1. Introduction

As solar energy is used for thermal processes, mainly the heating of fluids, the integration of photovoltaic (PV) systems with water heating technologies has emerged as a promising solution for sustainable energy production, particularly for residential and industrial applications.

The main application of solar energy is for use in water heating systems, using active and passive technologies [

1], phase change materials [

2,

3,

4,

5], and nanofluids [

6,

7,

8], which are applied in different solar collectors [

9]. Some studies have investigated numerical simulations [

10] and artificial intelligence [

11] in relation to such systems.

The application of PV-integrated energy for water heating is a central theme in recent research. Kotte et al. [

12] investigated the use of hot water storage systems as a method for storing excess solar energy at the household level. They focused on converting excess solar electricity into heat, which can then be stored in hot water tanks for later use. This “power-to-heat” approach allows homes to make effective use of excess solar energy that would otherwise be wasted, especially during sunny periods when solar generation exceeds household demand. The system works through the use of electric heating elements or heat pumps to convert electricity from solar panels into thermal energy, which is then stored in water tanks. Xiao et al. [

13] focused on the performance of PV systems that convert unused electricity into thermal energy for water heating. They analyzed the efficiency of converting excess PV-generated electricity into usable thermal energy in areas rich in solar resources. Yildiz et al. [

14] focused on the analysis of electricity consumption and thermal storage in domestic electric water heating systems to utilize excess PV generation. Their results indicated that thermal storage technologies integrated with PV systems can store excess electricity during peak solar hours and use it later for water heating, improving system efficiency and reducing grid dependency. In the search for more efficient thermal storage solutions. Burmester and Seah [

15] developed a control system for a direct current (DC) water heater powered by a PV system. Their primary goal was to maximize the efficiency of converting solar energy into heat through the use of instantaneous control to optimize the performance of the water heater based on the varying availability of solar energy. In photovoltaic systems, one of the challenges is the fluctuation in energy production due to changing weather conditions. The article proposed an instantaneous control approach that adjusts the power supplied to the water heater in real time, ensuring that the maximum amount of available solar energy is utilized while minimizing the need for additional power sources (e.g., grid electricity). Hachchadi et al. [

16] focused on experimental optimization of the heating element in a direct-coupled PV water heating system. This type of system uses solar energy captured by PV panels to efficiently heat water without the need for an inverter or additional storage system. The article explored various configurations and strategies to improve the performance of the solar water heater, specifically through optimizing the heating element that converts the electricity generated by the solar panels into heat. Experiments were conducted to analyze variables such as heating element power, conversion efficiency, and the effects of different environmental conditions (e.g., solar irradiance and ambient temperature) on system performance.

Hybrid systems consider the combination of photovoltaic systems with other water heating technologies. Buonomano et al. [

17] introduced an innovative approach to solar water heating system design by combining PV technology with advanced thermal storage. The system is based on a photovoltaic–thermal (PVT) collector that incorporates a planar liquid vapor thermal diode to optimize heat transfer and improve the overall performance of the water heating system. The system not only generates electricity from solar radiation but also uses the residual heat to heat water, thus improving energy efficiency. Mi et al. [

18] studied the optimal allocation of energy resources in integrated PVT heat pump systems for domestic hot water. Their optimization approach, using advanced algorithms, ensures that the PV array and heat pump operate at peak efficiency, resulting in significant energy savings. Tomar et al. [

19] studied the performance of a prototype PV/water heat pipe system embedded in an aluminum curtain wall for water heating. Their results showed that this configuration improved heat transfer efficiency and reduced energy consumption, making it a promising option for integrating solar heating into building facades. Kashan et al. [

20] investigated the performance of an innovative system combining microchannel solar collectors with a water-to-water heat pump for domestic hot water production in cold climates. They evaluated the efficiency, operational reliability, and suitability of the system compared to conventional solar thermal and photovoltaic systems. Martin-Escudero et al. [

21] presented a solar water heating system using a photovoltaic array coupled with a heat pump. Their research highlighted the benefits of this hybrid system, showing that the integration of a heat pump improves the overall efficiency and reliability of water heating. Clift and Suehrcke [

22] proposed a method for optimizing the control of PV-powered electric storage and heat pump water heaters. Their study contributes to the optimization of energy management in hybrid systems through focusing on the control strategies for regulating the interaction between PV power generation, electric storage, and heat pump technology. Simko et al. [

23] examined how the integration of solar PV systems with heat pumps and energy storage can improve the energy efficiency and sustainability of Australian homes. Solar PV is highlighted as an important renewable energy source, particularly given Australia’s abundant solar resources. When combined with heat pumps, which are highly efficient for heating and cooling, households can significantly reduce electricity consumption and carbon emissions. With energy storage playing a key role in increasing the efficiency of PV systems, researchers are investigating advanced storage technologies for hybrid PV systems. Sporleder et al. [

24] compared solar thermal and PV systems with heat pumps for seasonal thermal storage in district heating networks. They concluded that while PV systems with heat pumps can provide better efficiency for short-term heating needs, solar thermal systems are more suitable for long-term storage in district heating applications. Lecuona-Neumann et al. [

25] explored the design and performance of a simplified solar-powered cooking system that operates without the need for electronic components or batteries. This system directly connects PV panels to a heating element to convert solar energy into heat for cooking. The absence of electronics and batteries makes the system cost-effective, durable, and easy to maintain.

A critical area of research in PV-based water heating systems is the technoeconomic and environmental assessment of these technologies. Holland et al. [

26] explored the integration of peer-to-peer (P2P) energy trading with demand response (DR) strategies to optimize the operation of smart residential electric storage water heaters. Their goal was to improve energy efficiency and reduce costs by enabling households to trade excess electricity generated from renewable sources, such as solar panels, with other consumers within a local grid. Through the use of smart water heaters equipped with advanced control systems, households can schedule and shift their heating operations to off-peak hours or when there is excess renewable energy on the grid, reducing overall demand on the grid and lowering electricity costs. Hachchadi et al. [

27] conducted a comprehensive analysis comparing the environmental impacts and cost-effectiveness of PV and conventional solar hot water systems in cold climates. They found that while conventional solar thermal systems offer better thermal efficiency, PV-based systems outperform them in terms of operating costs and ease of integration with other renewable energy sources. Valencia-Cañola et al. [

28] focused on a direct expansion solar heat pump water heater powered by a PV array and the electric grid in Medellín, Colombia. They evaluated the thermoeconomic performance of this system and found that the combination of PV with heat pumps and grid electricity provides a cost-effective solution for domestic hot water, especially in areas with variable solar radiation. Del Alma et al. [

29] investigated the feasibility of integrating PV panels with water flow glazing (WFG) technology to achieve zero-energy buildings. The study focused on assessing the energy efficiency and economic viability of the system through simulations and experimental testing on a real-world prototype. The work of Marańda et al. [

30] on parametric studies of PV energy use in residential microgrids with water heating further highlighted the growing interest in optimizing energy consumption in microgrid environments. They found that the use of PV energy in combination with smart grids for water heating could significantly reduce the consumption of electricity and improve the sustainability of residential energy systems.

The integration of multiple renewable energy sources—such as wind, solar, and hydrogen—with water heating systems is an emerging trend. Tukenmez et al. [

31] investigated a hybrid system that combines PV and wind energy to support clean hydrogen production and provide electricity and hot water for industrial processes. The system’s ability to operate under varying environmental conditions offers significant benefits to energy-intensive sectors through ensuring a consistent supply of energy and hot water. Pezo et al. [

32] explored the use of net zero-energy building technologies, including photovoltaic panels, organic Rankine cycles, and reversible heat pumps for hot water heating. Their case study, conducted in Chile, demonstrated that the combination of these technologies in a mid-rise residential building can achieve significant energy savings and provide a sustainable solution for residential hot water needs. Zhang et al. [

33] investigated the use of phase change materials (PCMs) in hybrid PV systems for near-zero energy buildings. The integration of PCMs with PV-powered water heating systems enhances energy storage, allowing for better management of heating demand during periods of low solar irradiation. Their optimization of operational strategies demonstrated that PCM-based systems can significantly improve the energy efficiency of residential and commercial buildings. Marańda et al. [

30] conducted a parametric study on the use of PV energy in residential microgrids for water heating. The study examined how PV-generated electricity can be integrated into residential microgrids and highlighted the benefits and challenges of using PV systems for water heating.

Another study in the literature has examined the performance of solar photovoltaic water heating systems with direct coupling to DC resistive heating elements and compared them with solar thermal systems [

34], including an analysis of the electrical resistance of the heating element under different climatic conditions; in particular, the use of maximum power point tracking compared to fixed optimized load resistance increased the annual yield by 20–35%.

The state of the art shows that although significant advances have been made in solar water heating systems based on photovoltaic energy, no studies have been developed to determine the efficiency of these systems applied to water heating in residences. Therefore, the main objective of this research work is to carry out an experimental study of water heating using a solar photovoltaic system in direct current.

