Grain Structure Control of Additively Manufactured Metallic Materials

Abstract

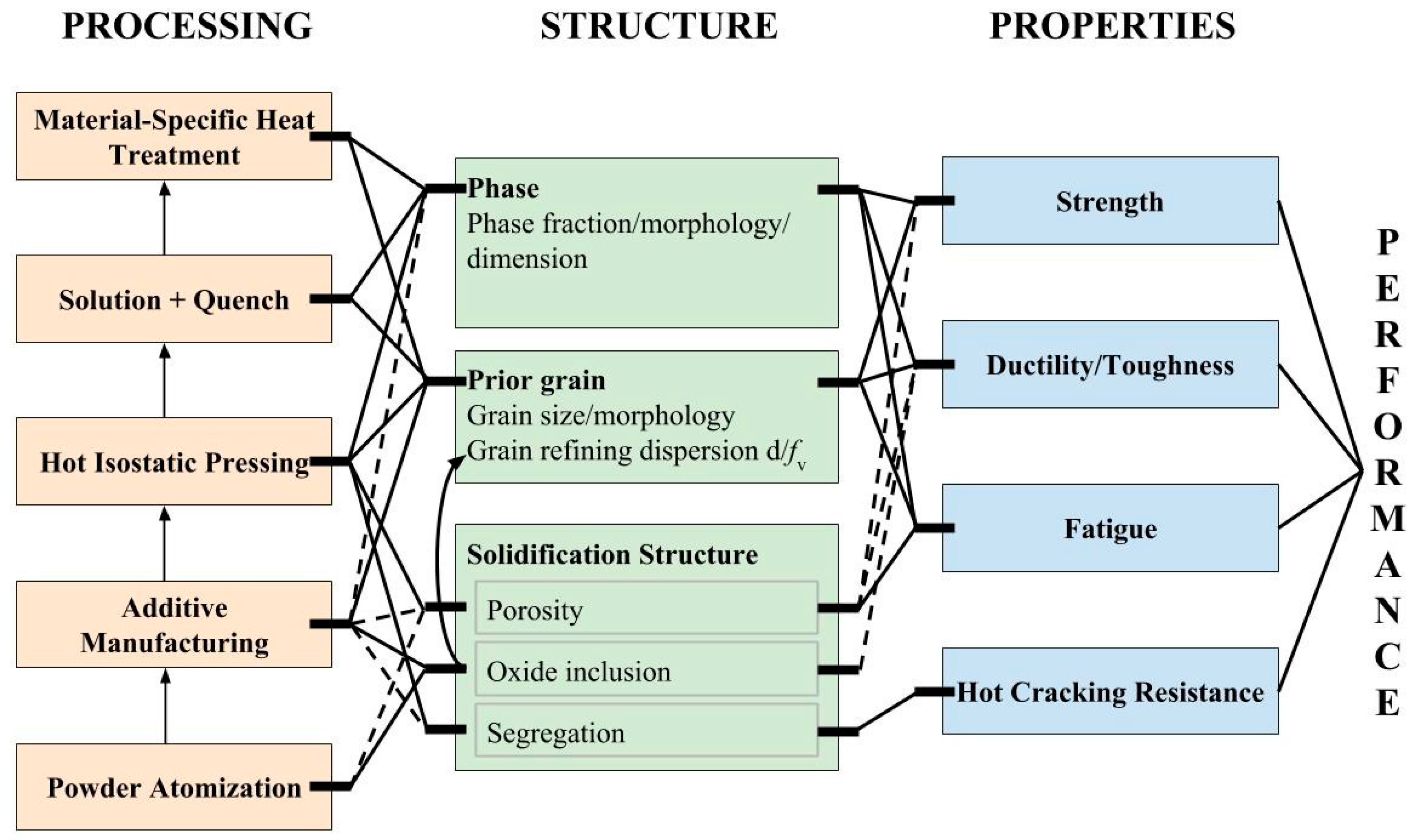

:1. Introduction

