Diagnosis of Pre-Tightening Force Loosening for Top Cover Bolts in Generator Sets

Abstract

1. Introduction

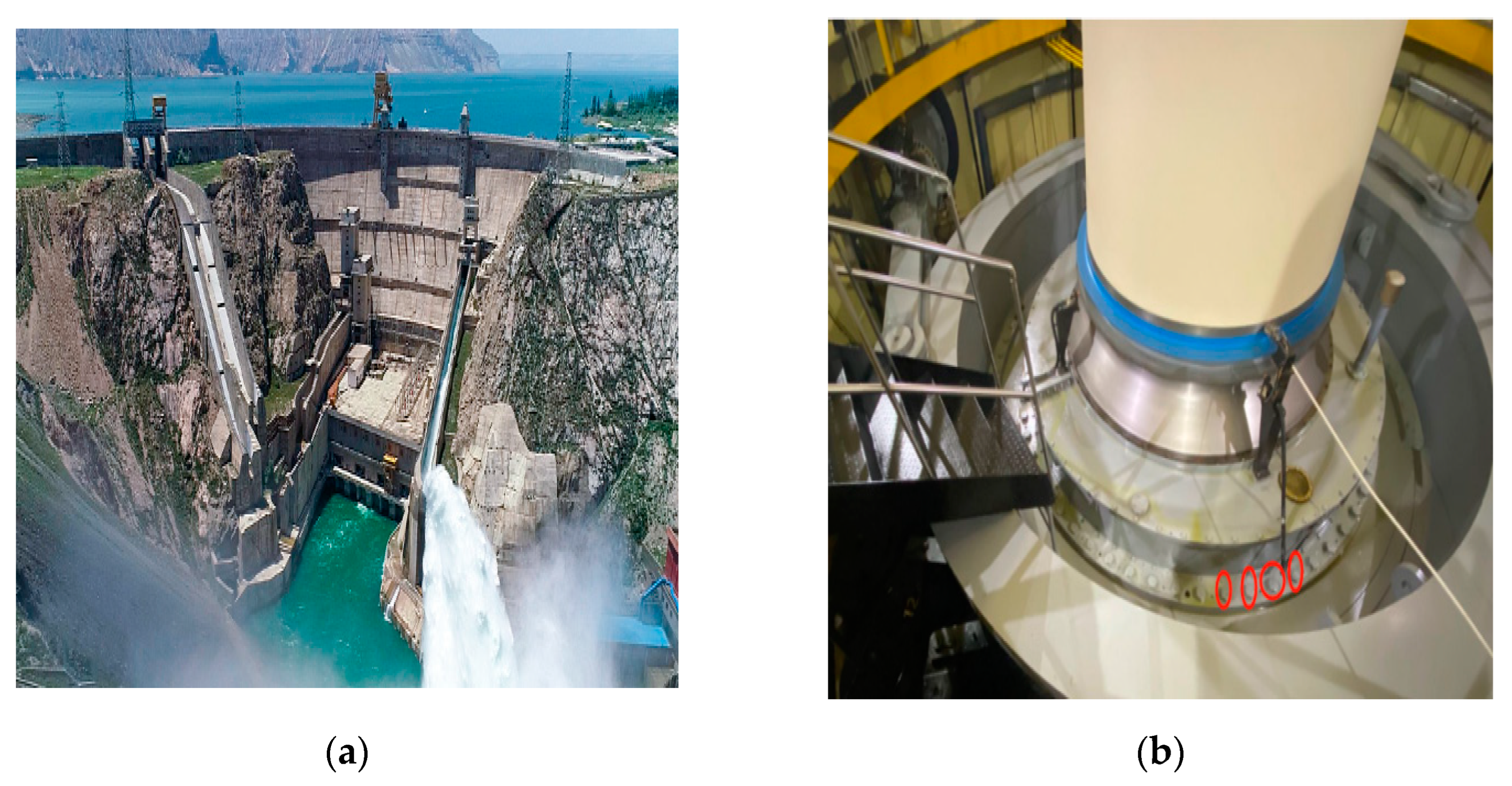

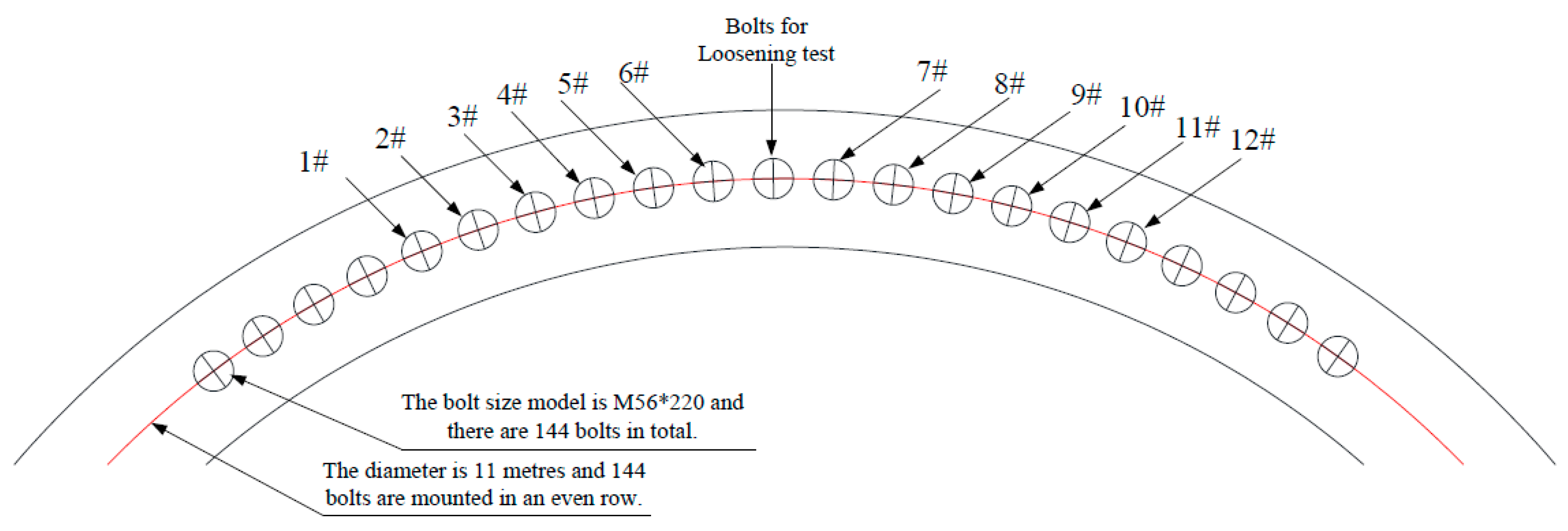