2. Materials and Methods

In this study, a prototype DC solar PV water heating system is developed. The main objective is to evaluate the performance of the direct PV power supply (

Figure 1a) compared to the solar PV heating system using an MPPT (

Figure 1b). The first experimental configuration supplies power directly from the solar PV panels and the second configuration uses an electronic maximum power point tracking (MPPT) device.

The photovoltaic array consists of four monocrystalline silicon panels connected in series and facing north at an angle of 25°; we used Amerisolar model AS-6M-370W (Worldwide Energy and Manufacturing USA Co., Ltd., Burlingame, CA, USA), with a maximum power of 370 W, an open circuit voltage of 48 V, a short circuit current of 9.85 A, an operating voltage of 39.4 V, and a maximum current of 9.4 A. The total area of the solar array is 7.88 m2.

The MPPT controller is the SZSSTH brand model SSTH-40A (Shenzhen SSTH Technology Co., Ltd., Shenzhen, China), with a power of 4000 W, a voltage range from 12 V to 96 V, a maximum current of 40 A, and a PV voltage of up to 230 V. MPPT, or maximum power point tracking, is an algorithm that is included in charge controllers used to extract the maximum available power from PV modules under certain conditions [

35].

The heating element is the BKR brand model sg-2503 l152f bkr (S&S Industrial Surplus, Kawkawlin, MI, USA), with a power of 5000 W, voltage of 240 V, and resistance of 12.42 Ohms.

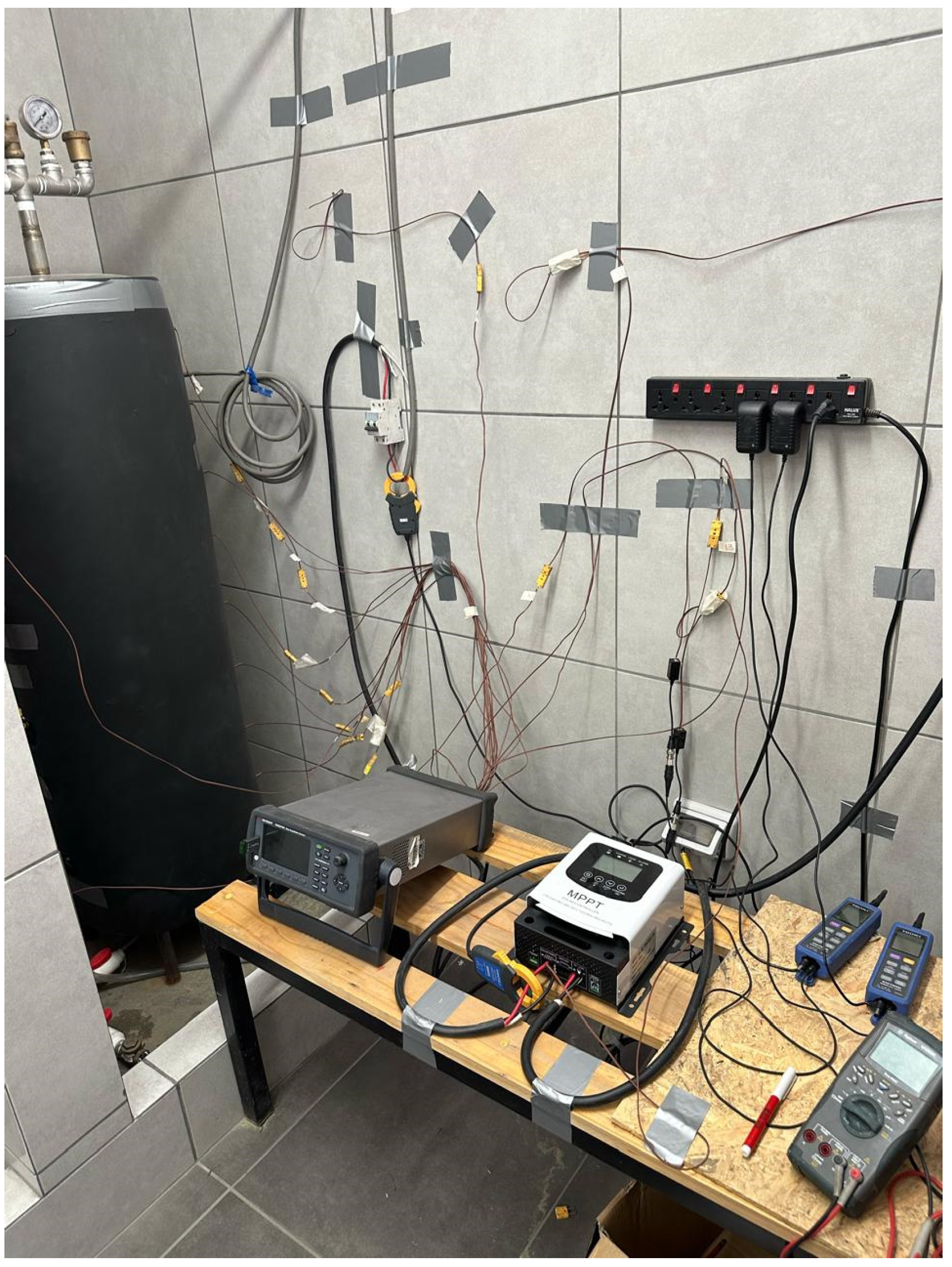

A photograph of the experimental model is shown in

Figure 2.

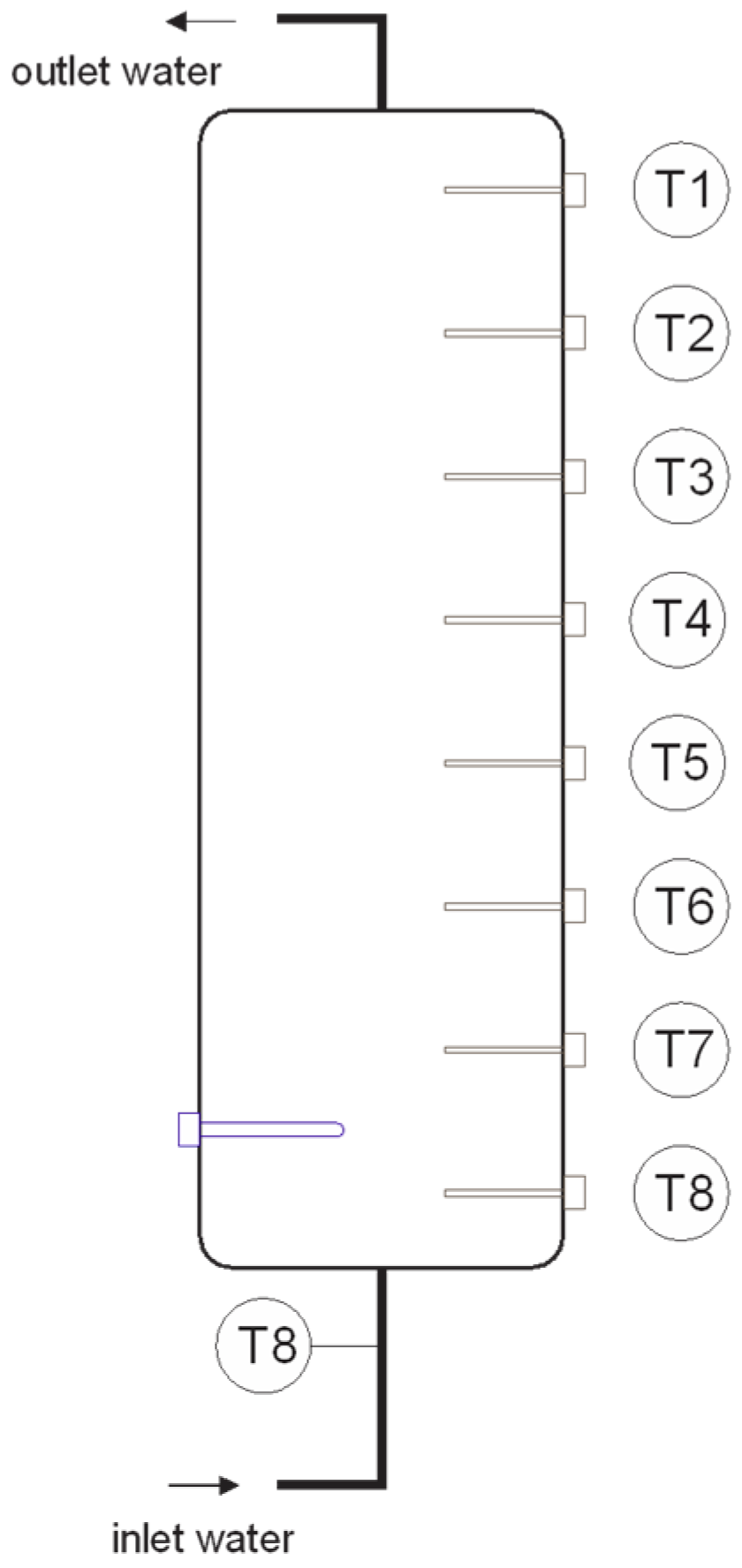

The water tank is a stainless steel cylinder with a diameter of 0.386 m, a height of 1.256 m, and a volume of 147 L, insulated with 25 mm thick elastomeric foam.