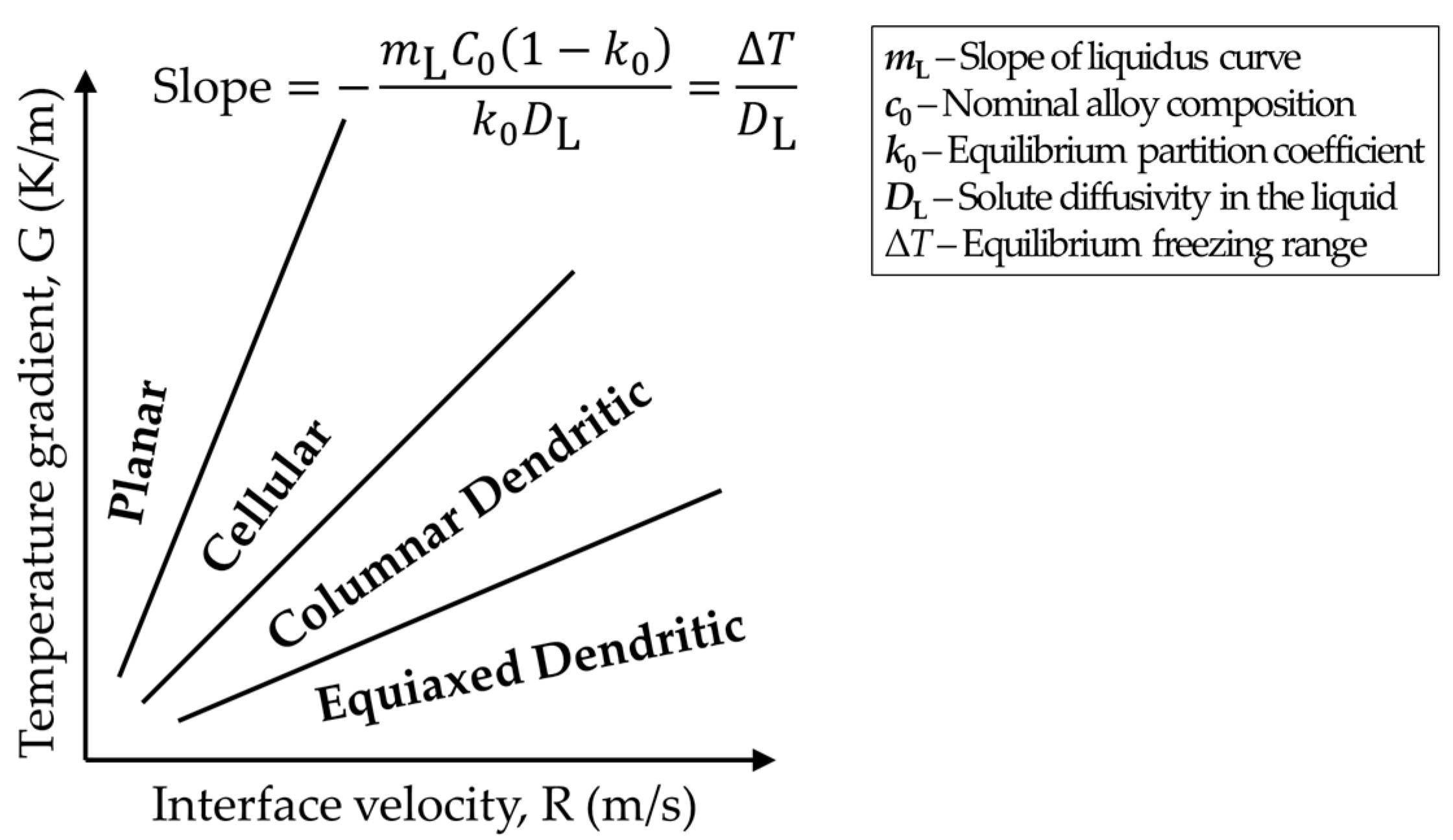

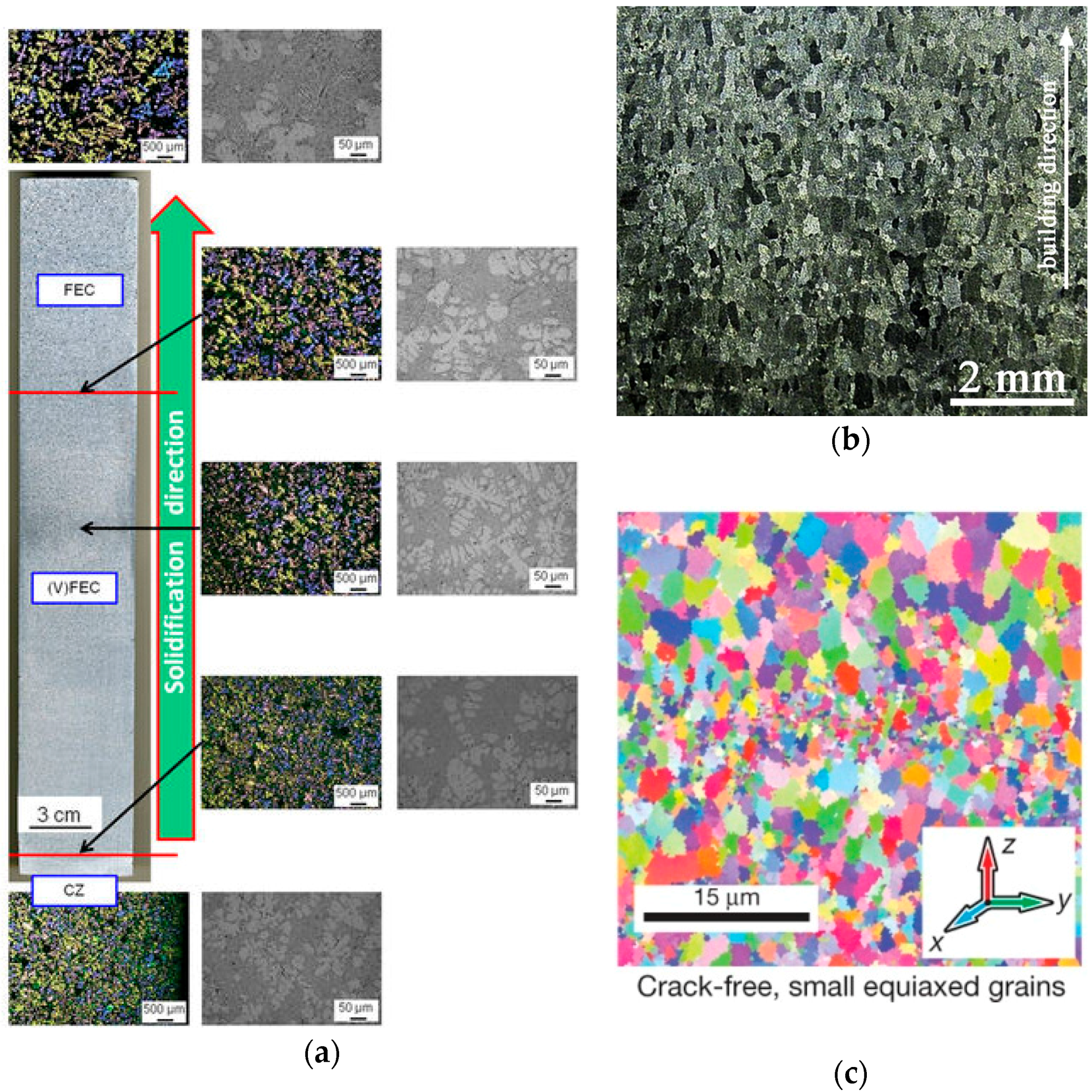

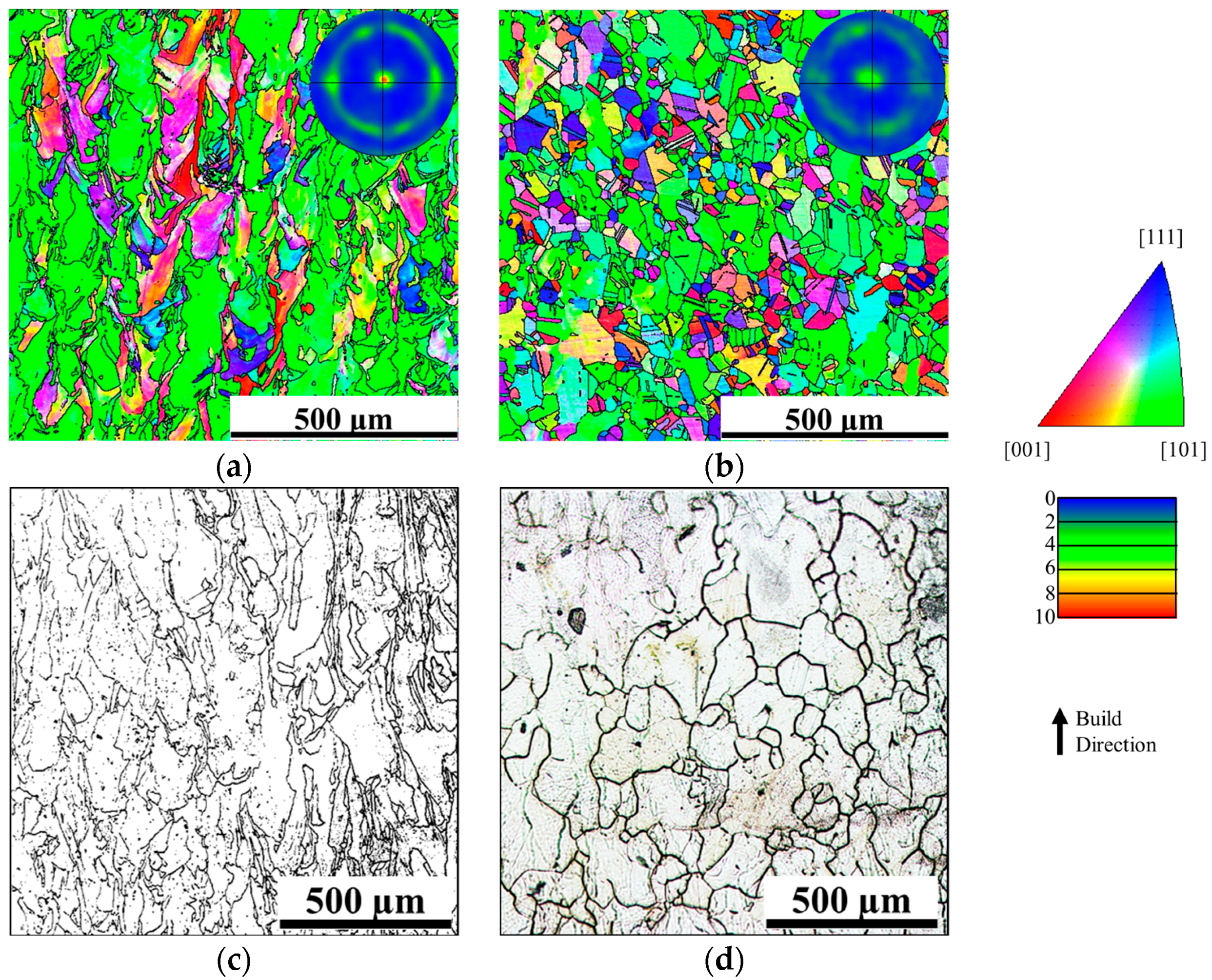

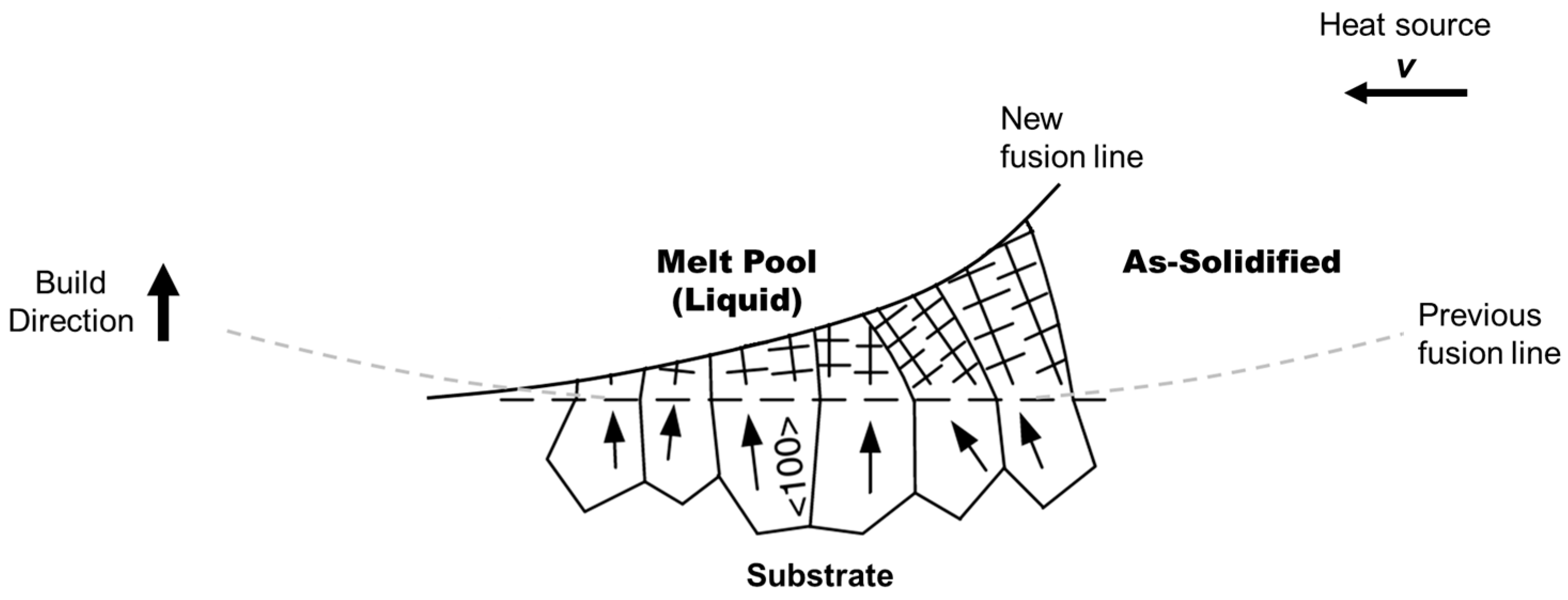