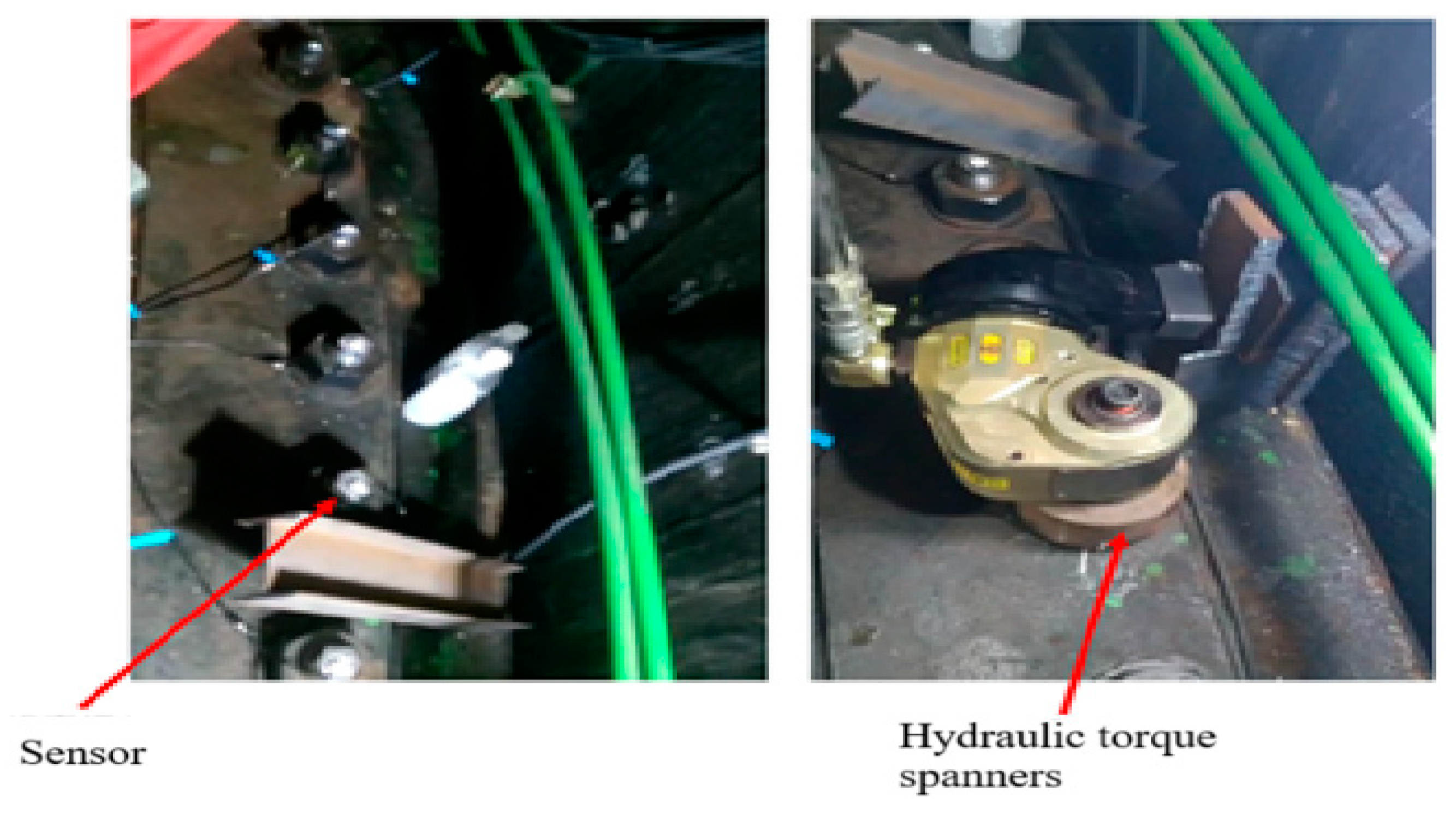

2. Materials

3. Methods

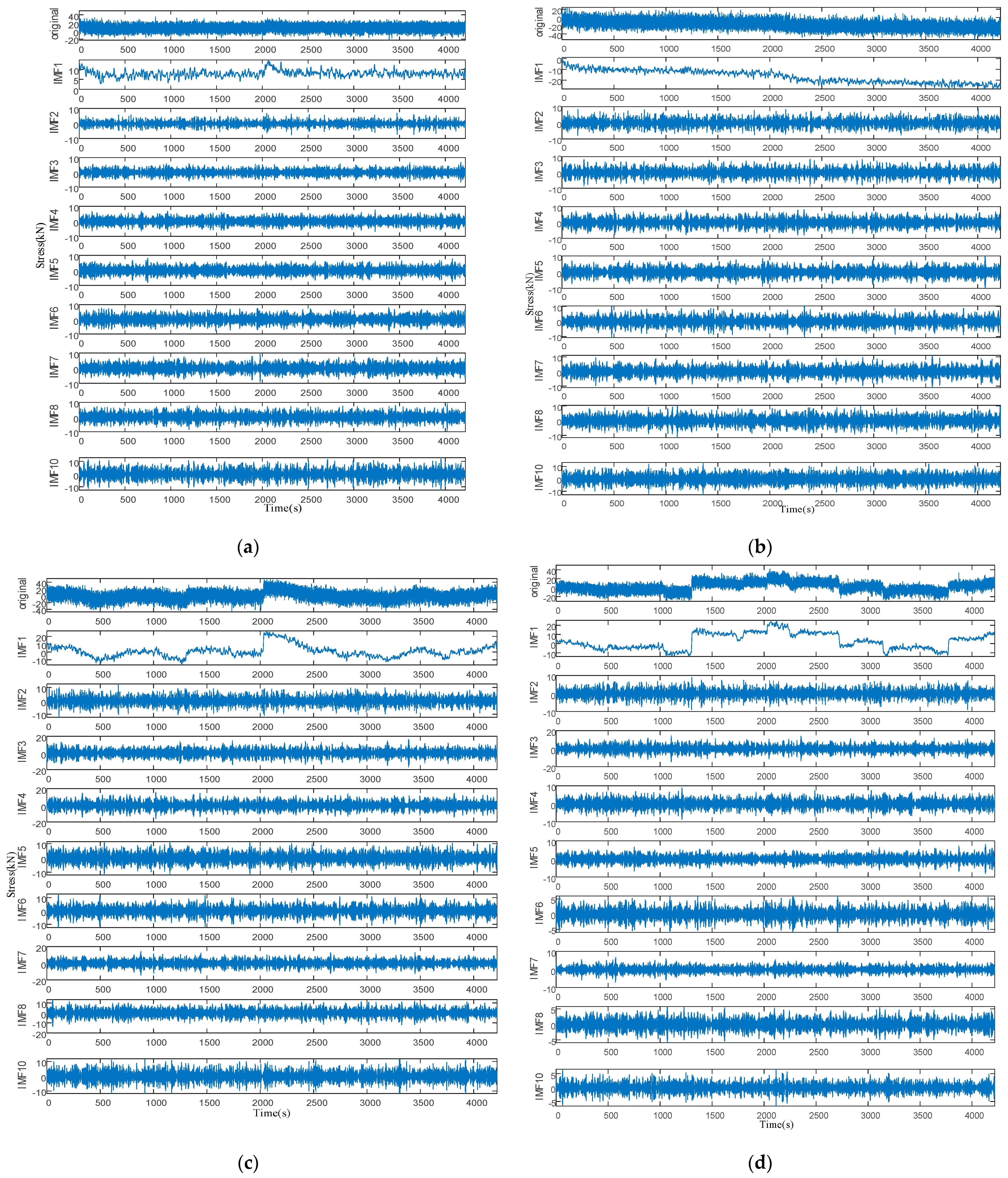

4. Results and Discussions

5. Conclusions

- Bolt loosening causes fluctuations in the pre-tightening force of local bolts and alters the stress transfer characteristics of the entire bolt group. These changes are most noticeable in the surrounding bolts, with sensitivity decreasing with distance from the loosened bolt;