Teflon-coated K-type (Chromel/Aumel) thermocouples with a diameter of 1 mm were used for temperature measurement (Omega Engineering, Inc., Norwalk, CT, USA). These sensors are installed inside the tank at positions T1 to T8 and allow for monitoring of the water temperature during the heating process.

For current measurement, a Hioki (Hioki E.E. Corp., Nagano, Japan) CT7731 current sensor was used with a conversion signal of 10 mV/A; this signal was then recorded using the data acquisition system. The DC voltage was measured and recorded directly on the data acquisition system.

An Apogee SP-110 pyranometer (Apogee Instruments, Inc., North Logan, UT, USA) with an output of 0 to 400 mV and a silicon cell photodiode with a sensitivity of 0.2 mV/W m−2 was used to measure solar irradiance. The pyranometer measures global irradiance in the plane of the photovoltaic array.

The data acquisition system was a Keysight (Keysight Technologies, Colorado Springs, CO, USA) model DAQ970A, and the data were recorded to an external USB memory drive. A 20 channel DAQM901A-20 acquisition card was used. The acquisition interval was set to every 10 s.

2.1. Experimental Procedure

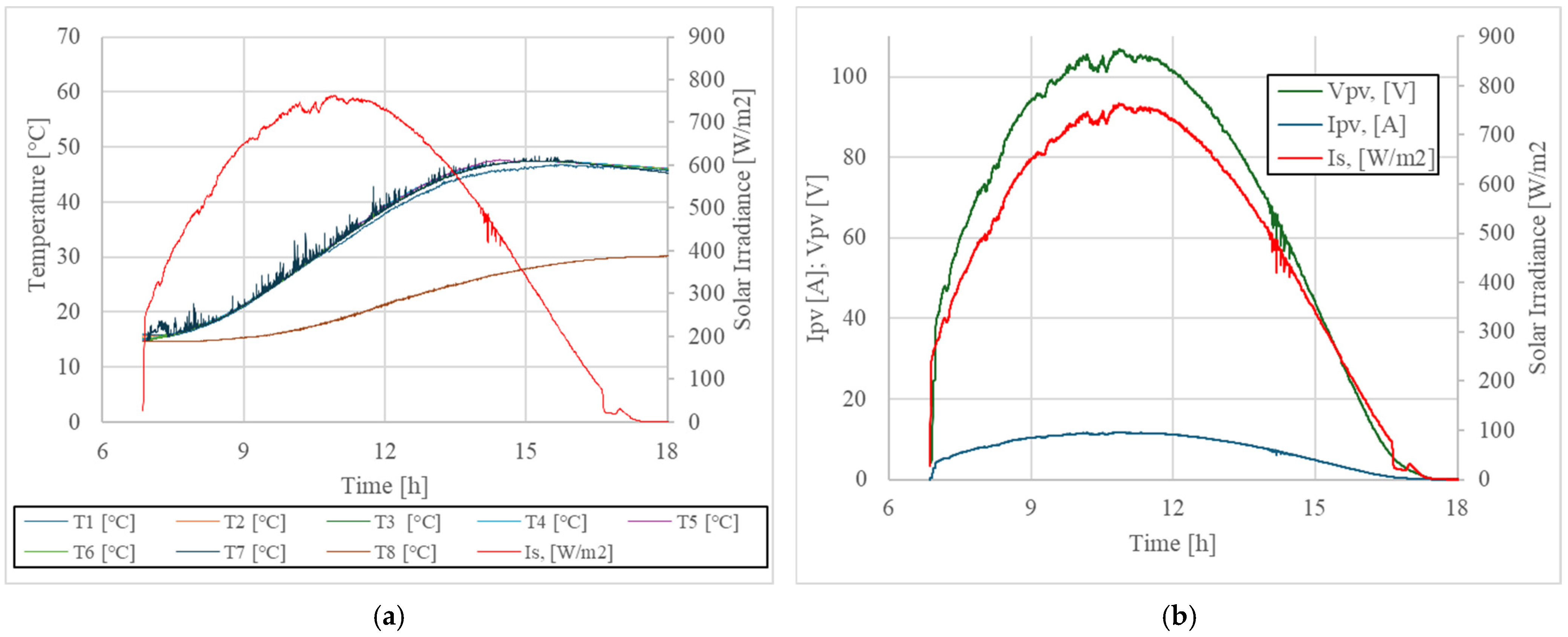

The experiments were conducted between May and August 2023 in the city of Arequipa, Peru (16°24′31.78″ S; 71°32′26.80″), which is located at 2440 m above sea level. This time of year has the lowest solar irradiance and ambient temperature. Each test was repeated at least 5 times to ensure repeatability, starting at a water temperature of 15 °C; the test ended when the water reached 60 °C or when the day ended. The experiment started before sunrise with the water in the tank at the same temperature; then, the thermocouples, electrical sensors, and pyranometer were connected to the data acquisition system. Data acquisition was started to verify that everything was working properly; then, the solar panels were connected to the heating element according to the corresponding experiment (using MPPT or direct). The experiment ended when the water in the tank reached 60 °C or when the end of the afternoon arrived and there was no more solar photovoltaic heating.

2.2. Parameters Studied

The data inputs are water temperature inside the tank, voltage and current at the heating element, voltage and current at the PV panels, voltage and current of the MPPT controller, and solar irradiance. The formulas below correspond to Watt’s law and electric power and to the first law of thermodynamics.

Solar Power:

This is the energy from the Sun received by the PV panels.

where

is the solar power [W];

Is is the solar irradiance [W/m

2]; an

A is the PV array area [m

2].

PV Power:

This is the electrical output of the PV panels.

where

is the PV power [W];

Ipv is the PV current [A]; and

Vpv is the PV voltage [V].

MPPT Power:

This is the electrical power of the output in the MPPT.

where

is the MPPT power [W];

Imppt is the MPPT current [A]; and

Vmppt is the MPPT voltage [V].

Thermal Energy:

This is the thermal energy stored as internal energy in the water inside the tank. The first law of thermodynamics states that the change in the internal energy of a system is equal to the heat exchanged in the system minus the work performed by the system:

where

du is the change in internal energy of the system;

δq is the heat exchanged by the system; and

δw is the work performed by the system.

For a closed system, where the work is zero, and if the process occurs at constant pressure, the following formula can be used:

where Cp is the specific heat at constant pressure and dT is the change in temperature.

