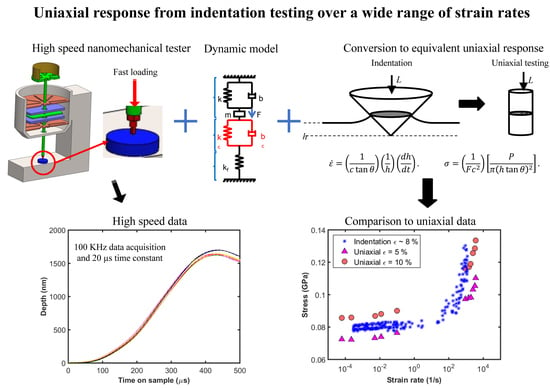

2.1. Measuring Strain Rate Dependence of Hardness

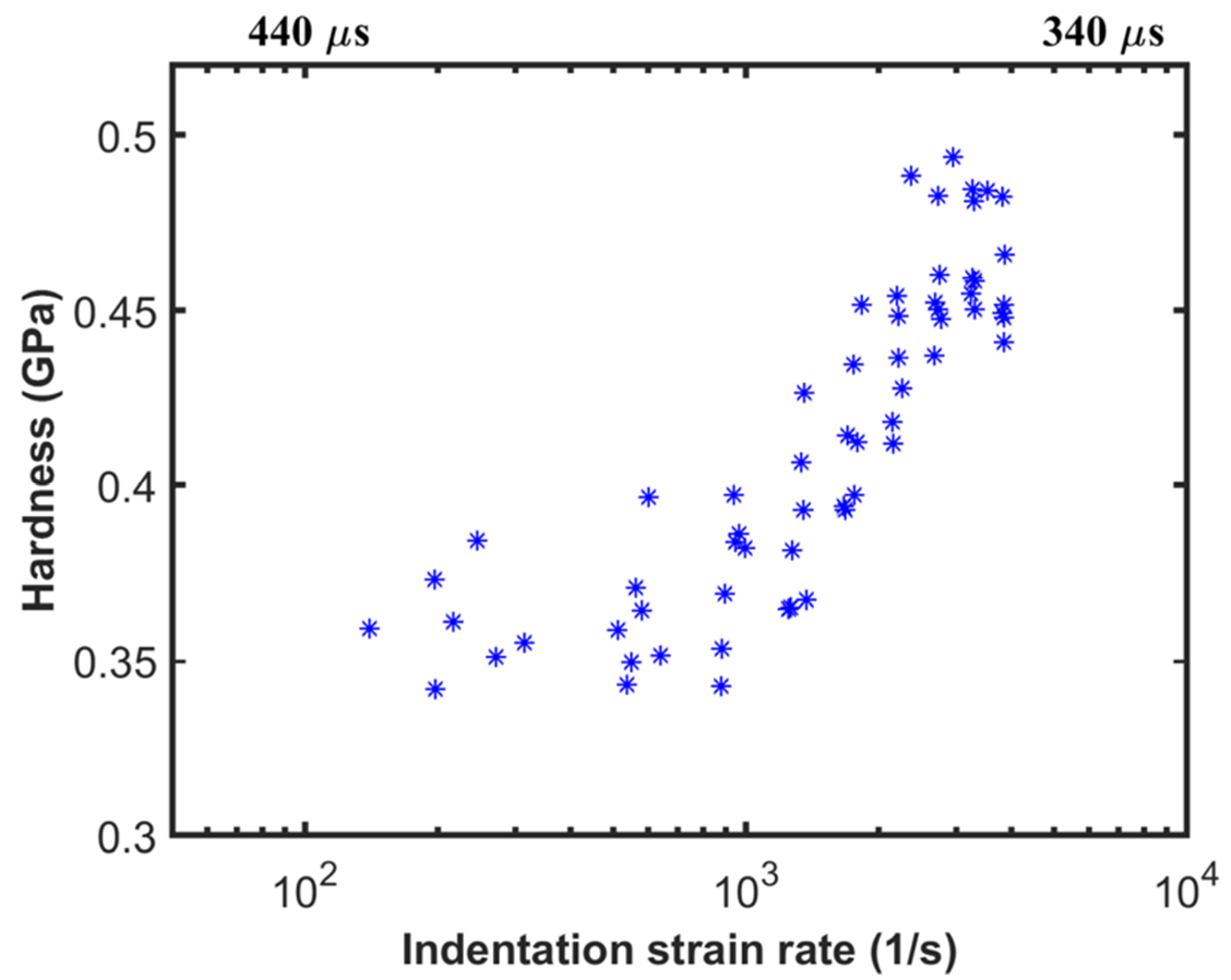

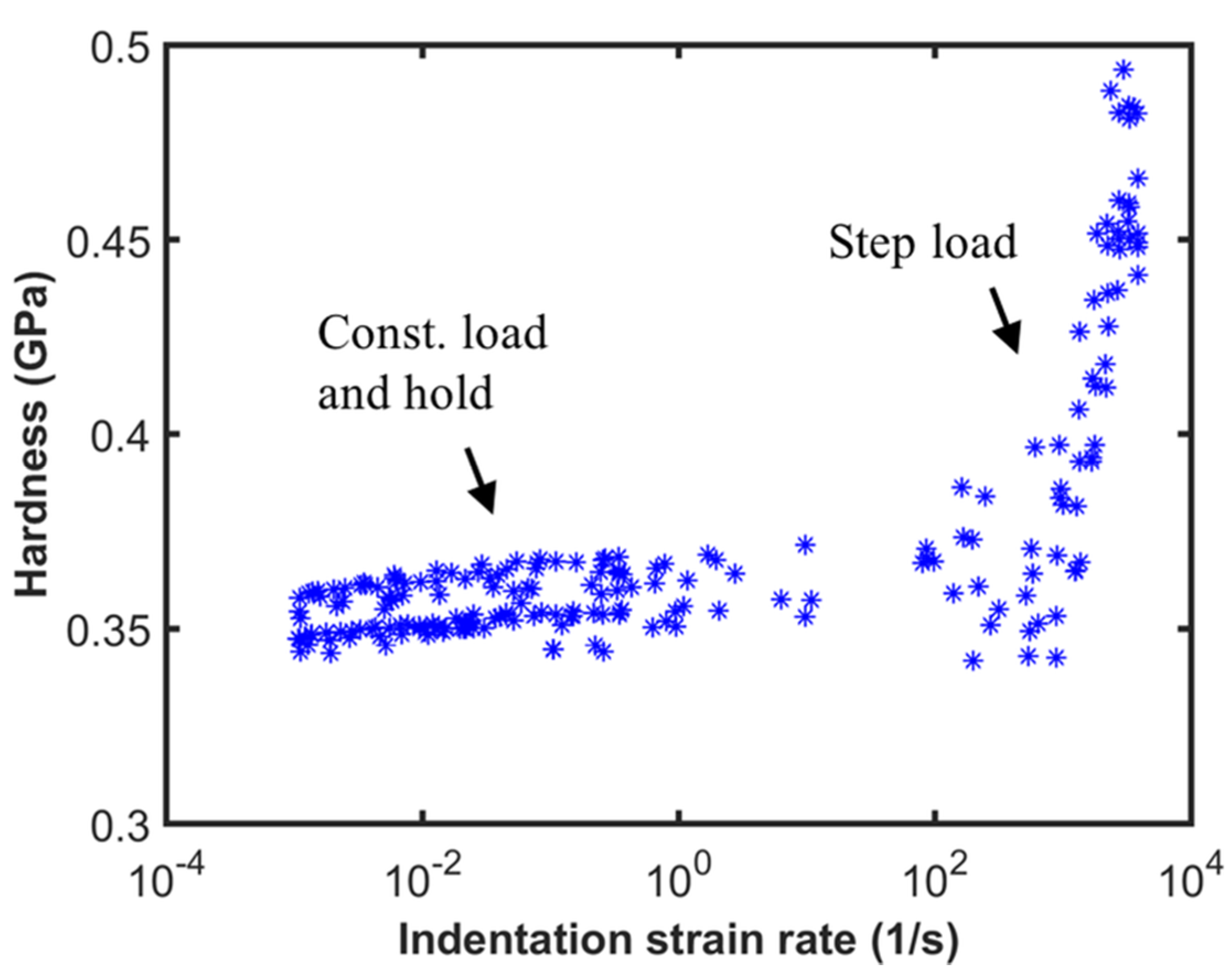

As mentioned earlier, indentation based techniques have been widely used to measure the strain rate dependence of hardness in the lower strain rate regime (<1 1/s). The strain rate during an indentation test is often defined as the ratio of the indenter velocity to the depth of indentation. Accessing higher strain rates requires higher indentation velocities at a given depth, or a lower depth for a given velocity or a combination of both. In order to minimize the contributions from indentation size effect (ISE) [

17], it is preferable to access higher strain rates by achieving higher velocities at large depths. This can be accomplished by performing a step load test wherein the force is ramped as fast as the actuator used can physically accomplish the change. This results in sweeping a wide range of strain rates in the high strain rate regime in a single indentation test. The major requirements to perform these tests is a testing system with fast response actuators and sensors and a model for instrument’s dynamics and electronics to accurately factor out the instrument’s contribution from the measured response. These will be described in greater detail in the subsequent subsections.