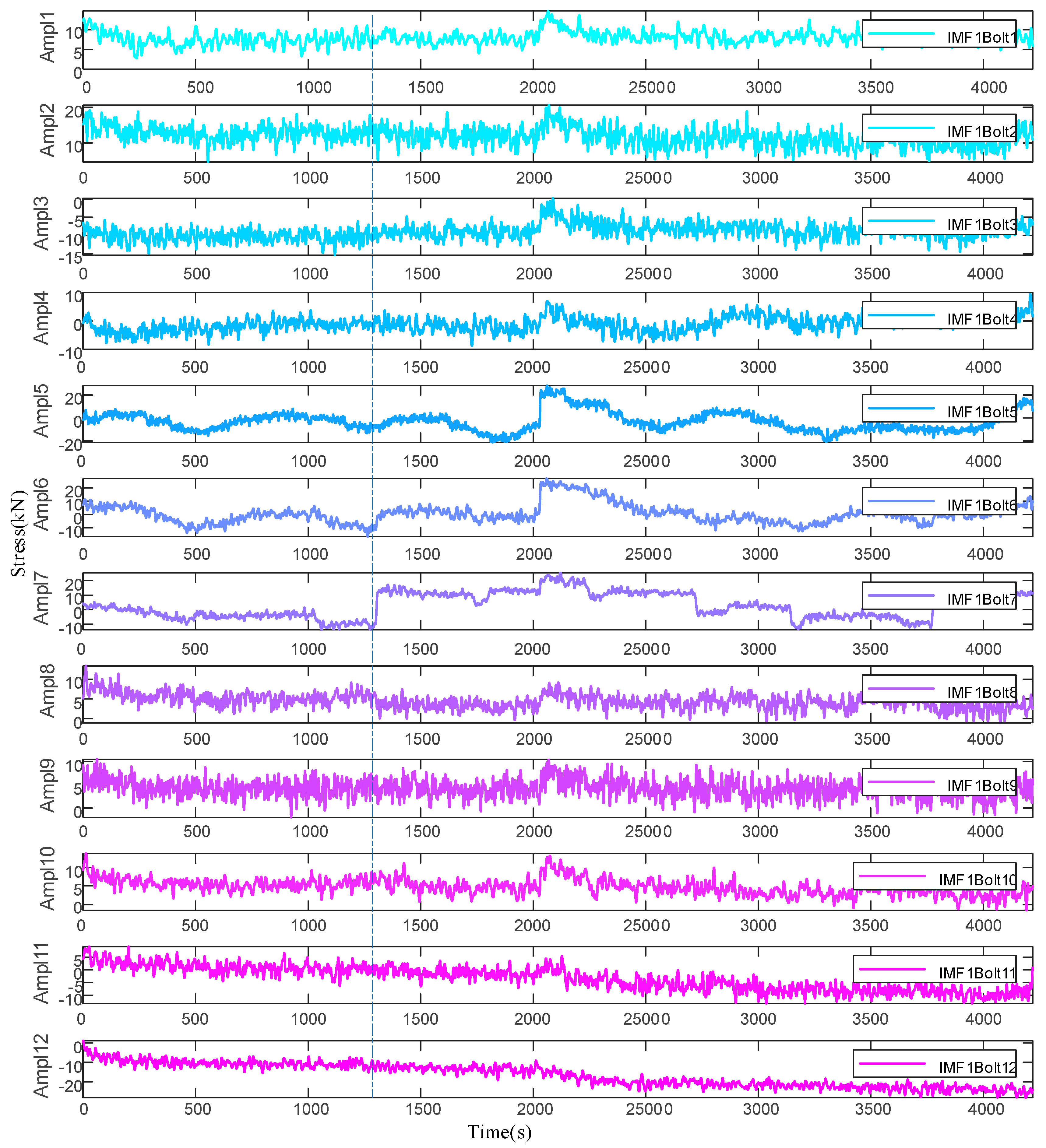

- The VMD method effectively decomposes stress signals during the loosening process, revealing that the first modal is highly sensitive to bolt loosening. This modal can reliably monitor the bolt-tightening state, providing a foundation for fault diagnosis and early warning;

