Optimizing Solar-Powered EV Charging: A Techno-Economic Assessment Using Horse Herd Optimization

Abstract

1. Introduction

- Develop an optimization framework that determines the best locations for residential, commercial, and industrial EV charging infrastructure based on power loss minimization in the distribution systems.

- Develop an optimization framework to determine the optimal size of rooftop solar PV systems for integration into residential and commercial parking lots.

- In the literature, many algorithms such as PSO and GA have been applied to solve the above optimization problems. In this paper, HHO has been explored to solve the optimization problem.

- Carry out a thorough cost–benefit analysis of the commercial EV parking lot in order to maximize the profit of the parking lot owner.

2. Problem Overview and Formulation

- Proposed a framework to determine optimal locations where I-FCS, CPL, and RPL should be placed to minimize losses;

- Developed HHO to solve the proposed optimization problem;

- Provided the energy, economic, and environmental benefits of integrating PV with EVs in the distribution system.

2.1. Objective Function

2.2. Constraints

2.3. Solar Rooftop Photovoltaic System

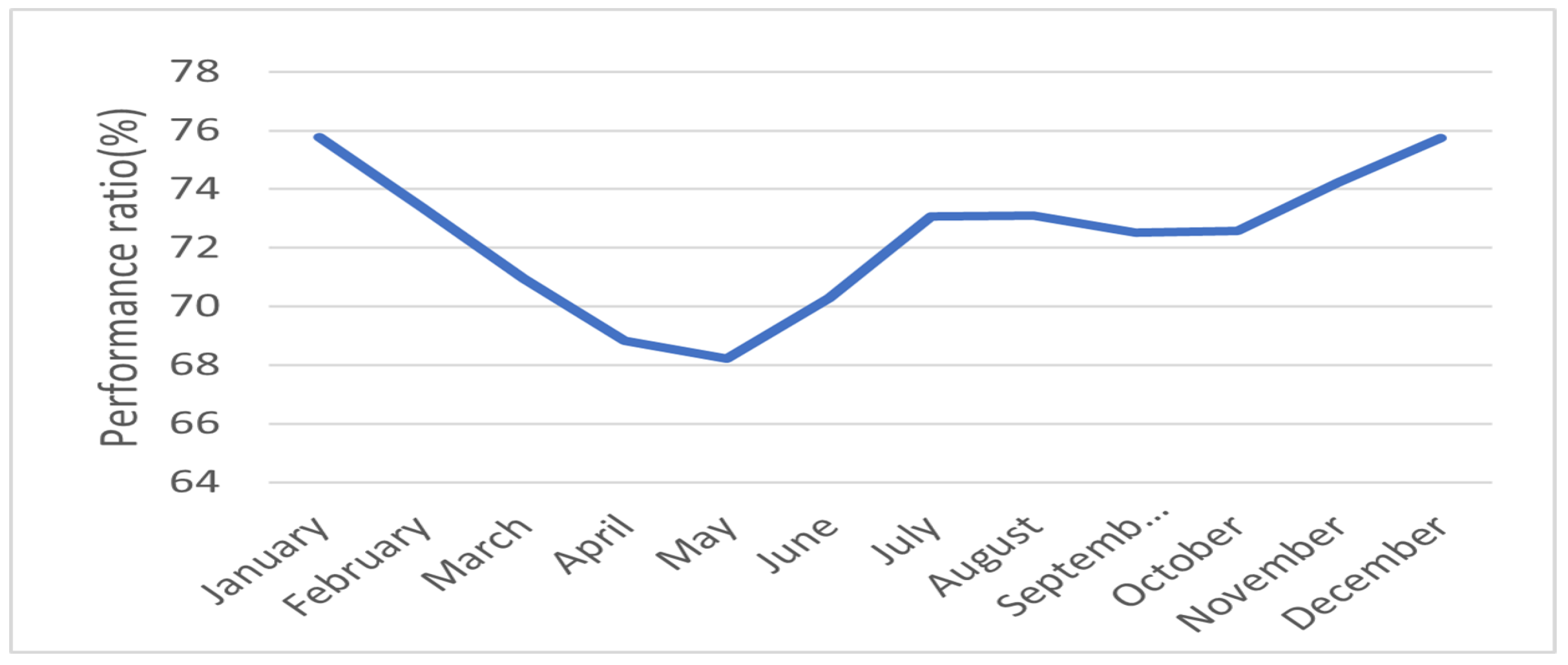

2.3.1. Energy Performance

- (i)

- Performance ratio (PR)

- (ii)

- Energy density ()

- (iii)

- Energy payback time (EPBT)

- (iv)

- Energy return on energy invested (EROI)

2.3.2. Economic Performance

- (i)

- Cost of electricity (COE)

- (ii)

- Payback period (PBP)

2.3.3. Environmental Performance

- (i)

- Carbon footprint emission ()

- (ii)

- Carbon footprint mitigation ()