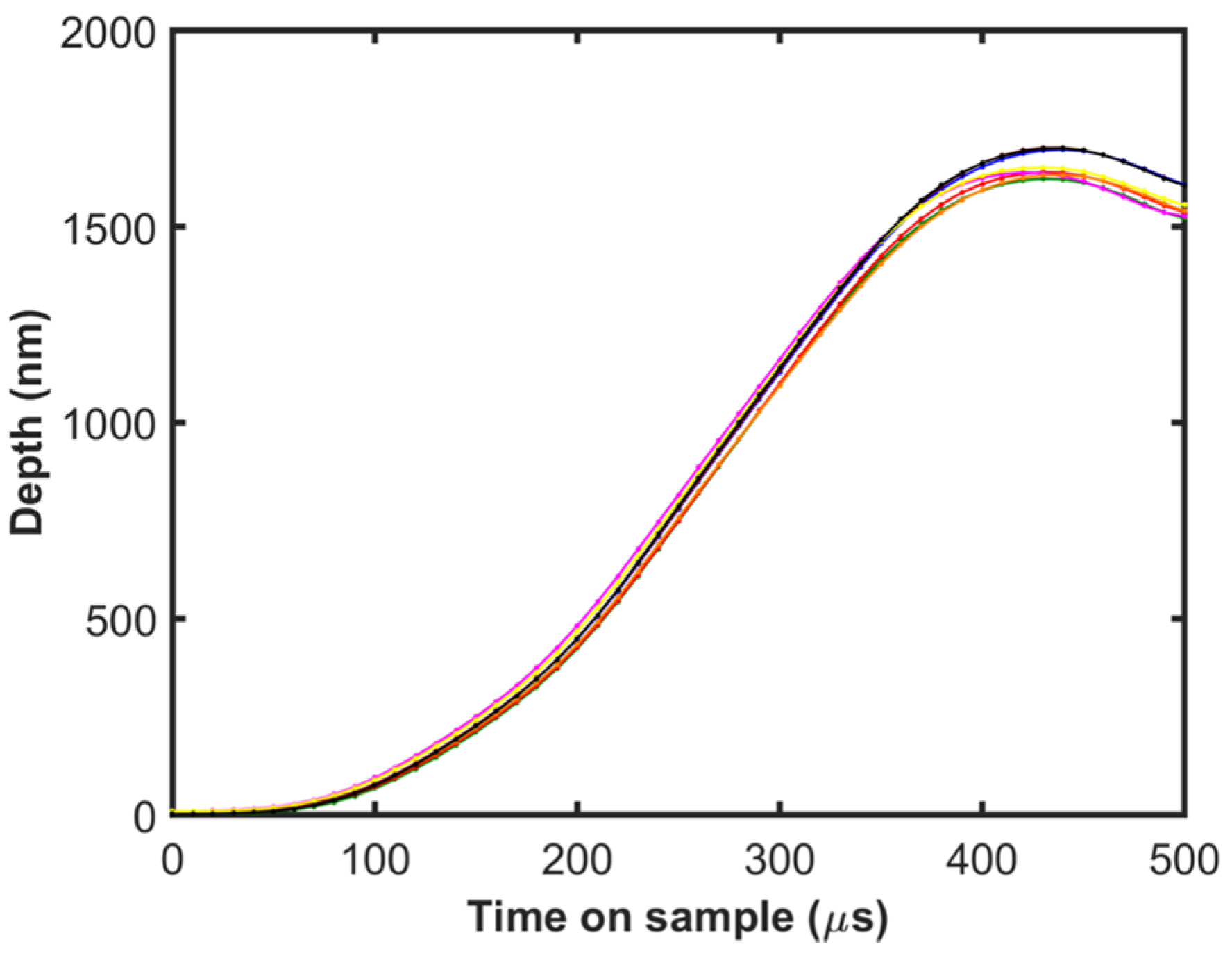

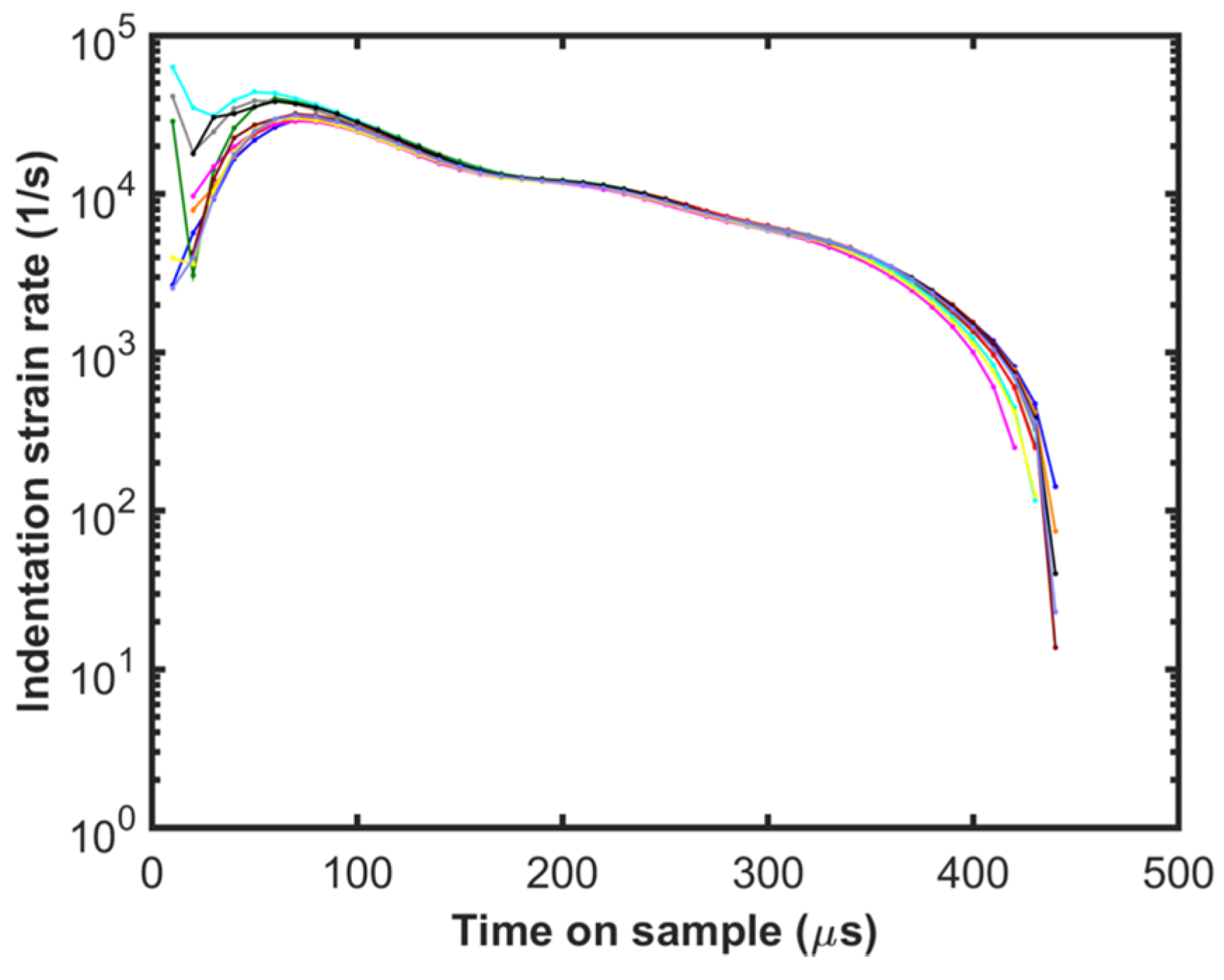

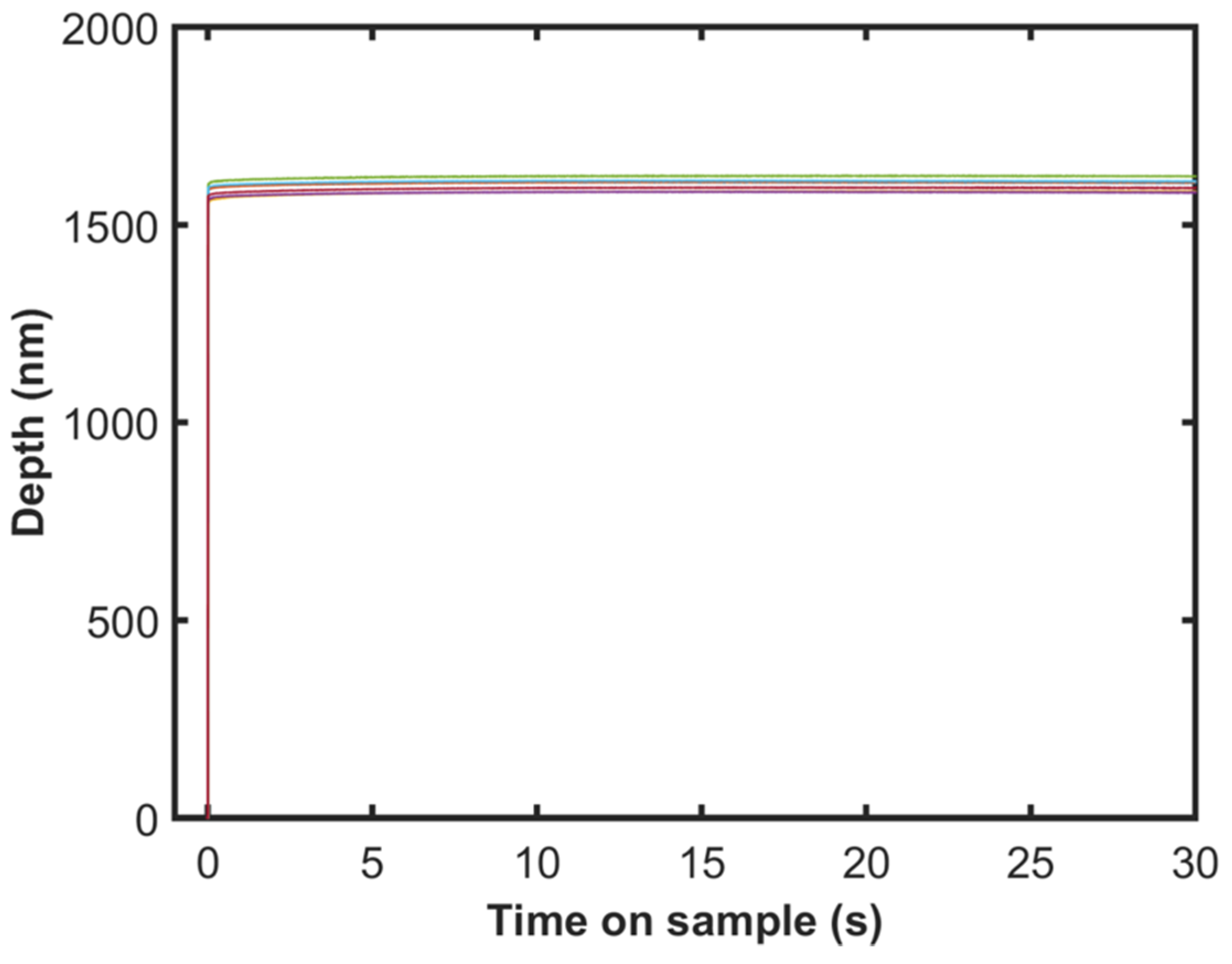

Step load tests and the conventional constant load and hold (CLH) indentation tests were performed to a static load of 16 mN to cover a wide range of indentation strain rates. In both the cases, the tip is brought in contact with the sample at a slow approach rate of 200 nm/s. The CLH tests were performed by ramping the load to 16 mN at a loading rate of 5 N/s after contact and subsequently maintaining a constant force for 30 s. In the case of step load tests, a step force of 16 mN was input to the force actuator after contact. Note that the step load tests are not impact tests as the tip approaches the sample slowly before contact and the fast loading is only after contact. Unlike the CLH test, due to the fast loading in a step load test, there are significant inertial effects which result in actual load on sample being much higher than the applied step force of 16 mN for a short span. This is immediately followed by a decrease in the load on the sample due to the exhaustion of the dynamic forces, resulting in unloading of the contact even while the actuator applies the 16 mN force. This will be discussed in greater detail in

Section 3.1. All the tests were performed on a 10 mm diameter commercial purity aluminum (1100 aluminum) sample which was polished and subsequently annealed at 350 °C for 4 h before testing. Ten repetitive step load and CLH tests were performed to ensure repeatability in the data. A diamond Berkovich tip (Micro Star Technologies, Huntsville, TX, USA) was used for all the tests. The load frame stiffness determination and tip area calibration was done using the results of constant strain rate tests (0.2 1/s) on fused silica. For these tests, the contact stiffness was continuously measured as a function of depth using a phase lock amplifier (Nanomechanics Inc., Oak Ridge, TN, USA) oscillating at 100 Hz frequency and a 2 nm displacement amplitude.