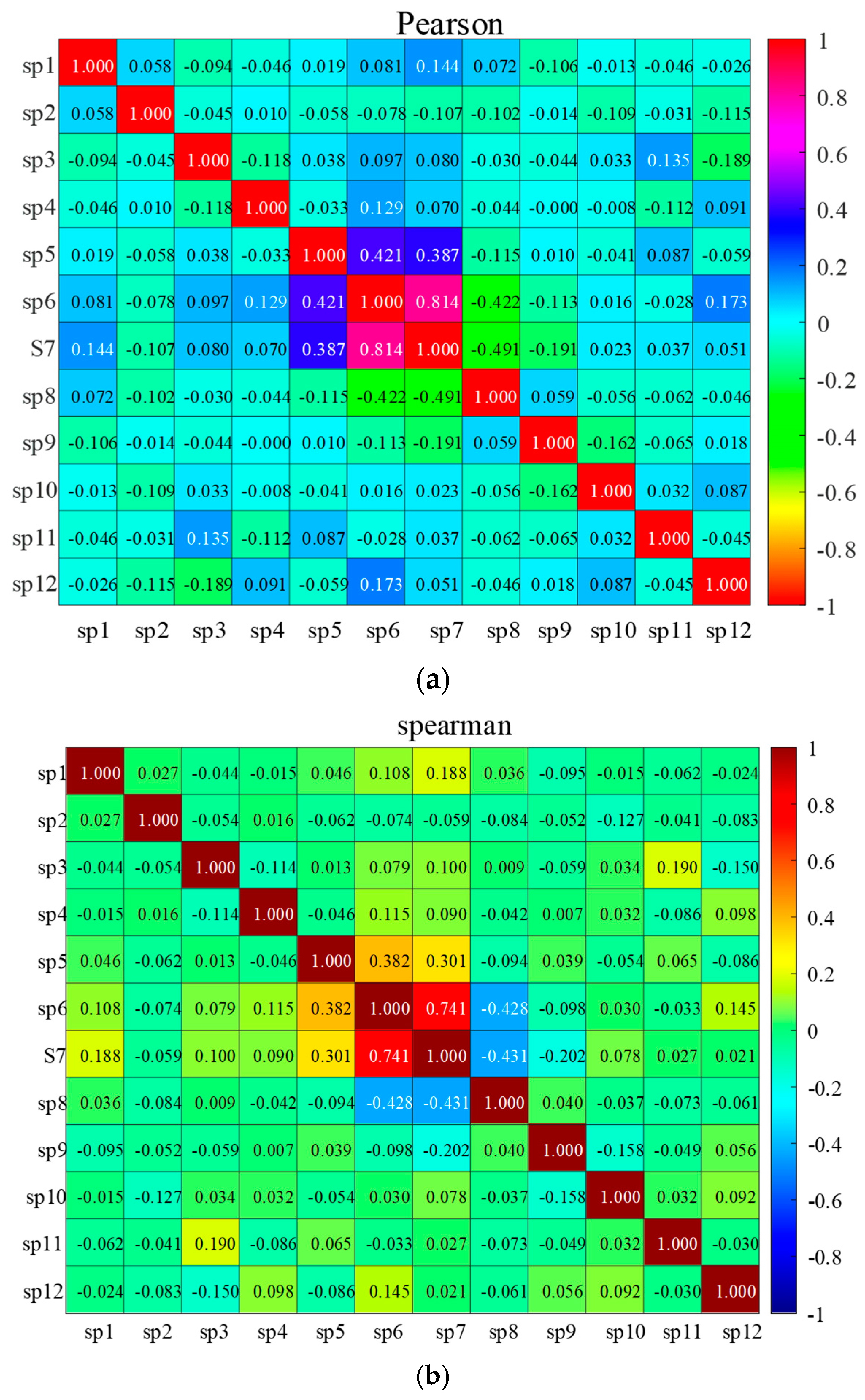

- The results of the Pearson and Spearman correlation analyses of each bolt show that after a bolt loosens, the correlation parameters of the adjacent bolts increase significantly, showing a positive correlation, while the correlation parameters of other bolts hardly change significantly. This further proves that when a bolt loosens, it will cause an increase in the stress of adjacent bolts.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Nikravesh, S.M.Y.; Goudarzi, M. A review paper on looseness detection methods in bolted structures. Lat. Am. J. Solids Struct. 2017, 14, 2153–2176. [Google Scholar]

- Shu, X.; Guo, Y.; Yang, W.; Wei, K.; Zhu, Y.; Zou, H. A Detailed Reliability Study of the Motor System in Pure Electric Vans by the Approach of Fault Tree Analysis. IEEE Access 2020, 8, 5295–5307. [Google Scholar] [CrossRef]

- Tang, Q.; Shu, X.; Zhu, G.; Wang, J.; Yang, H. Reliability Study of BEV Powertrain System and Its Components—A Case Study. Processes 2021, 9, 762. [Google Scholar] [CrossRef]

- Chen, R.; Chen, S.; Yang, L.; Wang, J.; Xu, X.; Luo, T. Looseness diagnosis method for connecting bolt of fan foundation based on sensitive mixed-domain features of excitation-response and manifold learning. Neurocomputing 2017, 219, 376–388. [Google Scholar] [CrossRef]

