Abstract

Ternary blends of poly(lactic acid) (PLA), poly(3-hydroxybutyrate) (PHB) and poly(ε-caprolactone) (PCL) with a constant weight percentage of 60%, 10% and 30% respectively were compatibilized with soybean oil derivatives epoxidized soybean oil (ESO), maleinized soybean oil (MSO) and acrylated epoxidized soybean oil (AESO). The potential compatibilization effects of the soybean oil-derivatives was characterized in terms of mechanical, thermal and thermomechanical properties. The effects on morphology were studied by field emission scanning electron microscopy (FESEM). All three soybean oil-based compatibilizers led to a noticeable increase in toughness with a remarkable improvement in elongation at break. On the other hand, both the tensile modulus and strength decreased, but in a lower extent to a typical plasticization effect. Although phase separation occurred, all three soybean oil derivatives led somewhat to compatibilization through reaction between terminal hydroxyl groups in all three biopolyesters (PLA, PHB and PCL) and the readily reactive groups in the soybean oil derivatives, that is, epoxy, maleic anhydride and acrylic/epoxy functionalities. In particular, the addition of 5 parts per hundred parts of the blend (phr) of ESO gave the maximum elongation at break while the same amount of MSO and AESO gave the maximum toughness, measured through Charpy’s impact tests. In general, the herein-developed materials widen the potential of ternary PLA formulations by a cost effective blending method with PHB and PCL and compatibilization with vegetable oil-based additives.

Keywords:

PLA; toughness; ternary blend; compatibilization; vegetable oils; environmentally friendly 1. Introduction

In the last decade poly(lactic acid) (PLA) has become one of the most promising biopolymers due to its balanced properties (mechanical, thermal, barrier, etc.) together with a cost competitive price and easy processing by conventional techniques. For these reasons, PLA finds increasing uses in a wide range of industrial sectors such as automotive [1,2,3,4], medical devices [5,6], construction and building, 3D printing [7,8], packaging [9,10,11,12], wood plastic composites (WPCs) [13,14], and so on. Nevertheless, PLA is a very fragile polymer with very low toughness. With the aim of increasing its toughness, important research has been carried out in the last decade. These research works have focused on different approaches to overcome this important drawback for most industrial uses. One approach is the use of plasticizers such as poly(ethylene glycol) (PEG) [15], acetyl tributyl citrate (ATBC) [16,17], triethyl citrate (TEC) [18], lactic acid oligomers [19,20,21], and so on. This solution is interesting as an important elongation at break is achieved, but other mechanical resistant properties (modulus, strength) are remarkably reduced. Another approach is copolymerization, for example, poly(lactide)-g-poly(butylene succinate-co-adipate) [22], but it is not a cost-effective solution. The third approach is blending PLA with other polymers to obtain toughened formulations. There are many works focused on binary blends of PLA with poly(ε-caprolactone) (PCL) [23,24], poly(hydroxyalkanoates) (PHAs) [9,10,25], thermoplastic starch (TPS) [26,27], poly(butylene succinate) (PBS) [28,29], poly(butylene succinate-co-adipate) (PBSA) [30], poly(butylene adipate-co-terephthalate) (PBAT) [31], cellulose [32], and so on. Due to the low miscibility of PLA with most polymers, the use of compatibilizers and/or reactive extrusion have been proposed as technical solutions to improve compatibility in binary PLA-based blends [30,33]. Moreover, ternary blends with PLA have also given good results in terms of improved toughness as tailored properties can be obtained by selecting the appropriate components and/or compatibilizers [24,34,35,36,37,38,39].

This search for high environmentally friendly tough PLA formulations also includes the use of low environmental impact additives, for example, plasticizers, compatibilizers, chain extenders, and so on. Vegetable oils (VOs) represent an interesting alternative to petroleum-derived polymers and additives [40,41,42]. VOs are composed of a triglyceride structure in which, three fatty acids are linked to a glycerol-base structure through ester bonds. Some fatty acids are very interesting from a chemical point of view due to presence of one or several unsaturations. These unsaturations allow different chemical modifications that can be used to tailor the desired properties [43]. Among all fatty acids, oleic, linoleic and linolenic acids, which contain one, two and three carbon-carbon double bonds respectively, play a key role in VO functionalization. There is a wide variety of VOs but industrially, linseed oil (LO) and soybean oil (SO) represent a high volume market. Today, it is possible to find epoxidized, maleinized and acrylated-epoxidized vegetable oils at industrial scale with different purposes. Epoxidized soybean oil (ESO) and epoxidized linseed oil (ELO) find interesting uses in the poly(vinyl chloride) (PVC) plasticization industry, as well as in the thermosetting industry as base resins for green composites. Torres-Giner et al. reported new PVC wood flour composites with epoxidized linseed oil (ELO) which played a dual role in plasticization and polymer-particle compatibilization [44]. The plasticization effect of epoxidized vegetable oils has also been studied in different biopolyesters, such as PLA and PHB, leading to a slight decrease in the glass transition temperature but important improvements on toughness [45,46,47]. Due to the high reactivity of the oxirane ring towards hydroxyl groups, epoxidized vegetable oils have also been used as compatibilizers in composite materials [48]. Samper et al. reported the potential of ELO-based composites with basalt fibers as substitutes of glass fiber composites, using different crosslinking agents [49,50]. Acrylated epoxidized soybean oil (AESO) finds increasing uses in partially biobased thermosetting acrylic and unsaturated polyester resins. Different research works have focused on the development of thermosetting resins with AESO directly [51] or with different copolymers, such as methacrylated eugenol [52], N-vinyl-2-pyrrolidone [53], isosorbide methacrylate [54], rosin-based acrylamide [55] and so on, with potential uses in composites. AESO has also been reported as additive in toughened PLA formulations [37]. Maleinized linseed oil has been proposed for a wide variety of industrial applications which include base for soluble resins, biolubricant formulations, wood treatments, base for vegetable polyols, among others. Carbonell-Verdu et al. reported a dual effect of maleinized cottonseed oil (MCSO) on PLA films: on one hand, some plasticization occurred and on the other hand, a chain extension/branching phenomenon was observed [56]. This chain extension effect was also reported by Ernzen et al. with polyamide 6 [57]. Ferri et al. also reported a compatibilization effect of maleinized linseed oil (MLO) on PLA blends with thermoplastic starch [58], and a clear improvement on toughness of neat PLA [59]. This positive effect of a maleinized vegetable oil on toughness was also found for poly(3-hydroxybutyrate) (PHB) as suggested by Garcia-Garcia et al. [60] In addition to its potential in the polymer industry, aqueous solutions of maleinized soybean oil (MSO) have been successfully used as formaldehyde-free coatings in textiles as reported by Ford et al. [61].

This work explores the potential of soybean oil derivatives, namely epoxidized soybean oil (ESO), epoxidized-acrylated soybean oil (AESO) and maleinized soybean oil (MSO) as an environmentally friendly solution to increase the compatibility of toughened poly(lactic acid) (PLA) formulations via melt blending with two other polyesters, namely poly(3-hydroxybutyrate) (PHB) and poly(ε-caprolactone) (PCL). The functionalities present in ESO, AESO and MSO (epoxy, acrylic acid and maleic anhydride respectively) could react with the hydroxyl terminal groups in all three polyesters thus leading to a compatibilization effect. The results are compared with a petroleum-based epoxy styrene-acrylic oligomer (ESAO) to assess the potential of the soybean oil derivatives for industrial formulations. This oligomer is widely used with individual polyesters as chain extender to overcome the effects of hydrolysis during processing at high temperatures and, in addition, it is also used as compatibilizer in polyester blends as its functional groups (acrylic, epoxy) can react with hydroxyl groups in biopolyesters. For these reasons, ESAO has been selected as control material to compare the effectiveness of the soybean oil-based compatibilizers.