2.2. Measuring Instrumentation

In order to perform a step load test, the testing system requires a force actuator that can apply the desired force in a short time interval, which is typically less than a millisecond, and a displacement sensor that can accurately capture the rapid change in the displacement during that time. In addition, a high data acquisition rate is required. In a typical commercially-available nanoindentation system with an electromagnetic actuator, force is controlled by the current to the coil, which is a command signal, and the displacement is measured by a capacitance gage, which is a measured signal. To perform a step load test, a step function in current is sent as a command input to the actuator. Due to the finite time constant of the force signal, the actual force delivered by the actuator is not an instantaneous step function, but an exponential function with a finite rise time. The time constant of a signal is a parameter that characterizes the response of a signal to a unit step input. For first order linear-time invariant systems, it is the time required to reach 63% of its step input value or one third the time required to reach 95% of its step input. Hence, if the time scale of the test is comparable to the time constants of the measurement signals, corrections to the signals are required. In order to minimize these corrections, it is desirable to have measurement time constants much shorter than the time scale of measurement.

The step load tests in the current work were performed using a commercially available nanoindenter, iNano® from Nanomechanics Inc., Oak Ridge, TN, USA. It uses an electromagnetically-actuated InForce50 actuator with a force time constant of 290 µs, a displacement time constant of 20 µs, and data acquisition rate of 100 kHz. Force is the command signal and the displacement is the measured signal. The displacement sensor has sub nanometer noise levels even at a short time constant of 20 µs. This is critical for high strain rate testing as the velocity and acceleration are calculated by taking the first and second derivative of the displacement signal and any noise is amplified, especially by the second derivative.

2.3. Model for the Instrument’s Dynamics and Electronics

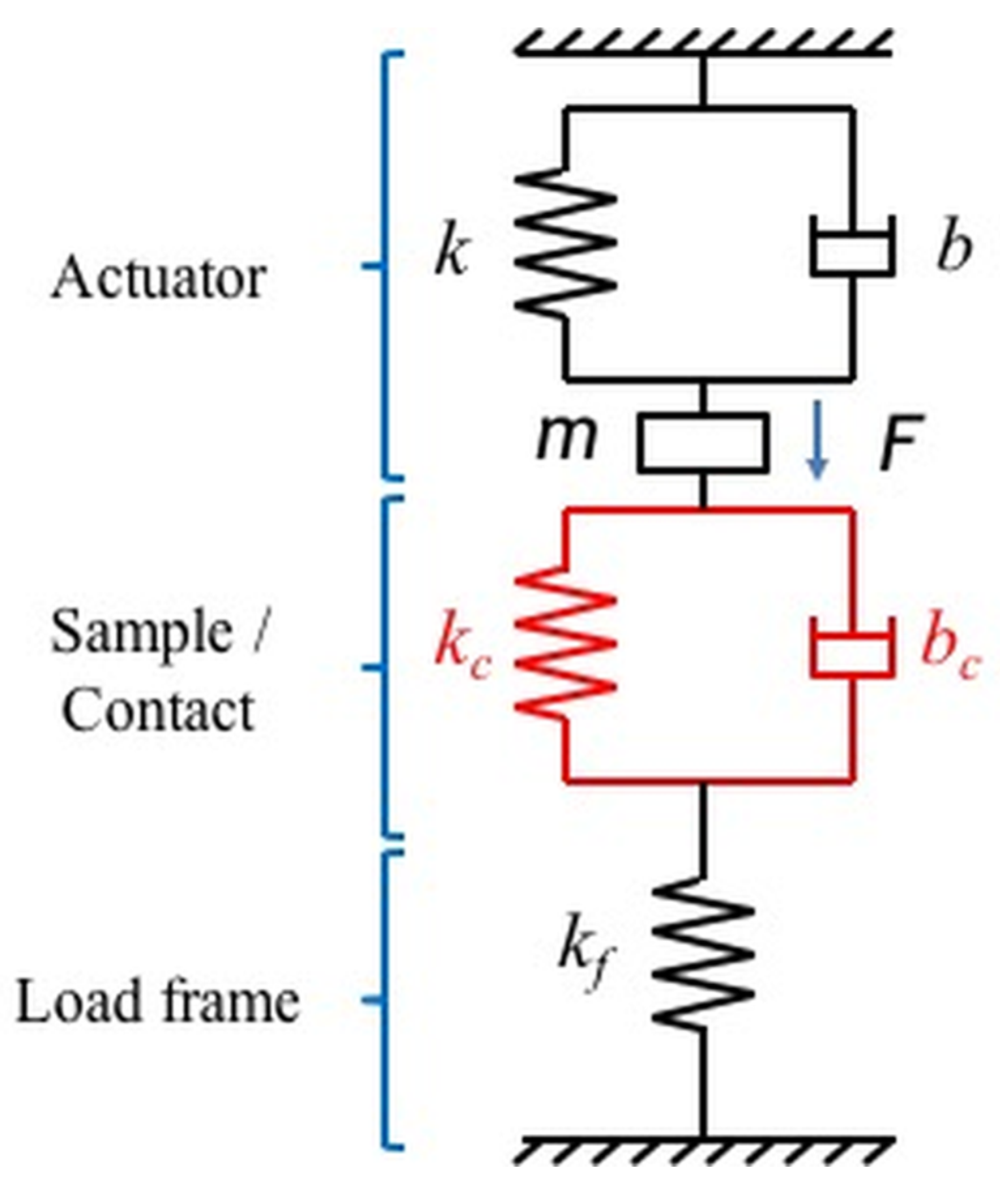

At high strain rates, the instrument’s dynamic contribution can dominate the measured response and can lead to inaccuracies in the measurement. In order to account for the instrument’s dynamic contribution, a simple one degree of freedom (one DOF) damped harmonic oscillator model is proposed to model the electromagnetically-actuated indentation system. A schematic of the model is shown in

Figure 1. The actuator is modeled as a single mass, spring, and dashpot system where the mass,

m, is the moving mass of the coil and the indenter shaft, damping coefficient,

b, is the damping generated due to resistance to the motion of the air in the capacitance gage and the eddy current damping in an electromagnetic actuator and the spring constant,

k, is the spring constant of the leaf springs that support the indenter shaft. The sample or the contact is modeled as a spring and dashpot, which represents the contact stiffness and damping, respectively. As the moving mass of the sample is very small compared to the mass of the system, it is neglected. The load frame which holds the indentation system is modeled as a spring for simplicity.