- Xu, C.; Huang, C.-C.; Zhu, W.-D. Bolt loosening detection in a jointed beam using empirical mode decomposition–based nonlinear system identification method. Int. J. Distrib. Sens. Netw. 2019, 15, 155014771987565. [Google Scholar] [CrossRef]

- Shu, X.; Yang, H.; Zhou, H.; Wei, K.; Guo, Y.; He, S. Fault diagnosis and failure analysis of motor controller by the approach of Bayesian inference. Int. J. Veh. Des. 2021, 86, 52–70. [Google Scholar] [CrossRef]

- Wang, F.; Song, G. Bolt-looseness detection by a new percussion-based method using multifractal analysis and gradient boosting decision tree. Struct. Health Monit. 2020, 19, 2023–2032. [Google Scholar] [CrossRef]

- Shu, X.; Guo, Y.; Yang, H.; Zou, H.; Wei, K. Reliability Study of Motor Controller in Electric Vehicle by the Approach of Fault Tree Analysis. Eng. Fail. Anal. 2021, 121, 105165. [Google Scholar]

- Li, Q.; Jing, X. A systematic second-order output spectrum based method for fault diagnosis with a local tuning approach. J. Sound Vib. 2020, 475, 115283. [Google Scholar] [CrossRef]

- Tang, Q.; Shu, X.; Wang, J.; Yuan, K.; Zhang, M.; Zhou, H. Research on failure characteristics of electric logistics vehicle powertrain gearbox based on current signal. Energies 2024, 17, 3228. [Google Scholar] [CrossRef]

- Li, Q.; Jing, X. A novel second-order output spectrum based local tuning method for locating bolt-loosening faults. Mech. Syst. Signal Process. 2021, 147, 107104. [Google Scholar] [CrossRef]

