Effects of Hot-Hydrostatic Canned Extrusion on the Stock Utilization, Microstructure and Mechanical Properties of TiBw/TC4 Composites with Quasi-Continuous Network

Abstract

:1. Introduction

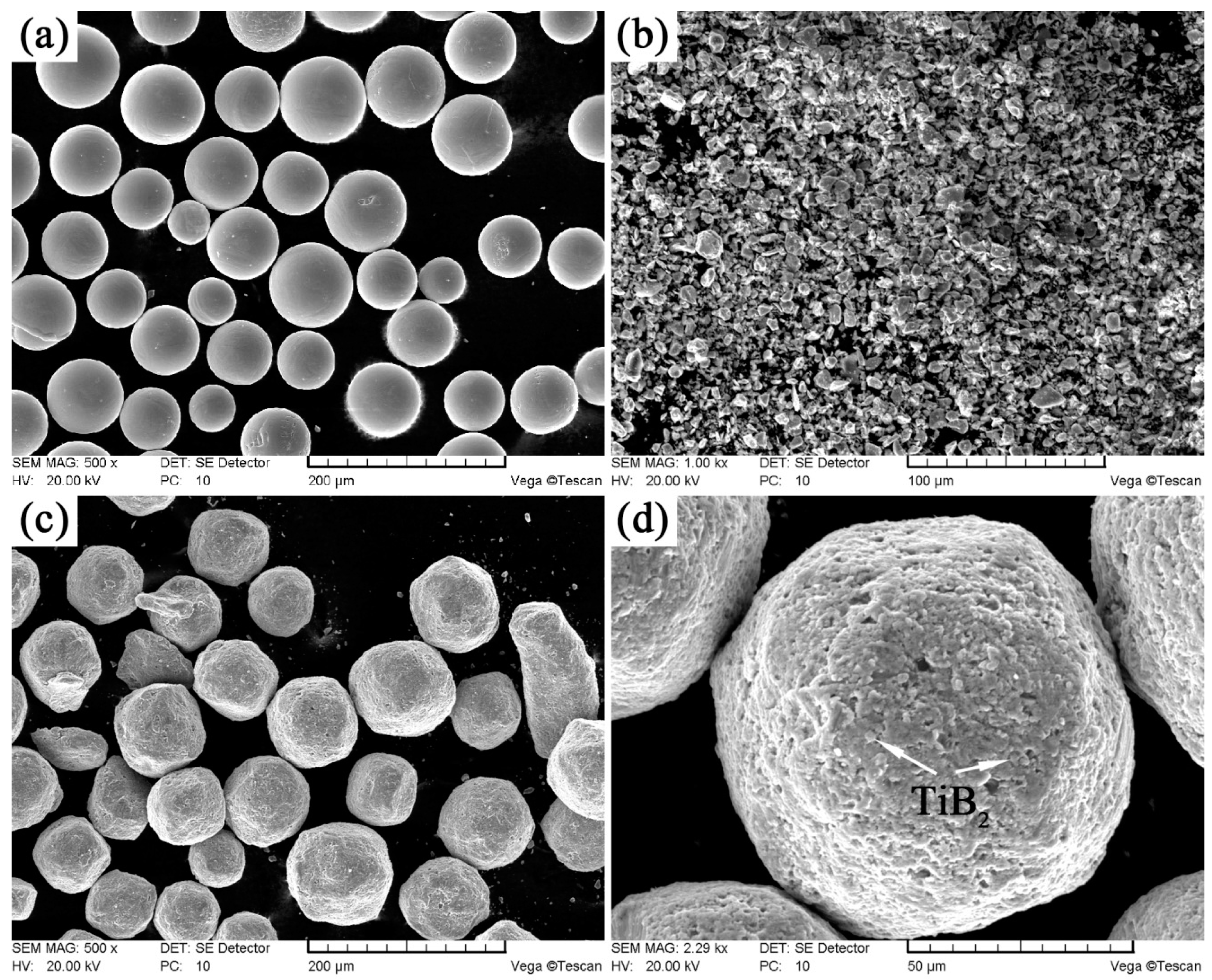

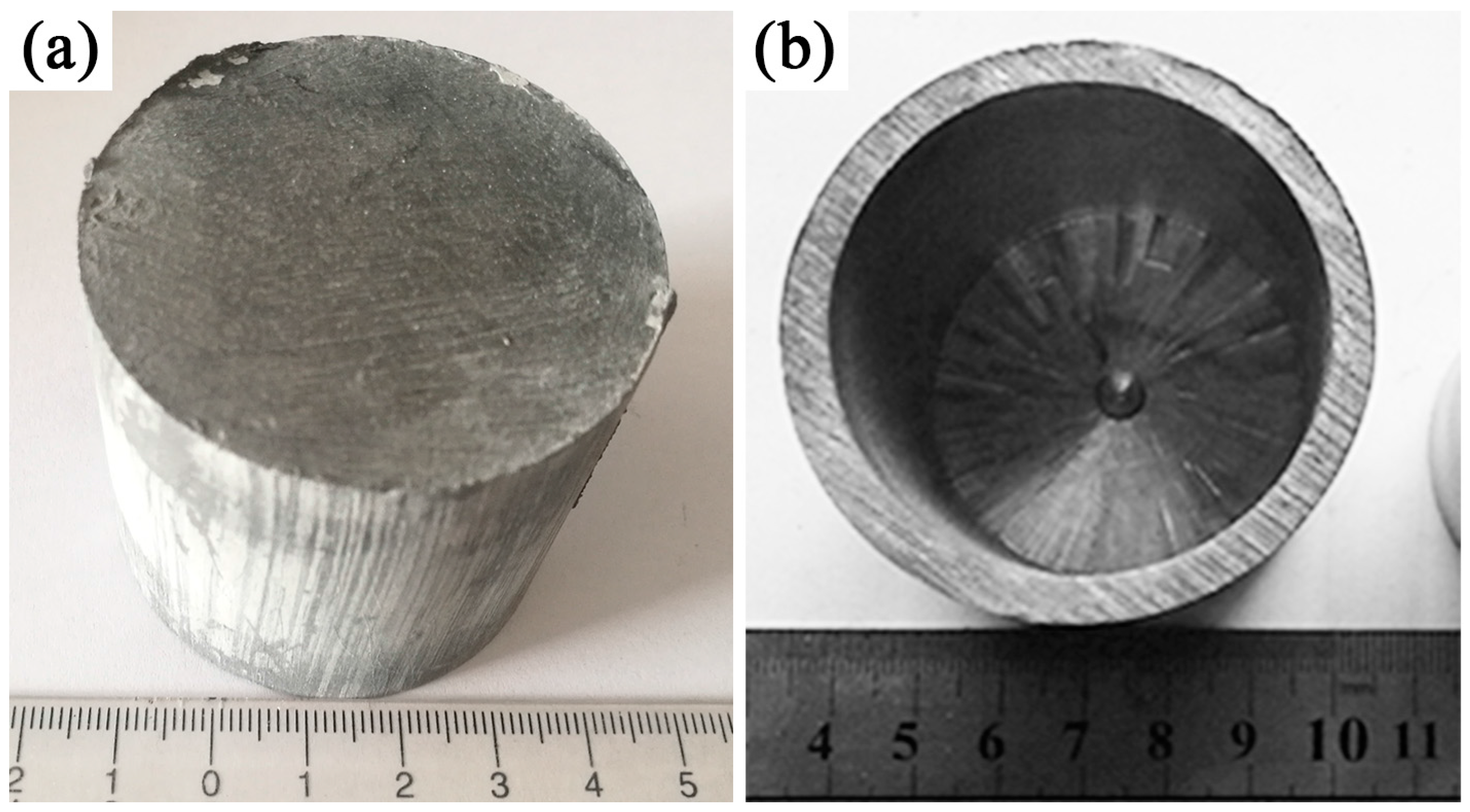

2. Experimental Procedures

3. Results and Discussion

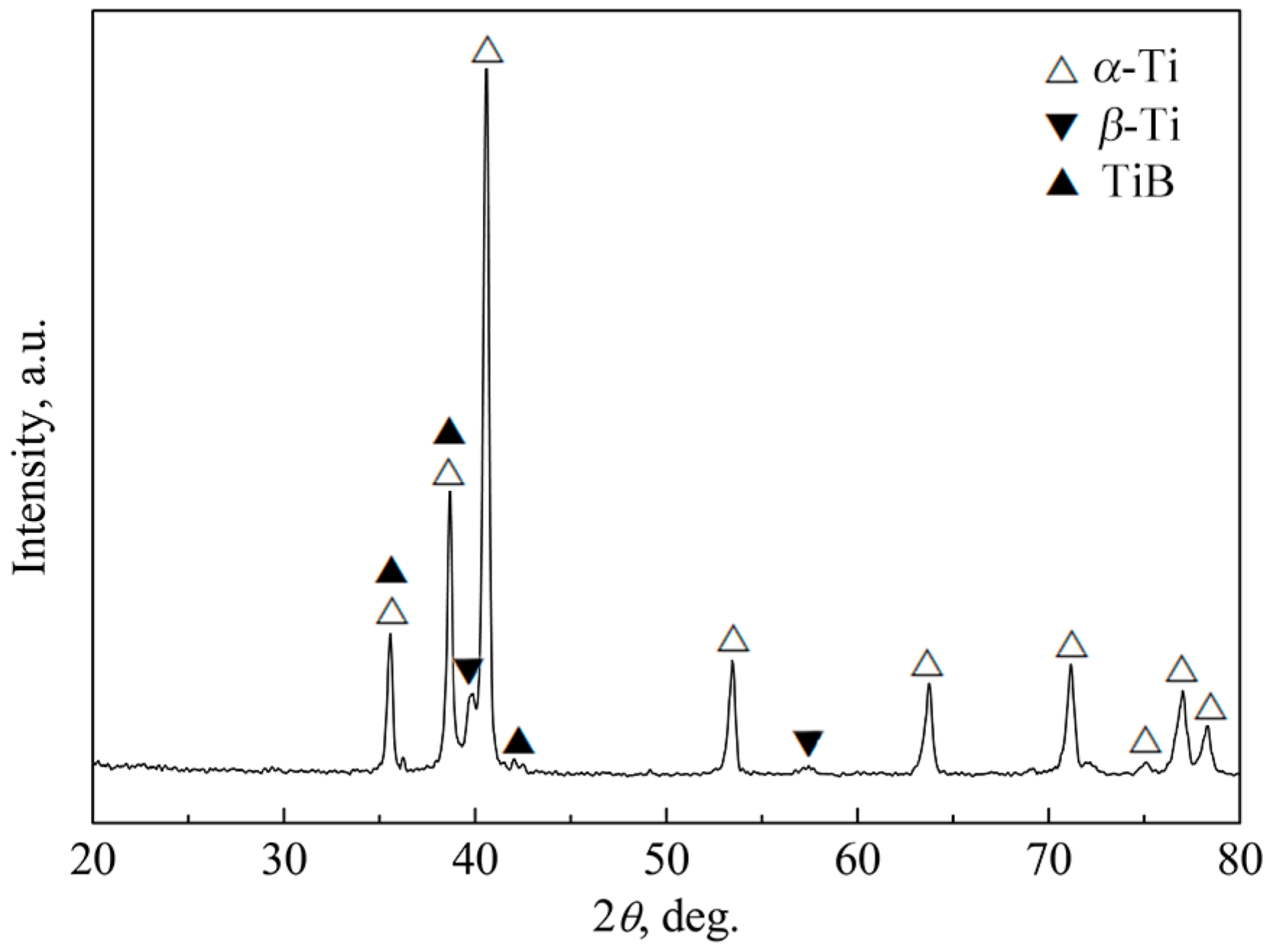

