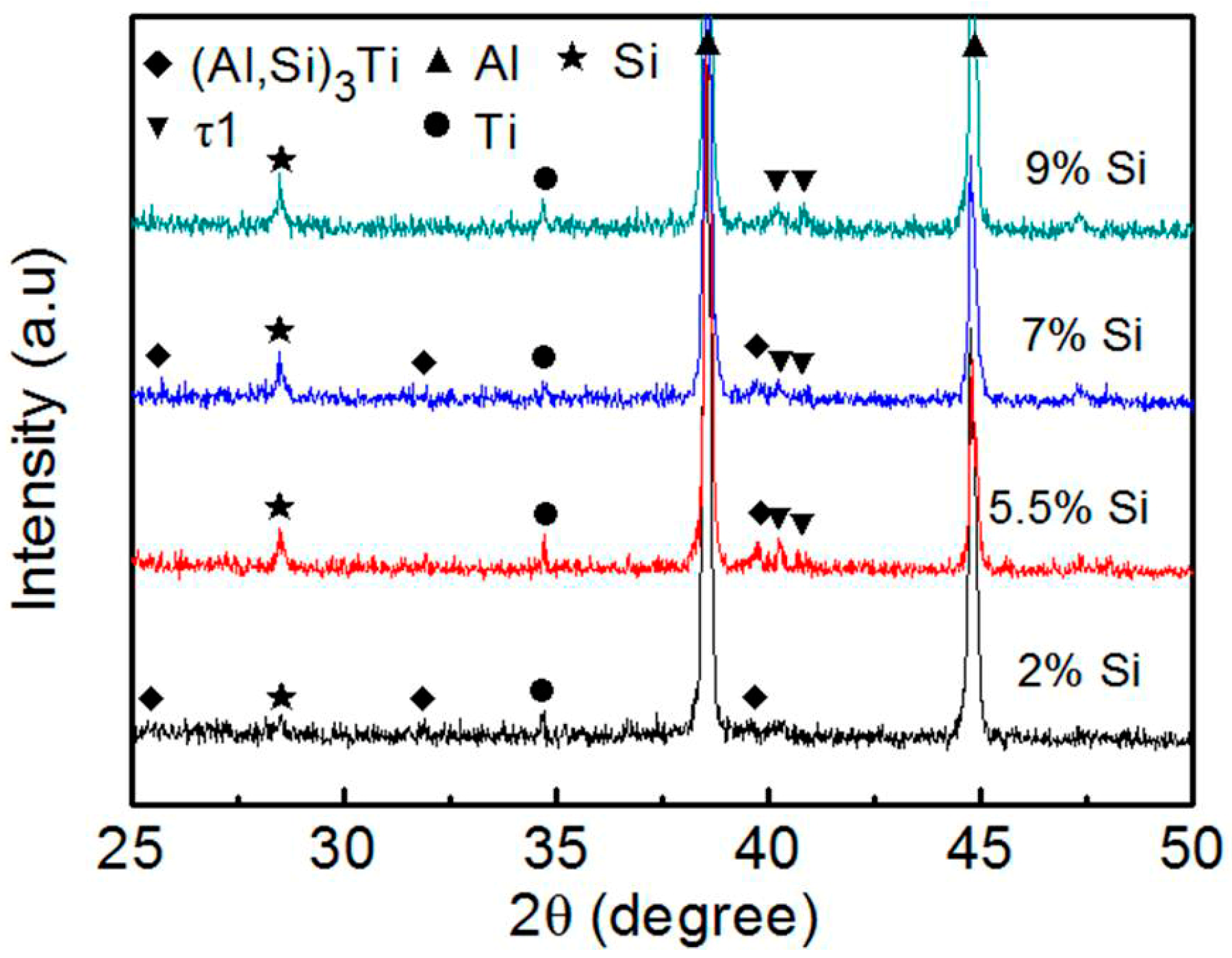

3Ti and τ1 phases. This can be further demonstrated by the XRD result shown by

Figure 8, there is only one Al–Ti–Si ternary phase of (Al,Si)

3Ti for the alloy with 2 wt % Si, one ternary phase of τ1 for the alloy with 9 wt % Si and a two-phase mixture of (Al,Si)

3Ti and τ1 for the other two alloys. In view of the present result, it can be deduced that the reaction product gradually transformed from (Al,Si)

3Ti phase to τ1 phase as the Si addition increased from 2 wt % to 9 wt %. That is, high-content Si in the alloys can accelerate the formation of τ1 phase with high Si concentration.

For the Al–5Ti–5.5Si system, the reaction product is a mixture of (Al,Si)

3Ti and τ1 phases when heated for 10 min, while it only contains one phase of (Al,Si)

3Ti after being heated for 30 min. So, it can be deduced that the first formed product should be τ1 phase, and then the τ1 phase would gradually transformed into (Al,Si)

3Ti as the heating proceeded. This deduction is consistent with the proposal that the (Al,Si)

3Ti phase is thermodynamically stable at 993K (720 °C),while τ1 is a transitional or metastable phase [

31]. As discussed above, the phase constituent of the reaction product is determined by Si content in it, and this Si content is highly depended on the Si concentration in the Al melt. The high former content should be supported by the high latter concentration. During heating, the first-formed liquid phase is resulted from the melting of residual Al–Si eutectics that have not dissolved into the primary Al phase in time [

9]. For a hypoeutectic Al–Si alloy, such as the Al–Si matrix alloys that are used in this work, the first–formed eutectic liquid phase has high-content Si, which promotes the formation of reaction product with high Si content, i.e., τ1 phase. As the heating time increased, the Si content in the melt was decreased due to the consumption from the reaction and the partial melting of primary Al grains. Subsequently, part of Si atoms in τ1 phase dissolved into the liquid phase again in order to achieve a new equilibrium state, resulting in the transformation of τ1 into (Al,Si)

3Ti. In addition, the newly-formed reaction product was also possibly (Al,Si)

3Ti phase for the long–time heated compacts due to the obstacle of the compact and thick layer to Si diffusion towards the product/Ti interface and the decrease of Si concentration in the liquid phase. As shown by

Figure 7b, c, the reaction products for the alloys heated for 10 min contain τ1 phase, but as illustrated by

Figure 4a and

Figure 6a,b, no τ1 phase can be found when heated for 30 min.