- Chen, D.; Huo, L.; Li, H.; Song, G. A fiber bragg grating (FBG)-enabled smart washer for bolt pre-load measurement: Design, analysis, calibration, and experimental validation. Sensors 2018, 18, 2586. [Google Scholar] [CrossRef] [PubMed]

- Zhao, N.; Huo, L.; Song, G. A nonlinear ultrasonic method for real-time bolt looseness monitoring using PZT transducer–enabled vibro-acoustic modulation. J. Intell. Mater. Syst. Struct. 2020, 31, 364–376. [Google Scholar] [CrossRef]

- Zhang, Z.; Liu, M.; Liao, Y.; Su, Z.; Xiao, Y. Contact acoustic nonlinearity (CAN)-based continuous monitoring of bolt loosening: Hybrid use of high-order harmonics and spectral sidebands. Mech. Syst. Signal Process. 2018, 103, 280–294. [Google Scholar] [CrossRef]

- Wang, F.; Song, G. Bolt early looseness monitoring using modified vibro-acoustic modulation by time-reversal. Mech. Syst. Signal Process. 2019, 130, 349–360. [Google Scholar] [CrossRef]

- Pavelko, I.; Pavelko, V.; Kuznetsov, S.; Ozolinsh, I. Bolt-joint structural health monitoring by the method of electromechanical impedance. Aircr. Eng. Aerosp. Technol. Int. J. 2014, 86, 207–214. [Google Scholar] [CrossRef]

- Xu, J.; Dong, J.; Li, H.; Zhang, C.; Ho, S.C. Looseness monitoring of bolted spherical joint connection using electro-mechanical impedance technique and BP neural networks. Sensors 2019, 19, 1906. [Google Scholar] [CrossRef]

- Min, J.; Park, S.; Yun, C.-B.; Lee, C.-G.; Lee, C. Impedance-based structural health monitoring incorporating neural network technique for identification of damage type and severity. Eng. Struct. 2012, 39, 210–220. [Google Scholar] [CrossRef]

- Ramana, L.; Choi, W.; Cha, Y.-J. Fully automated vision-based loosened bolt detection using the Viola–Jones algorithm. Struct. Health Monit. 2019, 18, 422–434. [Google Scholar] [CrossRef]

- Huynh, T.C.; Park, J.H.; Jung, H.J.; Kim, J.T. Quasi-autonomous bolt-loosening detection method using vision-based deep learning and image processing. Autom. Constr. 2019, 105, 102844. [Google Scholar] [CrossRef]

- Wu, G.; Xu, C. Bolt looseness detection based on chaos ultrasonic excitation. J. Vib. Shock 2018, 37, 208–213. [Google Scholar]

- Yang, J.; Chang, F.K. Detection of bolt loosening in C-C composite thermal protection panels: I. Diagnostic principle. Smart Mater. Struct. 2006, 15, 581. [Google Scholar]

- Jhang, K.Y.; Quan, H.H.; Ha, J.; Kim, N.Y. Estimation of clamping force in high-tension bolts through ultrasonic velocity measurement. Ultrasonics 2006, 44, e1339–e1342. [Google Scholar] [PubMed]

- Joshi, S.; Pathare, R. Ultrasonic instrument for measuring bolt stress. Ultrasonics 1984, 22, 261–269. [Google Scholar] [CrossRef]

- Yasui, H.; Kawashima, K. Acoustoelastic measurement of bolt axial load with hypothetical velocity ratio method. Trans. Jpn. Soc. Mech. Eng. Ser. A 2000, 66, 390–396. [Google Scholar] [CrossRef][Green Version]

- Zhang, M.; Shen, Y.; Xiao, L.; Qu, W. Application of subharmonic resonance for the detection of bolted joint looseness. Nonlinear Dyn. 2017, 88, 1643–1653. [Google Scholar] [CrossRef]

- Amerini, F.; Meo, M. Structural health monitoring of bolted joints using linear and nonlinear acoustic/ultrasound methods. Struct. Health Monit. 2011, 10, 659–672. [Google Scholar] [CrossRef]

- Huynh, T.C.; Dang, N.L.; Kim, J.T. Preload monitoring in bolted connection using piezoelectric-based smart interface. Sensors 2018, 18, 2766. [Google Scholar] [CrossRef]

