Experimental Exploration of Metal Cable as Reinforcement in 3D Printed Concrete

Abstract

1. Introduction

- develop a suitable entrainment device and determine a suitable medium to act as reinforcement,

- globally establish pull-out characteristics such as bond strength and anchorage length of this medium in printed and cast concrete,

- achieve ductile failure behaviour of printed concrete beams in bending,

- explore any process-characteristic behaviour, aspects, and issues to be considered in further development of this concept.

2. Technique and Process of Entraining Reinforcement Cable in 3D Printed Concrete

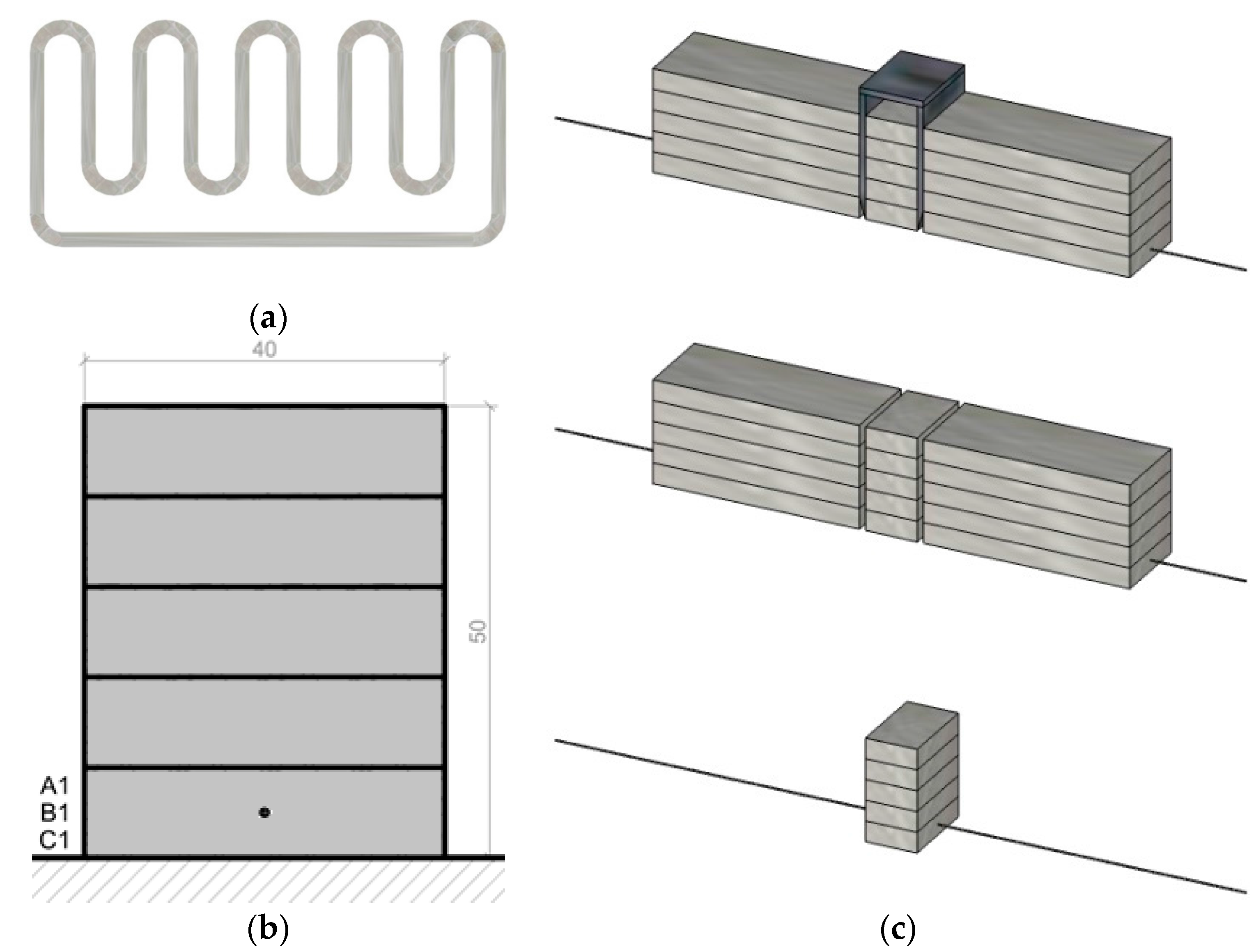

3. Cable Reinforcement

4. Pull-Out Test

4.1. Method

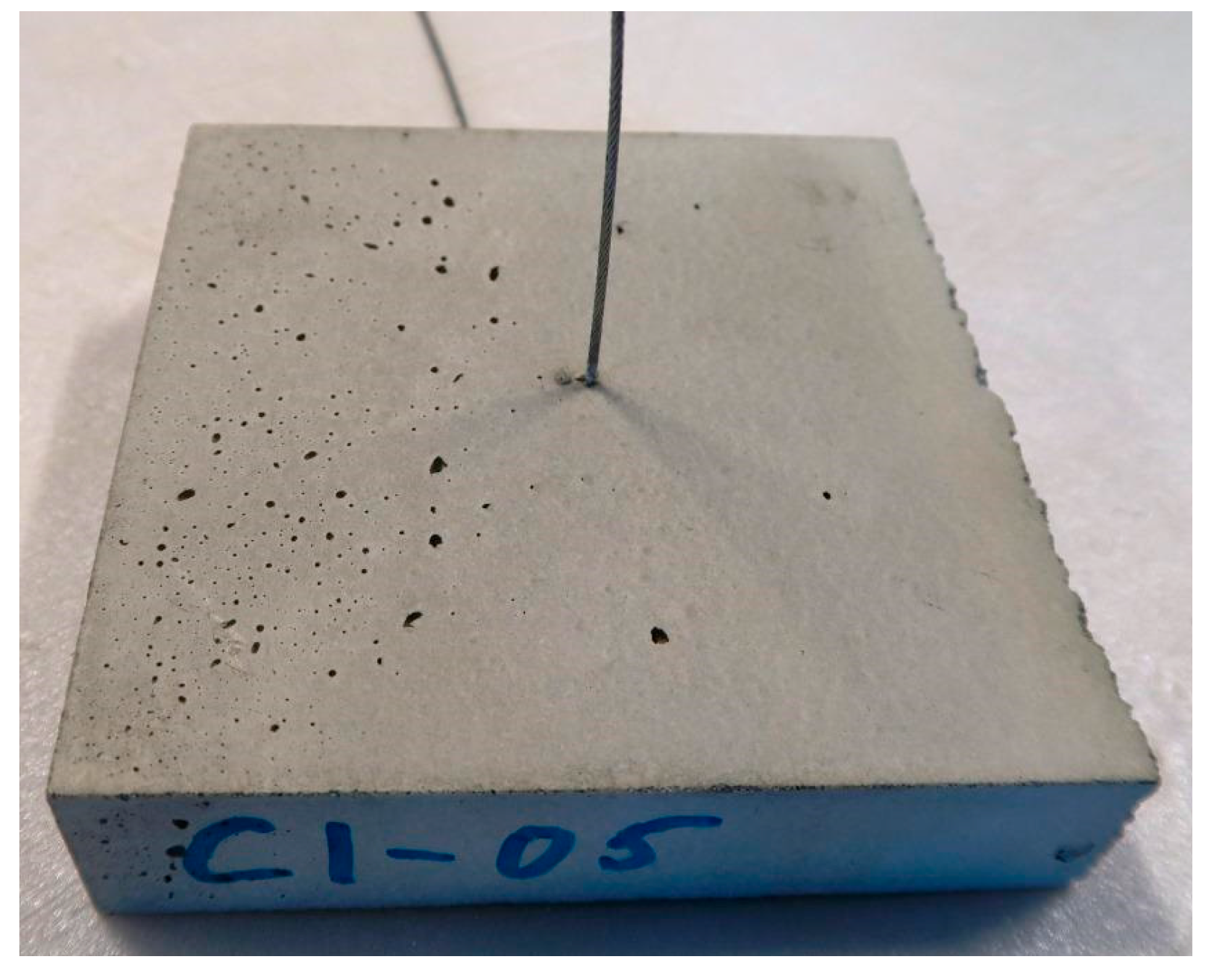

4.1.1. Specimen Preparation-Cast

