Nanostructured ZnO in a Metglas/ZnO/Hemoglobin Modified Electrode to Detect the Oxidation of the Hemoglobin Simultaneously by Cyclic Voltammetry and Magnetoelastic Resonance

Abstract

:1. Introduction

2. Materials and Methods

2.1. Reagents and Materials

2.2. Apparatus

3. Experimental

3.1. ZnO Nanoparticle Synthesis and Film Deposition

3.1.1. Synthesis of the ZnO Nanoparticles

3.1.2. ZnO Film Deposition onto the Magnetoelastic Resonant Platform

3.2. Hemoglobin Immobilization

4. Results and Discussion

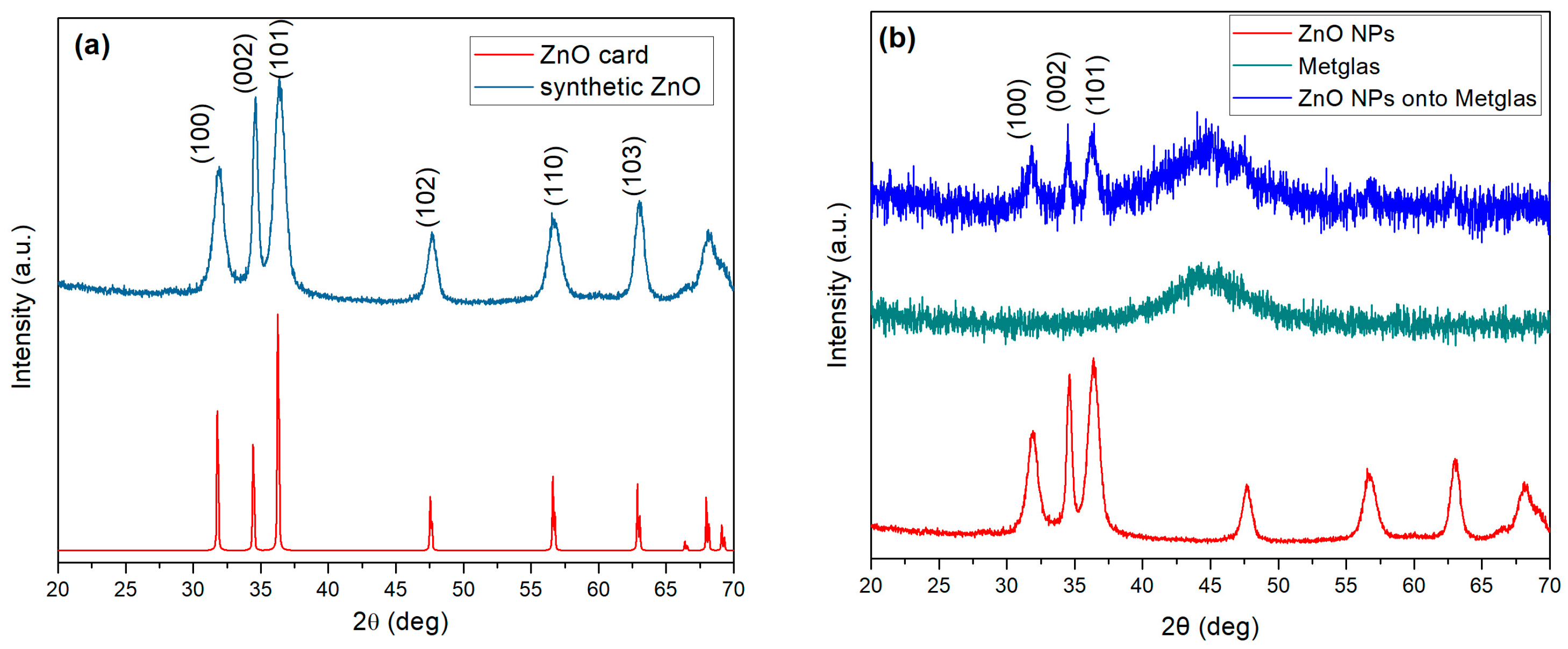

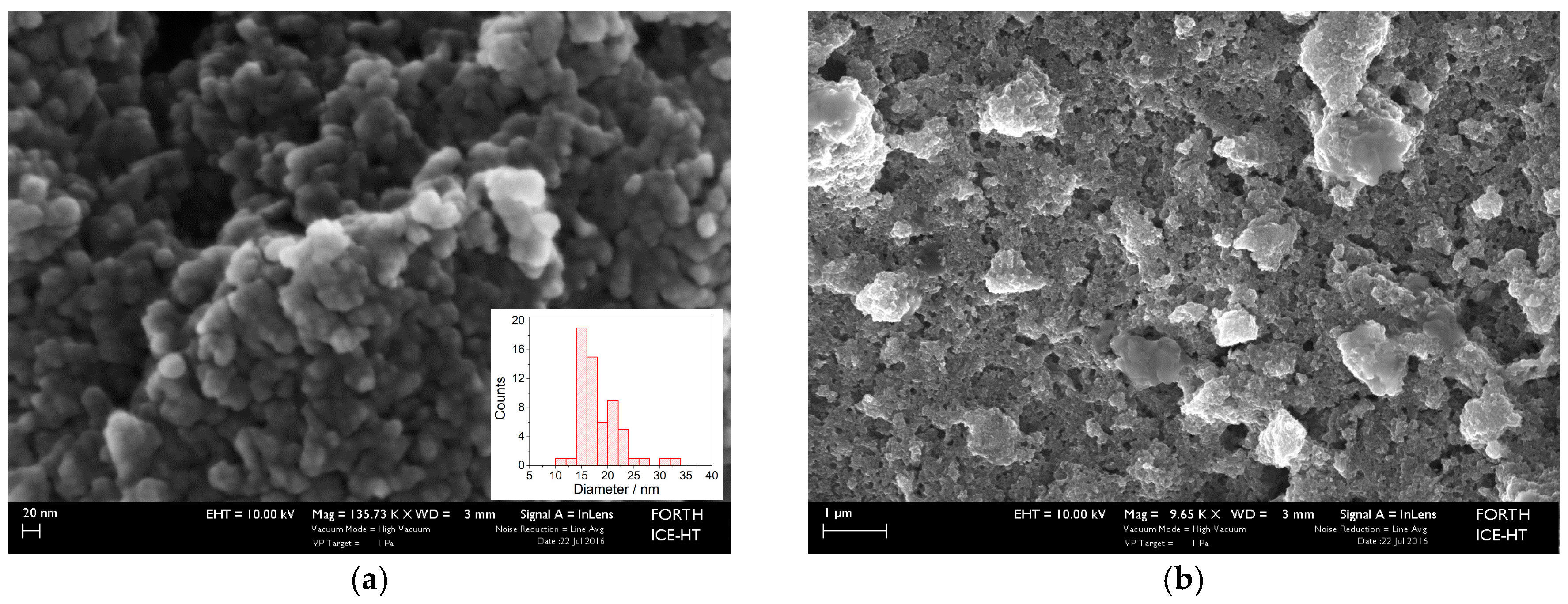

4.1. Characterization of ZnO Nanoparticles and Film