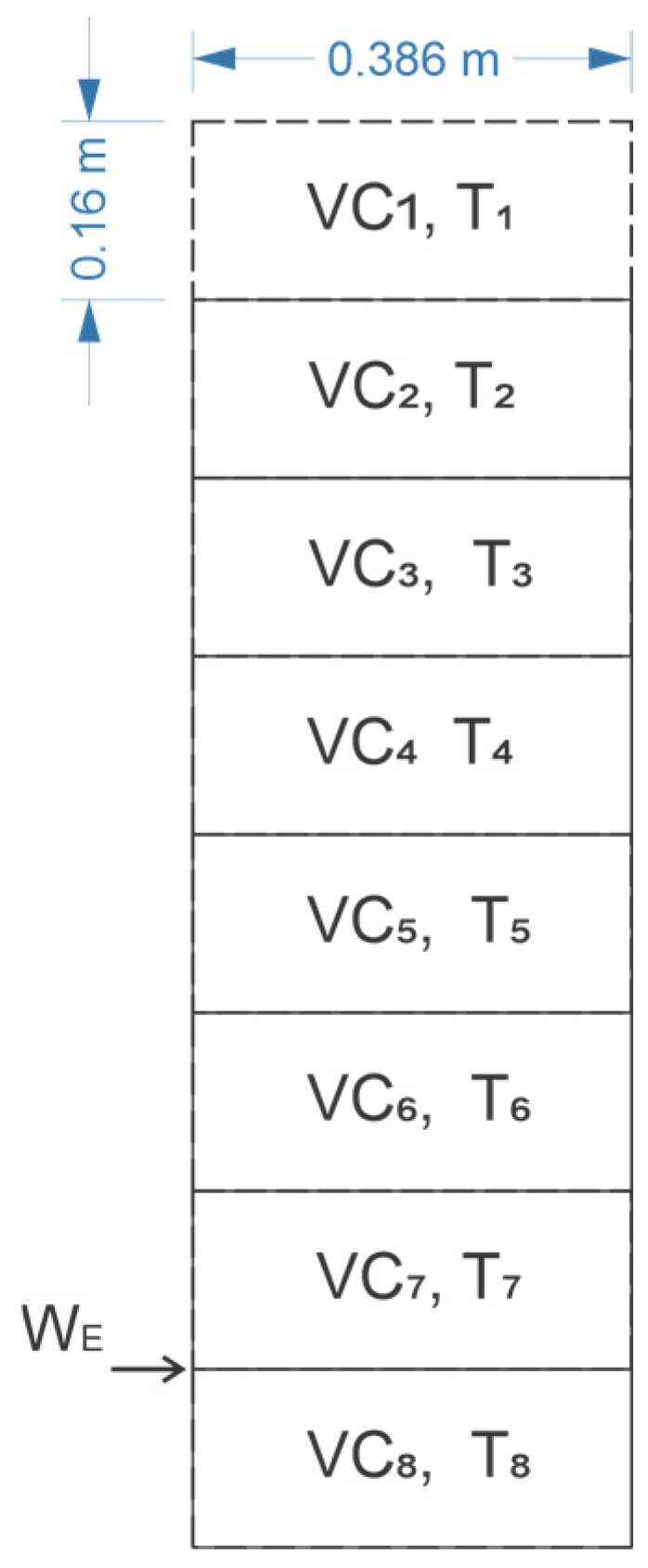

In the water tank (

Figure 3), the temperature during the heating process is known for each control volume Vi. An approximation of T = Tbulk can be used, assuming that the temperature of the entire control volume is constant. In the same figure, W

E is the electrical energy input to the heating element. To achieve the energy balance, the temperatures T

1 to T

8 are determined from the placed thermocouples, each control volume is set according to an equal division of the total volume such that m

i = 19 kg is considered, and the variation in internal energy is calculated independently in each control volume. For this comparative analysis, heat losses are not considered negligible due to the insulation installed. The variation in internal energy with time is considered, i.e., as the water heats up, the internal energy varies, the whole process is transient and evaluated in each control volume, and for each elapsed time interval, the internal energy variations of each control volume are summed. Heat transfer between the control volumes and heat losses through the tank walls were not considered.

For the variation in the internal energy of the control volume (VC), the following formula was applied:

Thermal Energy for the total control volume:

where

Qth is the thermal energy [J];

m is the mass of the control volume [kg];

Cp is the specific heat at constant pressure [J/kg °C];

is the temperature for control volume n and time I; and

is the temperature for control volume n and time i − 1.

Stored internal energy:

where

Qth is the stored thermal energy [J];

is the thermal energy in time i [J]; and

is the thermal energy in time i − 1 [J].

Thermal Power:

where

is the thermal power [W];

Qth is the thermal energy [J]; and

Δt is time [s].

Electrical Energy:

where

E is the electrical energy [J];

P is the power energy [W]; and Δt is time [s].

Accumulated Electrical Energy:

This is the accumulated electrical energy since the start of the test.

where

E is the accumulated electrical energy [J];

is the electrical energy in t [J]; and

is the electrical energy in t − 1 [J].

PV Efficiency:

This is the efficiency of the PV solar panel.

where

is the efficiency of the PV solar panel [W/W];

is the PV power [W]; and

is the solar power [W].

MPPT Efficiency:

This is the efficiency of the MPPT solar panel.

where

is the efficiency of the PV solar panel [W/W];

is the MPPT power [W]; and

is the PV power [W].

Thermal Efficiency:

This is defined for two configurations (with MPPT and with direct PV power supply).

Thermal Efficiency with MPPT:

This is the thermal power divided by the electrical output power of MPPT.

where

is the thermal efficiency with MPPT [W/W];

is the thermal power [W]; and

is the MPPT power [W].

Thermal Efficiency with Direct PV Power Supply:

where

is thermal efficiency with direct PV power supply [W/W];

is thermal power [W]; and

is PV power [W]

Total Efficiency:

This is the total efficiency of the water heating system.

where

is the total efficiency [W/W];

is the thermal power [W]; and

is the solar power [W].

2.3. Uncertainties Studied

The uncertainties studied (

Table 1) were determined with the characteristics of the instrumentation, and in the case of indirect measurements, Moffat’s uncertainty propagation theory was used [

36], i.e.,

where

is the uncertainty of R and

is the uncertainty of the x

n variable.

In the planning of the experimental model, measurement equipment with a low margin of error was selected to obtain relatively low uncertainties that do not affect the calculation of parameters such as power and efficiency. It was observed that in hours of low solar radiation, solar power and thermal power are low, which causes efficiency values that distort the curves. To avoid this phenomenon, a calibration of all the instruments was performed, allowing the presentation of real values in the calculations.

4. Discussion

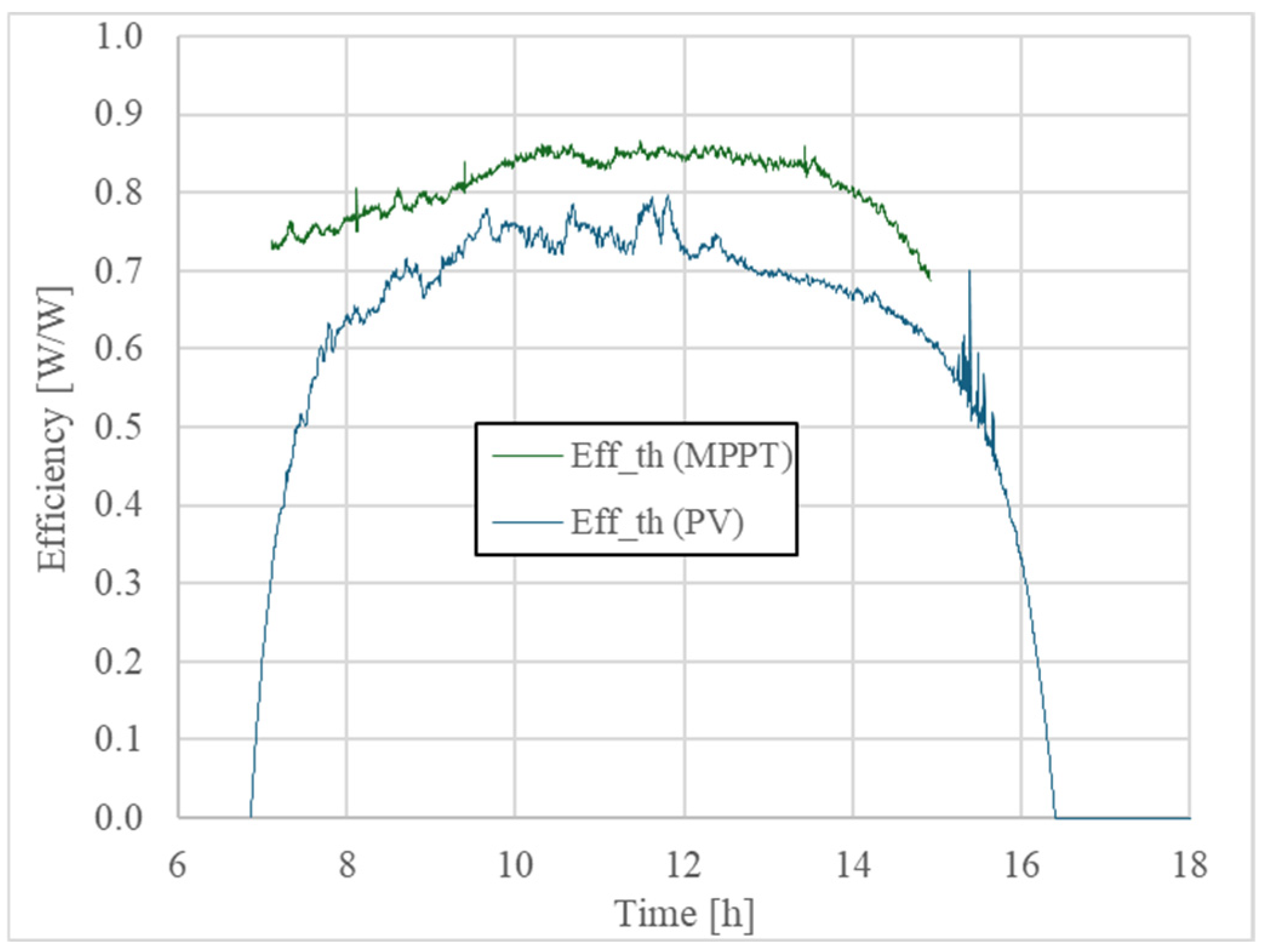

The results of the tests indicate greater efficiencies using the MPPT device, especially in the warm-up time from 20 °C to 60 °C. Next, three important comparisons are made to confirm the information with other reliable sources of information.