3.1. Phase Identification

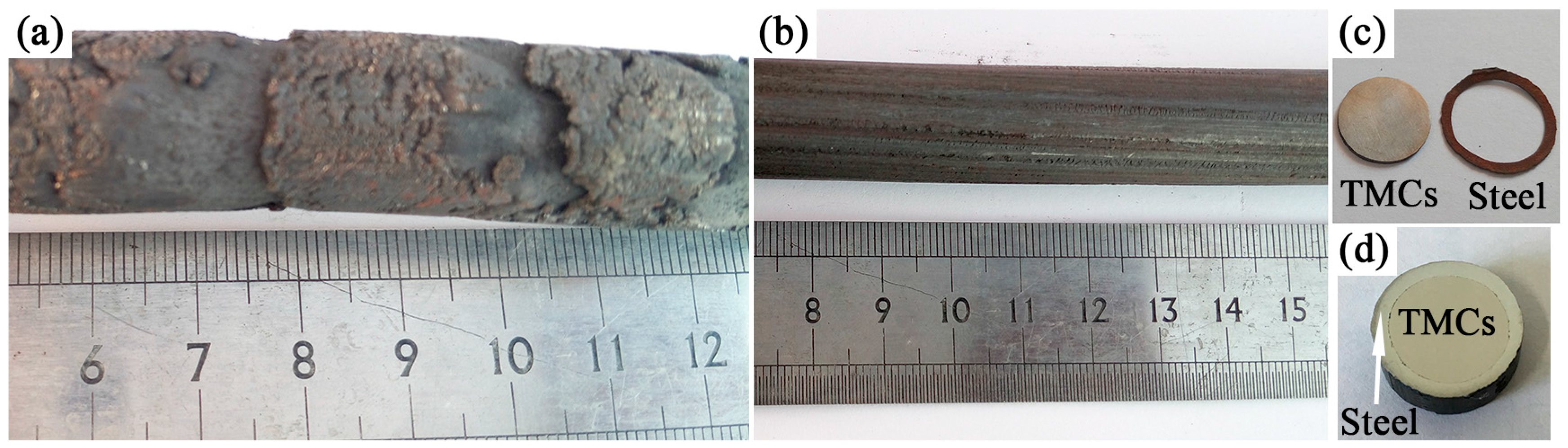

3.2. Stock Utilization

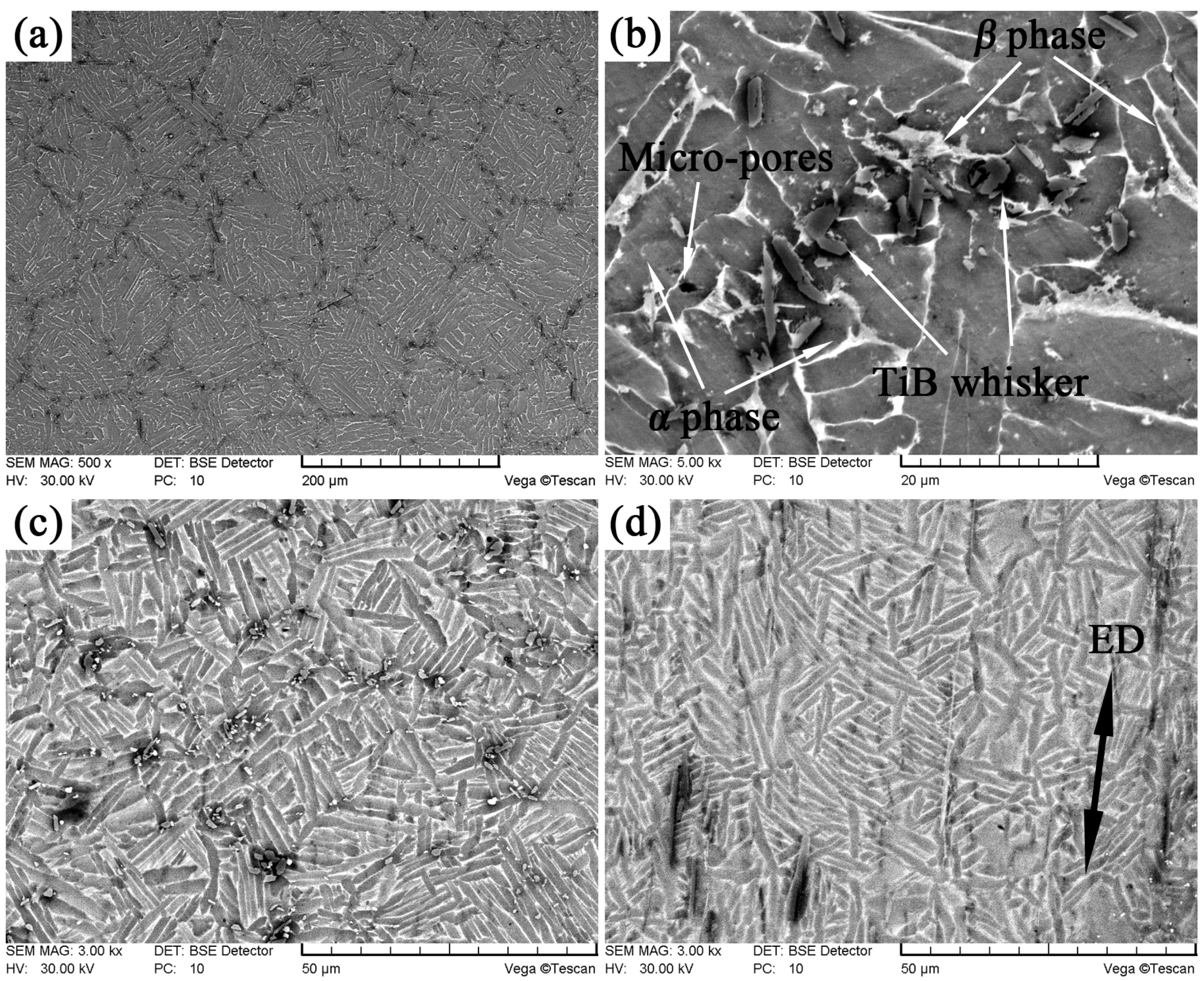

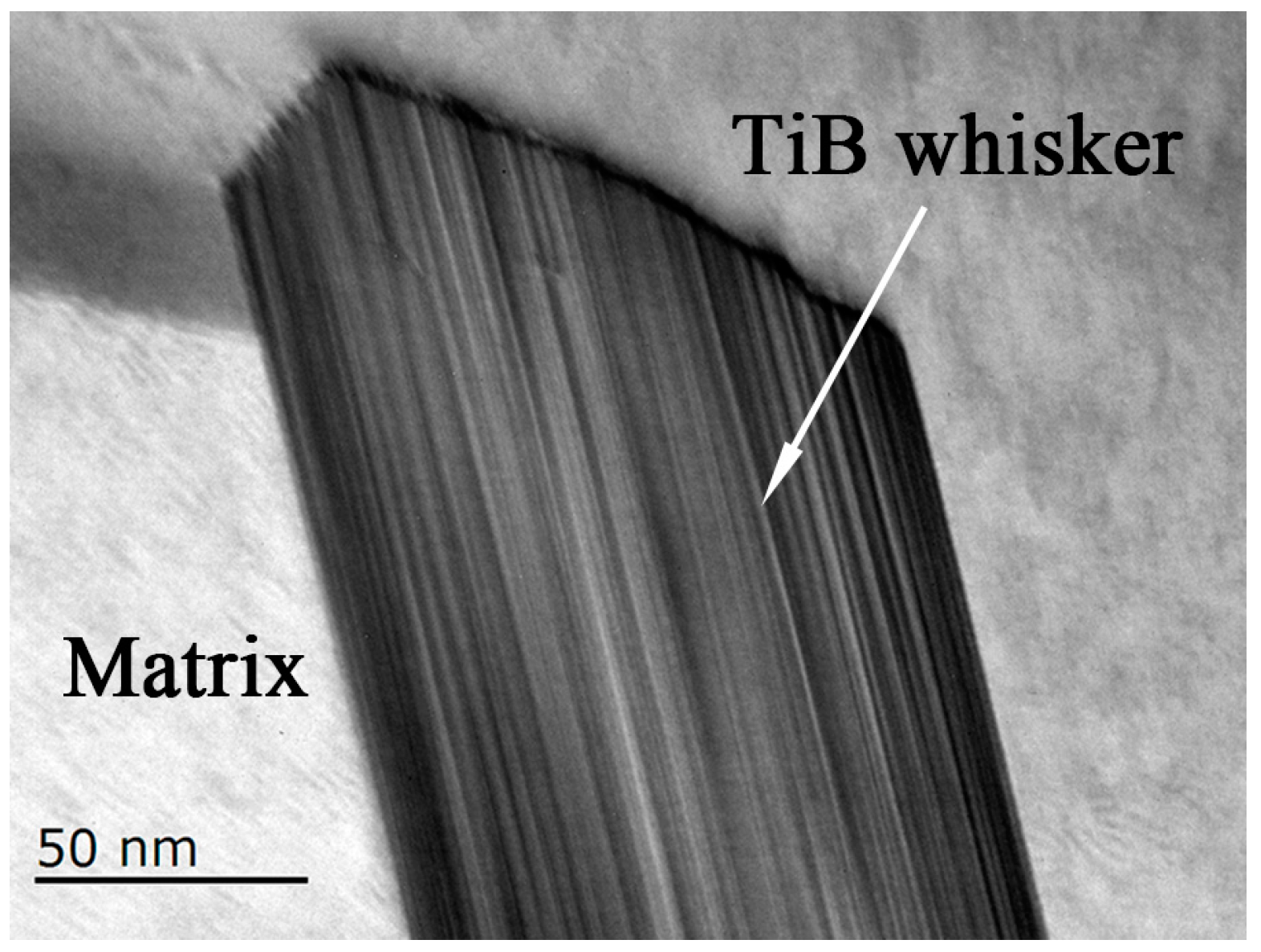

