Abstract

Fuzzy-ball fluids have emerged as a novel class of chemical sealaplugging materials with significant potential for enhancing both traditional oilfield operations and clean energy technologies. They are characterized by unique viscoelastic properties, plugging, self-adapting capabilities, and the ability to regulate multi-phase fluid flow under extreme subsurface conditions. In oilfield applications, fuzzy-ball fluids offer solutions for drilling, hydraulic fracturing, workover operations, and enhanced oil recovery in shallow, deep, and offshore reservoirs. In clean energy fields such as hydrogen storage, carbon capture, utilization, and storage, and geothermal energy, they show promise in improving energy efficiency, storage security, and environmental sustainability. This review explores the fundamental principles and mechanisms behind fuzzy-ball fluids, examines their field applications in the oil and gas industry, and investigates their potential in emerging clean energy technologies. This study also identifies key challenges, including material stability, economic viability, and environmental impact, which must be addressed to ensure the successful deployment of fuzzy-ball fluids. Furthermore, we outline future research directions, emphasizing material optimization, large-scale field trials, environmental impact assessments, and interdisciplinary collaboration to accelerate the commercialization of fuzzy-ball fluid technologies. By addressing these challenges, fuzzy-ball fluids could play a transformative role in both conventional and clean energy fields, contributing to sustainable and efficient energy solutions.

1. Introduction

The global shift toward sustainable and efficient energy technologies has driven remarkable innovations in advanced materials and fluids designed to enhance energy production, storage, and distribution [1]. Among these innovations, fuzzy-ball fluids have emerged as a transformative class of chemical plugging materials. Characterized by their exceptional viscoelastic properties, adapting mechanisms, adhesive performance, and ability to maintain stability under extreme reservoir conditions for enhanced oil recovery and control lost circulation [2,3], fuzzy-ball fluids hold significant promise for revolutionizing both traditional oil and gas operations and emerging clean energy technologies [4].

Since their invention in 2010, fuzzy-ball fluids have demonstrated outstanding performance across various phases of oil and gas field development, particularly in tight formations such as coalbed methane [5] and tight sand gas [6]. Their unique composition allows them to regulate fluid flow, adapt to reservoir dynamics, and withstand challenging environments involving high pressure, temperature, and corrosive fluids. These attributes have enabled their successful application in drilling, hydraulic fracturing, workover operations, and enhanced oil recovery (EOR) in shallow, deep, and offshore reservoirs. Compared to conventional materials, fuzzy-ball fluids offer a more adaptive and efficient solution for managing complex subsurface conditions.

Beyond the oil and gas field, interest in fuzzy-ball fluids is rapidly growing in clean energy applications, including hydrogen storage, carbon capture, utilization, and storage (CCUS), and geothermal energy systems. In these contexts, fuzzy-ball fluids exhibit unique potential to enhance storage security, improve energy efficiency, and ensure the safe containment of critical gases such as carbon dioxide and hydrogen sulfide [7]. For instance, their viscoelastic behavior and ability to plug micro-fractures can enhance the integrity of storage reservoirs, while its adaptability under multi-phase flow conditions makes it suitable for complex energy systems.

Despite its promise, the broader adoption of fuzzy-ball fluids faces critical challenges. These include ensuring material stability under extreme and complex subsurface conditions, improving economic feasibility compared to traditional methods, and addressing environmental concerns related to fluid components. A comprehensive understanding of these issues is essential to advancing the deployment of fuzzy-ball fluids in both oil and gas and clean energy technologies.

This study provides a detailed examination of the fundamentals and mechanisms underlying fuzzy-ball fluids, offering an in-depth analysis of their composition, behavior, and field performance in various oilfield development phases. While prior studies have explored the historical application of fuzzy-ball fluids in oil and gas wells [8], they have not addressed the complex case-by-case variations in composition and mechanisms critical to specific applications. To address this gap, a case-based overview of fuzzy-ball fluid applications and strategies is presented in this review.

Additionally, this study explores the theoretical feasibility of deploying fuzzy-ball fluids in clean energy technologies, including their potential for hydrogen storage and CCUS. The future research directions are identified, including emphasizing the importance of interdisciplinary collaboration in advancing fuzzy-ball fluid technologies. By synthesizing current research and addressing existing knowledge gaps, this review aims to provide a comprehensive framework for understanding and utilizing fuzzy-ball fluids in both traditional and renewable energy fields, providing a guide for innovative and sustainable energy solutions.