Summarily, Cu, Mg, and Zn elements did not participate in the reaction of Ti powders with Al melt and had no effect on the phase constituent of the reaction product. The reaction products of all the Al–Ti–X (X = Cu, Mg, and Zn) systems were the unique Al3Ti phase during the whole heating process. But, for the Al–Ti–Si system, Si element took part in the reaction. The first-formed product was a Al–Ti–Si ternary compound of τ1 phase with high Si concentration, and then the τ1 phase gradually transformed into another ternary compound of (Al,Si)3Ti phase with low Si content as the heating proceeded, or (Al,Si)3Ti phase directly formed due to the decrease of Si content in the Al melt and the obstacle of the thickened reaction shells to atom diffusion. The amount of τ1 phase and its existing time all increased as the Si content in the alloy increased because high-content Si could accelerate the formation of τ1 phase.

4.2. Effects of Alloying Elements on the Thickness of Reaction Shells

The aim of this work is to supply foundation for achieving core–shell structured Ti@compoundp with thick and compact compound shell during preparing Al matrix composites via powder thixoforming. So, the microstructure of the resulting reinforcements should be verified besides the phase constituents discussed above. The microstructure in this work mainly includes the thickness and compactness of the reaction shells.

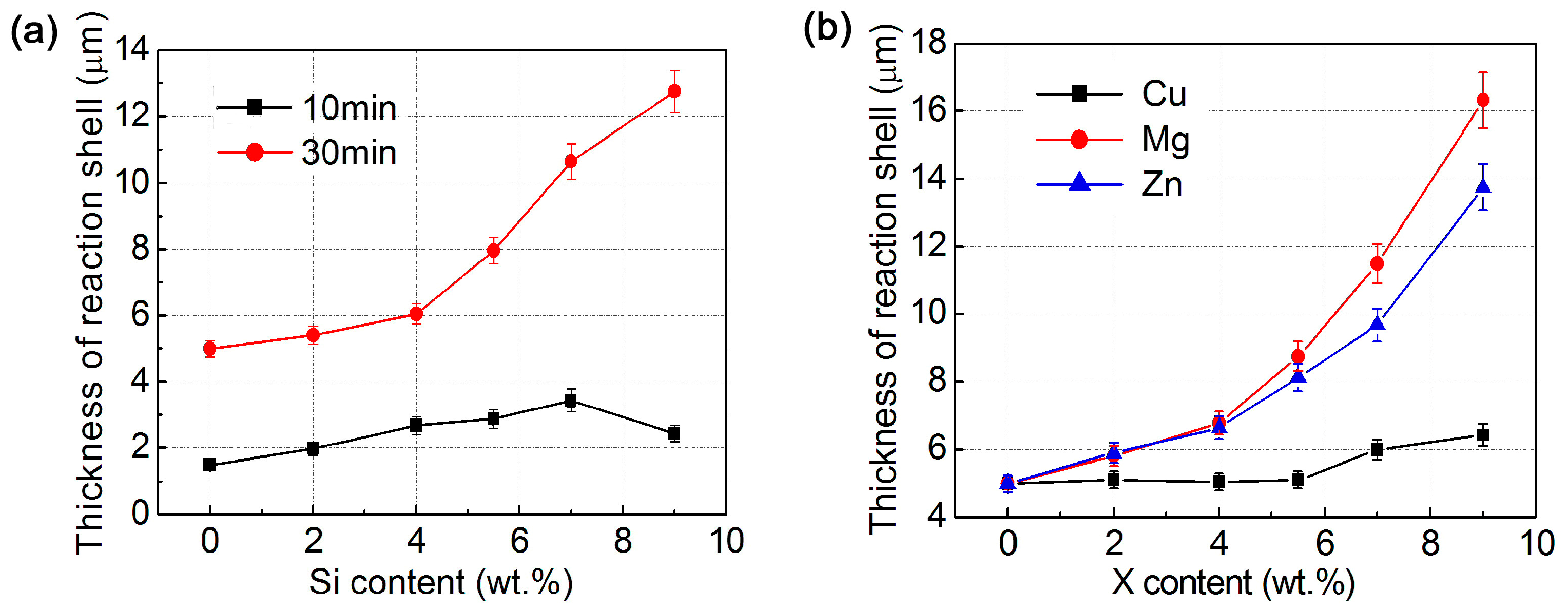

To accurately verify the effect of alloying elements on the thicknesses of the reaction shells, quantitative examinations were carried out, as shown by

Figure 9. But, it can be found that the reaction products in most cases are not compact shells, but in agglomerates with different–sized irregular particles around the Ti cores (

Figure 4,

Figure 6 and

Figure 7). The reason for leading to this result is attributed to the volume expansion from the reaction, which has been discussed in the following section. To examine the thickness, the amount of the reaction product was equivalent to a compact shell around a Ti core.