2.4. Mathematical Modeling of Cost–Benefit Analysis

2.4.1. EV Charging

2.4.2. Cost–Benefit Analysis

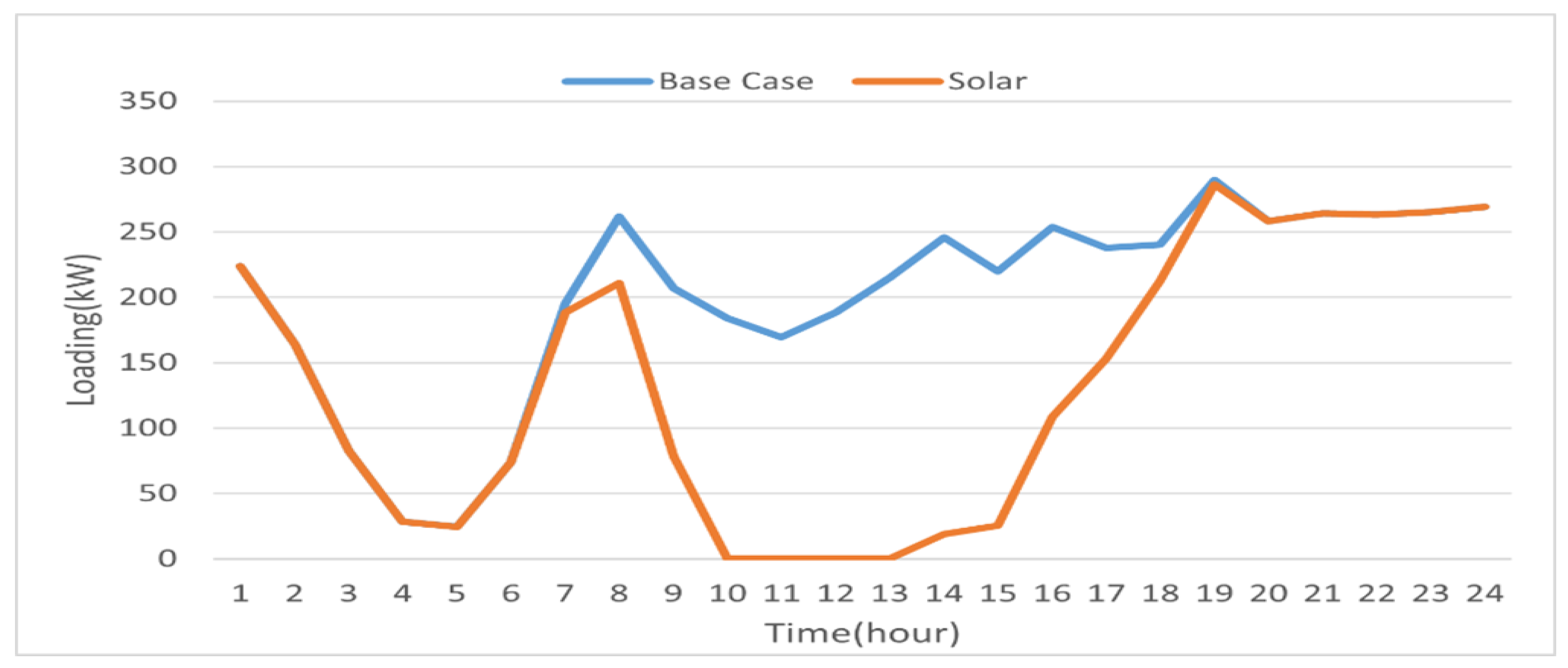

2.5. Scheduling of Vehicles

- : indicator for high RTP at time t;

- : electricity price at time t;

- : peak electricity price over the scheduling horizon;

- : indicates a high RTP zone;

- : indicates a low RTP zone.

Constraints

- Charging or discharging of an EV should be in between arrival and departure time of that vehicle.

- The SOC of an EV at any instant neither goes below the minimum SOC nor exceeds the required SOC value.

- The charging rate of a battery at any instant should not exceed the charger rating.

- The utilized solar power at any instant should not exceed the solar generation at that instant.