2. Fuzzy-Ball Fluids: Composition, Properties, and Mechanisms

Nowadays, there are some existing plugging technologies. Understanding the composition, rheological properties, and mechanisms of fuzzy fluids and other existing plugging technologies, such as polymer-based fluids and nanoparticle-based fluids, can highlight their unique advantages and limitations in similar applications. A direct comparison is shown in Table 1.

Table 1.

Comparison of existing sealaplugging technologies.

In general, fuzzy-ball fluids excel in injectability, plugging efficiency, and adaptability, making them highly effective under various reservoir conditions. Its unique self-adaptive and self-plugging mechanisms allow it to efficiently adapt to complex reservoir conditions, while also having low environmental impact and moderate cost. In comparison, polymer-based fluids, while cost-effective and versatile, rely on gel formation and high-viscosity plugging, which can present challenges in terms of injectability and adaptability under extreme conditions [9]. Nanoparticle-based fluids perform well in microscale and low-temperature conditions, achieving sealing through pore throat plugging and wettability alteration, but they are costly and less effective for large-scale sealing [10]. Conventional fluids, though simple and inexpensive, depend on physical blocking and viscosity control, lacking the advanced functionalities required to address complex reservoir challenges, and oil-based fluids have a significant environmental impact. To some extent, fuzzy-ball fluids provide a relatively comprehensive choice for modern oilfield applications.

Fuzzy-ball fluids are innovative smart fluids designed for petroleum reservoir applications. Their ability to adapt flow behavior under varying reservoir conditions makes them highly effective in addressing key challenges in oilfield operations. They selectively plug high-permeability zones, redirecting injected fluids to lower-permeability areas. This selective plugging enhances field performance by achieving objectives such as preventing lost circulation, improving wellbore stability during drilling, creating new fractures during hydraulic fracturing, and mitigating formation damage caused by the precipitation of solid particles in unconsolidated or poorly consolidated reservoirs. Additionally, they enhance the mechanical properties of the reservoir rock during various operations, including drilling, fracturing, well workovers, and interventions. More so, fuzzy-ball fluids contribute to more efficient oil extraction by targeting oil-rich zones during EOR. Their effectiveness is attributed to two key behaviors: adapting and plugging under reservoir conditions. These unique behaviors stem from their chemical composition, molecular structure, and rheological properties.

The following sub-sections will provide an in-depth analysis of fuzzy-ball fluids, focusing on their composition, molecular structure, rheological properties, and the mechanisms underlying their self-adapting and self-plugging capabilities.

2.1. Composition and Structure

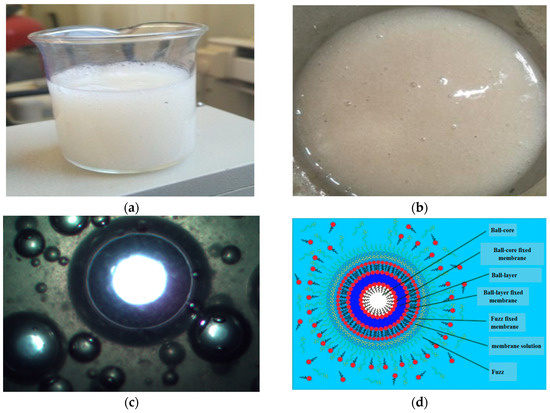

Fuzzy-ball fluids are two-phase gas–liquid systems uniquely designed for enhanced performance in petroleum reservoirs, as shown in Figure 1. They exhibit specific chemical and physical properties that enable them to adapt to diverse reservoir conditions, making them invaluable for applications such as oil recovery, refracturing, and wellbore stability (Figure 1a,b).

Figure 1.

Visual representation of fuzzy-ball fluids. (a) Laboratory setup. (b) Field application. (c) Microscopic view. (d) Schematic illustration of vesicle core and fuzz layer [8].

A typical fuzzy-ball fluid consists of two main components: an outer layer, referred to as the “fuzz”, and an inner core composed of fuzzy-ball structures (Figure 1c). The fuzzy-ball fluid composes polymers or surfactants and is formed by a ball core, ball-core fixed membrane, ball layer, ball-layer fixed membrane, fuzz, fuzz fixed membrane, and membrane solution, interacting with surrounding rock and fluids to selectively adapt to varying permeability zones within the reservoir. The inner fuzzy ball contains ball structures—spherical or quasi-spherical assemblies of surfactants resulting in the gaseous phase. These vesicles, typically 15 to 150 μm in size, are formed from anionic surfactants such as sodium dodecyl benzene sulfonate and sodium dodecyl sulfate [11]. Its high ductility and deformability enable it to navigate complex pore structures effectively.

