Investigations for Thermal and Electrical Conductivity of ABS-Graphene Blended Prototypes

Abstract

:1. Introduction

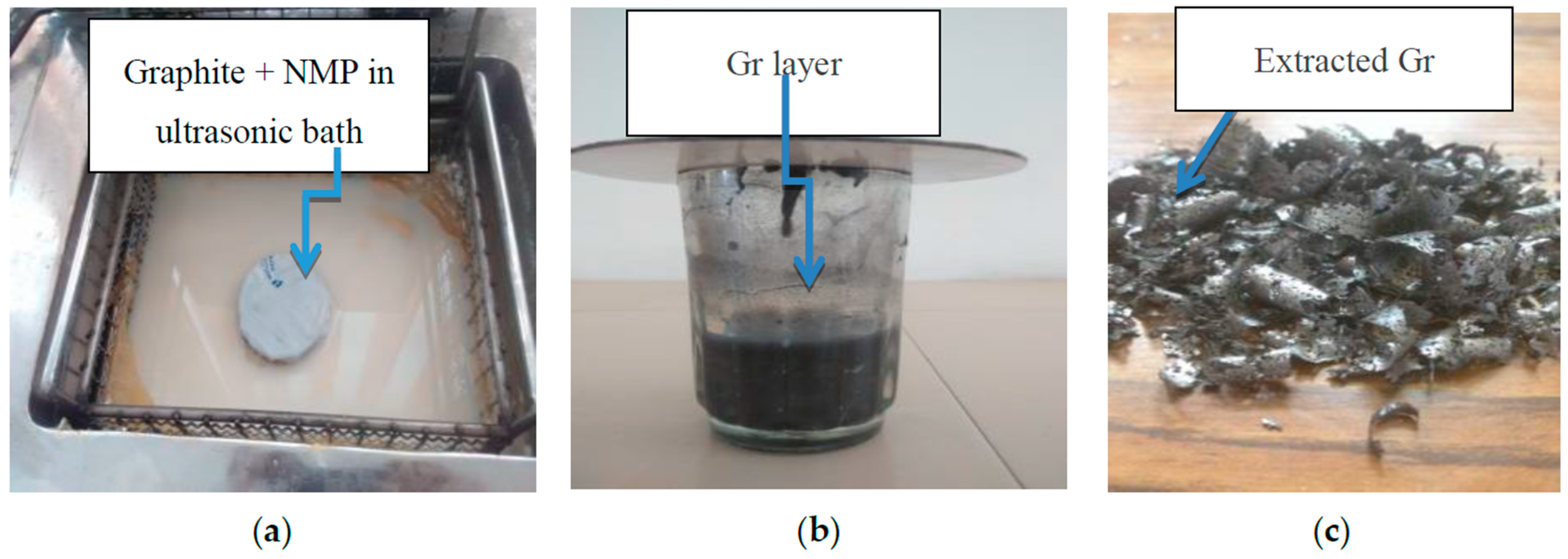

2. Experimentation

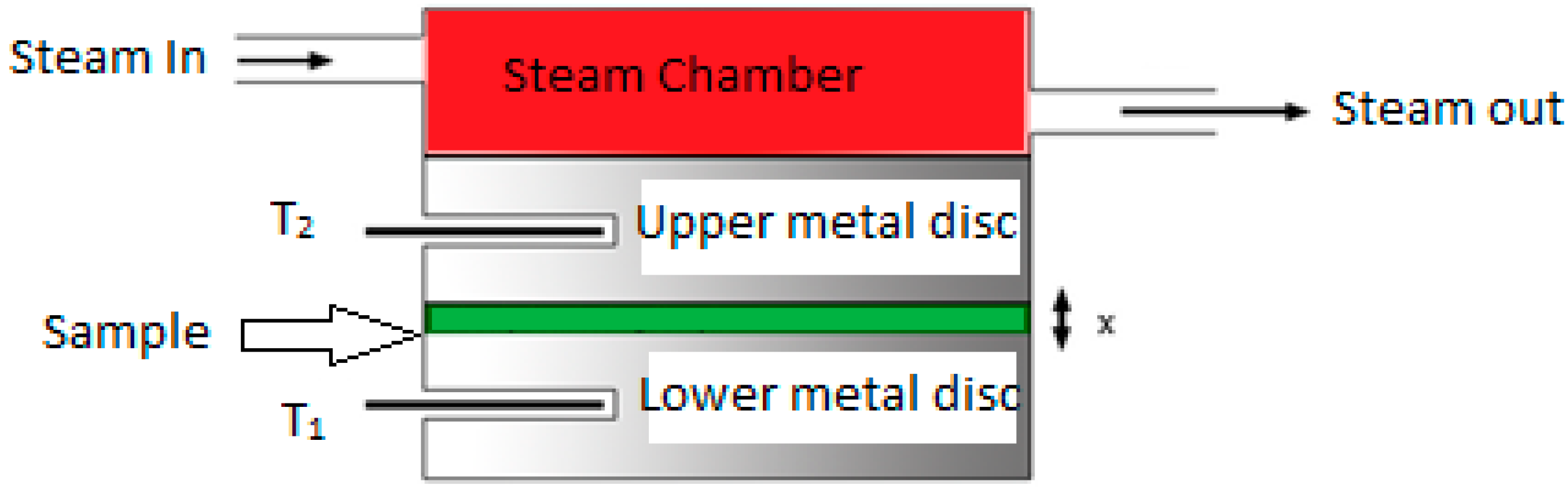

2.1. Thermal Conductivity Measurement

- k—Thermal conductivity of the sampleA—Cross sectional areat2 − t1—Temperature difference across samplesx—Thickness of the samplem—Mass of the discc—Specific heat capacity of disc