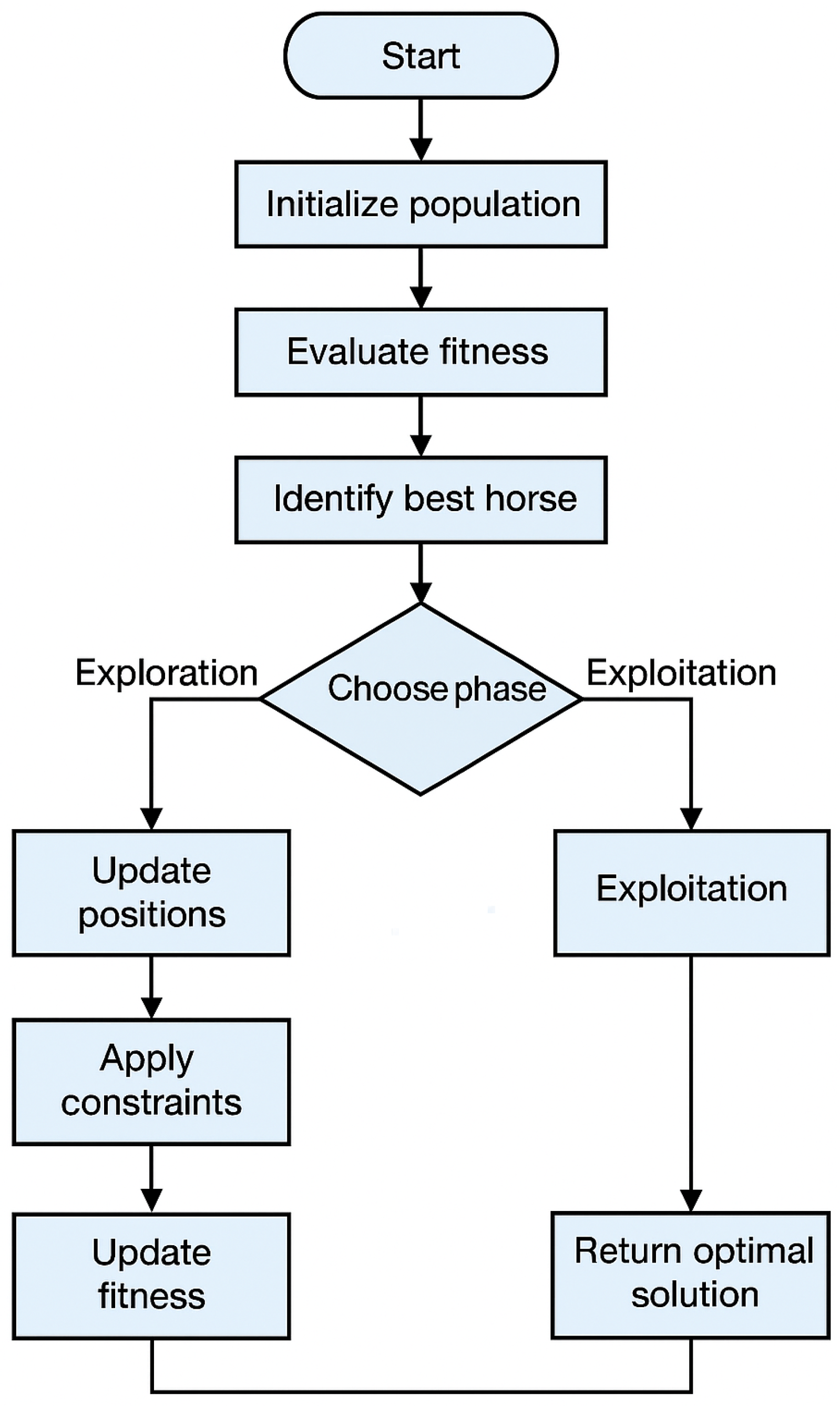

3. Methodology

- Horse Herd Optimization (HHO)

- Algorithm Summary

- Initialize the positions of horses randomly.

- Evaluate fitness for all horses.

- Repeat until termination:

- Apply exploration or exploitation based on iteration progress.

- Update positions using herd dynamics.

- Evaluate fitness and update .

- Return as the optimal solution.

3.1. Initialization

3.2. Fitness Evaluation

3.3. Exploration Phase

- and are random positions of other horses in the herd;

- and are random variables between .

3.4. Exploitation Phase

- s is a scaling factor that decreases over iterations;

- is a small random value to avoid local optima.

3.5. Herd Dynamics

- are weight factors

- is a perturbation caused by neighboring horses.

3.6. Boundary Handling

3.7. Termination Criteria

- A predefined maximum number of iterations is reached;

- The fitness reaches an acceptable error threshold.