A fuzzy-ball fluid is characterized by its viscoelastic behavior, with low viscosity at high shear rates, allowing it to be easily injected into reservoirs and maintaining stability in challenging environments. Moreover, its compatibility with water-based mud systems, polymers, and other displacement fluids enhances its operational versatility. These features make it effective in a variety of applications, including managing formation damage, refracturing operations, and enhancing wellbore integrity.

Fuzzy-ball structures are critical to the functionality of fuzzy-ball fluids, preferentially flowing into high-permeability zones due to their low flow resistance while avoiding low-permeability regions. This selective behavior ensures effective fluid diversion, targeted plugging, and minimal formation damage, optimizing hydrocarbon recovery. Meanwhile, the fuzz enhances mechanical properties, ensuring the fluid’s stability and functionality during operations such as drilling, fracturing, and well interventions.

On a molecular level, fuzzy-ball fluids can be visualized as ball cores surrounded by a ball layer. The ball-core bilayers consist of surfactant molecules with hydrophilic heads forming the aqueous phase and hydrophobic tails forming the inner membrane. The fuzz layer extends outward, offering adaptability and mechanical stability, as depicted in Figure 1d.

The chemical composition of a typical fuzzy-ball fluid includes various agents such as hydroxyethyl starch to strengthen the fluid, polyanionic cellulose for floss generation, and sodium hydroxide to stabilize the pH value [12]. These components work synergistically to enhance fluid performance under diverse conditions.

This unique composition and flexibility in formulation enables fuzzy-ball fluids to address specific challenges such as selective plugging, permeability heterogeneity, and formation stability, ensuring efficient and reliable operation in diverse reservoir environments.

2.2. Rheological Properties

Rheological properties play an important role in the functionality and adaptability of reservoir fluids. In the case of fuzzy-ball fluids, these properties are critical, as they describe the fluid’s flow behavior under various conditions and are influenced by their unique composition and structure, including the ball core and fuzz layer.

The rheological properties of fuzzy-ball fluids prepared with different surfactants exhibit significant variations. For instance, the surfactant reduces the friction independently of the weighting materials used [13]. Cationic surfactants should be selected for preparing acid-resistant fuzzy-ball fluids, while those prepared with anionic surfactants such as SDS (sodium dodecyl sulfate) and SDBS (sodium dodecyl benzene sulfonate) demonstrate poor acid resistance [14]. Also, the rheological properties of fuzzy-ball fluids also exhibit significant differences among various fluid types, highlighting their suitability for different reservoir applications. Fuzzy-ball fluids exhibit a lower plastic viscosity compared to oil-based and polymer-based fluids, which enhances their injectability in low-permeability zones. However, while lower viscosity facilitates injection, it may also lead to increased fluid loss or reduced control over placement in certain reservoir conditions, which should be carefully considered in field applications. Furthermore, the yield stress of fuzzy-ball fluids surpasses other fluid types, indicating superior ability to resist deformation, making it ideal for wellbore stability and selective plugging.

2.3. Self-Adapting and Plugging Mechanisms

Fuzzy-ball fluids are characterized by their adapting and plugging capabilities, which originate from their unique structure and dynamic behavior. Moreover, their simple preparation process, which does not require additional specialized equipment, enables them to exhibit exceptional adaptability under complex geological conditions and demonstrate high efficiency in sealing flow channels [15]. This performance is due to the interplay of mechanical deformation, dynamic sealing, and chemical interactions within the rock matrix.

2.3.1. Self-Adapting Mechanisms

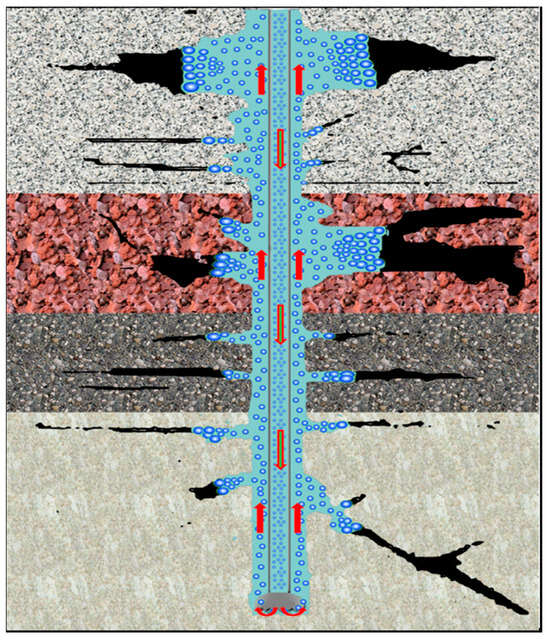

The adapting nature of fuzzy-ball fluids is largely attributed to their ball-like structures, which consist of high-strength, gas-filled bubbles capable of deforming to diverse flow channel geometries. This deformation adaptation mechanism allows the fluids to penetrate pores, fractures, and seepage channels of varying sizes, ensuring retention and efficient plugging even in highly heterogeneous formations, as shown in Figure 2.