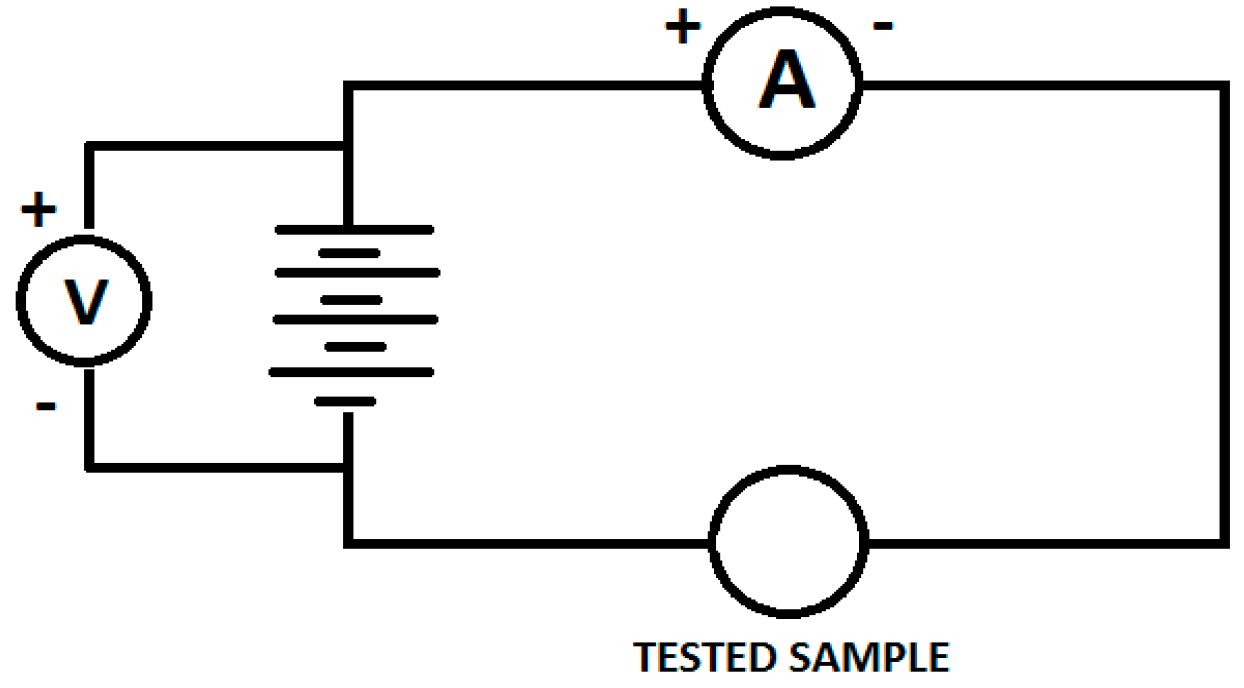

2.2. Electrical Conductivity Test

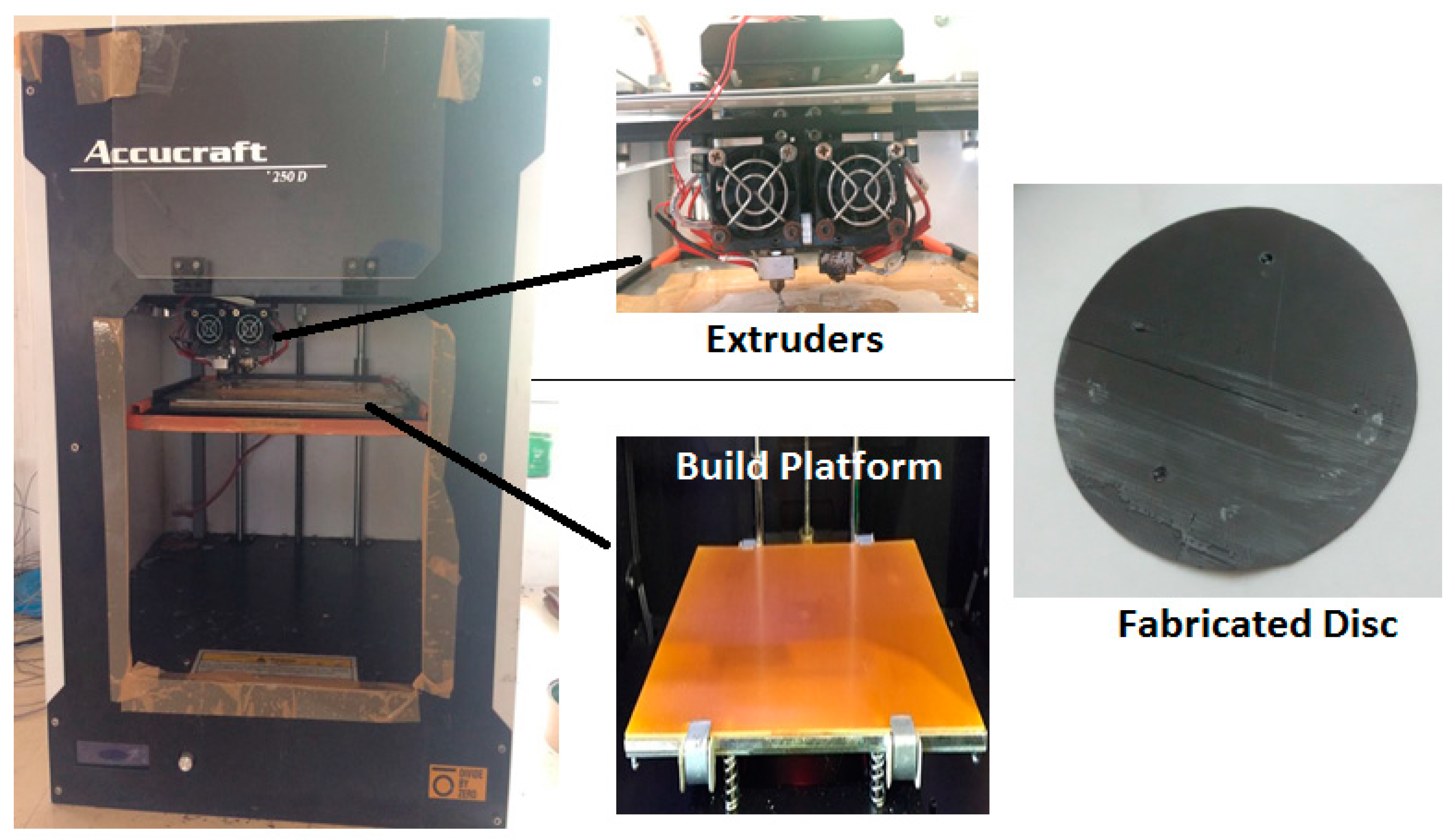

2.3. Printing of Functional Prototypes

3. Results and Discussion

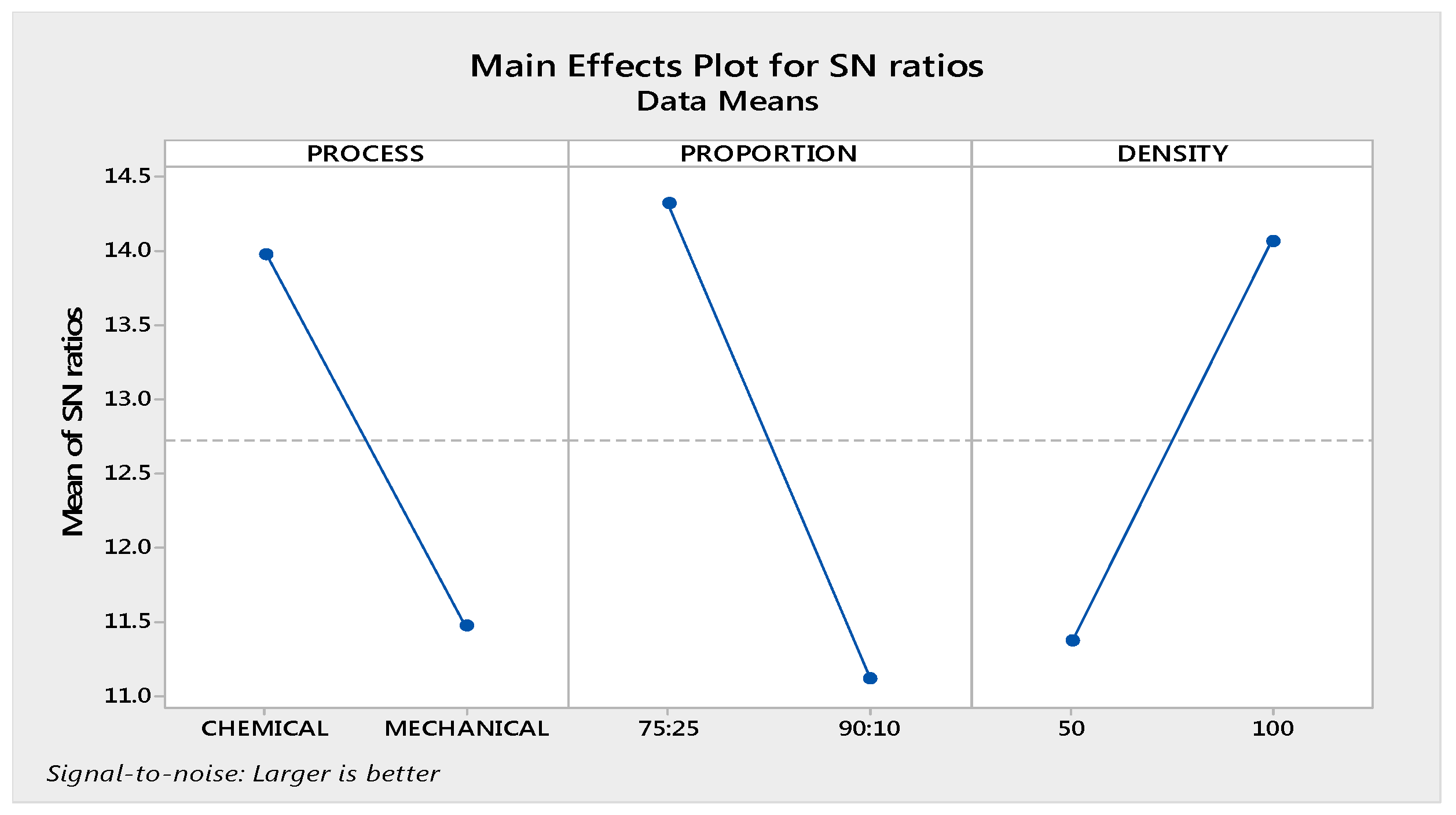

3.1. Optimization of Electrical Conductivity

- m = overall mean of SN datamA1= mean of SN data for process at level 1mB1 = mean of SN data for proportion at level 1mC2 = mean of SN data for density at level 2yopt2 = (1/10)ηopt/10 for properties, lesser is betteryopt2 = (10)ηopt/10 for properties, Larger is better

3.2. Optimization of Thermal Conductivity

- m = overall mean of SN datamA1 = mean of SN data for process at level 1mB1 = mean of SN data for proportion at level 1mC2 = mean of SN data for density at level 2yopt2 = (1/10)ηopt/10 for properties, lesser is betteryopt2 = (10)ηopt/10 for properties, Larger is better

