Height-Dependent Inter-Array Temperature Difference and Position-Dependent Intra-Array Temperature Gradient

Abstract

1. Introduction

2. Methodology

2.1. Experimental Setup

2.2. Instrumentation and Data Acquisition

2.3. Data Filtering and Analysis

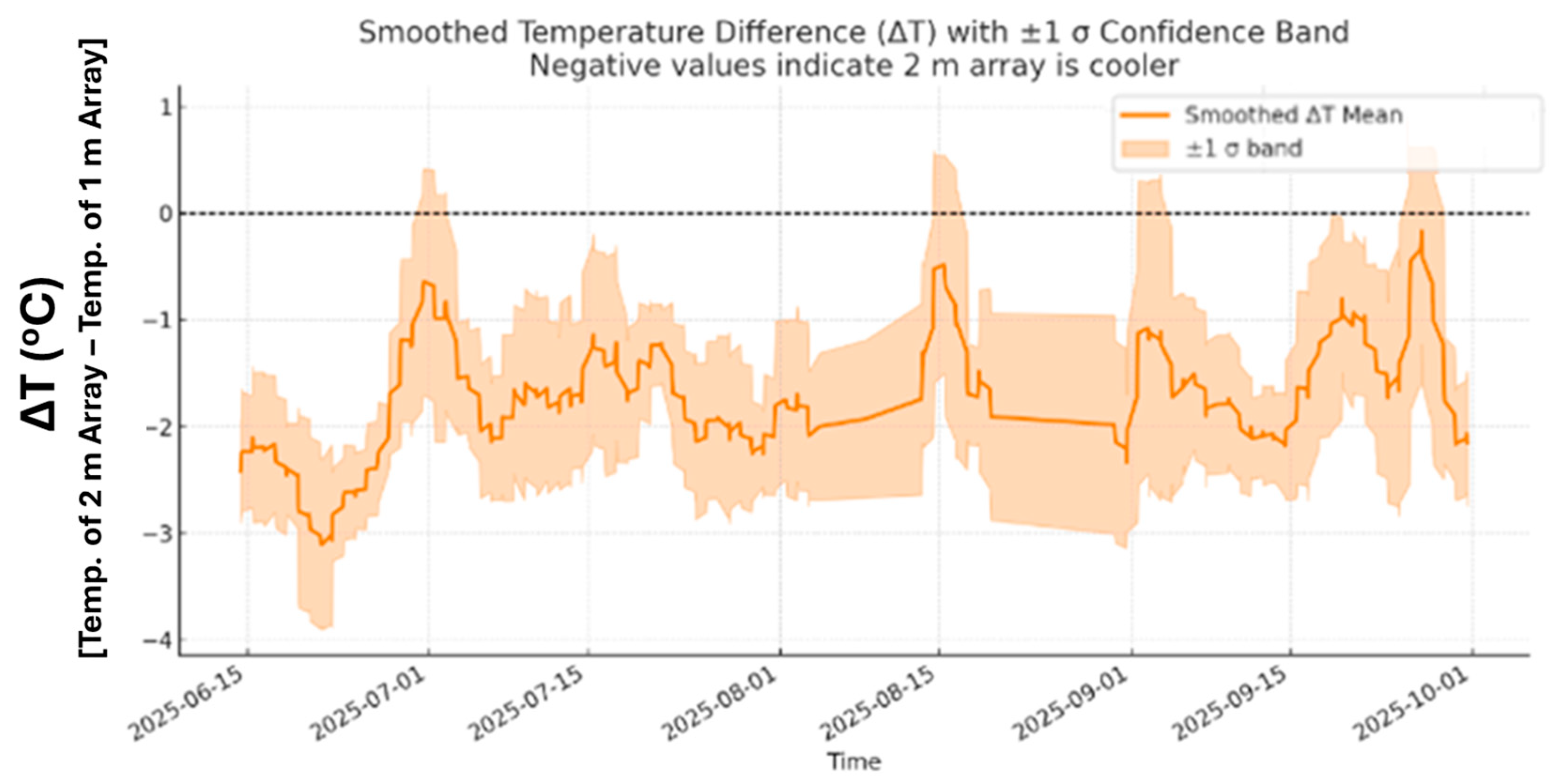

