Evaluation of Asphalt Mixture Low-Temperature Performance in Bending Beam Creep Test

Abstract

1. Introduction

1.1. Background

- -

- Comparative classification of asphalt mixtures by determining stiffness and rheological parameters, including elastic moduli and viscosity coefficients. The viscosity coefficient is directly related to the time of relaxation of thermal stresses at low temperatures. Stiffness, on the other hand, is a parameter directly affecting the amount of generated thermal stresses.

- -

- Determination of advanced characteristics of asphalt mixtures for the purpose of modeling asphalt pavement behavior at low temperatures using thermo-viscoelastic models. The material can be modeled with parameters of the rheological model and/or master curves.

- -

- In combination with the strength of the material, the method can be used to calculate thermal stresses in asphalt pavements and predict the probability of thermal cracking at variable cooling rates.

- -

- Development of functional requirements for asphalt mixtures in the field of resistance to low-temperature cracking according to Construction Products Regulations (in the future).

1.2. Objectives

2. Materials and Methods

2.1. Materials

2.1.1. Bitumens

2.1.2. Asphalt Mixtures

2.2. Methods

2.2.1. Bending Beam Rheometer Test for Bitumen Testing

2.2.2. Bending Beam Creep Test for Asphalt Mixtures

2.2.3. Determination of the Low-Temperature Rheological Properties of Asphalt Mixtures

2.2.4. Validation of the Bending Beam Creep Test for Asphalt Mixtures

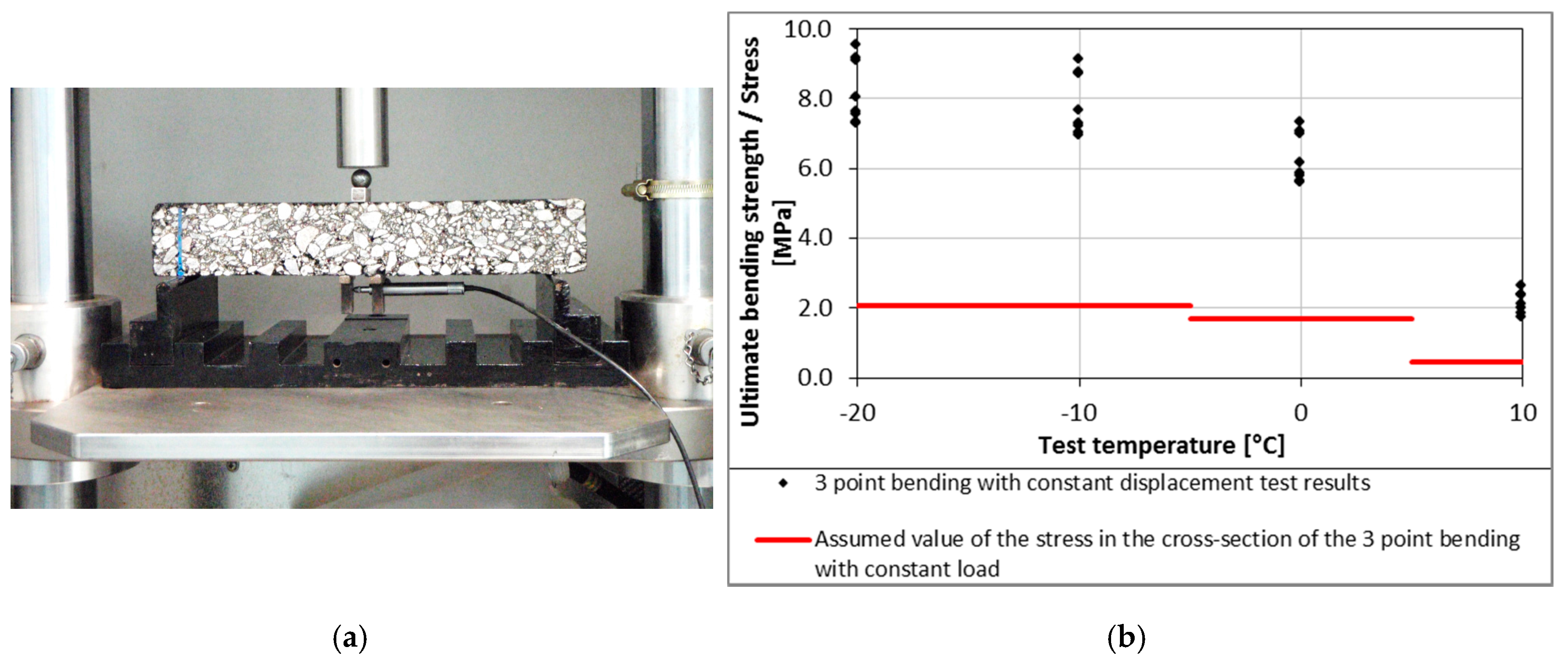

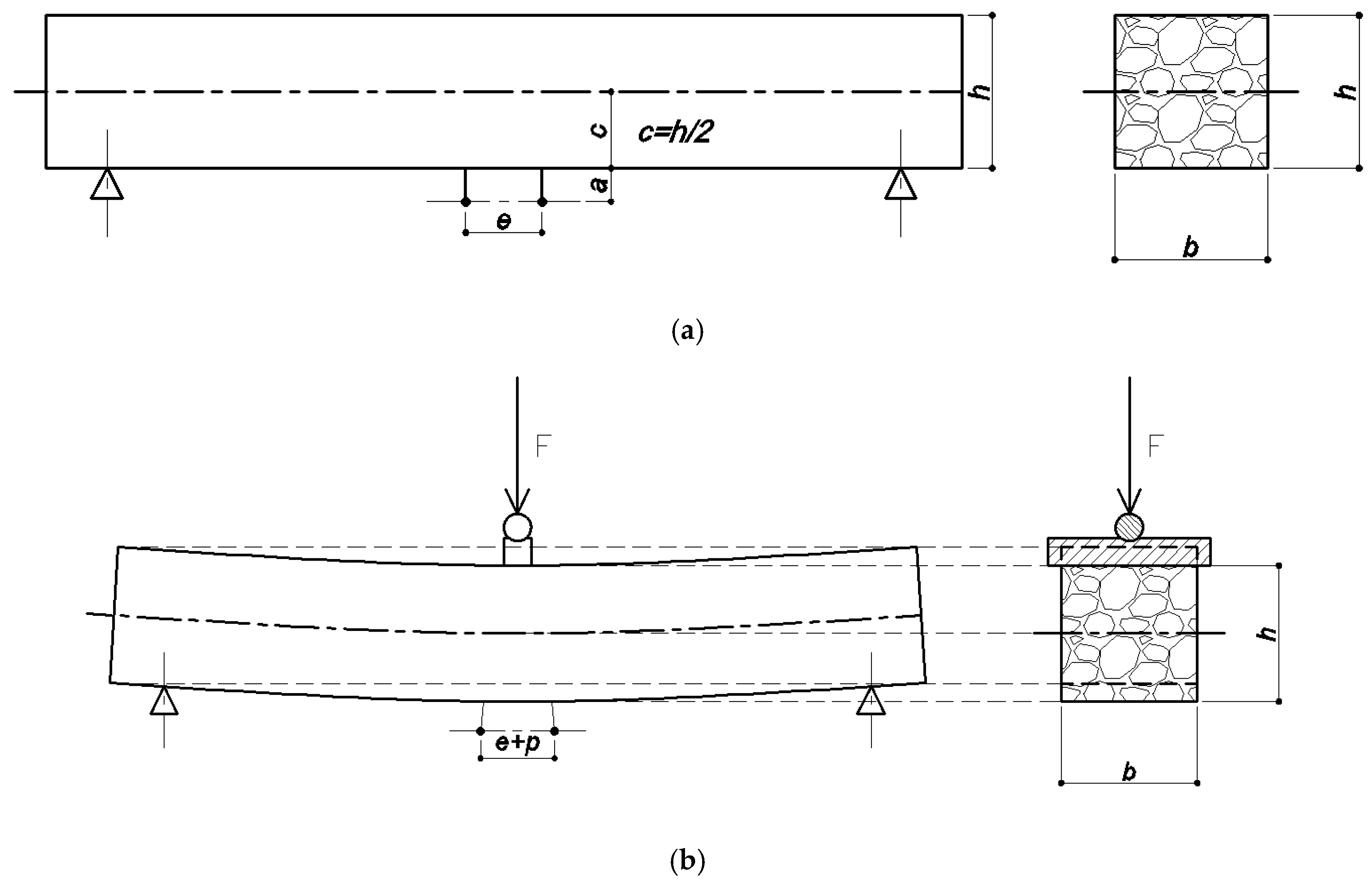

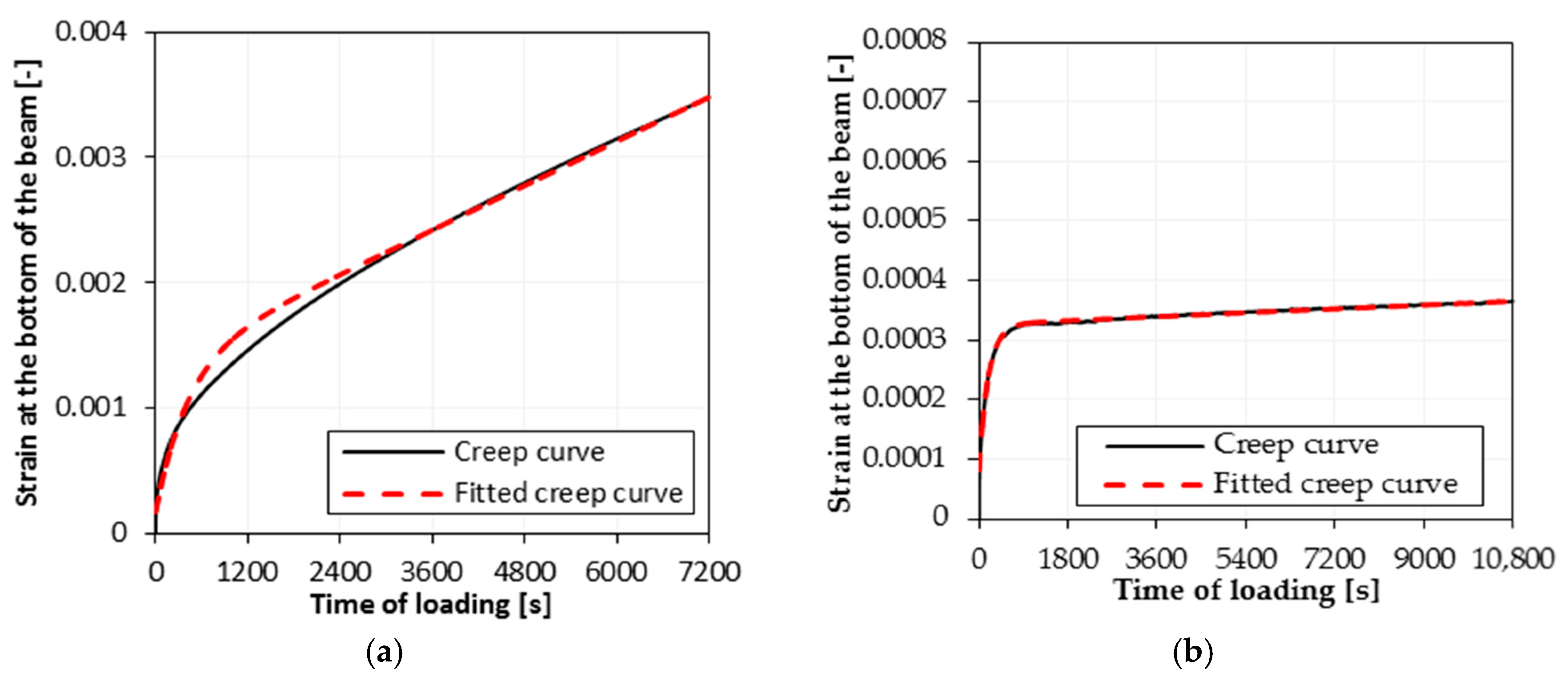

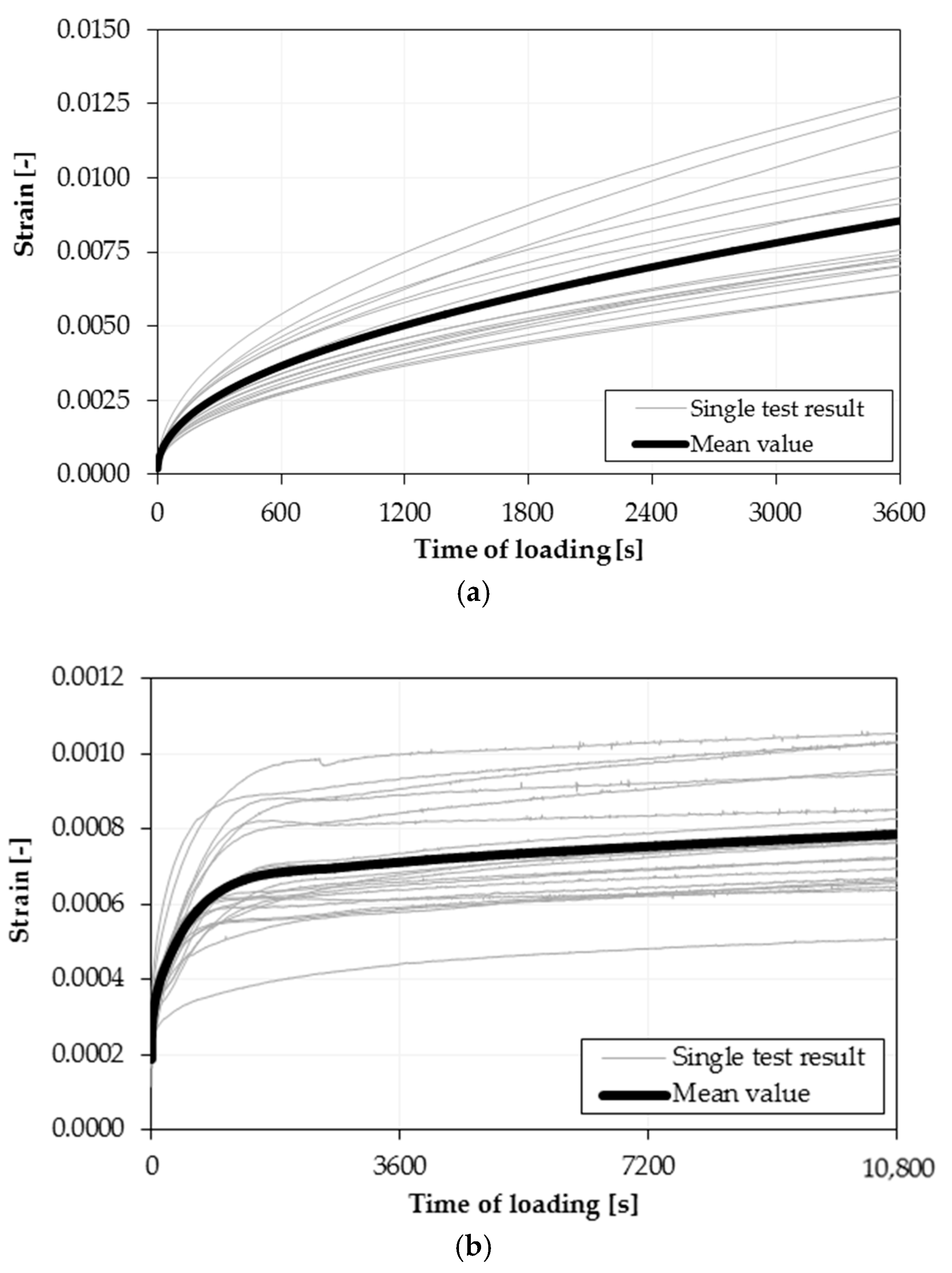

3. Results

4. Discussion

4.1. Analysis of the Burgers Rheological Properties of Aspfalt Mixtures

4.2. The Influence of the Mixture and Bitumen Properties on the Low-Temperature Behavior of Asphalt Mixtures

4.3. Relationship between Results Obtained from Bending Beem Creep Test of Asphalt Mixtures and Asphalt Binders

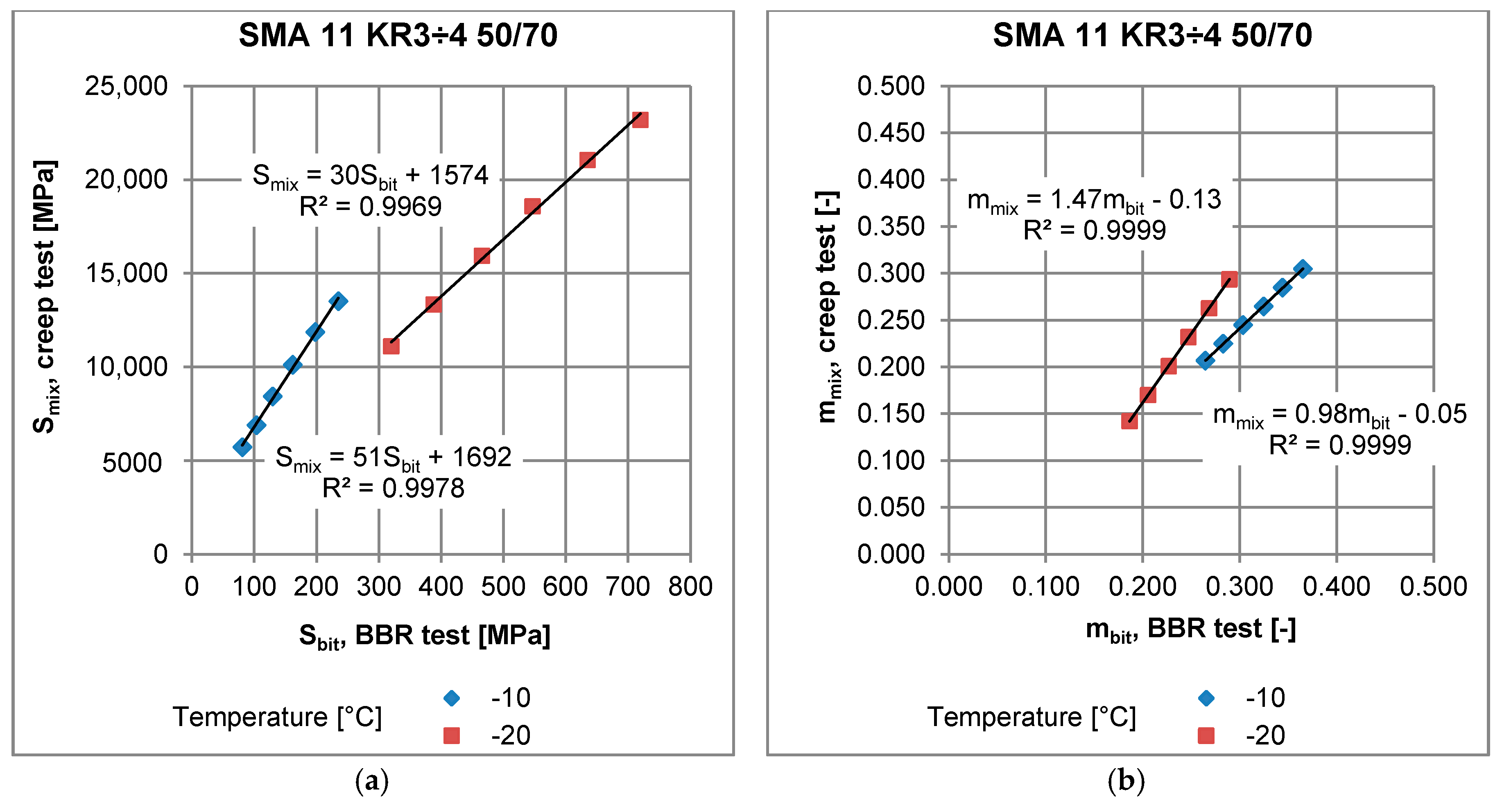

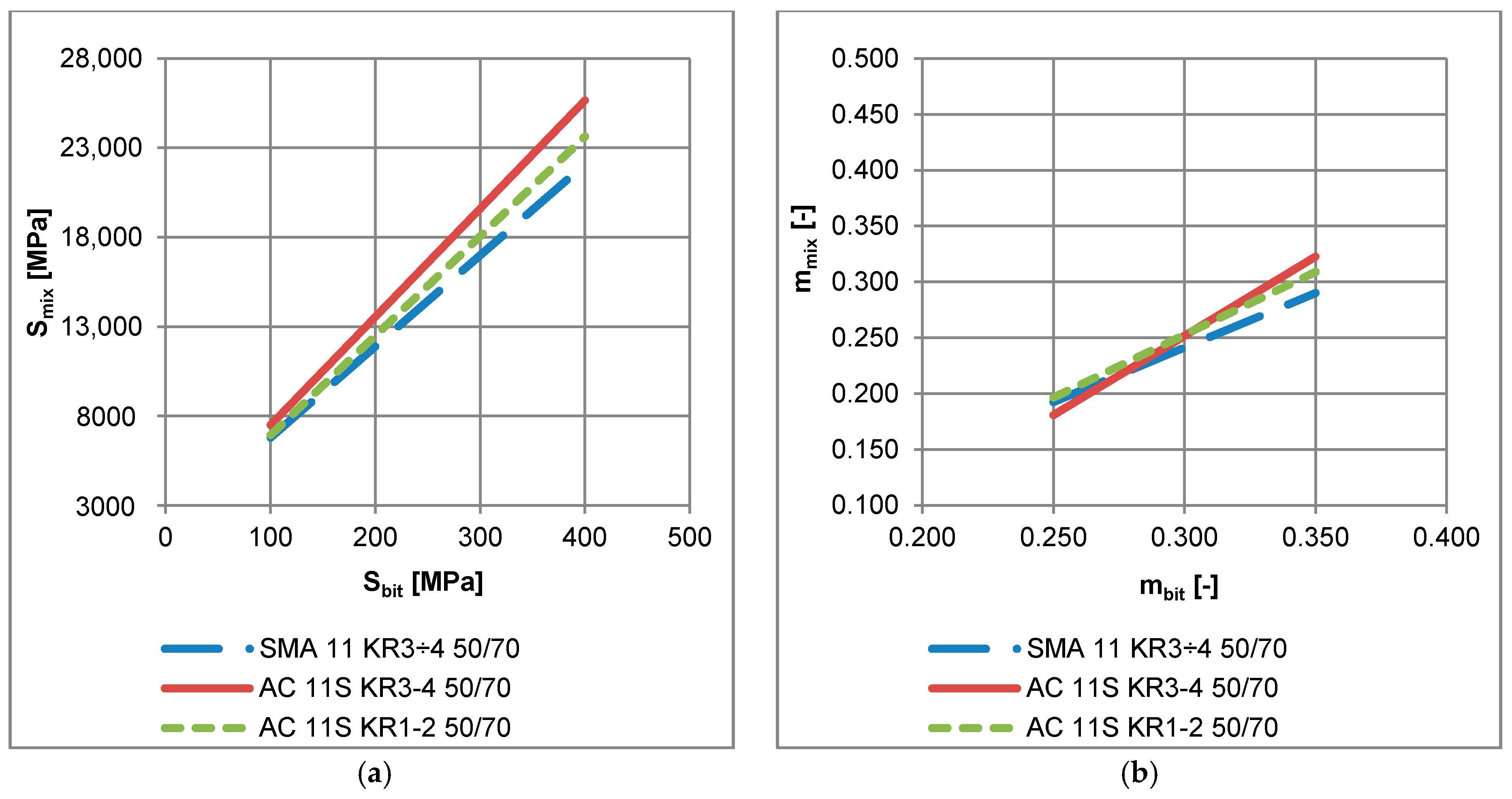

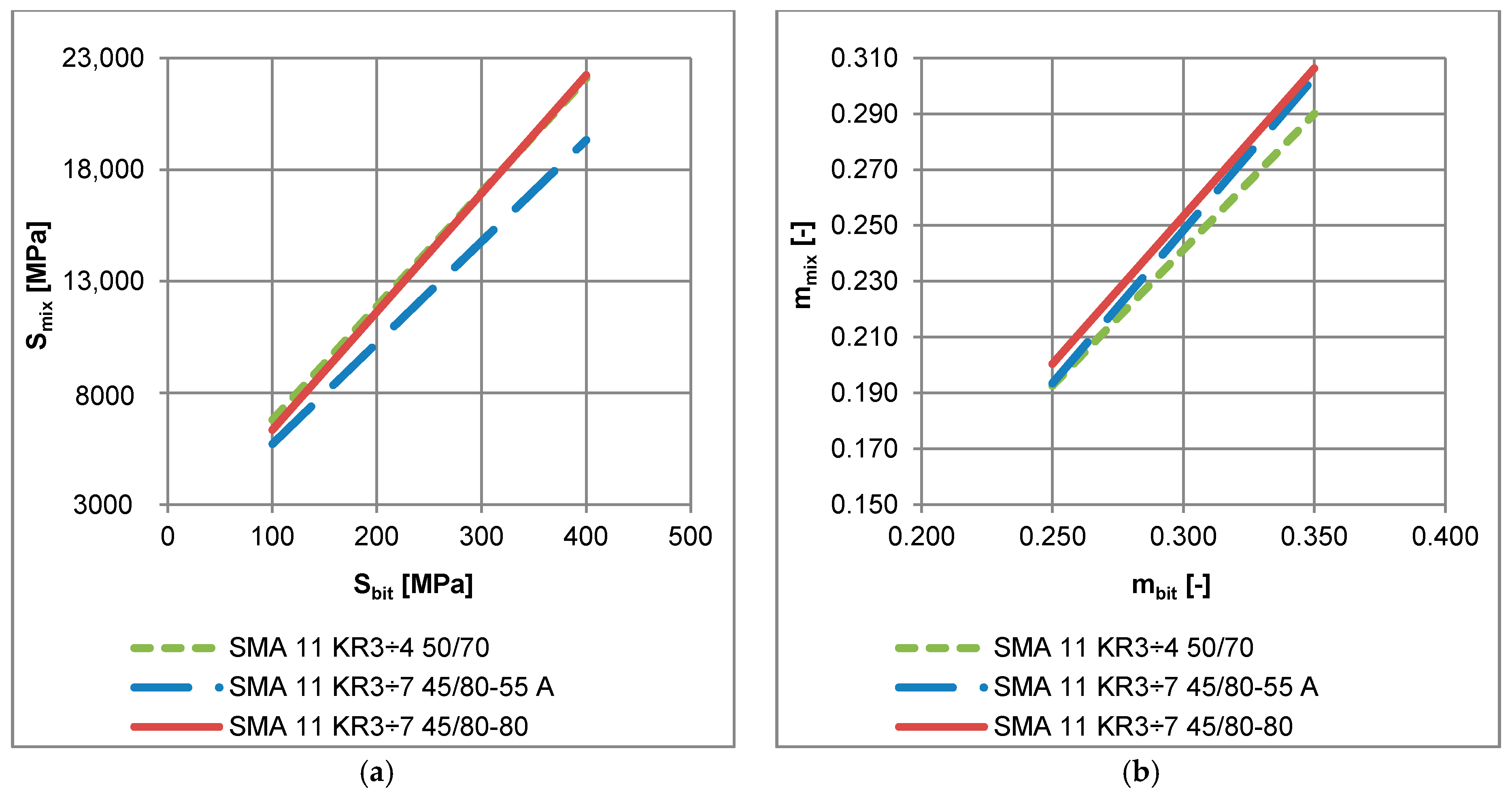

- Smix—stiffness modulus of asphalt mixture obtained from the Bending Beam Creep test;

- Sbit—stiffness modulus of asphalt binder obtained from the BBR test;

- mmix—slope of creep curve of asphalt mixture obtained from the Bending Beam Creep test;

- mbit—slope of creep curve of asphalt binder obtained from the BBR test;

- aS, bS, am, bm—regression parameters for a given mixture and test temperature, presented in Table 6.

5. Summary and Conclusions

- The impact of the asphalt mix composition and properties of the asphalt binder on the low-temperature viscoelastic properties of the asphalt mixture was analyzed and discussed in the paper. The three-point bending beam test of asphalt mixtures was used after detailed validation.

- The three-point bending beam test of asphalt mixtures was used to determine the low-temperature performance of asphalt mixtures. The performance was evaluated by means of master curves of stiffness modulus, viscoelastic parameters and regression parameters between binder and mixture properties at low temperature. Results obtained from both validation and main test presented highly accurate results. The average coefficient of variation for the validation and main test was in the range from 5 to 25%.