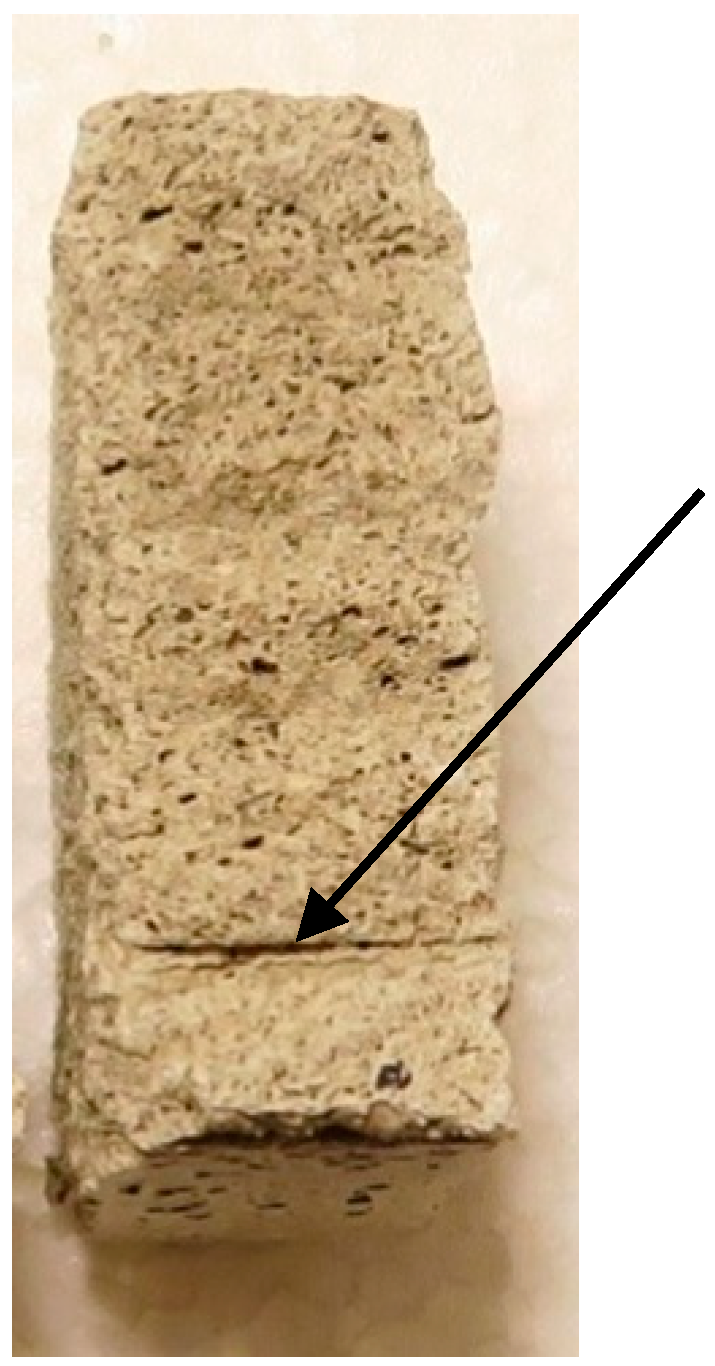

4.1.2. Specimen Preparation—Printed

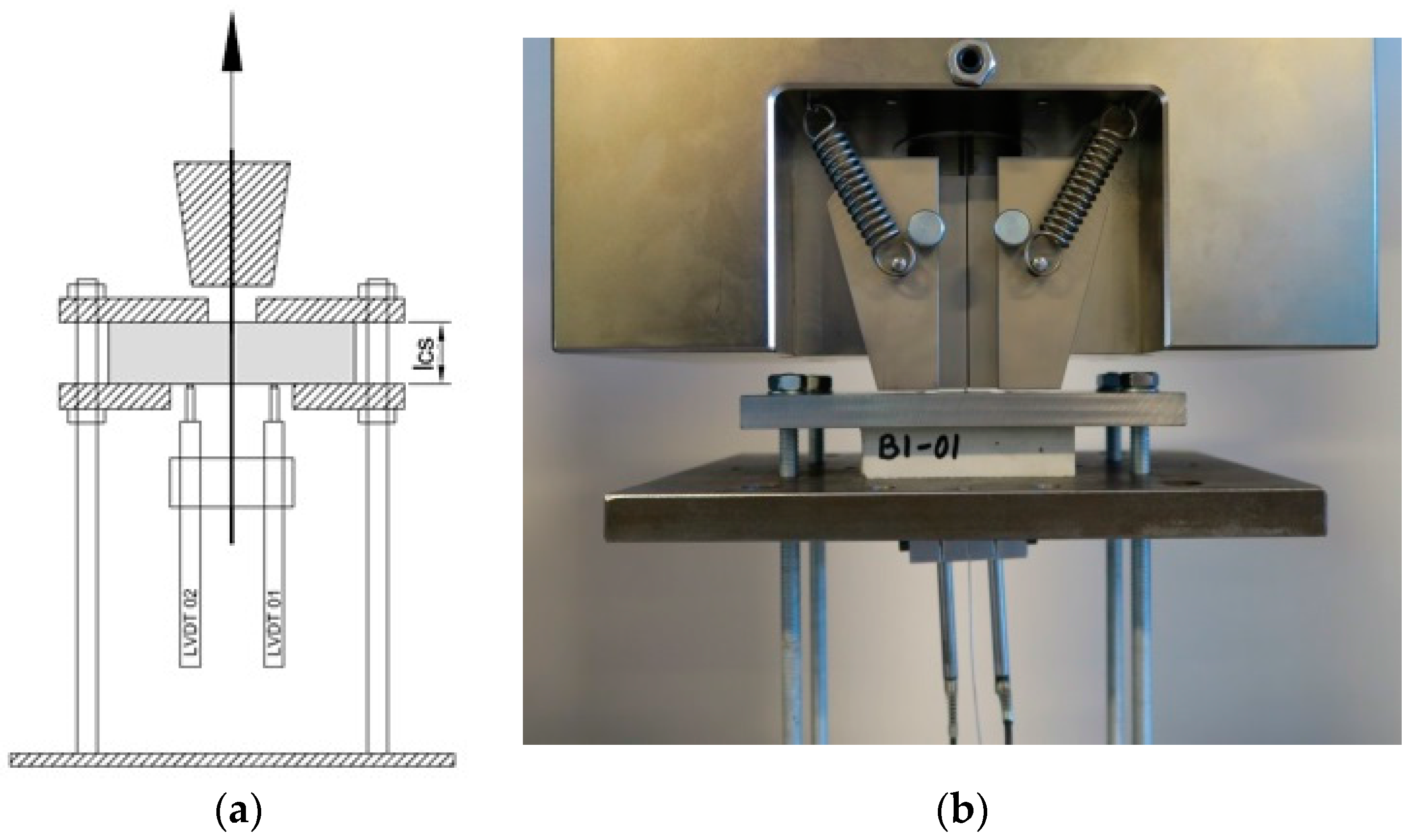

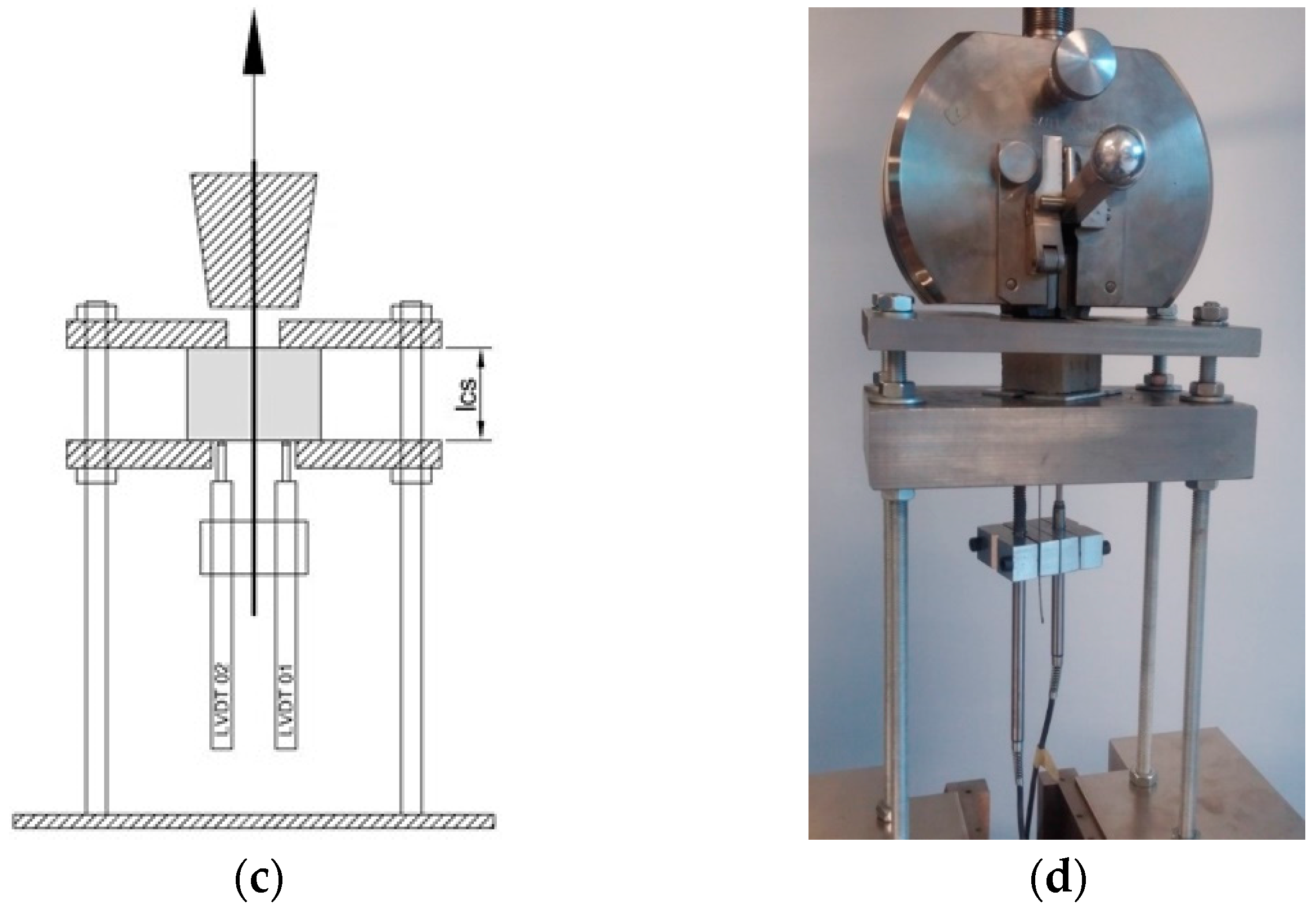

4.1.3. Experimental Set-Up

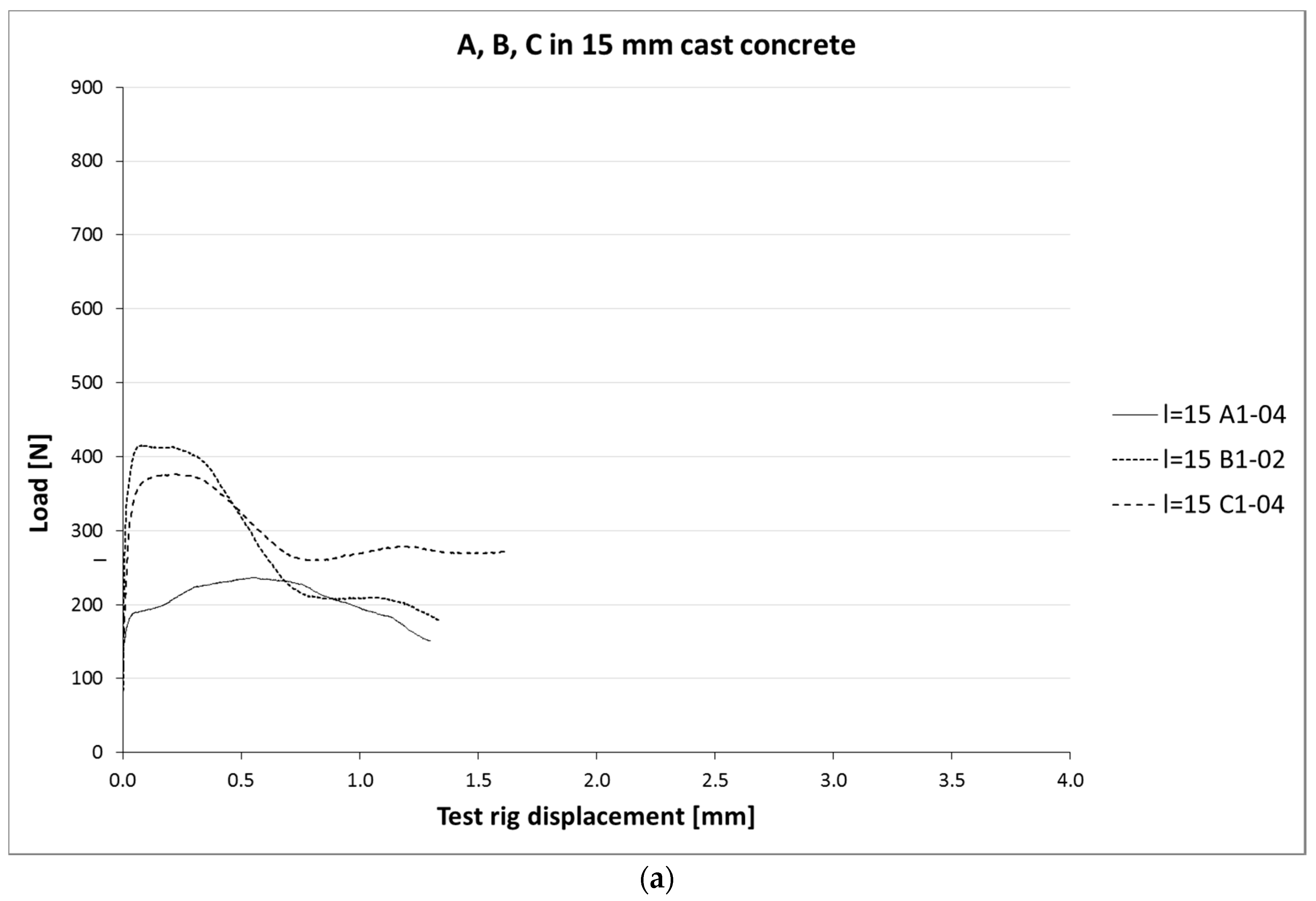

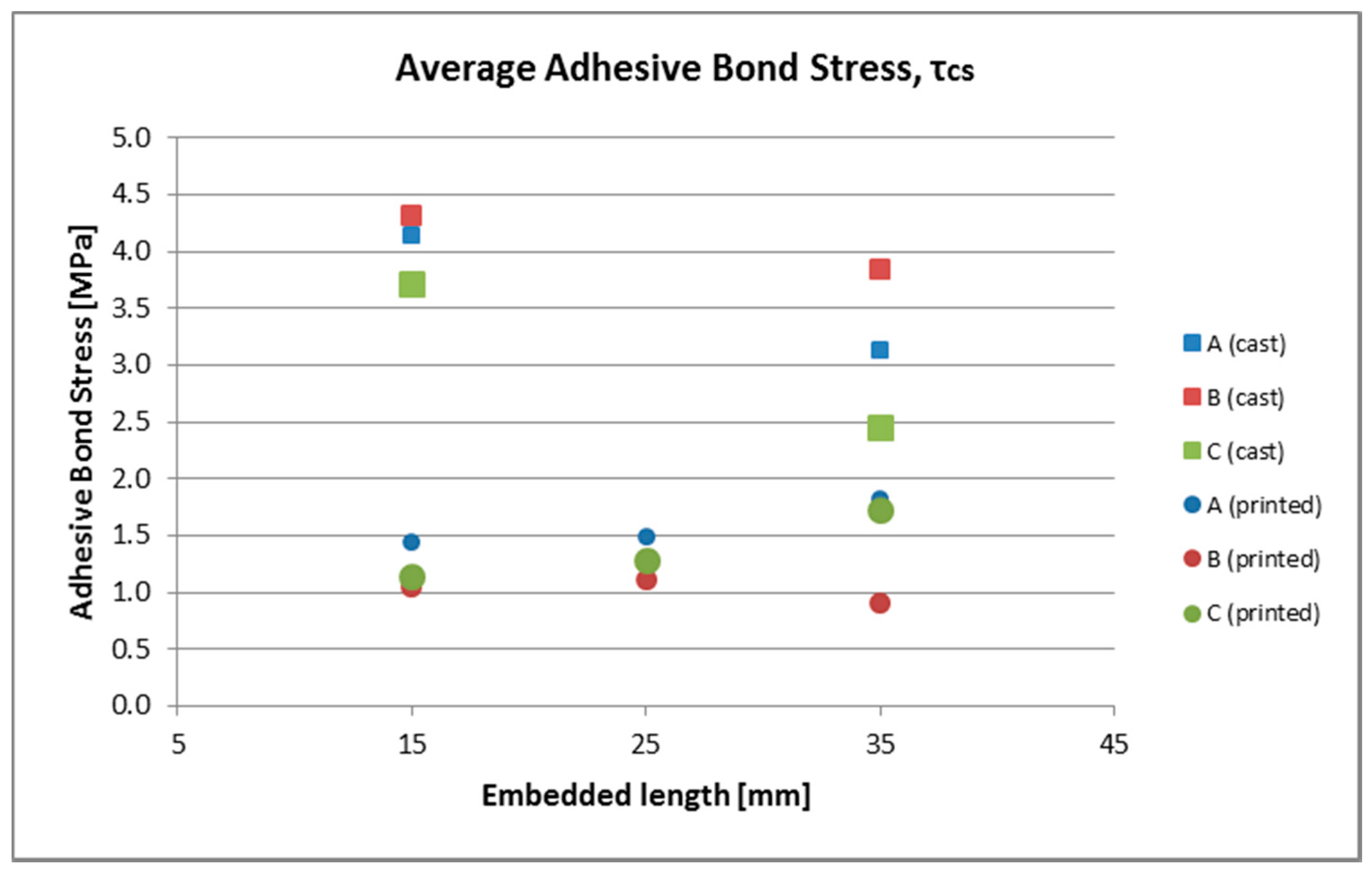

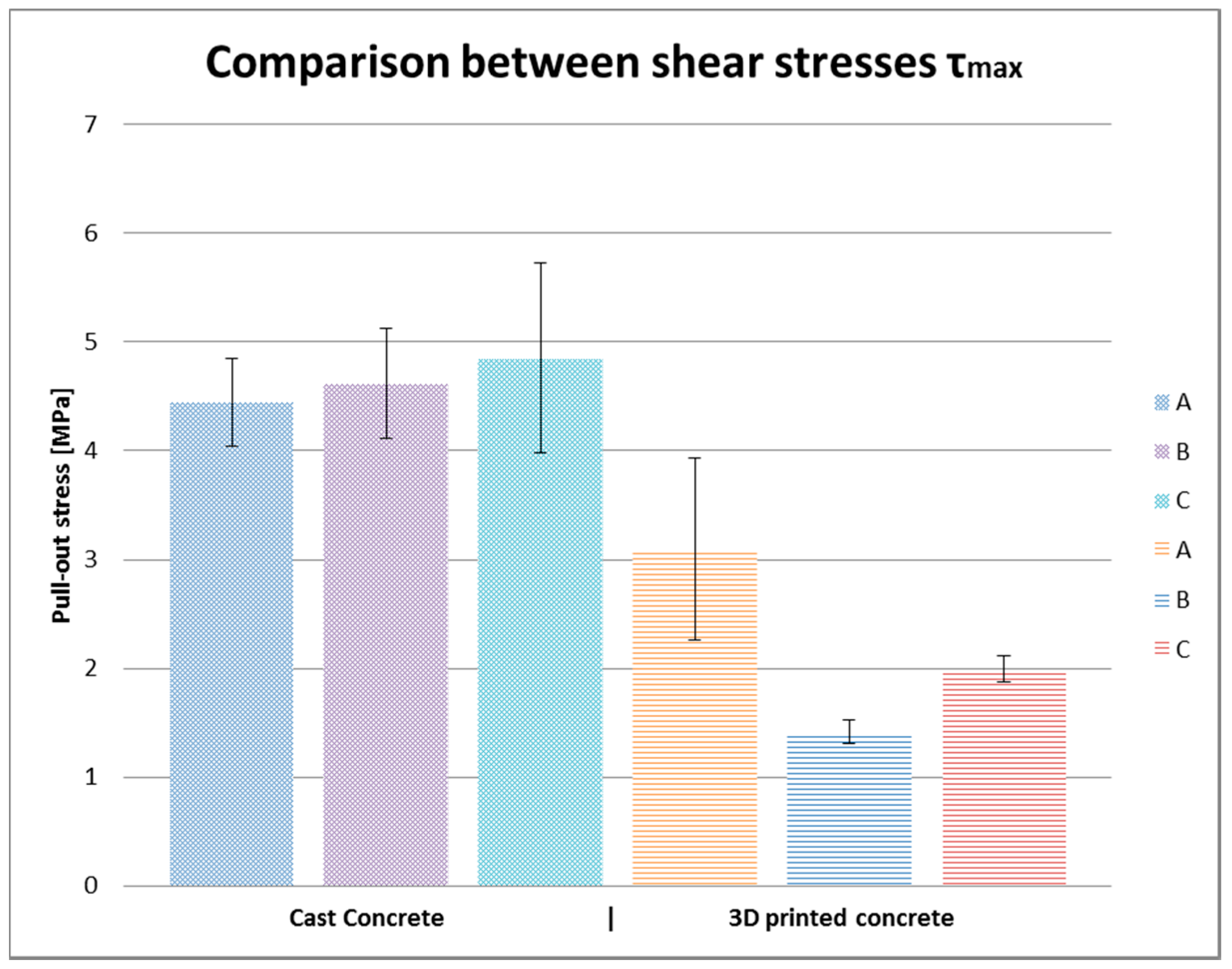

4.2. Results

4.3. Discussion

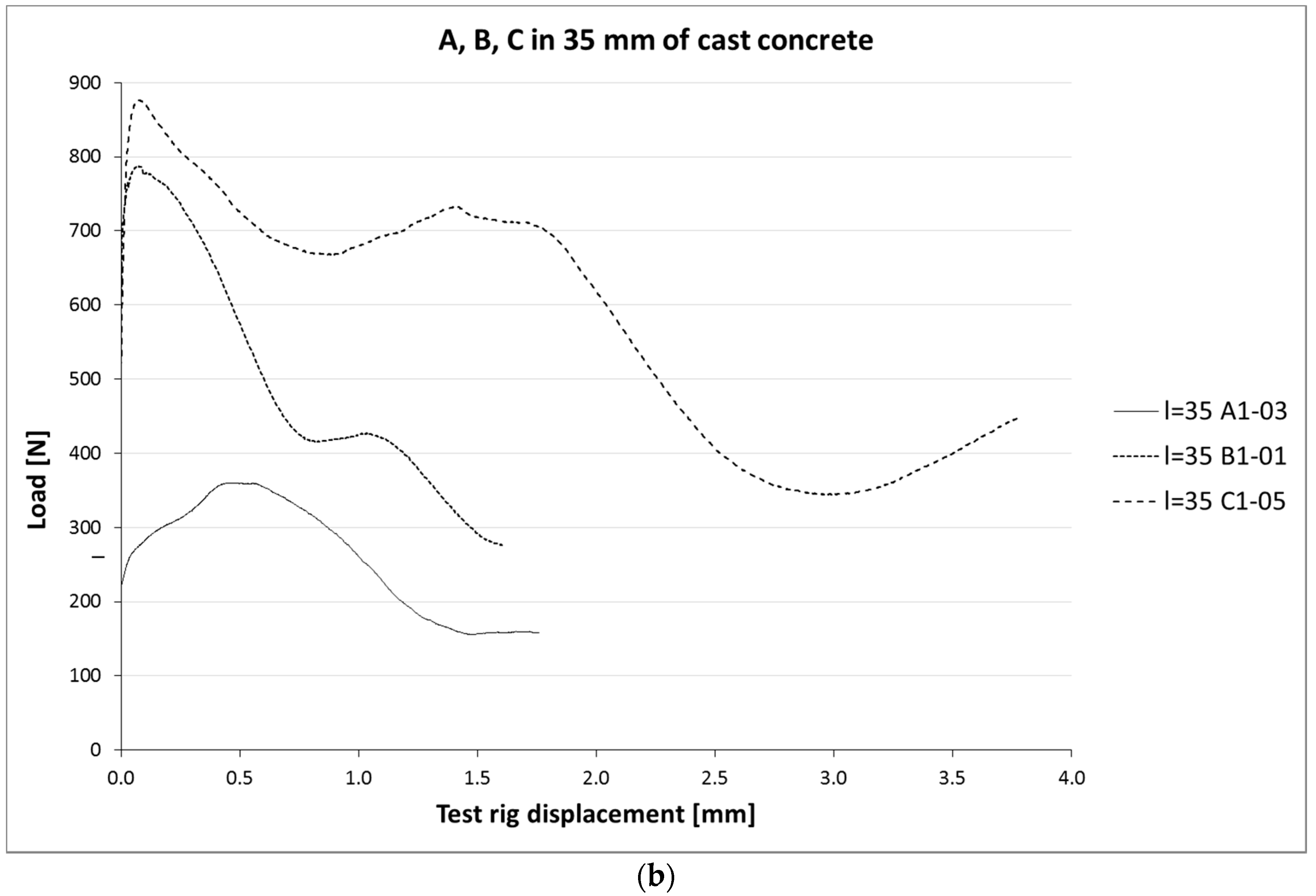