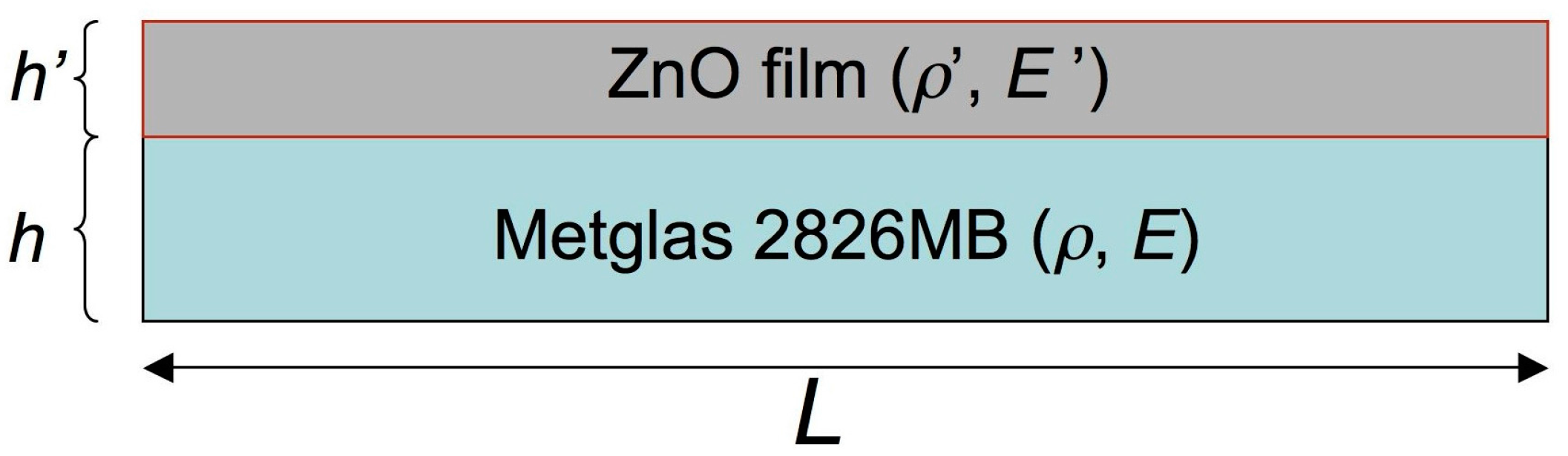

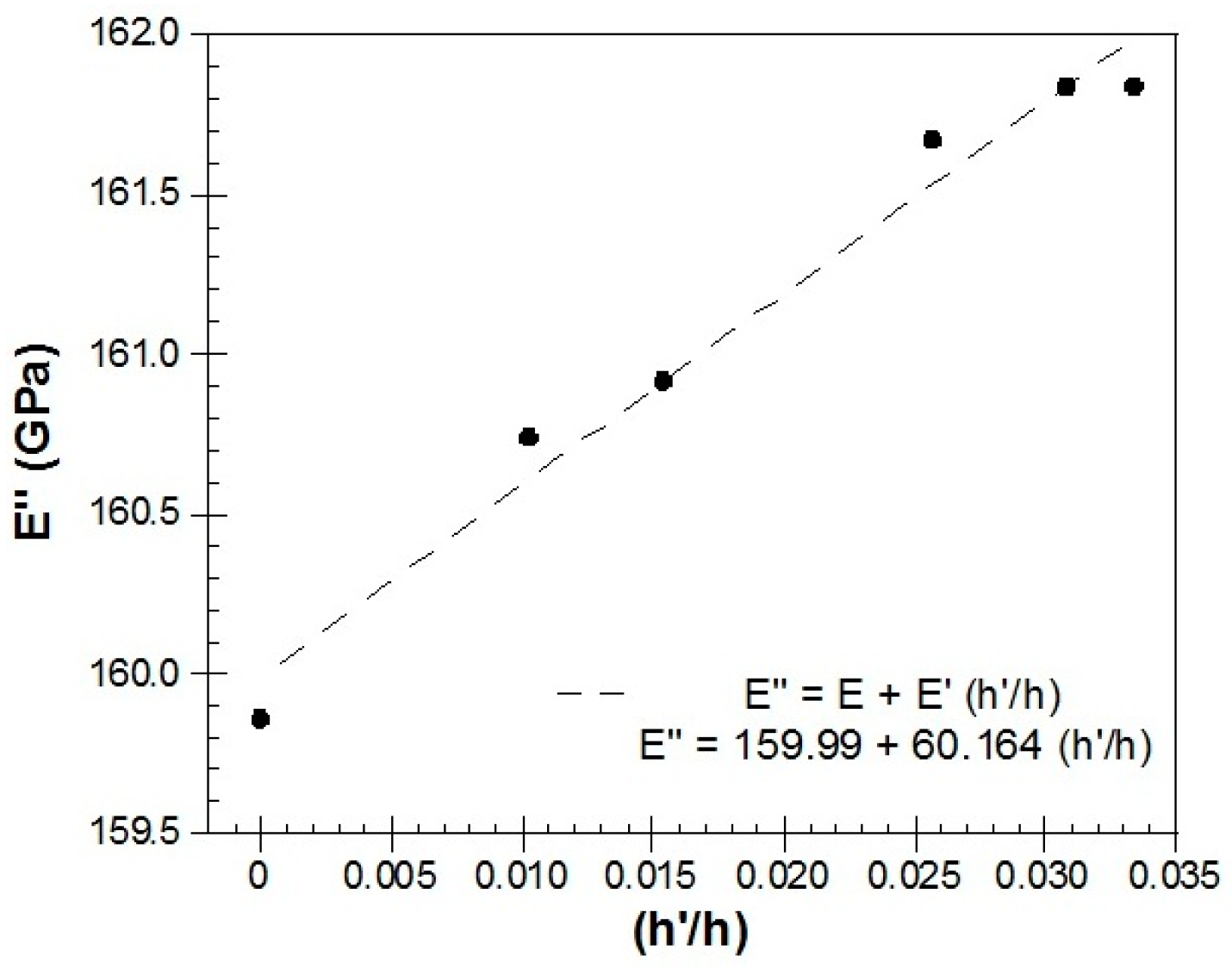

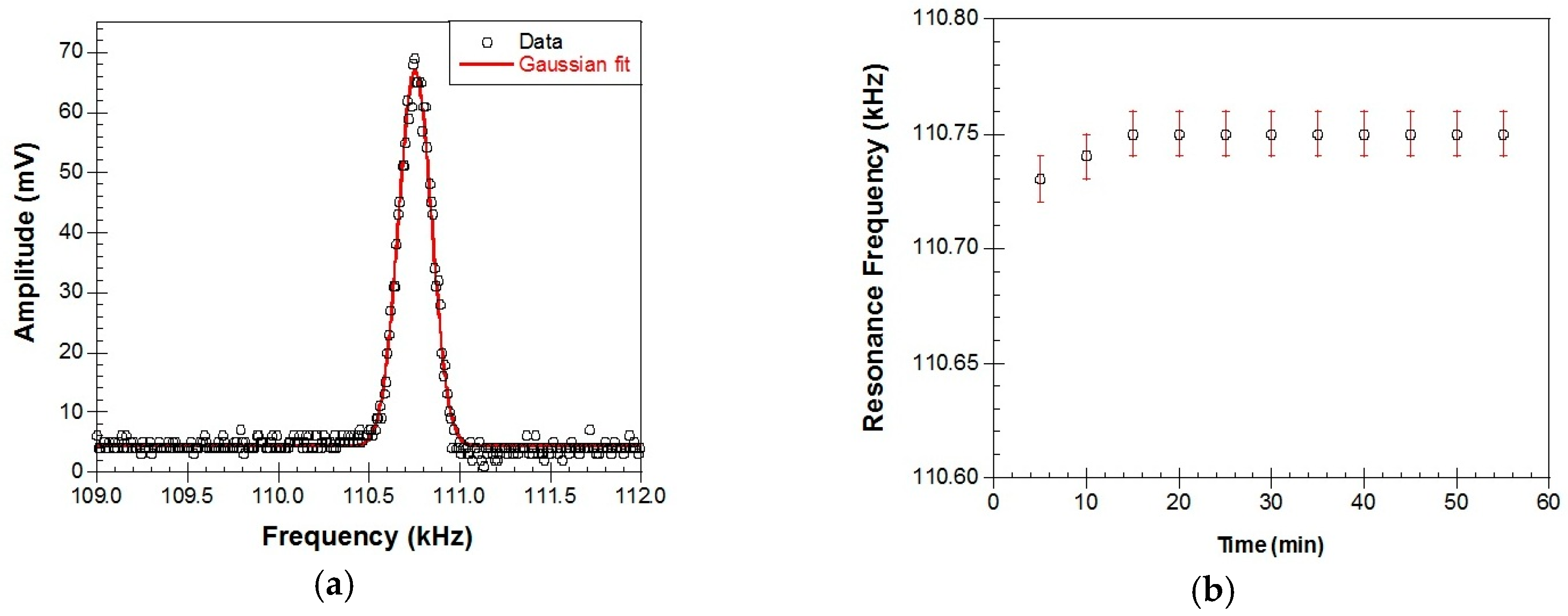

4.2. ZnO Deposited Film Elastic Modulus Determination

4.3. Simultaneous Electrochemical and Magnetoelastic Detection of H2O2 Using a Metglas/ZnO/Hemoglobin Electrode-Sensor

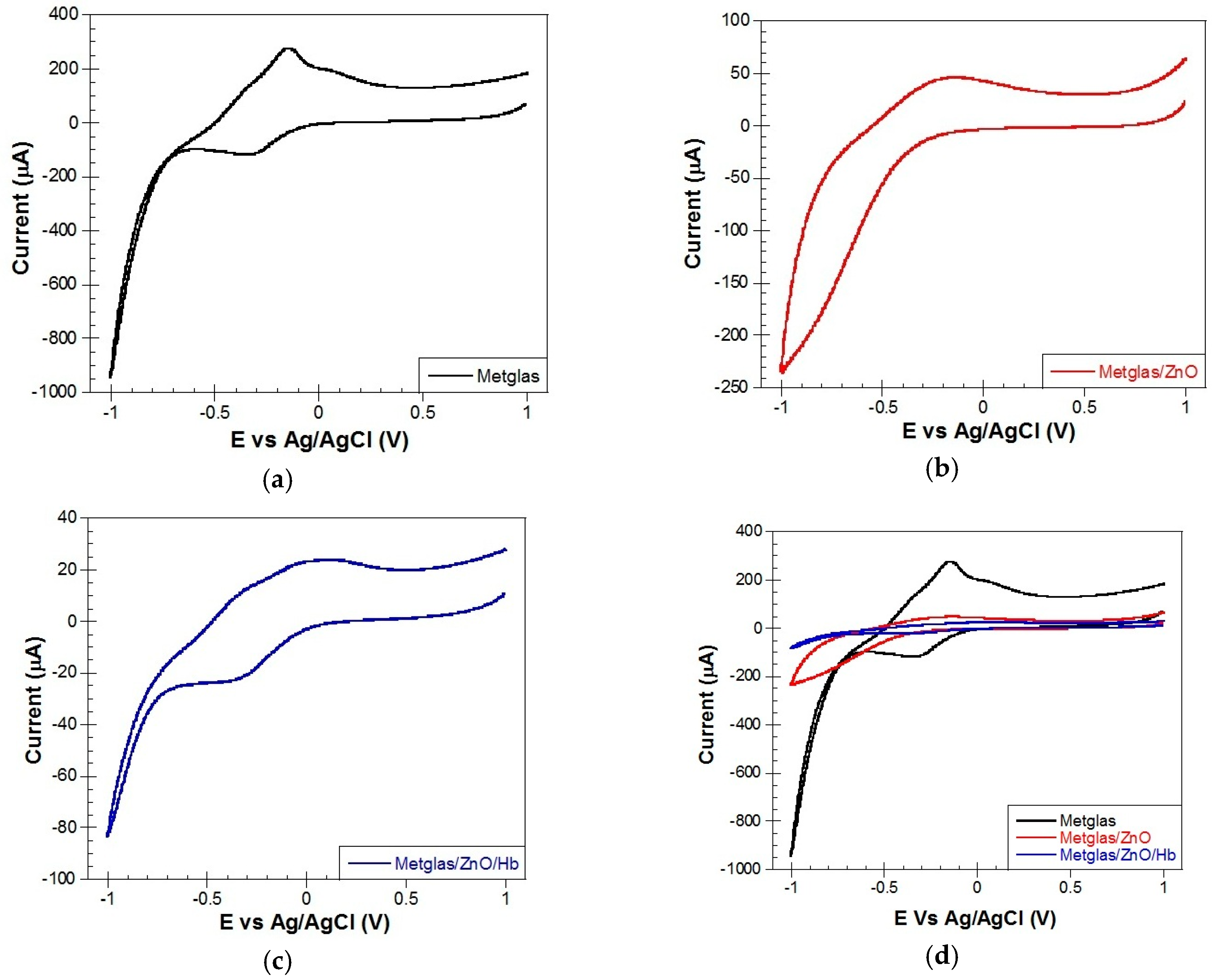

4.3.1. Electrochemical Behavior of Metglas, Metglas/ZnO, Metglas/ZnO/Hb Film Electrodes

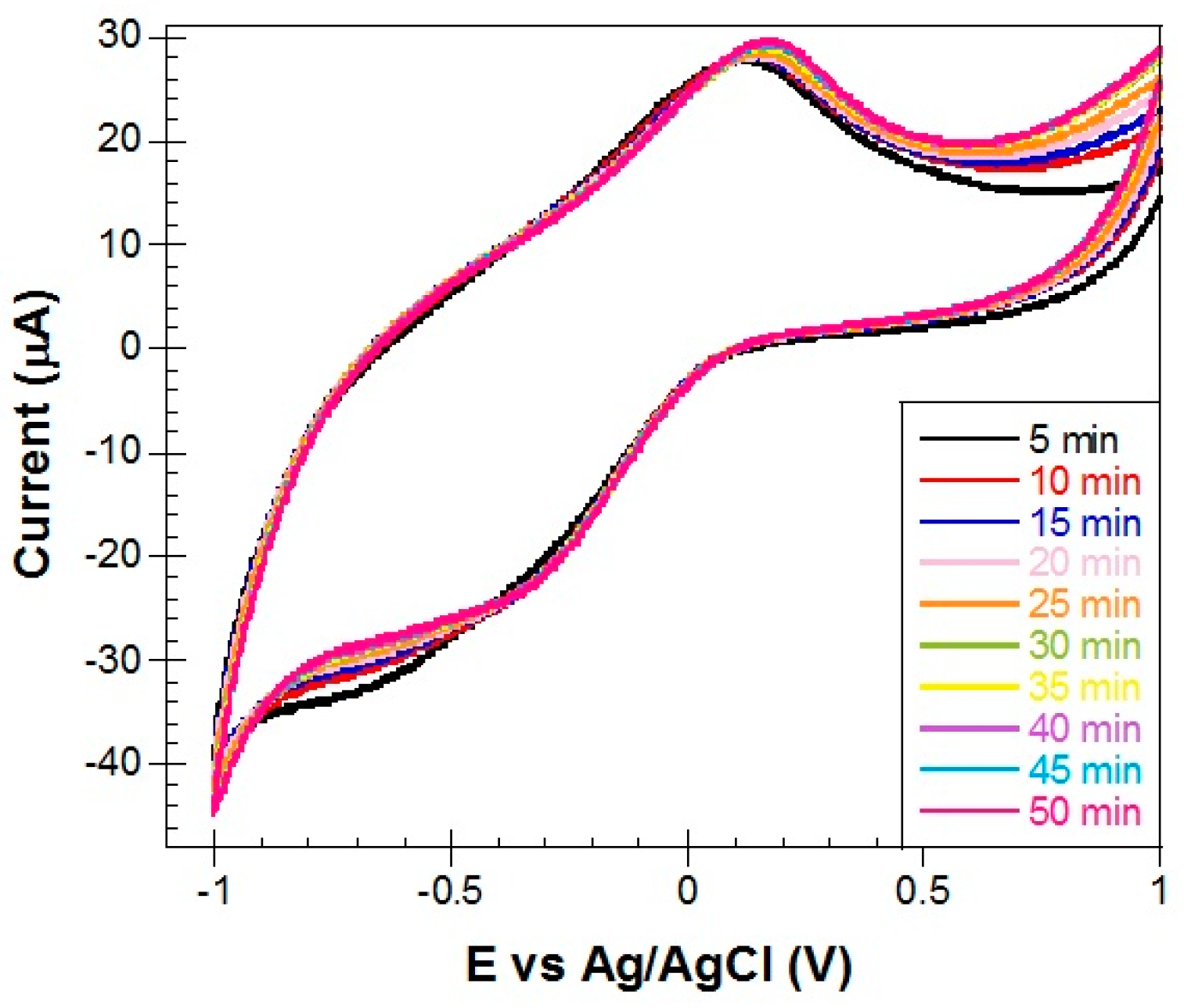

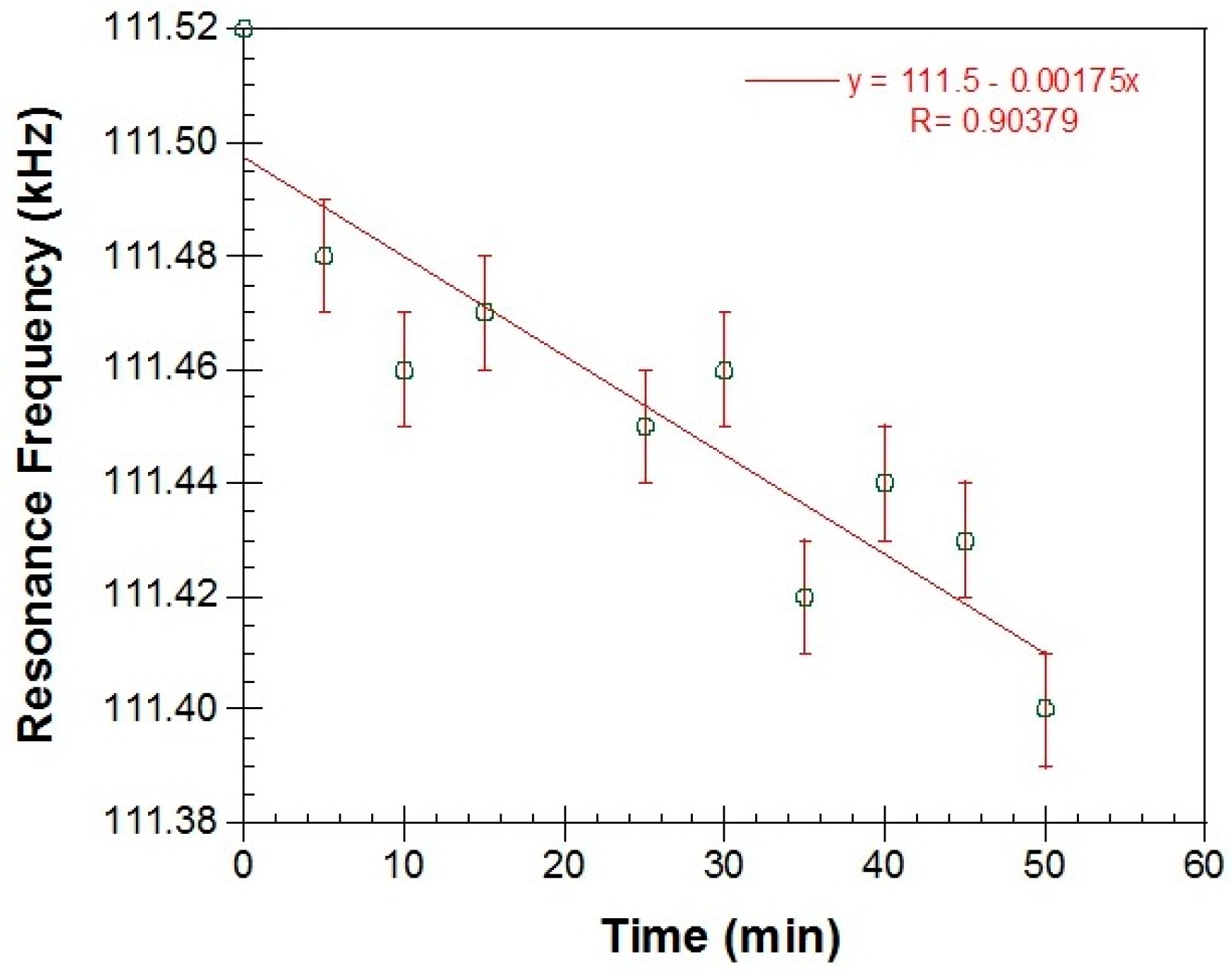

4.3.2. Simultaneous Electrochemical and Magnetoelastic Resonant Detection of H2O2