2. Results and Discussion

2.1. Effect of Soybean-Derived Compatibilizers on Mechanical Properties and Morphology of Ternary PLA/PHB/PCL Blends

Table 1 summarizes the mechanical properties of the ternary PLA60/PHB10/PCL30 blend with different additives. Neat PLA is a quite brittle polymer with an elongation at break of 7.87%. Its tensile modulus and strength are 3.6 GPa and 58.2 MPa respectively. The PLA60/PHB10/PCL30 blend, shows a noticeable increase in elongation at break up to values of 15.3%. Due to the flexible nature of the PCL component, the tensile strength and modulus decrease down to values of 48.4 MPa and 2.0 GPa respectively. It is well known that PCL is highly immiscible with PLA, while PHB (especially low molecular grades) shows some (although restricted) miscibility [62,63,64]. This lack of full miscibility does not allow a continuous phase and subsequently, load transfer between phases is not optimum. To overcome or minimize this phenomenon, compatibilizers are added to blends. As can be seen in Table 1, all three soybean oil-based compatibilizers improve the ductile properties thus giving evidence of some plasticization and/or compatibilization. Similar results were reported by Li et al. in PLA toughened formulations with poly(butadiene) core-shell particles and a multi-functionalized glycidyl/acrylic shell to react with the PLA matrix and partially compatibilize the system [65]. For the PLA60/PHB10/PCL30 blend, the elongation at break increases up to values of 44% with 1 phr conventional petroleum-based multifunctional compatibilizer, ESAO. It is worthy to note that AESO gives similar elongation at break values of 45%, as well as similar tensile strength and modulus, with values of 43–44 MPa and 1.8–1.9 GPa respectively. It has been suggested that the multifunctional oligomer ESAO, as well as the acrylated oil, could lead to compatibilization through reaction with hydroxyl terminal groups in all three biopolyesters in the blend, but also some branching and/or crosslinking could potentially occur. That is why mechanical resistant properties are not remarkably reduced, compared to the uncompatibilized blend [37,66]. It is worth highlighting the high elongation at break that ESO gives to the blend, reaching values of about 130%. In contrast, tensile strength is lower than that provided by ESAO and AESO. This could suggest that the main acting mechanism of ESO is plasticization and slight interphase compatibilization through reaction of oxirane rings with hydroxyl groups in PLA, PHB and PCL. A similar synergistic plasticization plus compatibilization behavior has been observed by Balart et al. on green composites of PLA and hazelnut shell flour with epoxidized linseed oil (ELO). They report a slight plasticization phenomenon with a low decrease in Tg and on the other hand, the wetting of the lignocellulosic particles increases in a great extent due to the reaction of ELO with hydroxyl groups present in both PLA and lignocellulosic particles [13]. Finally, addition of 5 phr MSO also leads to a remarkable increase in elongation at break, up to 65.8% with a noticeable decrease in both tensile strength and modulus down to similar values of the blend compatibilized with ESO. Ferri et al. revealed the synergistic effect that maleinized linseed oil (MLO) can provide to binary PLA/TPS blends with 30 wt% TPS. They reported a remarkable increase in elongation at break up to 160% and a clear compatibilization, detectable by SEM observation as well as a decrease in Tg by 10 °C with the only addition of 6 phr MLO [58].

Table 1.

Mechanical properties, tensile modulus (Et), tensile strength (σt), elongation at break (εb) hardness and impact strength, of ternary PLA60/PHB10/PCL30 blend with different additives.

With regard to the hardness of the materials developed in this study, the uncompatibilized blend offers a Shore D hardness close to 72. It is worth noting the high Shore D values that AESO-compatibilized blend provides, with values of about 88. This is in agreement with the above-mentioned mechanical properties and it is directly related to the branching/crosslinking phenomenon of AESO. Regarding the impact-absorbed energy obtained by Charpy’s impact tests, the following assessments can be made. Neat PLA (notched sample) shows a very low impact strength of 1.63 kJ m−2. The uncompatibilized blend shows a remarkable increase in toughness with an impact strength of 5.06 kJ m−2, which is almost five times the value of the neat PLA. This indicates that the physical blending of PLA with PHB and PCL gives a toughen PLA formulation. Nevertheless, the poor compatibility between the three polyesters (mainly between PLA and PCL) does not allow optimum load transfer. As it can be seen in Table 1, all three soybean oil-based compatibilizers provide a remarkable increase in impact strength up to values of almost 11 kJ m−2 for the AESO- and MSO-compatibilized blend. These results indicate the positive effect of these additives in compatibilizing the blend.

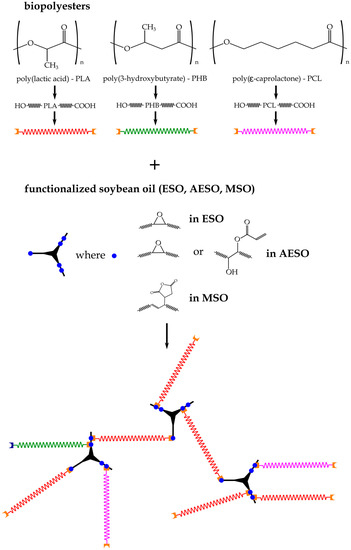

This good mechanical performance is due to two main phenomena. On one hand, the chemically modified soybean oils (with more polar groups) offer a similar solubility parameter to that of biopolyesters, thus allowing interactions between them. This phenomenon mainly leads to a plasticization effect. On the other hand, the functionalities of the soybean oil-based compatibilizers (epoxy in ESO, epoxy and acrylate in AESO, and maleic anhydride in MSO) can readily react with the hydroxyl terminal groups in all three biopolyesters thus leading do several processes such as chain extension, branching and/or crosslinking [67]. These two phenomena (plasticization and chemical reaction) overlaps and the overall effects are positive on mechanical performance as seen in Table 1. Plasticization provides increased elongation at break and reaction (chain extension, branching and/or crosslinking) leads to increased toughness as these reactions are responsible for a low decrease in mechanical resistant properties while the elongation at break (due to the plasticization effect) is remarkably increased. The combination of relatively high mechanical resistant properties, together with a high increase in elongation at break, leads to a noticeable increase in impact strength. The possible reactions of the biopolyesters with the functionalized soybean oil compatibilizers are summarized in Scheme 1.

Scheme 1.

Schematic representation of the possible reactions between the chemically modified soybean oil additives (epoxidized soybean oil (ESO), acrylated epoxidized soybean oil (AESO) and maleinized soybean oil (MSO)) and biopolyesters in ternary blend.

