Processes of Fatigue Destruction in Nanopolymer-Hydrophobised Ceramic Bricks

Abstract

:1. Introduction

2. Materials and Methods

2.1. Characteristics of Materials

- Oligomeric dialkyl siloxanes characterised by the following physical parameters:

- -

- viscosity η = 1.08 × 10−3 Pa·s;

- -

- surface tension σ = 23.51 × 10−3 N/m;

- -

- surface tension-to-viscosity ratio η/γ = 21.77;

- -

- density at 20 °C—ρ = 0.80 g/cm3.

- Aqueous methyl silicone resin in potassium hydroxide characterised by:

- -

- preparation-water ratio 1:8;

- -

- viscosity η = 0.98 × 10−3 Pa·s;

- -

- surface tension γ = 77.24 × 10−3 N/m;

- -

- surface tension-to-viscosity ratio η/γ = 78.82;

- -

- density at 20 °C—ρ = 1.03 g/cm3 [31].

- Parameters of water for comparison:

- -

- viscosity η = 0.89 × 10−3 Pa·s;

- -

- surface tension γ = 72 × 10−3 N/m;

- -

- surface tension-to-viscosity ratio η/γ = 80.90;

- -

- density at 20 °C—ρ = 0.99 g/cm3.

2.2. Methods

2.3. Determination of the Properties of Hydrophobised Bricks

3. Discussion

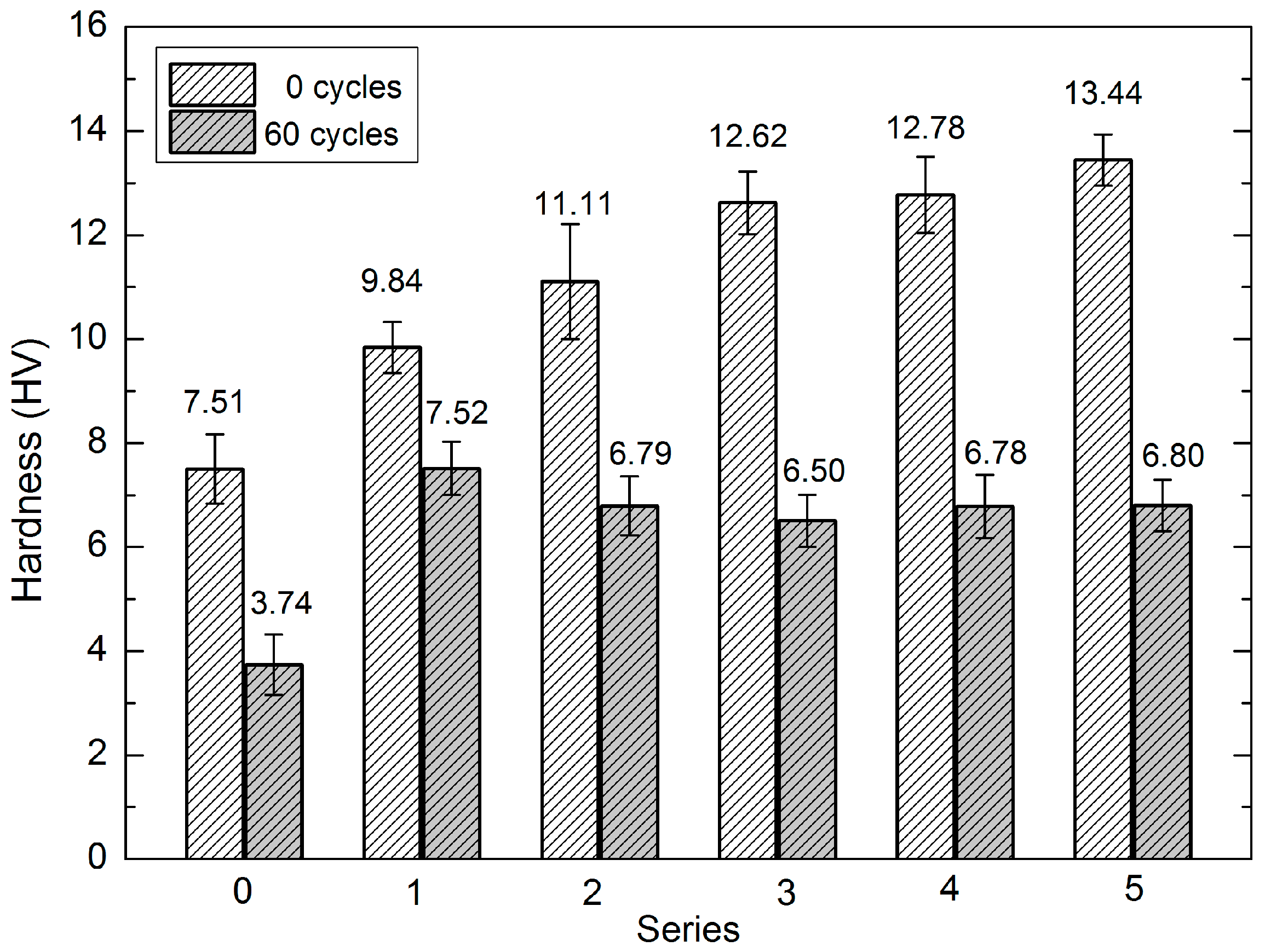

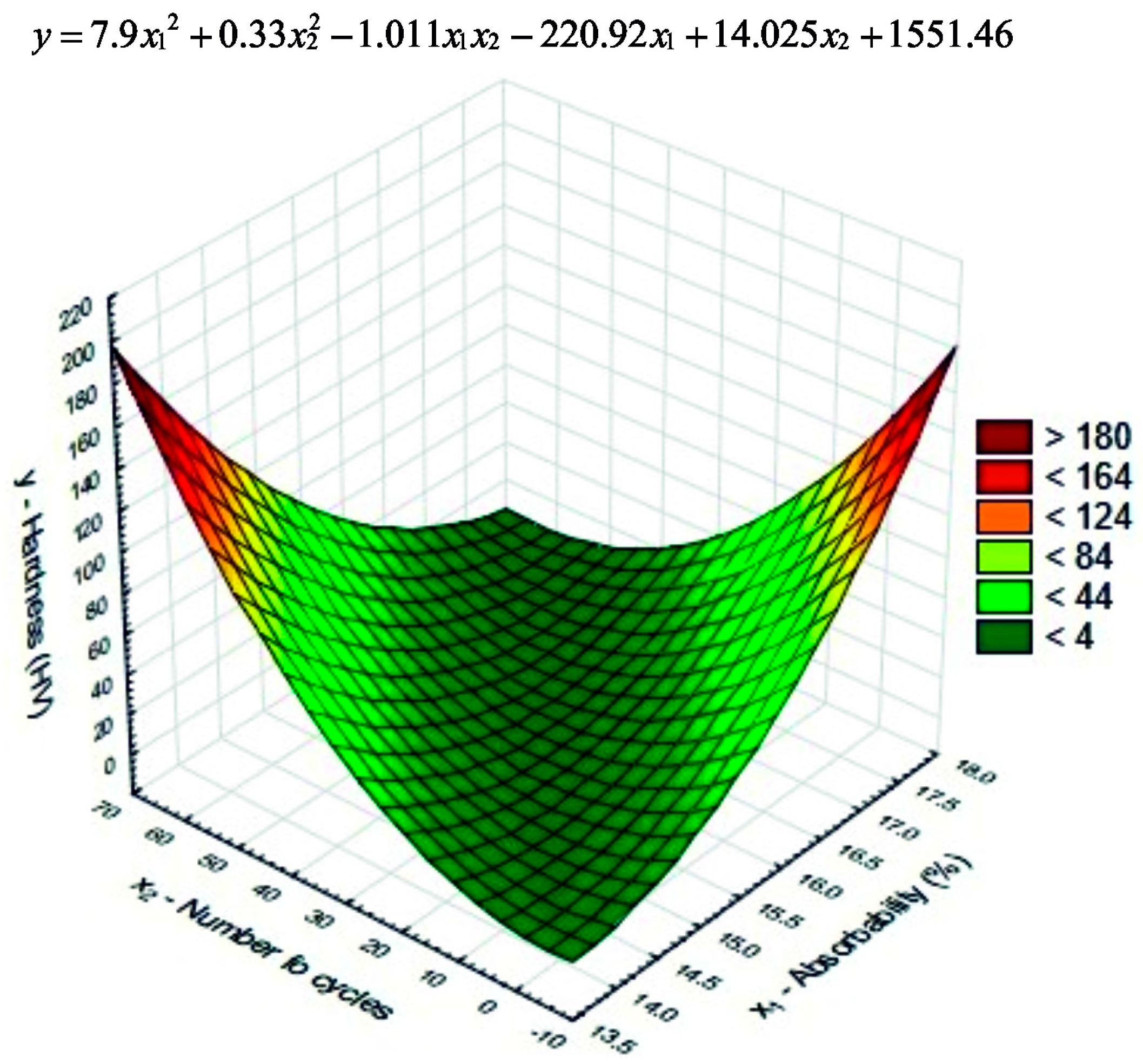

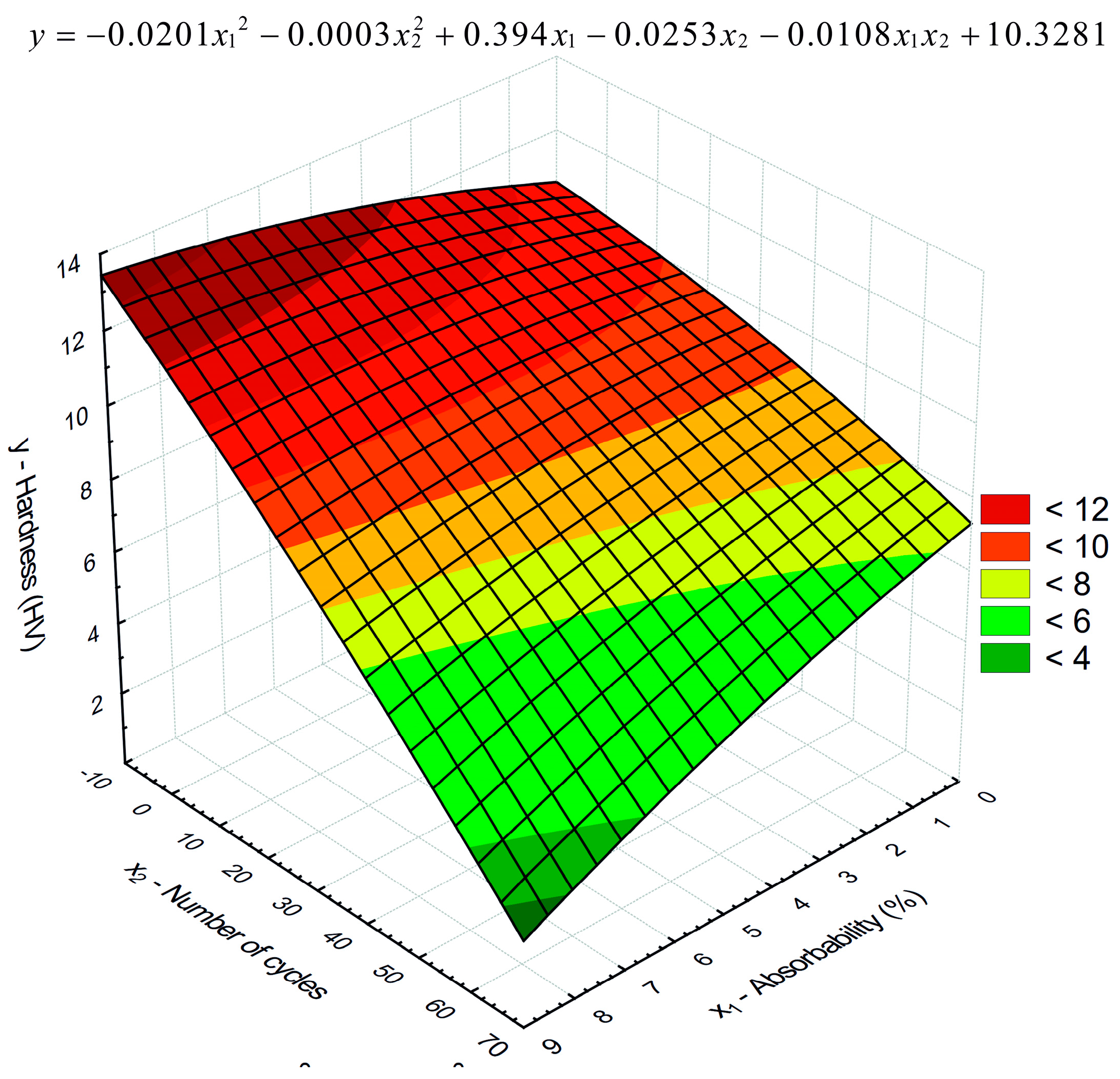