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Duan, G.; Li, Y.; Wen, Y.; Ma, X.; Wang, Y.; Ji, J.; Wu, P.; Zhang, Z.; Yang, H. Direct electrochemistry and electrocatalysis of Hemoglobin/ZnO-Chitosan/nano-Au modified glassy carbon electrode. Electroanalysis 2008, 20, 2454–2459. [Google Scholar] [CrossRef]

- Rifkind, J.; Nagababu, E.; Ramasamy, S.; Ravi, L.B. Hemoglobin redox reactions and oxidative stress. Redox Rep. 2003, 8. [Google Scholar] [CrossRef] [PubMed]

- Liu, J.F.; Roussel, C.; Lagger, G.; Tacchini, P.; Girault, H.H. Antioxidant sensors based on DNA-modified electrodes. Anal. Chem. 2005, 77, 7687–7694. [Google Scholar] [CrossRef] [PubMed]

- Jing, Z.H.; Zhan, J.H. Fabrication and gas sensing properties of porous ZnO nanoplates. Adv. Mater. 2008, 20, 4547–4551. [Google Scholar] [CrossRef]

- Fang, X.; Bando, Y.; Liao, M.; Gautam, U.K.; Zhi, C.; Dierre, B.; Liu, B.; Zhai, T.; Sekiguchi, T.; Koide, Y.; et al. Single-crystalline ZnS nanobelts as ultraviolet-light sensors. Adv. Mater. 2009, 21, 2034–2039. [Google Scholar] [CrossRef]

- Wei, A.; Xu, C.X.; Sun, X.W.; Huang, W.; Lo, G.Q. Field emission from hydrothermally grown ZnO nanoinjectors. J. Display Technol. 2008, 4, 9–12. [Google Scholar]

- Wang, Z.L. Towards self-powered nanosystems: From nanogenerators to nanopiezotronics. Adv. Funct. Mater. 2008, 18, 3553–3567. [Google Scholar] [CrossRef]

