Transition of Emission Colours as a Consequence of Heat-Treatment of Carbon Coated Ce3+-Doped YAG Phosphors

Abstract

1. Introduction

2. Experimental Details

3. Results

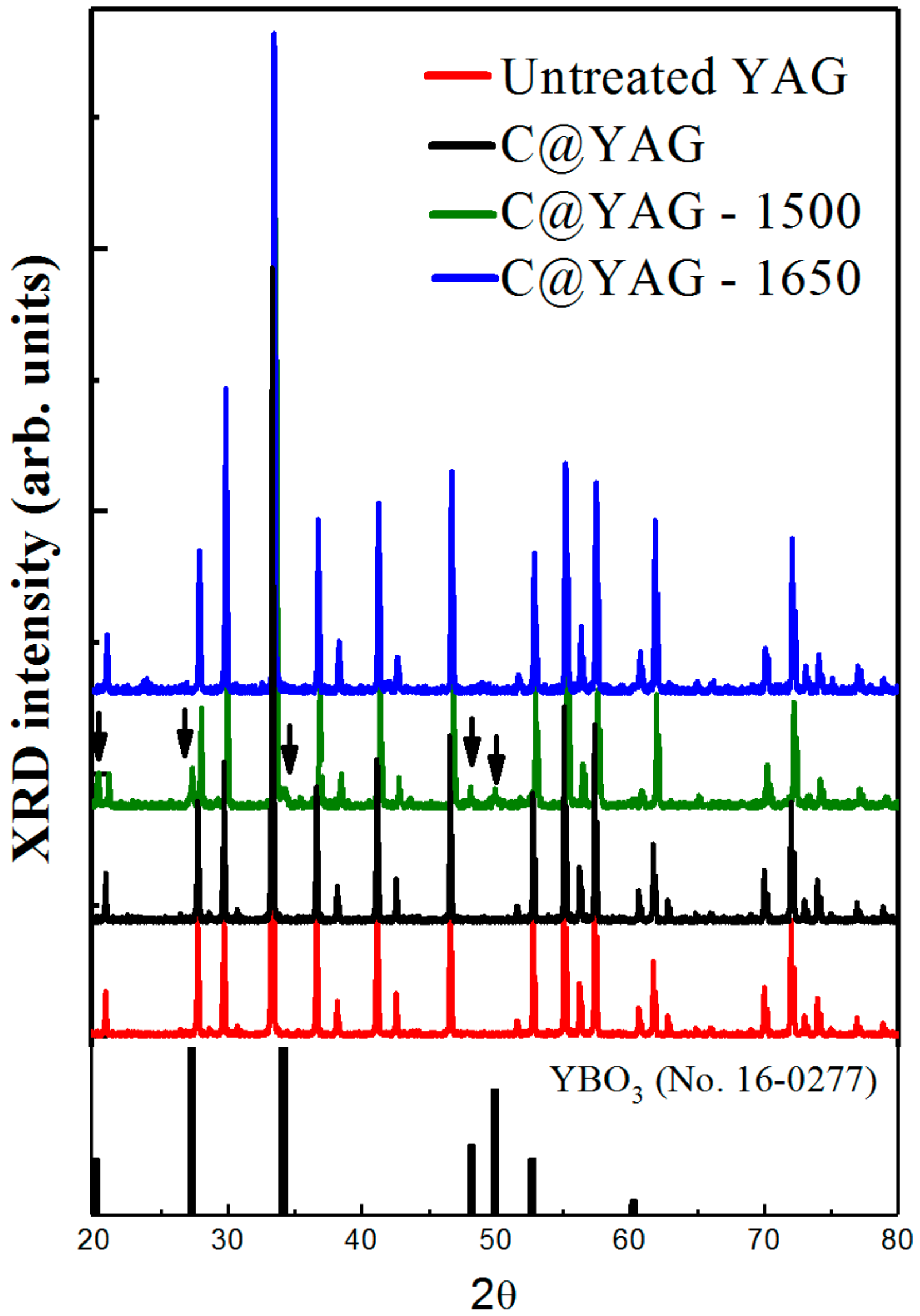

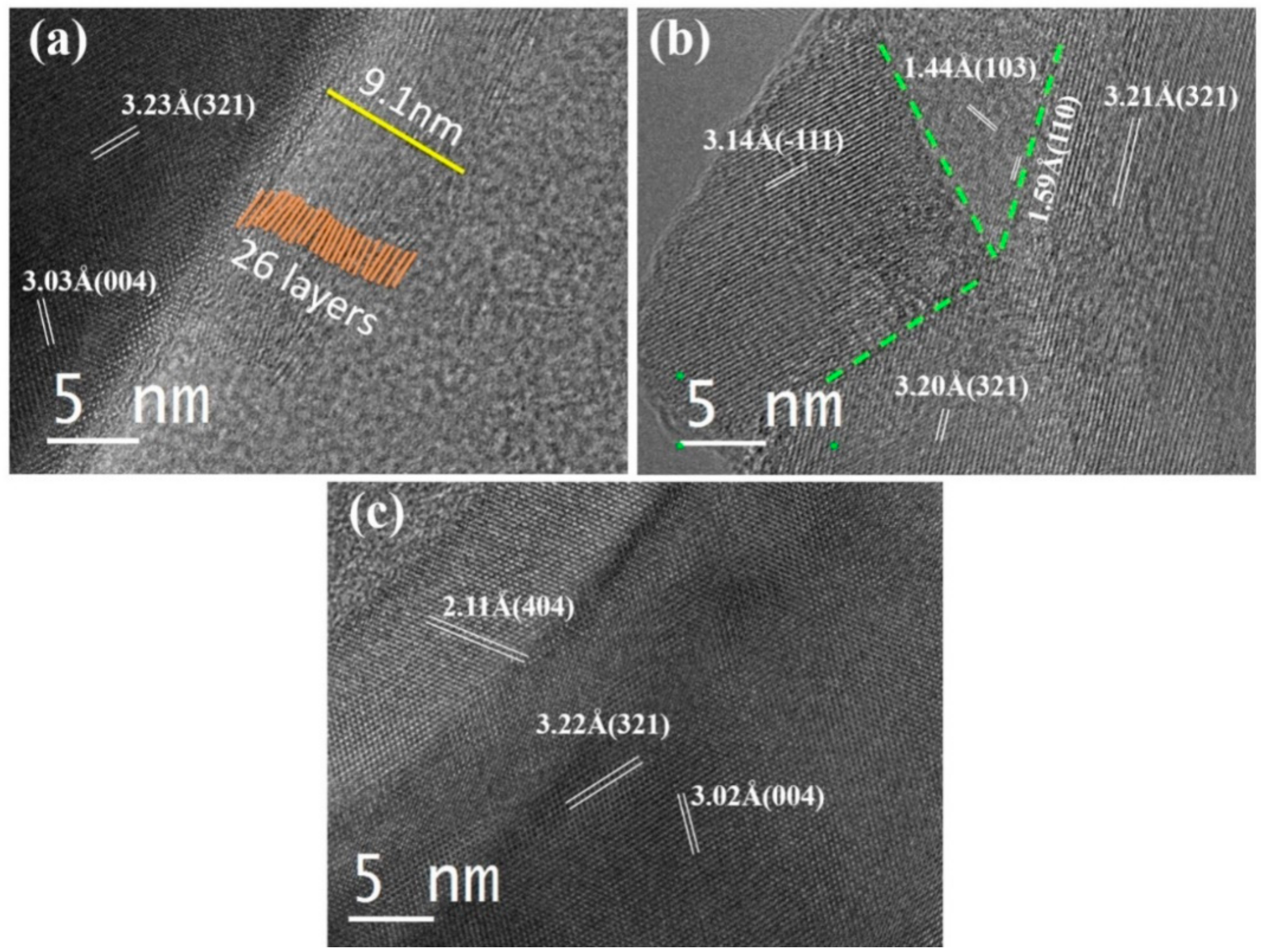

3.1. IIIa Phase Formation, Microstructure and Morphology