Figure 9 indicates that the equivalent thicknesses all increased as the Si, Cu, Mg, and Zn contents increased for the corresponding systems heated for 30 min. That is, the increases in the alloying element contents all of the accelerated the reaction and enhanced the reaction rate. In contrast, the effect of Cu was very limited, and the thickness was almost invariable as its content increased from 2 wt % to 5.5 wt %, and only slightly increased when Cu content exceeded 5.5 wt % (

Figure 9b). The effect of Mg was the largest and those of Si and Zn were considerable (

Figure 9).

These phenomena can be visually verified by the presented micrographs. The shell thicknesses in the Al–5.5Ti–5X (X = Si, Mg, and Zn) systems were obviously larger than that in the Cu-containing alloy, those in the Si- and Zn-containing systems were seemly equivalent, but obviously smaller than that in the Mg-containing alloy (

Figure 4). The effects of the alloying element contents can be seen by taking the micrographs of the Al–Ti–Si system as an example; only a thin shell formed for the 2 wt % Si alloy (

Figure 6a), then significantly thickened as Si content increased (

Figure 4a), and most of Ti has reacted and only a tiny core was left when Si content increased to 9 wt % (

Figure 6b). But, for this system heated for 10 min, the thickness first increased as Si content increased from 2 wt % to 7 wt % and then decreased (

Figure 9a). This change tendency can be clearly seen through comparing the micrographs shown in

Figure 7. As discussed above, the reason for resulting in this difference from the case of heating for 30 min is contributed to the different microstructure compactness of the shells that originated from the different phase constituents. But, for the other systems, this phenomenon has not be found because the reaction phase did not change with the heating time and always maintained the unique phase of Al

3Ti.

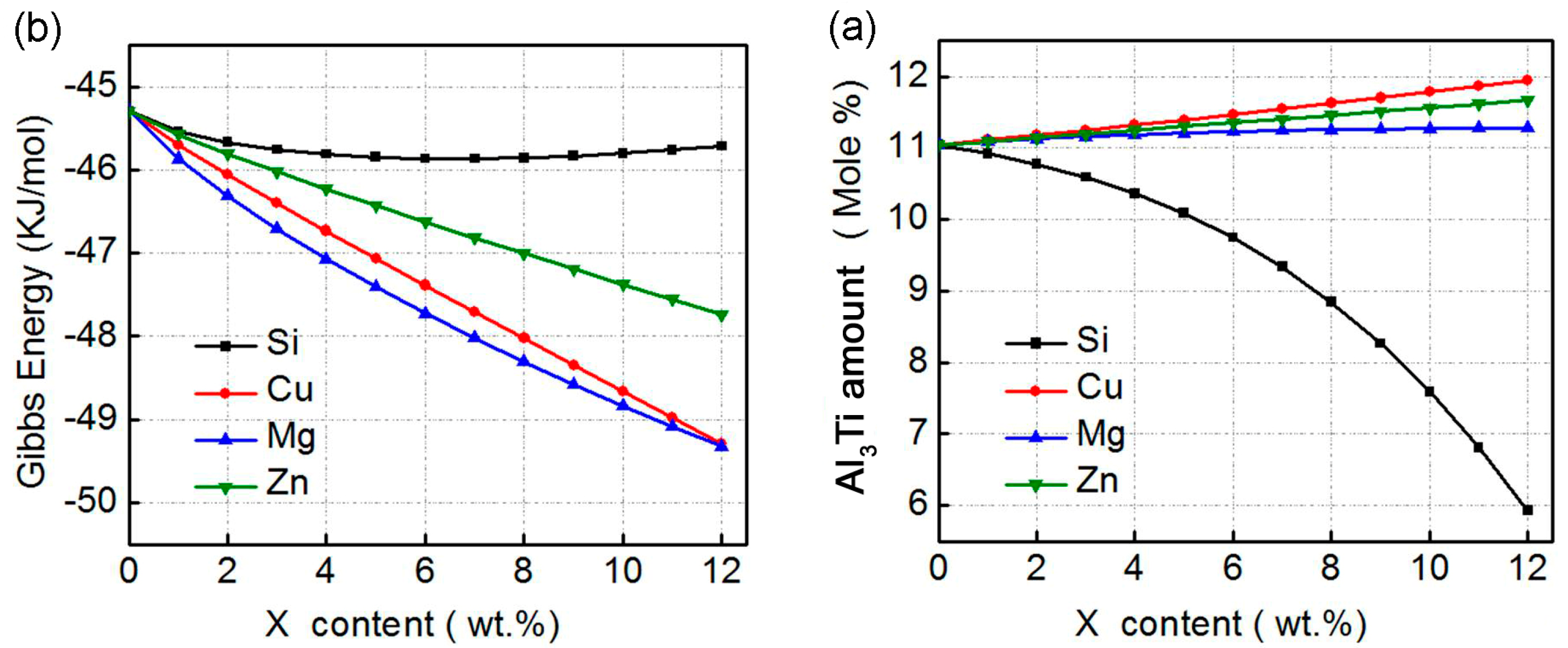

The results from the above thermodynamic calculations indicate that both the formation enthalpy and Gibbs free energy reduce as the Si content increases in a given range. This essentially means that Si element thermodynamically accelerates the formation of Al–Ti–Si ternary compounds in the Al–Ti–Si system. In view of dynamics, the reaction rate should be also promoted as the Si content increases because Si element is a participator of the reaction. So, the reaction shell thickened as the Si content increased for the cases of heating for 30 min (

Figure 9a). The thermodynamic analysis also indicates that Mg, Cu, and Zn elements all can improve the stability of Al

3Ti phase as their contents increase (

Figure 2b), and thus accelerate the formation of Al

3Ti phase and thickens the reaction shells. For a binary hypoeutectic Al alloy, the temperature at which eutectic liquid phase forms should lower as the solute (such as Mg, Zn, and Cu, also including Si) content increases during heating, and the amount of the resulting liquid phase must increase at a given temperature. It is expected that the contact of solid Ti particles with Al melt is closer, and the contact area is also larger than those with solid Al particles or less-amount Al melt. So, the reactions were accelerated and the shells thickened as the alloying element contents increased (

Figure 9).