- Qi, Q.; Zhang, T.; Liu, L.; Zheng, X.J.; Yu, Q.J.; Zeng, Y.; Yang, H.B. Selective acetone sensor based on dumbbell-like ZnO with rapid response and recovery. Sens. Actuators B 2008, 134, 166–170. [Google Scholar] [CrossRef]

- Solanki, P.R.; Kaushik, A.; Ansari, A.A.; Sumana, G.; Malhotra, B.D. Zinc oxide-chitosan nanobiocomposite for urea sensor. Appl. Phys. Lett. 2008, 93, 163903. [Google Scholar] [CrossRef]

- Zhang, Y.; Nayak, T.R.; Hong, H.; Cai, W. Biomedical applications of zinc oxide nanomaterials. Cur. Mol. Med. 2013, 13, 1633–1645. [Google Scholar] [CrossRef]

- Mirzaei, H.; Darroudi, M. Zinc oxide nanoparticles: Biological synthesis and biomedical applications. Ceram. Int. 2017, 43, 907–914. [Google Scholar] [CrossRef]

- Wei, A.; Pan, L.; Huang, W. Recent progress in the ZnO nanostructure-based sensors. Mater. Sci. Eng. B 2011, 176, 1409–1421. [Google Scholar] [CrossRef]

- Dar, G.N.; Umar, A.; Zaidi, S.A.; Baskoutas, S.; Hwang, S.W.; Abaker, M.; Al-Hajry, A.; Al-Sayari, S.A. Ultra-high sensitive ammonia chemical sensor based on ZnO nanopencils. Talanta 2012, 89, 155–161. [Google Scholar] [CrossRef] [PubMed]

- Mehta, S.K.; Singh, K.; Umar, A.; Chaudhary, G.R.; Singh, S. Ultra-high sensitive hydrazine chemical sensor based on low-temperature grown ZnO nanoparticles. Electrochim. Acta 2012, 69, 128–133. [Google Scholar] [CrossRef]