Figure 2.

Schematic representation of the self-adapting mechanism of fuzzy-ball fluids under varying downhole conditions.

As can be seen from Figure 2, the arrows indicate the direction of fluid flow and the self-adaptive mechanism of fuzzy-ball fluid exhibits unique behaviors under varying temperature and pressure conditions.

In the wellbore, where temperatures are relatively low and pressures are high, the micro-bubbles of the fuzzy-ball fluid slightly contract due to the low temperature, facilitating fluid flow, while being compressed under high pressure to maintain structural integrity and ensure stable transportation.

At the bottomhole, where high temperature and high pressure coexist, the size of the micro-bubbles in the fuzzy-ball fluid reaches a dynamic balance under the influence of these two forces. High temperature tends to cause the bubbles to expand, while high pressure tends to compress them. Ultimately, the volume of the bubbles adjusts to an intermediate state based on the specific temperature and pressure conditions. High temperature causes the bubbles to thermally expand, increasing their volume and enhancing their ability to plug larger pores, while extremely high pressure compresses the bubbles, allowing them to pass through tight pore spaces.

In the formation, where temperature variations are significant, the fuzzy-ball fluid expands in high-temperature zones to enhance plugging and contracts in low-temperature zones to penetrate deeper into narrow channels. Simultaneously, due to the uneven pressure distribution in the formation, the bubbles are compressed in high-pressure regions to pass through dense pores and expand in low-pressure regions to improve plugging efficiency. At the front end, where the pressure is low, the bubbles gradually increase in size, raising flow resistance. Additionally, irregular underground leakage channels further increase flow resistance until the pressure of the working fluids equals the formation pressure. At this point, the bubbles stop flowing within the leakage channels, effectively halting further leakage. Subsequent bubbles also cease flowing and, together with the front-end bubbles, accumulate into a conical shape. Meanwhile, owing to the high formation temperature, heat exchange occurs between the bubbles and the formation, causing them to expand further and strengthen their plugging capability.

Moreover, chemical interactions between the fluid’s polymers and surfactants and the rock minerals play a complementary role. These interactions involve adsorption and bonding processes that enhance the mechanical properties of the reservoir rock, including its tensile and shear strength, while reducing collapse stress and increasing leakage pressure. Such interactions also contribute to dynamic adaptation by reinforcing the plugging structures, ensuring long-term stability under fluctuating reservoir conditions. By integrating chemical and mechanical synergies, the performance of fuzzy-ball fluids can be optimized under various operational parameters.

2.3.2. Self-Plugging Mechanisms

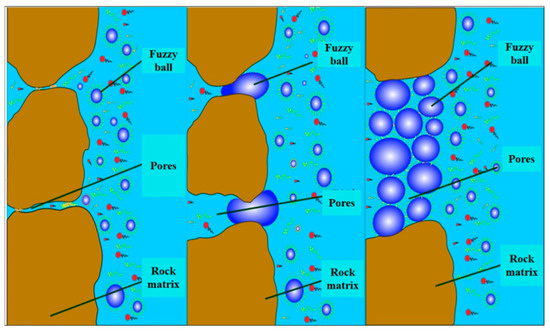

Fuzzy-ball fluids exhibit dynamic plugging capabilities that are integral to their effectiveness under reservoir conditions. When introduced into a seepage channel, these fluids conform to its shape and morphology, adjusting the vesicle structures through stacking, stretching, and filling behaviors. This adjustment creates robust seals that effectively block fluid flow, as shown in Figure 3.

Figure 3.

Schematic representation of the plugging mechanism of fuzzy-ball fluids.

As can be seen in Figure 3, the plugging efficiency of fuzzy-ball fluids is influenced by the dimensions of the fractures or channels, as well as their chemical interactions with the formation. When the fracture width is greater than the diameter of the ball, the balls stack to form a “plane binary tree” structure, creating a robust, large-scale plugging effect that dissipates pressure from the fluid column and optimally matches the plugging agent to the channel dimensions.