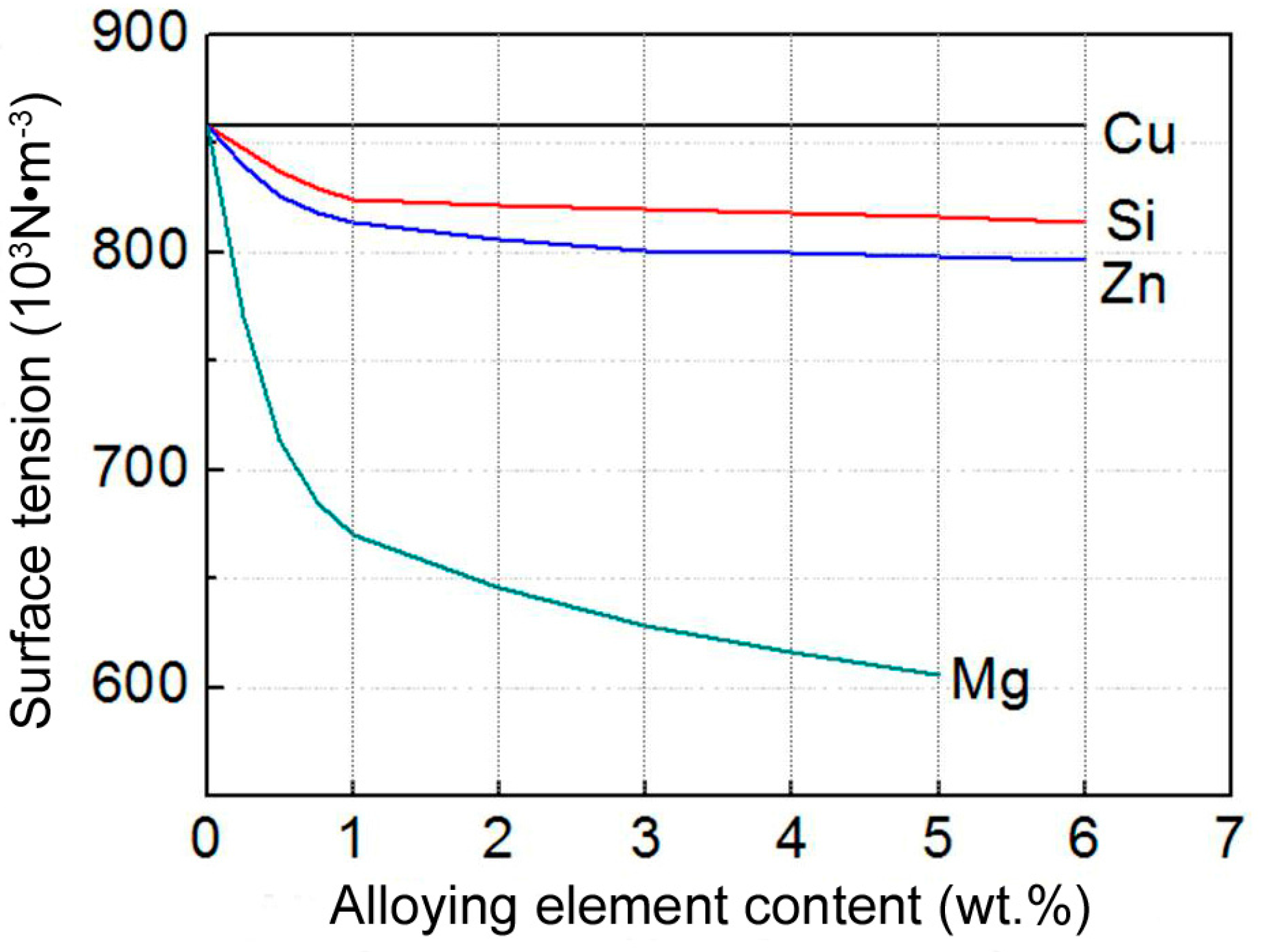

Furthermore, Mg is a surface-active element and can decrease the interfacial energy of solid–liquid interface [

32].

Figure 10 presents the relationship between the alloying element contents and surface tensions of the corresponding binary aluminum alloy melts at temperatures of above liquidus 50–80K (50–80 °C) [

33]. When compared with Si, Zn, and Cu, Mg element significantly decreases the surface tension of Al–Mg melt as its content increases. So, the wettability and thus the contact condition between the solid Ti particles and Al melt was improved, which accelerated the reaction and thickens the reaction shells.

The melting point of Zn is quite low (692.65K (419.65 °C) [

34]), and the Zn powders will prematurely melt at the time of alloying with the Al powders, the Zn melt then accelerates the surrounding Al powders to dissolve into it to form Al melt. The more the Zn amount is, the more the generated Al melt amount is. So, the reaction was also promoted as the Zn content increased (

Figure 9b).