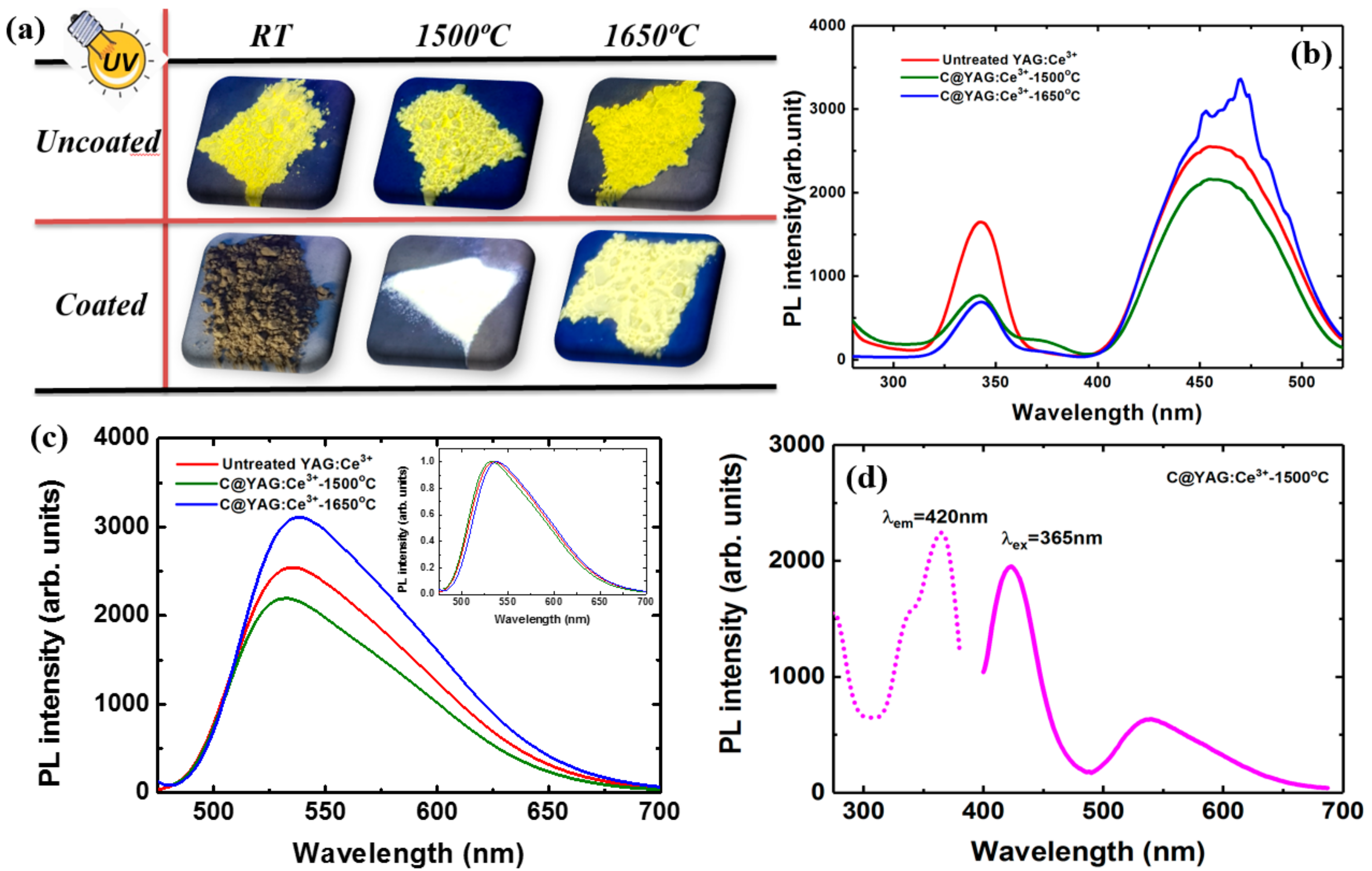

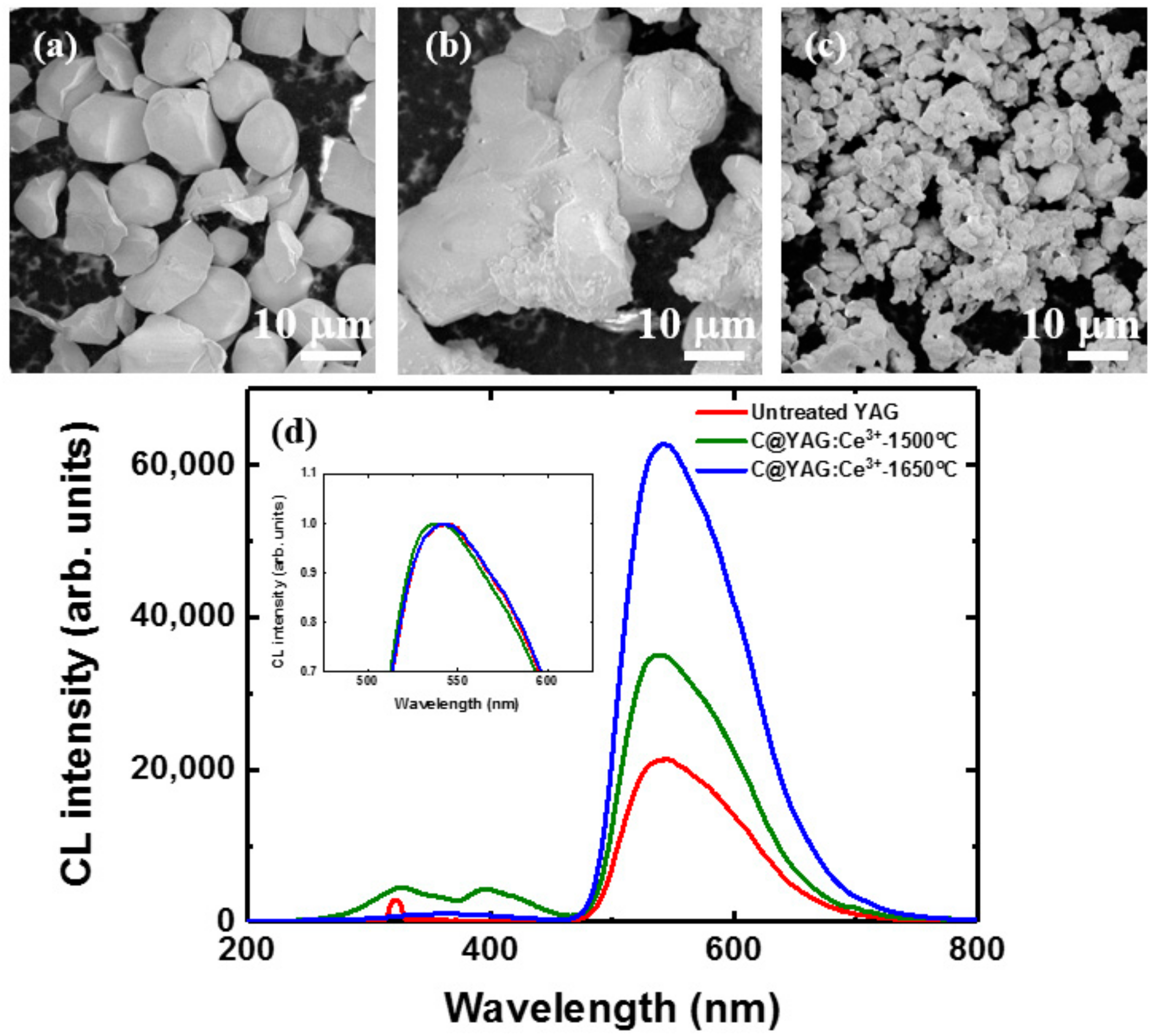

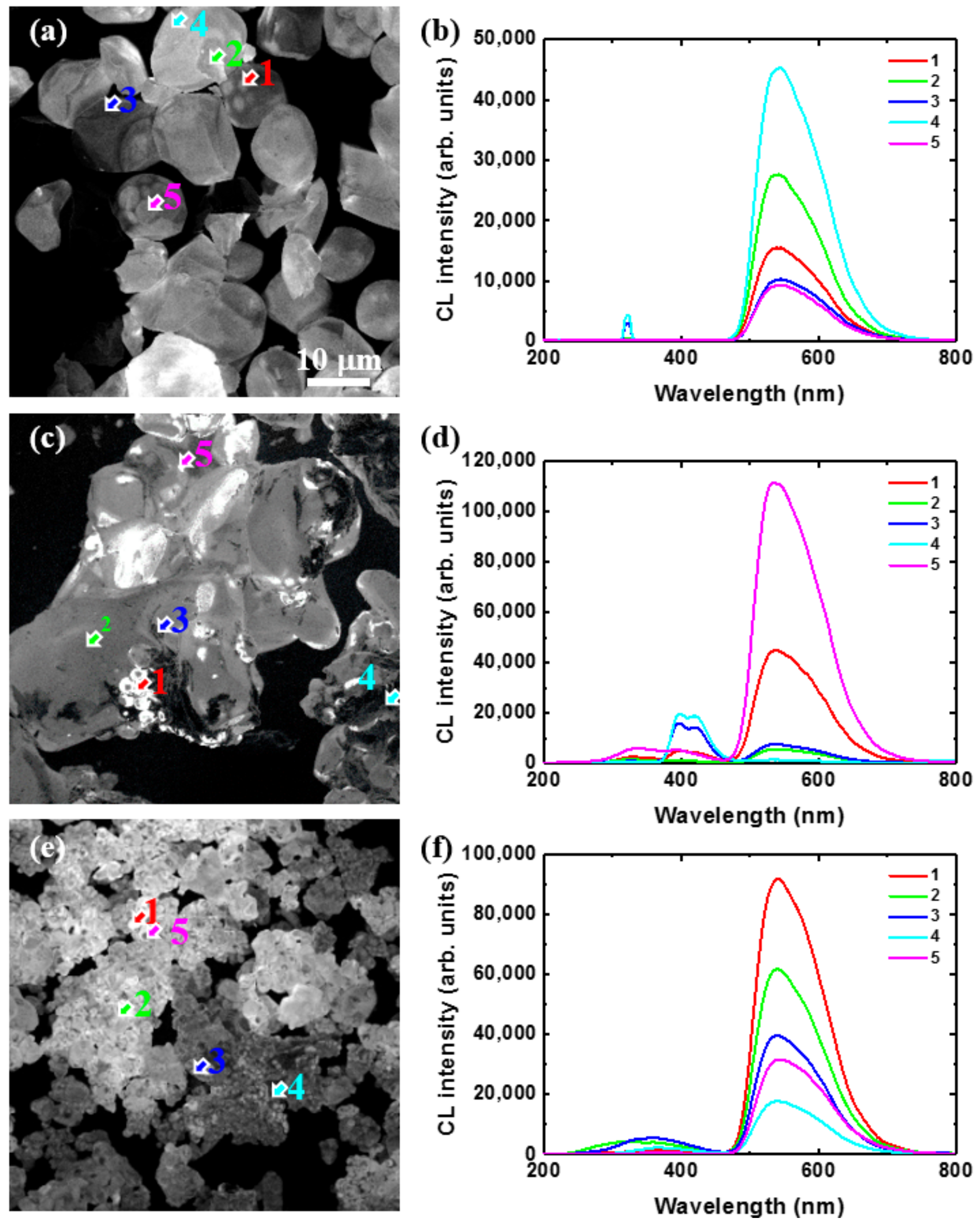

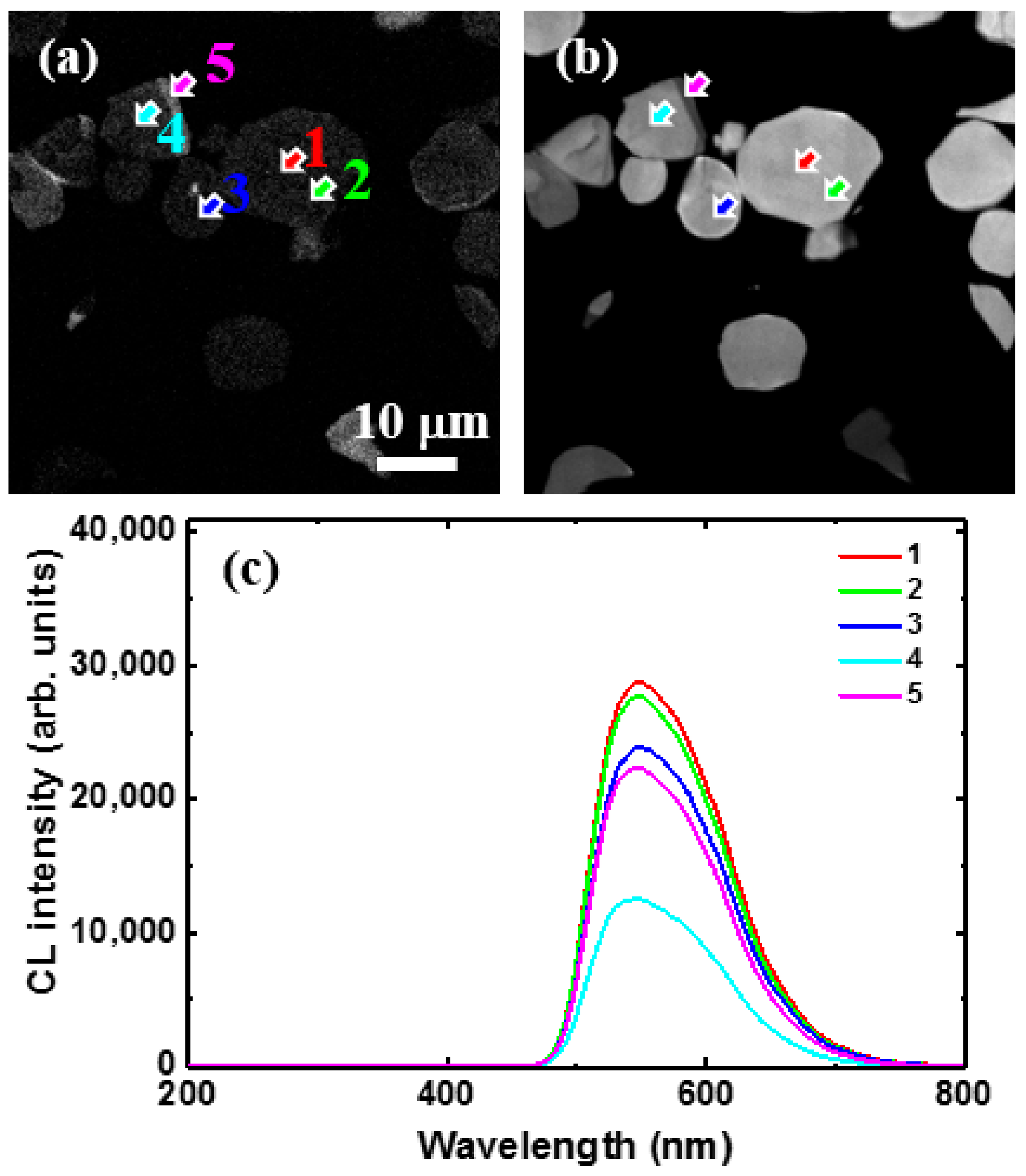

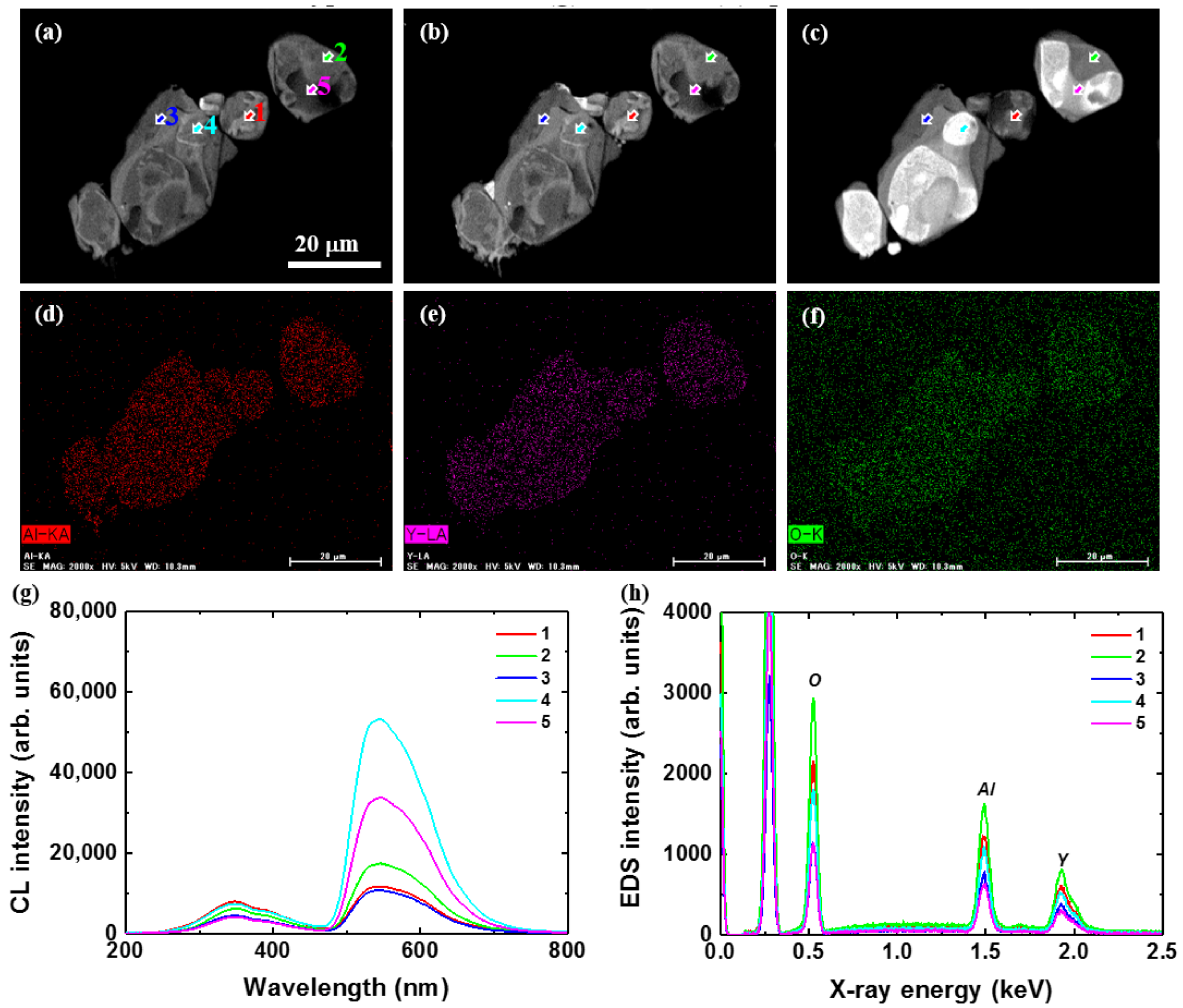

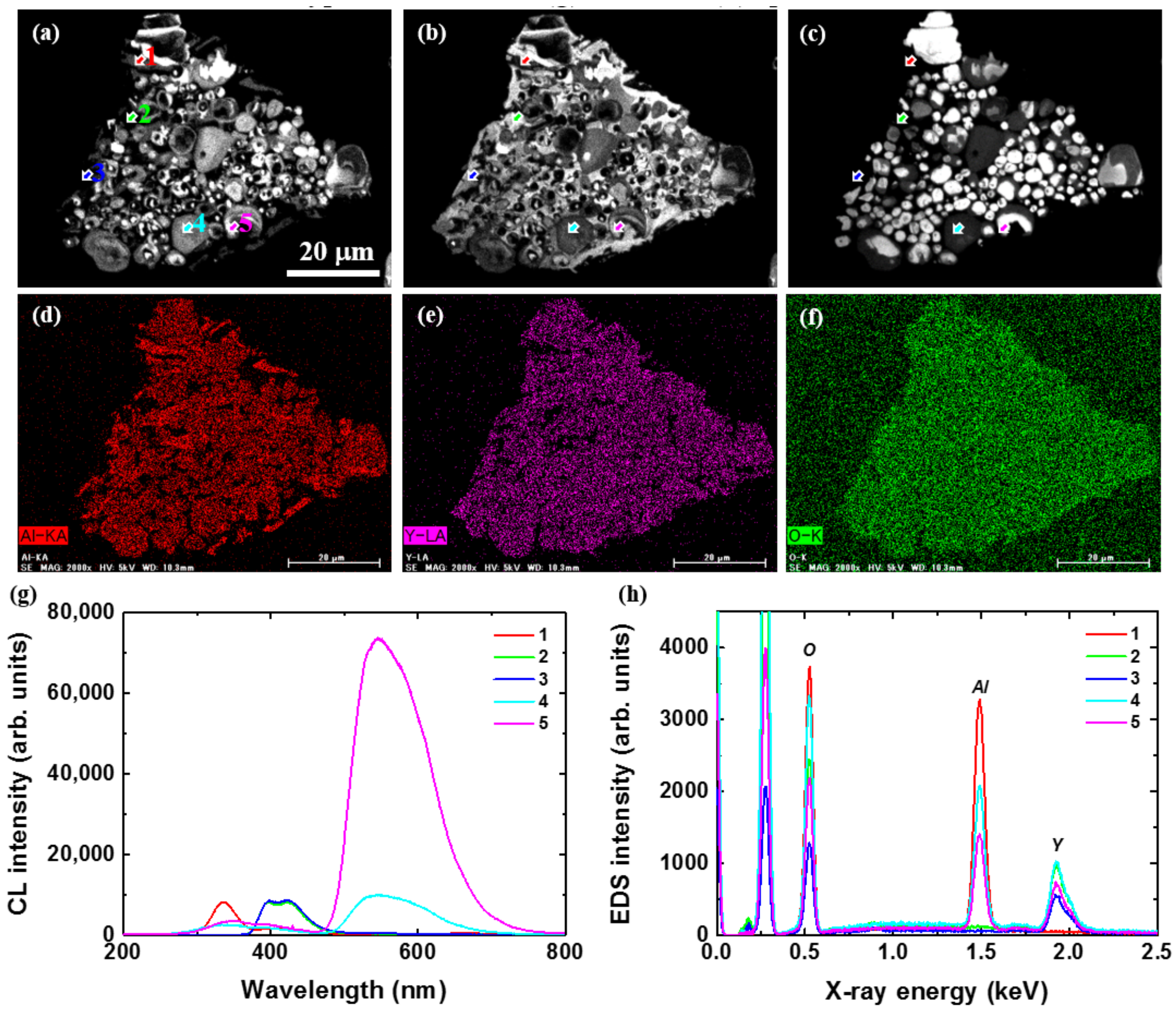

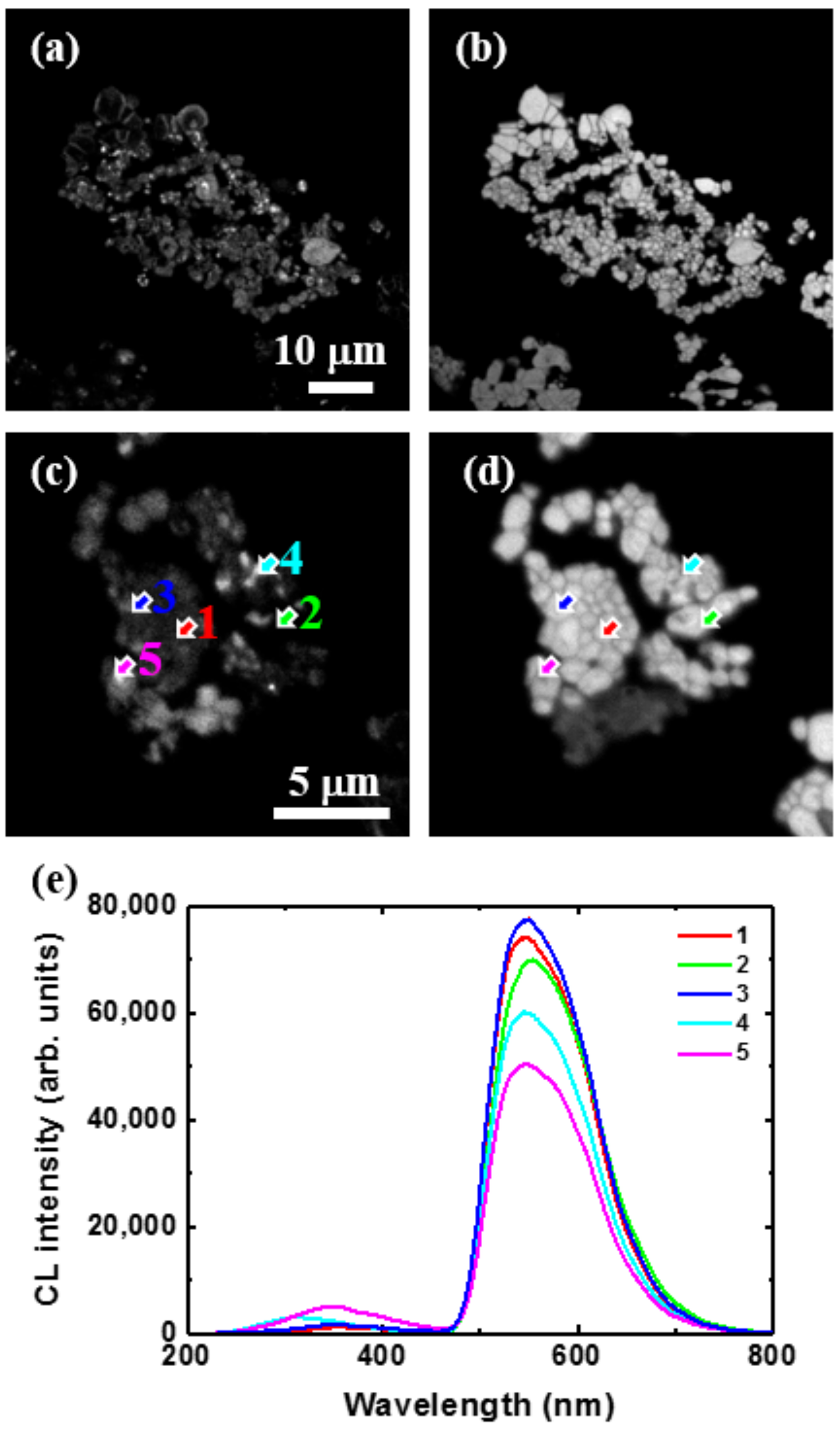

3.2. IIIb Average Photoluminescence and Local