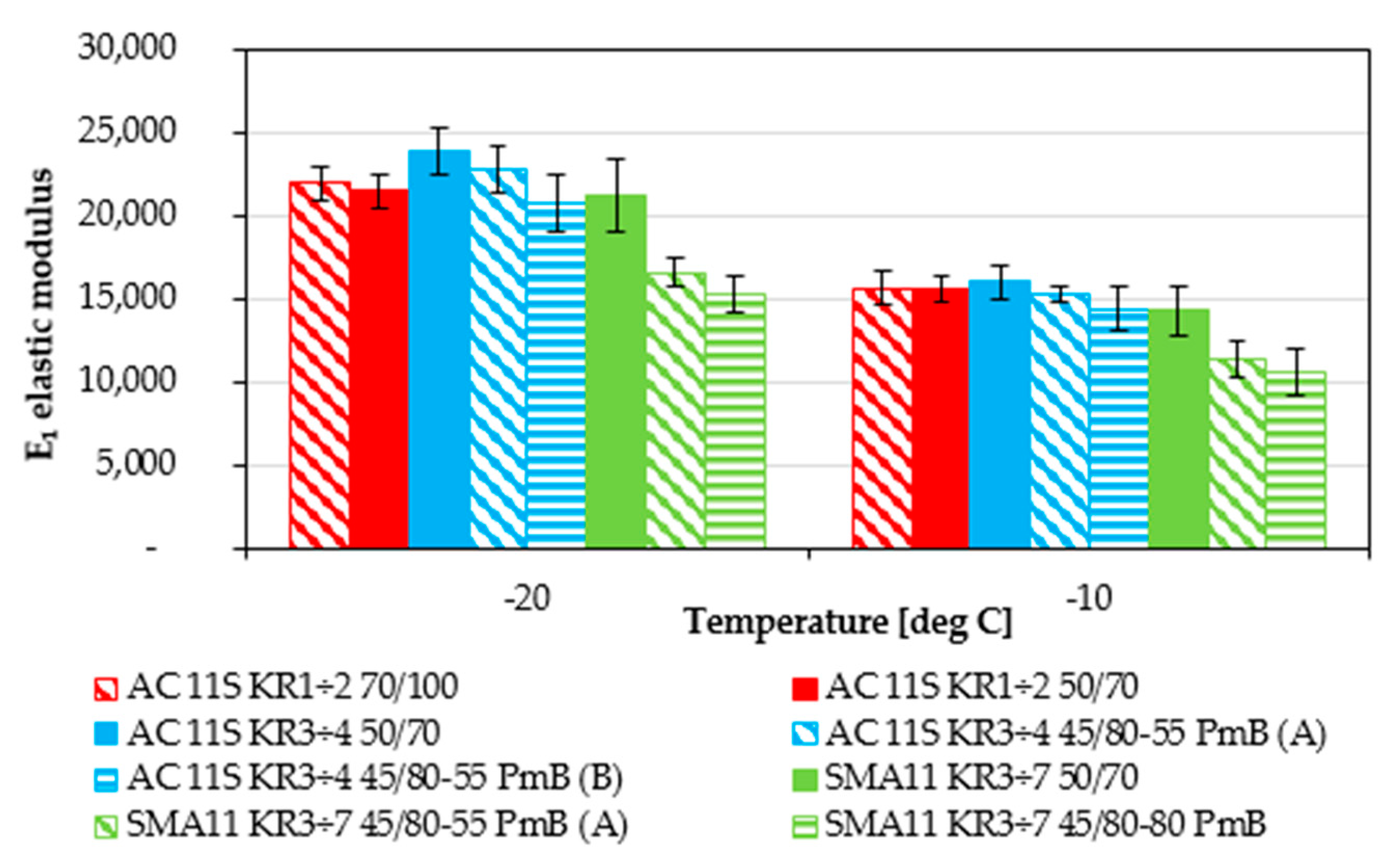

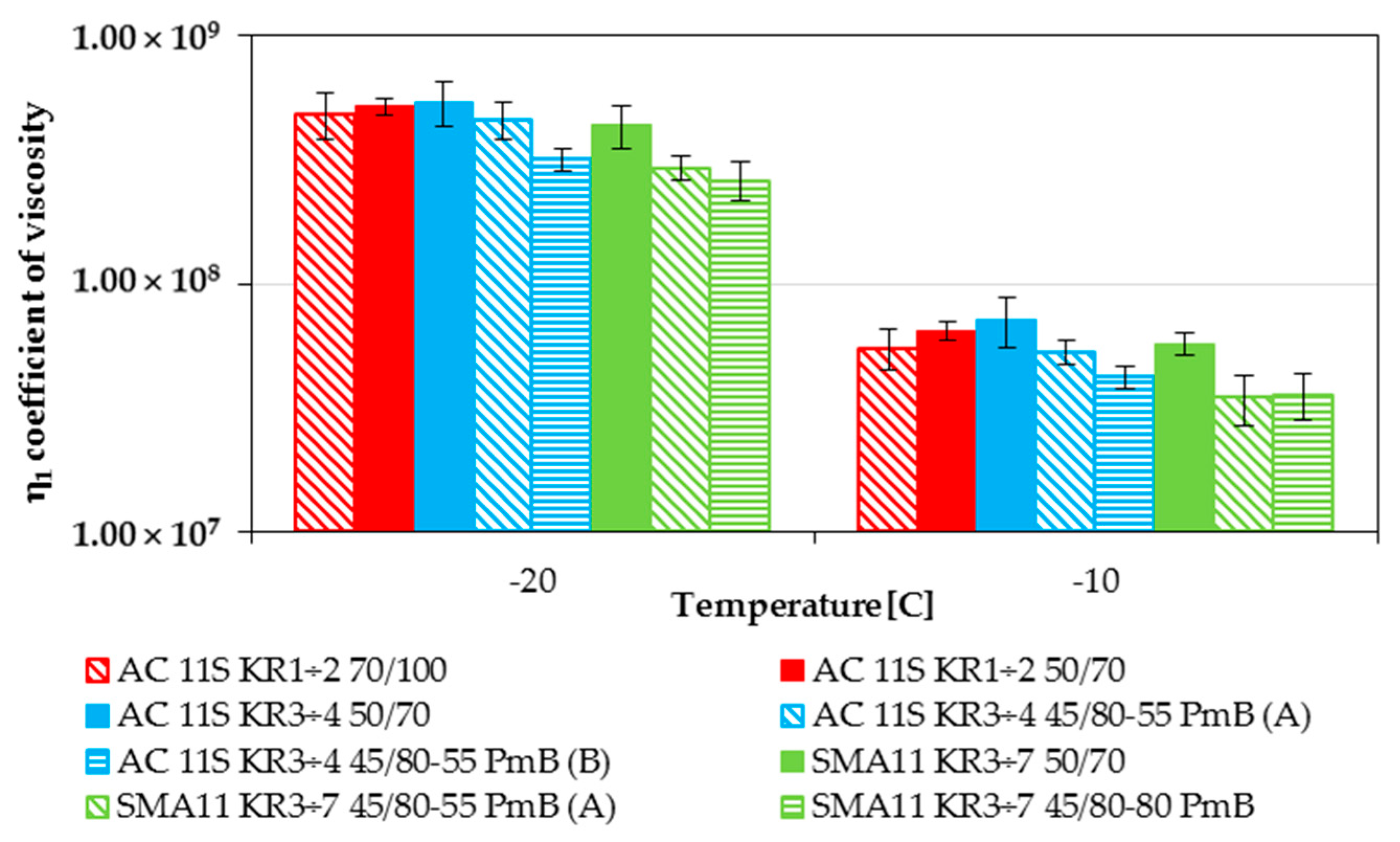

- The Burgers model parameters E1, E2, η1, η2 were used to characterize the viscoelastic behavior of asphalt mixtures. An increase in modulus E1 causes an increase in tensile stresses during cooling of the asphalt layer and contributes to an increase in the number of low-temperature cracks. Lower values of η1 are more desirable, as they indicate faster relaxation of thermal stresses induced in the asphalt layer.

- SMA 11 with polymer-modified bitumen 45/80-55 and 45/80-80 presented the best low-temperature performance expressed by the lowest values of E1 and η1 in comparison with remaining mixtures: AC 11 with neat and modified bitumens and SMA 11 with neat bitumen 50/70. Promising η1 values were also presented by the AC 11S mixture with one of the polymer-modified bitumens 45/80-55.