4. Case Study and Results

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclatures

| Index | Definition |

| PV system’s annual energy generation (kWh) | |

| Total area of array (m2) | |

| Embodied energy (kWh) | |

| C | Capital cost (Rs.) |

| Maintenance and repair cost (Rs.) | |

| Replacement cost (Rs.) | |

| Salvage cost (Rs.) | |

| M | The SPV system’s average yearly maintenance and repair costs |

| Replacement cost of PCU at 15 years’ interval | |

| Capital cost | |

| Cost of grid electricity (INR/kWh) | |

| Energy required to charge the battery to desired SOC | |

| Battery capacity of the vehicle | |

| Required SOC of EV battery | |

| Current SOC of EV battery | |

| Total energy required for charging all the vehicles | |

| Energy available for discharging scenario | |

| Minimum SOC limit that the battery can discharge | |

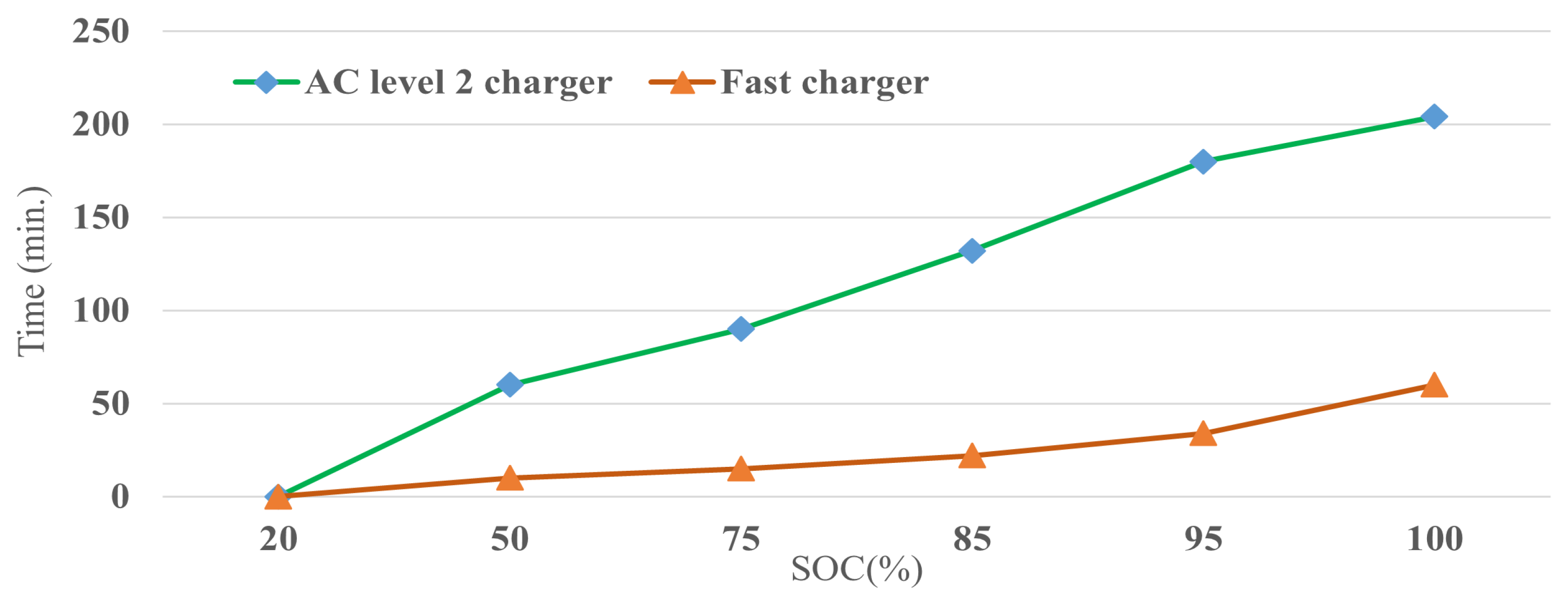

| Charging time | |

| Charging power | |

| Loading by the vehicle | |

| Battery capacity of the vehicle | |

| Cost of charging before implying solar (USD/day) | |

| Energy extracted from grid before implying solar (kWh/day) | |

| Real-time price at hour (USD/kWh) | |

| Cost of charging after implying solar (USD/day) | |

| Energy extracted from grid after implying solar (kWh/day) | |

| Cost of generating solar power (USD/day) | |

| Arrival time of the vehicle | |

| Charging duration of the vehicle | |

| Departure time of the vehicle | |

| SOC of the vehicle at any t instant | |

| Charging rate of the battery at any t instant | |

| Maximum charging rate of the charger at any t instant | |

| Solar energy utilization at any t instant | |

| Maximum solar energy available at any t instant |

List of Acronyms

| Acronym | Definition |

| RPL | Residential Parking Lot |

| CPL | Commercial Parking Lot |

| I-FCS | Industrial Fast Charging Station |

| SPV | Solar Photovoltaic |

| EV | Electric Vehicle |

| PL | Parking Lot |

| PV | Photovoltaic |

| HHO | Horse Herd Optimization |

| SOC | State of Charge |

| RTP | Real-Time Pricing |

| PR | Performance Ratio |

| EPBT | Energy Payback Time |

| COE | Cost of Electricity |

| LCC | Life-Cycle Cost |

| PCU | Power Conditioning Unit |

| CFe | Carbon Footprint Emission |

| CFm | Carbon Footprint Mitigation |

Appendix A. Sensitivity of HHO Parameter

| Population Size | Max Iterations | Best Fitness (MW) | Mean Fitness (MW) | Std. Dev. (MW) | CPU Time (s) |

|---|---|---|---|---|---|

| 20 | 100 | 2.6554 | 2.6618 | 0.0072 | 15.42 |

| 30 (baseline) | 100 | 2.6518 | 2.6545 | 0.0048 | 20.76 |

| 40 | 100 | 2.6515 | 2.6539 | 0.0045 | 26.94 |

| 30 | 80 | 2.6521 | 2.6553 | 0.0051 | 17.10 |

| 30 | 120 | 2.6517 | 2.6543 | 0.0048 | 24.92 |

| 30 | 150 | 2.6517 | 2.6542 | 0.0047 | 30.31 |

References

- Oruganti, K.S.P.; Vaithilingam, C.A.; Rajendran, G.; Ramasamy, A. Cost-benefit analysis of sustainable solar-powered workplace electric vehicle charging station. In Theoretical, Modelling and Numerical Simulations Toward Industry 4.0; Springer: Singapore, 2020; pp. 71–86. [Google Scholar]

- Deshmukh, S.S.; Pearce, J.M. Electric vehicle charging potential from retail parking lot solar photovoltaic awnings. Renew. Energy 2021, 169, 608–617. [Google Scholar] [CrossRef]

- Li, Y.; Pei, W.; Zhang, Q.; Xu, D.; Ma, H. Optimal layout of electric vehicle charging station locations considering dynamic charging demand. Electronics 2023, 12, 1818. [Google Scholar] [CrossRef]

- Altaf, M.; Yousif, M.; Ijaz, H.; Rashid, M.; Abbas, N.; Khan, M.A.; Waseem, M.; Saleh, A.M. PSO-based optimal placement of electric vehicle charging stations in a distribution network in smart grid environment incorporating backward forward sweep method. IET Renew. Power Gener. 2024, 18, 3173–3187. [Google Scholar] [CrossRef]