In moderately wide channels, where the width of the fractures is approximately equal to the ball diameter, balls are absorbed into the fractures, deforming from spheres to ovals to seal the fractures and increase resistance against water invasion. For narrower channels, where the fracture width is smaller than the ball diameter, the vesicles form a strong gel-like barrier on the wellbore surface, effectively blocking water flow into the formation.

Additionally, the rapid aggregation and alignment of balls in narrow channels enhance their plugging capability, while moderate and wide channels require more time for ball coverage but still achieve effective sealing. The hydrophilic nature of the fluid ensures compatibility with formation water, reducing risks of water encroachment and filtrate invasion.

Furthermore, damage-control additives in the formulation help preserve reservoir integrity, highlighting the superior adaptability and plugging efficiency of fuzzy-ball fluids compared to conventional systems.

Fuzzy-ball fluids outperform traditional oil-based, water-based, and polymer-based fluids in terms of adaptability and plugging efficiency. Unlike conventional fluids, which often struggle with complex reservoir conditions, fuzzy-ball fluids leverage their unique combination of mechanical adaptability and chemical synergy to deliver efficient performance. These dynamic plugging capabilities, combined with the ability to withstand and adapt to extreme changes to reservoir conditions, underscore their versatility and effectiveness in modern oilfield applications. These advantages are supported by extensive experimental and modeling studies.

3. Applications for Oilfield Development

Fuzzy-ball fluids offer transformative solutions across a broad range of oilfield operations, leveraging their adaptive chemical and physical properties to enhance efficiency, reduce risks, and tackle challenging reservoir conditions.

3.1. Drilling

In drilling operations, fuzzy-ball fluids (known as fuzzy-ball drilling fluids) have emerged as a significant advancement in wellbore stability and loss circulation prevention technologies. Fuzzy-ball drilling fluids are formulated using similar chemical agents, with slightly higher concentrations of membrane and strengthening agents. These enhanced concentrations provide fuzzy-ball drilling fluids with two functionalities:

- High plugging capacity can effectively prevent loss circulation and minimize reservoir damage.

- Formation strengthening enhances the compressive strength of the rock, reducing the likelihood of wellbore collapse during drilling.

Fuzzy-ball drilling fluids are recommended for challenging drilling environments where issues like near-wellbore damage, loss circulation, and wellbore collapse are prevalent. Their rheological properties are dynamic, adapting to varying shear rates to optimize cuttings transport and ensure efficient borehole cleaning, even under high-pressure and high-temperature conditions. Additionally, fuzzy-ball drilling fluids exhibit remarkable chemical stability in saline and acidic environments, ensuring compatibility with sensitive and unconventional reservoirs.

The ball of fuzzy-ball drilling fluids plays a crucial role in enhancing drilling fluids’ sealing properties, allowing selective plugging of formation pores. This mechanism contributes to improved pressure control, effectively mitigating the risk of blowouts and ensuring stable wellbore performance.

A triaxial and compressive test study highlighted the superior mechanical strengthening capabilities of fuzzy-ball drilling fluids compared to conventional fluids such as potassium chloride and polymer-based fluids. Specifically, fuzzy-ball drilling fluids demonstrated a higher elastic modulus, improved cohesion, and better internal friction angles, resulting in enhanced wellbore stability.

Through both experimental and field application methods, the geological and engineering factors that contribute to poor cementing quality in severe leakage zones were analyzed, and the experimental results demonstrated that the fuzzy-ball fluids, which effectively resolved the issue of cement slurry leakage and improved cementing quality, eliminated the need for remedial measures during testing, thereby reducing operational costs [16].

Mineral analysis and scanning electron microscopy experiments demonstrate that fuzzy-ball fluids exhibit significantly superior inhibition performance and pressure-bearing capacity compared to other experimental fluids [17]. Field applications further verify that fuzzy-ball drilling fluid can effectively maintain wellbore stability even at or below the equivalent density of collapse pressure, ensuring a smooth drilling process without complex accidents and fully meeting the anti-wellbore collapse requirements for coalbed methane drilling.

Conventional freshwater was initially used during the drilling process but encountered unexpected difficulties during the second spud-in. Subsequently, fuzzy-ball drilling fluid was introduced for the third spud-in and applied to the horizontal section. The fuzzy-ball drilling fluid demonstrated excellent performance, effectively mitigating issues such as fluid loss and formation collapse. By the completion of the drilling operation, a total footage of 4189.49 m was achieved, with the two main boreholes successfully completed and liners installed, reaching a 95% target rate at the producing zone [18].