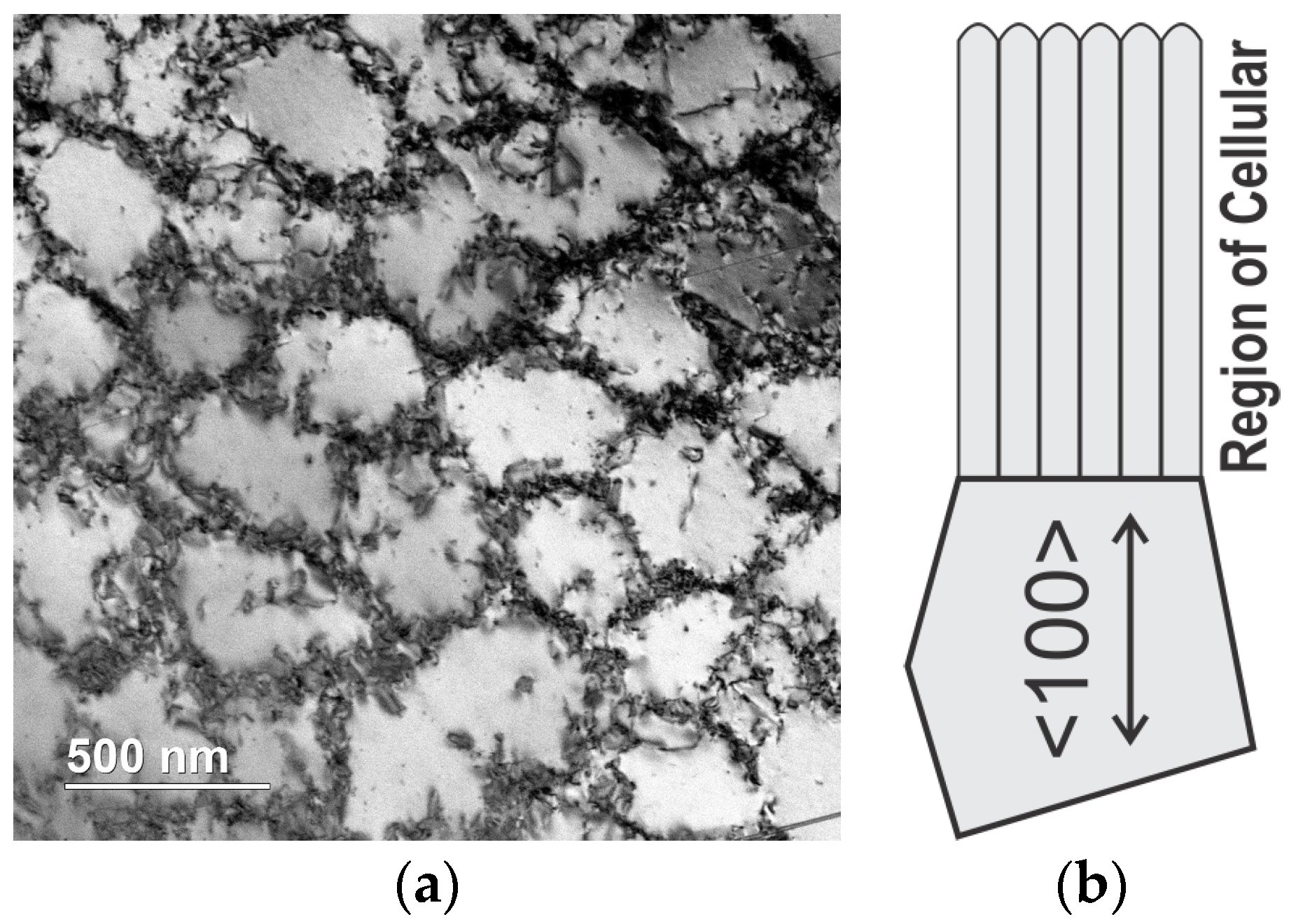

2. Grain Morphology Control

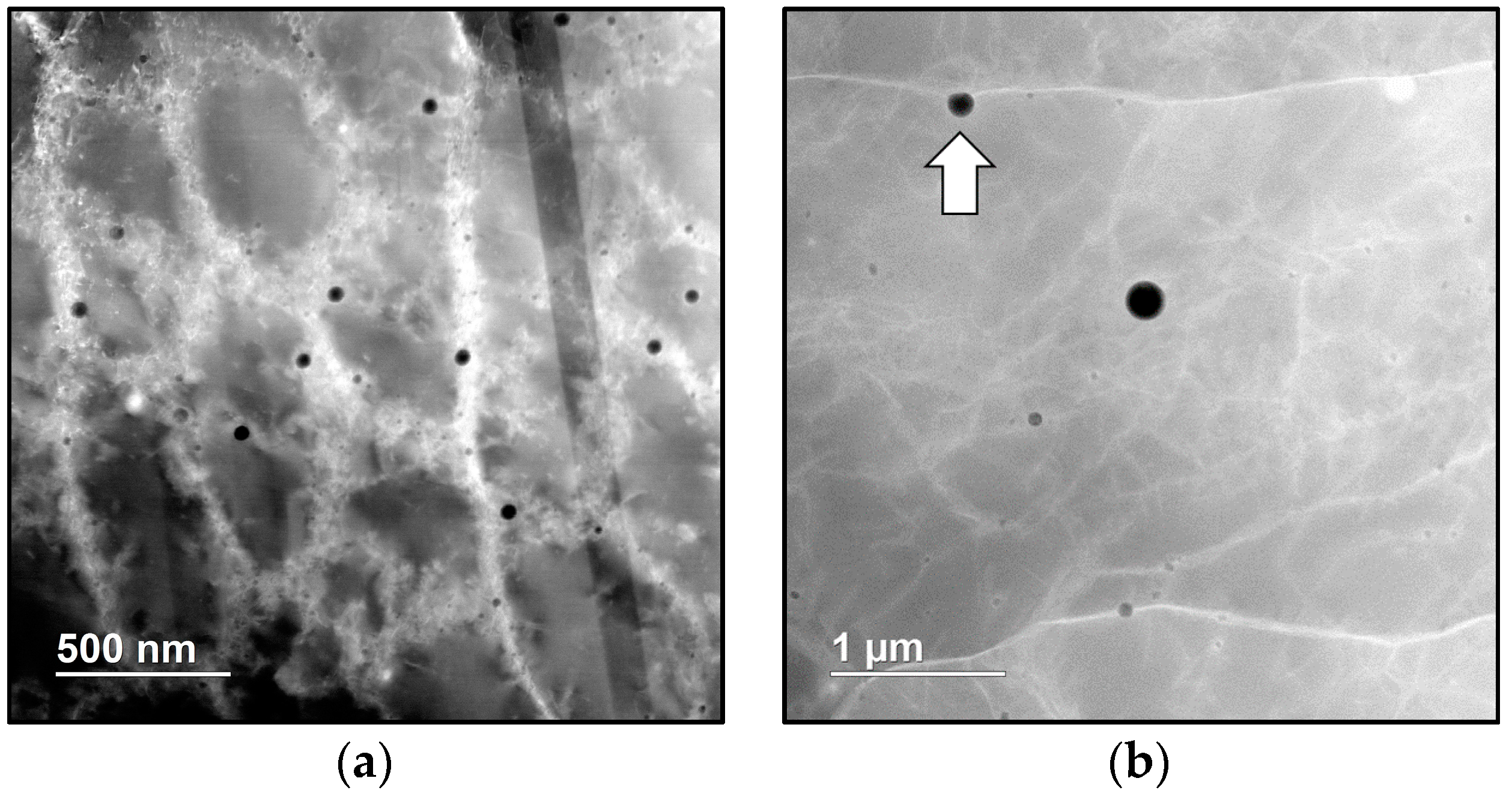

2.1. Via AM Processes