3.1. Hardness of Hydrophobised Bricks

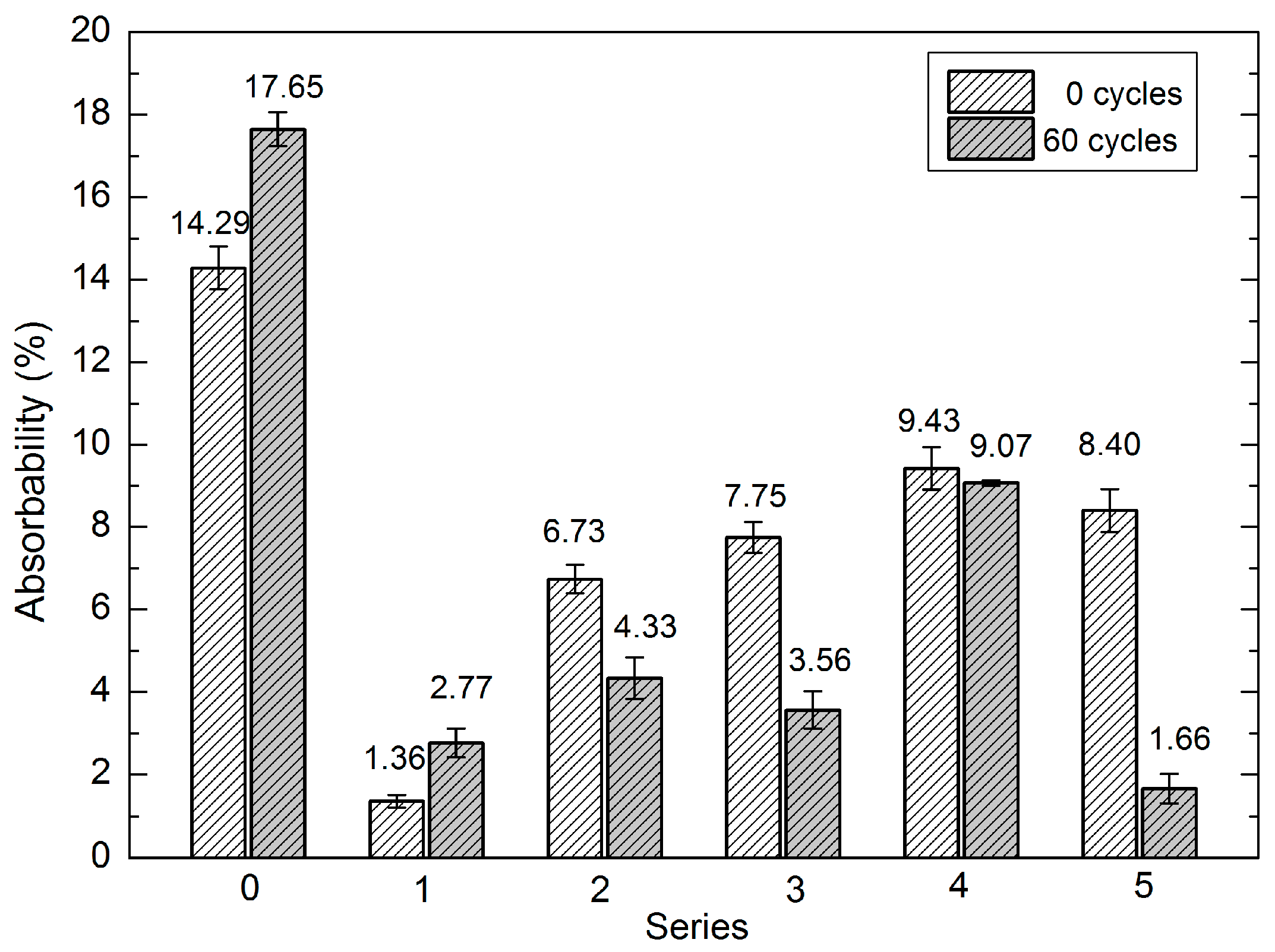

3.2. Absorbability of Hydrophobised Bricks

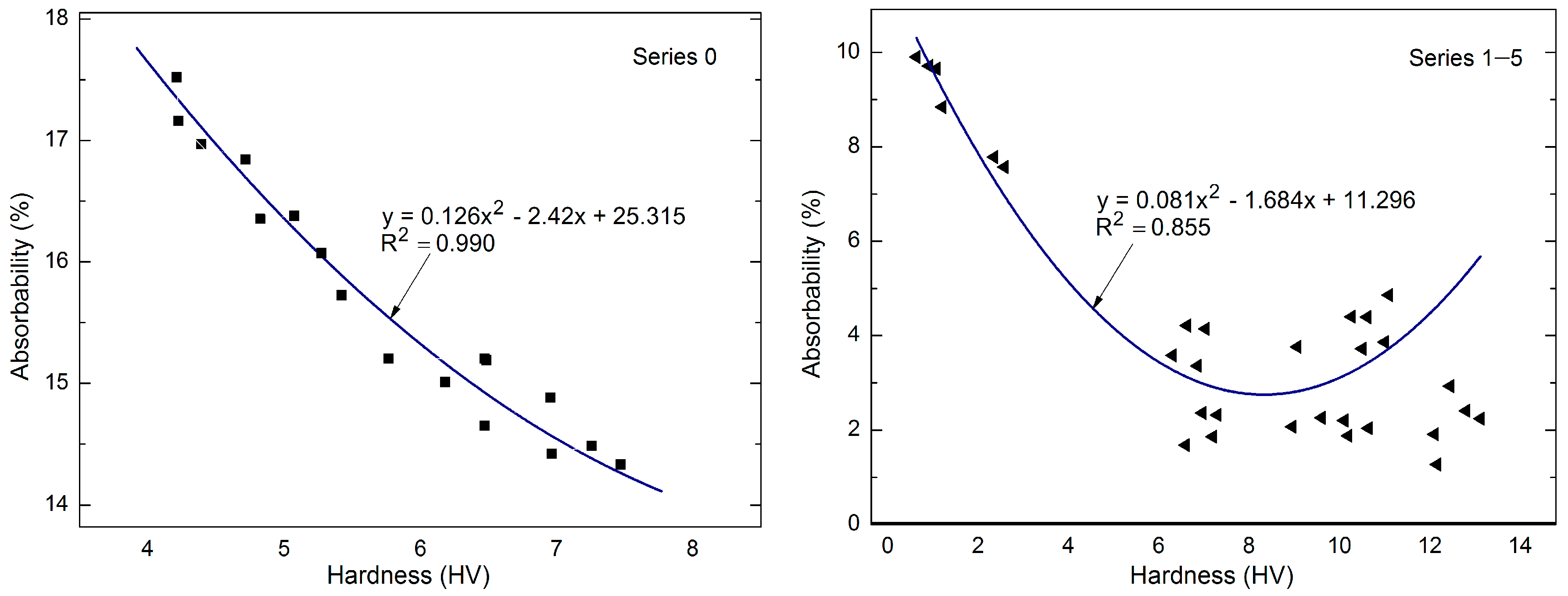

3.3. Correlation between Absorbability and Hardness of Hydrophobised Bricks

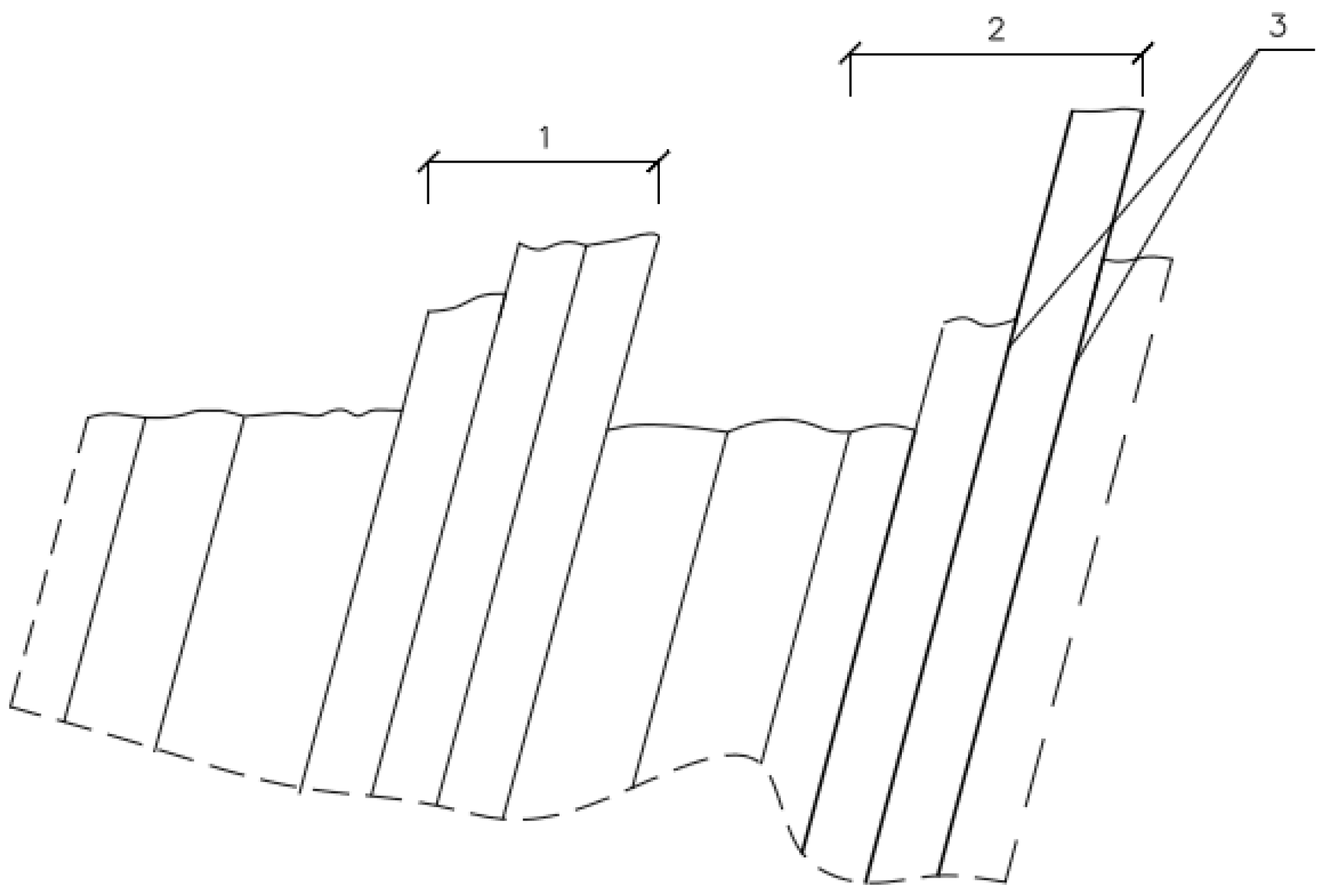

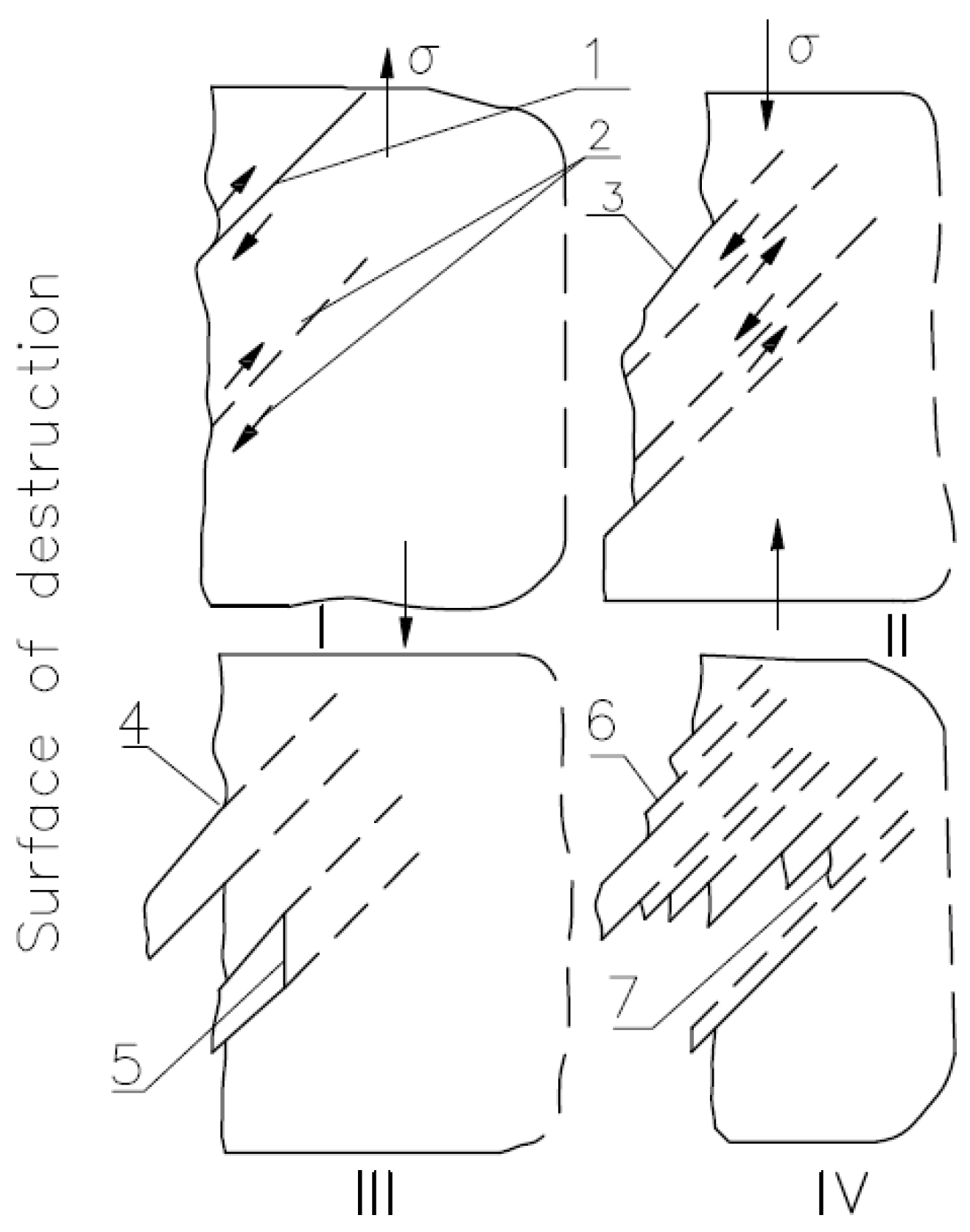

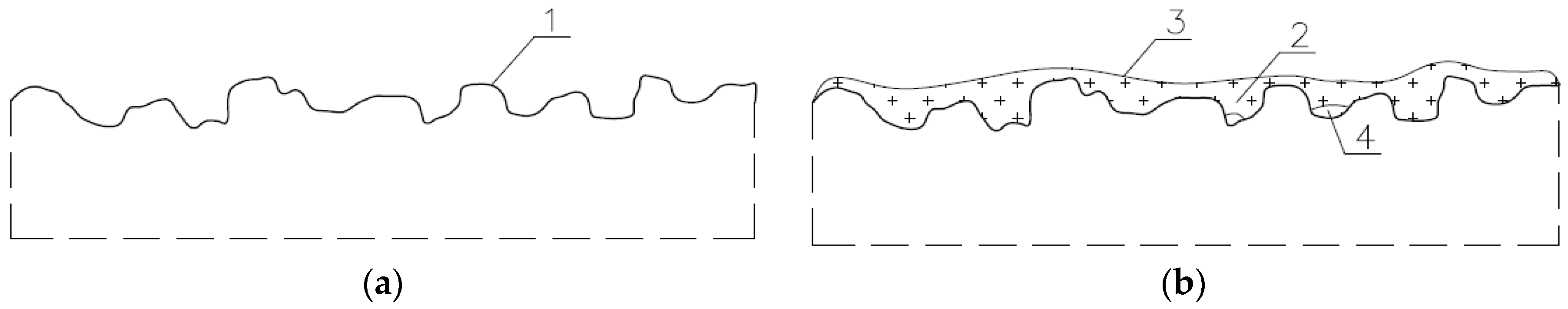

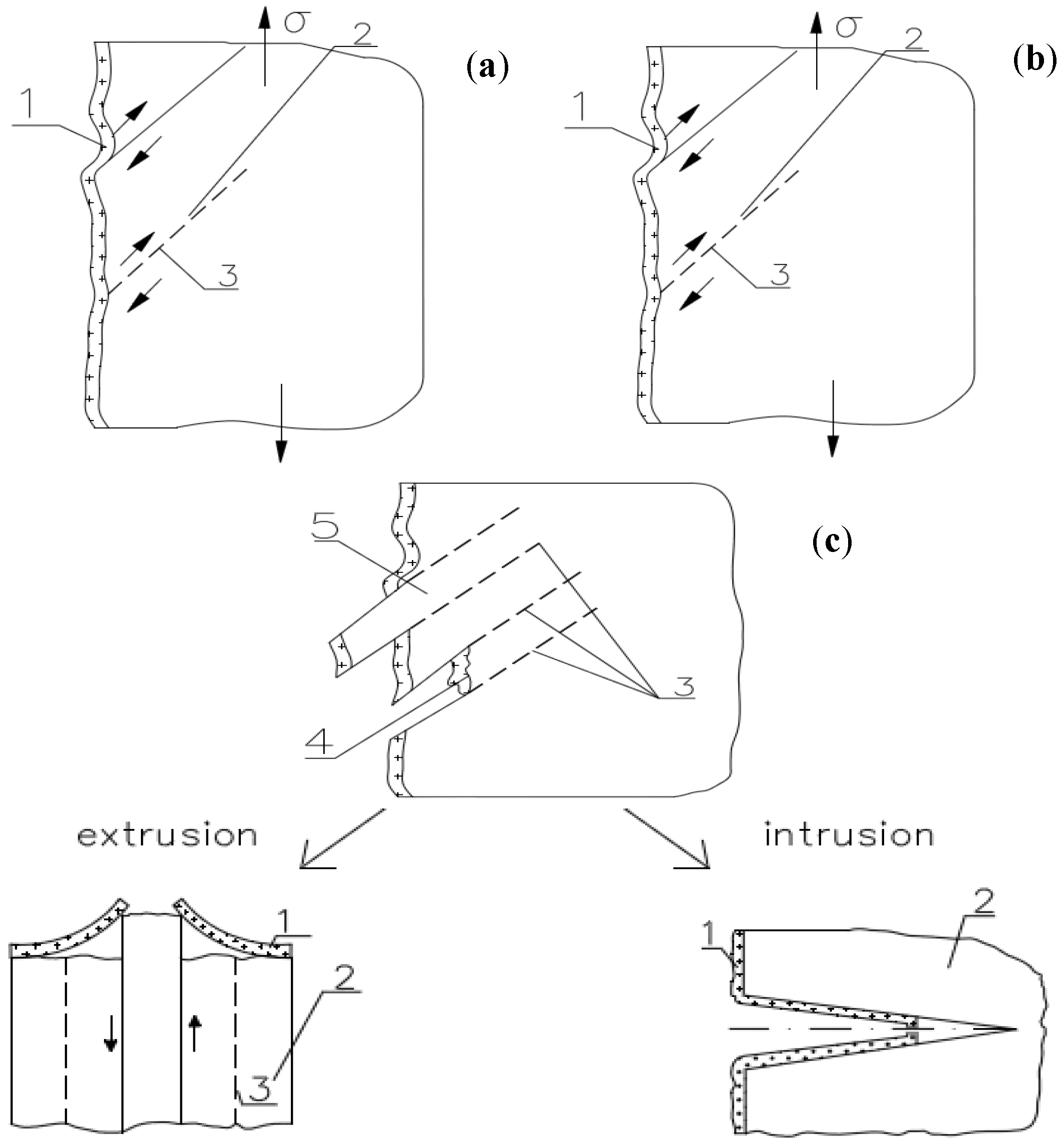

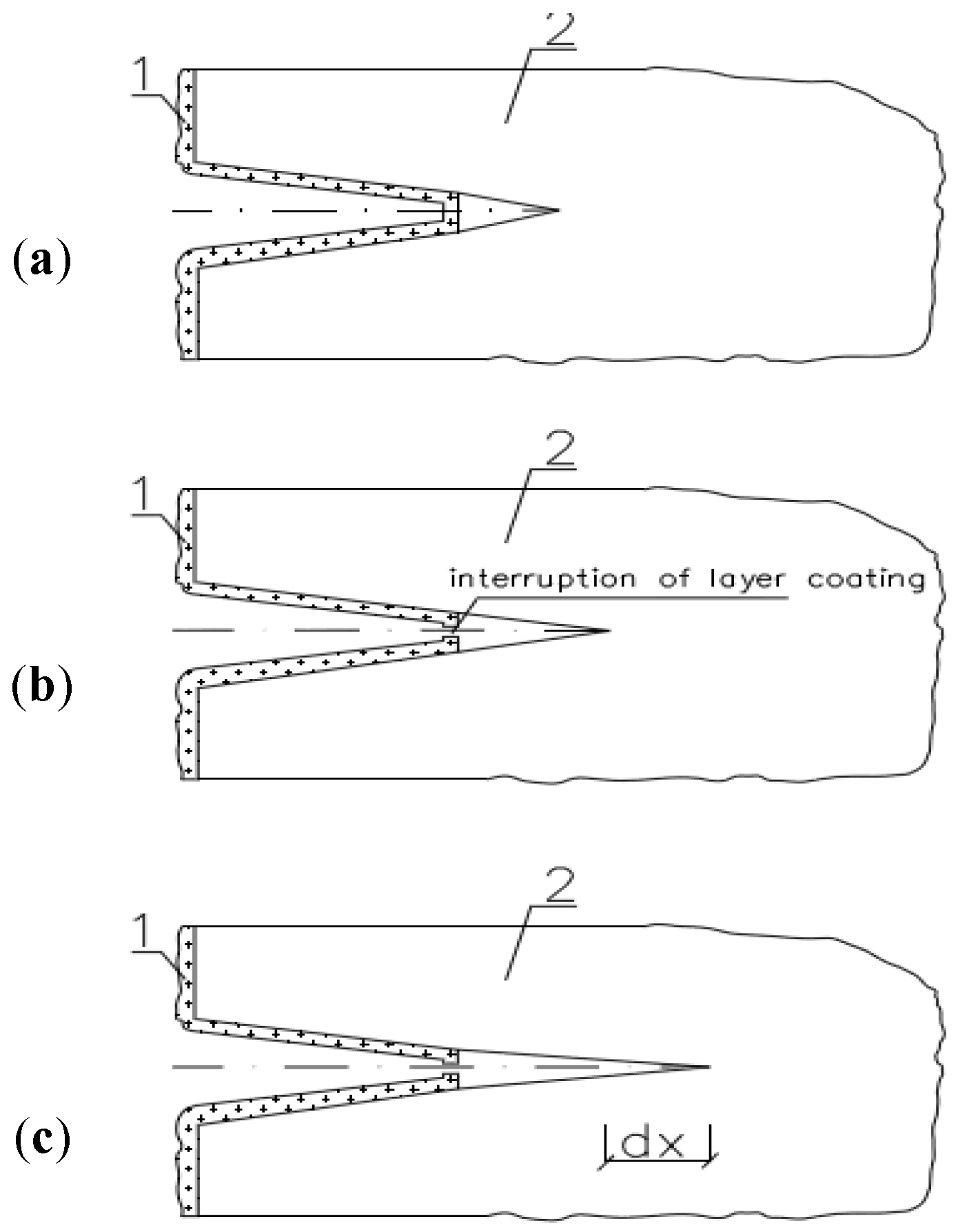

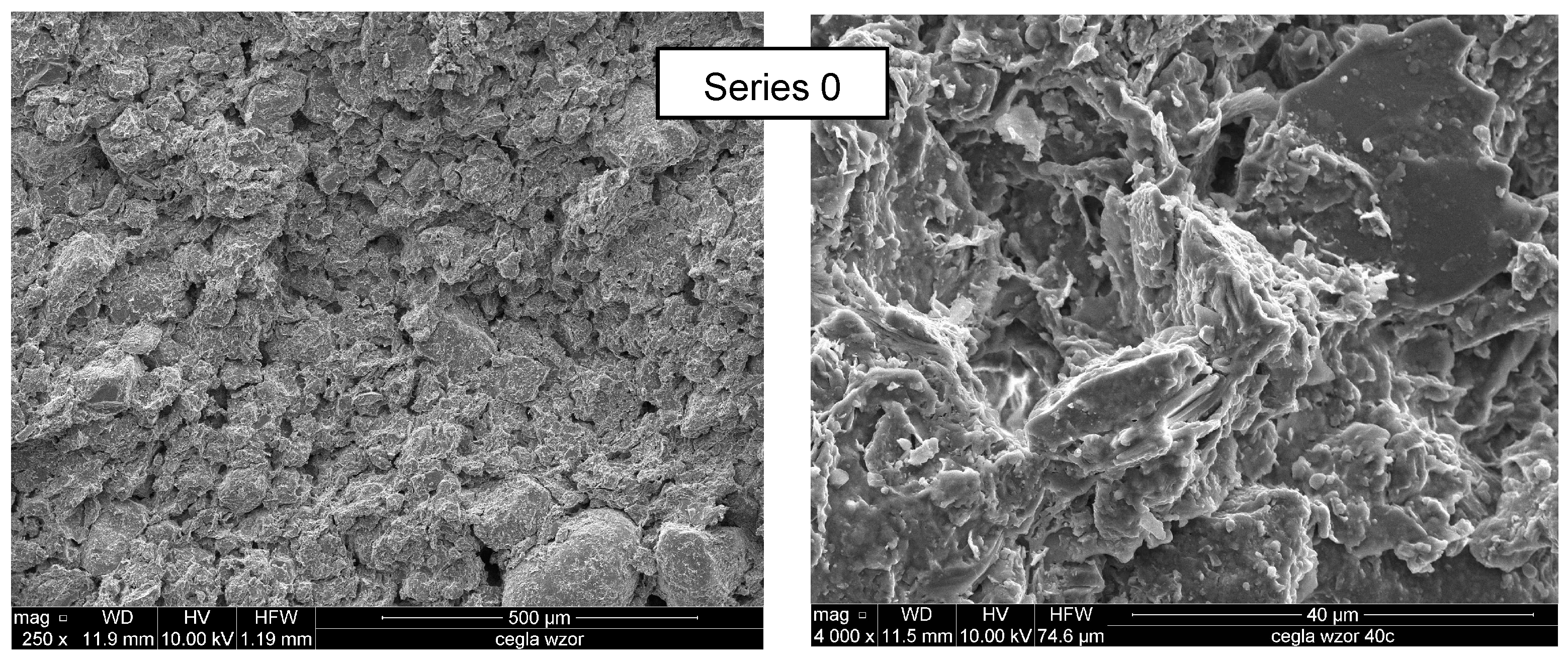

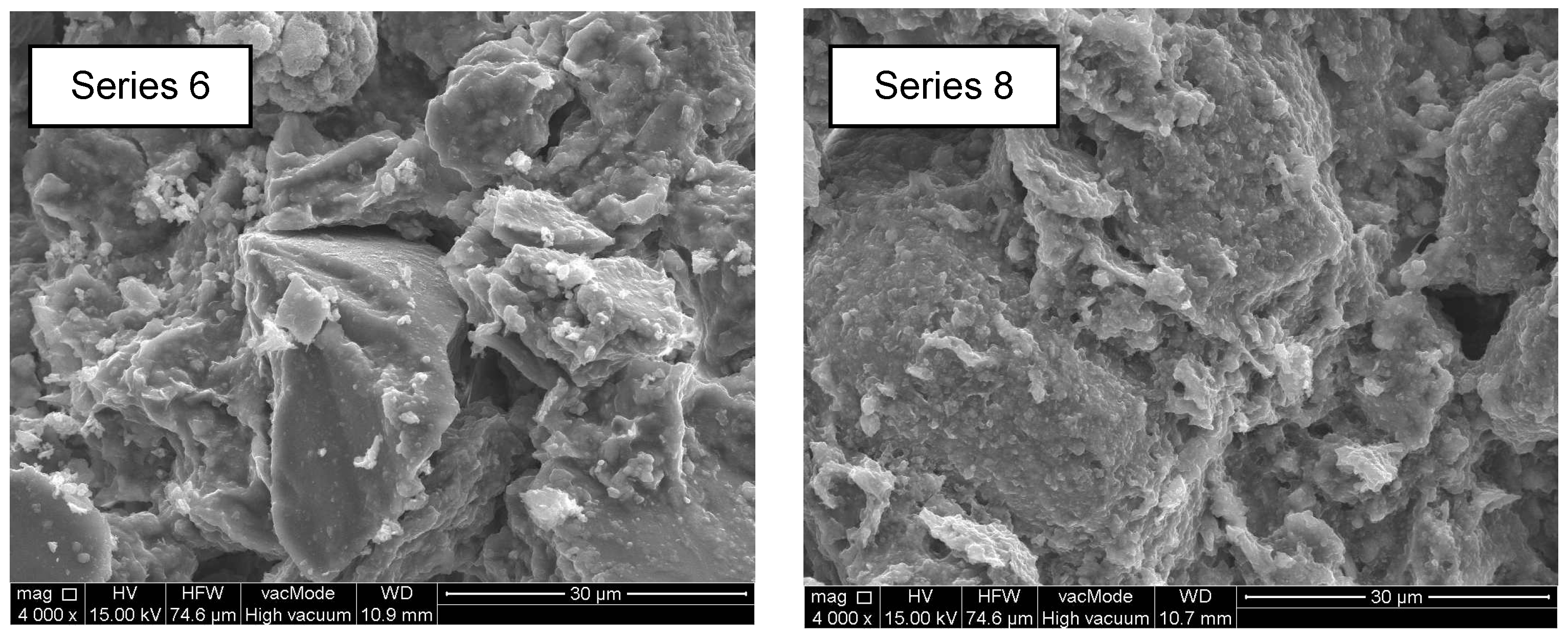

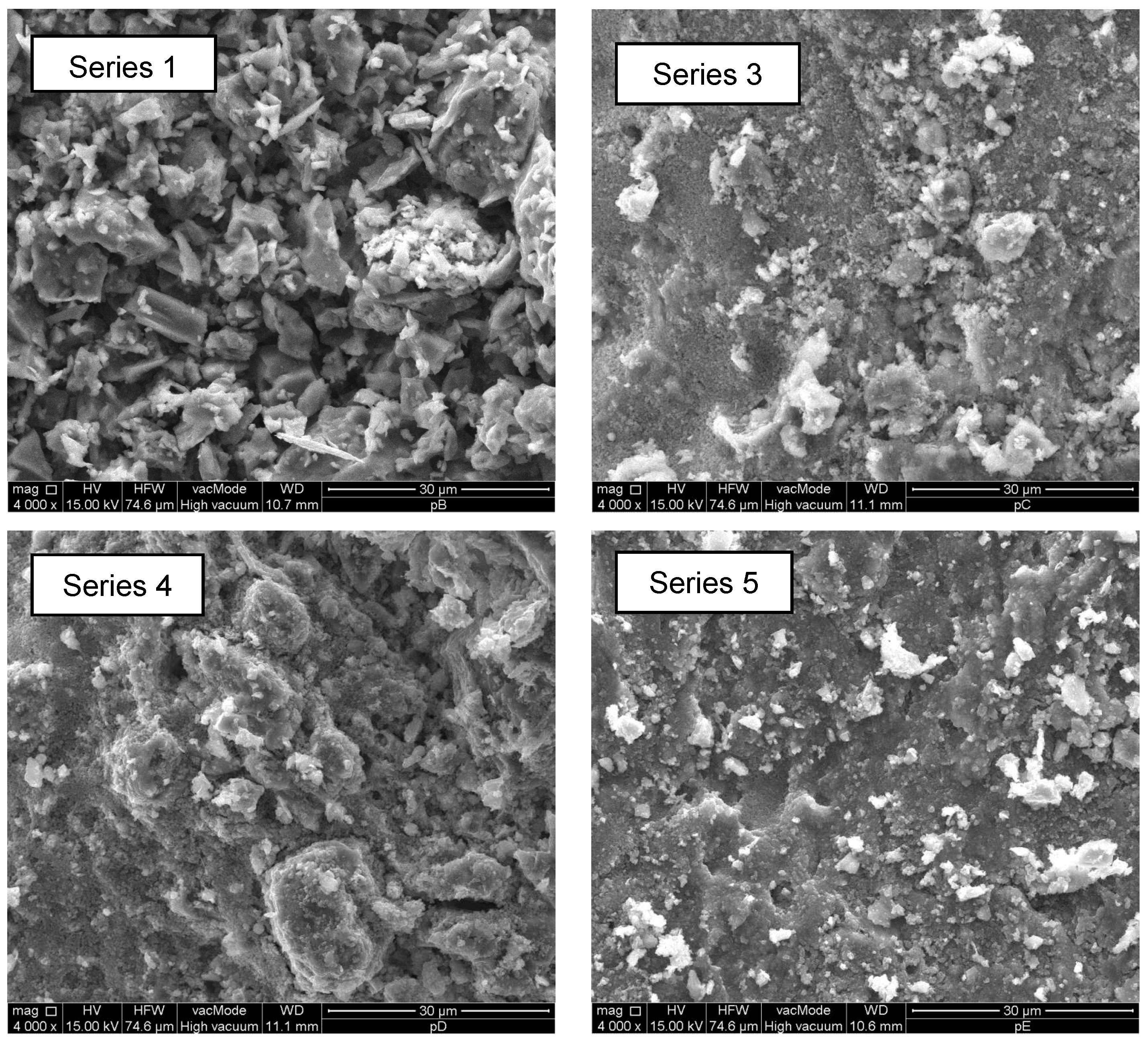