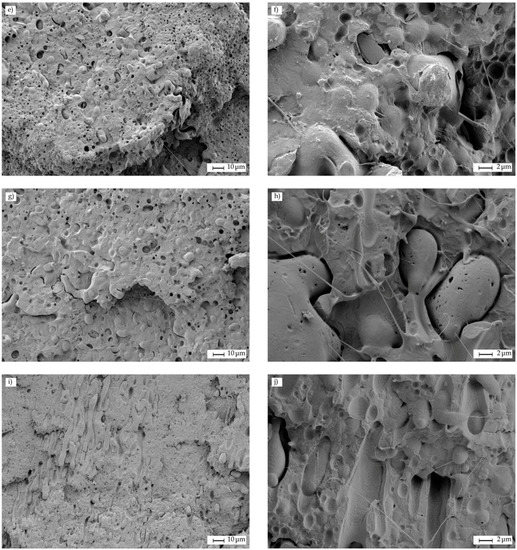

The mechanical behavior of uncompatibilized and compatibilized PLA60/PHB10/PCL30 is directly related to its morphology. Previous results have demonstrated the immiscibility (or very poor) between PLA and PCL [68], as well as the binary system composed of PHB and PCL [69]. In both cases, the simple addition of PCL which appears as randomly dispersed spherical, positively contributes to improve toughness. This increase in toughness is much higher in the PLA/PCL blend than in the PHB/PCL blend as reported by these previous studies. Figure 1 shows the morphology of the fractured samples from impact tests. The uncompatibilized blend shows a clear droplet-like surface morphology with a PLA matrix in which submicron PHB and PCL droplets are finely dispersed. At high magnification, the droplet structure (Figure 1b) is clearly revealed. It is worthy to note the presence of a high number of spherical voids, which are mainly related to removed PCL droplets due to its low compatibility with PLA. The morphology of the blend compatibilized with all three soybean oil-based additives is completely different as it can be observed at both low (left) and high (right) magnification in Figure 1. The morphology of the blend compatibilized with ESO offers quite good phase continuity as well as important signs of plastic deformation during the impact test. Some voids can be detected and full continuity is not achieved but the plasticization effect of the functionalized vegetable oil gives with interactions with all three biopolyesters leads to a different fracture surface (Figure 1c,d). AESO-compatibilized blend shows the typical droplet-like morphology but presence of voids is less intense. This is due to the partial compatibilization effect of AESO with hydroxyl groups that allows more intense interactions between PCL and the surrounding PLA matrix (Figure 1e,f). In fact, it can be clearly seen at high magnification (Figure 1d) that some of the spherical areas, mainly attributable to PCL (as its content is higher than PHB), show a fully wetted surface and this is an important change with regard to uncompatibilized blend. Similar behavior has been observed in ternary blends of PLA, TPS and PCL as indicated by Mittal et al. [23]. MSO-compatibilized blend also shows a change in its morphology, compared to uncompatibilized blend. Although phase separation occurs (Figure 1g) and is evident at low magnification (500×), it is not clearly distinguishable the matrix and the dispersed droplet-like structure at higher magnification (Figure 1h). Similar findings were reported by Ferri et al. in PLA/TPS blends compatibilized with different amounts of maleinized linseed oil (MLO). They also suggested dual effect of MLO: on one hand, a plasticization effect and, on the other hand, compatibilization through reaction with hydroxyl groups in starch and biopolyester [58]. Similar results are provided by a conventional epoxy styrene-acrylic oligomer, ESAO. Although phase separation is still detectable (Figure 1i,j), the typical spherical shapes, change to elongated shapes due to plastic deformation due to the reactivity of epoxy groups towards hydroxyl groups in all three biopolyesters as reported by Torres-Giner et al. with poly(hydroxyalkanoates) and sepiolite composites, compatibilized with this multi-functional epoxy styrene-acrylic oligomer [70].

Figure 1.

Field emission scanning electron microscopy (FESEM) images of the fractured samples from impact tests corresponding to the PLA60/PHB10/PCL30 blend with different compatibilizers at 500× (left) and 3000× (right). (a,b) uncompatibilized; (c,d) compatibilized with 5 phr ESO; (e,f) compatibilized with 5 phr AESO; (g,h) compatibilized with 5 phr MSO; (i,j) compatibilized with 1 phr epoxy styrene-acrylic oligomer (ESAO).

The selective extraction with acetic acid mainly affects to PCL and PHB, while the PLA matrix remains almost unaltered as can be seen in Figure 2. Uncompatibilized blend (Figure 2a,b) shows a homogeneous rough surface in which, PCL and PHB have been selectively removed. ESO compatibilizer seems to give the highest homogeneity (Figure 2c,d) while both AESO and MSO seem to give less homogeneity, probably due to heterogeneous mixing with the blend during the extrusion, leading to some highly compatibilized areas that coexist with poorly compatibilized areas. With regard to petroleum-based ESAO, it is worthy to note that seems to offer reduced domain shapes and evidences of plastic deformation are clearly distinguishable after selective extraction (Figure 2i,j).

Figure 2.

FESEM images of the fractured samples from impact tests corresponding to the PLA60/PHB10/PCL30 blend with different compatibilizers at 500× (left) and 3000× (right), subjected to selective extraction with glacial acetic acid. (a,b) uncompatibilized; (c,d) compatibilized with 5 phr ESO; (e,f) compatibilized with 5 phr AESO; (g,h) compatibilized with 5 phr MSO; (i,j) compatibilized with 1 phr ESAO.

2.2. Effect of Soybean-Derived Compatibilizers on Thermal Properties of Ternary PLA/PHB/PCL Blends

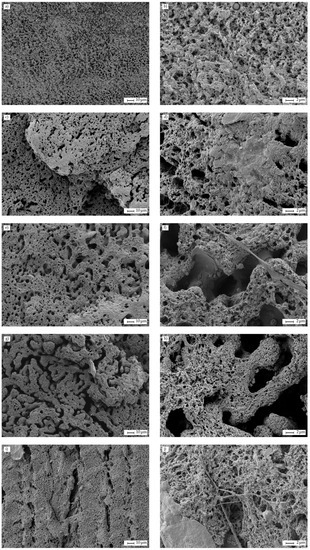

Figure 3 shows a comparative plot of the differential scanning calorimetry (DSC) thermal profiles of the uncompatibilized and the different compatibilized PLA60/PHB10/PCL30 blend. Due to some overlapping processes it is not possible to distinguish in a clear way the particular thermal transitions of each polymer in the blend and the effects of the soybean oil-based compatibilizers. These overlapping processes are the following: on one hand, the typical glass transition of PLA is located at about 55–60 °C and overlaps with the melt peak of PCL (58–60 °C). On the other hand, the melt temperature range for PLA (155–170 °C) overlaps with the typical melt peak temperature of PHB at about 170 °C. It has also been reported that PHB also affects the cold crystallization process in PLA by restricting chain packing in ordered form [71]. Even with the presence of some compatibilizers, conventional DSC is not sensitive enough to measure the slight changes that all compatibilizers provide to the thermal transitions of biopolyesters. Nevertheless, modulated DSC could be used to clearly separate the main thermal transitions even if they appear overlapped. Conventional DSC without modulated signal is useful to identify the melt peaks of the two main components, PLA and PCL, and know different temperature ranges such as the upper service temperature (below 50 °C) and the processing window for these blends (between 175 and 230 °C to avoid degradation). With regard to the thermal transitions, the use of dynamic mechanical thermal analysis is also useful to identify them in a clear way as it will be discussed later.

Figure 3.

Comparative differential scanning calorimetry (DSC) thermograms (2nd heating) of PLA60/PHB10/PCL30 blend with different compatibilizers.

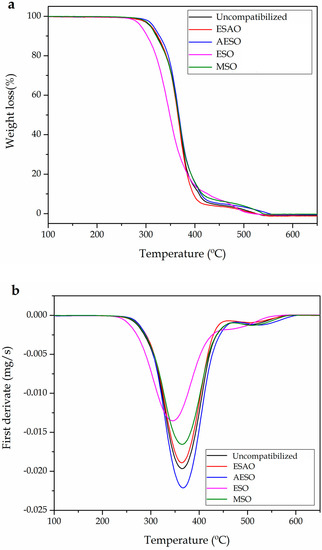

With regard to the thermal stability, Figure 4 gathers the thermogravimetric analysis (TGA) and first derivative (DTG) curves for uncompatibilized and compatibilized PLA60/PHB10/PCL30 blend. As can be assessed from the TGA profiles, ELO is the only compatibilizer that provides decreased thermal stability to the blend but, in contrast, it is the compatibilizer which enhances the highest elongation at break values as above mentioned. The onset degradation temperature, measured at a constant weight loss of 5% (T5) changes from 308.2 °C (uncompatibilized blend) down to 289.1 °C for the ESO-compatibilized blend (Table 2). This tendency is also observed for the maximum degradation rate temperature (Tmax) which corresponds to the peak value of the DTG curves. In particular, the Tmax for the uncompatibilized blend is 364.6 °C and decreases by 20 °C for the ESO-compatibilized blend. All other soybean oil-based compatibilizers, including petroleum-based ESAO, do not lead to a remarkable change in the Tmax values, located at about 364–365 °C. It is worthy to note the stabilizing effect of AESO in the initial stages of the degradation process, which could be related to the branching/crosslinking effect that AESO can provide [37].