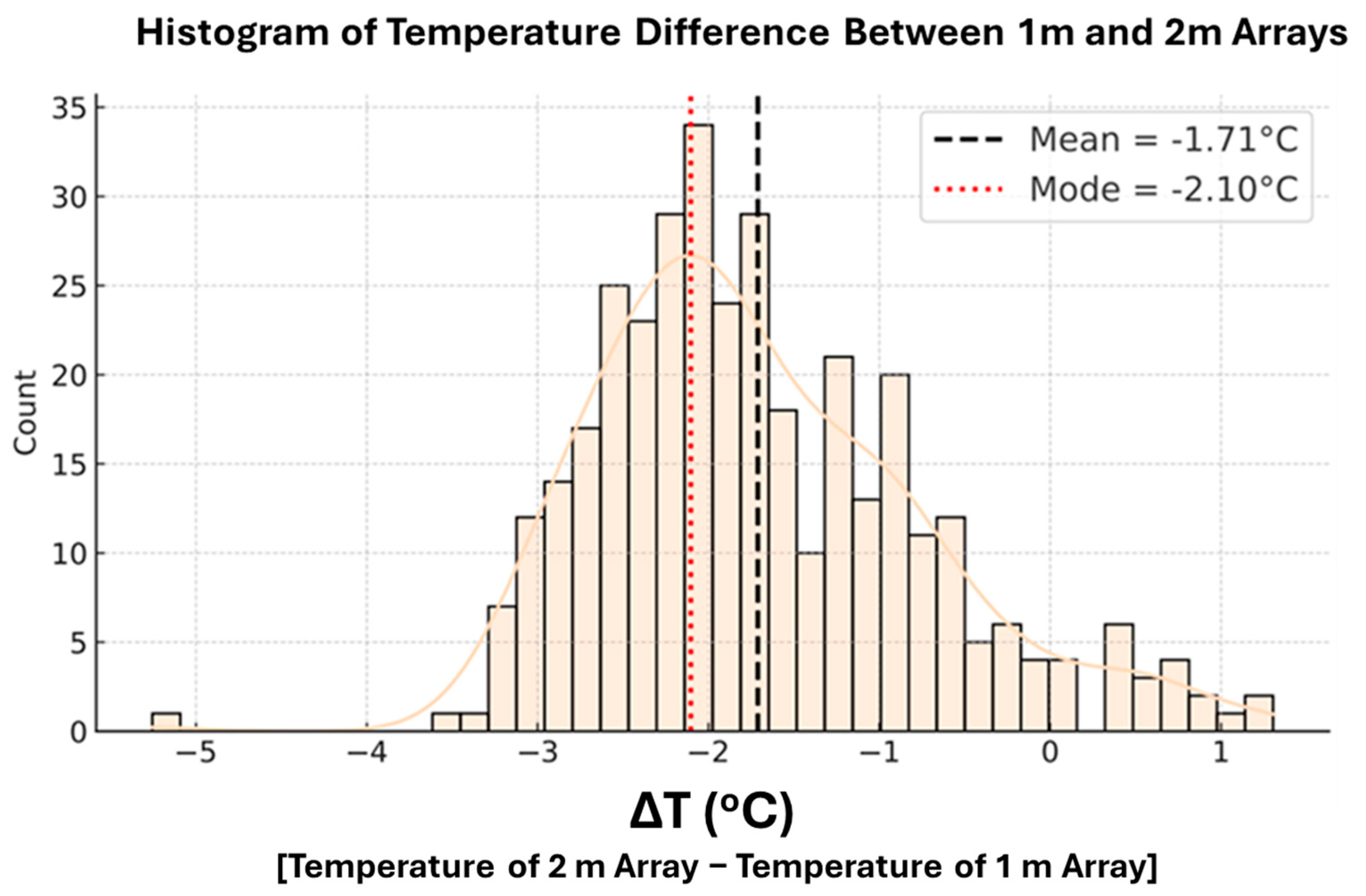

- Temperature difference between arrays with different heights (see Section 3.1): The difference in module backsheet temperature between the 1 m and 2 m arrays was statistically evaluated as a function of irradiance, wind speed, month, and time of day.