3.3. Microstructure Observation

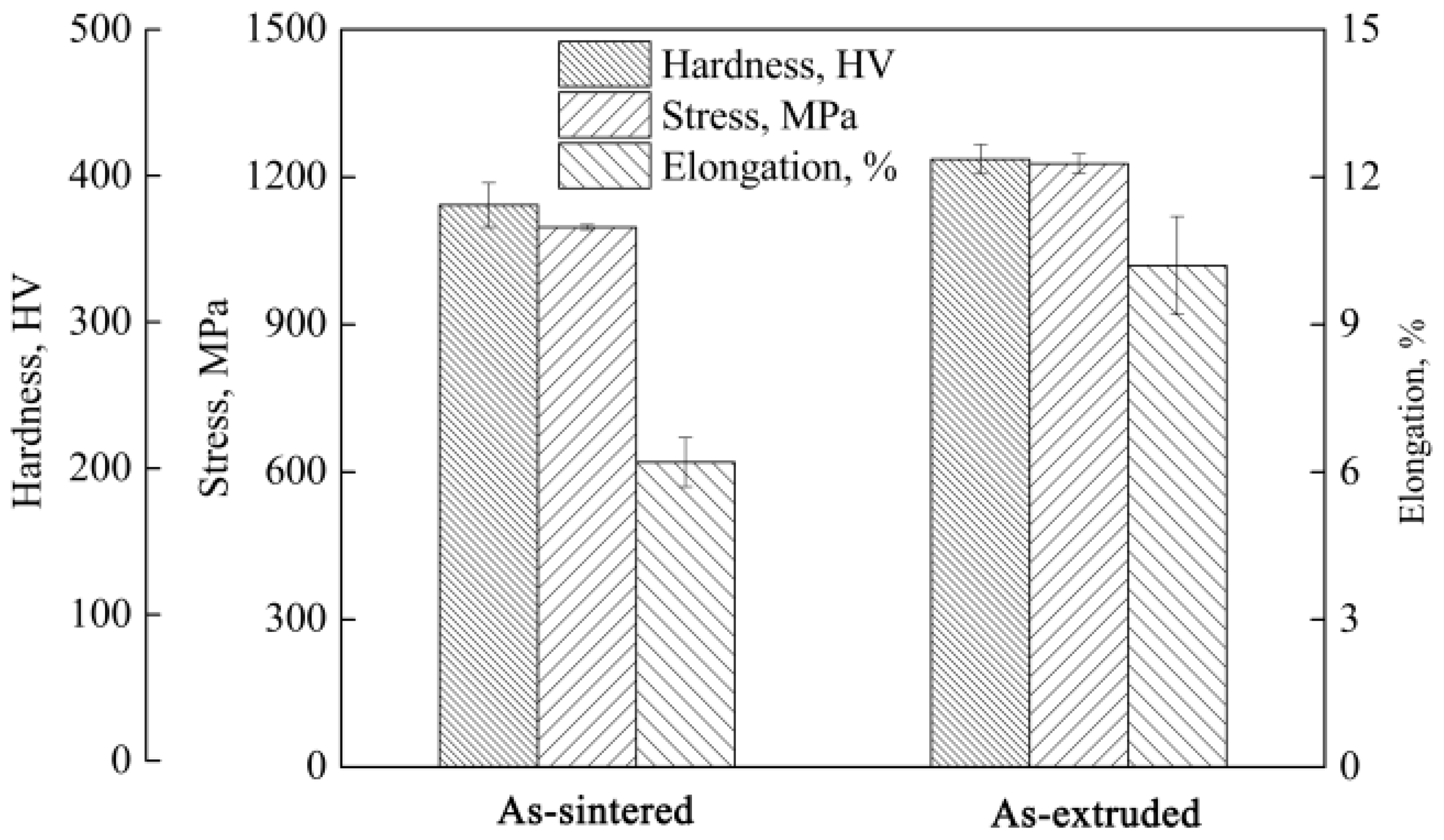

3.4. Mechanical Properties

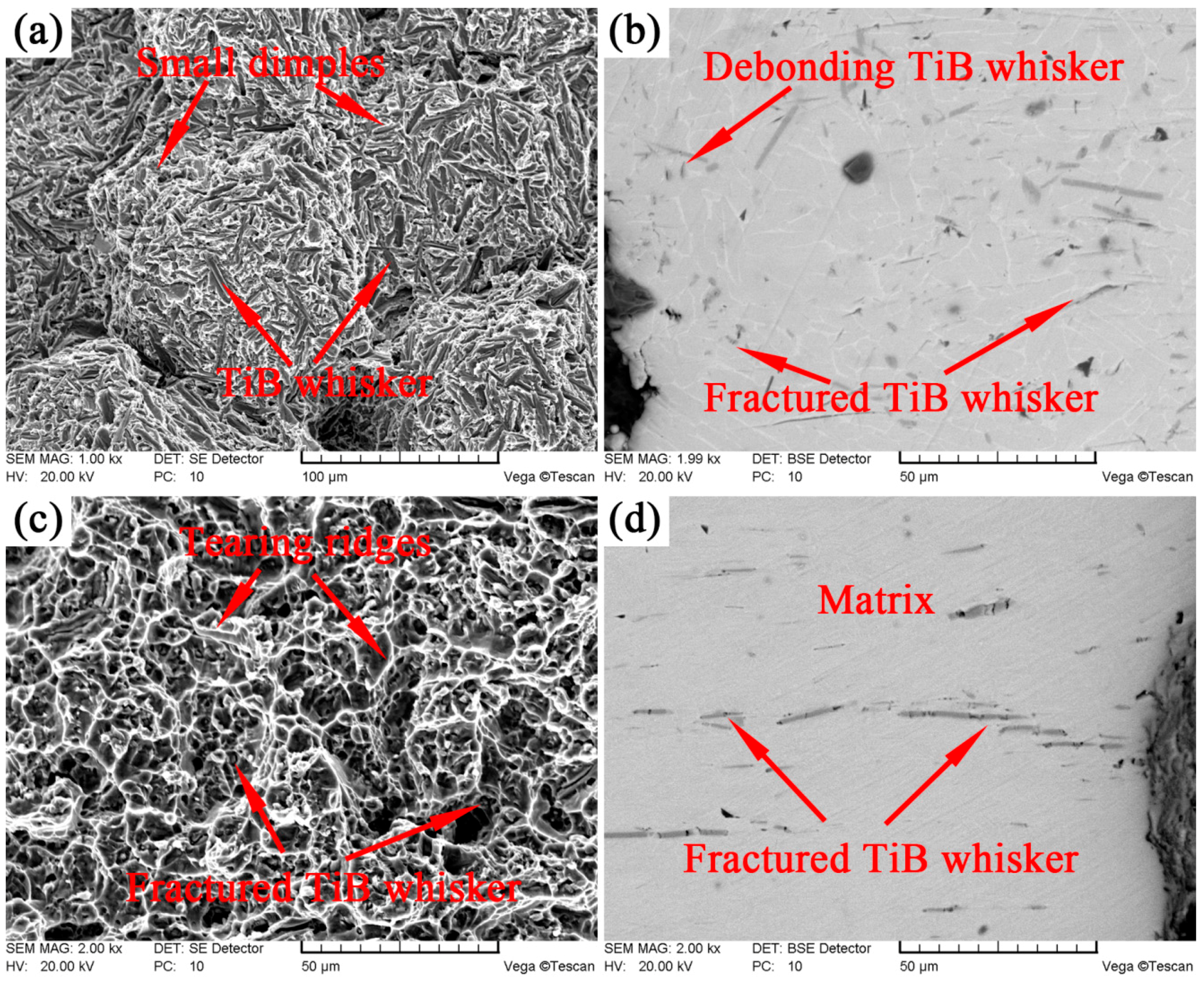

3.5. Fractography

4. Conclusions

- (1)

- When the composites were extruded without steel can, the surface of the composites had deep cracks due to the disharmonious deformation of the inside and outside of the composites. When the composites were extruded with steel can, the stock utilization could reach more than 90% and increase by 20~30% compared with the composites extruded without steel can.