A detailed scanning electron microscope analysis was conducted to investigate fuzzy-ball drilling fluids’ bonding mechanisms in coalbed methane formations while drilling [19]. After treating coal powder with fuzzy-ball drilling fluids for 96 h, the coal powder treated with fuzzy-ball drilling fluids exhibited strong interparticle connections, forming cohesive networks that enhanced rock integrity.

Additionally, fuzzy-ball drilling fluids effectively filled and sealed micro- and macro-pores in the coal matrix, reducing permeability and reinforcing formation against collapse. The SEM image also shows strong interparticle bonding in the treated sample, with coal particles forming cohesive networks that enhanced the overall structural integrity of the formation. This bonding mechanism not only reduced permeability but also strengthened the coal matrix, preventing the collapse of the formation under stress. The dense coating of fuzzy-ball drilling fluids acts as a barrier, stabilizing the coal particles while inhibiting fluid invasion into the formation. These observations are consistent with the mechanical test results, confirming that fuzzy-ball drilling fluids significantly enhance wellbore stability by sealing formation pores and improving the structural integrity of the coal matrix.

For deepwater oil and gas well drilling, where high-salinity brine and low temperatures often disrupt conventional drilling fluids, fuzzy-ball drilling fluids have proven highly effective. According to Wei et al., fuzzy-ball drilling fluids exhibit excellent tolerance to salinity and temperature variations, ensuring stable rheological properties in challenging conditions. Furthermore, fuzzy-ball drilling fluids maintain high yield stress values across a range of salinity levels and temperatures (10–80 °C), with apparent viscosity increasing slightly as salinity and temperature decrease.

Building on these successes, fuzzy-ball drilling fluids have been widely used for drilling fractured formations, including sandstone reservoirs and coalbed methane wells that have undergone hydraulic fracturing. Beyond preventing lost circulation, well kicks, and wellbore collapse, these fluids also minimize formation damage, ultimately enhancing reservoir productivity.

3.2. Re-Hydrofracturing

In re-hydrofracturing operations, fuzzy-ball fluids known as fuzzy-ball temporary blocking fluids are specialized diverting agents used in hydraulic fracturing to seal existing fractures and redirect fluids toward underdeveloped zones, improving proppant retention and hydrocarbon recovery. Their selective plugging capability enhances fracture propagation, prioritizing stimulation in target regions. In addition, the fuzzy-ball temporary blocking fluid can withstand high temperatures of up to 130 °C, meeting the needs of temporary plugging and diverting fracturing in deep carbonate rocks [20]. Moreover, the injection of temporary blocking fluids, which exhibit the ability to achieve stable pressure in a shorter time, contributes to enhancing the rock’s resistance to deformation.

Fuzzy-ball temporary blocking fluids exhibit viscoelastic properties that minimize fluid leak-off and maintain stability under diverse reservoir conditions. Surfactants within the fluid reduce interfacial tension, enabling deeper penetration and expansion of the fracture network [21]. Experimental studies confirm that fuzzy-ball temporary blocking fluids effectively mitigate formation damage by reducing water permeability while maintaining gas flow, preserving reservoir integrity, and sustaining productivity.

Additionally, fuzzy-ball temporary blocking fluids control fine migration and enhance proppant stability by forming interconnected networks that bind fines, prevent blockages, and improve fracture conductivity [22]. Their multifunctional capabilities make them vital technology for modern fracturing and refracturing operations, optimizing recovery and reservoir performance.

A documented field study reported that in Well 3X, the refracturing operation was performed using fuzzy-ball temporary blocking fluid to mitigate formation damage due to water invasion. The pressure distribution curve revealed the effectiveness of fuzzy-ball temporary blocking fluid in plugging the original fractures and blocking water-bearing layers. Initially, the pressure increased rapidly after the fuzzy-ball temporary blocking fluid injection, reaching around 19 MPa. Following a sharp decline to 16 MPa, it was evident that fuzzy-ball temporary blocking fluid had entered the coal seam fractures. Further pressure declines were observed as the pump schedule was stopped, confirming the formation’s successful sealing by fuzzy-ball temporary blocking fluid.