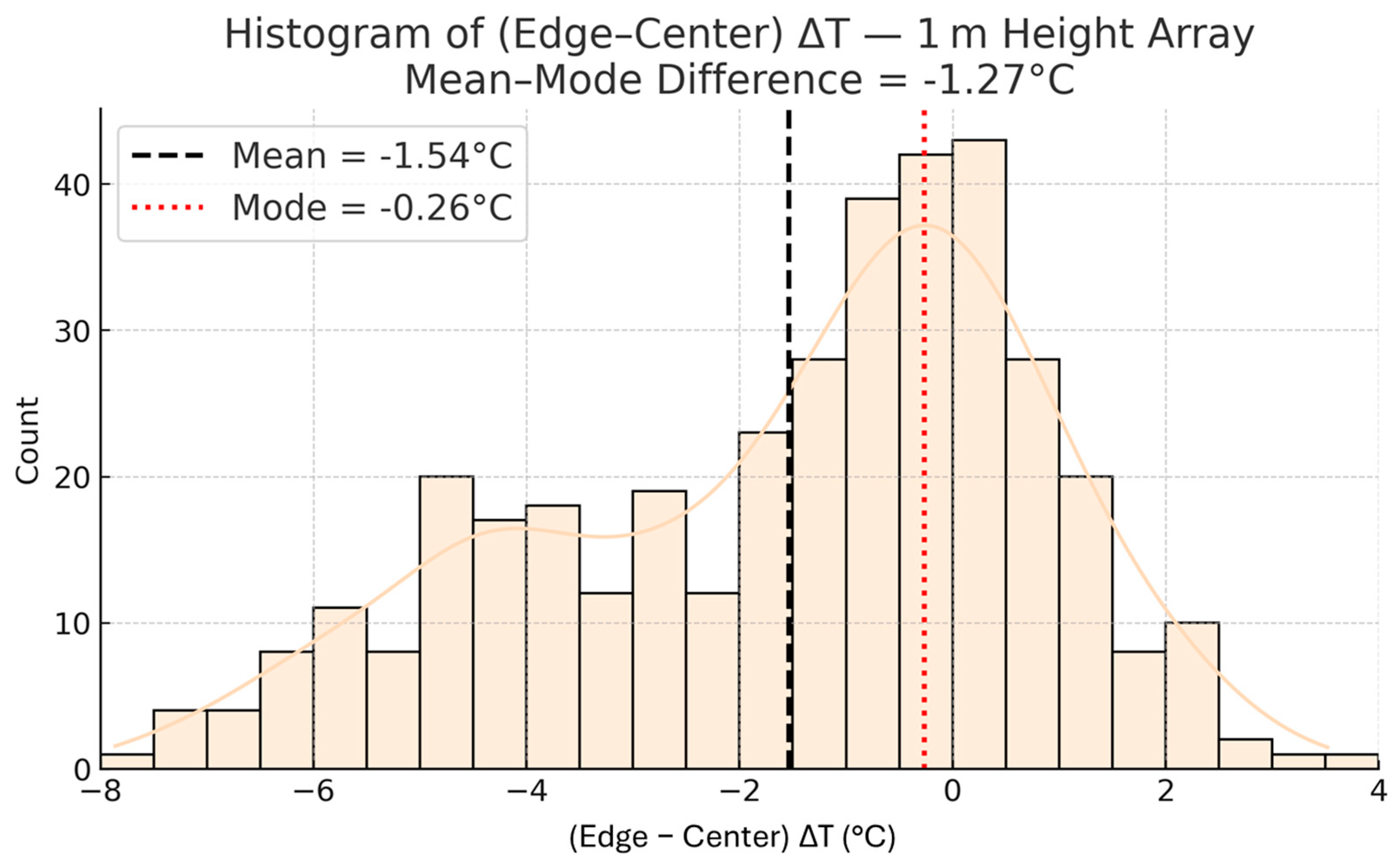

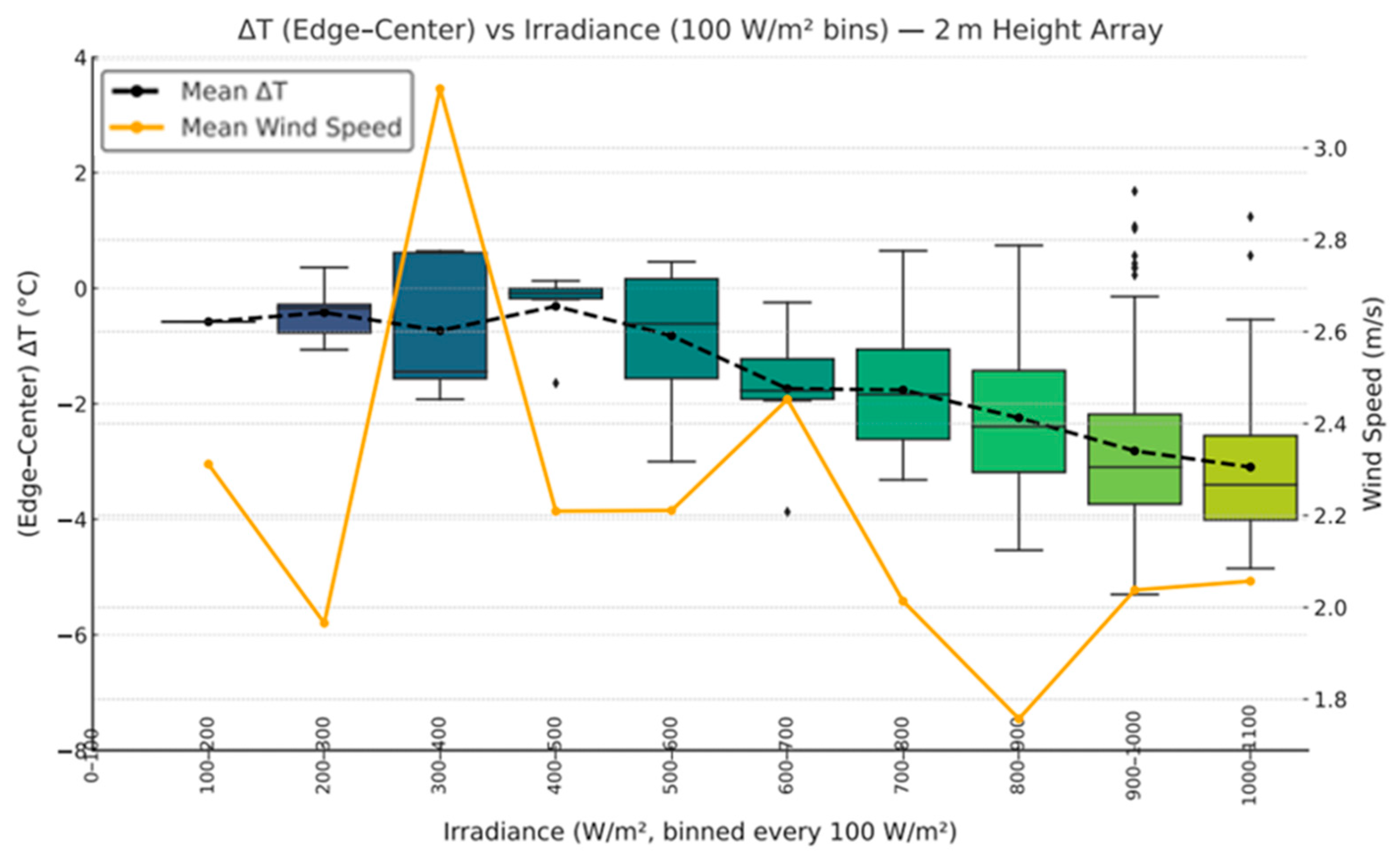

- Temperature gradient within each array (see Section 3.2): The edge–center temperature gradient (ΔTedge-center) was computed and statistically analyzed for both arrays to assess spatial temperature variation and compare gradient magnitudes.

- Combined effects of weather parameters (see Section 3.3): A summary on the combined effects of irradiance, wind speed, and ambient temperature on the inter-array and intra-array ΔT values is provided.

3. Results and Discussion

3.1. Temperature Difference Between 1 m and 2 m PV Arrays

3.1.1. Results

3.1.2. Discussion

3.2. Temperature Gradient Between Edge and Center Modules

3.2.1. Results

3.2.2. Discussion

3.3. Combined Parameter Influence—Summary

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Smith, S.E.; Viggiano, B.; Ali, N.; Silverman, T.J.; Obligado, M.; Calaf, M.; Cal, R.B. Increased panel height enhances cooling for photovoltaic solar farms. Appl. Energy 2022, 323, 119819. [Google Scholar] [CrossRef]