- Asghari Rad, H.; Jafari-Nokandi, M.; Hosseini, S.M. Optimal Allocation of Plug-in Electric Vehicle Parking Lots for Maximum Serviceability and Profit in the coupled distribution and transportation networks. Sci. Iran. 2024, 31, 1178–1196. [Google Scholar] [CrossRef]

- Babu, K.V.S.M.; Chakraborty, P.; Pal, M. Planning of fast charging infrastructure for electric vehicles in a distribution system and prediction of dynamic price. Int. J. Electr. Power Energy Syst. 2024, 155, 109502. [Google Scholar]

- Prajapati, S.; Fernandez, E. Solar PV parking lots to maximize charge operator profit for EV charging with minimum grid power purchase. Energy Sources Part A Recover. Util. Environ. Eff. 2025, 47, 3319–3329. [Google Scholar] [CrossRef]

- Mudgal, Y.; Tiwari, R. Residential Parking Lot Pricing Strategy Considering Scheduling of Electric Vehicles. J. Inst. Eng. (India) Ser. 2024, 106, 1129–1141. [Google Scholar] [CrossRef]

- Baherifard, M.A.; Kazemzadeh, R.; Yazdankhah, A.S.; Marzband, M. Intelligent charging planning for electric vehicle commercial parking lots and its impact on distribution network’s imbalance indices. Sustain. Energy Grids Netw. 2022, 30, 100620. [Google Scholar] [CrossRef]

- Nafeh, A.E.S.A.; Omran, A.E.F.A.; Elkholy, A.; Yousef, H.M. Optimal economical sizing of a PV-battery grid-connected system for fast charging station of electric vehicles using modified snake optimization algorithm. Results Eng. 2024, 21, 101965. [Google Scholar] [CrossRef]

- Khalid, M.; Thakur, J.; Bhagavathy, S.M.; Topel, M. Impact of public and residential smart EV charging on distribution power grid equipped with storage. Sustain. Cities Soc. 2024, 104, 105272. [Google Scholar] [CrossRef]

- Citroni, R.; Mangini, F.; Frezza, F. Efficient integration of ultra-low power techniques and energy harvesting in self-sufficient devices: A comprehensive overview of current progress and future directions. Sensors 2024, 24, 4471. [Google Scholar] [CrossRef] [PubMed]

- Junid, A.; Yap, E.H.; Ng, P.K. Electric vehicle charging at telco base station and bidirectional charging at hillslope descent technical-commercial cost-benefit study and scheduling-reservation system. In Proceedings of the 2018 International Conference on Smart Grid and Clean Energy Technologies (ICSGCE), Kajang, Malaysia, 29 May–1 June 2018; pp. 137–144. [Google Scholar]

- Varone, A.; Heilmann, Z.; Porruvecchio, G.; Romanino, A. Solar parking lot management: An IoT platform for smart charging EV fleets, using real-time data and production forecasts. Renew. Sustain. Energy Rev. 2024, 189, 113845. [Google Scholar] [CrossRef]

- Sharma, S.; Niazi, K.; Verma, K.; Rawat, T. Coordination of different DGs, BESS and demand response for multi-objective optimization of distribution network with special reference to Indian power sector. Int. J. Electr. Power Energy Syst. 2020, 121, 106074. [Google Scholar] [CrossRef]

- Yadav, S.K.; Bajpai, U. Performance evaluation of a rooftop solar photovoltaic power plant in Northern India. Energy Sustain. Dev. 2018, 43, 130–138. [Google Scholar] [CrossRef]

- Quansah, D.A.; Adaramola, M.S.; Appiah, G.K.; Edwin, I.A. Performance analysis of different grid-connected solar photovoltaic (PV) system technologies with combined capacity of 20 kW located in humid tropical climate. Int. J. Hydrogen Energy 2017, 42, 4626–4635. [Google Scholar] [CrossRef]

- Jordan, D.C.; Kurtz, S.R. Photovoltaic degradation rates—An analytical review. Prog. Photovoltaics Res. Appl. 2013, 21, 12–29. [Google Scholar] [CrossRef]

- Government of India. CEA Annual Report 2022–23. 2023. Available online: https://cea.nic.in/annual-report/?lang=en (accessed on 15 May 2025).

- Kanwar, N.; Gupta, N.; Niazi, K.; Swarnkar, A. Optimal distributed generation allocation in radial distribution systems considering customer-wise dedicated feeders and load patterns. J. Mod. Power Syst. Clean Energy 2015, 3, 475–484. [Google Scholar] [CrossRef]

- Guner, S.; Ozdemir, A. Stochastic energy storage capacity model of EV parking lots. IET Gener. Transm. Distrib. 2017, 11, 1754–1761. [Google Scholar] [CrossRef]

- Anggraini, D.; Amelin, M.; Söder, L. Electric Vehicle Charging Considering Grid Limitation in Residential Areas. In Proceedings of the 2024 IEEE Transportation Electrification Conference and Expo (ITEC), Chicago, IL, USA, 19–21 June 2024; pp. 1–6. [Google Scholar]

- Zhang, Y.; You, P.; Cai, L. Optimal charging scheduling by pricing for EV charging station with dual charging modes. IEEE Trans. Intell. Transp. Syst. 2018, 20, 3386–3396. [Google Scholar] [CrossRef]

- Vashisth, S.; Agrawal, P.K.; Gupta, N.; Niazi, K.; Swarnkar, A. Multi-stage planning of fast charging stations for PEVs using traffic-based approach. Sustain. Energy, Grids Netw. 2022, 30, 100662. [Google Scholar] [CrossRef]

- NREL. NREL Solar Calculator. 2025. Available online: https://pvwatts.nrel.gov/ (accessed on 1 May 2025).