Figure 4.

Comparative thermogravimetric (TGA) thermograms of PLA60/PHB10/PCL30 blend with different compatibilizers, (a) weight loss and (b) DTG first derivative.

Table 2.

Main parameters of the thermal degradation of ternary PLA60/PHB10/PCL30 blend with different compatibilizers, obtained by thermogravimetric analysis.

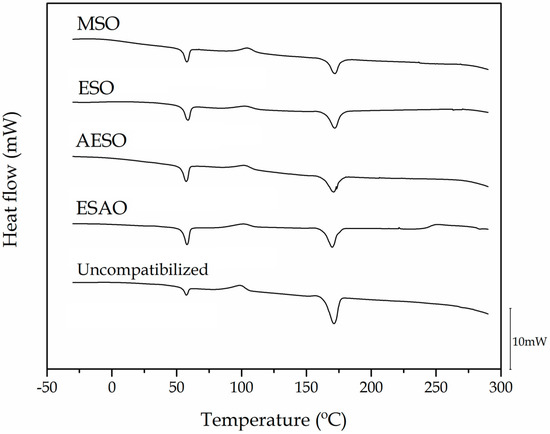

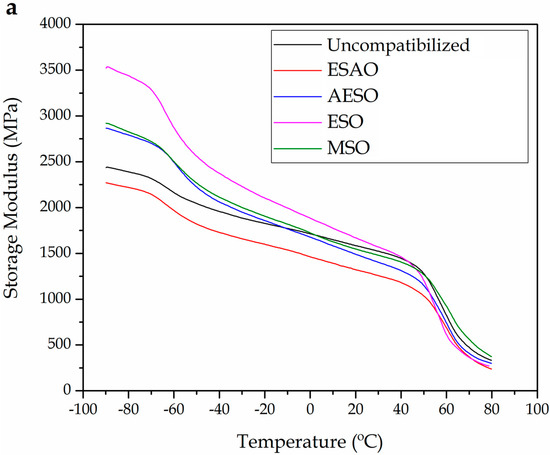

As has been stated previously, conventional (not modulated) DSC is not sensitive enough to separate some overlapping thermal transitions that occur in the individual components of the blend, and, in consequence, the effects of the different compatibilizers cannot be clearly assessed. For this reason, dynamic-mechanical thermal analysis (DMTA) has been used, as an alternative to measure the characteristic glass transition temperatures of the uncompatibilized and compatibilized blends. The Tg for neat PLA is between 55–60 °C while the Tg of PHB and PCL is located at −5 and −60 °C, respectively. Figure 5 shows a comparative plot of both the storage modulus (E’) and the damping factor (tan δ) for all uncompatibilized and compatibilized PLA60/PHB10/PCL30 blends. It is possible to observe the Tg values of all three PLA, PHB and PCL in the uncompatibilized blend by a step change in the storage modulus curve. Although it is possible to assess the Tg value as the onset in the E’ step, it is preferable to define the Tg as the peak maximum in the corresponding damping factor curve. Thus, the characteristic Tg values are −58, −5 and 65 °C for PCL, PHB and PLA respectively (notice that as PHB represents only a 10 wt% of the total blend, its Tg value is remarkably diluted). Addition of 5 phr ESO gives interesting behavior. At low temperatures (from −90 to 20 °C) it gives increased rigidity, but at moderate temperatures (20–80 °C) it seems to be the least stiff material in accordance with previous mechanical characterization. It has a clear effect on the Tg values of all three biopolyesters but the main changes are detected for the Tg of PCL which changes down to values of −60 °C and the decrease in the Tg of PLA down to values of 61.5 °C. This is a clear evidence of the partial plasticization ESO provides to the blend. The other two soybean oil-based compatibilizers, AESO and MSO give similar results in terms of storage modulus and damping factor with temperature. They also show high stiff behavior compared to uncompatibilized blend at low temperatures and more flexible over 0 °C. The changes in Tg values that AESO and MSO provide are quite interesting. With regard to AESO, the Tg of PCL changes to −50 °C and, similarly, the Tg of PLA increases up to 66 °C. This is giving evidences of the branching/crosslinking ability of acrylic compounds in polyester-type polymers as reported by Mauck et al. [37]. With regard to MSO, it gives a Tg of PCL at −55 °C and an increased Tg of PLA up to 68.5 °C thus indicating its ability to form branch or even crosslinked structures by reaction with the polyester-type polymers in a similar way to acrylic groups. The petroleum-based ESAO compound gives a more flexible behavior compared to uncompatibilized blend for all the temperature range. Due to its crosslinking potential, ESAO gives the highest Tg values for PLA-rich phase at about 69.5 °C.

Figure 5.

Comparative dynamic-mechanical thermal analysis (DMTA) curves of PLA60/PHB10/PCL30 blend with different compatibilizers, (a) storage modulus, E’ and (b) damping factor (tan δ).

In addition to dynamic mechanical thermal analysis, other thermomechanical properties have been measured to assess the effect of the different compatibilizers. Table 3 summarizes the Vicat softening temperature (VST), heat deflection temperature (HDT) and the coefficient of linear thermal expansion (CLTE) of the blend below the Tg of PLA since over this, PCL melts and the obtained results are highly influenced by this process, leading to erroneous values. Regarding VST values, no remarkable changes are detectable, although the blends with AESO and ESAO show slightly higher values than those offered by ESO and MSO, but in any case, the differences are negligible. Regarding HDT values, all compatibilized blends show slightly lower values as flexural conditions are more sensitive to temperature than Vicat test. The highest decrease corresponds to ESO-compatibilized blend. These results are in agreement with previous mechanical results which indicated maximum elongation at break was achieved with 5 phr ESO. Accordingly, the CLTE of the ESO-compatibilized blend reaches the highest values changing from 99.0 µm m−1 °C−1 (uncompatibilized blend) up to 143.6 µm m−1 °C−1. The lowest CLTE was obtained for ESAO, accordingly to previous results as this multi-functional oligomer can lead to crosslinking in combination with chain extension and/or polyester compatibilization.

Table 3.

Thermomechanical properties of ternary PLA60/PHB10/PCL30 blend with different compatibilizers: Vicat softening temperature (VST), heat deflection temperature (HDT) and the coefficient of thermal linear expansion (CLTE) obtained by thermomechanical analysis (TMA).

3. Materials and Methods

3.1. Materials

The blends were manufactured with PLA, PHB and PCL, whose main properties are summarized in Table 4. Scheme 2 shows their corresponding chemical structures.

Table 4.

Summary of the commercial grade polymers used for blends manufacturing and some of their relevant properties.

Scheme 2.

Schematic representation of the chemical structure of the base polyesters for the blend.