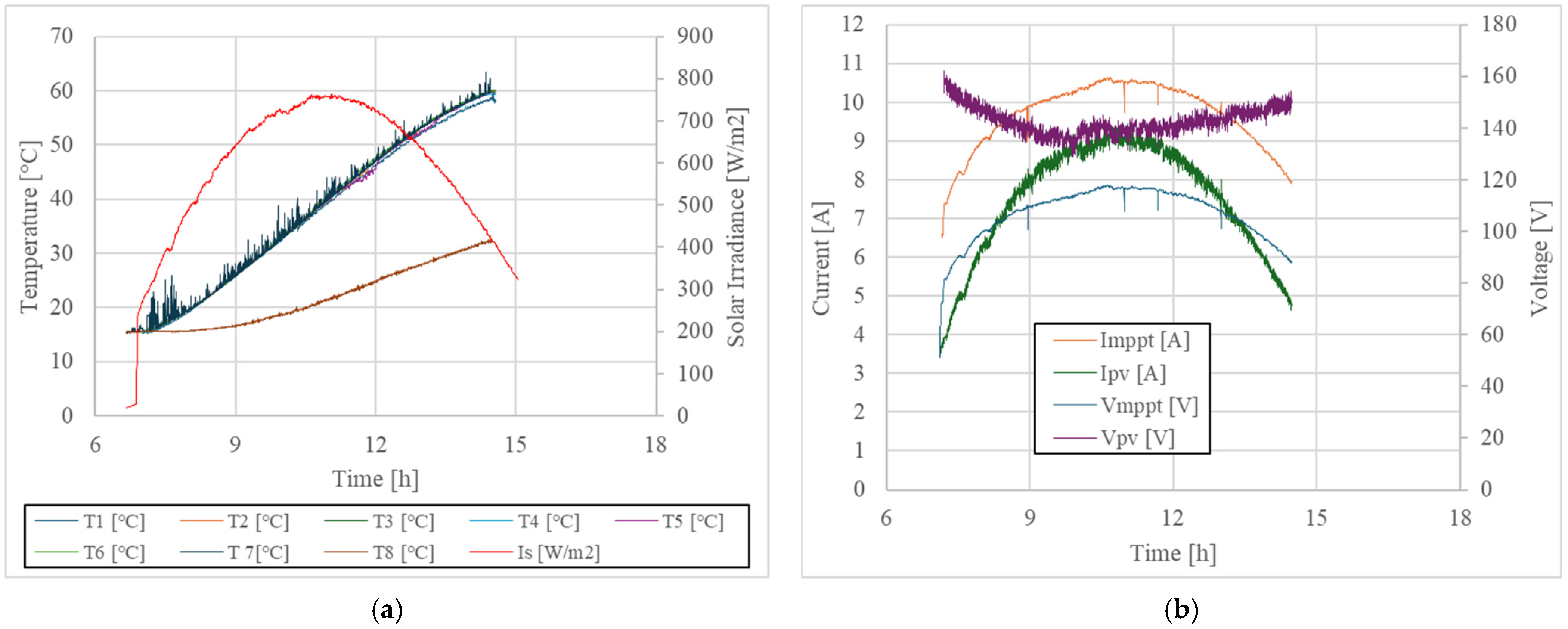

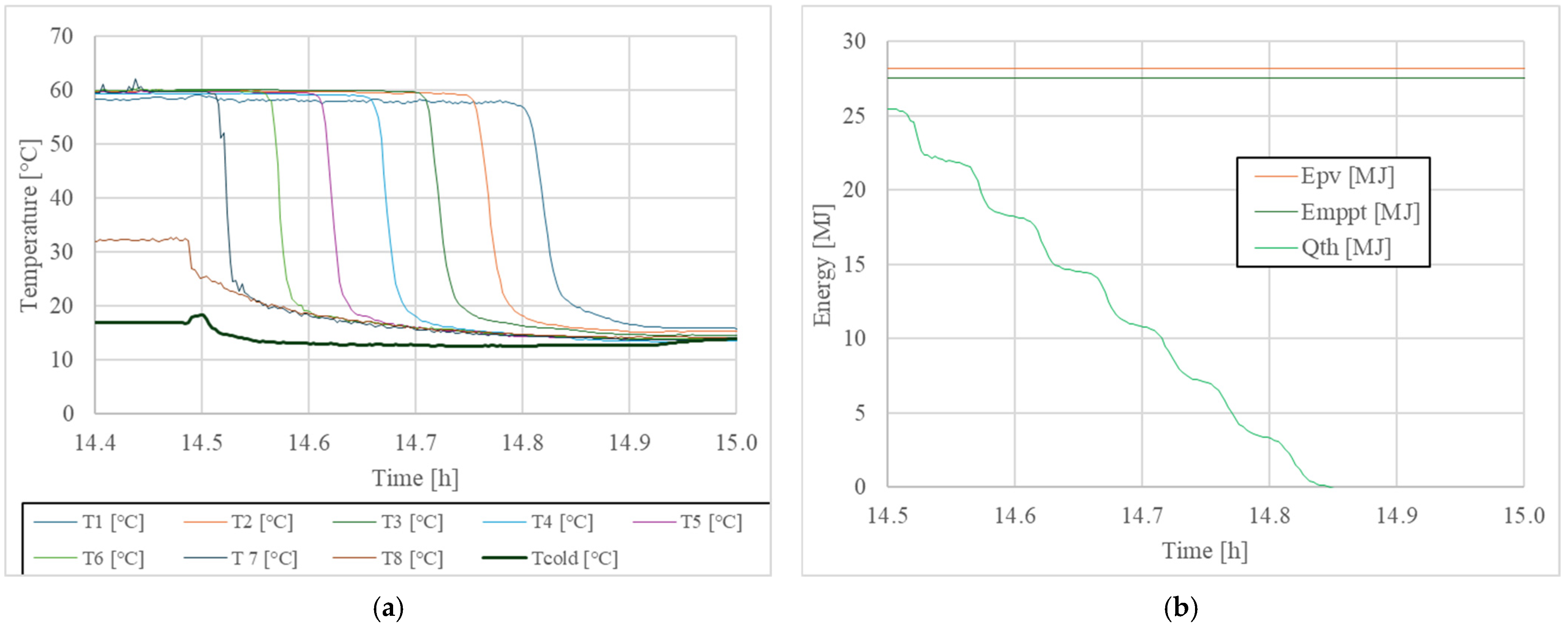

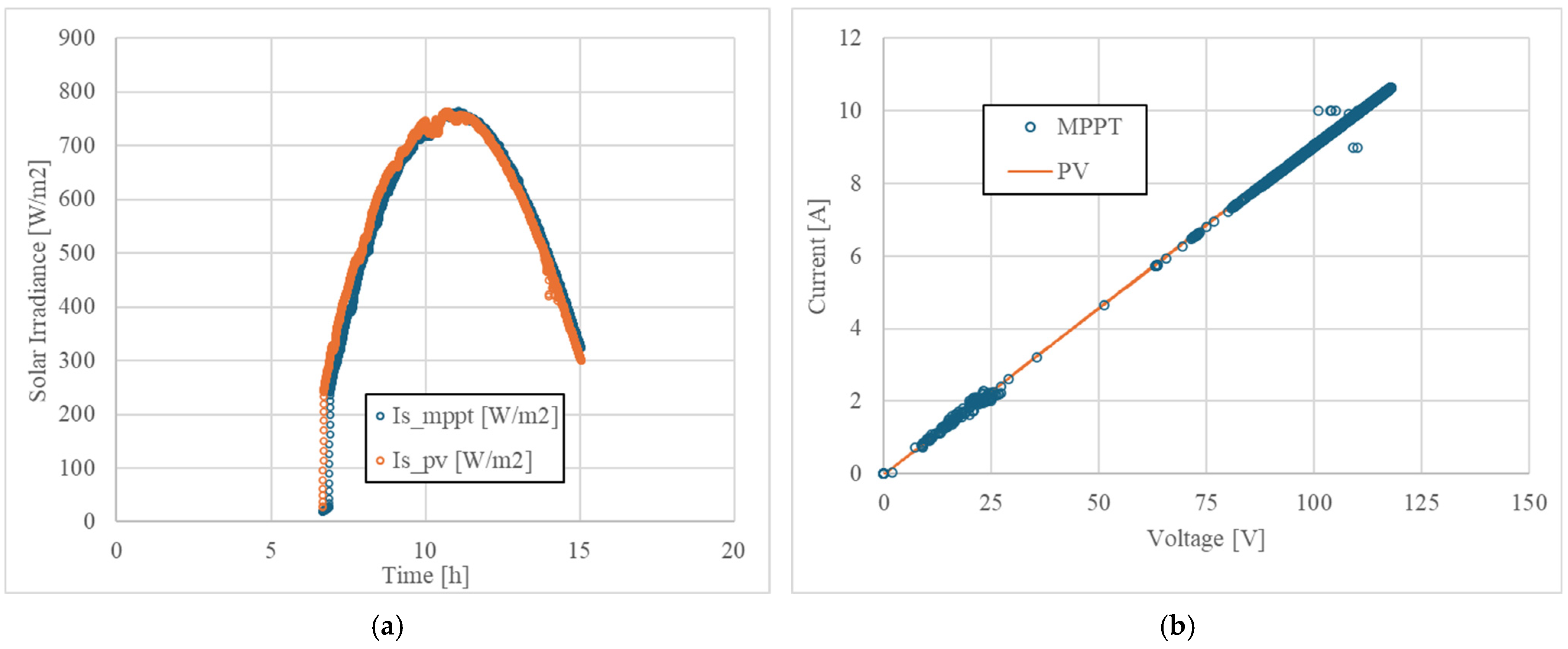

Figure 12a shows the solar irradiance for the two configurations (MPPT and direct PV power supply). Both cases coincide in the test period, which is a guarantee that the solar irradiance is the same for both cases.