- Sharma, B.; Gupta, N.; Niazi, K.; Swarnkar, A. Estimating impact of price-based demand response in contemporary distribution systems. Int. J. Electr. Power Energy Syst. 2022, 135, 107549. [Google Scholar] [CrossRef]

| Particular | Specification |

|---|---|

| Location | Jaipur |

| Latitude | 26.95 |

| Longitude | 75.85 |

| DC System Size (kW) | 400 |

| Module Type | Standard |

| Array Type | Fixed |

| Tilt Angle | |

| Azimuth Angle | |

| System Losses (%) | 14.08 |

| DC-to-AC Size Ratio | 1.2 |

| Type of Inverter | Grid-tied string inverter |

| Inverter Efficiency (%) | 96 |

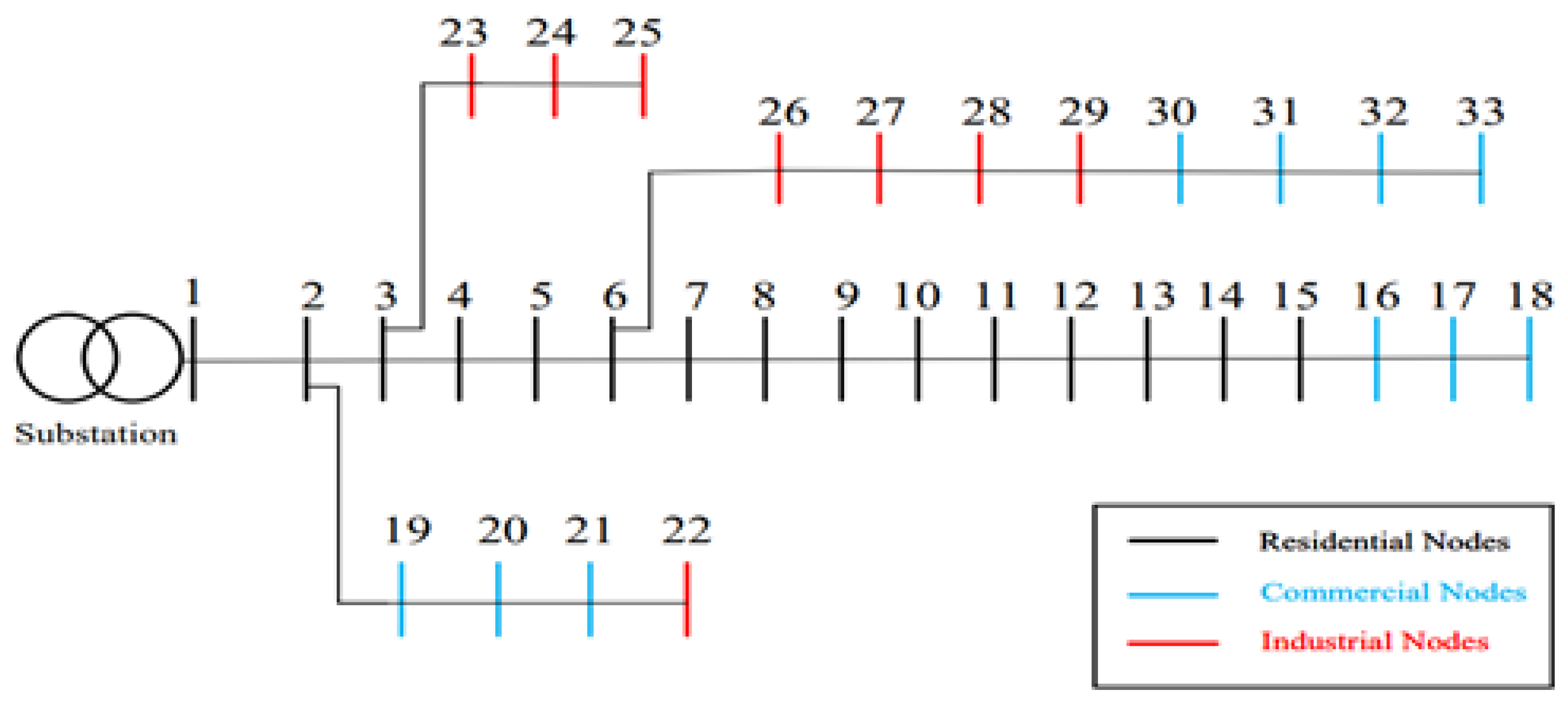

| Class | Allocation Demand (%) | Allocation Demand (kW) | Allocated Nodes |

|---|---|---|---|

| R | 34.86 | 1295 | 1 to 15 |

| C | 29.60 | 1100 | 16 to 21, 30 to 33 |

| I | 35.54 | 1320 | 22 to 29 |

| Parameters | Value |

|---|---|

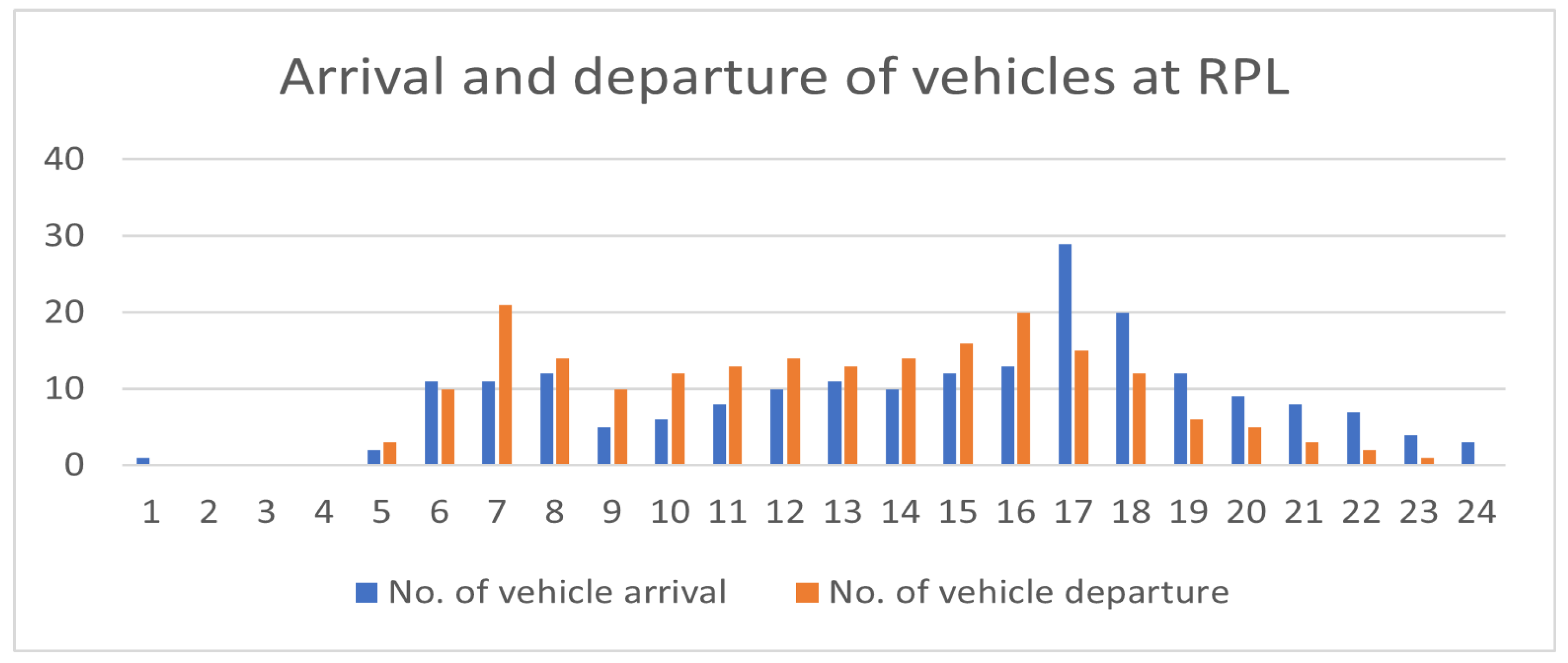

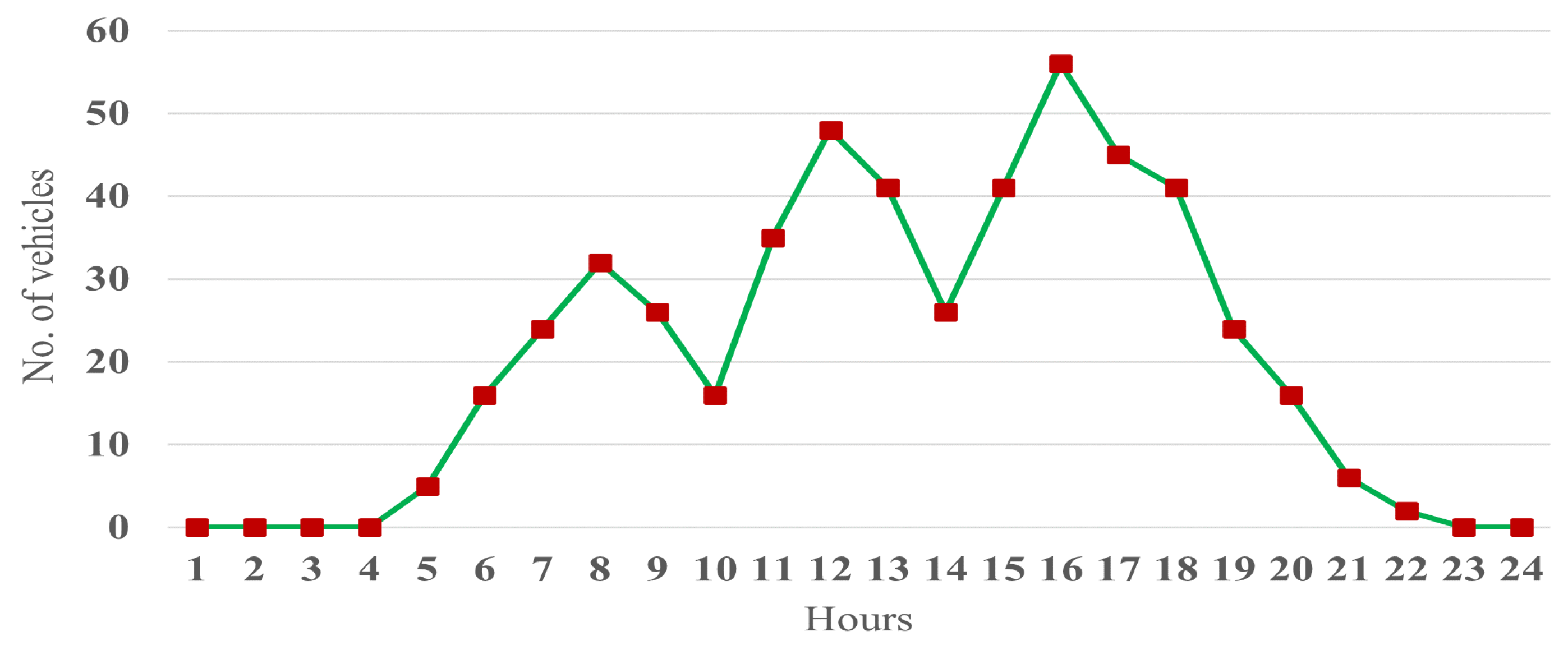

| Capacity of RPL/CPL | 200 |

| No. of vehicles at CPL | 178 |

| No. of vehicles at RPL | 204 |

| No. of vehicles at IFCS | 500 |

| No. of chargers at CPL | 35 |

| No. of chargers at RPL | 30 |

| No. of chargers at IFCS | 10 |

| Initial SOC range of vehicles at CPL | 20–50 |

| Final SOC range of vehicles at CPL | 85–95 |