Cathodoluminescence Properties Related to Chemical Composition and Structure

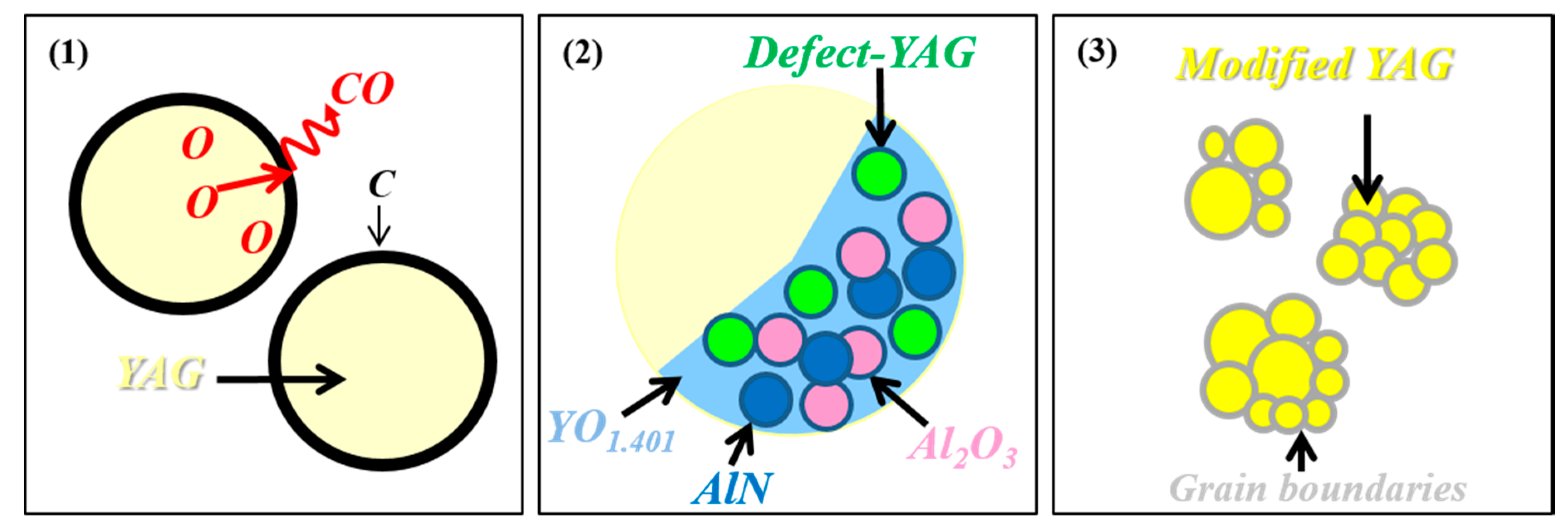

4. Discussion

5. Conclusions

Supplementary Materials

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Pan, Y.X.; Wu, M.M.; Su, Q. Tailored photoluminescence of YAG: Ce phosphor through various methods. J. Phys. Chem. Solids 