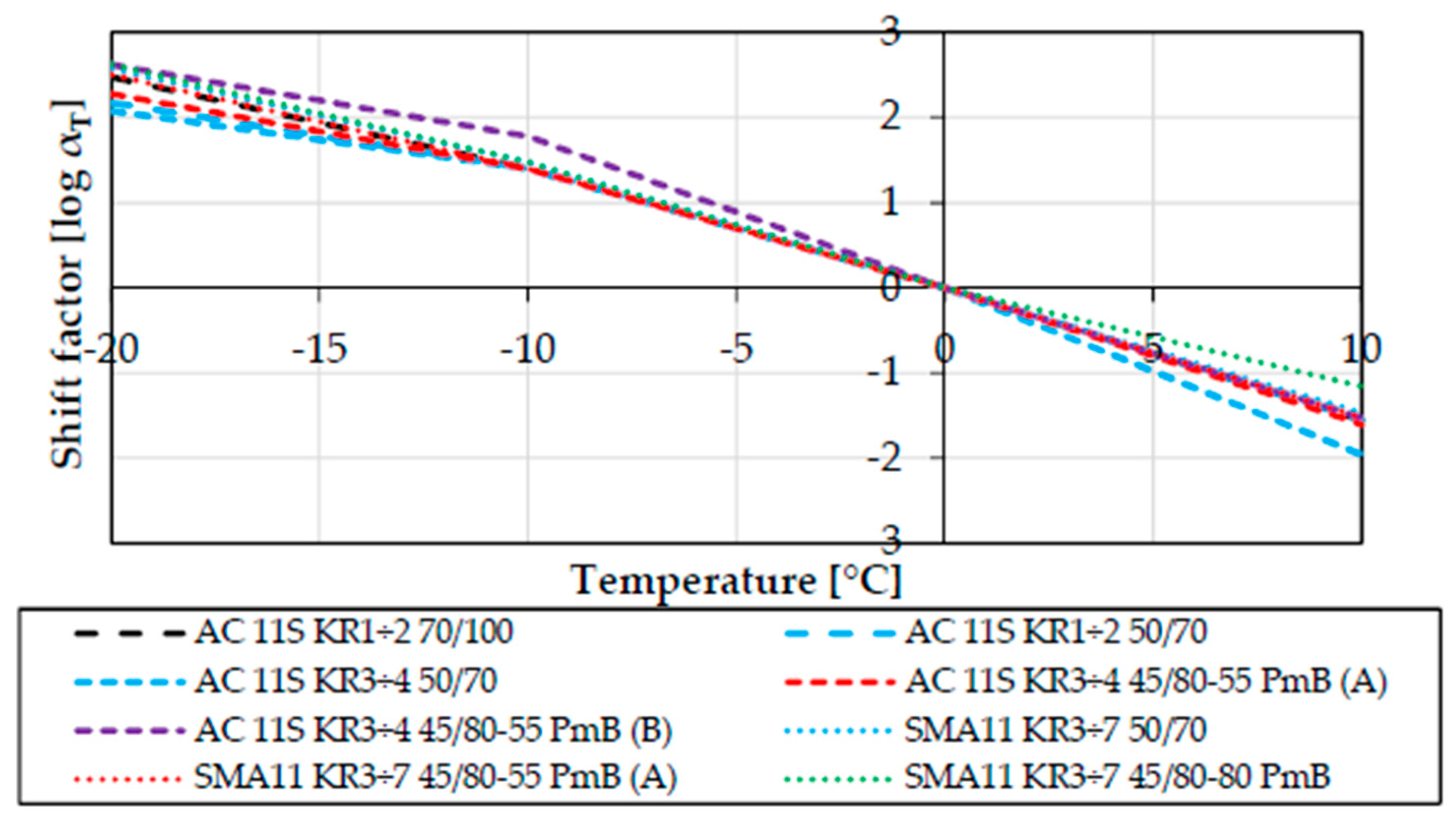

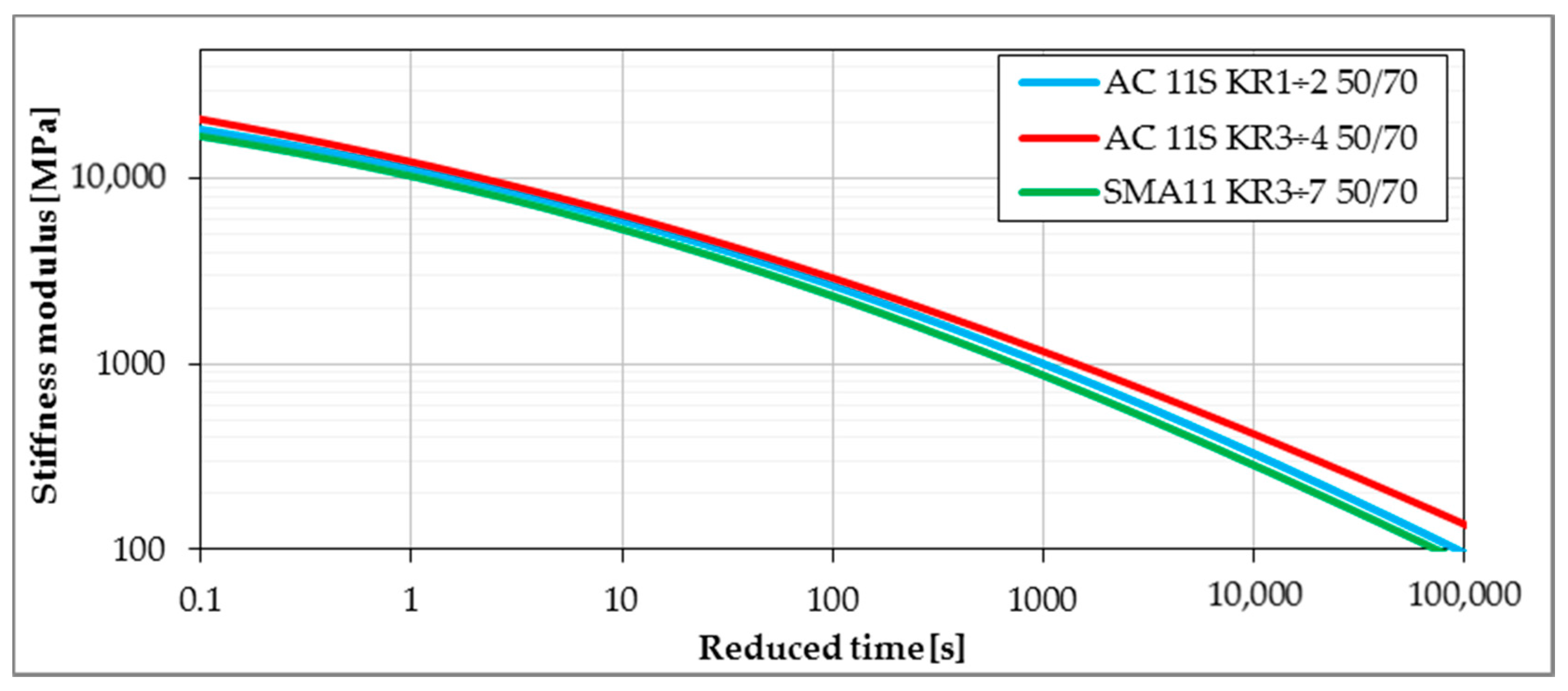

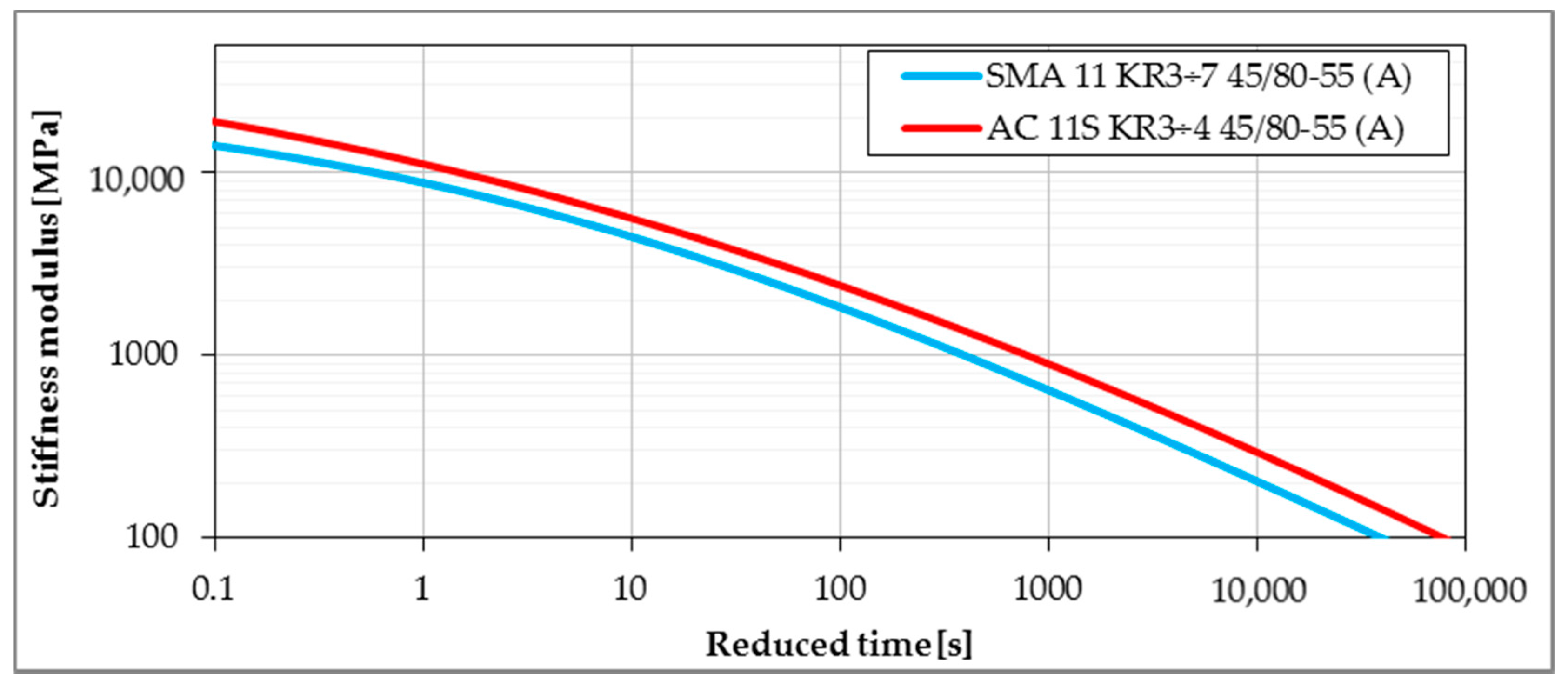

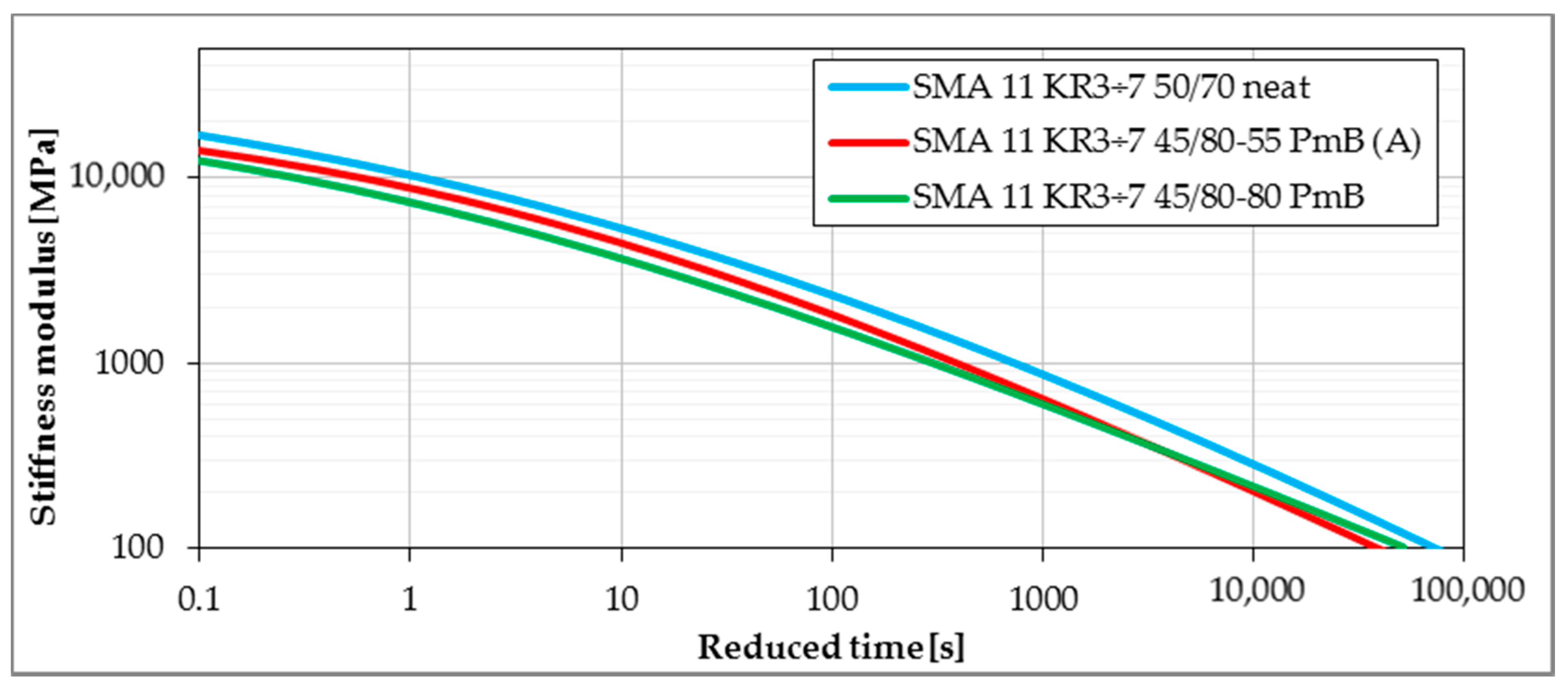

- The analysis of master curves of stiffness modulus indicates that the source of the bitumen as well as the modification process both have a strong impact on low-temperature performance of the asphalt mixture. While both modified bitumens 45/80-55 presented lower values of the stiffness moduli in comparison with the reference mixture with 50/70 neat bitumen, the difference between bitumens from two different refineries was much larger than in the case of other mixture aspects.

- Mixture type and the level of modification of the bitumen had an impact on the low-temperature performance of the tested mixtures as well. The best performance was observed for the SMA mixtures. A higher polymer content improved the low-temperature performance as well.

- The conducted tests showed that the impact of the source of bitumen and its production process (and not necessarily bitumen penetration) on the low-temperature performance of the asphalt mixture is comparable to the impact of mixture type and the impact of polymer content in the binder.

- Both stiffness moduli and m-values of bitumen and asphalt mixtures were obtained at the same times after load application: 8, 15, 30, 60, 120 and 240 s. Results are given for two test temperatures: −10 °C and −20 °C. The results obtained from the bending beam test for asphalt mixtures are very well correlated with those obtained for asphalt binders from the BBR test with coefficient of determination R2 > 0.99.

- The analysis of viscoelastic parameters, master curves and correlations between binder and mixture stiffness and m-value indicates that the same asphalt binder applied in different asphalt mixtures can provide different low-temperature performances of the asphalt mixture. This indicates that analysis based solely on bitumen testing will not evaluate the low-temperature performance appropriately.

- The bending beam creep test method can be applied in development of functional requirements for asphalt mixtures in the field of resistance to low-temperature cracking according to Construction Products Regulations (in the future).

- -

- The test is long and time-consuming; however, previous tests have confirmed that at low temperatures, it is necessary to take into consideration longer load times, such as 10,800 s.

- -

- Sample dimensions and scale effect. Asphalt mixtures with maximum grain size reaching 16 mm and more require a larger sample dimensions.

- -

- There is a complex state of stresses in the pavement under the influence of low temperatures. The bending beam creep test does not directly represent the tensile stresses generated in asphalt mixtures at low temperatures.

- -

- In order to prepare the criteria for asphalt mixture resistance to low-temperature cracking, it is necessary to carry out field assessment and calibration of the method—this subject will be addressed in further research.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Marasteanu, M.; Zofka, A.; Turos, M.; Li, X.; Velasquez, R.; Xue, L.; Buttlar, W.; Paulino, G.; Braham, A.; Dave, E.; et al. Investigation of Low Temperature Cracking in Asphalt Pavements. A Transportation Pooled Fund Study; Report No MN/RC 2007-43; University of Minnesota: Minneapolis, MN, USA, 2007. [Google Scholar]

- Marasteanu, M.; Buttlar, W.; Bahia, H.; Williams, C. Investigation of Low Temperature Cracking in Asphalt Pavements, National Pooled Fund Study—Phase II; Report No MN/RC 2012-23; University of Minnesota: Minneapolis, MN, USA, 2012. [Google Scholar]

- Vinson, T.S.; Janoo, V.C. Low Temperature and Thermal Fatigue Cracking; Summary Report No SR-OSU-A-003A-89-1; University of California: Berkeley, CA, USA, 1989. [Google Scholar]

- Herb, W.; Velasquez, R.; Stefan, H.; Marasteanu, M.O.; Clyne, T. Simulation and Characterization of Asphalt Pavement Temperatures. Road Mater. Pavement 2009, 10, 233–247. [Google Scholar] [CrossRef][Green Version]

- Pszczoła, M.; Judycki, J.; Ryś, D. Evaluation of pavement temperatures in Poland during winter conditions. Transp. Res. Proc. 2016, 14, 738–747. [Google Scholar] [CrossRef]