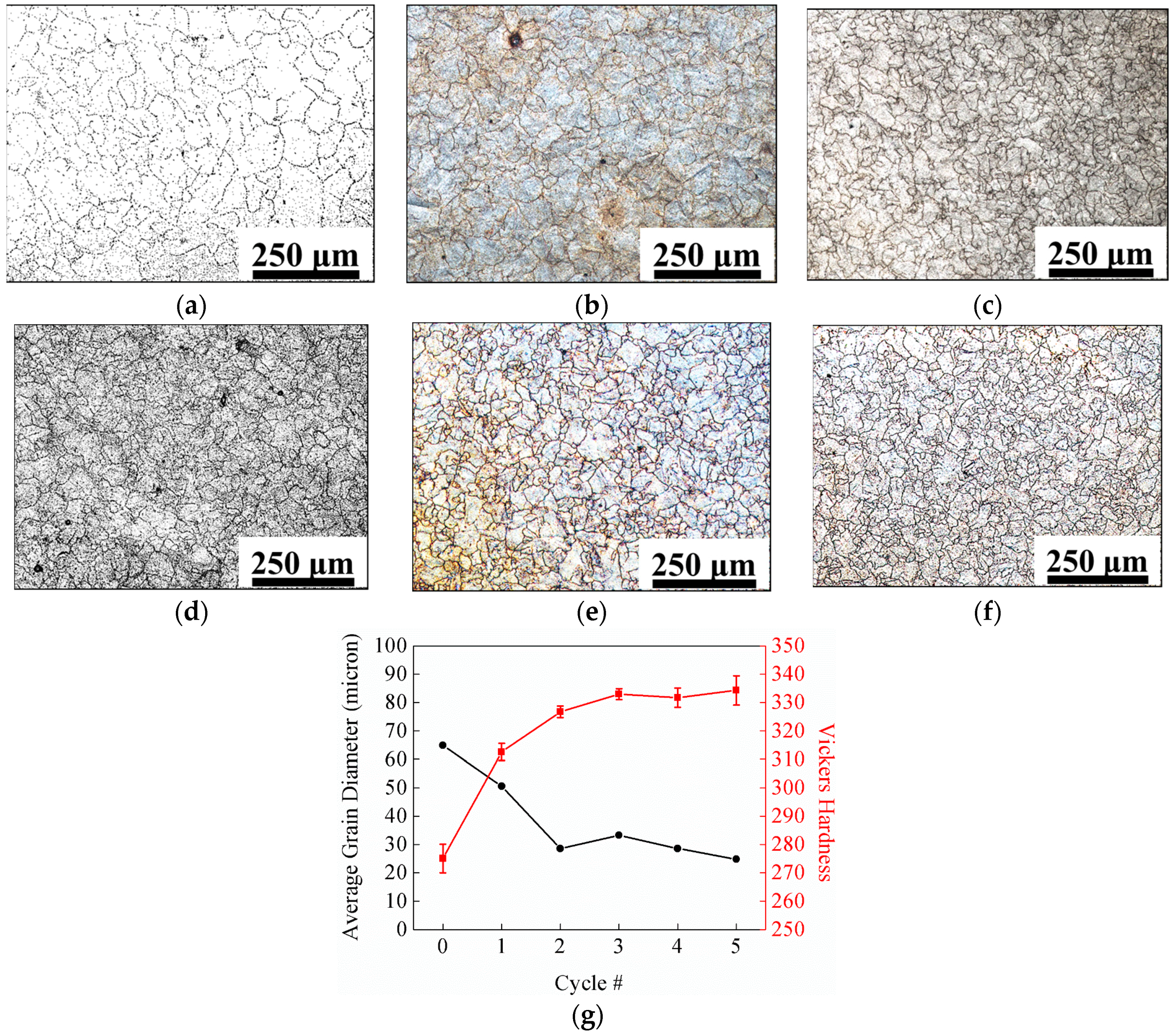

2.2. Via Post Heat-Treatments

3. Grain Size Optimization

3.1. Via AM Processes

3.2. Via Post Heat-Treating Processess

4. Perspectives on the Design of New Materials for AM

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Collins, P.C.; Brice, D.A.; Samimi, P.; Ghamarian, I.; Fraser, H.L. Microstructural Control of Additively Manufactured Metallic Materials. Annu. Rev. Mater. Res. 2016, 46, 63–91. [Google Scholar] [CrossRef]