2004, 65, 845–850. [Google Scholar] [CrossRef]

- Lu, J.; Prabhu, M.; Song, J.; Li, C.; Xu, J.; Ueda, K.; Kaminskii, A.A.; Yagi, H.; Yanagitani, T. Optical properties and highly efficient laser oscillation of Nd: YAG ceramics. Appl. Phys. B 2000, 71, 469–473. [Google Scholar] [CrossRef]

- Blasse, G.; Bril, A. A new phosphor for flying-spot cathode-ray tubes for color television: Yellow-emitting Y3Al5O12–Ce3+. Appl. Phys. Lett. 1967, 11, 53–55. [Google Scholar] [CrossRef]

- Potdevin, A.; Briois, V.; Caperaa, N.; Santilli, C.V.; Chadeyron, G.; Mahiou, R. A thorough spectroscopic study of luminescent precursor solution of Y3Al5O12: Tb3+: Influence of acetylacetone. RSC Adv. 2016, 6, 41962–41971. [Google Scholar] [CrossRef]

- Wang, H.M.; Huang, Z.Y.; Lu, Z.W.; Wang, Q.Y.; Jiang, J.S. Determination of the elastic and plastic deformation behaviors of Yb: Y3Al5O12 transparent ceramic by nanoindentation. J. Alloys Compd. 2016, 682, 35–41. [Google Scholar] [CrossRef]

