Influence of Hot Rolling and Heat Treatment on the Microstructural Evolution of β20C Titanium Alloy

Abstract

:1. Introduction

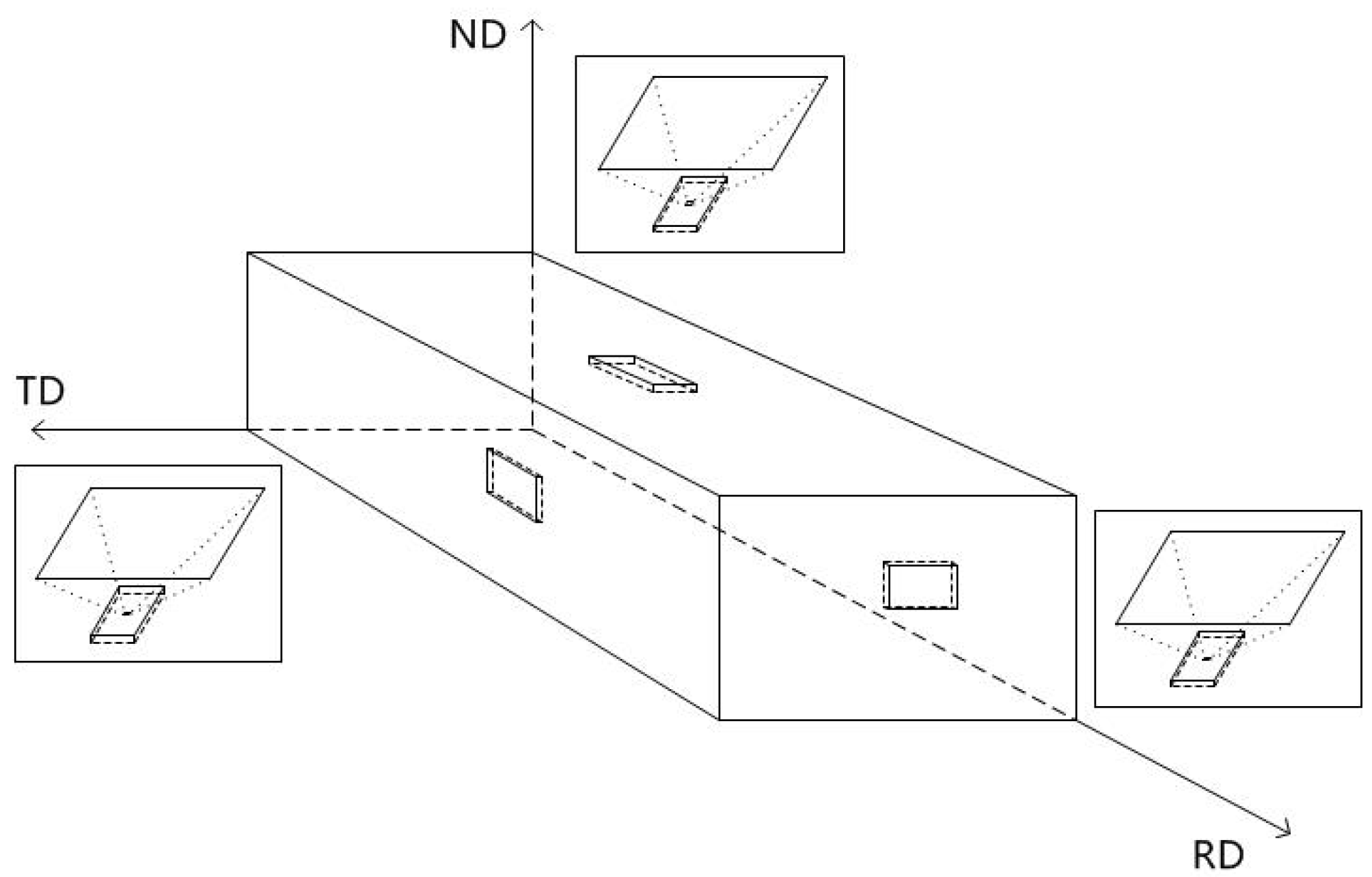

2. Experimental

3. Results and Discussion

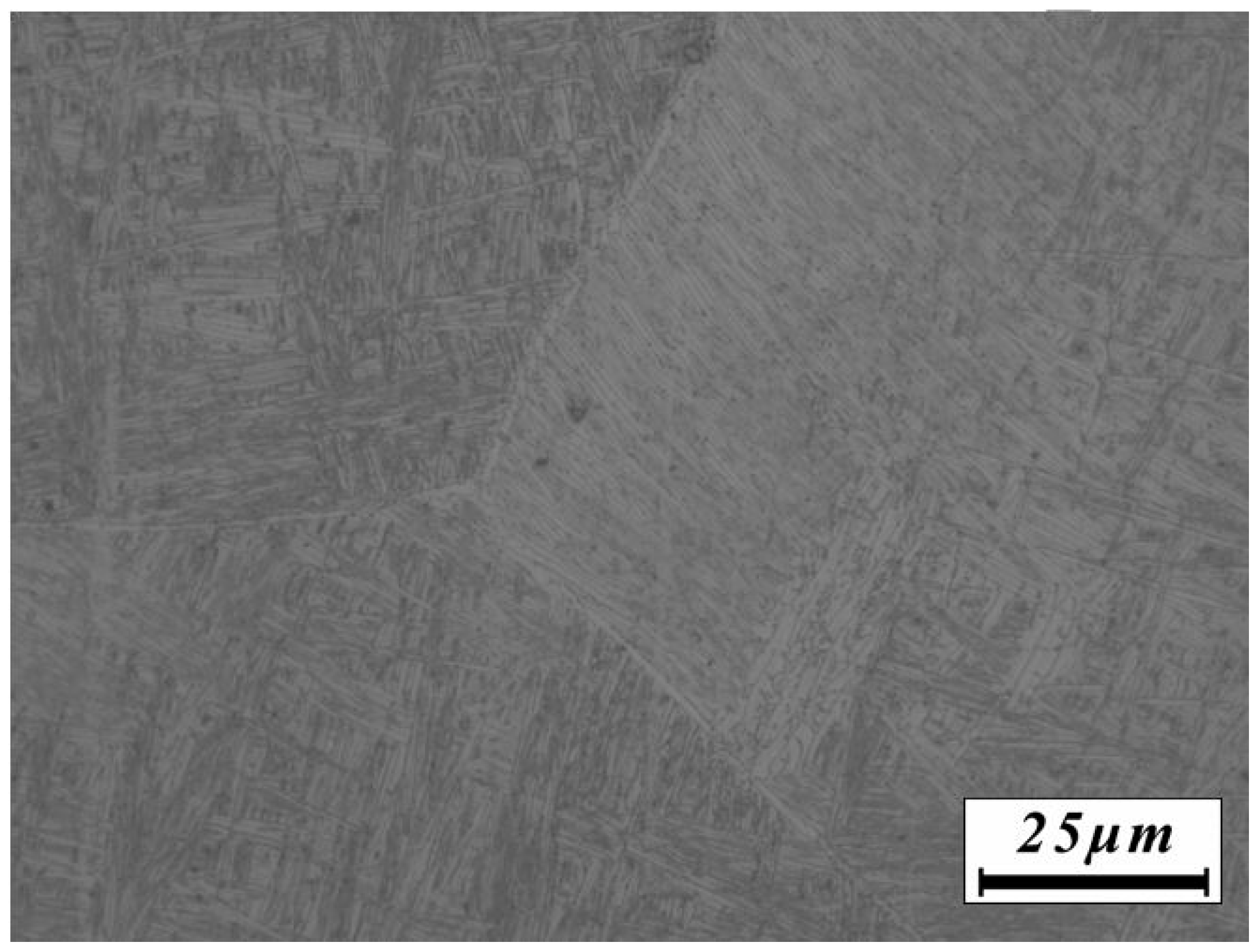

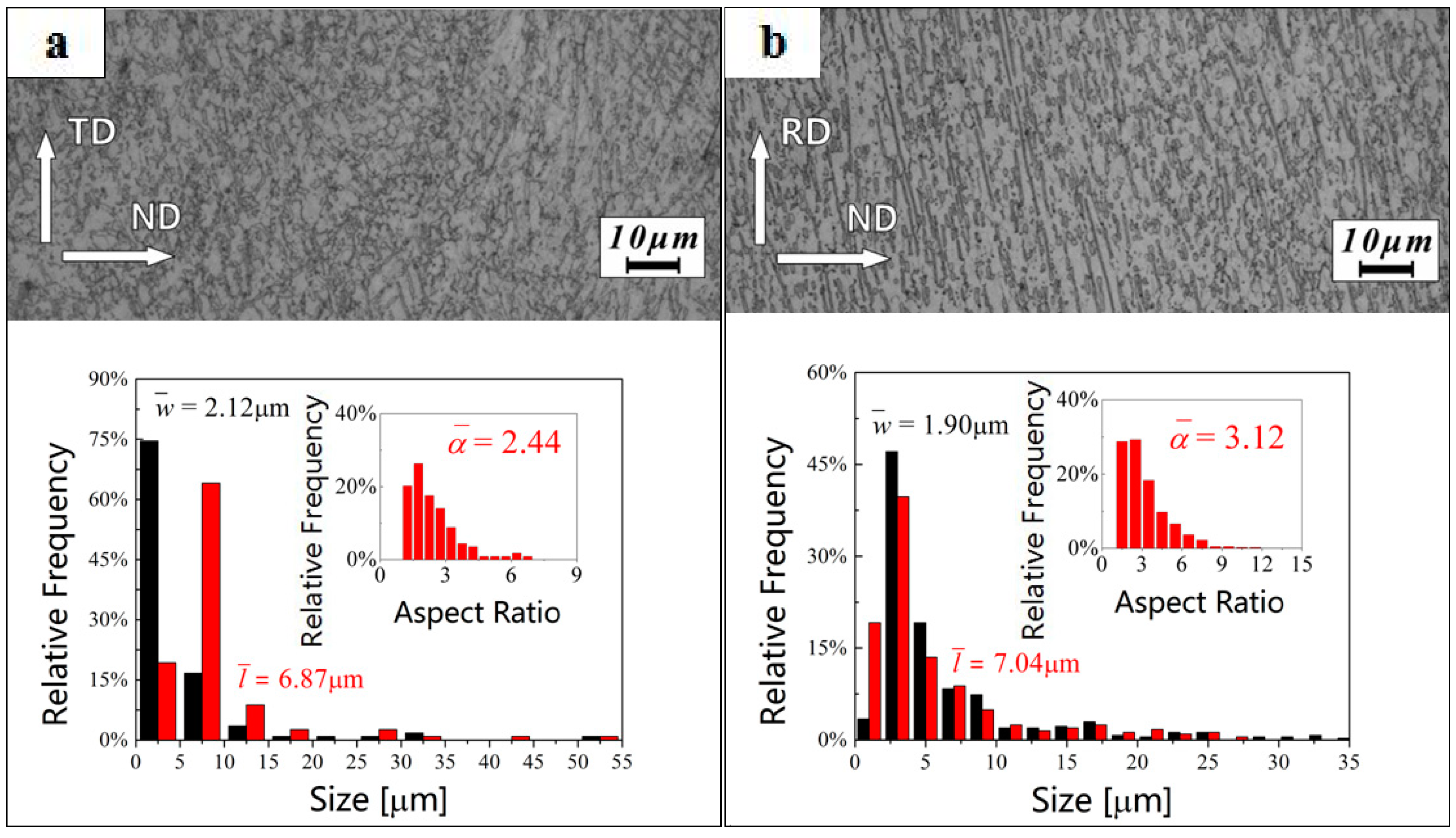

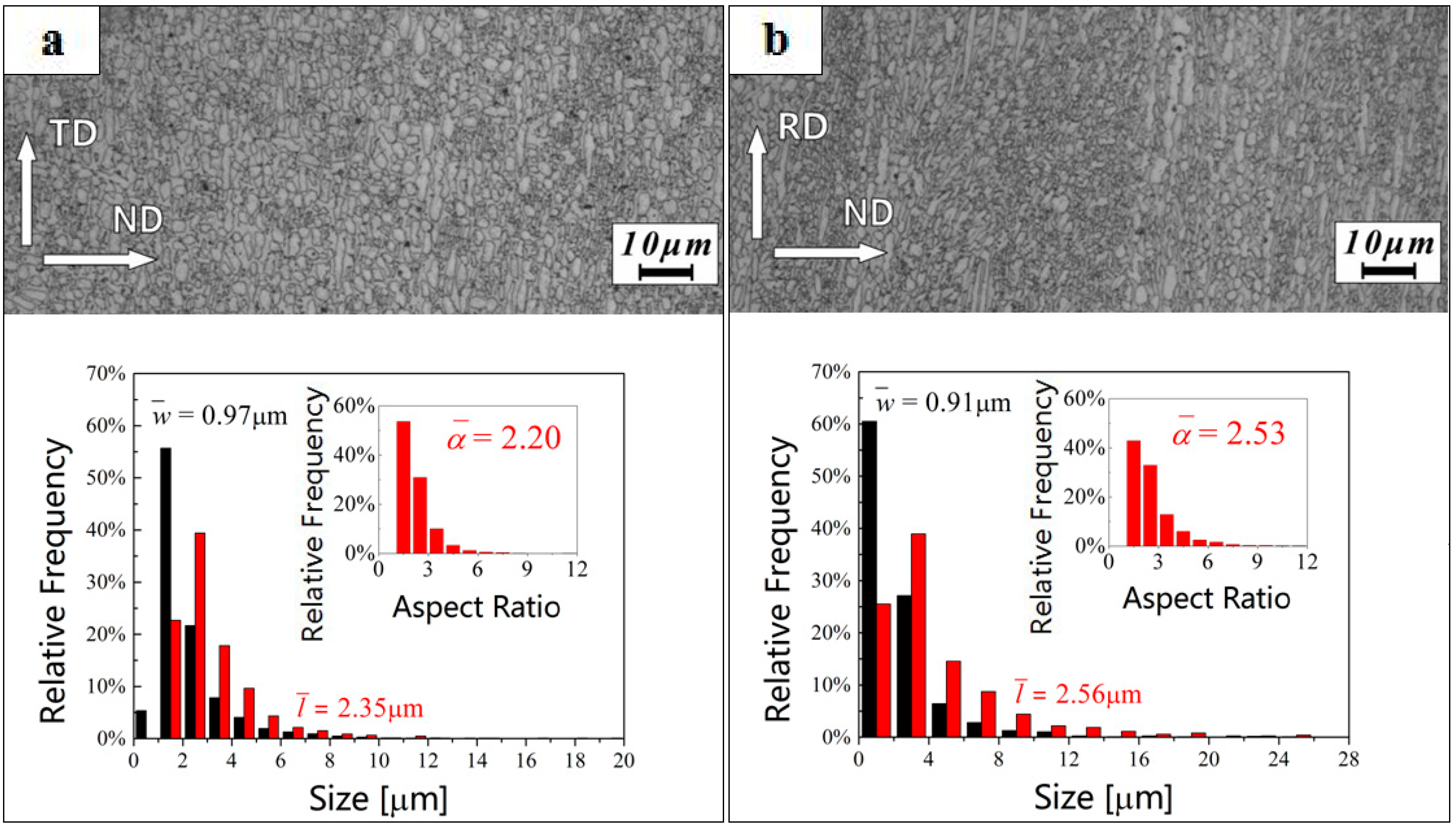

3.1. Microstructural Evolution

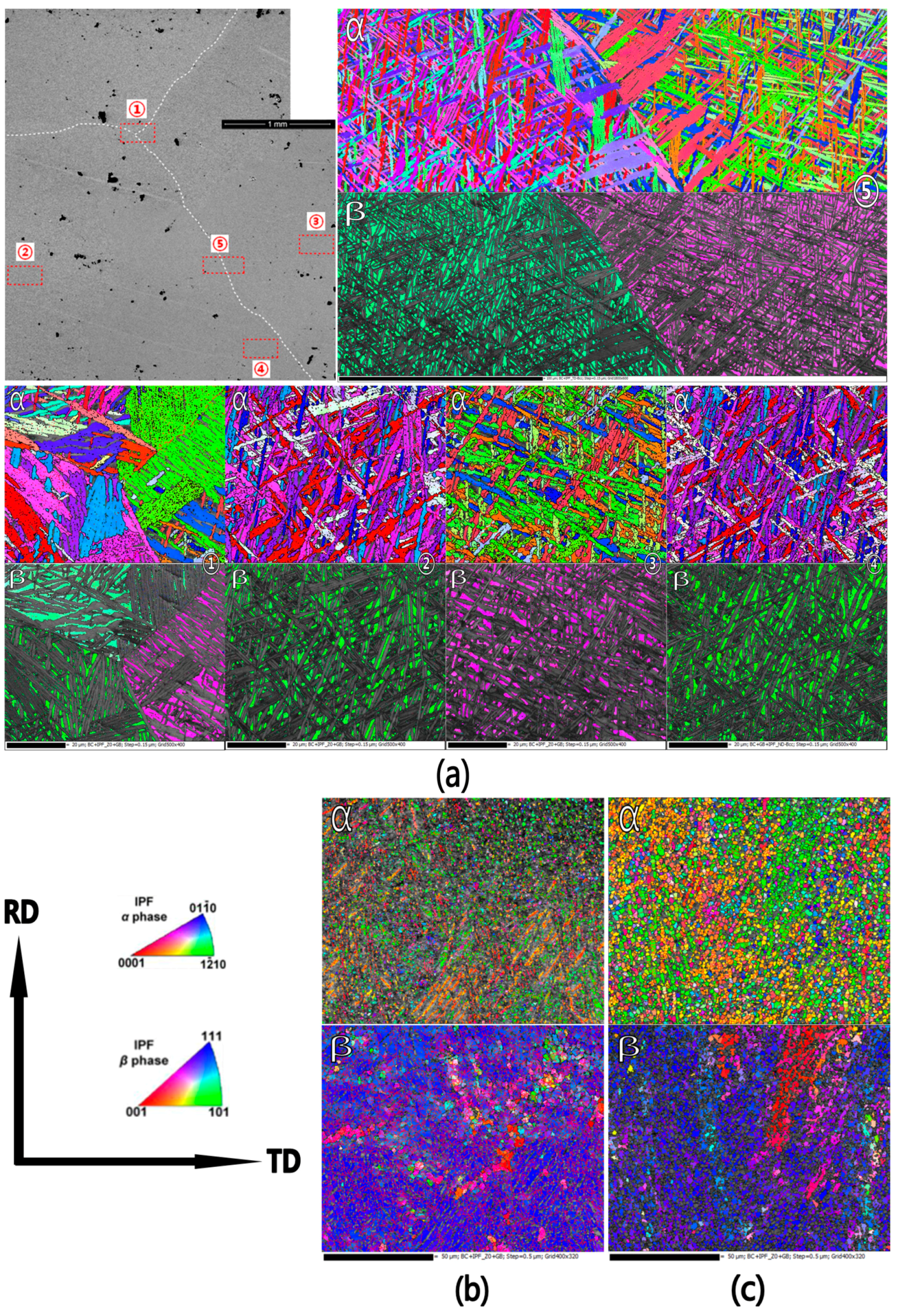

3.2. EBSD Microstructure

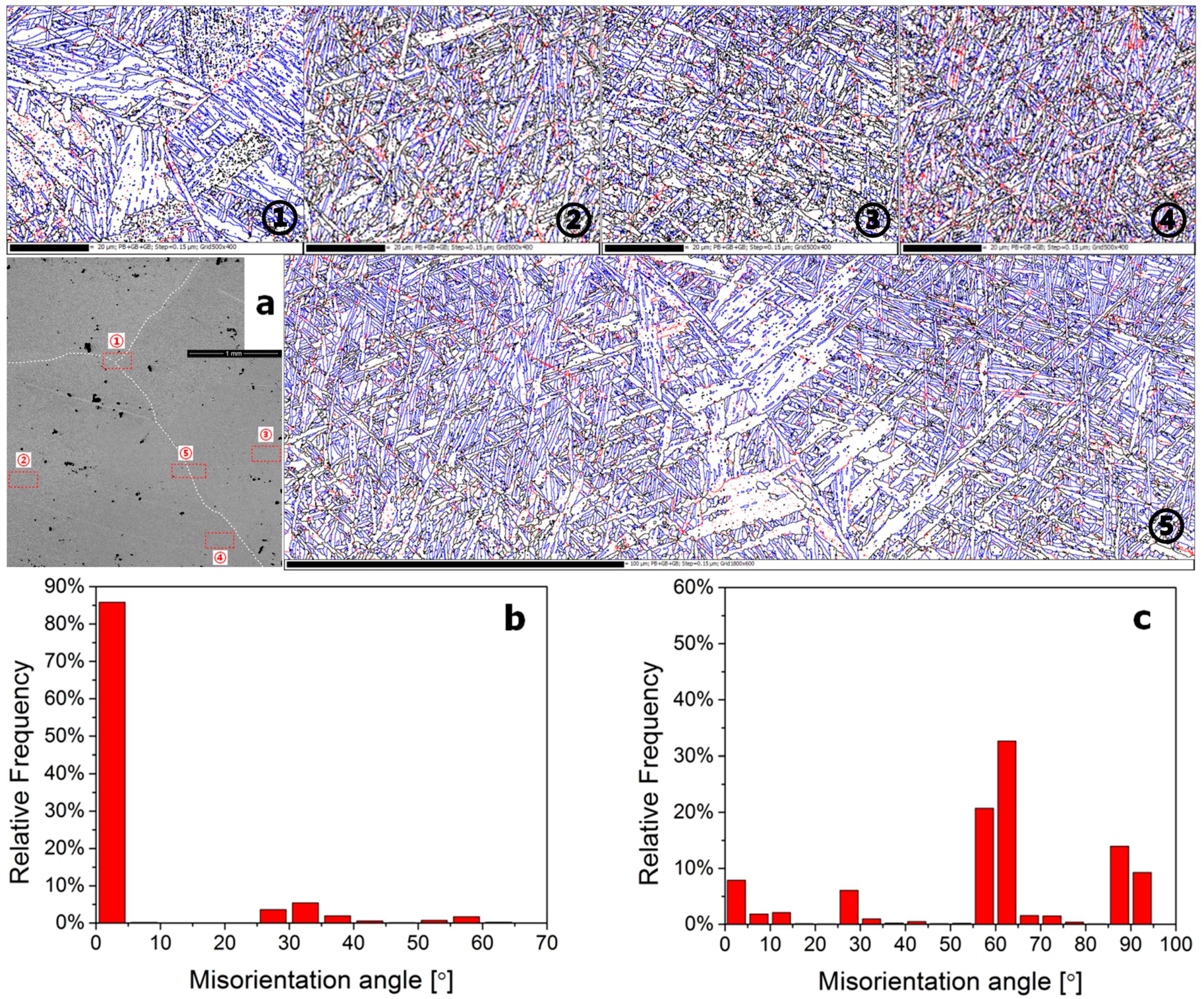

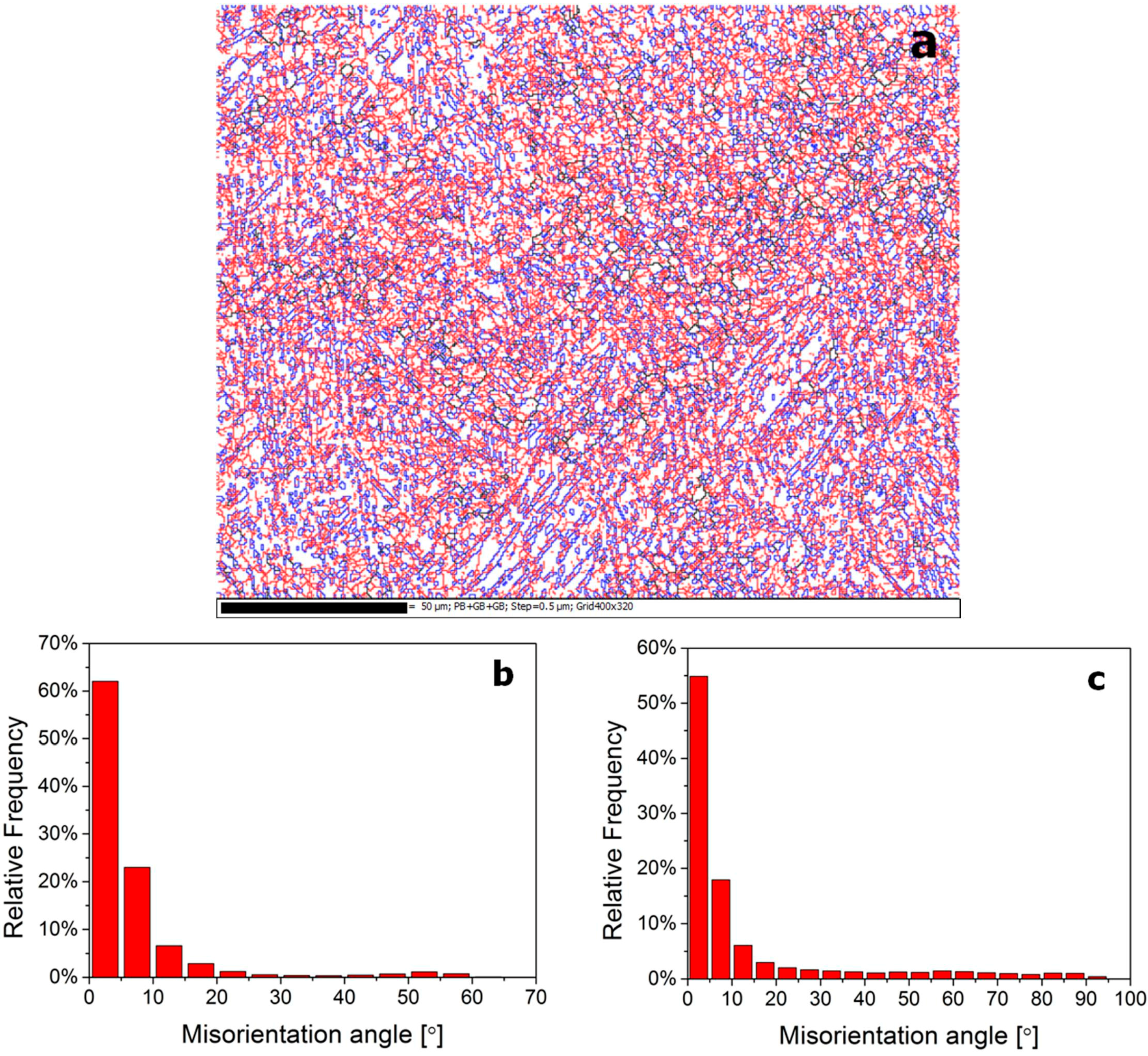

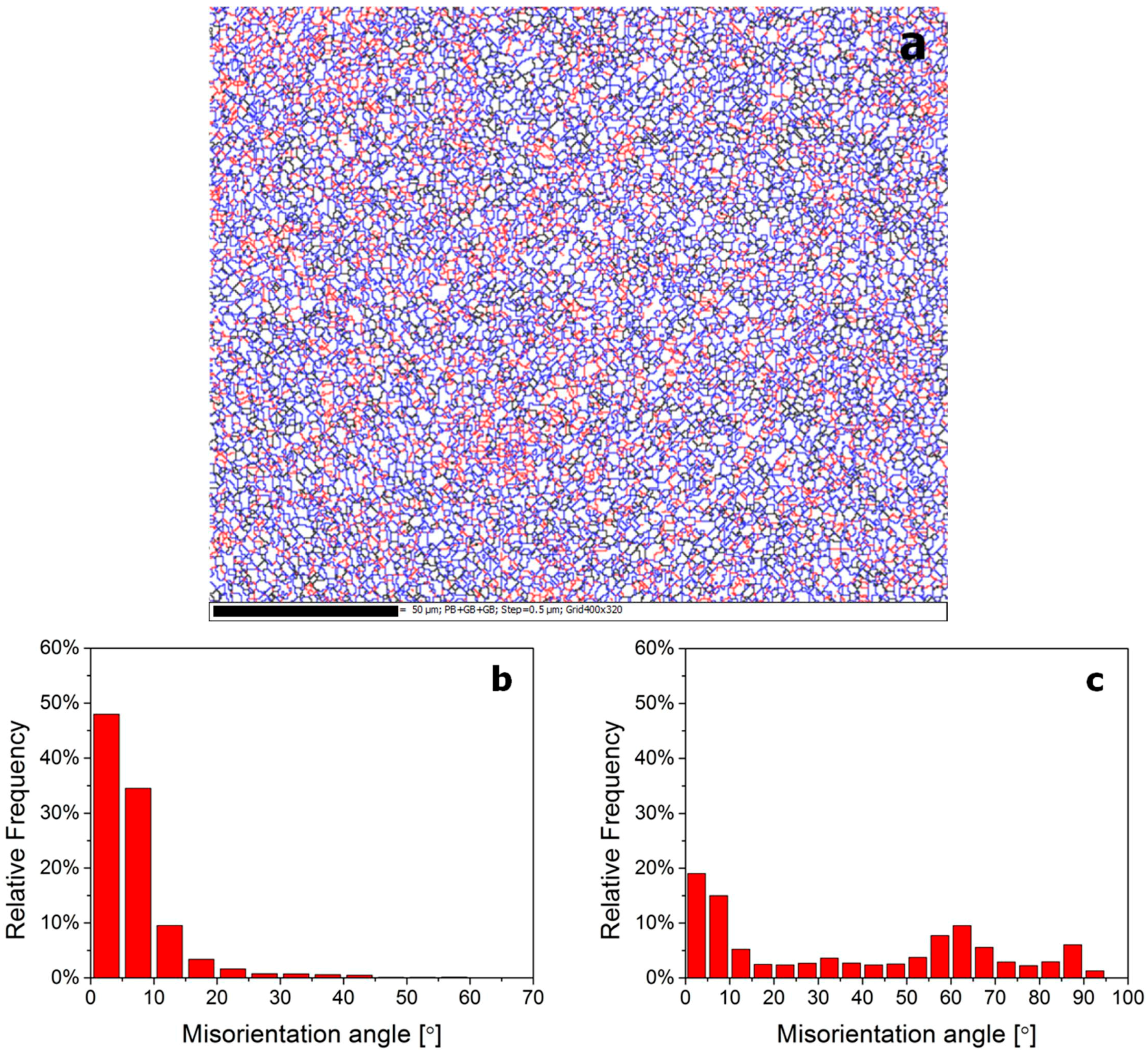

3.3. Misorientation Statistical Analysis