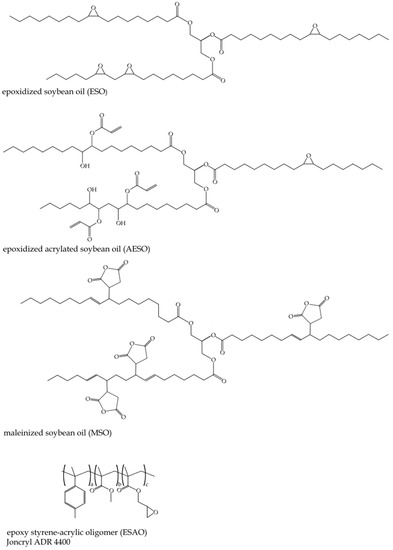

Three different soybean oil (SO) derivatives were used as compatibilizers for the blends: epoxidized soybean oil (ESO), maleinized soybean oil (MSO) and acrylated epoxidized soybean oil (AESO). Both ESO and AESO were supplied by Sigma Aldrich S.A. (Madrid, Spain) and were used without any other purification. On the other hand, MSO was synthesized as indicated elsewhere [56], from soybean oil supplied by Gran Velada (Zaragoza, Spain) and maleic anhydride supplied by Sigma Aldrich S.A. (Madrid, Spain). For comparison purposes, a multifunctional epoxy-based styrene-acrylic oligomer (ESAO), Joncryl ADR 4400 from BASF S.A. (Barcelona, Spain), was used. Scheme 3 shows the chemical structure of all four compatibilizers.

Scheme 3.

Schematic representation of the chemical structure of compatibilizers used for ternary PLA60/PHB10/PCL30 blends.

3.2. Manufacturing of Ternary PLA/PHB/PCL Blends

All three biopolyesters were dehumidified in a MDEO dehumidifier from Industrial Marsé (Barcelona, Spain). PHB and PLA were dried at 60 °C for 24 h while PCL was dried at 45 °C for 24 h. All three vegetable oil derived compatibilizers, ESO, AESO and MSO (in liquid form) were heated to 40 °C to reduce their viscosity and enhance mixing. A constant blend composition was used. Our previous works suggested that a PLA/PHB/PCL blend with a wt% composition of 60/10/30 respectively offers quite balanced properties with improved impact toughness. To evaluate the effects of the three soybean-based compatibilizers, 5 phr (parts of compatibilizer per hundred parts of base blend) of ESO, AESO and MSO were added individually to the base blend. For comparison purposes, an additional formulation containing 1 phr of the petroleum-based compatibilizer, namely ESAO, was used.

The compatibilized blends were manufactured in a twin-screw co-rotating extrusion machine from Construcciones Mecánicas Dupra S.L. (Alicante, Spain). This extruder is characterized by a screw diameter of 25 mm and a length to diameter, L/D ratio of 24. The temperature profile was set to 160, 165, 170 and 175 °C, from the hopper to the extrusion die. The retention time was about 50 s. It is important to remark that biopolyesters, in general, and PHB in particular are highly sensitive to hydrolysis at high temperatures so that, the retention time must not exceed 1 min to avoid further degradation. After cooling, the developed materials were pelletized and further processed by injection moulding in a Sprinter 11 from Erinca S.L. (Barcelona, Spain) equipped with a 18 mm screw diameter. The temperature profile was set to 165 °C (hopper), 170 °C and 175 °C (injection nozzle).

3.3. Mechanical Characterization

Tensile properties were obtained in a universal test machine ELIB 50 from S.A.E. Ibertest (Madrid, Spain) as recommended by ISO 527-1:2012. A 5 kN load cell was used and the crosshead speed was set to 5 mm min−1. Shore D hardness values were obtained in a 676-D durometer from J. Bot Instruments (Barcelona, Spain) as indicated in ISO 868:2003. The impact strength was obtained using a Charpy’s pendulum (6 J) on notched samples (“V” type notch with a radius of 0.25 mm) as indicated in ISO 179-1:2010. At least, five different measurements were carried out for each formulation and average values of the different properties were calculated. All tests were conducted at room temperature.

3.4. Morphology Characterization

The morphology of the fractured samples from impact tests was resolved by field emission scanning electron microscopy (FESEM) in a FESEM microscope ZEISS ULTRA 55 from Oxford Instruments (Abingdon, United Kingdom) working at an accelerating voltage of 2 kV. Samples were subjected to a sputtering process with a gold-palladium alloy in a EMITECH SC7620 sputter-coater from Quorum Technologies, Ltd. (East Sussex, UK). To evaluate the extent of the phase separation, a selective extraction of PCL and PHB was applied with glacial acetic acid supplied by Sigma Aldrich (Madrid, Spain). Fractured samples were immersed in glacial acetic acid solution for 1 h and then, dried and prepared for FESEM observation.

3.5. Thermal Characterization

The main thermal properties of the compatibilized blends were obtained by differential scanning calorimetry (DSC) in a Mettler-Toledo 821 (Schwerzenbach, Switzerland) calorimeter. Small pieces with an average weight comprised between 5 and 7 mg were subjected to a temperature program in three steps: initially, a heating stage from −50 up to 200 °C was applied; then, a cooling process down to −50 °C was scheduled and, finally, a second heating ramp from −50 up to 300 °C was programmed. The heating/cooling rate was set to 10 °C min−1 for all three steps. Additionally, all stages were run under nitrogen atmosphere (66 mL min−1) using standard aluminum crucibles with a capacity of 40 µL.

3.6. Thermo-Mechanical Characterization

Dynamic-mechanical thermal analysis (DMTA) was carried out in a DMA1 dynamic analyzer from Mettler-Toledo (Schwerzenbach, Switzerland) working in single cantilever flexural conditions. Samples with dimensions of 10 × 7 × 1 mm3, were subjected to a temperature sweep from −90 up to 80 °C at a constant heating rate of 2 °C min−1. The selected frequency was 1 Hz and the maximum flexural deformation was set to 10 µm.

Complementary, the Vicat softening temperature (VST) and the heat deflection temperature (HDT) of the uncompatibilized and compatibilized PLA60/PHB10/PCL30 blends were obtained in a Vicat/HDT dual station model VHDT 20 from Metrotec S.A. (San Sebastián, Spain). VST values were obtained using the B50 method with a load of 50 N and a heating rate of 50 °C h−1 as recommended in ISO 306. With regard to the HDT measurements, samples with dimensions of 80 × 10 × 4 mm3 were placed between supports at a separation of 60 mm. The applied load was calculated as indicated in ISO 75-1 and was 320 g. The heating rate was set to 120 °C h−1.

Finally, the dimensional-thermal stability of the developed materials was estimated by thermomechanical analysis (TMA) in a Q400 thermoanalyzer from TA Instruments (Newcastle, DE, USA) with rectangular samples (10 × 10 × 4 mm3). A dynamic temperature ramp was programmed from −90 up to 80 °C at a heating rate of 2 °C min−1 and a constant load of 0.02 N. All thermal tests were run in triplicate.

4. Conclusions

Although the blend from poly(lactic acid) (PLA) (60 wt%), poly(3-hydroxybutyrate (PHB) (10 wt%) and poly(ε-caprolactone) (PCL) (30 wt%) offers improved toughness with regard to neat PLA, the lack (or very poor) miscibility between these three polyesters does not allow optimum results. The use of compatibilizers stands for a technical and cost effective solution to overcome this lack of miscibility. Nevertheless, most of the commercial compatibilizers are petroleum-based additives. This work assesses the potential use of new environmentally friendly additives derived from soybean oil, namely epoxidized soybean oil (ESO), acrylated epoxidized soybean oil (AESO) and maleinized soybean oil (MSO). All three soybean-based compatibilizers have a positive effect on mechanical properties of the blend. In particular, the elongation at break is remarkably improved from 15.3% (uncompatibilized blend) up to values of 130% for the blend with 5 phr ESO. The impact strength is also improved from 5.09 kJ m−2 (uncompatibilized blend) up to values of about 11 kJ m−2 for blends with MSO and AESO. These soybean oil-based compatibilizers show similar effects to those provided by a commercial multi-functional epoxy styrene-acrylic oligomer, ESAO (Joncryl®), widely used as chain extender in polyesters. The use of these vegetable oil-based compatibilizers could represent an environmentally friendly solution to increase compatibility/miscibility in immiscible or partially miscible polyester blends.