- Pucci, T.; Dumont, A.-G.; Di Benedetto, H. Thermomechanical and Mechanical Behaviour of Asphalt Mixtures at Cold Temperature: Road and Laboratory Investigations. Road Mater. Pavement 2004, 5, 45–72. [Google Scholar] [CrossRef]

- Rys, D.; Judycki, J.; Pszczola, M.; Jaczewski, M.; Melun, L. Comparison of low-temperature cracks intensity on pavements with high modulus asphalt concrete and conventional asphalt concrete bases. Constr. Build. Mater. 2017, 147, 478–487. [Google Scholar] [CrossRef]

- Jackson, N.M. Analysis of Thermal Fatigue Distress of Asphalt Concrete Pavements. Ph.D. Thesis, Oregon State University, Corvallis, OR, USA, 1992; p. 188. [Google Scholar]

- Wang, T.; Su, L.; Zhai, J. A case study on diurnal and seasonal variation in pavement temperature. Int. J. Pavement Eng. 2014, 15, 402–408. [Google Scholar] [CrossRef]

- Judycki, J. A new viscoelastic method of calculation of low-temperature thermal stresses in asphalt layers of pavements. Int. J. Pavement Eng. 2016, 19, 24–36. [Google Scholar] [CrossRef]

- Judycki, J. Verification of the new viscoelastic method of thermal stress calculation in asphalt layers of pavements. Int. J. Pavement Eng. 2016, 1–13. [Google Scholar] [CrossRef]

- Mamlouk, M.S.; Zaniewski, J.P. Materials for Civil and Construction Engineers, 2nd ed.; Pearson Prentice Hall, Pearson Education, Inc.: Upper Saddle River, NJ, USA, 2006; ISBN 0-13-147714-5. [Google Scholar]

- Anderson, D.A.; Christensen, D.W.; Bahia, H.U.; Dongre, R.; Sharma, M.G.; Antle, C.E.; Button, J. Binder Characterization and Evaluation; SHRP A-369; Physical Characterization Strategic Highway Research Program National Research Council: Washington, DC, USA, 1994; Volume 3. [Google Scholar]

- American Association of State Highway and Transportation Officials (AASHTO). Standard T313-05, Standard Method of Test for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR), Standard Specifications for Transportation Materials and Methods of Sampling and Testing, 25th ed.; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2005. [Google Scholar]

- American Association of State Highway and Transportation Officials (AASHTO). Standard T314-02, Standard Method of Test for Determining the Fracture Properties of Asphalt Binder in Direct Tension (DT), Standard Specifications for Transportation Materials and Methods of Sampling and Testing, Part 2B: Tests, 22nd ed.; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2002. [Google Scholar]

- Zofka, A.; Marasteanu, M.; Li, X.; Clyne, T.; McGraw, J. Simple Method to Obtain Asphalt Binders Low Temperature Properties from Asphalt Mixtures Properties. J. Assoc. Asph. Pav. 2005, 74, 255–282. [Google Scholar]

- Zofka, A.; Marasteanu, M.; Turos, M. Determination of Asphalt Mixture Creep Compliance at Low Temperatures by Using Thin Beam Specimens. J. Transp. Res. Rec. 2008, 2057, 134–139. [Google Scholar] [CrossRef]

- Velásquez, R.; Zofka, A.; Turos, M.; Marasteanu, M. Bending Beam Rheometer Testing of Asphalt Mixtures. Int. J. Pavement Eng. 2011, 12, 461–474. [Google Scholar] [CrossRef]

- Velásquez, R.; Marasteanu, M.; Turos, M.; Labuz, J. Effect of Beam Size on the Creep Stiffness of Asphalt Mixtures at Low Temperatures. In Proceedings of the 7th International RILEM Symposium ATCBM09 on Advanced Testing and Characterization of Bituminous Materials, Rhodes, Greece, 27–29 May 2009; Loizos, A., Partl, M., Eds.; CRC Press/Balkema: Boca Raton, FL, USA, 2009; pp. 313–322, ISBN 978-0-415-55856-3. [Google Scholar]

- Moon, K.H.; Falchetto, A.C.; Wang, D.; Wistuba, M.P.; Tebaldi, G. Low-temperature performance of recycled asphalt mixtures under static and oscillatory loading. Road Mater. Pavement 2017, 18, 297–314. [Google Scholar] [CrossRef]

- Falchetto, A.C.; Moon, K.H.; Wistuba, M.P. An alternative method for computing thermal stress in asphalt mixture: The Laplace transformation. Road Mater. Pavement 2017, 18, 226–240. [Google Scholar] [CrossRef]

- Falchetto, A.C.; Moon, K.H.; Wistuba, M.P. Development of a simple correlation between bending beam rheometer and thermal stress restrained specimen test low-temperature properties based on a simplified size effect approach. Road Mater. Pavement 2017, 18, 339–351. [Google Scholar] [CrossRef]