ηopt = 24.09

yopt = 16.01 W/mK

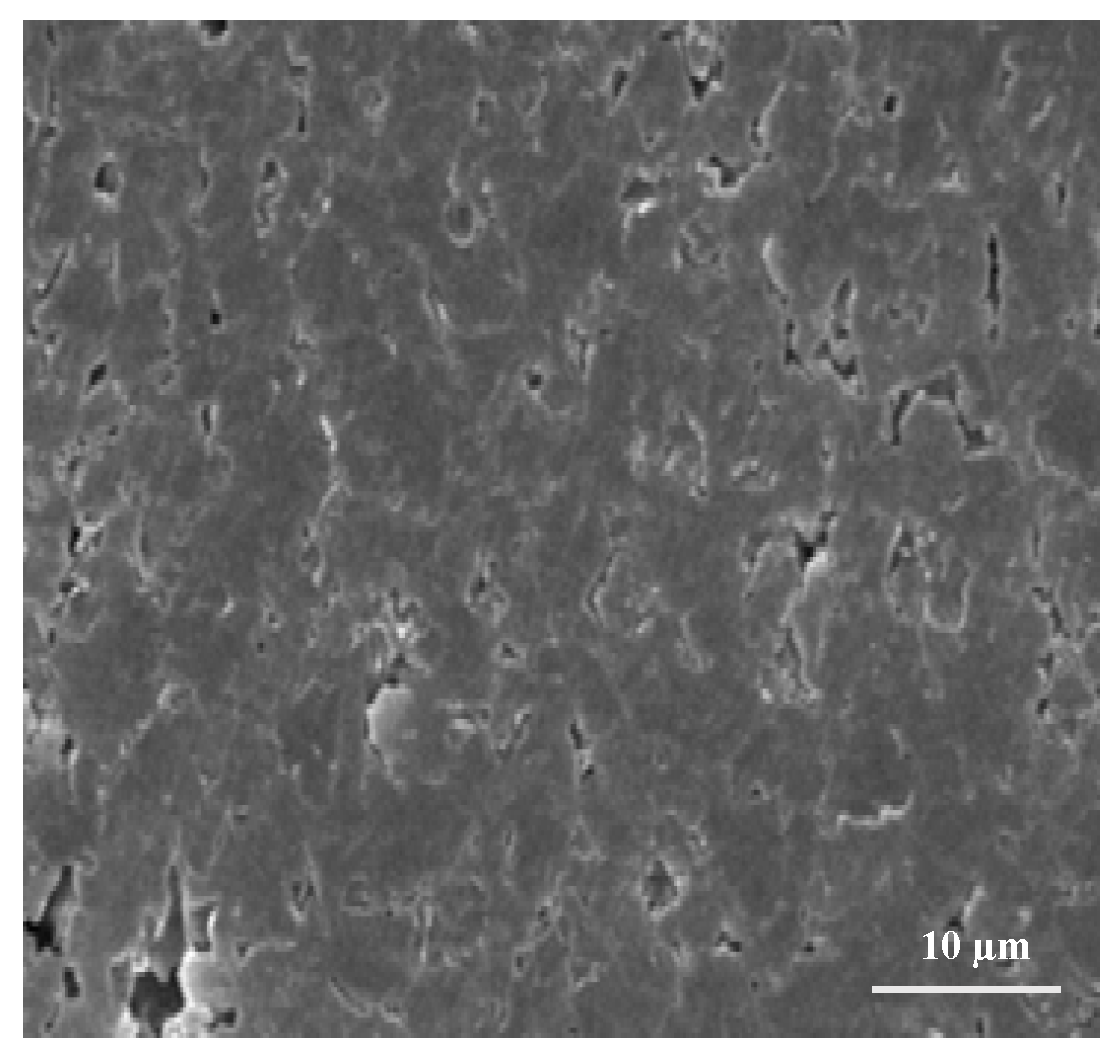

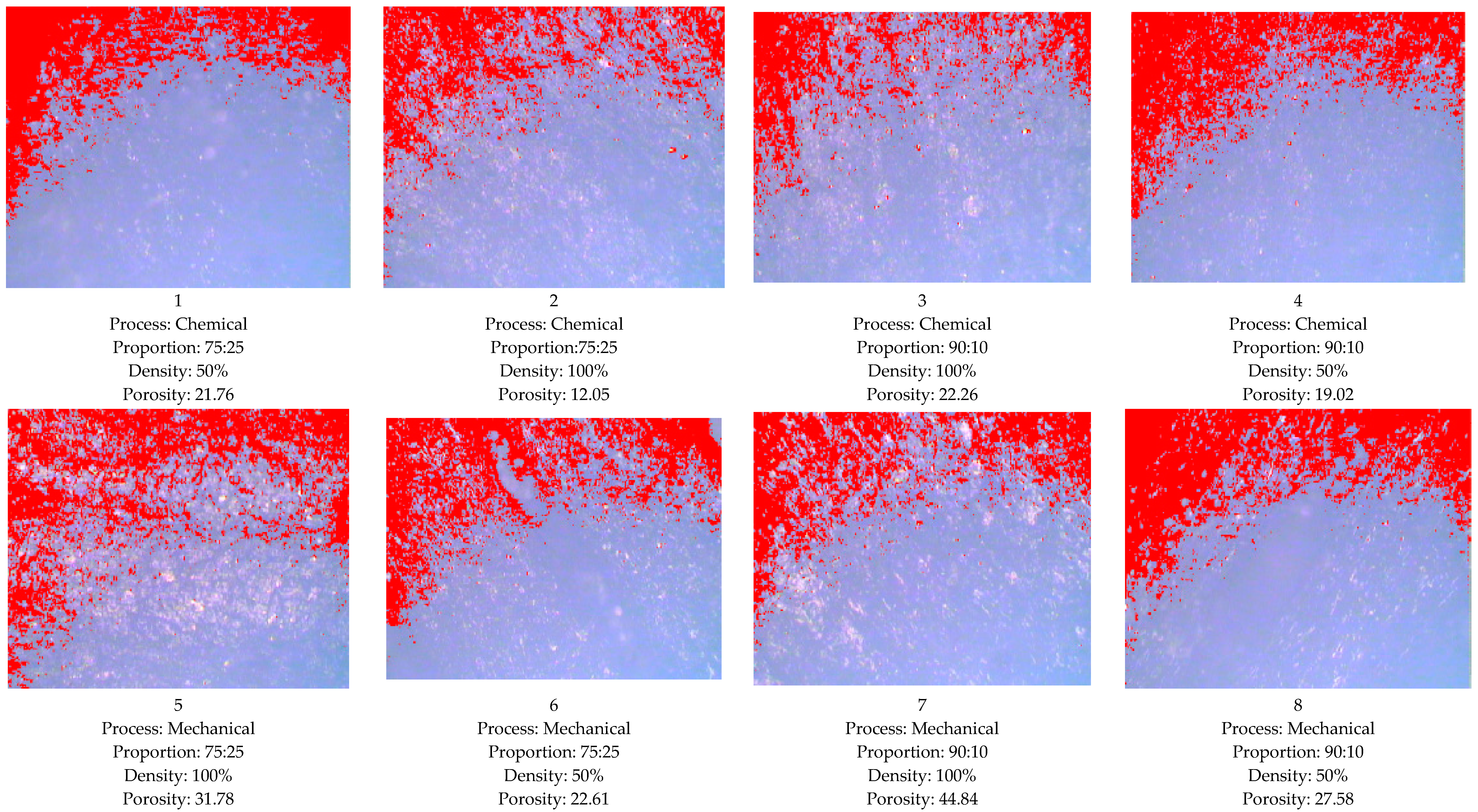

3.3. Optical Micrograph Observations for Porosity

4. Conclusions

Supplementary Materials

Supplementary File 1Acknowledgments

Author Contributions

Conflicts of Interest

References

- Han, Z.; Fina, A. Thermal conductivity of carbon nanotubes and their polymer nanocomposites: A review. Prog. Polym. Sci. 2011, 36, 914–944. [Google Scholar] [CrossRef]

- Shindé, S.L.; Goela, J. High Thermal Conductivity Materials; Springer: New York, NY, USA, 2006; Volume 91. [Google Scholar]

- Sandhu, S.G. Investigations for Development of ABS-Grephene Blended Feed Stock Filament for FDM Applications. Master’s Thesis, Guru Nanak Dev Engineering College, Ludhiana, India, 2017. [Google Scholar]

- Novoselov, K.S.; Geim, A.K.; Morozov, S.V.; Jiang, D.; Zhang, Y.; Dubonos, S.V.; Grigorieva, I.V.; Firsov, A.A. Electric field effect in atomically thin carbon films. Science 2004, 306, 666–669. [Google Scholar] [CrossRef] [PubMed]

- Singh, R.; Singh, S. Development of nylon based FDM filament for rapid tooling application. J. Inst. Eng. Ser. C 2014, 95, 103–108. [Google Scholar] [CrossRef]