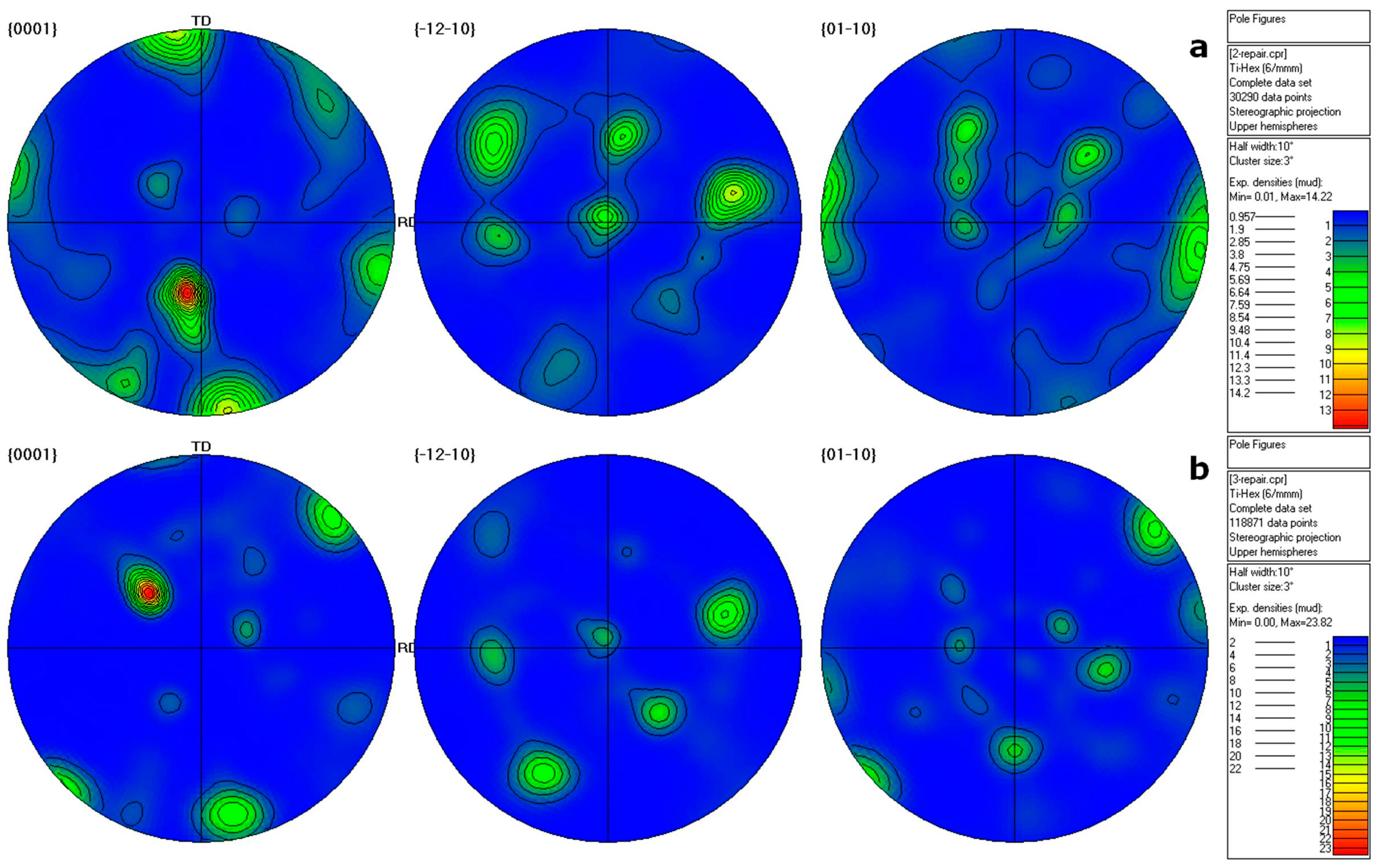

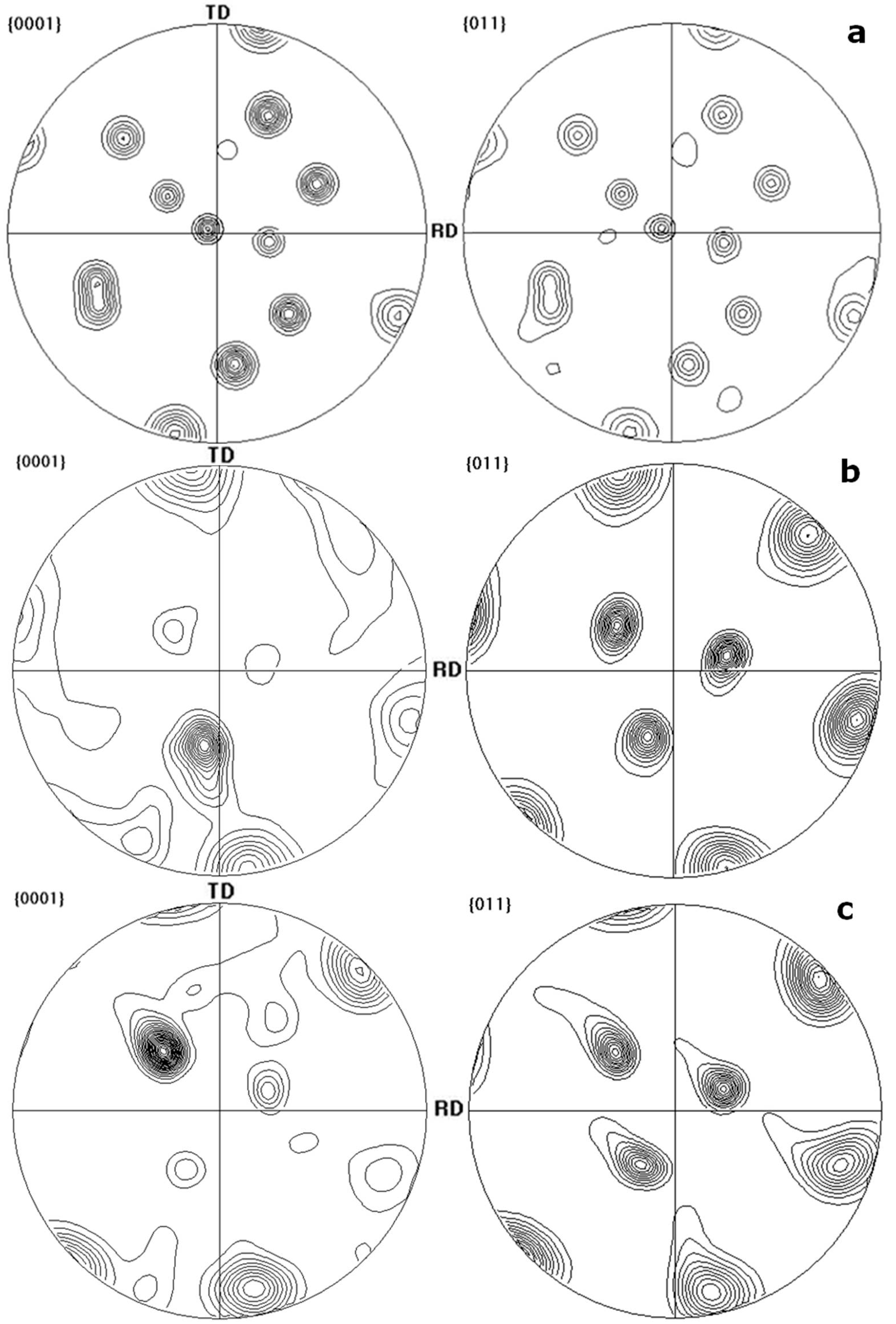

3.4. Orientation Relationship between α and β Phases

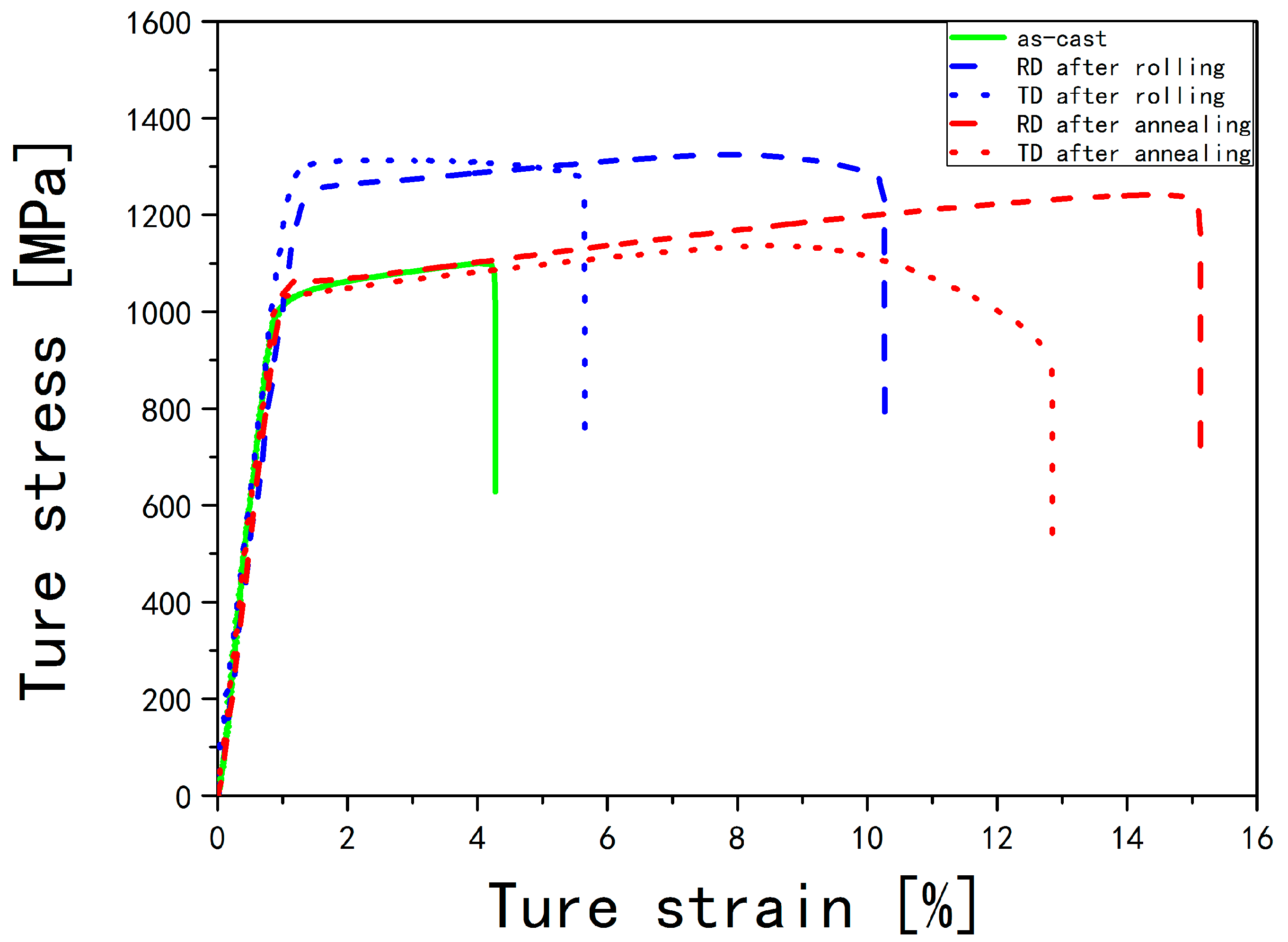

3.5. Mechanical Properties

4. Conclusions

- (1)

- Indicated by the microstructural orientation maps and histograms of misorientation distributions obtained from EBSD data, dynamic recovery occurs mainly in the β phase, and α phase undergoes both dynamic recovery and continuous incomplete dynamic recrystallization with the fraction of HAGBs at 21.1% under hot-rolling while the texture forms. The original β grains fragment into