4.3.1. Cast Specimens

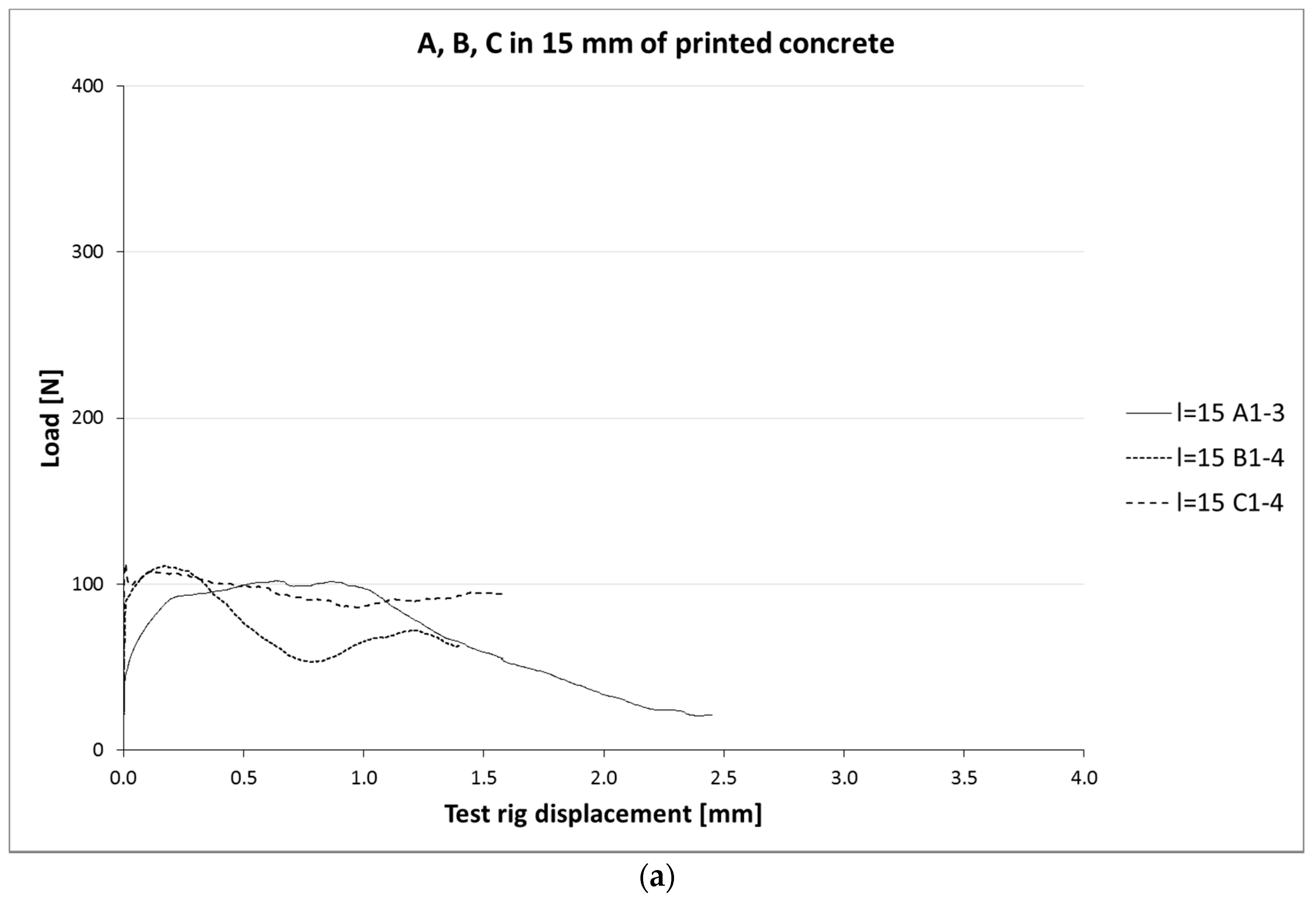

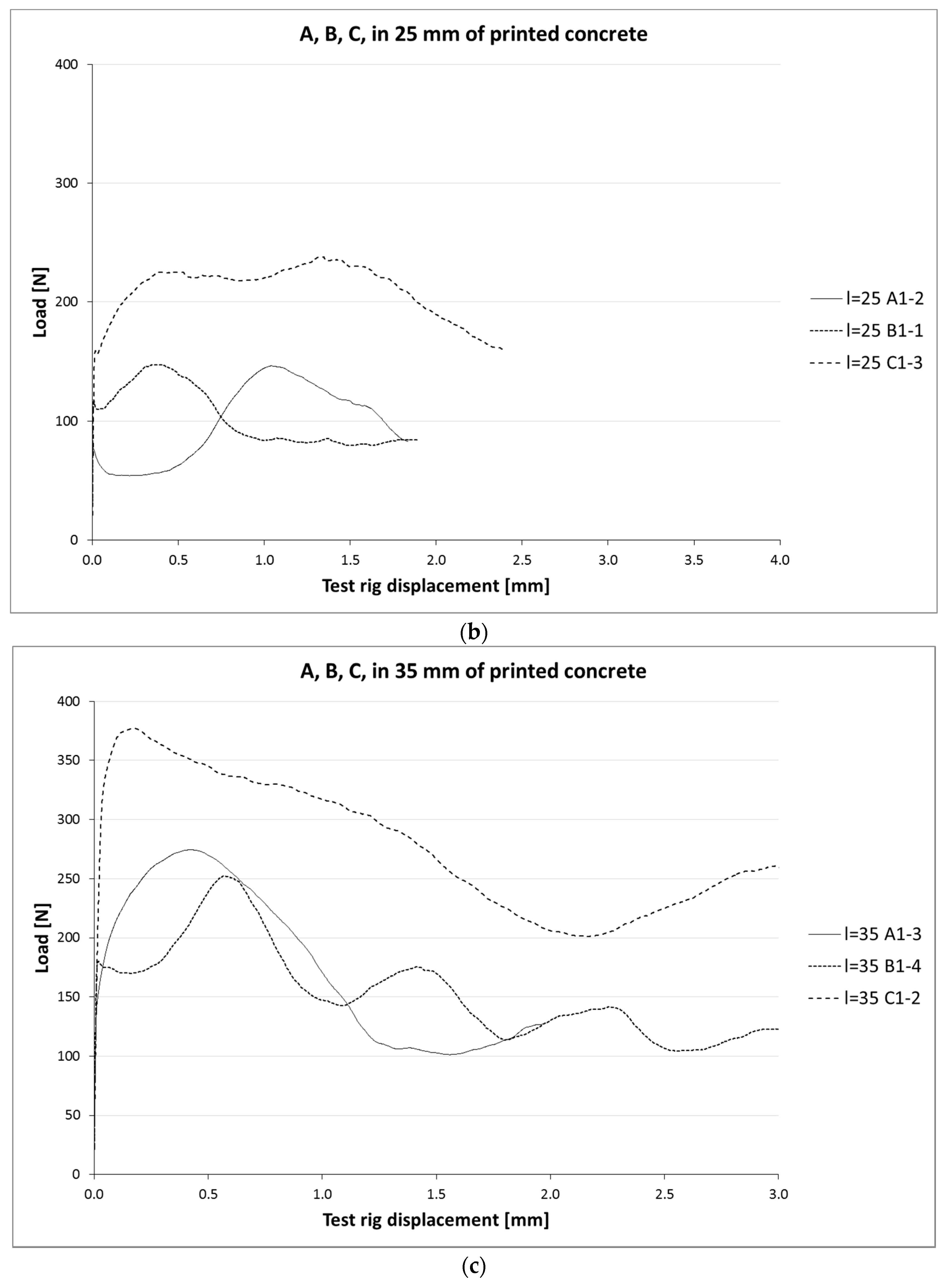

4.3.2. Printed Specimens

4.3.3. Previous Research

4.4. Conclusions on Pull-Out Test

5. Four-Point Bending Test

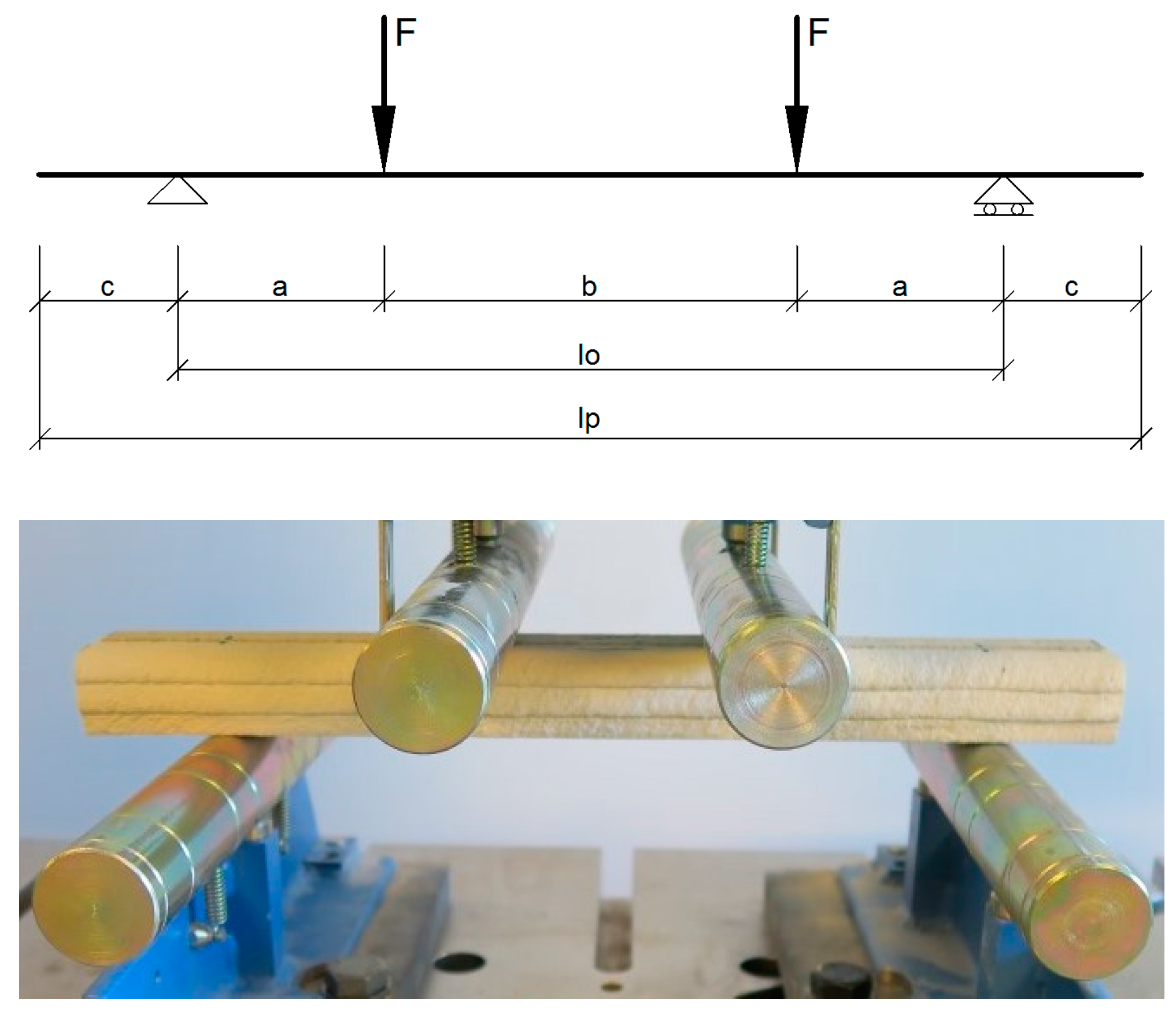

5.1. Method

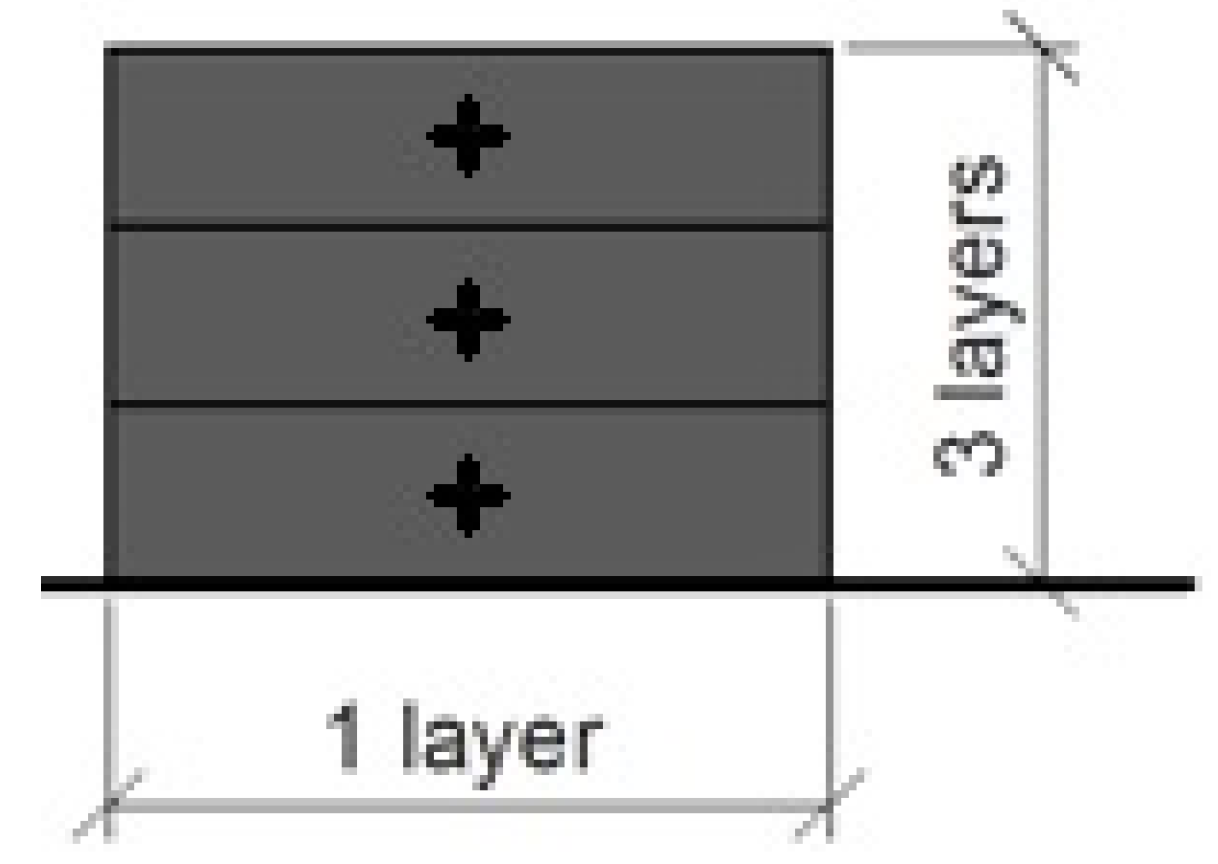

5.1.1. Specimen Design

5.1.2. Specimen Preparation