Figure 12b shows the current vs. voltage for both tests. In both cases, the current and voltage are linearly proportional. However, with MPPT, the control electronics allow for higher voltages to be used, corresponding to higher currents. This is the fundamental difference that makes the MPPT system more efficient than the direct PV power supply.

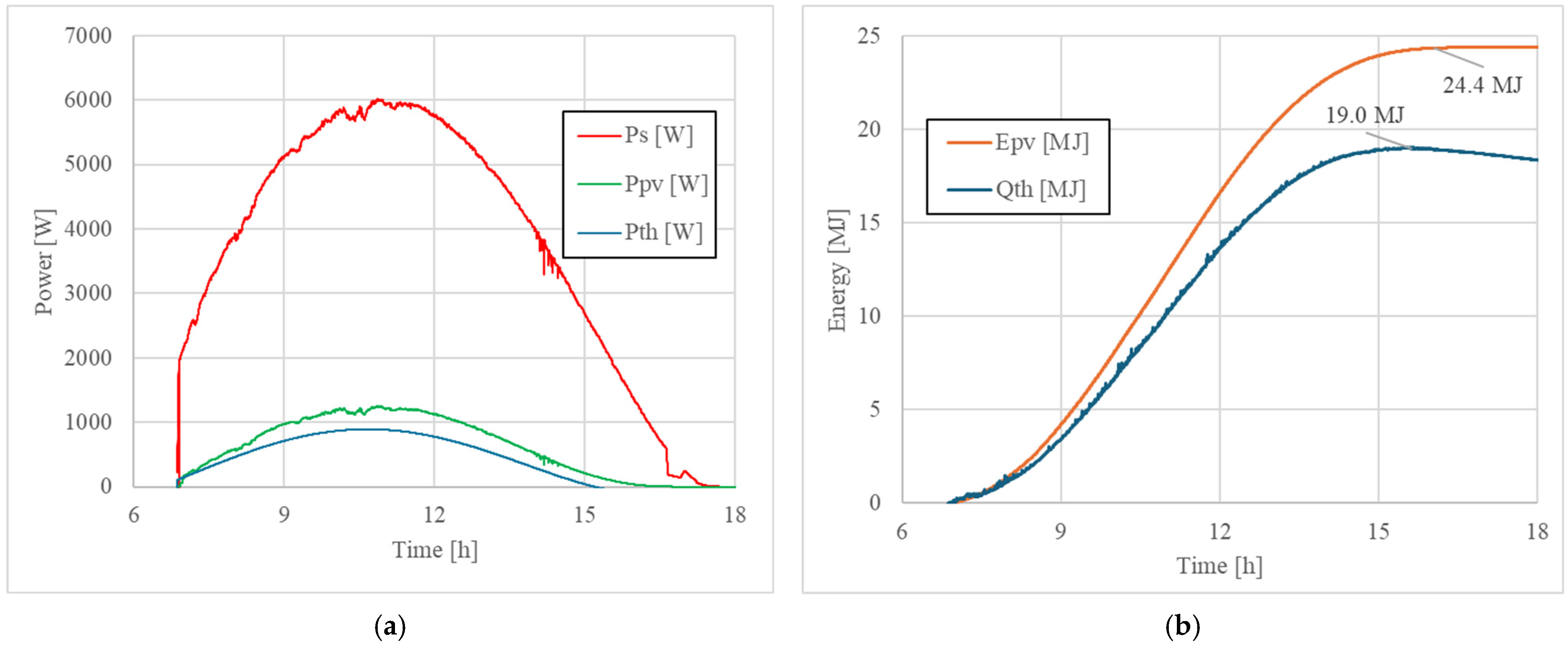

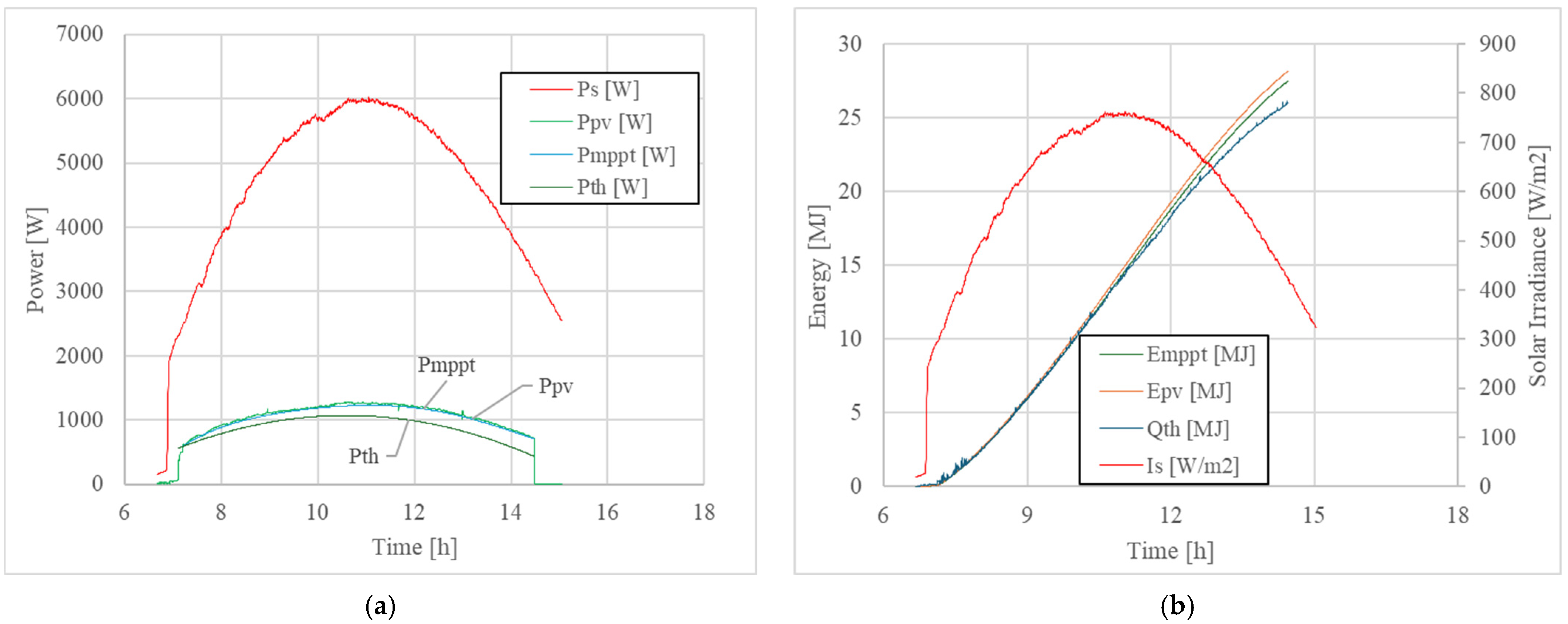

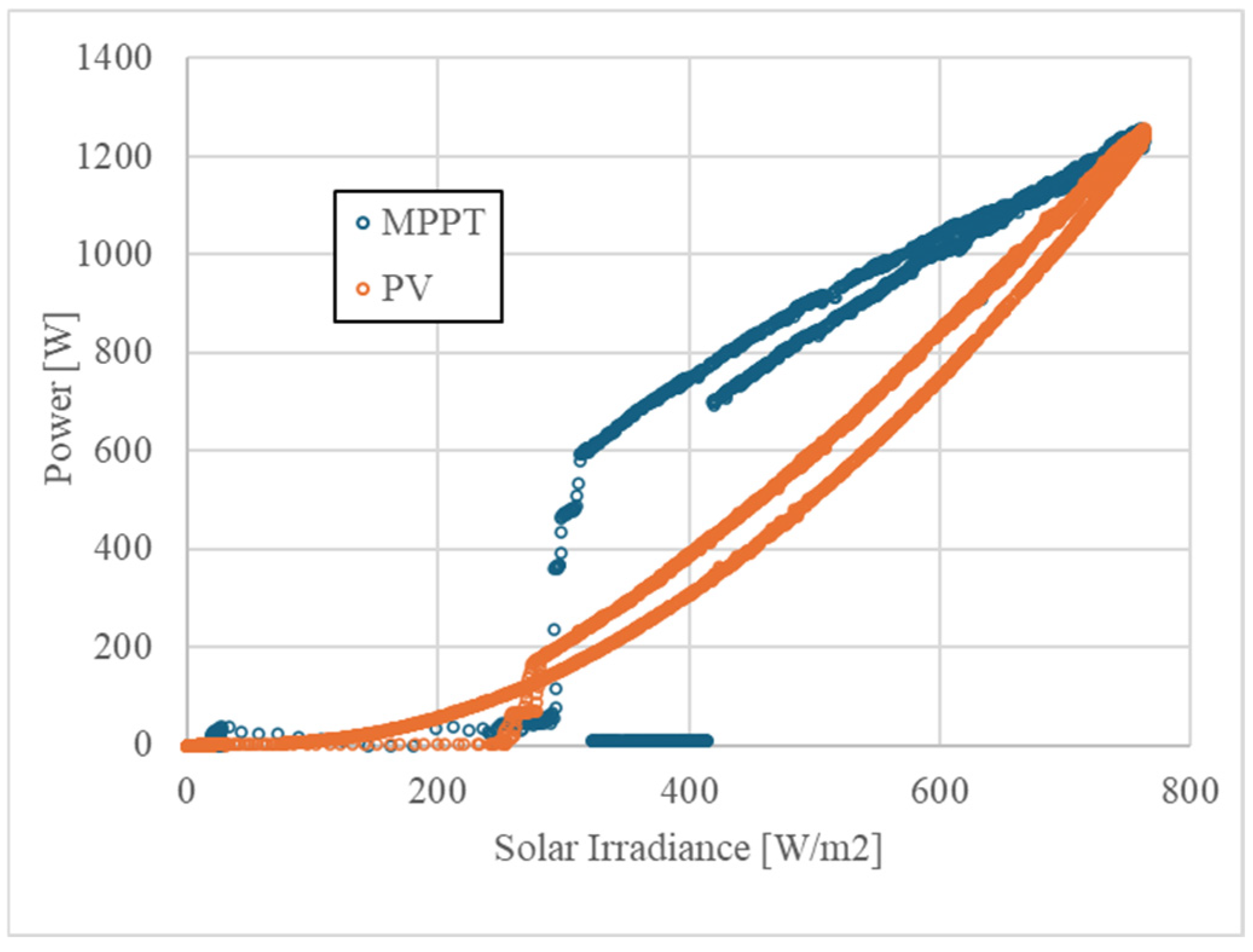

The electrical power reaching the heating element depends on whether or not MPPT is used (

Figure 13). These results are consistent with those described in the work of Hachchadi et al. [

16]. Similar results are also observed in the tests on the photovoltaic solar cooker without an electronic power controller [

25].

MPPT control considerably improves the efficiency of the heating process. Similar results were obtained by Burmester et al. [

15].