- Prilliman, M.; Smith, S.E.; Stanislawski, B.J.; Keith, J.M.F.; Silverman, T.J.; Calaf, M.; Cal, R.B. Technoeconomic analysis of changing PV array convective cooling through changing array spacing. IEEE J. Photovolt. 2022, 12, 6. [Google Scholar] [CrossRef]

- Stanislawski, B.; Margairaz, F.; Cal, R.B.; Calaf, M. Potential of module arrangements to enhance convective cooling in solar photovoltaic arrays. Renew. Energy 2020, 157, 851–858. [Google Scholar] [CrossRef]

- Zhang, W.; Gong, T.; Ma, S.; Zhou, J.; Zhao, Y. Study on the influence of mounting dimensions of PV array on module temperature in open-joint photovoltaic ventilated double-skin façades. Sustainability 2020, 13, 5027. [Google Scholar] [CrossRef]

- Wen, Y.; Li, X.; Hu, W.; Yang, F.; Yang, K.; Wang, J. Experimental research on the temperature distribution characteristics of photovoltaic array. Appl. Therm. Eng. 2025, 265, 125507. [Google Scholar] [CrossRef]

- IHS Markit. Higher Voltage Standards Help Reduce LCOE for PV Systems. 2021. Available online: https://cdn.ihsmarkit.com/www/pdf/0221/Higher-Voltage-Standards-Help-Reduce-LCOE-for-PV-Systems.pdf (accessed on 12 November 2025).