- Fierro, G.P.M.; Meo, M. IWSHM 2017: Structural health monitoring of the loosening in a multi-bolt structure using linear and modulated nonlinear ultrasound acoustic moments approach. Struct. Health Monit. 2018, 17, 1349–1364. [Google Scholar] [CrossRef]

- Lee, J.W. Bolt-joint structural health monitoring technique using transfer impedance. J. Korea Acad. Ind. Coop. Soc. 2019, 20, 387–392. [Google Scholar]

- Sun, W.; Zhang, Y. Numerical simulation of bolt looseness monitoring based on impedance method. Appl. Mech. Mater. 2013, 351–352, 1264–1268. [Google Scholar] [CrossRef]

- Shao, J.; Tao, W.; Wang, Z.; Wei, D.; Li, Y. Bolt Looseness Detection Using Piezoelectric Impedance Frequency Shift Method. China Mech. 2019, 30, 1395–1399+1408. [Google Scholar]

- Chen, G.; Chen, Y.; Chen, Y.; Ji, S. Dynamics modeling and experimental modal analysis of bolt loosening for lightning rod. J. Vibroeng. 2020, 22, 657–671. [Google Scholar] [CrossRef]

- Wang, G.; Li, H.; Yang, Y.; Qiao, Z.; Zou, Z.; Du, D.; Liu, D.; Guo, X.; Wu, H. Vibro-acoustic modeling, validation, and optimization of porous foam composite laminates. Appl. Math. Model. 2023, 119, 273–294. [Google Scholar]

- Wang, G.; Zhao, S.; Chen, J.; Zhong, Z. A novel compound fault diagnosis method for rolling bearing based on Graph Label Manifold Metrics Transfer. Meas. Sci. Technol. 2023, 34, 065010. [Google Scholar] [CrossRef]

- Wang, G.; Zhao, S.; Zhong, Z.; Zeng, D. Research on Shaft Current Damage Identification of Variable Condition Motor Bearings Based on Multiscale Feature Label Propagation and Manifold Metric Transfer. Lubricants 2023, 11, 69. [Google Scholar] [CrossRef]

- Wang, G.; Han, Q.; Wang, T. Fault Diagnosis of Gear Rotor System Based on Collaborative Filtering Recommendation Method. Dyn. Fault Diagn. Nonlinear Rotors Impellers 2022, 5, 19–49. [Google Scholar]

- Shu, X.; Li, Y.; Wei, K.; Yang, W.; Zuo, H.; Yang, B.; Wei, S.; Punyawudho, K.; Zhang, M. Research on the failure mechanism and characteristic evolution of lithium-ion battery under different operation temperatures and extrusion deformation. Eng. Fail. Anal. 2025, 172, 109425. [Google Scholar] [CrossRef]

- Shu, X.; Li, Y.; Yang, B.; Wang, Q.; Punyawudho, K. Research on the Electrochemical Impedance Spectroscopy Evolution of Sodium-Ion Batteries in Different States. Molecules 2024, 29, 4963. [Google Scholar] [CrossRef]

- Wei, K.; Zhou, H.; Shu, X.; Xie, S.; Punyawudho, K. Research on economic benefits and adaptability of different ELV powertrain topologies. IEEE Access 2024, 12, 92494–92505. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, C.; Xie, S.; Shu, X.; Wan, Y.; Pan, P.; Mo, F.; Wang, W. Diagnosis of Pre-Tightening Force Loosening for Top Cover Bolts in Generator Sets. Energies 2025, 18, 1604. https://doi.org/10.3390/en18071604

Li C, Xie S, Shu X, Wan Y, Pan P, Mo F, Wang W. Diagnosis of Pre-Tightening Force Loosening for Top Cover Bolts in Generator Sets. Energies. 2025; 18(7):1604. https://doi.org/10.3390/en18071604

Chicago/Turabian StyleLi, Chongshi, Songlin Xie, Xiong Shu, Yuan Wan, Pingheng Pan, Fan Mo, and Weiyu Wang. 2025. "Diagnosis of Pre-Tightening Force Loosening for Top Cover Bolts in Generator Sets" Energies 18, no. 7: 1604. https://doi.org/10.3390/en18071604

APA StyleLi, C., Xie, S., Shu, X., Wan, Y., Pan, P., Mo, F., & Wang, W. (2025). Diagnosis of Pre-Tightening Force Loosening for Top Cover Bolts in Generator Sets. Energies, 18(7), 1604. https://doi.org/10.3390/en18071604