- Chrissanthopoulos, A.; Baskoutas, S.; Bouropoulos, N.; Dracopoulos, V.; Tasis, D.; Yannopoulos, S.N. Novel ZnO nanostructures grown on carbon nanotubes by thermal evaporation. Thin Solid Films 2007, 515, 8524–8528. [Google Scholar] [CrossRef]

- Baskoutas, S.; Giabouranis, P.; Yannopoulos, S.N.; Dracopoulos, V.; Toth, L.; Chrissanthopoulos, A.; Bouropoulos, N. Preparation of ZnO nanoparticles by thermal decomposition of zinc alginate. Thin Solid Films 2007, 515, 8461–8464. [Google Scholar] [CrossRef]

- Baruah, S.; Dutta, J. Hydrothermal growth of ZnO nanostructures. Sci. Technol. Adv. Mater. 2009, 10, 013001. [Google Scholar] [CrossRef] [PubMed]

- Morkoç, H.; Özgur, Ü. Chapter I: General properties of ZnO. In Zinc Oxide: Fundamentals, Materials and Device Technology; WILEY-VCH Verlag GmbH & Co.: Weinheim, Germany, 2009; pp. 1–76. [Google Scholar]

- Polarz, S.; Roy, A.; Lehmann, M.; Driess, M.; Kruis, F.E.; Hoffmann, A.; Zimmer, P. Structure–property–function relationships in nanoscale oxide sensors: A case study based on zinc oxide. Adv. Funct. Mater. 2007, 17, 1385–1391. [Google Scholar] [CrossRef]

- Chen, W.; Cai, S.; Ren, Q.Q.; Wen, W.; Zhao, Y.D. Recent advances in electrochemical sensing for hydrogen peroxide: A review. Analyst 2012, 137, 49–58. [Google Scholar] [CrossRef] [PubMed]

- Shamsipur, M.; Pashabadi, A.; Molaabasi, F. A novel electrochemical hydrogen peroxide biosensor based on hemoglobin capped gold nanoclusters-chitosan composite. RSC Adv. 2015, 5, 61725–61734. [Google Scholar] [CrossRef]

- Xu, Y.; Hu, C.; Hu, S. A hydrogen peroxide biosensor based on direct electrochemistry of hemoglobin in Hb-Ag sol films. Sens. Actuators B 2008, 130, 816–822. [Google Scholar] [CrossRef]

- Weissbluth, M. Hemoglobins (Cooperativity and Electronic Properties); Springer: Berlin/Heidelberg, Germany, 1974; ISBN 3-540-06582-2. [Google Scholar]

- Zhang, C.L.; Liu, M.C.; Li, P.; Xian, Y.Z.; Chang, Y.X.; Zhang, F.F.; Wang, X.L.; Jin, L.T. Fabrication of ZnO nanorods modified electrode and its application to the direct electrochemical determination of hemoglobin and cytochrome c. Chin. J. Chem. 2005, 23, 144–148. [Google Scholar] [CrossRef]

- Stoyanov, P.G.; Grimes, C.A. A remote query magnetostrictive viscosity sensor. Sens. Actuators A 2000, 80, 8–14. [Google Scholar] [CrossRef]

- Van der Burgt, C.M. Dynamical physical parameters of the magnetostrictive excitation of extensional and torsional vibrations in ferrites. Philips Res. Rep. 1953, 8, 91–132. [Google Scholar]

- Luborsky, F.E. Chapter 6: Amorphous ferromagnets. In Handbook of Magnetic Materials; North-Holland Publishing: Amsterdam, The Netherlands, 1980; ISBN 978-0-444-85311-0. [Google Scholar]

- Bouropoulos, N.; Kouzoudis, D.; Grimes, C. The real-time, in situ monitoring of calcium oxalate and brushite precipitation using magnetoelastic sensors. Sens. Actuators B 2005, 109, 227–232. [Google Scholar] [CrossRef]

- Topoglidis, E.; Astuti, Y.; Duriaux, F.; Gratzel, M.; Durrant, J.R. Direct electrochemistry and nitric oxide interaction of heme proteins adsorbed on nanocrystalline tin oxide electrodes. Langmuir 2003, 19, 6894–6900. [Google Scholar] [CrossRef]

- Reynolds, D.C.; Look, D.C.; Jogai, B. Fine structure on the green band in ZnO. J. Appl. Phys. 2001, 89, 6189–6191. [Google Scholar] [CrossRef]

- Chen, H.; Gu, S.; Tang, K.; Zhu, S.; Zhu, Z.; Ye, J.; Zhang, R.; Zheng, Y. Origins of green band emission in high-temperature annealed N-doped ZnO. J. Lumin. 2011, 131, 1189–1192. [Google Scholar] [CrossRef]

- Borseth, T.M.; Svenson, B.G.; Kuznetsov, A.Y.; Klason, P.; Zhao, Q.X.; Willander, M. Identification of oxygen and zinc vacancy optical signals in ZnO. Appl. Phys. Lett. 2006, 89, 262112. [Google Scholar] [CrossRef]

- Schmidt, S.; Grimes, C.A. Elastic modulus measurement of thin films coated onto magnetoelastic ribbons. IEEE Trans. Mag. 2001, 37, 2731–2733. [Google Scholar] [CrossRef]