- Falchetto, A.C.; Wistuba, M.P.; Marasteanu, M.O. Size effect in asphalt mixture at low temperature: Types I and II. Road Mater. Pavement 2017, 18, 235–257. [Google Scholar] [CrossRef]

- Moon, K.H.; Falchetto, A.C.; Hu, J.W. Investigation of asphalt binder and asphalt mixture low temperature creep properties using semi mechanical and analogical models. Constr. Build. Mater. 2014, 53, 568–583. [Google Scholar] [CrossRef]

- Zofka, A.; Yut, I. Prediction of asphalt creep compliance using artificial neural networks. Arch. Civ. Eng. 2012, 58, 2. [Google Scholar] [CrossRef]

- Ho, C.-H.; González, M.F.M.; Linares, C.P.M. Effect of asphalt thin beams mixed with three nominal maximum aggregate sizes in the bending beam rheometer on the prediction of thermal properties of bituminous material. Front. Struct. Civ. Eng. 2017, 11, 1–7. [Google Scholar] [CrossRef]

- Linares, C.P.M.; Ho, C.-H.; González, M.F.M. Impact of Multi-Scale Asphalt Thin Beams in the Bending Beam Rheometer on the Prediction of Thermal Cracking of Bituminous Material. Procedia Eng. 2016, 161, 235–240. [Google Scholar] [CrossRef][Green Version]

- Gong, X.; Romero, P.; Dong, Z.; Li, Y. Investigation on the low temperature property of asphalt fine aggregate matrix and asphalt mixture including the environmental factors. Constr. Build. Mater. 2017, 156, 56–62. [Google Scholar] [CrossRef]

- Judycki, J. Bending Test of Asphaltic Mixtures under Statical Loading. In Design and Quality Control of Bituminous Mixes, Proceedings of the 4th International Symposium on the Role of Mechanical Tests for the Characterization, Budapest, Hungary, 23–25 October 1990; Book Series: RILEM Proceedings; Taylor & Francis: Oxfordshire, UK, 1990; Volume 8, pp. 207–227. [Google Scholar]

- Pszczola, M.; Judycki, J. Testing of Low Temperature Behaviour of Asphalt Mixtures in Bending Creep Test. In Proceedings of the 7th International RILEM Symposium ATCBM09 on Advanced Testing and Characterization of Bituminous Materials, Rhodes, Greece, 27–29 May 2009; Loizos, A., Partl, M., Eds.; CRC Press/Balkema: Boca Raton, FL, USA, 2009; pp. 303–312, ISBN 978-0-415-55856-3. [Google Scholar]

- Yin, A.; Yang, X.; Yang, S.; Jiang, W. Multiscale Fracture Simulation of Three-Point Bending Asphalt Mixture Beam Considering Material Heterogeneity. Eng. Fract. Mech. 2011, 78, 2414–2428. [Google Scholar] [CrossRef]

- Chen, Y. Creep Tests and Viscoelastic Analysis of Rubber Asphalt Concrete. In Proceedings of the Seventh International Conference on Traffic and Transportation Studies, Kunming, China, 3–5 August 2010; pp. 1371–1377, ISBN 9780784411230. [Google Scholar]

- Jaczewski, M.; Judycki, J.; Jaskuła, P. Modelling of Asphalt Mixes under Long Time Creep at Low Temperatures. Transp. Res. Proc. 2016, 14, 3527–3535. [Google Scholar] [CrossRef]

- Falchetto, A.C.; Moon, K.H. Micromechanical–Analogical Modelling of Asphalt Binder and Asphalt Mixture Creep Stiffness Properties at Low Temperature. Road Mater. Pavement 2015, 16, 111–137. [Google Scholar] [CrossRef]

- Zhao, L.H.; Chen, J.; Wang, S. Viscoelastic Analysis of Asphalt Mixture Based on Creep Test. Res. J. Appl. Sci. Eng. Technol. 2013, 5, 819–822. [Google Scholar]

- Zhao, L.H. Numerical Simulation of the Bending Creep Test for Asphalt Mixture. Adv. Mat. Res. 2012, 446–449, 2608–2612. [Google Scholar] [CrossRef]

- Pszczoła, M.; Jaczewski, M.; Szydłowski, C.; Judycki, J.; Dołżycki, B. Evaluation of Low Temperature Properties of Rubberized Asphalt Mixtures. Procedia Eng. 2017, 172, 897–904. [Google Scholar] [CrossRef]

- American Association of State Highway and Transportation Officials (AASHTO). Standard AASHTO R-28, Standard Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV), Standard Specifications for Transportation Materials and Methods of Sampling and Testing, 25th ed.; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2005. [Google Scholar]

- Polish Technical Guidelines WT-2 2014; The General Directorate for National Roads and Motorways: Warsaw, Poland, 2014.

- American Association of State Highway and Transportation Officials (AASHTO). Standard T313-12, Standard Method of Test for Determining the Flexural Creep Stiffness of Asphalt Binder Using the Bending Beam Rheometer (BBR), Standard Specifications for Transportation Materials and Methods of Sampling and Testing, 25th ed.; American Association of State Highway and Transportation Officials (AASHTO): Washington, DC, USA, 2005. [Google Scholar]

- Judycki, J.; Pszczola, M.; Jaskula, P. The modification of the bending beam creep test for asphalt mixtures and assesment of their rheological parameters. In Proceedings of the VII International Conference, Durable and Safe Pavement Structures, Kielce, Poland, 8–9 May 2001; pp. 91–100. (In Polish). [Google Scholar]

- Anderson, D.A.; Morasteanu, M.O. Physical hardening of asphalt binders relative to their glass transition temperature. Transp. Res. Rec. 1999, 1661, 27–34. [Google Scholar] [CrossRef]

- Hesp, S.A.M.; Iliuta, S.; Shirokoff, J.W. Reversible aging in asphalt binders. Energy Fuel 2007, 21, 1112–1121. [Google Scholar] [CrossRef]

- Togunde, O.P.; Hesp, S.A.M. Physical hardening in asphalt mixtures. Int. J. Pavement Res. Technol. 2012, 5, 46–53. [Google Scholar] [CrossRef]

- Lu, X.; Isacsson, U. Laboratory study on the low temperature physical hardening of conventional and polymer modified bitumens. Constr. Build. Mater. 2000, 14, 79–88. [Google Scholar] [CrossRef]

- Tabatabaee, H.; Mangiafico, S.; Velasquez, R.; Bahia, H.U. Investigation of Low Temperature Cracking in Asph. Pavements; National Pooled Fund Study—Phase II, Task 2, Subtask on Physical Hardening; University of Wisconsin-Madison: Madison, WI, USA, 2010. [Google Scholar]

- Judycki, J. Influence of low-temperature physical hardening on stiffness and tensile strength of asphalt concrete and stone mastic asphalt. Constr. Build. Mater. 2014, 61, 191–199. [Google Scholar] [CrossRef]

- Judycki, J. Analysis of Some Rheological Properties of Asphalt Concrete under Static Loads, (In Polish: Analiza Niektórych Właściwości Reologicznych Drogowego Betonu Asfaltowego Poddanego Działaniu Obciążeń Statycznych). Ph.D. Thesis, Gdansk University of Technology, Gdansk, Poland, 1975. [Google Scholar]

- Di Benedetto, H.; Sauzeat, C.; Bilodeau, K.; Buannic, M.; Mangiafico, S.; Nguyen, Q.T.; Pouget, S.; Tapsoba, N.; Van Rompu, J. General overview of the time-temperature superposition principle validity for materials containing bituminous binder. Int. J. Road Airpt. 2011, 1, 35–52. [Google Scholar] [CrossRef]

- Judycki, J. Non-linear viscoelastic behaviour of conventional and modified asphaltic concrete under creep. Mater. Struct. 1992, 25, 95–101. [Google Scholar] [CrossRef]

- Ferry, J.D. Viscoelastic Properties of Polymers, 3rd ed.; John Wiley & Sons: New York, NY, USA, 1980. [Google Scholar]

- Monismith, C.L.; Alexander, R.L.; Secor, K.E. Rheological Behavior of Asphalt Concrete. J. Assoc. Asph. Pav. 1966, 35, 400–450. [Google Scholar]

- Mitchell, M.R.; Link, R.E.; Zofka, A.; Yut, I. Alternative procedure for determination of hot mix asphalt creep compliance. J. Test. Eval. 2011, 39, 102760. [Google Scholar] [CrossRef]

- Marasteanu, M.O.; Anderson, D.A. Improved Model for Bitumens Rheological Characterization. In Proceedings of the Eurobitume Workshop on Performance-Related Properties for Bituminous Binders, Kirchberg, Luxembourg, 3–6 May 1999. Paper No. 133. [Google Scholar]

- Mazurek, G. The Viscoelastic Characteristics of the Asphalt Concrete Modified with Different Synthetic Waxes Using a Modified Huet-Sayegh Model. In Proceedings of the 10th International Conference Environmental Engineering, Vilnius, Lithuania, 27–28 April 2017. [Google Scholar] [CrossRef]

- Mazurek, G.; Iwanski, M. Modelling of Asphalt Concrete Stiffness in the Linear Viscoelastic Region. In Proceedings of the World Multidisciplinary Civil Engineering-Architecture-Urban Planning Symposium—WMCAUS, Prague, Czech Republic, 12–16 June 2017. [Google Scholar] [CrossRef]

- Rowe, G.M.; Sharrock, M.J. Alternate shift factor relationship for describing the temperature dependency of the visco-elastic behaviour of asphalt materials. Transp. Res. Rec. 2011, 2207, 125–135. [Google Scholar] [CrossRef]