- Sames, W.J.; List, F.A.; Pannala, S.; Dehoff, R.R.; Babu, S.S. The metallurgy and processing science of metal additive manufacturing. Int. Mater. Rev. 2016, 61, 315–360. [Google Scholar] [CrossRef]

- Smith, J.; Xiong, W.; Yan, W.; Lin, S.; Cheng, P.; Kafka, O.L.; Wagner, G.J.; Cao, J.; Liu, W.K. Linking process, structure, property, and performance for metal-based additive manufacturing: Computational approaches with experimental support. Comput. Mech. 2016, 57, 583–610. [Google Scholar] [CrossRef]

- Xiong, W.; Olson, G.B. Cybermaterials: Materials by design and accelerated insertion of materials. NPJ Comput. Mater. 2016, 2, 15009. [Google Scholar] [CrossRef]

- Xiong, W.; Olson, G.B. Integrated computational materials design for high-performance alloys. MRS Bull. 2015, 40, 1035–1044. [Google Scholar] [CrossRef]

- Wu, X.; Liang, J.; Mei, J.; Mitchell, C.; Goodwin, P.S.; Voice, W. Microstructures of laser-deposited Ti–6Al–4V. Mater. Des. 2004, 25, 137–144. [Google Scholar] [CrossRef]

- Al-Bermani, S.S.; Blackmore, M.L.; Zhang, W.; Todd, I. The origin of microstructural diversity, texture, and mechanical properties in electron beam melted Ti-6Al-4V. Metall. Mater. Trans. A 2010, 41, 3422–3434. [Google Scholar] [CrossRef]

- Ma, M.; Wang, Z.; Zeng, X. A comparison on metallurgical behaviors of 316L stainless steel by selective laser melting and laser cladding deposition. Mater. Sci. Eng. A 2017, 685, 265–273. [Google Scholar] [CrossRef]

- Helmer, H.; Bauereiß, A.; Singer, R.F.; Körner, C. Grain structure evolution in Inconel 718 during selective electron beam melting. Mater. Sci. Eng. A 2016, 668, 180–187. [Google Scholar] [CrossRef]

- Zhu, Y.; Liu, D.; Tian, X.; Tang, H.; Wang, H. Characterization of microstructure and mechanical properties of laser melting deposited Ti-6.5Al-3.5Mo-1.5Zr-0.3Si titanium alloy. Mater. Des. 2014, 56, 445–453. [Google Scholar] [CrossRef]

- Kou, S. Welding Metallurgy, 2nd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2003; Volume 822. [Google Scholar]

- Wei, H.L.; Mazumder, J.; Debroy, T. Evolution of solidification texture during additive manufacturing. Sci. Rep. 2015, 5, 16446. [Google Scholar] [CrossRef] [PubMed]

- Kok, Y.H.; Tan, X.P.; Loh, N.H.; Tor, S.B.; Chua, C.K. Geometry dependence of microstructure and microhardness for selective electron beam-melted Ti–6Al–4V parts. Virtual Phys. Prototyp. 2016, 11, 183–191. [Google Scholar] [CrossRef]

- Dupont, J.N. Fundamentals of Weld Solidification. In ASM Handbook, Volume 6A: Welding Fundamentals and Processes; Lienert, T., Siewert, T., Babu, S., Acoff, V., Eds.; ASM International: Materials Park, OH, USA, 2011; p. 700. [Google Scholar]

- Hunt, J.D. Steady State Columnar and Equiaxed Growth of Dendrites and Eutectic. Mater. Sci. Eng. 1984, 65, 75–83. [Google Scholar] [CrossRef]

- Bolzoni, L.; Xia, M.; Babu, N.H. Formation of equiaxed crystal structures in directionally solidified Al-Si alloys using Nb-based heterogeneous nuclei. Sci. Rep. 2016, 6, 39554. [Google Scholar] [CrossRef] [PubMed]

- Wang, T.; Zhu, Y.Y.; Zhang, S.Q.; Tang, H.B.; Wang, H.M. Grain morphology evolution behavior of titanium alloy components during laser melting deposition additive manufacturing. J. Alloys Compd. 2015, 632, 505–513. [Google Scholar] [CrossRef]

- Martin, J.H.; Yahata, B.D.; Hundley, J.M.; Mayer, J.A.; Schaedler, T.A.; Pollock, T.M. 3D printing of high-strength aluminium alloys. Nature 2017, 549, 365–369. [Google Scholar] [CrossRef] [PubMed]