Zhang et al. studied the microstructure and mechanical properties of an ultrafine-grained Al

3Ti/Al–5.5Cu composite prepared by PM and pointed out that Al–Cu eutectic liquid phase formed when the composite compact was heated to 821 K (548 °C), and the liquid phase then penetrated into cracks in the Al

3Ti layers to further participate in the reaction [

35]. But Al–Cu binary phase diagram indicates that the maximum solubility of Cu in Al solid solution is up to 5.7wt % [

34]. It is expected that most of Cu element might dissolve into the Al powders during the initial stage of heating due to the low content (5.5 wt %), and thus, eutectic liquid phase could not prematurely form. But, when the Cu content exceeded a given value (i.e., 7 wt %), liquid phase would form and its amount increased as the Cu content further increased. Based on this standpoint, the effect of Cu element shown in

Figure 9b can be well interpreted. In addition,

Figure 10 indicates that Si and Zn also slightly decrease the Al melt surface energy, and thus, the reactions are also promoted, but Cu element almost has no this effect.

That is, Si, Mg, Zn, and Cu all accelerated the reaction of Ti powders with Al matrix, and thus thickened the reaction shells as their contents increased. Comparatively, the effect of Mg was the largest, that of Cu was the smallest and only operated when its content exceeded 5.5 wt %, and Si and Zn had an equivalent middle effect. The common influence mechanism of the four elements is that they all promoted the premature formation of Al melt and the melt amount increased with increasing their contents. So, the contact condition between the Ti powders and Al matrix was improved because the contact was closer and the contact area was larger than those between the Ti powders and Al powders. However, the role of Si is also mainly ascribed to its participation in the reaction. Sometimes Si element decreased the shell thickness due to the variation of product phase constituents with Si content or heating time. The solubility of Cu in Al phase was quite high, and thus eutectic liquid phase formed till the Cu content reached a given value, so its effect did not carry out until the content exceeded 5.5 wt %. Mg could significantly decrease the interface energy between Ti powders and Al melt, and thus further improved the contact condition. But, for Zn element, increasing its content accelerated the premature formation of liquid phase due to its low melting point and the increase in the liquid amount.

4.3. Effect of Alloying Elements on the Microstructure Compactness of Reaction Shells

For the core-shell-structured Ti@compound

p, the compound shells should be enough compact so as to play strengthening and toughening roles besides having a given thickness. But, the reaction products in most cases were in agglomerates with irregular and different-sized interconnected particles, or were in shells but contained small cracks (

Figure 4,

Figure 6 and

Figure 7). As described above, the reason that resulted in these microstructures is the stress concentration from volume expansion occurred during transformation of Ti into compounds. It can be expected that the stress concentration is related to two main factors, one is the shell thickness and the other is the phase constituent.

The quantitative relationship between the stress concentration and the reaction shell thickness can be expressed as (taking forming Al

3Ti shell as an example) [

36]:

where

is the stress concentration in Al

3Ti shell;

,

are the modulus of elasticity and Poisson’s ratio of Al

3Ti phase, respectively;

is the thickness of Al

3Ti shell and

is the radius of residual Ti core;

R and

R0 are the radii of the reinforcing particle and the original Ti powder, respectively. It can be found that the thicker the shell thickness

is, the larger the stress concentration

is, and thus the easier the shell fracture is. Our previous investigation on partial remelting of 2024Al–Ti green compact indicated that the stress could be up to 15.89 GPa when a Al

3Ti shell with 2 μm thickness formed around a Ti powder with diameter of 9.28 μm, which is higher than the theoretical strength of Al

3Ti phase (14.4 GPa) [

10]. Under this condition, microcracks possibly generated within the shell. In addition, the stress is also concerned to the reaction rate for the shells with a same thickness; the stress concentration should increase as the reaction rate is quickened due to the decreased time for redistributing the stress. Of course, a higher reaction rate must result in a thicker shell in a given reaction time.

Based on the above discussion about the reaction shell thickness or reaction rate, it can be proposed that at a given heating time (i.e., 30 min) and a given element content (i.e., 5.5 wt %), the tendency to fracture of the reaction shell is the largest for the Al–Ti–Mg system, the least for the Al–Ti–Cu system, and equivalent middle for the Si- and Zn-containing systems. As shown by

Figure 4, the reaction shell have fractured into the individual, different-sized particles for the Al–Ti–Mg system (

Figure 4c), the shells for the Si- and Zn-containing systems are in the interconnected-particle agglomerates (

Figure 4a,d), and that for the Al–Ti–Cu alloy is in a quite compact shell (

Figure 4b).

In addition, for all of the systems, the shell thickness increased as the heating time was prolonged, and thus, the fracture tendency should be promoted with the heating time. This can be verified by

Figure 7b and

Figure 4a; for the Al–Ti–Si compact heated for 10 min, the reaction product is in a shell with small cracks (

Figure 7b), but for the compact heated for 30 min, the product is in an interconnected particle agglomerate around the Ti core (

Figure 4a). This can also be demonstrated by our previous investigations on the microstructure evolutions during partial remelting of A356–Ti and 2024Al–Ti compacts [

9,

10].

Similar to the effect of heating time, the increase in element content also enhances the fracture tendency due to the increased shell thickness. This can be seen through comparing

Figure 7a,b; the reaction shell is quite compact for the 2 wt % Si-containing alloy, while cracks appeared as the Si content increased to 5 wt %. But, for the cases with 7 and 9 wt % Si, they did not obey this tendency due to the variation of phase constituent, which will be discussed as following.