- Mostafa, N.; Syed, H.M.; Igor, S.; Andrew, G. A study of melt flow analysis of an ABS-Iron composite in fused deposition modelling process. Tsinghua Sci. Technol. 2009, 14, 29–37. [Google Scholar] [CrossRef]

- Singh, R.; Singh, S.; Fraternali, F. Development of in-house composite wire based feed stock filaments of fused deposition modelling for wear-resistant materials and structures. Compos. Part B Eng. 2016, 98, 244–249. [Google Scholar] [CrossRef]

- Singh, C.J.; Singh, R.; Boparai, K.S.; Penna, R.; Fraternali, F. Dimensional accuracy analysis of coupled fused deposition modeling and vapour smoothing operations for biomedical applications process. Compos. Part B Eng. 2017, 117, 138–149. [Google Scholar]

- Farina, I.; Fabbrocino, F.; Carpentieri, G.; Modano, M.; Amendola, A.; Goodall, R.; Feo, L.; Fraternali, F. On the reinforcement of cement mortars through 3D printed polymeric and metallic fibers. Compos. Part B Eng. 2016, 90, 76–85. [Google Scholar] [CrossRef]

- Naddeo, F.; Naddeo, A.; Cappetti, N. Novel “load adaptive algorithm based” procedure for 3D printing of lattice-based components showing parametric curved micro-beams. Compos. Part B Eng. 2017, 115, 51–59. [Google Scholar] [CrossRef]

- Naddeo, F.; Naddeo, A.; Cappetti, N. Novel “load adaptive algorithm based” procedure for 3D printing of cancellous bone-inspired structures. Compos. Part B Eng. 2017, 115, 60–69. [Google Scholar] [CrossRef]

- Singh, N.; Hui, D.; Singh, R.; Ahuja, I.P.S.; Feo, L.; Fraternali, F. Recycling of plastic solid waste: A state of art review and future applications. Compos. Part B Eng. 2017, 115, 409–422. [Google Scholar] [CrossRef]

- Singh, R.; Singh, N.; Fabbrocino, F.; Fraternali, F.; Ahuja, I. Waste management by recycling of polymers with reinforcement of metal powder. Compos. Part B Eng. 2016, 105, 23–29. [Google Scholar] [CrossRef]

- Singh, R.; Bedia, P.; Fraternali, F.; Ahuja, I. Effect of single particle size, double particle size and triple particle size Al2O3 in Nylon-6 matrix on mechanical properties of feed stock filament for FDM. Compos. Part B Eng. 2016, 106, 20–27. [Google Scholar] [CrossRef]

- Fraternali, F.; Spadea, S.; Berardi, V.P. Effects of recycled PET fibers on the mechanical properties and seawater curing of Portland cement-based concretes. Constr. Build. Mater. 2014, 61, 293–302. [Google Scholar] [CrossRef]

- Spadea, S.; Farina, I.; Carrafiello, A.; Fraternali, F. Recycled nylon fibers as cement mortar reinforcement. Constr. Build. Mater. 2015, 80, 200–209. [Google Scholar] [CrossRef]

- Farina, I.; Fabbrocino, F.; Colangelo, F.; Feo, L.; Fraternali, F. Surface roughness effects on the reinforcement of cement mortars through 3D printed metallic fibers. Compos. Part B Eng. 2016, 99, 305–311. [Google Scholar] [CrossRef]

- Amendola, A.; Nava, E.H.; Goodall, R.; Todd, I.; Skelton, R.E.; Fraternali, F. On the additive manufacturing, post-tensioning and testing of bi-material tensegrity structures. Compos. Struct. 2015, 131, 66–71. [Google Scholar] [CrossRef]

- Amendola, A.; Smith, C.J.; Goodall, R.; Auricchio, F.; Feo, L.; Benzoni, G.; Fraternali, F. Experimental response of additively manufactured metallic pentamode materials confined between stiffening plates. Compos. Struct. 2016, 142, 254–262. [Google Scholar] [CrossRef]

- Fraternali, F.; Carpentieri, G.; Amendola, A. On the mechanical modeling of the extreme softening/stiffening response of axially loaded tensegrity prisms. J. Mech. Phys. Solids 2015, 74, 136–157. [Google Scholar] [CrossRef]

- Fraternali, F.; Amendola, A. Mechanical modeling of innovative metamaterials alternating pentamode lattices and confinement plates. J. Mech. Phys. Solids 2017, 99, 259–271. [Google Scholar] [CrossRef]

- Amendola, A.; Benzoni, G.; Fraternali, F. Non-linear elastic response of layered structures, alternating pentamode lattices and confinement plates. Compos. Part B Eng. 2017, 115, 117–123. [Google Scholar] [CrossRef]

- Potts, J.R.; Dreyer, D.R.; Bielawski, C.W.; Ruoff, R.S. Graphene-based polymer nanocomposites. Polymer 2011, 25, 5–25. [Google Scholar] [CrossRef]

- Riaz, U.; Ashraf, S.M. Conductive Polymer Composites and Blends. In Nanostructured Polymer Blends; Elsevier Inc.: UK, 2013; Volume 1. [Google Scholar]