- Lu, Q.Y.; Wong, C.H. Applications of non-destructive testing techniques for post-process control of additively manufactured parts. Virtual Phys. Prototyp. 2017, 12, 301–321. [Google Scholar] [CrossRef]

- Sochalski-Kolbus, L.M.; Payzant, E.A.; Cornwell, P.A.; Watkins, T.R.; Babu, S.S.; Dehoff, R.R.; Lorenz, M.; Ovchinnikova, O.; Duty, C. Comparison of Residual Stresses in Inconel 718 Simple Parts Made by Electron Beam Melting and Direct Laser Metal Sintering. Metall. Mater. Trans. A 2015, 46, 1419–1432. [Google Scholar] [CrossRef]

- Vrancken, B.; Thijs, L.; Kruth, J.-P.; Van Humbeeck, J. Heat treatment of Ti6Al4V produced by Selective Laser Melting: Microstructure and Mechanical properties. J. Alloys Compd. 2012, 541, 177–185. [Google Scholar] [CrossRef]

- Gu, D.D.; Meiners, W.; Wissenbach, K.; Poprawe, R. Laser additive manufacturing of metallic components: Materials, processes and mechanisms. Int. Mater. Rev. 2012, 57, 133–164. [Google Scholar] [CrossRef]

- Lewandowski, J.J.; Seifi, M. Metal Additive Manufacturing: A Review of Mechanical Properties. Annu. Rev. Mater. Res. 2016, 46, 151–186. [Google Scholar] [CrossRef]

- Hillert, M. Inhibition of grain growth by second-phase particles. Acta Metall. 1988, 36, 3177–3181. [Google Scholar] [CrossRef]

- Olson, G.B. Overview: Science of Steel. In Innovations in Ultrahigh-Strength Steel Technology; Olson, G.B., Azrin, M., Wright, E.S., Eds.; U.S. Army Laboratory Command, Materials Technology Laboratory: Watertown, MA, USA, 1987; pp. 3–66. [Google Scholar]

- Zhong, Y.; Liu, L.; Wikman, S.; Cui, D.; Shen, Z. Intragranular cellular segregation network structure strengthening 316L stainless steel prepared by selective laser melting. J. Nucl. Mater. 2016, 470, 170–178. [Google Scholar] [CrossRef]

- Saeidi, K.; Kvetková, L.; Lofaj, F.; Shen, Z.; Kaito, T.; Narita, T.; Jiguang, S.; Nishida, T.; Fujiwara, M. Austenitic stainless steel strengthened by the in situ formation of oxide nanoinclusions. RSC Adv. 2015, 5, 20747–20750. [Google Scholar] [CrossRef]

- Babu, S.S.; David, S.A.; Vitek, J.M.; Mundra, K.; DebRoy, T. Development of macro- and microstructures of carbon–manganese low alloy steel welds: Inclusion formation. Mater. Sci. Technol. 1995, 11, 186–199. [Google Scholar] [CrossRef]

- Chai, C.S.; Eagar, T.W. Slag-metal equilibrium during submerged arc welding. Metall. Trans. B 1981, 12, 539–547. [Google Scholar] [CrossRef]

- Kluken, A.O.; Grong, Ø. Mechanisms of inclusion formation in Al−Ti−Si−Mn deoxidized steel weld metals. Metall. Trans. A 1989, 20, 1335–1349. [Google Scholar] [CrossRef]

- Yan, F.; Xiong, W.; Sciammarella, F.; Faierson, E.; Olson, G.B. Microstructure optimization of DED- processed PH48S stainless maraging steel. Engineering. accepted. Available online: https://archive.org/details/FYAN_012017_Engineering (accessed on 31 October 2017).

- Stjohn, D.H.; Prasad, A.; Easton, M.A.; Qian, M. The Contribution of Constitutional Supercooling to Nucleation and Grain Formation. Metall. Mater. Trans. A 2015, 46, 4868–4885. [Google Scholar] [CrossRef]

- Qian, M.; Cao, P.; Easton, M.A.; Mcdonald, S.D.; Stjohn, D.H. An analytical model for constitutional supercooling-driven grain formation and grain size prediction. Acta Mater. 2010, 58, 3262–3270. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yan, F.; Xiong, W.; Faierson, E.J. Grain Structure Control of Additively Manufactured Metallic Materials. Materials 2017, 10, 1260. https://doi.org/10.3390/ma10111260

Yan F, Xiong W, Faierson EJ. Grain Structure Control of Additively Manufactured Metallic Materials. Materials. 2017; 10(11):1260. https://doi.org/10.3390/ma10111260

Chicago/Turabian StyleYan, Fuyao, Wei Xiong, and Eric J. Faierson. 2017. "Grain Structure Control of Additively Manufactured Metallic Materials" Materials 10, no. 11: 1260. https://doi.org/10.3390/ma10111260

APA StyleYan, F., Xiong, W., & Faierson, E. J. (2017). Grain Structure Control of Additively Manufactured Metallic Materials. Materials, 10(11), 1260. https://doi.org/10.3390/ma10111260