- (2)

- After extrusion, the mechanical properties of the composites had an obvious improvement. The improvement was caused by grain refinement, orientation distribution of the whiskers and better connectivity of the matrix.

- (3)

- The TiB whiskers were randomly distributed in the as-sintered composites but oriented in the as-extruded composites. During the extrusion process, the TiB whiskers whose longitudinal axes were inconsistent with the extrusion direction would twist to the extrusion direction with the flow of the matrix and the whiskers whose longitudinal axes were consistent with the extrusion direction were prone to break.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Luan, J.H.; Jiao, Z.B.; Chen, G.; Liu, C.T. Improved ductility and oxidation resistance of cast Ti–6Al–4V alloys by microalloying. J. Alloys Compd. 2014, 602, 235–240. [Google Scholar] [CrossRef]

- Gorsse, S.; Miracle, D.B. Mechanical properties of Ti-6Al-4V/TiB composites with randomly oriented and aligned TiB reinforcements. Acta Mater. 2003, 51, 2427–2442. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Li, A.B.; Yang, F.Y.; Peng, H.X. In situ TiBw/Ti-6Al-4V composites with novel reinforcement architecture fabricated by reaction hot pressing. Scr. Mater. 2009, 60, 996–999. [Google Scholar] [CrossRef]

- Morsi, K.; Patel, V.V. Processing of titanium-titanium boride dual matrix composites. J. Mater. Process. Technol. 2008, 196, 236–242. [Google Scholar] [CrossRef]

- Williams, J.C.; Starke, E.A. Progress in structural materials for aerospace systems. Acta Mater. 2003, 51, 5775–5779. [Google Scholar] [CrossRef]

- Koo, M.Y.; Park, J.S.; Park, M.K.; Kim, K.T.; Hong, S.H. Effect of aspect ratios of in situ formed TiB whiskers on the mechanical properties of TiBw/Ti–6Al–4V composites. Scr. Mater. 2012, 66, 487–490. [Google Scholar] [CrossRef]

- Imayev, V.; Gaisin, R.; Gaisina, E.; Imayev, R.; Fecht, H.J.; Pyczak, F. Effect of hot forging on microstructure and tensile properties of Ti–TiB based composites produced by casting. Mater. Sci. Eng. A 2014, 609, 34–41. [Google Scholar] [CrossRef]

- Tjong, S.C.; Mai, Y.W. Processing-structure-property aspects of particulate- and whisker-reinforced titanium matrix composites. Compos. Sci. Technol. 2008, 68, 583–601. [Google Scholar] [CrossRef]

- Schuh, C.; Dunand, D.C. Whisker alignment of Ti–6Al–4V/TiB composites during deformation by transformation superplasticity. Int. J. Plast. 2001, 17, 317–340. [Google Scholar] [CrossRef]

- Zhang, X.; Lu, W.; Zhang, D.; Wu, R.; Bian, Y.; Fang, P. In situ technique for synthesizing (TiB + TiC)/Ti composites. Scr. Mater. 1999, 41, 39–46. [Google Scholar] [CrossRef]

- Zhang, W.C.; Wang, M.M.; Chen, W.Z.; Feng, Y.J.; Yu, Y. Preparation of TiBw/Ti–6Al–4V composite with an inhomogeneous reinforced structure by a canned hot extrusion process. J. Alloys Compd. 2016, 669, 79–90. [Google Scholar] [CrossRef]

- Huang, L.J.; Yang, F.Y.; Hua, H.T.; Rong, X.D.; Geng, L.; Wu, L.Z. TiB whiskers reinforced high temperature titanium Ti60 alloy composites with novel network microstructure. Mater. Des. 2013, 51, 421–426. [Google Scholar] [CrossRef]

- Yu, Y.; Zhang, W.C.; Dong, W.Q.; Han, X.Z.; Pei, C.L.; Jiao, X.Y.; Feng, Y.J. Research on heat treatment of TiBw/Ti6Al4V composites tubes. Mater. Des. 2015, 73, 1–9. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Wang, B.; Wu, L.Z. Effects of volume fraction on the microstructure and tensile properties of in situ TiBw/Ti6Al4V composites with novel network microstructure. Mater. Des. 2013, 45, 532–538. [Google Scholar] [CrossRef]

- Huang, L.J.; Geng, L.; Wang, B.; Xu, H.Y.; Kaveendran, B. Effects of extrusion and heat treatment on the microstructure and tensile properties of in situ TiBw/Ti6Al4V composite with a network architecture. Compos. Part A 2012, 43, 486–491. [Google Scholar] [CrossRef]

- Prasad, Y.V.R.K.; Sesharyulu, T. Processing maps for hot working of titanium alloys. Mater. Sci. Eng. A 1998, 243, 82–88. [Google Scholar] [CrossRef]

- Semiatin, S.L.; Seetharaman, V.; Weiss, I. Flow behavior and globularization kinetics during hot working of Ti–6Al–4V with a colony alpha microstructure. Mater. Sci. Eng. A 1999, 263, 257–271. [Google Scholar] [CrossRef]