misoriented small domains, and the α grains are elongated along the RD, becoming sparser and coarser. In the optical microstructural maps, the average aspect ratio of the lamellar α phase is found to be 2.44 observed from the RD and 3.12 observed from the TD.

- (2)

- Under annealing, the static recovery takes place mainly in β phase, and α phase undergoes static recrystallization with an increasing fraction of HAGBs (21.1%→60.7%). The α grains are equiaxed with the refined grain sizes of 1.63 µm, as observed from the RD and 1.66 µm observed from the TD. In addition, it is shown by the pole figures that the texture strengthens with a relatively high concentration of {0001} poles.

- (3)

- Comparing the pole figures of the corresponding crystal plane groups after hot rolling, the orientation relationship of α/β in β20C are found to be changed after hot rolling. There was no longer a strict Burgers relationship between α and β phases even after the static recrystallization process of α phase during annealing.

- (4)

- The as-cast β20C alloy has the smallest ultimate tensile strength (1096 MPa) and elongation (4.13%). In the RD, β20C has a greatest strength (1332 MPa) after hot-rolling and a greatest elongation (14.8%) after annealing. The ductility in the RD is always better than that in the TD under the same conditions.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Lutjering, G.; Williams, J.C. Titanium, 1st ed.; Springer: Berlin/Heidelberg, Germany, 2003. [Google Scholar]

- Boyer, R.R. Titanium for aerospace: Rationale and applications. Adv. Perform. Mater. 1995, 2, 349–368. [Google Scholar] [CrossRef]

- Jones, N.; Dashwood, R.; Dye, D. Thermomechanical processing of Ti-5Al-5Mo-5V-3Cr. Mater. Sci. Eng. A 2008, 490, 369–377. [Google Scholar] [CrossRef]