Additionally, during the refracturing process, the fracturing curve followed an ascending pattern, which typically indicates blockage by coal fines or proppants. The formation of radial fractures along natural fracture directions was supported by pressure drop patterns at specific intervals (e.g., 3480, 4620, and 8040 s) observed in the pressure curve. As a result of the successful blockage, gas production increased significantly, with average daily water production dropping by 73.76% post-refracturing and gas production following a steady rise, suggesting the efficient management of water encroachment and fracture extension. This case exemplifies how fuzzy-ball temporary blocking fluid can reduce water invasion and increase gas productivity by blocking water channels and enhancing fracture connectivity in coalbed methane wells.

Building on these successes, fuzzy-ball temporary blocking fluids have been applied in the refracturing of over twenty oil, gas, and coalbed methane wells to mitigate significant production declines caused by formation damage.

3.3. Improving Oil Recovery

Fuzzy-ball-assisted flooding fluids are highly effective in enhancing oil recovery from heterogeneous reservoirs, especially in scenarios following secondary (e.g., water flooding) or tertiary recovery processes (e.g., polymer or surfactant flooding) [23]. Fuzzy-ball-assisted flooding fluids are advantageous in reservoirs with significant permeability heterogeneity, where conventional flooding techniques struggle to uniformly displace oil toward production wells. The application procedure involves a cyclic injection process: in the initial phase, conventional secondary or tertiary flooding is applied to recover oil from high-permeability zones. Subsequently, fuzzy-ball-assisted flooding fluids are injected to selectively plug these high-permeability pathways, thereby diverting subsequent fluid injections into lower-permeability zones, which are often bypassed in traditional recovery methods. This mechanism makes fuzzy-ball-assisted flooding fluids especially suitable for improving oil recovery in multilayered commingled reservoirs.

The formulation of fuzzy-ball-assisted flooding fluids is based on the chemical composition, with slightly higher concentrations of core, membrane, and strengthening agents to optimize their performance for oil recovery applications. The surfactants within the vesicle core of fuzzy-ball-assisted flooding fluids significantly reduce interfacial tension, enhancing the displacement of oil trapped in pore spaces. Simultaneously, the fuzz layer stabilizes the fluid’s rheological and mechanical properties under reservoir conditions, ensuring consistent performance even in extreme conditions. While no studies have explicitly investigated its compatibility with gas injection-based enhanced oil recovery (EOR) techniques, fuzzy-ball-assisted flooding fluids exhibit strong potential in this area. Its selective plugging capabilities could improve the sweep efficiency of gases like nitrogen or carbon dioxide, enabling more uniform gas distribution across heterogeneous reservoirs. Moreover, fuzzy-ball-assisted flooding fluids could play a crucial role in thermal recovery methods, such as in situ combustion, by stabilizing fluid flow and heat transfer within the reservoir, thereby preventing early thermal breakthrough.

The application of fuzzy-ball-assisted flooding fluids post-polymer flooding is effective due to its viscoelastic and sealant properties. As discussed in [24], fuzzy-ball-assisted flooding fluids significantly enhance oil recovery in both high- and low-permeability zones. Although polymer flooding increases oil recovery compared to conventional water flooding, its limited ability to selectively plug high-permeability zones results in suboptimal performance in heterogeneous reservoirs. Fuzzy-ball-assisted flooding fluids address this limitation by effectively plugging high-permeability zones, enabling subsequent injections to be diverted into low-permeability zones, which are often under-swept in traditional flooding scenarios. This selective plugging mechanism leads to a significant improvement in sweep efficiency and oil recovery from low-permeability zones [25].

Scholars recently demonstrated the significant role of chemical additives in the performance of fuzzy-ball-assisted flooding fluids, with typical fuzzy-ball-assisted flooding fluids achieving a substantial 50.94% contribution to EOR. This highlights the synergistic effects of the flocculant and strengthening agents, where the flocculant enhances the mobilization of residual oil by improving sweep efficiency and reducing oil entrapment, while the strengthening agent stabilizes fractures and enhances fluid diversion. When the floss agent is removed, the EOR contribution declines sharply to 18.35%, indicating its critical role in ensuring the effective displacement of trapped oil. Conversely, fuzzy-ball-assisted flooding fluids containing only the strengthening agent contribute 30.71% to EOR, suggesting that while the strengthening agent supports fracture stability and reduces leak-off, it is insufficient for optimal oil recovery without the complementary action of the flocculant.

These findings imply that the design of fuzzy-ball-assisted flooding fluids for EOR should prioritize the careful selection and balance of chemical additives to maximize the synergistic effects. Incorporating both agents in appropriate proportions is essential to ensuring the fluid’s ability to penetrate, mobilize, and recover oil effectively while maintaining the structural stability of the fractures. This also suggests that fuzzy-ball-assisted flooding fluids formulations should be designed to fit specific reservoir conditions, with particular attention to optimizing flocculant concentrations to achieve the desired sweep and displacement efficiency. In reservoirs where mechanical stability is critical, strengthening agents should be enhanced but not at the expense of the flocculant’s functionality, as the combined formulation is crucial for maximizing EOR outcomes.