Acknowledgments

This work was supported by the Ministry of Economy and Competitiveness (MINECO) grant number MAT2014-59242-C2-1-R. L. Quiles-Carrillo acknowledges Generalitat Valenciana (GV) for financial support through a FPI grant (ACIF/2016/182) and the Spanish Ministry of Education, Culture, and Sports (MECD) for his FPU grant (FPU15/03812).

Author Contributions

Rafael Balart and María Jesús Garcia-Campo conceived and designed the experimental section and selection of materials. María Jesús Garcia-Campo and Luis Quiles-Carrillo performed most of the experiments, revised and collected the most relevant secondary literature. Nestor Montanes contributed to SEM preparation, characterization and data interpretation. Miguel Jorge Reig-Pérez contributed to processing of blends and optimization of the extrusion and injection moulding conditions while Jaime Masia contributed to thermomechanical characterization, interpretation and data analysis. Rafael Balart wrote the manuscript with the assistance of Luis Quiles-Carrillo and Nestor Montanes regarding the artwork. The manuscript was revised by all authors and all suggestions were considered.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Notta-Cuvier, D.; Odent, J.; Delille, R.; Murariu, M.; Lauro, F.; Raquez, J.M.; Bennani, B.; Dubois, P. Tailoring polylactide (PLA) properties for automotive applications: Effect of addition of designed additives on main mechanical properties. Polym. Test. 2014, 36, 1–9. [Google Scholar] [CrossRef]

- Nagarajan, V.; Mohanty, A.K.; Misratt, M. Perspective on polylactic acid (PLA) based sustainable materials for durable applications: Focus on toughness and heat resistance. ACS Sustain. Chem. Eng. 2016, 4, 2899–2916. [Google Scholar] [CrossRef]

- Raquez, J.M.; Habibi, Y.; Murariu, M.; Dubois, P. Polylactide (PLA)-based nanocomposites. Prog. Polym. Sci. 2013, 38, 1504–1542. [Google Scholar] [CrossRef]

- Bouzouita, A.; Samuel, C.; Notta-Cuvier, D.; Odent, J.; Lauro, F.; Dubois, P.; Raquez, J.M. Design of highly tough poly(l-lactide)-based ternary blends for automotive applications. J. Appl. Polym. Sci. 2016, 133, 9. [Google Scholar] [CrossRef]

- Bergstrom, J.S.; Hayman, D. An overview of mechanical properties and material modeling of polylactide (PLA) for medical applications. Ann. Biomed. Eng. 2016, 44, 330–340. [Google Scholar] [CrossRef] [PubMed]

- Leroy, A.; Ribeiro, S.; Grossiord, C.; Alves, A.; Vestberg, R.H.; Salles, V.; Brunon, C.; Gritsch, K.; Grosgogeat, B.; Bayon, Y. FTIR microscopy contribution for comprehension of degradation mechanisms in PLA-based implantable medical devices. J. Mater. Sci. Mater. Med. 2017, 28, 13. [Google Scholar] [CrossRef] [PubMed]

- Ferreira, R.T.L.; Amatte, I.C.; Dutra, T.A.; Burger, D. Experimental characterization and micrography of 3D printed PLA and PLA reinforced with short carbon fibers. Compos. B Eng. 2017, 124, 88–100. [Google Scholar] [CrossRef]

- Song, Y.; Li, Y.; Song, W.; Yee, K.; Lee, K.Y.; Tagarielli, V.L. Measurements of the mechanical response of unidirectional 3D-printed PLA. Mater. Des. 2017, 123, 154–164. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Samper, M.D.; Aldas, M.; Lopez, J. On the use of PLA-PHB blends for sustainable food packaging applications. Materials 2017, 10, 26. [Google Scholar] [CrossRef] [PubMed]

- Burgos, N.; Armentano, I.; Fortunati, E.; Dominici, F.; Luzi, F.; Fiori, S.; Cristofaro, F.; Visai, L.; Jimenez, A.; Kenny, J.M. Functional properties of plasticized bio-based poly(lactic acid)_poly(hydroxybutyrate) (PLA_PHB) films for active food packaging. Food Bioprocess Technol. 2017, 10, 770–780. [Google Scholar] [CrossRef]

- Masmoudi, F.; Bessadok, A.; Dammak, M.; Jaziri, M.; Ammar, E. Biodegradable packaging materials conception based on starch and polylactic acid (PLA) reinforced with cellulose. Environ. Sci. Pollut. Res. 2016, 23, 20904–20914. [Google Scholar] [CrossRef] [PubMed]

- Moustafa, H.; El Kissi, N.; Abou-Kandil, A.I.; Abdel-Aziz, M.S.; Dufresne, A. PLA/PBAT bionanocomposites with antimicrobial natural rosin for green packaging. ACS Appl. Mater. Interfaces 2017, 9, 20132–20141. [Google Scholar] [CrossRef] [PubMed]

- Balart, J.F.; Fombuena, V.; Fenollar, O.; Boronat, T.; Sanchez-Nacher, L. Processing and characterization of high environmental efficiency composites based on pla and hazelnut shell flour (HSF) with biobased plasticizers derived from epoxidized linseed oil (ELO). Compos. B Eng. 2016, 86, 168–177. [Google Scholar] [CrossRef]

- Qiang, T.; Yu, D.M.; Gao, H.H. Impact strength and fractal characteristic of pla-based wood plastic composites. In Advanced Building Materials and Sustainable Architecture; Shao, Y., Hao, S., Luo, Y., Xing, J., Liu, Z., Eds.; Trans Tech Publications Ltd.: Durnten-Zurich, Switzerland, 2012; Volume 174–177, pp. 683–686. [Google Scholar]

- Pluta, M.; Piorkowska, E. Tough crystalline blends of polylactide with block copolymers of ethylene glycol and propylene glycol. Polym. Test. 2015, 46, 79–87. [Google Scholar] [CrossRef]

- Arrieta, M.P.; Lopez, J.; Lopez, D.; Kenny, J.M.; Peponi, L. Development of flexible materials based on plasticized electrospun pla-phb blends: Structural, thermal, mechanical and disintegration properties. Eur. Polym. J. 2015, 73, 433–446. [Google Scholar] [CrossRef]

- Fortunati, E.; Puglia, D.; Iannoni, A.; Terenzi, A.; Kenny, J.M.; Torre, L. Processing conditions, thermal and mechanical responses of stretchable poly (lactic acid)poly (butylene succinate) films. Materials 2017, 10, 16. [Google Scholar] [CrossRef] [PubMed]

- Maiza, M.; Benaniba, M.T.; Quintard, G.; Massardier-Nageotte, V. Biobased additive plasticizing polylactic acid (PLA). Polimeros 2015, 25, 581–590. [Google Scholar] [CrossRef]

- Burgos, N.; Martino, V.P.; Jimenez, A. Characterization and ageing study of poly(lactic acid) films plasticized with oligomeric lactic acid. Polym. Degrad. Stab. 2013, 98, 651–658. [Google Scholar] [CrossRef]

- Burgos, N.; Tolaguera, D.; Fiori, S.; Jimenez, A. Synthesis and characterization of lactic acid oligomers: Evaluation of performance as poly(lactic acid) plasticizers. J. Polym. Environ. 2014, 22, 227–235. [Google Scholar] [CrossRef]