The one DOF model shown in

Figure 1 is one of the simplest possible dynamic models for an indentation system and given the complexity of most indentation systems, demonstrating that the testing system can be accurately described by this model is critical for high strain rate testing where the instruments contribution can dominate the measured response. Once the simple model for the actuator is validated its dynamic contribution can be simply factored out to accurately determine the response of the sample.

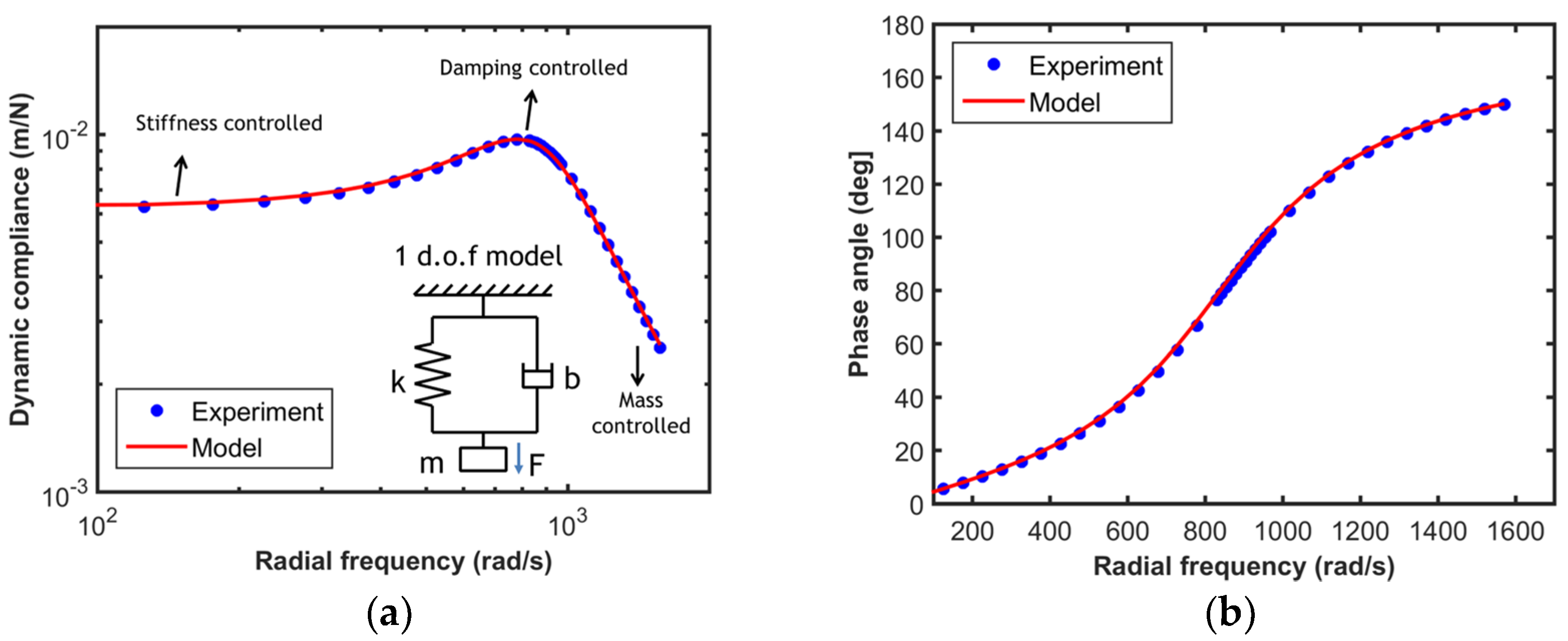

In order to validate the one DOF model for the actuator, a frequency sweep experiment is performed, wherein the actuator is excited dynamically at a fixed sinusoidal force oscillation amplitude over a wide range of frequency in free air (i.e., without a sample), The resultant dynamic displacement amplitude and the phase lag between the force and displacement signals are measured using a phase lock amplifier (PLA).

Figure 2a shows the results of a typical frequency sweep experiment for an InForce50 actuator, wherein the measured dynamic compliance of the instrument in free air, which is the ratio of the dynamic displacement amplitude (

) to the dynamic force amplitude (

), is plotted as a function of the excitation frequency (

). This is commonly referred to as the transfer function of the instrument. The dynamic compliance (

C) and phase (

ø) for a one DOF oscillator can be theoretically calculated using the following equations.

The experimental data shown in the plot can be fit to a functional form given in Equation (1) to assess the suitability of using the one DOF model for the instrument. The solid red line in the plot shows the one DOF model fit to the experimental data. This plot clearly demonstrates that the actuator can be accurately modeled as a simple one DOF oscillator. The mass (

m), damping coefficient (

b), and spring constant (

k) of the actuator used for the current work are 180.45 mg, 0.106 Ns/m, and 243 N/m, respectively.

Figure 2b shows the experimental data and the model prediction for the phase angle between the displacement and force signals, reinforcing the excellent agreement in the results observed from the transfer function plot and also demonstrating the accuracy of the phase angle measurements. While the one DOF model presented here is simple, it can even be used under non-ambient conditions (vacuum or elevated temperature) for electromagnetic actuators as they do not require a medium for damping. This enables high strain rate experiments under vacuum or elevated temperatures.

In addition to the dynamic effects of the instrument, understanding and accounting for the time constants of the measurement signals is important for making accurate high strain rate measurements. As discussed in

Section 2.2, time constant correction to the signals is required if the time scale of testing is comparable to the measurement time constant. A simple first order correction can be performed to the signal to account for the finite time constant, by the following equation:

where

is the corrected signal,

is the measured signal,

is the rate of change of the measured signal, and

is the time constant.