- Malinov, S.; Sha, W.; Markovsky, P. Experimental study and computer modelling of the β⇒α + β phase transformation in β21s alloy at isothermal conditions. J. Alloys Comp. 2003, 348, 110–118. [Google Scholar] [CrossRef]

- Kou, H.; Chen, Y.; Tang, B.; Cui, Y.; Sun, F.; Li, J.; Xue, X. An experimental study on the mechanism of texture evolution during hot-rolling process in a β titanium alloy. J. Alloys Comp. 2014, 603, 23–27. [Google Scholar] [CrossRef]

- Duerig, T.W.; Albrecht, J.; Richter, D.; Fischer, P. Formation and reversion of stress induced martensite in Ti-10V-2Fe-3Al. Acta Metall. 1982, 30, 2161–2172. [Google Scholar] [CrossRef]

- Bo, T.; Bin, T.; Fengbo, H.; Guanjun, Y.; Jinshan, L. Influence of strain rate on stress induced martensitic transformation in β solution treated TB8 alloy. J. Alloys Comp. 2013, 565, 1–5. [Google Scholar] [CrossRef]

- Furuhara, T.; Annaka, S.; Tomio, Y.; Makic, T. Superelasticity in Ti-10V-2Fe-3Al alloys with nitrogen addition. Mater. Sci. Eng. A 2006, 438–440, 825–829. [Google Scholar] [CrossRef]

- Chen, W.; Song, Z.; Xiao, L.; Sun, Q.; Sun, J.; Ge, P. Effect of prestrain on microstructure and mechanical behavior of aged Ti-10V-2Fe-3Al alloy. J. Mater. Res. 2009, 24, 2899–2908. [Google Scholar] [CrossRef]