| Initial SOC range of vehicles at RPL | 20–40 |

| Final SOC range of vehicles at RPL | 85–95 |

| Initial SOC range of vehicles at IFCS | 20–50 |

| Final SOC range of vehicles at IFCS | 75–85 |

| Battery capacity of vehicles at RPL | 24–40 |

| Battery capacity of vehicles at CPL | 24/30 |

| Battery capacity of vehicles at IFCS | 30/50 |

| Load | Optimum Location | Power Loss | Minimum Voltage |

|---|---|---|---|

| Base load | - | 2.38 MW | 0.9131 |

| Case study | 2, 19, 22 | 2.65 MW | 0.9125 |

| 2* Case study | 2, 19, 23 | 3.26 MW | 0.9120 |

| 3* Case study | 2, 19, 23 | 3.88 MW | 0.9110 |

| 4* Case study | 2, 19, 23 | 4.64 MW | 0.9109 |

| Optimization Method | Worst Fitness (MW) | Best Fitness (MW) | Mean Fitness | CPU Time (s) | Standard Deviation |

|---|---|---|---|---|---|

| GA | 2.6883 | 2.6746 | 2.6830 | 36.53 | 0.0054 |

| PSO | 2.6803 | 2.6659 | 2.6721 | 25.31 | 0.0053 |

| HHO | 2.6663 | 2.6518 | 2.6545 | 20.76 | 0.0048 |

| Particular | Value |

|---|---|

| Capital cost (Rs.) | 24,669,090 |

| Maintenance and repair cost (Rs.) | 3,791,716 |

| Replacement cost (Rs.) | 2,126,969 |

| Salvage cost (Rs.) | 4,118,837 |

| Life-cycle cost (Rs.) | 26,468,938 |

| Cost of electricity (Rs.⁄kWh) | 1.45 |

| System cost (Rs.⁄) | 61.67 |