- Li, S.F.; Kondoh, K.; Imai, H.; Chen, B.; Jia, L.; Umeda, J.; Fu, Y.B. Strengthening behavior of in situ-synthesized (TiC–TiB)/Ti composites by powder metallurgy and hot extrusion. Mater. Des. 2016, 95, 127–132. [Google Scholar] [CrossRef]

- Hu, H.T.; Huang, L.J.; Geng, L.; Liu, C.; Wang, B. Effects of extrusion on microstructure and tensile properties of 3D network structured TiBw/Ti60 composites fabricated by reaction hot pressing. J. Alloys Compd. 2014, 582, 569–575. [Google Scholar] [CrossRef]

- Feng, Y.J.; Zhang, W.C.; Zeng, L.; Cui, G.R.; Chen, W.Z. Room-temperature and high-temperature tensile mechanical properties of TA15 titanium alloy and TiB whisker-reinforced TA15 matrix composites fabricated by vacuum hot-pressing sintering. Materials 2017, 10, 424. [Google Scholar] [CrossRef] [PubMed]

- Zhu, S.; Yang, H.; Guo, L.G.; Fan, X.G. Effect of cooling rate on microstructure evolution during α/β heat treatment of TA15 titanium alloy. Mater. Charact. 2012, 70, 101–110. [Google Scholar] [CrossRef]

- Huang, G.F.; Han, Y.F.; Guo, X.L.; Qiu, D.; Wang, L.Q.; Lu, W.J. Effects of extrusion ratio on microstructural evolution and mechanical behavior of in situ synthesized Ti-6Al-4V composites. Mater. Sci. Eng. A 2017, 688, 155–163. [Google Scholar] [CrossRef]

- Feng, Y.J.; Zhang, W.C.; Cui, G.R.; Wu, J.P.; Chen, W.Z.J. Effects of the extrusion temperature on the microstructure and mechanical properties of TiBw/Ti6Al4V composites fabricated by pre-sintering and canned extrusion. J. Alloys Compd. 2017, 721, 383–391. [Google Scholar] [CrossRef]

- Feng, Y.J.; Zhang, W.C.; Cui, G.R.; Chen, W.Z.; Yu, Y. Room temperature tensile fracture characteristics of the oriented TiB whisker reinforced TA15 matrix composites fabricated by pre-sintering and canned extrusion. Mater. Sci. Eng. A 2017, 707, 40–43. [Google Scholar] [CrossRef]

- Ya, B.; Zhou, B.W.; Yang, H.S.; Huang, B.K.; Jia, F.; Zhang, X.G. Microstructure and mechanical properties of in situ casting TiC/Ti6Al4V composites through adding multi-walled carbon nanotubes. J. Alloys Compd. 2015, 637, 456–460. [Google Scholar] [CrossRef]

- Hall, E. The deformation and aging of mild steel. Proc. Phys. Soc. Sect. B 1951, 64, 747. [Google Scholar] [CrossRef]

- Petch, N. The cleavage of polycrystals. J. Iron Steel Inst. 1953, 174, 25–28. [Google Scholar]

- Guo, X.; Wang, L.; Wang, M.; Qin, J.; Zhang, D.; Lu, W. Effects of degree of deformation on the microstructure, mechanical properties and texture of hybrid-reinforced titanium matrix composites. Acta Mater. 2012, 60, 2656–2667. [Google Scholar] [CrossRef]

- Fukuda, H.; Chou, T.-W. A probabilistic theory of the strength of short-fibre composites with variable fibre length and orientation. J. Mater. Sci. 1982, 17, 1003–1011. [Google Scholar] [CrossRef]

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Feng, Y.; Li, B.; Cui, G.; Zhang, W. Effects of Hot-Hydrostatic Canned Extrusion on the Stock Utilization, Microstructure and Mechanical Properties of TiBw/TC4 Composites with Quasi-Continuous Network. Materials 2017, 10, 1227. https://doi.org/10.3390/ma10111227

Feng Y, Li B, Cui G, Zhang W. Effects of Hot-Hydrostatic Canned Extrusion on the Stock Utilization, Microstructure and Mechanical Properties of TiBw/TC4 Composites with Quasi-Continuous Network. Materials. 2017; 10(11):1227. https://doi.org/10.3390/ma10111227

Chicago/Turabian StyleFeng, Yangju, Bing Li, Guorong Cui, and Wencong Zhang. 2017. "Effects of Hot-Hydrostatic Canned Extrusion on the Stock Utilization, Microstructure and Mechanical Properties of TiBw/TC4 Composites with Quasi-Continuous Network" Materials 10, no. 11: 1227. https://doi.org/10.3390/ma10111227

APA StyleFeng, Y., Li, B., Cui, G., & Zhang, W. (2017). Effects of Hot-Hydrostatic Canned Extrusion on the Stock Utilization, Microstructure and Mechanical Properties of TiBw/TC4 Composites with Quasi-Continuous Network. Materials, 10(11), 1227. https://doi.org/10.3390/ma10111227