- Meng, F.; Huang, F.; Guo, Y.; Chen, J.; Chen, X.; Hui, D.; He, P.; Zhou, X.; Zhou, Z.-W. In situ intercalation polymerization approach to polyamide-6/graphite nanoflakes for enhanced thermal conductivity. Compos. Part B Eng. 2017, 117, 165–173. [Google Scholar] [CrossRef]

- Ivanova, O.; Williams, C.; Campbell, T. Additive manufacturing (AM) and nanotechnology: Promises and challenges. Rapid Prototyp. J. 2013, 19, 353–364. [Google Scholar] [CrossRef]

- Campbell, T.A.; Ivanova, O.S. 3D printing of multifunctional nanocomposites. Nano Today 2013, 8, 119–120. [Google Scholar] [CrossRef]

- Perez, A.R.T.; Roberson, D.A.; Wicker, R.B. Fracture surface analysis of 3D-printed tensile specimens of novel ABS-based materials. J. Fail. Anal. Prev. 2014, 14, 343–353. [Google Scholar] [CrossRef]

- Postiglione, G.; Natale, G.; Griffini, G.; Levi, M.; Turri, S. UV-assisted three-dimensional printing of polymer nanocomposites based on inorganic fillers. Polym. Compos. 2015. [Google Scholar] [CrossRef]

- Llewellyn-Jones, T.M.; Drinkwater, B.W.; Trask, R.S. 3D printed components with ultrasonically arranged microscale structure. Smart Mater. Struct. 2016, 25, 02LT01. [Google Scholar] [CrossRef]

- Love, L.J.; Kunc, V.; Rios, O.; Duty, C.E.; Elliott, A.M.; Post, B.K.; Smith, R.J.; Blue, C. The importance of carbon fiber to polymer additive manufacturing. J. Mater. Res. 2014, 29, 1893–1898. [Google Scholar] [CrossRef]

- Tekinalp, H.L.; Kunc, V.; Velez-Garcia, G.M.; Duty, C.E.; Love, L.J.; Naskar, A.K.; Blue, C.; Ozcan, S. Highly oriented carbon fiber–polymer composites via additive manufacturing. Compos. Sci. Technol. 2014, 105, 144–150. [Google Scholar] [CrossRef]

- Shofner, M.L.; Lozano, K.; Rodríguez-Macías, F.J.; Barrera, E.V. Nanofiber-reinforced polymers prepared by fused deposition modeling. J. Appl. Polym. Sci. 2003, 89, 3081–3090. [Google Scholar] [CrossRef]

- Farahani, R.D.; Dalir, H.; Le Borgne, V.; Gautier, L.A.; El Khakani, M.A.; Lévesque, M.; Therriault, D. Direct-write fabrication of freestanding nanocomposite strain sensors. Nanotechnology 2012, 23, 085502. [Google Scholar] [CrossRef] [PubMed]

- Compton, B.G.; Lewis, J.A. 3D-printing of lightweight cellular composites. Adv. Mater. 2014, 26, 5930–5935. [Google Scholar] [CrossRef] [PubMed]

- Postiglione, G.; Natale, G.; Griffini, G.; Levi, M.; Turri, S. Conductive 3D microstructures by direct 3D printing of polymer/carbon nanotube nanocomposites via liquid deposition modeling. Compos. Part A Appl. Sci. Manufactur. 2015, 76, 110–114. [Google Scholar] [CrossRef]

- Duguay, A.J.; Nader, J.W.; Kiziltas, A.; Gardner, D.J.; Dagher, H.J. Exfoliated graphite nanoplatelet-filled impact modified polypropylene nanocomposites: Influence of particle diameter, filler loading, and coupling agent on the mechanical properties. Appl. Nanosci. 2014, 4, 279–291. [Google Scholar] [CrossRef]

- Thanh, T.D.; Kaprálková, L.; Hromádková, J.; Kelnar, I. Effect of graphite nanoplatelets on the structure and properties of PA6-elastomer nanocomposites. Eur. Polym. J. 2014, 50, 39–45. [Google Scholar] [CrossRef]

- ASTM D1238-13, Standard Test Method for Melt Flow Rates of Thermoplastics by Extrusion Plastometer; ASTM International: West Conshohocken, PA, USA, 2013. Available online: https://www.astm.org/Standards/D1238.htm (accessed on 28 July 2017).

- Sombatsompop, N.; Wood, A.K. Measurement of thermal conductivity of polymers using an improved Lee’s disc apparatus. Polym. Test. 1997, 16, 203–223. [Google Scholar] [CrossRef]

- Colangelo, F.; Messina, F.; Di Palma, L.; Cioffi, R. Recycling of non-metallic automotive shredder residues and coal fly-ash in cold-bonded aggregates for sustainable concrete. Compos. Part B Eng. 2017, 116, 46–52. [Google Scholar] [CrossRef]