- Darie-Nita, R.N.; Vasile, C.; Irimia, A.; Lipsa, R.; Rapa, M. Evaluation of some eco-friendly plasticizers for PLA films processing. J. Appl. Polym. Sci. 2016, 133, 11. [Google Scholar] [CrossRef]

- Yang, X.; Xu, H.; Odelius, K.; Hakkarainen, M. Poly(lactide)-g-poly(butylene succinate-co-adipate) with high crystallization capacity and migration resistance. Materials 2016, 9, 15. [Google Scholar] [CrossRef] [PubMed]

- Mittal, V.; Akhtar, T.; Matsko, N. Mechanical, thermal, rheological and morphological properties of binary and ternary blends of PLA, TPS and PCL. Macromol. Mater. Eng. 2015, 300, 423–435. [Google Scholar] [CrossRef]

- Mittal, V.; Akhtar, T.; Luckachan, G.; Matsko, N. PLA, TPS and PCL binary and ternary blends: Structural characterization and time-dependent morphological changes. Colloid Polym. Sci. 2015, 293, 573–585. [Google Scholar] [CrossRef]

- Bartczak, Z.; Galeski, A.; Kowalczuk, M.; Sobota, M.; Malinowski, R. Tough blends of poly(lactide) and amorphous poly([R,S]-3-hydroxy butyrate)—morphology and properties. Eur. Polym. J. 2013, 49, 3630–3641. [Google Scholar] [CrossRef]

- Karagoz, S.; Ozkoc, G. Effects of a diisocyanate compatibilizer on the properties of citric acid modified thermoplastic starch/poly(lactic acid) blends. Polym. Eng. Sci. 2013, 53, 2183–2193. [Google Scholar] [CrossRef]

- Muller, J.; Gonzalez-Martinez, C.; Chiralt, A. Combination of poly(lactic) acid and starch for biodegradable food packaging. Materials 2017, 10, 22. [Google Scholar] [CrossRef] [PubMed]

- Luzi, F.; Fortunati, E.; Jimenez, A.; Puglia, D.; Pezzolla, D.; Gigliotti, G.; Kenny, J.M.; Chiralt, A.; Torre, L. Production and characterization of PLA_PBS biodegradable blends reinforced with cellulose nanocrystals extracted from hemp fibres. Ind. Crops Prod. 2016, 93, 276–289. [Google Scholar] [CrossRef]

- Supthanyakul, R.; Kaabbuathong, N.; Chirachanchai, S. Poly(l-lactide-b-butylene succinate-b-l-lactide) triblock copolymer: A multi-functional additive for PLA/PBS blend with a key performance on film clarity. Polym. Degrad. Stab. 2017, 142, 160–168. [Google Scholar] [CrossRef]

- Ojijo, V.; Ray, S.S. Super toughened biodegradable polylactide blends with non-linear copolymer interfacial architecture obtained via facile in-situ reactive compatibilization. Polymer 2015, 80, 1–17. [Google Scholar] [CrossRef]

- Dou, Q.; Cai, J. Investigation on polylactide (PLA)/poly(butylene adipate-co-terephthalate) (PBAT)/bark flour of plane tree (PF) eco-composites. Materials 2016, 9, 14. [Google Scholar] [CrossRef] [PubMed]

- Gao, H.H.; Qiang, T. Fracture surface morphology and impact strength of cellulose/PLA composites. Materials 2017, 10, 11. [Google Scholar] [CrossRef] [PubMed]

- Wu, N.J.; Zhang, H. Mechanical properties and phase morphology of super-tough PLA/PBAT/EMA-GMA multicomponent blends. Mater. Lett. 2017, 192, 17–20. [Google Scholar] [CrossRef]

- Zolali, A.M.; Favis, B.D. Partial to complete wetting transitions in immiscible ternary blends with PLA: The influence of interfacial confinement. Soft Matter 2017, 13, 2844–2856. [Google Scholar] [CrossRef] [PubMed]

- Sangeetha, V.H.; Valapa, R.B.; Nayak, S.K.; Varghese, T.O. Super toughened renewable poly(lactic acid) based ternary blends system: Effect of degree of hydrolysis of ethylene vinyl acetate on impact and thermal properties. RSC Adv. 2016, 6, 72681–72691. [Google Scholar] [CrossRef]

- Ross, S.; Mahasaranon, S.; Ross, G.M. Ternary polymer blends based on poly(lactic acid): Effect of stereo-regularity and molecular weight. J. Appl. Polym. Sci. 2015, 132, 8. [Google Scholar] [CrossRef]

- Mauck, S.C.; Wang, S.; Ding, W.Y.; Rohde, B.J.; Fortune, C.K.; Yang, G.Z.; Ahn, S.K.; Robertson, M.L. Biorenewable tough blends of polylactide and acrylated epoxidized soybean oil compatibilized by a polylactide star polymer. Macromolecules 2016, 49, 1605–1615. [Google Scholar] [CrossRef]

- Carmona, V.B.; Correa, A.C.; Marconcini, J.M.; Mattoso, L.H.C. Properties of a biodegradable ternary blend of thermoplastic starch (TPS), poly(epsilon-caprolactone) (PCL) and poly(lactic acid) (PLA). J. Polym. Environ. 2015, 23, 83–89. [Google Scholar] [CrossRef]

- Chen, R.; Abdelwahab, M.A.; Misra, M.; Mohanty, A.K. Biobased ternary blends of lignin, poly(lactic acid), and poly(butylene adipate-co-terephthalate): The effect of lignin heterogeneity on blend morphology and compatibility. J. Polym. Environ. 2014, 22, 439–448. [Google Scholar] [CrossRef]

- Islam, M.R.; Beg, M.D.H.; Jamari, S.S. Development of vegetable-oil-based polymers. J. Appl. Polym. Sci. 2014, 131, 13. [Google Scholar] [CrossRef]

- Mosiewicki, M.A.; Aranguren, M.I. Recent developments in plant oil based functional materials. Polym. Int. 2016, 65, 28–38. [Google Scholar] [CrossRef]

- Xia, Y.; Larock, R.C. Vegetable oil-based polymeric materials: Synthesis, properties, and applications. Green Chem. 2010, 12, 1893–1909. [Google Scholar] [CrossRef]

- Biermann, U.; Bornscheuer, U.; Meier, M.A.R.; Metzger, J.O.; Schafer, H.J. Oils and fats as renewable raw materials in chemistry. Angew. Chem. Int. Ed. 2011, 50, 3854–3871. [Google Scholar] [CrossRef] [PubMed]

- Torres-Giner, S.; Montanes, N.; Fenollar, O.; Garcia-Sanoguera, D.; Balart, R. Development and optimization of renewable vinyl plastisol/wood flour composites exposed to ultraviolet radiation. Mater. Des. 2016, 108, 648–658. [Google Scholar] [CrossRef]

- Ferri, J.M.; Samper, M.D.; Garcia-Sanoguera, D.; Reig, M.J.; Fenollar, O.; Balart, R. Plasticizing effect of biobased epoxidized fatty acid esters on mechanical and thermal properties of poly(lactic acid). J. Mater. Sci. 2016, 51, 5356–5366. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Ferri, J.M.; Montanes, N.; Lopez-Martinez, J.; Balart, R. Plasticization effects of epoxidized vegetable oils on mechanical properties of poly(3-hydroxybutyrate). Polym. Int. 2016, 65, 1157–1164. [Google Scholar] [CrossRef]