As indicated above, the stress concentrations in different compounds are also different for the Al–Ti–Si system. This is resulted from the different volume expansion ratios for forming different compounds. The volume expansion ratio, Δ

V, occurred during reaction can be expressed by the equation [

36]:

where

and

are the total atomic volumes of reaction products and reactants, respectively. For this work, the products include Al

3Ti, (Al,Si)

3Ti, and τ1 phases, while the reactants only refer to pure Ti. According to the densities of Ti, Al

3Ti, and τ1 phases [

9,

10,

21], their molar volumes can be achieved as shown by

Table 7. The volume expansion ratios of Ti transforming into Al

3Ti and τ1 phases,

and

, can be calculated by using Equation (4). The result shows that the

and

are 2.55 and 1.8, respectively (

Table 7). That is, the volume is expanded by 2.55 and 1.8 times when Ti transforms into Al

3Ti and τ1 phases respectively, and the volume expansion for forming Al

3Ti phase is significantly larger than that for forming τ1 phase. But for the (Al,Si)

3Ti phase, its density cannot be determined because of the uncertainty of its composition (the Si content varies in a wide range up to 15.07 at % [

25]), and thus, the corresponding volume expansion ratio cannot be calculated. However, it is certain that its volume expansion ratio,

, must be smaller than the

, but larger than the

according to the Si contents in these phases. That is, the stress concentration in (Al,Si)

3Ti phase is between those in τ1 and Al

3Ti phases.

The reaction shells in the Al–Ti–Si system usually have two phases of (Al,Si)3Ti and τ1, and the proportion of τ1 phase decreased as the heating time prolonged and increased with increasing Si content, while those of the other three systems always have a single phase of Al3Ti. So, it is suggested that the stress concentrations, and thus the shell compactness for the Cu-, Mg-, and Zn-containing systems are only determined by the shell thickness or reaction rate, as discussed above. But, for the Al–Ti–Si system, the stress state and the resulting shell compactness are also affected by the phase constituent besides the shell thickness.

At a given shell thickness, the reaction shells in the Al–Ti–Si system should be more compact than those in the other three systems due to the lower stress concentration in (Al,Si)

3Ti and τ1 phases, and will become more and more compact with shortening heating time or increasing Si content because of the increased τ1 phase. As shown by

Figure 7b, the reaction product in the 5.5 wt % Si-containing system heated for 10 min is a relatively compact shell, but as shown by

Figure 4a, the shell have fractured into an agglomerate when the heating time increased to 30 min. It should be noted that the fracture is also partially contributed to the increased shell thickness. Increasing Si content not only thickens the shells, but also increases the proportion of τ1 phase. The former promotes the fracture of the shells, which can be verified by comparing

Figure 7a,b, as described above, also can be seen through comparing

Figure 4a and

Figure 6a,b, the product in the 2 wt % Si system is in a quite compact shell, that in the 5.5 wt % Si alloy have fractured into the interconnected particles and the fracture degree became more serious when the Si content increased to 9 wt %. But, the latter improves the compactness, which can be confirmed by comparing

Figure 6b–d, the shell for the 9 wt % Si system is quite compact, while those of the 5.5 wt % and 7 wt % Si systems contain cracks. It is just due to the obstacle of the compact shell to the reaction that the shell in the 9 wt % Si system is quite thin (

Figure 7d). That is, decreasing the heating time and increasing Si content are beneficial to obtain compact reaction shells, but the former parameter and sometimes the later parameter all decrease the shell thickness. Therefore, to achieve the desirable core-shell-structured Ti@compound

p with a compact and thick compound shell, increasing Si content is generally helpful, but a suitable heating time must be coupled.

Generally, the microstructure compactness of the reaction shells for the Al–Ti–X (X = Cu, Mg, and Zn) systems is only depended on the shell thickness, and become more and more loose as the Mg, Cu, and Zn contents or heating time increase due to the enhanced stress concentrations from the increased shell thickness. The influence degrees of these three elements are same to those on the shell thickness. But, for the Al–Ti–Si system, the compactness is also related to the phase constituent besides the shell thickness because of its dual-phase characteristic of the resulting reaction shells. The stress concentration generated in (Al,Si)3Ti phase is larger than that inτ1 phase, but smaller than that in Al3Ti phase. So, the shells of the Al–Ti–Si system usually are more compact than those of the other systems when the shell thicknesses are same. Increasing Si content is beneficial to obtain ideal core-shell-structured Ti@compoundp with a thick and compact compound shell, but simultaneously, a suitable heating time must be coupled.

4.4. Microstructures of the Reaction Shells in Semisolid Compacts

Figure 11 shows the microstructures of reinforcements in the semisolid Al–5Ti–5.5X (X = Si, Cu, and Zn) compacts. It can be seen that the reaction product in the Si–containing system is a homogeneous shell with a thickness of about 3.7 μm except the outside jagged structures (

Figure 11a) and the shell is quite compact (

Figure 11b). In addition, unlike with those shown by

Figure 7b,c, the shell only contains one uniform–gray compound. The EDS result indicates that the composition of this compound is consistent to that of τ1 (Al

5Ti

7Si

12) phase (location A in

Table 8) [

30], and the XRD results shows that there is only one Ti-containing compound of τ1 phase (

Figure 12). These mean that the reaction product in this case is unique τ1 phase and the transformation of τ1 phase into (Al,Si)

3Ti phase has not operated. It is known that the volume expansion for forming τ1 phase is the smallest, so the resulting product is in a compact shell (

Figure 11a). That is, ideal core-shell-structured Ti@τ1 reinforcing particles were obtained after partial remelting of the Al–Ti–Si compact.