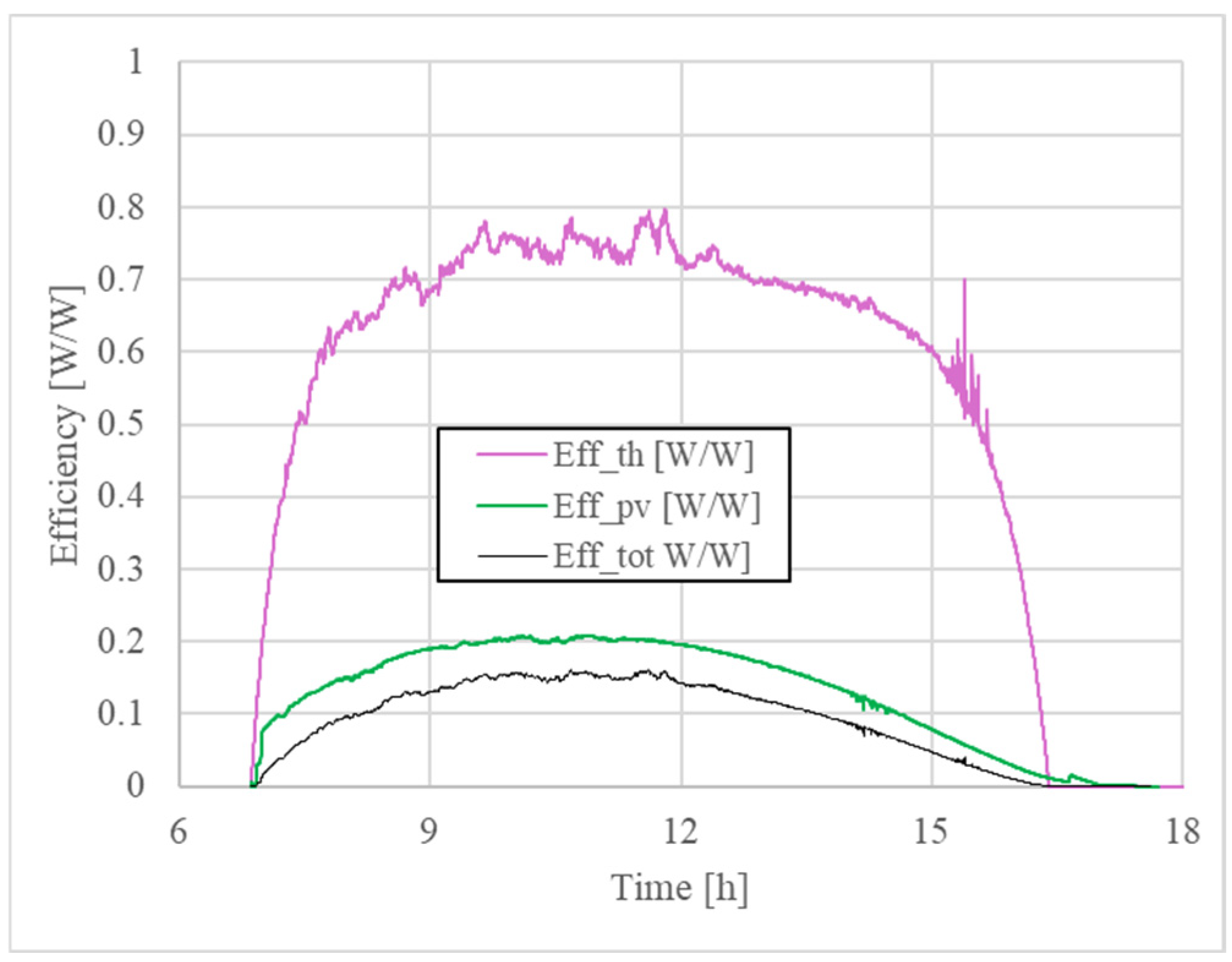

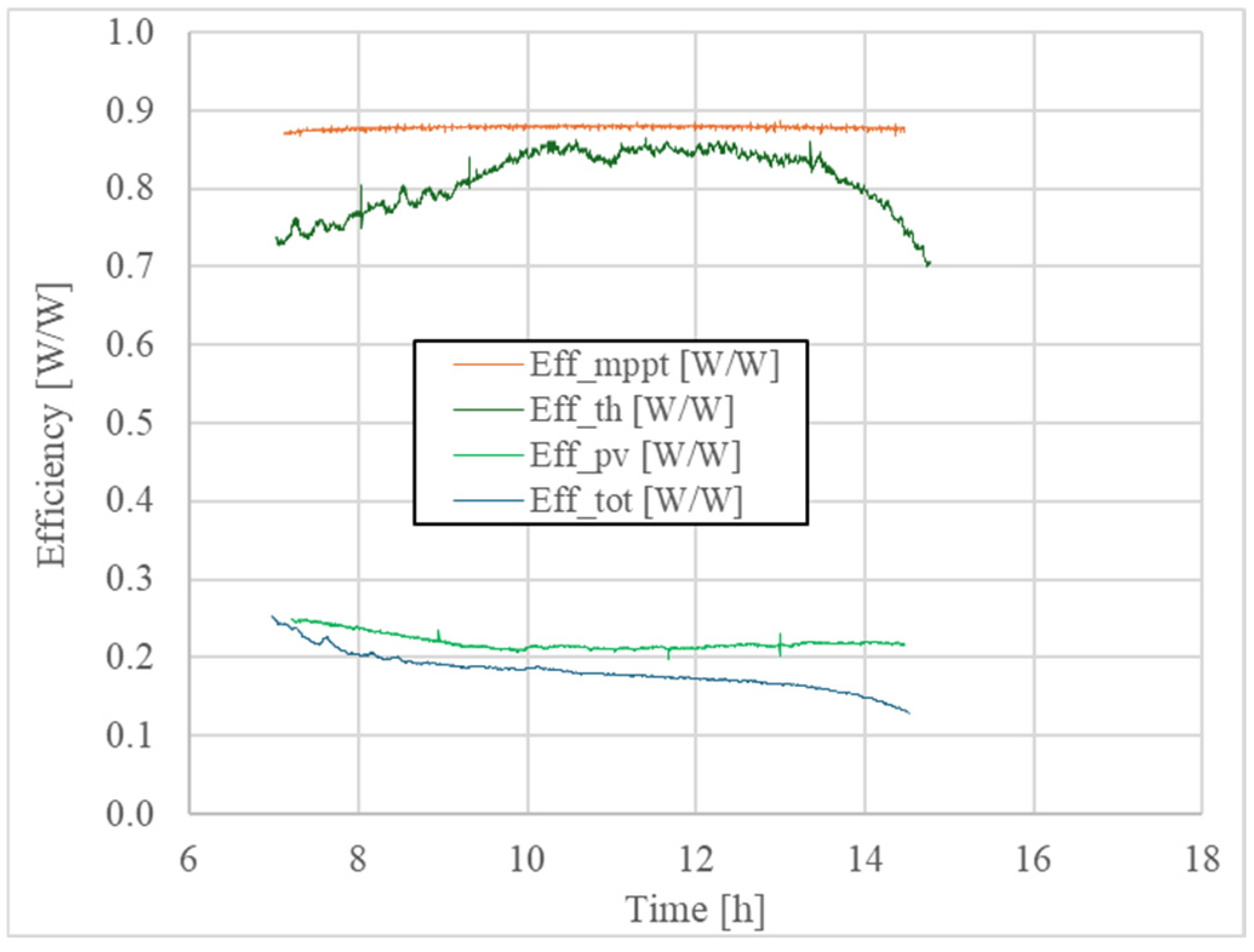

Figure 14 shows a comparison of the efficiency with direct PV power supply and MPPT.

It can be seen that for the direct PV power supply, the average total efficiency is 12%; meanwhile, with the MPPT, the average value is 18.2%. There is a clear improvement in efficiency when using a device with maximum power tracking, improving the heating process and reducing the time to reach the set temperature. These results are in agreement with those of Matuska and Sourek [

34].

In this study, it was estimated that the installation would increase the cost by USD 100 (the cost of the MPPT controller). However, it should be considered that the use of the MPPT guarantees water heating to 60 °C in 7 h 30 min, and with a direct PV power supply, the temperature reaches 47 °C over the course of the entire day.

Heat Losses

The water tank is insulated with a 25 mm thick layer of elastomeric foam; however, heat losses have been observed, mainly at night, due to conduction on the tank walls.

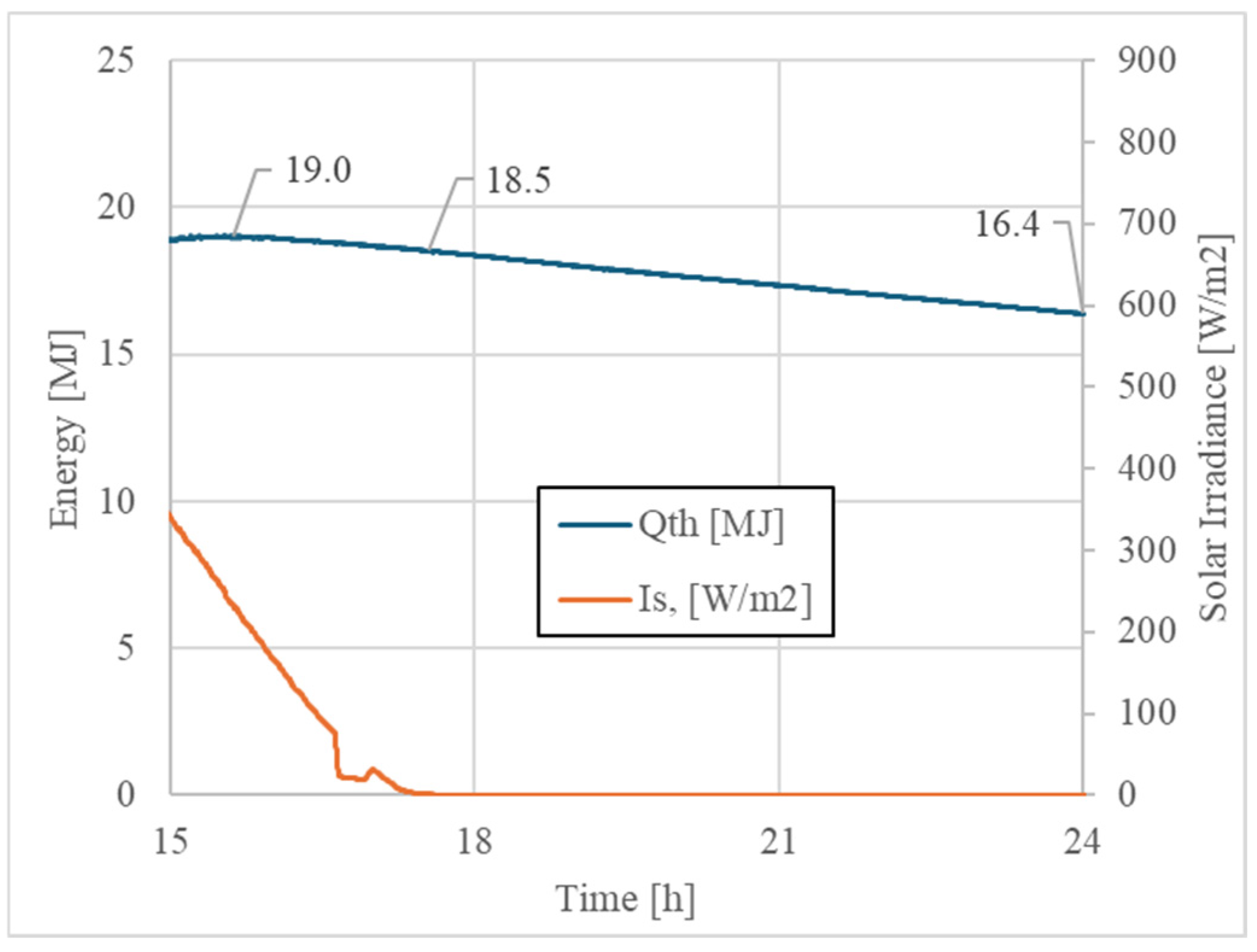

Figure 15 shows the variation in internal energy from 15:00 h to 24:00 h. The maximum energy stored was 19 MJ at 15:52 h, and when the solar irradiance is zero, the total energy in the tank is 18.5 MJ. At the end of the day (24:00 h), the energy drops to a value of 16.4 MJ. These heat losses occur due to the insulation on the tank walls and represent 11.4% in total. In this test, the air temperature was maintained at 18 °C on average.

5. Conclusions

In this research, we studied the process of water heating using photovoltaic electricity. Two types of tests were carried out: direct PV power supply heating and MPPT heating. Both tests provided heat using an electrical resistance located at the bottom of the tank. All tests were carried out at the laboratory level using thermal and electrical sensors to determine performance. Photovoltaic heating using MPPT yielded more efficient results and shorter heating times. In the case of direct PV supply, it was found that this method did not reach the programmed temperature on the first day and that there was a significant heat loss during the night, which significantly affected the efficiency.