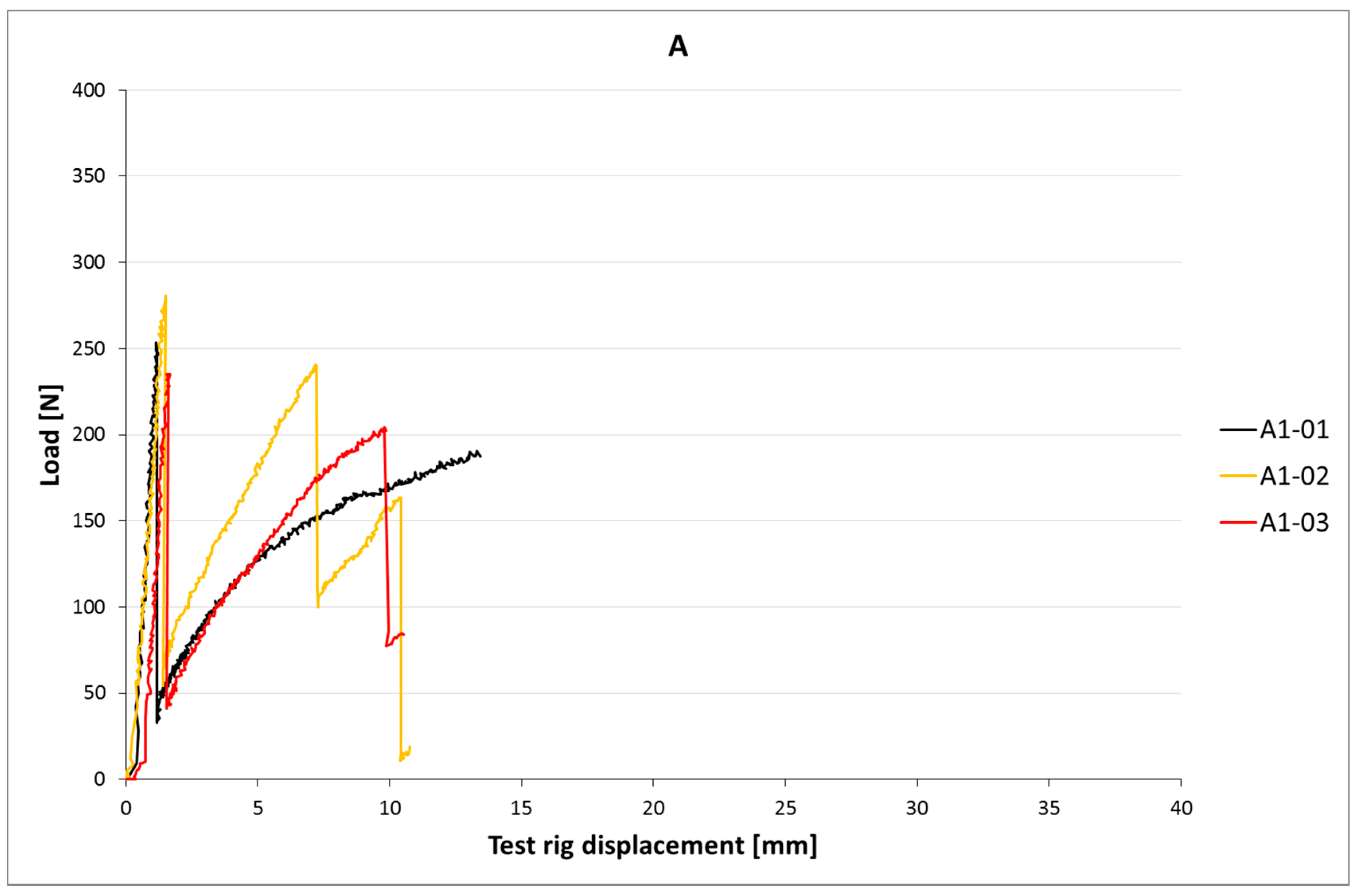

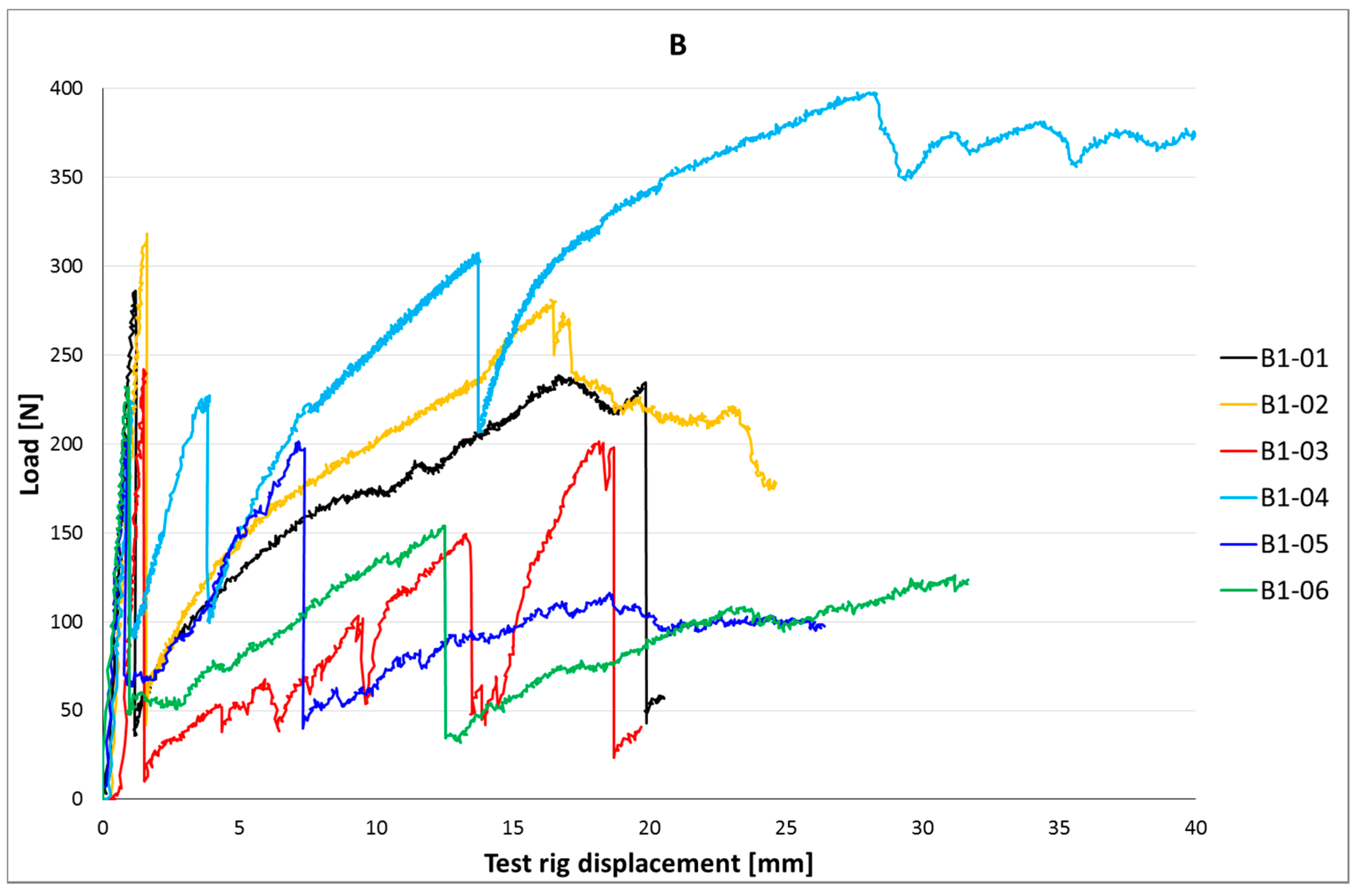

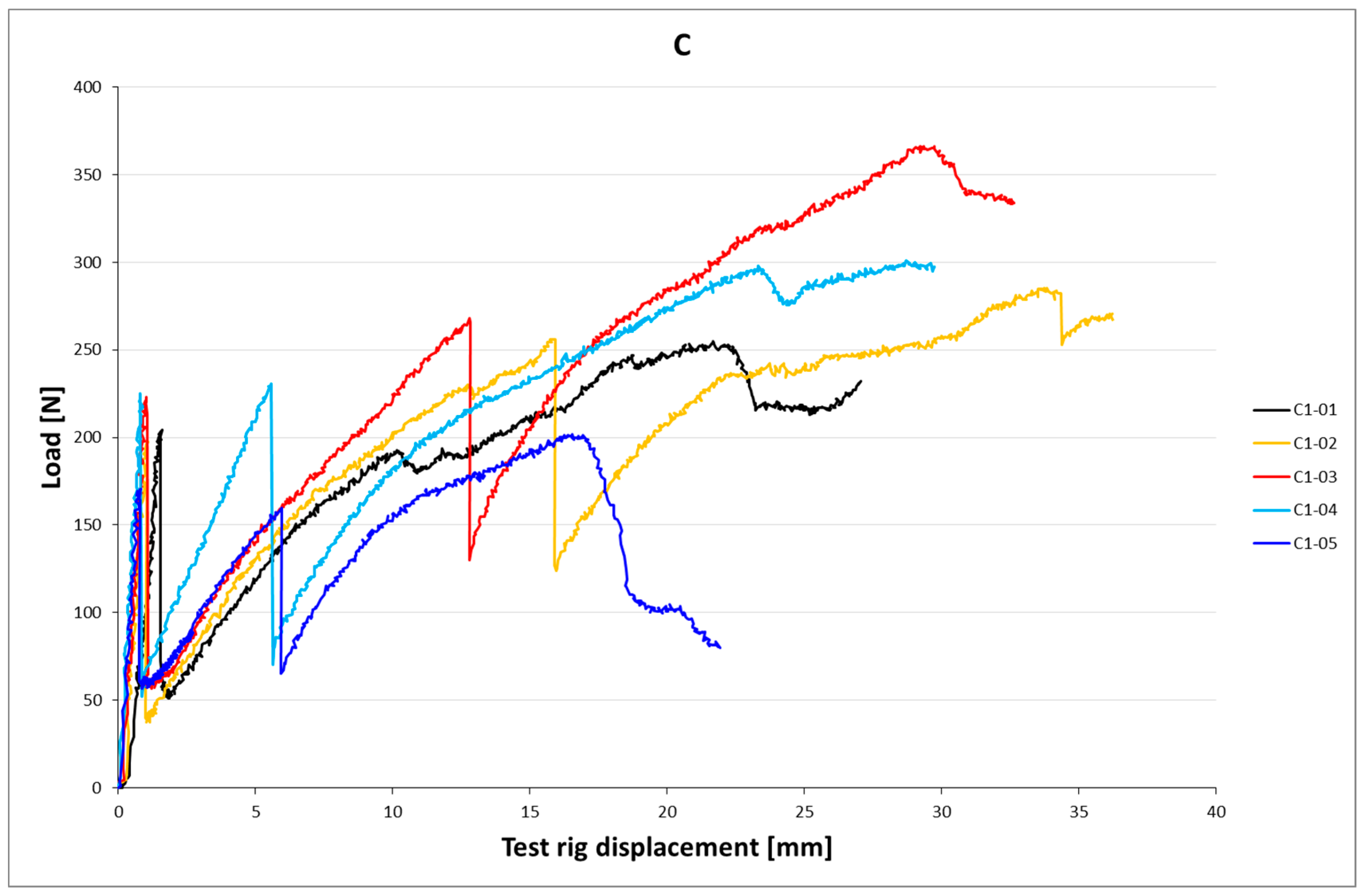

5.2. Results

5.3. Discussion

6. Summary and Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Khoshnevis, B.; Russel, R.; Kwon, H.; Bukkapatnam, S. Contour Crafting Large Prototypes. IEEE Robot. Autom. Mag. 2001, 8, 33–42. [Google Scholar] [CrossRef]

- Lim, S.; Le, T.; Webster, J.; Buswell, R.; Austin, S.; Gibb, A.; Thorpe, T. Fabricating Construction Components Using Layer Manufacturing Technology. In Proceedings of the Global Innovation in Construction Conference (GICC’09), Loughborough, UK, 13–16 September 2009. [Google Scholar]

- Totalkustom. Available online: http://www.totalkustom.com/3d-castle-completed.html (accessed on January 2016).