- Thu, L.D.; Trung, D.Q.; Lam, T.D.; Anh, T.X. Fabrication of far red emission phosphors Y3Al5O12: Eu (YAG: Eu) by co-precipitation method. J. Electron. Mater. 2016, 45, 2468–2471. [Google Scholar] [CrossRef]

- Hora, D.A.; Andrade, A.B.; Ferreira, N.S.; Teixeira, V.C.; Rezende, M.V.D. X-ray excited optical luminescence of Eu-doped YAG nanophosphors produced via glucose sol-gel route. Ceram. Int. 2016, 42, 10516–10519. [Google Scholar] [CrossRef]

- Peng, J.; Zhu, J.H.; Li, T. Numerical simulation and optimization of beam quality of 2.1 μm Cr, Tm, Ho: YAG laser with symmetric spherical resonator based on gradient-reflectivity mirror. Opt. Commun. 2016, 368, 20–26. [Google Scholar] [CrossRef]

- Schiopu, V.; Macrin, M.; Cernica, I. Synthesis of yttrium aluminium garnet doped with cerium for application in a new generation luminescent lighting devices. In Advanced Topics in Optoelectronics, Microelectronics, and Nanotechnologies III; Iancu, O., Manea, A., Schiopu, P., Eds.; International Society for Optics and Photonics (SPIE): Bellingham, WA, USA, 2007; Volume 6635, pp. U251–U256. [Google Scholar]

- Munoz-Garcia, A.B.; Seijo, L. Ce and la single- and double-substitutional defects in yttrium aluminum garnet: First-principles study. J. Phys. Chem. A 2011, 115, 815–823. [Google Scholar] [CrossRef] [PubMed]

- Munoz-Garcia, A.B.; Pascual, J.L.; Barandiaran, Z.; Seijo, L. Structural effects and 4f-5d transition shifts induced by La codoping in Ce-doped yttrium aluminum garnet: First-principles study. Phys. Rev. B 2010, 82, 064114. [Google Scholar] [CrossRef]

- Jung, K.Y.; Lee, H.W. Enhanced luminescent properties of Y3Al5O12: Tb3+, Ce3+ phosphor prepared by spray pyrolysis. J. Lumin. 2007, 126, 469–474. [Google Scholar] [CrossRef]

- Yang, H.; Kim, Y.S. Energy transfer-based spectral properties of Tb-, Pr-, or Sm-codoped YAG : Ce nanocrystalline phosphors. J. Lumin. 2008, 128, 1570–1576. [Google Scholar] [CrossRef]

- Jang, H.S.; Bin Im, W.; Lee, D.C.; Jeon, D.Y.; Kim, S.S. Enhancement of red spectral emission intensity of Y3Al5O12: Ce3+ phosphor via pr co-doping and tb substitution for the application to white leds. J. Lumin. 2007, 126, 371–377. [Google Scholar] [CrossRef]

- Park, K.; Kim, T.; Yu, Y.; Seo, K.; Kim, J. Y/gd-free yellow Lu3Al5O12:Ce3+ phosphor for white leds. J. Lumin. 2016, 173, 159–164. [Google Scholar] [CrossRef]

- Li, J.S.; Sun, X.D.; Li, X.D.; Liu, S.H.; Zhu, Q. (Y, Lu)AG: Ce phosphors synthesized by stearate melting method and their fluorescence properties. J. Inorg. Mater. 2015, 30, 177–182. [Google Scholar]

- Zhu, Q.Q.; Hao, L.Y.; Xu, X.; Agathopoulos, S.; Zheng, D.W.; Fang, C.H. A novel solid-state synthesis of long afterglow, Si-N co-doped, Y3Al5O12: Ce3+ phosphor. J. Lumin. 2016, 172, 270–274. [Google Scholar] [CrossRef]

- Qiang, Y.C.; Yu, Y.X.; Chen, G.L.; Fang, J.Y. Synthesis and luminescence properties of Ce3+-doped Y3Al3.5Ga1.5O12 green phosphor for white leds. J. Lumin. 2016, 172, 105–110. [Google Scholar] [CrossRef]

- Pasinski, D.; Zych, E.; Sokolnicki, J. The effect of N3- substitution for O2- on optical properties of YAG: Ce3+ phosphor. J. Alloys Compd. 2016, 668, 194–199. [Google Scholar] [CrossRef]

- Oya, T.; Okada, G.; Yanagida, T. Scintillation properties of Lu3Al5O12 co-doped with Nd and Ce. J. Ceram. Soc. Jpn. 2016, 124, 536–540. [Google Scholar] [CrossRef][Green Version]

- Tsai, C.-C. Color rendering index thermal stability improvement of glass-based phosphor-converted white light-emitting diodes for solid-state lighting. Int. J. Photoenergy 2014, 2014. [Google Scholar] [CrossRef]

- Yin, L.-J.; Dong, J.; Wang, Y.; Zhang, B.; Zhou, Z.-Y.; Jian, X.; Wu, M.; Xu, X.; van Ommen, J.R.; Hintzen, H.T. Enhanced optical performance of BaMgAl10O17: Eu2+ phosphor by a novel method of carbon coating. J. Phys. Chem. C 2016, 120, 2355–2361. [Google Scholar] [CrossRef]

- Yin, L.-J.; Xu, X.; Yu, W.; Yang, J.-G.; Yang, L.-X.; Yang, X.-F.; Hao, L.-Y.; Liu, X.-J. Synthesis of Eu2+-doped AlN phosphors by carbothermal reduction. J. Am. Ceram. Soc. 2010, 93, 1702–1707. [Google Scholar] [CrossRef]

- Piao, X.Q.; Horikawa, T.; Hanzawa, H.; Machida, K. Characterization and luminescence properties of Sr2Si5N8: Eu2+ phosphor for white light-emitting-diode illumination. Appl. Phys. Lett. 2006, 88, 161908. [Google Scholar] [CrossRef]

- Kuang, J.C.; Zhang, C.R.; Zhou, X.G.; Liu, Q.C.; Ye, C. Formation and characterization of cubic aln crystalline in a carbothermal reduction reaction. Mater. Lett. 2005, 59, 2006–2010. [Google Scholar] [CrossRef]

- Ozawa, M.; Loong, C.K. In situ x-ray and neutron powder diffraction studies of redox behavior in CeO2-containing oxide catalysts. Catal. Today 1999, 50, 329–342. [Google Scholar] [CrossRef]

- Cho, Y.; Dierre, B.; Sekiguchi, T.; Suehiro, T.; Takahashi, K.; Takeda, T.; Xie, R.-J.; Yamamoto, Y.; Hirosaki, N. Low-energy cathodoluminescence for (oxy)nitride phosphors. J. Vis. Exp. 2016, 117, 54249. [Google Scholar] [CrossRef] [PubMed]