- Chieng, B.W.; Ibrahim, N.A.; Then, Y.Y.; Loo, Y.Y. Epoxidized vegetable oils plasticized poly(lactic acid) biocomposites: Mechanical, thermal and morphology properties. Molecules 2014, 19, 16024–16038. [Google Scholar] [CrossRef] [PubMed]

- De Castro, D.O.; Frollini, E.; Ruvolo, A.; Dufresne, A. “Green polyethylene” and curaua cellulose nanocrystal based nanocomposites: Effect of vegetable oils as coupling agent and processing technique. J. Polym. Sci. Pt. B Polym. Phys. 2015, 53, 1010–1019. [Google Scholar] [CrossRef]

- Samper, M.D.; Fombuena, V.; Boronat, T.; Garcia-Sanoguera, D.; Balart, R. Thermal and mechanical characterization of epoxy resins (ELO and ESO) cured with anhydrides. J. Am. Oil Chem. Soc. 2012, 89, 1521–1528. [Google Scholar] [CrossRef]

- Samper, M.D.; Petrucci, R.; Sanchez-Nacher, L.; Balart, R.; Kenny, J.M. Properties of composite laminates based on basalt fibers with epoxidized vegetable oils. Mater. Des. 2015, 72, 9–15. [Google Scholar] [CrossRef]

- Obradovic, J.; Voutilainen, M.; Virtanen, P.; Lassila, L.; Fardim, P. Cellulose fibre-reinforced biofoam for structural applications. Materials 2017, 10, 10. [Google Scholar] [CrossRef] [PubMed]

- Liu, K.W.; Madbouly, S.A.; Kessler, M.R. Biorenewable thermosetting copolymer based on soybean oil and eugenol. Eur. Polym. J. 2015, 69, 16–28. [Google Scholar] [CrossRef]

- Liu, W.D.; Xie, T.S.; Qiu, R.H. Improvement of properties for biobased composites from modified soybean oil and hemp fibers: Dual role of diisocyanate. Compos. A Appl. Sci. Manuf. 2016, 90, 278–285. [Google Scholar] [CrossRef]

- Liu, W.D.; Xie, T.S.; Qiu, R.H. Biobased thermosets prepared from rigid isosorbide and flexible soybean oil derivatives. ACS Sustain. Chem. Eng. 2017, 5, 774–783. [Google Scholar] [CrossRef]

- Yang, Y.P.; Shen, M.G.; Huang, X.; Zhang, H.B.; Shang, S.B.; Song, J. Synthesis and performance of a thermosetting resin: Acrylated epoxidized soybean oil curing with a rosin-based acrylamide. J. Appl. Polym. Sci. 2017, 134, 7. [Google Scholar] [CrossRef]

- Carbonell-Verdu, A.; Garcia-Garcia, D.; Dominici, F.; Torre, L.; Sanchez-Nacher, L.; Balart, R. Pla films with improved flexibility properties by using maleinized cottonseed oil. Eur. Polym. J. 2017, 91, 248–259. [Google Scholar] [CrossRef]

- Ernzen, J.R.; Bondan, F.; Luvison, C.; Wanke, C.H.; Martins, J.D.; Fiorio, R.; Bianchi, O. Structure and properties relationship of melt reacted polyamide 6/malenized soybean oil. J. Appl. Polym. Sci. 2016, 133, 10. [Google Scholar] [CrossRef]

- Ferri, J.M.; Garcia-Garcia, D.; Sanchez-Nacher, L.; Fenollar, O.; Balart, R. The effect of maleinized linseed oil (MLO) on mechanical performance of poly(lactic acid)-thermoplastic starch (PLA-TPS) blends. Carbohydr. Polym. 2016, 147, 60–68. [Google Scholar] [CrossRef] [PubMed]

- Ferri, J.M.; Garcia-Garcia, D.; Montanes, N.; Fenollar, O.; Balart, R. The effect of maleinized linseed oil as biobased plasticizer in poly (lactic acid)-based formulations. Polym. Int. 2017, 66, 882–891. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Fenollar, O.; Fombuena, V.; Lopez-Martinez, J.; Balart, R. Improvement of mechanical ductile properties of poly(3-hydroxybutyrate) by using vegetable oil derivatives. Macromol. Mater. Eng. 2017, 302, 12. [Google Scholar] [CrossRef]

- Ford, E.N.J.; Rawlins, J.W.; Mendon, S.K.; Thames, S.F. Effect of acid value on the esterification mechanism of maleinized soybean oil with cotton. J. Coat. Technol. Res. 2012, 9, 637–641. [Google Scholar] [CrossRef]

- Pachekoski, W.M.; Dalmolin, C.; Agnelli, J.A.M. Miscibility study of PHB and PLA mixtures, using a PHB with high polydispersity. Polimeros 2015, 25, 76–82. [Google Scholar]

- Takayama, T.; Todo, M.; Tsuji, H.; Arakawa, K. Improvement of fracture properies of PLA/PCL polymer blends by control of phase structures. Kobunshi Ronbunshu 2006, 63, 626–632. [Google Scholar] [CrossRef]

- Wang, X.F.; Gao, Y.H.; Li, X.Y.; Xu, Y.Y.; Jiang, J.; Hou, J.H.; Li, Q.; Turng, L.S. Selective localization of graphene oxide in electrospun polylactic acid/poly(epsilon-caprolactone) blended nanofibers. Polym. Test. 2017, 59, 396–403. [Google Scholar] [CrossRef]

- Li, Z.K.; Song, S.X.; Zhao, X.C.; Lv, X.; Sun, S.L. Grafting modification of the reactive core-shell particles to enhance the toughening ability of polylactide. Materials 2017, 10, 12. [Google Scholar] [CrossRef] [PubMed]

- Choi, K.M.; Lim, S.W.; Choi, M.C.; Kim, Y.M.; Han, D.H.; Ha, C.S. Thermal and mechanical properties of poly(lactic acid) modified by poly(ethylene glycol) acrylate through reactive blending. Polym. Bull. 2014, 71, 3305–3321. [Google Scholar] [CrossRef]

- Quiles-Carrillo, L.; Montanes, N.; Sammon, C.; Balart, R.; Torres-Giner, S. Compatibilization of highly sustainable polylactide/almond shell flour composites by reactive extrusion with maleinized linseed oil. Ind. Crops Prod. 2017. [Google Scholar] [CrossRef]

- Ferri, J.M.; Fenollar, O.; Jorda-Vilaplana, A.; García-Sanoguera, D.; Balart, R. Effect of miscibility on mechanical and thermal properties of poly(lactic acid)/ polycaprolactone blends. Polym. Int. 2016, 65, 453–463. [Google Scholar] [CrossRef]

- Garcia-Garcia, D.; Ferri, J.M.; Boronat, T.; Lopez, J.; Balart, R. Processing and characterization of binary poly(hydroxybutyrate) (PHB) and poly(caprolactone) (PCL) blends with improved impact properties. Polym. Bull. 2016, 73, 3333–3350. [Google Scholar] [CrossRef]

- Torres-Giner, S.; Montanes, N.; Boronat, T.; Quiles-Carrillo, L.; Balart, R. Melt grafting of sepiolite nanoclay onto poly(3-hydroxybutyrate-co-4-hydroxybutyrate) by reactive extrusion with multi-functional epoxy-based styrene-acrylic oligomer. Eur. Polym. J. 2016, 84, 693–707. [Google Scholar] [CrossRef]

- Ni, C.Y.; Luo, R.C.; Xu, K.T.; Chen, G.Q. Thermal and crystallinity property studies of poly(l-lactic acid) blended with oligomers of 3-hydroxybutyrate or dendrimers of hvdroxyalkanoic acids. J. Appl. Polym. Sci. 2009, 111, 1720–1727. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).