| Scenario → Cost ↓ | Before Solar | After Solar | After Solar + Scheduling |

|---|---|---|---|

| Power purchased from grid (USD/day) | 218.52 | 75.38 | 70.43 |

| Solar generation (USD/day) | - | 30.34 | 30.34 |

| Total purchasing cost (USD/day) | 218.52 | 105.72 | 100.77 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chopra, K.; Shah, M.K.; Niazi, K.R.; Sharma, G.; Bokoro, P.N. Optimizing Solar-Powered EV Charging: A Techno-Economic Assessment Using Horse Herd Optimization. Energies 2025, 18, 4556. https://doi.org/10.3390/en18174556

Chopra K, Shah MK, Niazi KR, Sharma G, Bokoro PN. Optimizing Solar-Powered EV Charging: A Techno-Economic Assessment Using Horse Herd Optimization. Energies. 2025; 18(17):4556. https://doi.org/10.3390/en18174556

Chicago/Turabian StyleChopra, Krishan, M. K. Shah, K. R. Niazi, Gulshan Sharma, and Pitshou N. Bokoro. 2025. "Optimizing Solar-Powered EV Charging: A Techno-Economic Assessment Using Horse Herd Optimization" Energies 18, no. 17: 4556. https://doi.org/10.3390/en18174556

APA StyleChopra, K., Shah, M. K., Niazi, K. R., Sharma, G., & Bokoro, P. N. (2025). Optimizing Solar-Powered EV Charging: A Techno-Economic Assessment Using Horse Herd Optimization. Energies, 18(17), 4556. https://doi.org/10.3390/en18174556