- Baimpos, T.; Giannakopoulos, I.G.; Nikolakis, V.; Kouzoudis, D. Effect of gas adsorption on the elastic properties of faujasite films measured using magnetoelastic sensors. Chem. Mater. 2008, 20, 1470–1475. [Google Scholar] [CrossRef]

- Manoharan, M.P.; Desai, A.V.; Neely, G.; Haque, M.A. Synthesis and elastic characterization of zinc oxide nanowires. J. Nanomater. 2008, 1. [Google Scholar] [CrossRef]

- Landau, L.D.; Lifshitz, E.M. Theory of Elasticity. In A Course of Theoretical Physics, 2nd ed.; Pergamon Press: Oxford, UK, 1970. [Google Scholar]

- Livingston, J.D. Magnetomechanical properties of amorphous metals. Phys. Stat. Sol. A 1982, 70, 591–596. [Google Scholar] [CrossRef]

- Kobiakov, I.B. Elastic, piezoelectric and dielectric properties of ZnO and CdS single crystals in a wide range of temperatures. Solid State Commun. 1980, 35, 305–310. [Google Scholar] [CrossRef]

- Song, J.; Wang, X.; Riedo, E.; Wang, Z.L. Elastic property of vertically aligned nanowires. Nano Lett. 2005, 5, 1954–1958. [Google Scholar] [CrossRef] [PubMed]

- Desai, A.V.; Haque, M.A. Mechanical properties of ZnO nanowires. Sens. Actuators A 2007, 134, 169–176. [Google Scholar] [CrossRef]

- Ji, L.W.; Young, S.J.; Fang, T.H.; Liu, C.H. Buckling characterization of vertical ZnO nanowires using nanoindentation. Appl. Phys. Lett. 2007, 90, 033109. [Google Scholar] [CrossRef]

- Bai, X.D.; Gao, P.X.; Wang, Z.L.; Wang, E.G. Dual-mode mechanical resonance of individual ZnO nanobelts. Appl. Phys. Lett. 2003, 82, 4806–4808. [Google Scholar] [CrossRef]

- Wang, Z.L. Zinc oxide nanostructures: Growth, properties and applications. J. Phys. Condens. Matter 2004, 16, R829–R858. [Google Scholar] [CrossRef]

- Mollan, T.L.; Alayash, A.I. Redox reactions of Hemoglobin: Mechanism of toxicity and control. Antioxid. Redox Signal. 2013, 18, 2251–2253. [Google Scholar] [CrossRef] [PubMed]

- Gonga, C.; Shena, Y.; Chena, J.; Songa, Y.; Chena, S.; Songa, Y.; Wanga, L. Microperoxidase-11@PCN-333 (Al)/three-dimensional microporous carbon electrode for sensing hydrogen peroxide. Sens. Actuators B-Chem. 2017, 239, 890–897. [Google Scholar] [CrossRef]

- Topoglidis, E.; Cass, A.E.G.; O’Regan, B.; Durrant, J.R. Immobilization and bioelectrochemistry of proteins on nanoporous TiO2 and ZnO films. J. Electroanal. Chem. 2001, 517, 20–27. [Google Scholar] [CrossRef]

- Altube, A.; Pierna, A.R. Thermal and electrochemical properties of cobalt containing Finemet type alloys. Electrochem. Acta 2004, 49, 303–311. [Google Scholar] [CrossRef]

- Bard, A.J.; Faulkner, L.R. Electrochemical Methods Fundamentals and Applications, 2nd ed.; John Wiley & Sons: New York, NY, USA, 2001. [Google Scholar]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Sagasti, A.; Bouropoulos, N.; Kouzoudis, D.; Panagiotopoulos, A.; Topoglidis, E.; Gutiérrez, J. Nanostructured ZnO in a Metglas/ZnO/Hemoglobin Modified Electrode to Detect the Oxidation of the Hemoglobin Simultaneously by Cyclic Voltammetry and Magnetoelastic Resonance. Materials 2017, 10, 849. https://doi.org/10.3390/ma10080849

Sagasti A, Bouropoulos N, Kouzoudis D, Panagiotopoulos A, Topoglidis E, Gutiérrez J. Nanostructured ZnO in a Metglas/ZnO/Hemoglobin Modified Electrode to Detect the Oxidation of the Hemoglobin Simultaneously by Cyclic Voltammetry and Magnetoelastic Resonance. Materials. 2017; 10(8):849. https://doi.org/10.3390/ma10080849

Chicago/Turabian StyleSagasti, Ariane, Nikolaos Bouropoulos, Dimitris Kouzoudis, Apostolos Panagiotopoulos, Emmanuel Topoglidis, and Jon Gutiérrez. 2017. "Nanostructured ZnO in a Metglas/ZnO/Hemoglobin Modified Electrode to Detect the Oxidation of the Hemoglobin Simultaneously by Cyclic Voltammetry and Magnetoelastic Resonance" Materials 10, no. 8: 849. https://doi.org/10.3390/ma10080849

APA StyleSagasti, A., Bouropoulos, N., Kouzoudis, D., Panagiotopoulos, A., Topoglidis, E., & Gutiérrez, J. (2017). Nanostructured ZnO in a Metglas/ZnO/Hemoglobin Modified Electrode to Detect the Oxidation of the Hemoglobin Simultaneously by Cyclic Voltammetry and Magnetoelastic Resonance. Materials, 10(8), 849. https://doi.org/10.3390/ma10080849