- Khoshnevis, B.; Bodiford, M.; Burks, K.; Ethridge, E.; Tucker, D.; Kim, W.; Toutanji, H.; Fiske, M. Lunar contour crafting—A novel technique for ISRU-based habitat development. In Proceedings of the 43rd AIAA Aerospace Sciences Meeting and Exhibit, Aerospace Sciences Meetings, Reno, NV, USA, 10–13 January 2005. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Zhang, J. Extraterrestrial construction using contour crafting. In Solid Freeform Fabrication Proceedings; University of Texas: Austin, TX, USA, 2012; pp. 250–259. [Google Scholar]

- Colla, V.; Dini, E. Large scale 3D printing: From deep sea to the moon. In Low-Cost 3D Printing, for Science, Education & Sustainable Development; Canessa, E., Fonda, C., Zennaro, M., Eds.; ICTP: Trieste, Italy, 2013; pp. 127–132. [Google Scholar]

- Cesaretti, G.; Dini, E.; De Kestelier, X.; Colla, V.; Pambaguian, L. Building components for an outpost on the Lunar soil by means of a novel 3D printing technology. Acta Astronaut. 2014, 93, 430–450. [Google Scholar] [CrossRef]

- Joshi, S.C.; Sheikh, A.A. 3D printing in aerospace and its long-term sustainability. Virtual Phys. Prototyp. 2015, 10, 175–185. [Google Scholar] [CrossRef]

- 3ders. Available online: http://www.3ders.org/articles/20150909-lewis-grand-hotel-andrey-rudenko-to-develop-worlds-first-3d-printed-hotel.html (accessed on 26 September 2017).

- Cnet. Available online: http://www.cnet.com/news/dubai-unveils-worlds-first-3d-printed-office-building (accessed on January 2016).

- Mediaoffice. Available online: http://mediaoffice.ae/en/media-center/news/23/5/2016/3d-printed-office-building.aspx (accessed on January 2016).

- 3ders. Available online: http://www.3ders.org/articles/20161214-spain-unveils-worlds-first-3d-printed-pedestrian-bridge-made-of-concrete.html (accessed on 26 September 2017).

- 3ders. Available online: http://www.3ders.org/articles/20170602-cybe-construction-completes-3d-printing-of-168-sq-m-rdrone-laboratory-in-dubai.htm (accessed on 26 September 2017).

- De Ingenieur. Available online: https://www.deingenieur.nl/artikel/betonnen-fietsbrug-uit-de-printer (accessed on 26 September 2017).

- 3ders. Available online: http://www.3ders.org/articles/20170213-3d-printing-construction-company-apis-cor-prints-37-m2-house-near-moscow-plans-global-expansion.html (accessed on 26 September 2017).

- Cementonline. Available online: https://www.cementonline.nl/proefstuk-eerste-3d-geprinte-autobrug-sterker-dan-verwacht (accessed on 24 September 2017).

- 3ders. Available online: http://www.3ders.org/articles/20170907-3d-printed-concrete-office-hotel-coming-to-copenhagen.html (accessed on 24 September 2017).

- Tay, Y.W.D.; Panda, B.; Paul, S.C.; Mohamed, N.A.N.; Tan, M.J.; Leong, K.F. 3D printing trends in building and construction industry: A review. Virtual Phys. Prototyp. 2017, 12, 261–276. [Google Scholar] [CrossRef]

- Salet, T.A.M.; Bos, F.P.; Wolfs, R.J.M.; Ahmed, Z.Y. 3D concrete printing—A structural engineering perspective. In High Tech Concrete: Where Technology and Engineering Meet, Proceedings of the 2017 Fib Symposium, Maastricht, The Netherlands, 12–17 June 2017; Luković, M., Hordijk, D.A., Eds.; Springer: Berlin, Germany, 2017. [Google Scholar] [CrossRef]

- Youtube. Available online: https://www.youtube.com/watch?v=8_m-fmkuuUA (accessed on 17 July 2017).

- Wu, P.; Wang, J.; Wang, X. A critical review of the use of 3-D printing in the construction industry. Autom. Constr. 2016, 68, 21–31. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.; Le, T.; Austin, S.; Gibb, A.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Autom. Constr. 2012, 21, 262–268. [Google Scholar] [CrossRef]

- Borg Costanzi, C.; Ahmed, Z.; Schipper, R.; Bos, F.; Knaack, U.; Wolfs, R. 3D Printing concrete on temporary surfaces: The design and fabrication of a concrete shell structure. Autom. Constr. 2017. under review. [Google Scholar]

- Huashangluhai. Available online: www.hstdgm.com (accessed on 14 July 2017).

- Khoshnevis, B.; Hwang, D.; Yao, K.-T.; Yeh, Z. Mega-scale fabrication by contour crafting. Int. J. Ind. Syst. Eng. 2006, 1, 301–320. [Google Scholar] [CrossRef]

- Hambach, M.; Volkmer, D. Properties of 3D-printed fiber-reinforced Portland cement paste. Cem. Concr. Compos. 2017, 79, 62–70. [Google Scholar] [CrossRef]

- 4TU. Available online: https://www.4tu.nl/bouw/en/lighthouse2017/3D%20Concrete%20Printing%20for%20Structural%20Applications/ (accessed on 26 September 2017).

- Hack, N.; Lauer, W.V. Mesh-mould: Robotically fabricated spatial meshes as reinforced concrete formwork. Archit. Des. 2014, 84, 44–53. [Google Scholar] [CrossRef]

- Hack, N.; Lauer, W.V.; Gramazio, F.; Kohler, M. Mesh Mould: Robotically fabricated metal meshes as concrete formwork and reinforcement. In Proceedings of the 11th International Symposium on Ferrocement and 3rd ICTRC International Conference on Textile Reinforced Concrete, Aachen, Germany, 7–10 June 2015. [Google Scholar]

- Bos, F.P.; Ahmed, Z.Y.; Wolfs, R.J.M.; Salet, T.A.M. 3D printing concrete with reinforcement. In High Tech Concrete: Where Technology and Engineering Meet, Proceedings of the 2017 Fib Symposium, Maastricht, The Netherlands, 12–14 June 2017; Luković, M., Hordijk, D.A., Eds.; Springer: Berlin, Germany, 2017; pp. 2484–2493. [Google Scholar] [CrossRef]

- Bos, F.; Wolfs, R.; Ahmed, Z.; Salet, T. Additive manufacturing of concrete in construction: Potentials and challenges of 3D concrete printing. Virtual Phys. Prototyp. 2016, 11, 209–225. [Google Scholar] [CrossRef]

- Hagan, P.; Chen, J.; Saydam, S. The Load Transfer Mechanism of Fully Grouted Cable Bolts under Laboratory Tests. In Proceedings of the Coal Operators’ Conference, Wollongong, Australia, 12–14 February 2014. [Google Scholar]

- Chen, J.; Hagan, P.C.; Saydam, S. Sample Diameter Effect on Bonding Capacity of Fully Grouted Cable Bolts. Tunn. Undergr. Space Technol. 2017, 68, 238–243. [Google Scholar] [CrossRef]

- Benmokrane, B.; Chennouf, A.; Mitri, H.S. Laboratory evaluation of cement-based grouts and grouted rock anchors. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1995, 32, 633–642. [Google Scholar] [CrossRef]

- Haskett, M.; Oehlers, D.J.; Mohamed Ali, M.S. Local and global bond characteristics of steel reinforcing bars. Eng. Struct. 2008, 30, 376–383. [Google Scholar] [CrossRef]

- Fédération Internationale du Béton. Bond of Reinforcement in Concrete, State-of-Art-Report; International Federation for Structural Concrete: Lausanne, Switzerland, 2000; ISBN 978-2-88-394050-5. [Google Scholar]

- Cairns, J. Bond and anchorage of embedded steel reinforcement in Fib Model Code 2010. Struct. Concr. 2015, 45–55. [Google Scholar] [CrossRef]

- NEN-EN 1992-1-1 Eurocode 2. Ontwerp en Berekening van Betonconstructies, Deel 1-1: Algemene Regels en Regels Voor Gebouwen; Nederlands Normalisatie Instituut: Delft, The Netherlands, 2011. [Google Scholar]

- Melo, J.; Rossetto, T.; Varum, H. Experimental, Experimental study of bond–slip in RC structural elements with plain bars. Mater. Struct. 2015, 48, 2367–2381. [Google Scholar] [CrossRef]

- Abrams, D. Tests of bond between concrete and steel. In Bulletin No. 71; Engineering Experiment Station, University Illinois Bull: Carbondale, IL, USA, 1913. [Google Scholar]

- Fabbrocino, G.; Verderame, G.M.; Manfredi, G. Experimental behaviour of anchored smooth rebars in old type reinforced concrete buildings. Eng. Struct. 2005, 27, 1575–1585. [Google Scholar] [CrossRef]

- Verderame, G.M.; Ricci, P.; De Carlo, G.; Manfredi, G. Cyclic bond behaviour of plain bars. Part I: Experimental investigation. Constr. Build. Mater. 2009, 23, 3499–3511. [Google Scholar] [CrossRef]