While the transfer function plot demonstrates that the instrument can be modeled as a one DOF oscillator, it does not prove the accuracy of the model parameters

m,

b, and

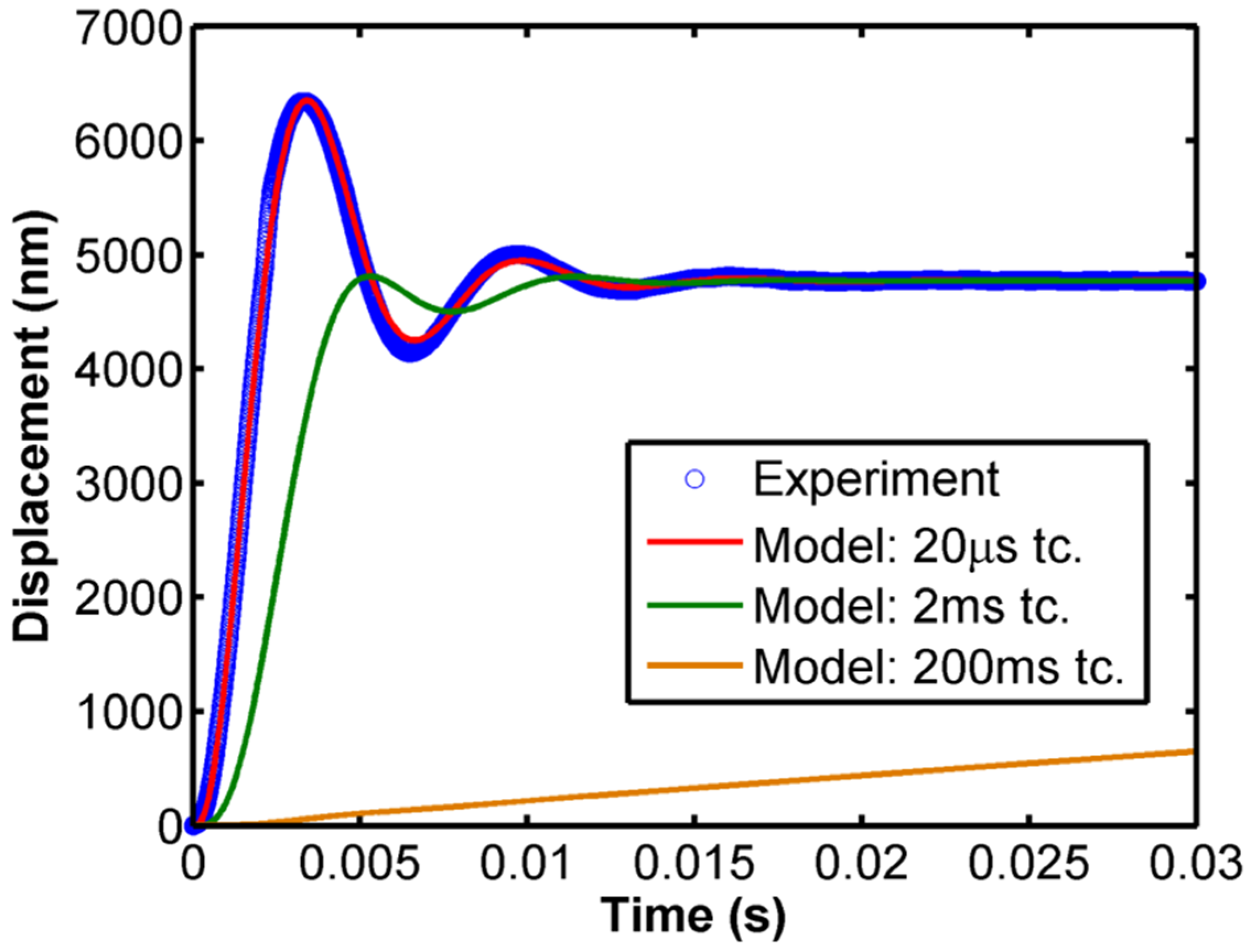

k when applied in conjunction with the time constants of the force and displacement signals which can have a significant effect during fast testing. In order to verify the accuracy of the time constant correction and dynamic model, a step load test is performed in free air wherein the force command signal is instantaneously stepped to 1 mN and the resultant displacement response is recorded at 100 kHz.

Figure 3 shows the comparison of the experimental data for a typical InForce50 actuator and model prediction for a one DOF model at different time constants. There is excellent agreement between the experimental data and model predictions for a 20 µs time constant displacement signal. This demonstrates the validity of the model for the instrument’s dynamics, as well as the electronics and, hence, can be used to accurately factor out the contribution of the instrument to the total measurement which will be discussed in greater detail in

Section 2.4. The plot also shows the predicted response for 1 ms and 200 ms time constant displacement signals which show significant deviation from the actual response. Note that the data acquisition rate for all of the curves is 100 kHz and the difference is only in the time constant. While having a high data acquisition rate is important, this plot clearly demonstrates the need for a short time constant to accurately capture dynamic events.

2.4. Calculation of the Indentation Strain Rate and Hardness

This section presents the procedure for calculating the indentation strain rate and hardness from the basic measurements, viz., force and displacement. As mentioned earlier, indentation strain rate is the ratio of indenter velocity (

) to the depth of penetration (

h). The depth of penetration is calculated by subtracting the displacement of the surface point from the measured displacement. The velocity (

) and acceleration (

) are calculated by taking the analytical first and second derivative, respectively, of the spline fit to the displacement-time response. In order to calculate the load on the sample, the dynamic contribution of the instrument needs to be factored out. This can be done by using the simple one DOF model for the actuator which has been shown to accurately describe the system in

Section 2.3. The equation to calculate the load on the sample (

P) factoring out the dynamic contribution of the instrument, is as follows:

where

F is the force output of the actuator and

h is the depth of penetration into the surface. Note that the load on the sample can be very different from the force output of the actuator depending on the dynamic contributions of the instrument. This difference is quite significant for the step load tests where the inertial term (

) dominates. For the case of the constant load and hold tests the contribution from the damping (

) and inertial terms is negligible as expected for static indentation.