3.4. Microscopic Observations of Hydrophobised Bricks

4. Conclusions

- (a)

- Increased mechanical and fatigue strength, e.g., resistance to damage induced by the tests, was achieved by the coating based on the aqueous silicon solution, which is associated with the chemical traits of silicones and the physical properties of the film.

- (b)

- The sonochemical reaction proceeds more rapidly and is more effective in the case of incorporation of silica molecules into the internal structure of dialkyl siloxane-based nanopolymers. This is closely related to the size of siloxane molecules and the type of substituents in the main chain (besides alkyl groups, there are hydrogen atoms, which facilitates formation of hydrogen bonds).

- (c)

- To compare conclusions (a) and (b), the fragility of the silicone coating makes it more susceptible to cracking, especially under the effect of the temperature gradient. The siloxane coating, which is more susceptible to deformation, simultaneously exhibits greater flexibility and higher susceptibility to roughness changes and formation of intrusions and extrusions; hence, it does not crack. Therefore, depending on the preparation applied, the image and course of the coating destruction vary.

- (d)

- A very interesting phenomenon of secondary reorganisation of the hydrophobising coating structure caused by water movement in brick pores and capillaries caused by temperature changes was noticed. This phenomenon is highly advantageous from the point of view of the effectiveness of the hydrophobising agent formula.

- (e)

- There is no close relationship between the amount of the silica filler added and the efficiency of hydrophobisation in terms of changes in the surface hardness and absorbability of the tested samples.