Comparatively, the shell in the Cu-containing system is quite thin (about 1.5 μm), although it seems also quite compact (

Figure 11c).

Figure 11d shows that the status of the Zn-having system is very similar to that of the Cu-containing alloy, but the shell thickness is rather thinner (about 1μm). The products in these two systems are all in a gray-color structure. The Al/Ti atomic ratios are basically identical and approximately equal to 3:1 (locations B and C in

Table 8). In addition, the XRD result also indicates that these two systems only have one Ti-having compound of Al

3Ti (

Figure 12).These imply that the reaction products in the Cu-and Zn-containing systems are all Al

3Ti phase, similar to those in the liquid cases discussed above.

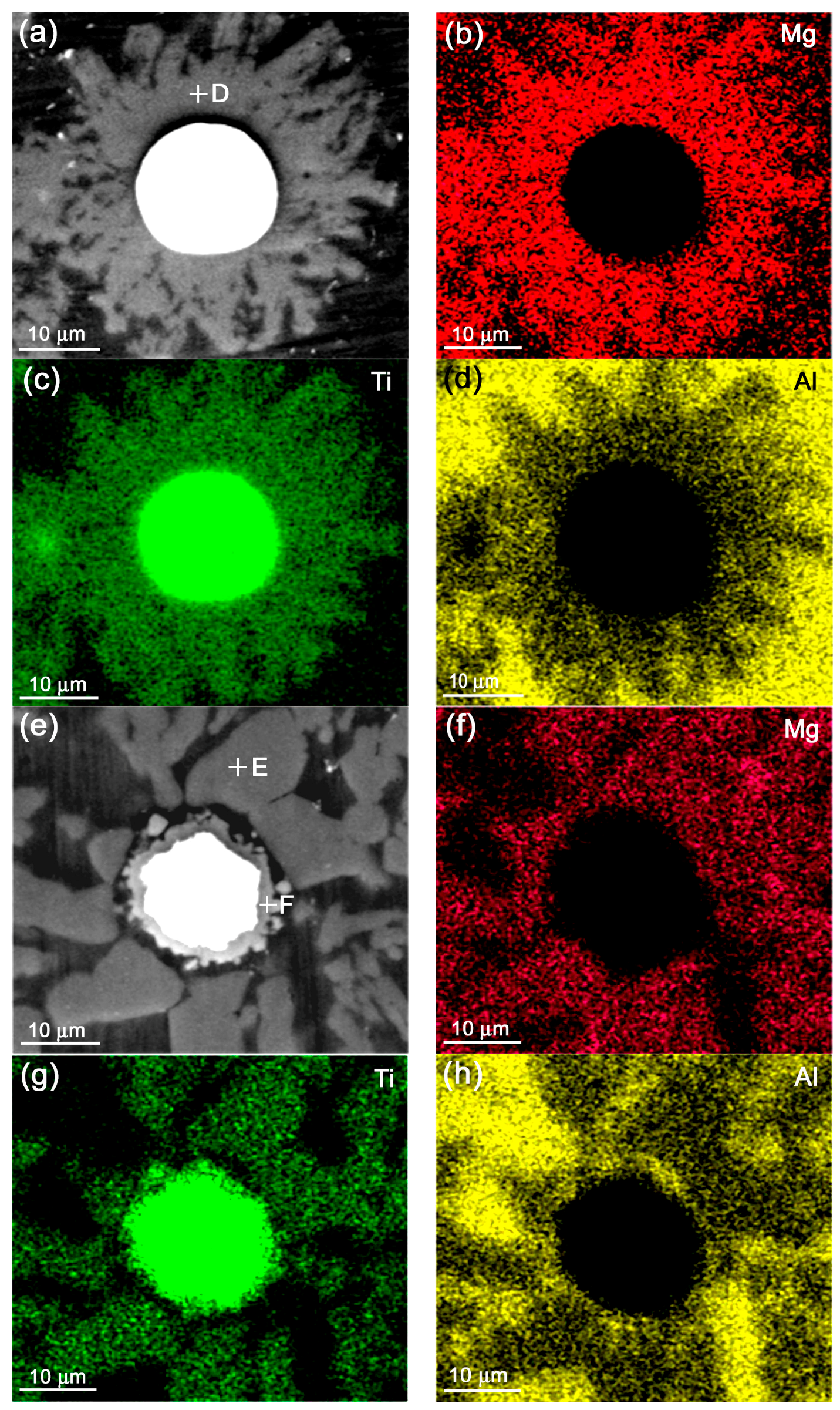

But, for the Mg-containing alloy, the result is different from that of the liquid-heating state. There are two kinds of situations in the semisolid state in view of the resulting reinforcement morphologies. One is that the reinforcement is composed of a Ti core and surrounding compound strips that radially distribute around the Ti core (

Figure 13a). More importantly, the compound is rich in Mg element (

Figure 13b) besides containing Ti (

Figure 13c) and Al (

Figure 13d) elements. The other is as shown by

Figure 13e, the reinforcement is consisted of a Ti core, a compact compound shell and the surrounding polygonal particles that are obviously separated by a matrix alloy layer from the center core-shell-structured particle. The EDS results indicate that the polygonal particles, similar to the compound strips in

Figure 13a, are rich in Mg and Ti elements besides containing Al, while the compact shell is rich in Ti and Al, and does not include Mg element (comparing

Figure 13e–h). The quantitative examinations from EDS show that both the strip- (point D in