- Casey, J.P. Breaking the 2,000 V PV System Threshold. PV Tech, 12 March 2025. Available online: https://www.pv-tech.org/breaking-the-2000v-pv-system-threshold/ (accessed on 8 October 2025).

- Nelson, B. Driving Innovation Together: The Path to 2000 V Systems in Utility-Scale Renewable Energy Projects. 2025. Available online: https://electrification.us.abb.com/insights/driving-innovation-together-path-2000v-systems-utility-scale-renewable-energy-projects-0 (accessed on 8 October 2025).

- Pavgi, A.; Oh, J.; Kuitche, J.; Tatapudi, S.; TamizhMani, G. Thermal Uniformity Mapping of PV Modules and Plants. In Proceedings of the IEEE 44th Photovoltaic Specialist Conference (PVSC), Washington, DC, USA, 25–30 June 2017. [Google Scholar]

- IEC 61215:2005; Crystalline Silicon Terrestrial Photovoltaic (PV) Modules–Design Qualification and Type Approval. International Electrotechnical Commission: Geneva, Switzerland, 2005.

- California Energy Commission (CEC). PV Module List-Full Data, California Energy Commission. 2025. Available online: https://www.energy.ca.gov/media/2367 (accessed on 12 September 2025).

- Sinha, A.; Buddha, V.S.P.; Schneller, E.J.; Davis, K.O.; TamizhMani, G. Solder bond degradation of fielded PV modules: Climate dependence of intermetallic compound growth. In Proceedings of the 46th IEEE Photovoltaic Specialists Conference (PVSC), Chicago, IL, USA, 16–21 June 2019; pp. 1393–1397. [Google Scholar]

- Gopalakrishna, H.; Sinha, A.; Carpenter, J.; Niverty, S.; Chawla, N.; Jordan, D.; Tamizhmani, G. Activation Energy for End-of-Life Solder Bond Degradation: Thermal Cycling of Field-Aged PV Modules. IEEE J. Photovolt. 2020, 10, 1762–1771. [Google Scholar] [CrossRef]

| Parameter | Symbol | Value |

|---|---|---|

| Maximum power at STC | Pmax | 320 Wp |

| Open circuit voltage at STC | VOC | 45.9 V |

| Short circuit current at STC | Isc | 9.41 A |

| Nominal Operating Cell Temperature | NOCT | 46 °C |

| Temperature coefficient of Isc | 0.042% °C−1 | |

| Temperature coefficient of Voc | −0.304% °C−1 | |

| Temperature coefficient of Pmax | −0.43% °C−1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license.

Share and Cite

Kumar, A.; Kothandapani, N.; Tatapudi, S.; Bhoite, S.; TamizhMani, G. Height-Dependent Inter-Array Temperature Difference and Position-Dependent Intra-Array Temperature Gradient. Energies 2026, 19, 111. https://doi.org/10.3390/en19010111

Kumar A, Kothandapani N, Tatapudi S, Bhoite S, TamizhMani G. Height-Dependent Inter-Array Temperature Difference and Position-Dependent Intra-Array Temperature Gradient. Energies. 2026; 19(1):111. https://doi.org/10.3390/en19010111

Chicago/Turabian StyleKumar, Akash, Nijanth Kothandapani, Sai Tatapudi, Sagar Bhoite, and GovindaSamy TamizhMani. 2026. "Height-Dependent Inter-Array Temperature Difference and Position-Dependent Intra-Array Temperature Gradient" Energies 19, no. 1: 111. https://doi.org/10.3390/en19010111

APA StyleKumar, A., Kothandapani, N., Tatapudi, S., Bhoite, S., & TamizhMani, G. (2026). Height-Dependent Inter-Array Temperature Difference and Position-Dependent Intra-Array Temperature Gradient. Energies, 19(1), 111. https://doi.org/10.3390/en19010111