- (f)

- Siliconates and small-molecule dialkyl siloxanes, which do not seal the structure and do not impair vapour and gas diffusion, form a relatively well-distributed coating in the brick structure. Dialkyl siloxane-based coatings modified with nanosilica form an excessive-density layer, which negatively affects brick absorbability. Modified methyl silicone-resin coatings exhibit an appropriate structure of polysiloxane gel, which was confirmed by its high effectiveness observed in the study.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Hall, C.; Hoff, W.D.; Nixon, M.R. Water movement in porous building materials, VI Evaporation and Drying Brick and Block Materials. Build. Environ. 1984, 19, 13–20. [Google Scholar] [CrossRef]

- Pavlík, Z.; Černý, R. Experimental assessment of hygrothermal performance of an interior thermal insulation system using a laboratory technique simulating on-site conditions. Energy Build. 2008, 40, 673–678. [Google Scholar] [CrossRef]

- Suchorab, Z.; Jedut, A.; Sobczuk, H. Water Content Measurement in Building Barriers and Materials Using Surface TDR Probe. Proc. ECOpole 2008, 2, 123–127. [Google Scholar]

- Wardeh, G.; Perrin, B. Freezing-thawing phenomena in fired clay materials and consequences on their durability. Constr. Build. Mater. 2008, 22, 820–828. [Google Scholar] [CrossRef]

- Suchorab, Z.; Widomski, M.; Lagod, G.; Sobczuk, H. Capillary Rise Phenomenon in Aerated Concrete. Monitoring and Simulations. Proc. ECOpole 2010, 4, 285–290. [Google Scholar]

- Edis, E.; Flores-Colen, J.; de Brito, J. Passive thermographic detection of moisture problems in facades with adhered ceramic cladding. Constr. Build. Mater. 2014, 51, 187–197. [Google Scholar] [CrossRef]

- Finken, G.R.; Bjarløv, S.P.; Peuhkuri, R.H. Effect of façade impregnation on feasibility of capillary active thermal internal insulation for a historic dormitory—A hygrothermal simulation study. Constr. Build. Mater. 2016, 113, 202–214. [Google Scholar] [CrossRef]

- Jerman, M.; Cerny, R. Effect of moisture content on heat and moisture transport and storage properties of thermal insulation materials. Energy Build. 2012, 53, 39–46. [Google Scholar] [CrossRef]

- Bodnar, A. Strength of Materials; Cracow University of Technolgy: Cracow, Poland, 2003. (In Polish) [Google Scholar]

- Gawędzki, A. Mechanics of Materials and Rod Structures; Poznan University of Technology: Poznan, Poland, 2003. (In Polish) [Google Scholar]

- Karaszewski, W. Fatigue failure of ceramic materials: A review of recent research. Tribologia 2004, 3, 169–178. (In Polish) [Google Scholar]

- Bangham, D.H.; Razouk, R.I. Adsorption and the wettability of solid surfaces. Trans. Faraday Soc. 1937, 33, 1459–1463. [Google Scholar] [CrossRef]

- Dietrich, L. Raport of Behavior of Cast Aluminium Alloys under Low Cycle Fatique and under Combined Stress States. In 6th Framework Program New Automative Components Designed and Manufactured by Intelligent Processing of Light Alloys; NADIA Contract No. 026563-2; IPPT: Warsaw, Poland, 2009; p. 90. [Google Scholar]

- Matsumoto, M.; Hokoi, S.; Hatano, M. Model for simulation of freezing and thawing processes in building materials. Build. Environ. 2001, 36, 733–742. [Google Scholar] [CrossRef]

- Tang, S.B.; Yu, Q.L.; Li, H.; Yu, C.Y.; Bao, C.Y.; Tang, C.A. Mesomechanical model of moisture diffusion and shrinkage cracking in building material—Model development. Constr. Build. Mater. 2013, 47, 511–515. [Google Scholar] [CrossRef]

- Hoła, I. Stress Destruction of Compresse Concrete Matured in Different Moisture-Tepmerature Conditions; Pawłowski, Z., Ed.; ZPBN. No 2; SIMP: Warsaw, Poland, 1997. (In Polish) [Google Scholar]

- Neimitz, A. Fracture Mechanics; Science Publisher PWN: Warsaw, Poland, 1998. (In Polish) [Google Scholar]

- German, J. Basics of Fracture Mechanics; Cracow University of Technology: Cracow, Poland, 2011. (In Polish) [Google Scholar]

- Suchorab, Z.; Barnat-Hunek, D.; Franus, M.; Lagod, G. Mechanical and physical properties of hydrophobized lightweight aggregate concrete with sewage sludge. Materials 2016, 9, 317. [Google Scholar] [CrossRef]

- Fic, S.; Barnat-Hunek, D. The effectiveness of hydrofobisation of porous building material by using the polymers and nanopolymers solution. Int. J. Mater. Sci. Eng. 2014, 2, 93–98. [Google Scholar]

- Fic, S.; Kłonica, M.; Szewczak, A. Adhesive properties of low molecular weight polymer modified with nanosilica and disintegrated ultrasonically for application in waterproofing ceramics. Polimery 2015, 60, 730–734. (In Polish) [Google Scholar] [CrossRef]

- Tittarelli, F. Oxygen diffusion through hydrophobic cement-based materials. Cem. Concr. Res. 2009, 39, 924–928. [Google Scholar] [CrossRef]

- Fic, S.; Vyrovoy, V.N.; Dorofeev, V.S. The Self-Assembly Processes of Composite Construction Materials Structure; Lublin University of Technology: Lublin, Poland, 2013; Available online: http://bc.pollub.pl/Content/6030/procesy.pdf (accessed on 14 November 2016). (In Polish)

- Sangid, M.D. The physics of fatigue crack initiation. Int. J. Fatigue 2013, 57, 58–72. [Google Scholar] [CrossRef]

- Nazar, M.E.; Sinha, S.N. Fatigue behaviour of interlocking grouted stabilised mud-fly ash brick masonry. Int. J. Fatigue 2007, 29, 953–961. [Google Scholar] [CrossRef]

- Casas, J.R. A probabilistic fatigue strength model for brick masonry under compression. Constr. Build. Mater. 2009, 23, 2964–2972. [Google Scholar] [CrossRef]

- Talreja, R.; Varna, J. (Eds.) Modeling Damage, Fatigue and Failure of Composite Materials, 1st ed.; Woodhead Publishing: London, UK, 2015.

- Podgaetskii, E.M. On conditions of change of sign of the Rehbinder effect in the case of single-component adsorption according to the Frumkin isotherm. Prot. Met. Phys. Chem. Surf. 2015, 51, 725–729. [Google Scholar] [CrossRef]

- Podgaetskii, E.M. Single component adsorption isotherm and Rehbinder effect conditions on a solid surface with a new surface layer equation. Prot. Met. Phys. Chem. Surf. 2016, 52, 381–386. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Smarzewski, P. Surface free energy of hydrophobic coatings of hybrid fiber reinforced high performance concrete. Mater. Technol. 2015, 49, 895–902. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Smarzewski, P.; Suchorab, Z. Effect of hydrophobisation on durability related properties of ceramic brick. Constr. Build. Mater. 2016, 111, 275–285. [Google Scholar] [CrossRef]

- Barnat-Hunek, D.; Smarzewski, P. Increased water repellence of ceramic buildings by hydrophobisation using high concentration of organic solvents. Energy Build. 2015, 103, 249–260. [Google Scholar] [CrossRef]

- Fowkes, F.M. Hydrophobic Surfaces; Academic Press: New York, NY, USA, 1969. [Google Scholar]

- Fic, S.; Szewczak, A. Influence of ultrasonic energy and inorganic fillers on the rheological properties of nanopolimeres. In Composite Materials and Their Use in Traditional and Energy-Efficient Construction; Lublin University of Technology: Lublin, Poland, 2014; pp. 105–113. (In Polish) [Google Scholar]

- Fic, S.; Klonica, M.; Szewczak, A. Effect of hydrophobization on the durability of building ceramics. Polimery 2016, 61, 46–48. (In Polish) [Google Scholar] [CrossRef]

- Hazlett, R.D. On surface roughness effects in wetting phenomena. J. Adhes. Sci. Technol. 1992, 6, 625–633. [Google Scholar] [CrossRef]

- Baldan, A. Adhesion phenomena in bonded joints. Int. J. Adhes. Adhes. 2012, 38, 95–116. [Google Scholar] [CrossRef]