Figure 13a) and particle-like (point E in

Figure 13e) compounds have the same composition (locations D and E in

Table 8), which is coincident with the composition of Al

18Mg

3Ti

2ternary compound [

37,

38,

39], while the shell-like compound (point F in

Figure 13e) has a Al/Ti atomic ratio of 3:1 (location F in

Table 8), which is just consistent to that of Al

3Ti phase. The XRD results also present that there are two kinds of Ti-containing compounds in this system, Al

18Mg

3Ti

2 and Al

3Ti (

Figure 12). That is, the out polygonal particles are Al

18Mg

3Ti

2 phase and the inner shell is Al

3Ti phase. In view of the relative distribution sites of these two compounds with the Ti core, it can be proposed that the first formed reaction product with Ti was Al

3Ti phase, and then the Al

3Ti phase gradually transformed into Al

18Mg

3Ti

2 phase during the subsequent heating. Namely, the Al

3Ti compound that was first formed during heating at the semisolid temperature is a transitional phase in the Al–Ti–Mg system and the final stable product is the ternary compound of Al

18Mg

3Ti

2. According to this standpoint, it is expected that there should also be an Al

3Ti ring around the Ti core in

Figure 13a, but it may be too thin to see it at the present conditions.

Similar to that at 993 K (720 °C), the preferential formation of Al

3Ti at the semisolid temperature of 893 K (620 °C) is also attributed to the large affinity between Ti and Al atoms for the Al–Ti–Mg system. But, the subsequent transformation of the first formed Al

3Ti into Al

18Mg

3Ti

2 phase should be resulted from the smaller thermostability of Al

3Ti than that of Al

18Mg

3Ti

2. The existing investigations indicated that the reaction product between solid Ti particles and Al–Mg matrix alloys was the unique Al

3Ti phase at above liquidus temperatures of the Al–Mg matrix alloys, but an Al

18Mg

3Ti

2 phase ring gradually formed around the Al

3Ti particles during annealing treatments at 723–820 K (450–547 °C), and all of the Al

3Ti particles would completely transform into the Al

18Mg

3Ti

2 particles after being enough annealed [

37,

38,

39]. In addition, during laser-welding of AZ31B Mg alloy and 6061 Al alloy using pure Ti interlayer, a small amount of Al

18Mg

3Ti

2 phase generated at the edge regions of the interfacial layer close to AZ31B alloy and the other regions were occupied by Al

3Ti phase [

40].This implies that Al

18Mg

3Ti

2 phase only formed in the edge regions in which the temperatures were relatively low, while Al

3Ti phase generated in the central regions with high temperatures during welding. This also indicates that the thermostability of Al

3Ti phase is lower than that of Al

18Mg

3Ti

2 phase at low temperatures for the Al–Ti–Mg system.

Figure 13a,d shows that only a small-sized Ti core was left and a larger amount of compounds have generated in the Mg-containing system, regardless of the product morphology. When compared with the other three systems (

Figure 11a–d), it can be found that the acceleration roles to the reaction decrease in a sequence of Mg, Si, Cu, and Zn. That is, Mg also has the largest acceleration role, but the effect of Zn was sharply decreased as compared with that of the liquid-heating state. The acceleration effect of Mg can also be found in the other investigations, both the Ti content and reaction temperature needed for forming Al

3Ti are decreased in Mg-containing Al alloys [

32,

39]. In fact, the acceleration effects of all the four elements were decreased to different degrees at the semisolid states due to the decreased temperatures (comparing the corresponding metallographs in

Figure 11and

Figure 13 with those in

Figure 4).

According to the Al–Zn binary phase diagram, the solubility of Zn in Al solid solution is very large (higher than 80 wt %) [

27]. So it can be expected that Zn atoms in the prematurely formed Zn liquid during the initial stage of partial remelting would subsequently dissolve into the surrounding Al powders, which led the liquid phase amount to decrease, and thus the acceleration affect on the reaction was reduced in a certain time period. But, for the case of liquid-heating state, most of Zn atoms in the first-formed Zn melt did not dissolve into the Al powders because the Al powders should also quickly begin melting due to the high heating temperature (993 K (720 °C)). That is, the effect of the dissolution of Zn atoms on the liquid amount is quite small or the time for maintaining small-amount liquid is very short, and thus its effect on the reaction is also small.

In fact, it is just due to the same reason that the effect of Cu was also obviously decreased at the semisolid temperature of 898 K (625 °C) (comparing

Figure 4b and

Figure 11c), only the decrease range is smaller than that of Zn element. So, it is proposed that the effect of an alloying element on the formation of liquid phase, and thus on the reaction rate is related to its solubility in Al phase and heating temperature. Finally, in view of the morphologies of the reinforcements, it can be found that the desirable core-shell-structured Ti@compound reinforcing particles with compact and thick compound shell only can be achieved during partial remelting of the Al–Ti–Si compact.

In summary, most of the results from the liquid–state experiments are consistent to those from the semisolid state ones except the product phase constituent in the Al–Ti–Mg system and the reaction rate in the Al–Ti–Zn system. The first reaction product with Ti in Al–Ti–Mg system was still Al3Ti phase at the semisolid state, but it then transformed into an Mg–Ti–Al ternary compound of Al18Mg3Ti2 possibly due to its smaller thermostability at this temperature. The reaction rates of all the four systems were obviously decreased at the semisolid states due to the decreased temperatures, but the decrease range in the Al–Ti–Zn system was so large that the resulting reaction rate became smaller than that in the Al–Ti–Cu system. The reason for leading to this result should be contributed to the large solubility of Zn in Al phase. More importantly, the desirable core-shell-structured Ti@compoundp can only be obtained during partial remelting of the Al–Ti–Si compact.