As this was an experimental study at the prototype level, the results specifically indicated the viability of water heating with both methods. It is important to highlight the economic difference between using or not using MPPT as it is a costly piece of equipment at present, which would affect both the initial investment and the payback period.

Applications of this technology can be focused on family homes, for example, in the heating of swimming pools. For heating large volumes of water, the technology could be used with a preheating tank using a heating element, an MPPT, and a solar array; a recirculation pump (between the tank and the pool) could be used to heat the pool water during daylight hours.

Another possible application is the supply of energy to isolated and resource-poor areas, avoiding the implementation of a complex water heating system for heating dormitories or communal accommodation. It should be noted that these results are still under development and that other factors may have to be considered (time needed to heat the water, water temperature, etc.).

Although a comparison with conventional thermal systems has not been addressed, PV heating systems allow for installation of the water storage tank inside the building where the hot water will be used, which reduces heat losses in the transport pipes and reduces the waste of cold water.

In these experiments, the MPPT (maximum power point tracking) charge controller was used as it has greater efficiencies compared to the PWM (pulse width modulation) charge controller, which reduces the input power of the solar panels and limits the electric current.

It is estimated that the installation would increase the cost of heating water to 60 °C in 7 h 30 to USD 100 (the cost of the MPPT controller). With a direct PV power supply, the temperature reaches 47 °C during the day.

Finally, it should be mentioned that while photovoltaic solar heating is an evolving technology, it is promising in terms of a drastic reduction in components and improved efficiency for domestic applications in residential buildings compared to conventional thermal systems.