Once the load on sample is calculated from Equation (4), the hardness is calculated using the conventional formula of load over the contact area. The contact area is calculated from the tip area function assuming a constant ratio of contact depth to total depth which, for this case, is found to be 0.99 based on the unloading data of the CLH tests.

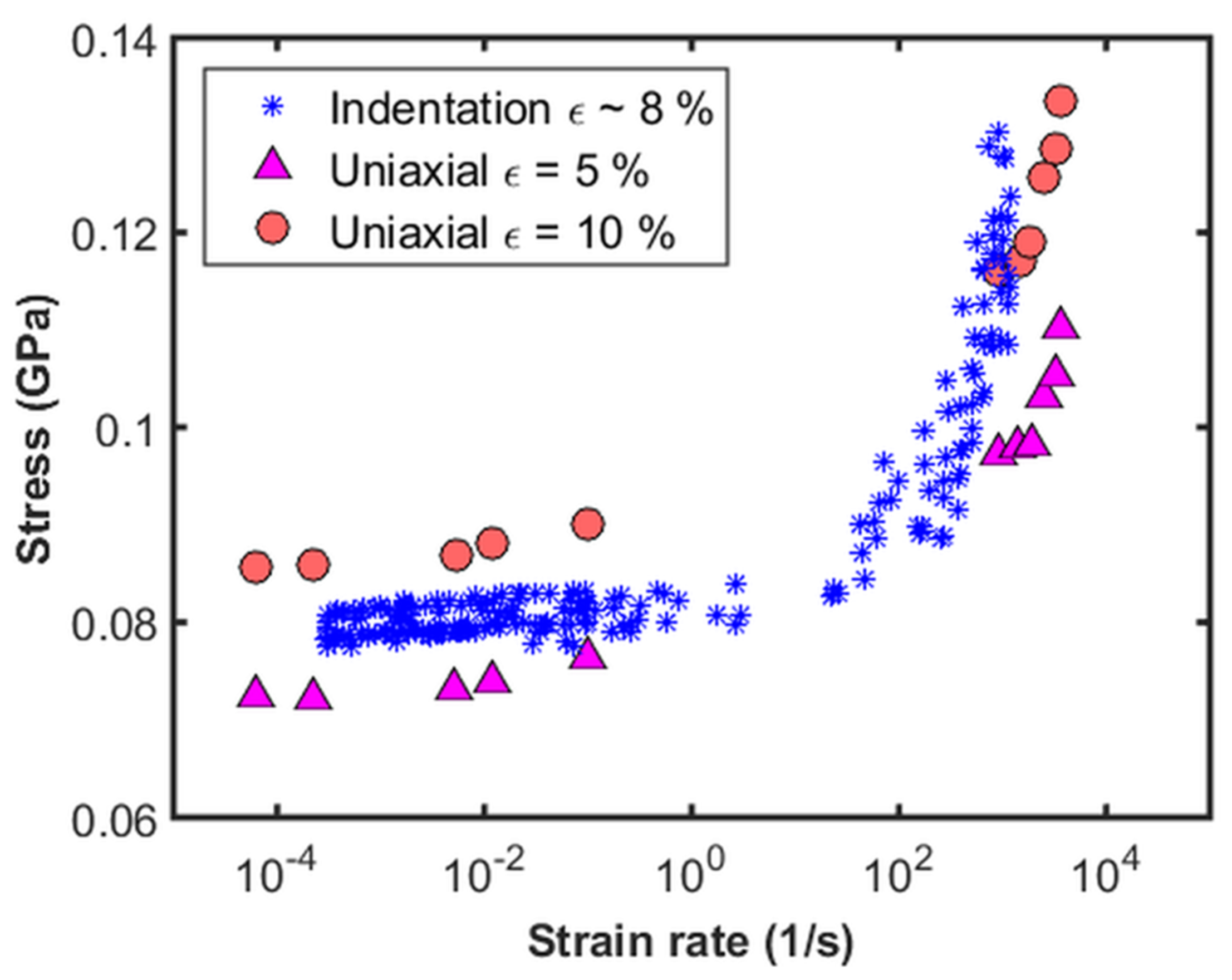

2.5. Estimating Equivalent Uniaxial Response

The experimental procedure and calculations described in the earlier sections enable the determination of hardness as a function of the indentation strain rate. However, in order to compare the data to the conventional measurements, which are based on uniaxial testing, uniaxial equivalent parameters have to be estimated from the indentation data, which is challenging given the complexity of the stress fields during indentation. Recently, Su et al. [

18] proposed a simple experimental technique based on the theoretical analysis of Bower et al. [

19] to determine uniaxial creep parameters from indentation. The equations used to calculate the uniaxial equivalent strain rate and stress are presented here while the details can be found in Su et al. [

18]. The equivalent uniaxial strain rate (

) and stress (

for a power-law creeping solid can be calculated from the basic indentation measurements (

h and

P) using the following equations:

In the above equations,

is the equivalent half cone angle, which is 70.3° for a Berkovich indenter and

F and

c are akin to constraint factor and pile-up/sink-in parameter, respectively.

F and

c are a function of the stress exponent and cone angle, and their functional dependence can be obtained from the recent work of Su et al. [

18].