- Kuczmaszewski, J. Fundamentals of Constructional and Technological Evaluations of Metal Adhesive Junctions Strength; College Publisher of Lublin University of Technology: Lublin, Poland, 1995. (In Polish) [Google Scholar]

- Rudawska, A. Selected Issues in Constituting Homogeneous and Hybrid Adhesive Joints; Lublin University of Technology: Lublin, Poland, 2013; Available online: http://bc.pollub.pl/dlibra/docmetadata?id=2383 (accessed on 14 November 2016). (In Polish)

- Griner, S.; Nowosielski, R. The adhesive strength of metallic glasses to polymers connections. Mater. Eng. 1996, 4, 106–110. (In Polish) [Google Scholar]

- Żenkiewicz, M. Adhesion and Modifying the Surface Layer of Macromolecular Plastics; WNT: Warsaw, Poland, 2000. (In Polish) [Google Scholar]

- Zare, Y. Determination of polymer–nanoparticles interfacial adhesion and its role in shape memory behavior of shape memory polymer nanocomposites. Int. J. Adhes. Adhes. 2014, 54, 67–71. [Google Scholar] [CrossRef]

- Van Oss, C.J.; Good, R.J.; Chaudhury, M.K. The role of van der Waals forces and hydrogen bonds in hydrophobic interactions between biopolymers and low energy surfaces. J. Colloid Interface Sci. 1986, 111, 378–390. [Google Scholar] [CrossRef]

- Van Gemert, D.; Czarnecki, L.; Maultzsch, M.; Schorn, H.; Beeldens, A.; Łukowski, P.; Knapen, E. Cement concrete and concrete–polymer composites: Two merging worlds: A report from 11th ICPIC Congress in Berlin, 2004. Cem. Concr. Compos. 2005, 27, 926–933. [Google Scholar] [CrossRef]

- Kramberger, J.; Sraml, M.; Glodez, S. Computational study of low-cycle fatigue behaviour of lotus-type porous material. Int. J. Fatigue 2016, 92, 623–632. [Google Scholar] [CrossRef]

- Kramberger, J.; Sterkus, K.; Glodez, S. Damage and failure modeling of lotus-type porous material subjected to low-cycle fatigue. Frat. Integr. Strutt. 2016, 35, 142–151. [Google Scholar]

- Zhang, W.; Liu, Y. Investigation on incremental fatigue crack growth mechanism using in situ SEM testing. Int. J. Fatigue 2012, 42, 14–23. [Google Scholar] [CrossRef]

- Polish Committee for Standardization. Natural Stone Test Methods. Determination of Real Density and Apparent Density, and of Total and Open Porosity; PN-EN 1936:2010; Polish Committee for Standardization: Warsaw, Poland, 2010. [Google Scholar]

- Polish Committee for Standardization. Advanced Technical Ceramics. Ceramic Composites. Physical Properties. Determination of Density and Apparent Porosity; PN-EN 1389:2005; Polish Committee for Standardization: Warsaw, Poland, 2005. [Google Scholar]

- STATISTICA. Available online: http://www.statsoft.com (accessed on 14 November 2016).

| Sample Preparation Procedure | |||

|---|---|---|---|

| Series | Addition of Nanosilica Relative to the Polymer Weight (%) | Polymer Disintegration by 15-min Sonication | Immersion of the Samples in the Preparation for 15 s N-Nanopolymer S-Silicon Solution |

| Series 0 | - | - | - |

| Series 1 | - | - | N |

| Series 1a | - | - | N—2x immersion |

| Series 2 | - | × | N |

| Series 2a | - | - | N—2x immersion |

| Series 3 | 0.5 | × | N |

| Series 4 | 1.0 | × | N |

| Series 5 | 1.5 | × | N |

| Series 6 | - | - | S |

| Series 7 | - | × | S |

| Series 8 | 0.5 | × | S |

| Series 9 | 1.0 | × | S |

| Series 10 | 1.5 | × | S |

| Series | Hardness (HV) | |||||

|---|---|---|---|---|---|---|

| Number of Cycles | ||||||

| 0 | 10 | 20 | 25 | 50 | 60 | |

| Series 0 | 7.77 | 6.73 | 6.70 | 6.02 | 4.27 | 3.92 |

| Series 1 | 9.90 | 9.71 | 9.65 | 8.84 | 7.78 | 7.57 |

| Series 1a | 10.82 | 10.71 | 10.31 | 9.16 | 7.50 | 7.17 |

| Series 2 | 11.30 | 11.21 | 10.47 | 9.27 | 7.24 | 6.83 |

| Series 2a | 13.03 | 12.95 | 10.86 | 9.60 | 6.10 | 5.40 |

| Series 3 | 12.66 | 12.37 | 10.85 | 9.81 | 7.06 | 6.51 |

| Series 4 | 12.88 | 12.53 | 10.32 | 10.24 | 7.49 | 6.94 |

| Series 5 | 13.33 | 13.01 | 12.31 | 10.40 | 7.40 | 6.80 |

| Series 6 | 9.62 | 9.73 | 10.63 | 9.50 | 9.38 | 9.35 |

| Series 7 | 10.37 | 10.82 | 11.62 | 9.78 | 9.28 | 9.18 |

| Series 8 | 11.73 | 11.94 | 12.37 | 9.79 | 7.79 | 7.39 |

| Series 9 | 9.70 | 9.43 | 11.90 | 9.90 | 9.65 | 9.60 |

| Series 10 | 10.05 | 10.01 | 9.55 | 8.85 | 7.60 | 7.35 |

| Series | Absorbability (%) | |||||

|---|---|---|---|---|---|---|

| Number of Cycles | ||||||

| 0 | 10 | 20 | 25 | 50 | 60 | |

| Series 0 | 14.12 | 14.53 | 14.93 | 15.32 | 17.27 | 17.76 |

| Series 1 | 0.84 | 1.12 | 1.28 | 1.41 | 2.56 | 2.79 |

| Series 1a | 4.39 | 3.72 | 2.20 | 2.07 | 2.32 | 2.36 |

| Series 2 | 6.86 | 5.86 | 4.40 | 3.76 | 4.14 | 4.21 |

| Series 2a | 4.62 | 1.33 | 1.20 | 1.32 | 1.92 | 2.04 |

| Series 3 | 7.93 | 1.27 | 2.04 | 2.26 | 3.36 | 3.58 |

| Series 4 | 9.29 | 5.74 | 5.55 | 6.06 | 8.61 | 9.12 |

| Series 5 | 8.24 | 2.41 | 1.91 | 1.88 | 1.86 | 1.68 |

| Series 6 | 7.21 | 4.19 | 3.87 | 4.13 | 5.43 | 5.69 |

| Series 7 | 9.47 | 2.04 | 2.24 | 4.78 | 7.48 | 8.02 |

| Series 8 | 9.25 | 2.17 | 1.37 | 1.81 | 4.01 | 4.45 |

| Series 9 | 9.12 | 2.24 | 1.67 | 2.16 | 4.61 | 5.1 |

| Series 10 | 8.95 | 2.58 | 1.95 | 2.62 | 5.97 | 6.64 |

© 2017 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license ( http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Fic, S.; Szewczak, A.; Barnat-Hunek, D.; Łagód, G. Processes of Fatigue Destruction in Nanopolymer-Hydrophobised Ceramic Bricks. Materials 2017, 10, 44. https://doi.org/10.3390/ma10010044

Fic S, Szewczak A, Barnat-Hunek D, Łagód G. Processes of Fatigue Destruction in Nanopolymer-Hydrophobised Ceramic Bricks. Materials. 2017; 10(1):44. https://doi.org/10.3390/ma10010044

Chicago/Turabian StyleFic, Stanisław, Andrzej Szewczak, Danuta Barnat-Hunek, and Grzegorz Łagód. 2017. "Processes of Fatigue Destruction in Nanopolymer-Hydrophobised Ceramic Bricks" Materials 10, no. 1: 44. https://doi.org/10.3390/ma10010044

APA StyleFic, S., Szewczak, A., Barnat-Hunek, D., & Łagód, G. (2017). Processes of Fatigue Destruction in Nanopolymer-Hydrophobised Ceramic Bricks. Materials, 10(1), 44. https://doi.org/10.3390/ma10010044