- Olard, F.; Di Benedetto, H. General “2S2P1D” Model and Relation between the Linear Viscoelastic Behaviours of Bituminous Binders and Mixes. Road Mater. Pavement 2003, 4, 185–224. [Google Scholar] [CrossRef]

| Property | Type of Bitumen | |||||

|---|---|---|---|---|---|---|

| 70/100 | 50/70 | 45/80-55A | 45/80-55B | 45/80-80 | ||

| Penetration at 25 °C, 0.1 mm, acc. to PN-EN 1426 | Original | 81 | 54 | 61 | 60 | 53 |

| RTFOT | 48 | 40 | 41 | 40 | 40 | |

| Ring & Ball (R&B) Temperature, °C, acc. to PN-EN 1427 | Original | 47.8 | 50.8 | 63.0 | 68.6 | 78.8 |

| RTFOT | 53.4 | 57.8 | 61.5 | 67.4 | 87.8 | |

| Performance Grade, acc. to AASHTO M 320 | 58–22 | 64–22 | 70–22 | 76–22 | 82–22 | |

| Limit temperature in BBR test, °C, | LST for S = 300 | −17 | −16 | −17 | −19 | −26 |

| LmT for m = 0.300 | −15 | −13 | −13 | −16 | −12 | |

| Properties | Type of Mixtures | ||

|---|---|---|---|

| Asphalt Mixture | AC 11 S KR1-2 | AC 11 S KR3-4 | SMA 11 KR3-7 |

| Type of layer | wearing course | wearing course | wearing course |

| Type of traffic | low | medium | medium and high |

| Bitumen types | 70/100 50/70 | 50/70 45/80-55A 45/80-55B | 50/70 45/80-55A 45/80-80 |

| Binder content (% by mass) | 5.8 | 5.6 | 6.5 |

| Aggregate type | crushed gravel | crushed granite | crushed granite |

| Filler type | limestone | limestone | limestone |

| Sieve size (mm) | % Passing (by mass) | ||

| 16 | 100 | 100 | 100 |

| 11.2 | 97 | 98 | 95 |

| 8 | 83 | 77 | 55 |

| 5.6 | 71 | 62 | 39 |

| 4 | 60 | 52 | 32 |

| 2 | 40 | 39 | 24 |

| 0.125 | 11 | 11 | 13 |

| 0.063 | 8 | 7.2 | 9.6 |

| Mixture Type | Bitumen Type | Temp. (°C) | Burgers Model Parameters | |||

|---|---|---|---|---|---|---|

| E1 (Mpa) | E2 (Mpa) | η1 (MPa⋅s) | η2 (MPa⋅s) | |||

| AC 11S KR1-2 | 50/70 | −20 | 21,982 | 7859 | 4.84 × 108 | 3.54 × 106 |

| −10 | 15,655 | 4735 | 5.50 × 107 | 1.40 × 106 | ||

| 0 | 10,665 | 892 | 3.15 × 106 | 4.17 × 105 | ||

| +10 | 5819 | 157 | 3.98 × 105 | 4.59 × 104 | ||

| 70/100 | −20 | 21,531 | 9987 | 5.21 × 108 | 2.81 × 106 | |

| −10 | 15,582 | 5421 | 6.49 × 107 | 1.49 × 106 | ||

| 0 | 10,023 | 1165 | 4.35 × 106 | 5.00 × 105 | ||

| +10 | 4957 | 220 | 5.16 × 105 | 6.49 × 104 | ||

| AC 11S KR3-4 | 50/70 | −20 | 23,897 | 10,032 | 5.41 × 108 | 2.53 × 106 |

| −10 | 16,009 | 5719 | 7.14 × 107 | 1.75 × 106 | ||

| 0 | 10,288 | 1357 | 5.34 × 106 | 5.52 × 105 | ||

| +10 | 5129 | 183 | 4.68 × 105 | 5.80 × 104 | ||

| 45/80-55 PmB (A) | −20 | 22,735 | 8496 | 4.60 × 108 | 3.06 × 106 | |

| −10 | 15,331 | 4839 | 5.29 × 107 | 1.63 × 106 | ||

| 0 | 10,325 | 983 | 3.85 × 106 | 5.26 × 105 | ||

| +10 | 5134 | 174 | 4.79 × 105 | 5.40 × 104 | ||

| 45/80-55 PmB (B) | −20 | 20,728 | 9885 | 3.18 × 108 | 2.34 × 106 | |

| −10 | 14,422 | 3975 | 4.22 × 107 | 1.44 × 106 | ||

| 0 | 8444 | 584 | 2.99 × 106 | 2.79 × 105 | ||

| +10 | 4576 | 146 | 5.34 × 105 | 4.18 × 104 | ||

| SMA 11 KR3-7 | 50/70 | −20 | 21,270 | 12,022 | 4.36 × 108 | 3.58 × 106 |

| −10 | 14,291 | 5326 | 5.71 × 107 | 1.65 × 106 | ||

| 0 | 8597 | 980 | 3.80 × 106 | 4.52 × 105 | ||

| +10 | 5408 | 218 | 4.94 × 105 | 6.26 × 104 | ||

| 45/80-55 PmB (A) | −20 | 16,609 | 10,080 | 2.95 × 108 | 3.35 × 106 | |

| −10 | 11,332 | 3700 | 3.48 × 107 | 1.44 × 106 | ||

| 0 | 8323 | 698 | 2.67 × 106 | 3.55 × 105 | ||

| +10 | 6387 | 134 | 3.57 × 105 | 4.04 × 104 | ||

| 45/80-80 PmB | −20 | 15,230 | 8879 | 2.62 × 108 | 3.04 × 106 | |

| −10 | 10,569 | 3262 | 3.57 × 107 | 1.20 × 106 | ||

| 0 | 6454 | 664 | 2.89 × 106 | 2.91 × 105 | ||

| +10 | 4422 | 218 | 7.69 × 105 | 5.82 × 104 | ||

| Mixture Type | Bitumen Type | Richards Model Parameters | ||||

|---|---|---|---|---|---|---|

| Max | β | γ | δ | λ | ||

| AC 11S KR1-2 | 50/70 | 4.873 | −9.323 | −0.329 | 0.455 | 0.0004 |

| 70/100 | 4.745 | −8.557 | −0.372 | 0.844 | 0.0009 | |

| AC 11S KR3-4 | 50/70 | 5.155 | −10.746 | −0.271 | 0.146 | 0.0001 |

| 45/80-55 PmB (A) | 4.929 | −10.457 | −0.329 | 0.642 | 0.0001 | |

| 45/80-55 PmB (B) | 4.932 | −10.382 | −0.332 | 1.211 | 0.0001 | |

| SMA 11 KR3-7 | 50/70 | 4.811 | −10.931 | −0.346 | 0.741 | 0.0001 |

| 45/80-55 PmB (A) | 4.628 | −11.085 | −0.399 | 1.050 | 0.0001 | |

| 45/80-80 PmB | 4.694 | −10.881 | −0.359 | 1.252 | 0.0001 | |

| Mixture Type | Bitumen Type | Flexural Strength | ||

|---|---|---|---|---|

| Mean (MPa) | Standard Deviation (MPa) | Coefficient of Variation (%) | ||

| AC 11S KR1-2 | 50/70 | 7.35 | 0.81 | 11.00 |

| 70/100 | 7.63 | 0.54 | 7.13 | |

| AC 11S KR3-4 | 50/70 | 7.57 | 0.60 | 7.92 |

| 45/80-55 PmB (A) | 9.19 | 0.35 | 3.82 | |

| 45/80-55 PmB (B) | 9.13 | 0.54 | 5.88 | |

| SMA 11 KR3-7 | 50/70 | 7.29 | 0.63 | 8.67 |

| 45/80-55 PmB (A) | 8.05 | 0.84 | 10.38 | |

| 45/80-80 PmB | 9.55 | 1.25 | 13.08 | |

| Type of Asphalt Mixture and Bitumen | Regression Parameters for Stiffness Modulus at Temperature | Regression Parameters for m-Value at Temperature | ||||||

|---|---|---|---|---|---|---|---|---|

| −10 °C | −20 °C | −10 °C | −20 °C | |||||

| aS | bS | aS | bS | am | bm | am | bm | |

| SMA 11 KR3-4 50/70 | 51 | 1692 | 30 | 1574 | 0.98 | −0.05 | 1.47 | −0.13 |

| SMA 11 KR3-7 45/80-55 A | 45 | 1177 | 24 | 2038 | 1.10 | −0.08 | 1.66 | −0.19 |

| SMA 11 KR3-7 45/80-80 | 53 | 1040 | 29 | 2101 | 1.06 | −0.06 | 1.47 | −0.15 |

| AC 11S KR1-2 70/100 | 55 | 1942 | 31 | 1931 | 0.97 | −0.06 | 2.56 | −0.38 |

| AC 11S KR1-2 50/70 | 56 | 1370 | 32 | −715 | 1.12 | −0.08 | 1.90 | −0.20 |

| AC 11S KR3-4 50/70 | 61 | 1428 | 37 | −1944 | 1.42 | −0.17 | 2.30 | −0.27 |

| AC 11S KR3-4 45/80-55 A | 59 | 1414 | 37 | −928 | 1.05 | −0.06 | 2.31 | −0.29 |

| AC 11S KR3-4 45/80-55 B | 65 | 1292 | 39 | −163 | 1.17 | −0.10 | 1.86 | −0.21 |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pszczola, M.; Jaczewski, M.; Rys, D.; Jaskula, P.; Szydlowski, C. Evaluation of Asphalt Mixture Low-Temperature Performance in Bending Beam Creep Test. Materials 2018, 11, 100. https://doi.org/10.3390/ma11010100

Pszczola M, Jaczewski M, Rys D, Jaskula P, Szydlowski C. Evaluation of Asphalt Mixture Low-Temperature Performance in Bending Beam Creep Test. Materials. 2018; 11(1):100. https://doi.org/10.3390/ma11010100

Chicago/Turabian StylePszczola, Marek, Mariusz Jaczewski, Dawid Rys, Piotr Jaskula, and Cezary Szydlowski. 2018. "Evaluation of Asphalt Mixture Low-Temperature Performance in Bending Beam Creep Test" Materials 11, no. 1: 100. https://doi.org/10.3390/ma11010100

APA StylePszczola, M., Jaczewski, M., Rys, D., Jaskula, P., & Szydlowski, C. (2018). Evaluation of Asphalt Mixture Low-Temperature Performance in Bending Beam Creep Test. Materials, 11(1), 100. https://doi.org/10.3390/ma11010100