- Yeomans, S.R. Galvanized Steel Reinforcement. In Corrosion of Steel in Concrete Structures; Poursaee, A., Ed.; Elsevier: Amsterdam, The Netherlands, 2016; ISBN 978-1-78-242381-2. [Google Scholar] [CrossRef]

- ISO 14657. Zinc-Coated Steel for the Reinforcement of Concrete; International Organization for Standardization: Geneva, Switzerland, 2005. [Google Scholar]

- ASTM A767/A767M-16. Standard Specification for Zinc-Coated (Galvanized) Steel Bars for Concrete Reinforcement; ASTM International: West Conshohocken, PA, USA, 2016. [Google Scholar] [CrossRef]

- Swamy, R. Design for durability with galvanized reinforcement. In Galvanized Steel Reinforcement in Concrete; Yeomans, S., Ed.; Elsevier: Oxford, UK, 2004; ISBN 978-0-08-044511-3. [Google Scholar]

- Kayali, O.; Yeomans, S. Bond of ribbed galvanized reinforcing steel in concrete. Cem. Concr. Compos. 2000, 22, 459–467. [Google Scholar] [CrossRef]

- Hamad, B.; Mike, J. Bond strength of hot-dip galvanized reinforcement in normal strength concrete structures. Constr. Build. Mater. 2005, 19, 275–283. [Google Scholar] [CrossRef]

- Pernicova, R.; Dobias, D.; Pokorny, P. Problems connected with use of hot-dip galvanized reinforcement in concrete elements. Procedia Eng. 2017, 172, 859–866. [Google Scholar] [CrossRef]

- NEN-EN 10080:2005. Steel for the Reinforcement of Concrete—Weldable Reinforcing Steel—General; Nederlands Normalisatie Instituut: Delft, The Netherlands, 2005. [Google Scholar]

- Banthia, N. A study of some factors affecting the fiber–matrix bond in steel fiber reinforced concrete. Can. J. Civ. Eng. 1990, 17, 610–620. [Google Scholar] [CrossRef]

- Chanvillard, G.; Aïtcin, P.-C. Pull-out behavior of corrugated steel fibers: Qualitative and statistical analysis. Adv. Cem. Based Mater. 1996, 4, 28–41. [Google Scholar] [CrossRef]

- Robins, P.; Austin, S.; Jones, P. Pull-out behaviour of hooked steel fibres. Mater. Struct. 2002, 35, 434–442. [Google Scholar] [CrossRef]

- Soetens, T.; van Gysel, A.; Matthys, S.; Taerwe, L. A semi-analytical model to predict the pull-out behaviour of inclined hooked-end steel fibres. Constr. Build. Mater. 2013, 43, 253–265. [Google Scholar] [CrossRef]

- He, Q.; Liu, C.; Yu, X. Improving steel fiber reinforced concrete pull-out strength with nanoscale iron oxide coating. Constr. Build. Mater. 2015, 79, 311–317. [Google Scholar] [CrossRef]

| Property | Symbol | Value | ||

|---|---|---|---|---|

| ID | A | B | C | |

| Name | - | Bekaert Syncrocord Force 0.6 | Bekaert Syncrocord Flex 0.9 | Bekaert Syncrocord Flex 1.2 |

| Coating | - | Galvanised | Galvanised | Galvanised |

| Diameter | d [mm] | 0.63 | 0.97 | 1.20 |

| Perimeter | p [mm] | 2.24 | 5.11 | 5.87 |

| Linear Density | ρlin [g/m] | 2.30 | 3.46 | 5.84 |

| 0.2% offset yield strain | ε0.2 | 1.61% | 1.72% | 1.90% |

| 0.2% offset yield stress | f0.2 [N] | 381 | 1140 | 1800 |

| Characteristic ultimate tensile strain | εuk | 2.32% | 2.10% | 2.40% |

| Characteristic ultimate tensile strength | fuk [N] | 420 | 1190 | 1925 |

| Axial Tensile Modulus of Elasticity | Eaxi [GPa] | 181.6 | 178.3 | 156.8 |

| Series | No. of Specimens | Concrete Manufacturing | Cable | lcs [mm] |

|---|---|---|---|---|

| C15A | 5 | Cast | A | 15 |

| C15B | 5 | Cast | B | 15 |

| C15C | 5 | Cast | C | 15 |

| C35A | 5 | Cast | A | 35 |

| C35B | 5 | Cast | B | 35 |

| C35C | 5 | Cast | C | 35 |

| P15A | 5 | Printed | A | 15 |

| P15B | 5 | Printed | B | 15 |

| P15C | 5 | Printed | C | 15 |

| P25A | 5 | Printed | A | 25 |

| P25B | 5 | Printed | B | 25 |

| P25C | 5 | Printed | C | 25 |

| P35A | 5 | Printed | A | 35 |

| P35B | 5 | Printed | B | 35 |

| P35C | 5 | Printed | C | 35 |

| Series | Fadh [N]; CoV | τadh [MPa] | Fu [N]; CoV | τu [MPa] | τadh/τu |

|---|---|---|---|---|---|

| C15A | 139.03; 17% | 4.15 | 238.83; 27% | 7.12 | 0.58 |

| C15B | 330.92; 10% | 4.31 | 417.50; 10% | 5.44 | 0.79 |

| C15C | 327.12; 17% | 3.72 | 396.95; 14% | 4.51 | 0.82 |

| C35A | 245.30; 6% | 3.13 | 347.76; 9% | 4.44 | 0.70 |

| C35B | 688.66; 10% | 3.85 | 826.44; 11% | 4.62 | 0.83 |

| C35C | 505.08; 28% | 2.46 | 995.87; 18% | 4.85 | 0.51 |

| P15A | 48.62; 17% | 1.45 | 79.57; 22% | 2.37 | 0.61 |

| P15B | 80.80; 30% | 1.05 | 102.02; 29% | 1.33 | 0.79 |

| P15C | 100.54; 24% | 1.14 | 113.62; 39% | 1.29 | 0.88 |

| P25A | 83.41; 19% | 1.49 | 173.24; 31% | 3.10 | 0.48 |

| P25B | 142.67; 34% | 1.12 | 177.49; 38% | 1.39 | 0.81 |

| P25C | 188.45; 13% | 1.28 | 321.70; 36% | 2.19 | 0.58 |

| P35A | 143.20; 18% | 1.83 | 242.40; 27% | 3.10 | 0.59 |

| P35B | 163.40; 11% | 0.91 | 253.88; 8% | 1.42 | 0.64 |

| P35C | 354.74; 4% | 1.73 | 409.63; 6% | 1.99 | 0.87 |

| Cable Type | Fu [N] | P [mm] | τmax,ave 15/25/35 [MPa] | lanchorage,adh [mm] | lanchorage,u [mm] |

|---|---|---|---|---|---|

| A | 420 | 2.24 | 2.86 | 117.9 | 65.6 |

| B | 1190 | 5.11 | 1.38 | 217.3 | 161.7 |

| C | 1925 | 5.87 | 1.82 | 237.1 | 179.9 |

| Beam Specimen | Mcr [103 Nmm] | Mu [103 Nmm] | Mu/Mcr | No. Cracks | Failure Mode |

|---|---|---|---|---|---|

| Analytical estimate | 17.1 | 13.6 | 80% | - | Cable break |

| A1 | 19.0 | 14.1 | 74% | 1 | Cable break |

| A2 | 21.0 | 18.0 | 86% | 1 | Cable break |

| A3 | 17.6 | 15.3 | 87% | 1 | Cable break |

| Average | 19.2 | 15.8 | 82% | - | - |

| Coeff. of variation | 9% | 13% | 9% | - | - |

| Analytical estimate | 17.1 | 38.6 | 304% | Cable break | |

| B1 | 18.8 | 17.6 | 93% | 2 | Cable slip |

| B2 | 23.9 | 21.1 | 88% | 1 | Cable slip |

| B3 | 18.1 | 15.0 | 83% | 2 | Max. defl. |

| B4 | 16.8 | 29.8 | 177% | 3 | Cable slip |

| B5 | 15.2 | 15.1 | 99% | 2 | Max. defl. |

| B6 | 17.4 | 11.5 | 66% | 2 | Max. defl. |

| Average | 20.3 | 18.4 | 101% | - | - |

| Coeff. of variation | 16% | 35% | 39% | - | - |

| Analytical estimate | 17.1 | 62.4 | 491% | Cable break | |

| C1 | 15.3 | 27.5 | 179% | 1 | Cable slip |

| C2 | 14.9 | 21.4 | 144% | 2 | Cable slip |

| C3 | 16.0 | 27.5 | 172% | 2 | Cable slip |

| C4 | 16.9 | 22.6 | 134% | 2 | Cable slip |

| C5 | 12.8 | 15.1 | 118% | 2 | Cable slip |

| Average | 15.2 | 22.8 | 149% | - | - |

| Coeff. of variation | 10% | 23% | 17% | - | - |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bos, F.P.; Ahmed, Z.Y.; Jutinov, E.R.; Salet, T.A.M. Experimental Exploration of Metal Cable as Reinforcement in 3D Printed Concrete. Materials 2017, 10, 1314. https://doi.org/10.3390/ma10111314

Bos FP, Ahmed ZY, Jutinov ER, Salet TAM. Experimental Exploration of Metal Cable as Reinforcement in 3D Printed Concrete. Materials. 2017; 10(11):1314. https://doi.org/10.3390/ma10111314

Chicago/Turabian StyleBos, Freek P., Zeeshan Y. Ahmed, Evgeniy R. Jutinov, and Theo A. M. Salet. 2017. "Experimental Exploration of Metal Cable as Reinforcement in 3D Printed Concrete" Materials 10, no. 11: 1314. https://doi.org/10.3390/ma10111314

APA StyleBos, F. P., Ahmed, Z. Y., Jutinov, E. R., & Salet, T. A. M. (2017). Experimental Exploration of Metal Cable as Reinforcement in 3D Printed Concrete. Materials, 10(11), 1314. https://doi.org/10.3390/ma10111314