- Lee, C.; Wei, X.; Kysar, J.W.; Hone, J. Measurement of the elastic properties and intrinsic strength of monolayer graphene. Science 2008, 321, 385–388. [Google Scholar] [CrossRef] [PubMed]

- Cho, Y.W.; Charles, J.A. Synthesis of nitrogen ceramic powders by carbothermal reduction and nitridation Part 3. Aluminum nitride. Mater. Sci. Technol. 1991, 7, 495–504. [Google Scholar] [CrossRef]

- Shyu, J.-J.; Yang, C.-W. Improvement of photoluminescence intensity of Ce-doped Y3Al5O12 phosphor by Si3N4 addition. Mater. Chem. Phys. 2017, 193, 339–347. [Google Scholar]

- Zorenko, Y.; Gorbenko, V.; Konstankevych, I.; Voloshinovskii, A.; Stryganyuk, G.; Mikhailin, V.; Kolobanov, V.; Spassky, D. Single-crystalline films of Ce-doped YAG and LuAG phosphors: Advantages over bulk crystals analogues. J. Lumin. 2005, 114, 85–94. [Google Scholar] [CrossRef]

- Hu, W.-W.; Zhu, Q.-Q.; Hao, L.-Y.; Xu, X.; Agathopoulos, S. Luminescence properties and energy transfer in AlN: Ce3+, Tb3+ phosphors. Mater. Res. Bull. 2014, 51, 224–227. [Google Scholar] [CrossRef]

- Colyott, L.E.; Akselrod, M.S.; McKeever, S.W.S. Phototransferred thermoluminescence in alpha-Al2O3: C. Radiat. Prot. Dosim. 1996, 65, 263–266. [Google Scholar] [CrossRef]

- Zorenko, Y.; Mares, J.A.; Prusa, P.; Nikl, M.; Gorbenko, V.; Savchyn, V.; Kucerkova, R.; Nejezchleb, K. Luminescence and scintillation characteristics of YAG: Ce single crystalline films and single crystals. Radiat. Meas. 2010, 45, 389–391. [Google Scholar] [CrossRef]

- Zorenko, Y.; Gorbenko, V.; Savchyn, V.; Vozniak, T.; Puzikov, V.; Danko, A.; Nizhankovski, S. Time-resolved luminescent spectroscopy of YAG: Ce single crystal and single crystalline films. Radiat. Meas. 2010, 45, 395–397. [Google Scholar] [CrossRef]

- Jadwisienczak, W.M.; Lozykowski, H.J.; Berishev, I.; Bensaoula, A.; Brown, I.G. Visible emission from AlN doped with Eu and Tb ions. J. App. Phys. 2001, 89, 4384–4390. [Google Scholar] [CrossRef]

- Nohara, A.; Takeshita, S.; Isobe, T. Mixed-solvent strategy for solvothermal synthesisof well-dispersed YBO3: Ce3+,Tb3+ nanocrystals. RSC Adv. 2014, 4, 11219–11224. [Google Scholar] [CrossRef]

- Zorenko, Y.; Zych, E.; Voloshinovskii, A. Intrinsic and Ce3+-related luminescence of YAG and YAG: Ce single crystals, single crystalline films and nanopowders. Opt. Mater. 2009, 31, 1845–1848. [Google Scholar] [CrossRef]

- Zorenko, Y.; Voznyak, T.; Gorbenko, V.; Zych, E.; Nizankovski, S.; Dan'ko, A.; Puzikov, V. Luminescence properties of Y3Al5O12: Ce nanoceramics. J. Lumin. 2011, 131, 17–21. [Google Scholar] [CrossRef]

- Zorenko, Y.; Voloshinovskii, A.; Savchyn, V.; Voznyak, T.; Nikl, M.; Nejezchleb, K.; Mikhailin, V.; Kolobanov, V.; Spassky, D. Exciton and Antisite Defect-Related Luminescence in Lu3Al5O12 and Y3Al5O12 Garnets; Wiley-VCH: Berlin, Germany, 2007; Volume 244, p. 10. [Google Scholar]

- Haneda, H.; Miyazawa, Y.; Shirasaki, S. Oxygen diffusion in single crystal yttrium aluminum garnet. J. Cryst. Growth 1984, 68, 581–588. [Google Scholar] [CrossRef]

| Sample | Emission Peak/nm | Origins | Ref. |

|---|---|---|---|

| YAG:Ce3+ | 320 (sharp) | Gd3+ impurity | [31] |

| 540 | YAG: Ce3+ | ||

| C@YAG:Ce3+-1500 °C | 330 | F+ center in Al2O3 | [33], This work |

| 350 | YAl ADin YAG/VN,Oiin AlN | [34,35,36] | |

| 395 | F+center in YAG | [34,38,39] | |

| 395–425 doublet | YBO3: Ce3+ | [37], This work | |

| 540 | YAG: Ce3+ | ||

| C@YAG:Ce3+-1650 °C | 310 | LE(AD) in YAG | [35,40] |

| 350 | YAl AD in YAG | [34,35] | |

| 540 | YAG:Ce3+ |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yin, L.-J.; Dierre, B.; Sekiguchi, T.; Van Ommen, J.R.; Hintzen, H.T.; Cho, Y. Transition of Emission Colours as a Consequence of Heat-Treatment of Carbon Coated Ce3+-Doped YAG Phosphors. Materials 2017, 10, 1180. https://doi.org/10.3390/ma10101180

Yin L-J, Dierre B, Sekiguchi T, Van Ommen JR, Hintzen HT, Cho Y. Transition of Emission Colours as a Consequence of Heat-Treatment of Carbon Coated Ce3+-Doped YAG Phosphors. Materials. 2017; 10(10):1180. https://doi.org/10.3390/ma10101180

Chicago/Turabian StyleYin, Liang-Jun, Benjamin Dierre, Takashi Sekiguchi, J. Ruud Van Ommen, Hubertus T. (Bert) Hintzen, and Yujin Cho. 2017. "Transition of Emission Colours as a Consequence of Heat-Treatment of Carbon Coated Ce3+-Doped YAG Phosphors" Materials 10, no. 10: 1180. https://doi.org/10.3390/ma10101180

APA StyleYin, L.-J., Dierre, B., Sekiguchi, T., Van Ommen, J. R., Hintzen, H. T., & Cho, Y. (2017). Transition of Emission Colours as a Consequence of Heat-Treatment of Carbon Coated Ce3+-Doped YAG Phosphors. Materials, 10(10), 1180. https://doi.org/10.3390/ma10101180