- Colangelo, F.; Cioffi, R. Mechanical properties and durability of mortar containing fine fraction of demolition wastes produced by selective demolition in South Italy. Compos. Part B Eng. 2017, 115, 43–50. [Google Scholar] [CrossRef]

| ABS:Gr (ByWeight) | Mechanically Blended MFI in g/10 min | Chemically Blended MFI in g/10 min |

|---|---|---|

| 50:50 | 0.82 | 1.63 |

| 60:40 | 1.62 | 2.27 |

| 70:30 | 2.20 | 3.20 |

| 80:20 | 2.46 | 3.94 |

| 90:10 | 2.51 | 4.12 |

| Serial No. | Input Parameters | Levels |

|---|---|---|

| 1 | Infilldensity | 50%, 100% |

| 2 | Blending process | Mechanical, Chemical + mechanical |

| 3 | Proportion of ABS:Gr (weight %) | 75:25, 90:10 |

| Blending Process | Proportion (by Weight) | Infill Density (Percentage) |

|---|---|---|

| Chemical | 75:25 | 50 |

| Chemical | 75:25 | 100 |

| Chemical | 90:10 | 50 |

| Chemical | 90:10 | 100 |

| Mechanical | 75:25 | 50 |

| Mechanical | 75:25 | 100 |

| Mechanical | 90:10 | 50 |

| Mechanical | 90:10 | 100 |

| Blending Process | Proportion (by Weight) | Infill Density (Percentage) | Electrical Conductivity (S-m) | SN Ratio |

|---|---|---|---|---|

| Chemical | 75:25 | 50 | 4.82 | 13.6609 |

| Chemical | 75:25 | 100 | 7.29 | 17.2546 |

| Chemical | 90:10 | 50 | 3.50 | 10.8814 |

| Chemical | 90:10 | 100 | 5.07 | 14.1002 |

| Mechanical | 75:25 | 50 | 4.30 | 12.6694 |

| Mechanical | 75:25 | 100 | 4.85 | 13.7148 |

| Mechanical | 90:10 | 50 | 2.60 | 8.2995 |

| Mechanical | 90:10 | 100 | 3.63 | 11.1981 |

| Source | DF | Seq SS | Adj SS | Adj MS | F | P | Percentage Contribution |

|---|---|---|---|---|---|---|---|

| Process | 1 | 12.538 | 12.538 | 12.538 | 24.64 | 0.008 | 25.29 |

| Proportion | 1 | 20.546 | 20.546 | 20.5459 | 40.37 | 0.003 | 41.44 |

| Density | 1 | 14.463 | 14.463 | 14.4629 | 28.42 | 0.006 | 29.17 |

| Residual Error | 4 | 2.036 | 2.036 | 0.5089 | 4.10 | ||

| Total | 7 | 49.582 |

| Level | Process | Proportion | Density |

|---|---|---|---|

| 1 | 13.97 | 14.32 | 11.38 |

| 2 | 11.47 | 11.12 | 14.07 |

| Delta | 2.50 | 3.21 | 2.69 |

| Rank | 3 | 1 | 2 |

| Blending Process | Proportion (by Weight) | Infill Density (Percentage) | Thermal Conductivity (W/mK) | SN Ratio |

|---|---|---|---|---|

| Chemical | 75:25 | 50 | 8.85 | 18.9389 |

| Chemical | 75:25 | 100 | 17.60 | 24.9103 |

| Chemical | 90:10 | 50 | 6.36 | 16.0691 |

| Chemical | 90:10 | 100 | 12.43 | 21.8894 |

| Mechanical | 75:25 | 50 | 2.40 | 7.6042 |

| Mechanical | 75:25 | 100 | 4.65 | 13.3491 |

| Mechanical | 90:10 | 50 | 2.41 | 7.6403 |

| Mechanical | 90:10 | 100 | 3.99 | 12.0195 |

| Source | DF | Seq SS | Adj SS | Adj MS | F | P | Percentage Contribution |

|---|---|---|---|---|---|---|---|

| Process | 1 | 212.124 | 212.124 | 212.124 | 245.14 | 0.000 | 75.20 |

| Proportion | 1 | 6.451 | 6.451 | 6.451 | 7.46 | 0.052 | 2.28 |

| Density | 1 | 60.037 | 60.037 | 60.037 | 69.38 | 0.001 | 21.28 |

| Residual Error | 4 | 3.461 | 3.461 | 0.865 | 1.22 | ||

| Total | 7 | 282.074 |

| Level | Process | Proportion | Density |

|---|---|---|---|

| 1 | 20.45 | 16.20 | 12.56 |

| 2 | 10.15 | 14.40 | 18.04 |

| Delta | 10.30 | 1.80 | 5.48 |

| Rank | 1 | 3 | 2 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, R.; Sandhu, G.S.; Penna, R.; Farina, I. Investigations for Thermal and Electrical Conductivity of ABS-Graphene Blended Prototypes. Materials 2017, 10, 881. https://doi.org/10.3390/ma10080881

Singh R, Sandhu GS, Penna R, Farina I. Investigations for Thermal and Electrical Conductivity of ABS-Graphene Blended Prototypes. Materials. 2017; 10(8):881. https://doi.org/10.3390/ma10080881

Chicago/Turabian StyleSingh, Rupinder, Gurleen S. Sandhu, Rosa Penna, and Ilenia Farina. 2017. "Investigations for Thermal and Electrical Conductivity of ABS-Graphene Blended Prototypes" Materials 10, no. 8: 881. https://doi.org/10.3390/ma10080881

APA StyleSingh, R., Sandhu, G. S., Penna, R., & Farina, I. (2017). Investigations for Thermal and Electrical Conductivity of ABS-Graphene Blended Prototypes. Materials, 10(8), 881. https://doi.org/10.3390/ma10080881