- Jackson, M.; Dashwood, R.; Flower, H.; Christodoulou, L. The microstructural evolution of near beta alloy Ti-10V-2Fe-3Al during subtransus forging. Metall. Mater. Trans. A 2005, 36, 1317–1327. [Google Scholar] [CrossRef]

- Bhattacharjee, A.; Varma, V.K.; Kamat, S.V.; Gogia, A.K.; Bhargava, S. Influence of β grain size on tensile behavior and ductile fracture toughness of titanium alloy Ti-10V-2Fe-3Al. Metall. Mater. Trans. A 2006, 37, 1423–1433. [Google Scholar] [CrossRef]

- Bhattacharjee, A.; Bhargava, S.; Varma, V.K.; Kamat, S.S.; Gogia, A.K. Effect of β grain size on stress induced martensitic transformation in β solution treated Ti-10V-2Fe-3Al alloy. Scripta Mater. 2005, 53, 195–200. [Google Scholar] [CrossRef]

- Fan, J.K.; Kou, H.C.; Lai, M.J.; Tang, B.; Chang, H.; Li, J.S. Hot deformation mechanism and microstructure evolution of a new near β titanium alloy. Mater. Sci. Eng. A 2013, 584, 121–132. [Google Scholar] [CrossRef]

- Jackson, M.; Jones, N.; Dye, D.; Dashwood, R. Effect of initial microstructure on plastic flow behavior during isothermal forging of Ti-10V-2Fe-3Al. Mater. Sci. Eng. A 2009, 501, 248–254. [Google Scholar] [CrossRef]

- Huiqin, C.; Chunxiao, C. Static globularization of TC11 alloy during hot working process. Rare Met. Mater. Eng. 2011, 40, 946–950. [Google Scholar]

- Zhao, Y.; Ge, P.; Yang, G.; Zhao, Y.; Mao, X. Forging simulation of Ti-1300 alloy by hot compressing testing. Rare Met. Mater. Eng. 2009, 3, 550–553. [Google Scholar]

- Jones, N.; Dashwood, R.; Dye, D.; Jackson, M. The flow behavior and microstructural evolution of Ti-5Al-5Mo-5V-3Cr during subtransus isothermal forging. Metall. Mater. Trans. A 2009, 40, 1944–1954. [Google Scholar] [CrossRef]

- Zhao, Z.; Guo, H.; Wang, X.; Yao, Z. Deformation behavior of isothermally forged Ti-5Al-2Sn-2Zr-4Mo-4Cr powder compact. J. Mater. Process. Technol. 2009, 209, 5509–5513. [Google Scholar] [CrossRef]

- Warchomicka, F.; Poletti, C.; Stockinger, M. Study of the hot deformation behaviour in Ti-5Al-5Mo-5V-3Cr-1Zr. Mater. Sci. Eng. A 2011, 528, 8277–8285. [Google Scholar] [CrossRef]

- Razavi, S.-M.-J.; Ferro, P.; Berto, F. Fatigue assessment of Ti-6Al-4V circular notched specimens produced by Selective Laser Melting. Metals 2017, 7, 291. [Google Scholar] [CrossRef]

- Razavi, S.M.J.; Ferro, P.; Berto, F.; Torgersen, J. Fatigue strength of blunt V-notched specimens produced by Selective Laser Melting of Ti-6Al-4V. Theor. Appl. Fract. Mech. 2017, in press. [Google Scholar] [CrossRef]

- GB/T 228-2002. In Metallic Materials-Tensile Testing at Ambient Temperature; Standard Press of China: Beijing, China, 2002. (In Chinese)

- Roy, S.; Suwas, S.; Tamirisakandala, S.; Srinivasanc, R.; Miracled, D.B. Microstructure and texture evolution during β extrusion of boron modified Ti-6Al-4V alloy. Mater. Sci. Eng. A 2012, 540, 152–163. [Google Scholar] [CrossRef]

- Furuhara, T.; Takagi, S.; Watanabe, H.; Maki, T. Crystallography of grain boundary a precipitates in a β titanium alloy. Metall. Mater. Trans. A 1996, 27, 1635–1646. [Google Scholar] [CrossRef]

| Alloy Element | Al | Cr | Mo | Fe | Zr | Sn | Zn | O | N | H | C |

|---|---|---|---|---|---|---|---|---|---|---|---|

| wt % | 5.12 | 2.5 | 4.48 | 0.52 | 1.8 | 1.1 | 2.9 | 0.08 | 0.02 | 0.002 | 0.01 |

| Variant Number | Corresponding Plane (hkl)β||(hkil)α | Corresponding Direction [uvw]β||[uvtw]α |

|---|---|---|

| 1 | (011)β||(0001)α | [−1−11]β||[2−1−10]α |

| 2 | - | [1−11]β||[2−1−10]α |

| 3 | (−101)β||(0001)α | [1−11]β||[2−1−10]α |

| 4 | - | [111]β||[2−1−10]α |

| 5 | (0−11)β||(0001)α | [111]β||[2−1−10]α |

| 6 | - | [−111]β||[2−1−10]α |

| 7 | (101)β||(0001)α | [−111]β||[2−1−10]α |

| 8 | - | [−1−11]β||[2−1−10]α |

| 9 | (−110)β||(0001)α | [−1−11]β||[2−1−10]α |

| 10 | - | [111]β||[2−1−10]α |

| 11 | (110)β||(0001)α | [1−11]β||[2−1−10]α |

| 12 | - | [−111]β||[2−1−10]α |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, X.; Yu, D.; Fan, Q.; Shi, R. Influence of Hot Rolling and Heat Treatment on the Microstructural Evolution of β20C Titanium Alloy. Materials 2017, 10, 1071. https://doi.org/10.3390/ma10091071

Liu X, Yu D, Fan Q, Shi R. Influence of Hot Rolling and Heat Treatment on the Microstructural Evolution of β20C Titanium Alloy. Materials. 2017; 10(9):1071. https://doi.org/10.3390/ma10091071

Chicago/Turabian StyleLiu, Xin, Donghui Yu, Qunbo Fan, and Ran Shi. 2017. "Influence of Hot Rolling and Heat Treatment on the Microstructural Evolution of β20C Titanium Alloy" Materials 10, no. 9: 1071. https://doi.org/10.3390/ma10091071

APA StyleLiu, X., Yu, D., Fan, Q., & Shi, R. (2017). Influence of Hot Rolling and Heat Treatment on the Microstructural Evolution of β20C Titanium Alloy. Materials, 10(9), 1071. https://doi.org/10.3390/ma10091071