A field study reported that the SY-1 well is characterized by well-developed physical properties in the middle reservoir layers (S72-3, S73-1, and S73-2) but exhibits significant heterogeneity in its lower layers. Historically, SY-1 showed strong connectivity with four surrounding injection wells, with a cumulative injection volume exceeding 50,000 m3 and a monthly injection rate of approximately 1200 m3. However, a conventional profile control operation conducted in 2015 yielded unsatisfactory results. Although the injection pressure rose from 4.2 MPa to 5.6 MPa, the operation led to a modest increase in the daily liquid production rate by 1.9 m3/d but a significant decrease in the daily oil production rate by 17.0 m3/d. Additionally, the water content increased by 9.2%.

The underwhelming performance was attributed to the inability of the injected fluid to effectively seal high-permeability channels, thereby failing to enhance oil displacement efficiency in low-permeability areas. To address this, a field trial with fuzzy-ball-assisted flooding fluid was undertaken. A volume of 150 m3 of fuzzy-ball fluid was prepared on-site, guided by practices involving similar plugging agents in adjacent wells. At the end of the operation, oil recovery was improved due to the self-selective plugging capability of the fuzzy-ball-assisted flooding fluid, targeting high-permeability pathways to improve overall recovery performance.

Following these successful trials, fuzzy-ball-assisted flooding fluids have been applied in dozens of wells to improve oil recovery during EOR operations in heterogeneous formations.

3.4. Well Workover

Fuzzy-ball fluids, also known as fuzzy-ball kill fluids, have proven to be highly effective in preventing sour gas kicks such as hydrogen sulfide (H2S) during well workover and abandonment operations in deep and low-pressure gas reservoirs [26]. They share a similar chemical composition to the formulation, though it often includes higher concentrations of strengthening and desulfurizing agents to enhance the performance in challenging reservoir conditions. Structurally, fuzzy-ball kill fluids are composed of two main components: the outer fuzz layer and the vesicle-based inner core. This unique structure enables compatibility with formation water, polymers, and other displacement systems, making them suitable for workover operations. In carbonate reservoirs with significant heterogeneity, vesicles within the fuzzy-ball kill fluids tend to migrate into high-permeability zones, effectively blocking these pathways while preserving the integrity of the reservoir.

The mechanisms by which fuzzy-ball kill fluids mitigate H2S are twofold, involving both plugging and chemical absorption processes. Plugging occurs as fuzzy-ball kill fluids block seepage channels, such as fractures, pore throats, and lost circulation paths, which commonly allow formation fluids to leak into the wellbore. Depending on the size relationship between vesicle diameter and flow channel width, three distinct plugging behaviors can occur: the formation of high-strength gel barriers on channel surfaces, the filling of channels with vesicles to create an impermeable seal, and the aggregation of vesicles into larger structures that block wider channels. These mechanisms often act simultaneously due to the varying widths of flow channels in the reservoir. The result is the effective sealing of seepage channels, preventing the upward migration of H2S and other fluids while stabilizing the wellbore. Additionally, fuzzy-ball kill fluids accumulate in void spaces and bind fine particles within fractures, forming an interconnected structure that transforms the reservoir from a discontinuous to a continuous phase. This process enhances the rock’s mechanical properties by improving cohesion, increasing the Poisson’s ratio, reducing brittleness, and strengthening the formation, all of which contribute to the stability of the wellbore during operations.

In addition to plugging, fuzzy-ball kill fluids mitigate H2S through chemical absorption, a process enabled by the inclusion of methyldiethanolamine (MDEA) as a desulfurizing agent. MDEA, a widely used tertiary amine, is highly selective toward H2S, offering excellent absorption capacity, minimal corrosivity, low regeneration energy, and high thermal stability [27]. When fuzzy-ball kill fluids are injected into the reservoir, MDEA reacts with H2S in two stages. The first stage involves the protonation of MDEA, where H2S gas reacts to form a tertiary ammonium ion and an unstable disulfide ion. In the second stage, the disulfide ion dissociates to form a stable sulfide ion in the presence of water. These reactions are exothermic, favoring the forward equilibrium and ensuring efficient H2S removal. By combining these chemical absorption processes with its superior plugging capabilities, fuzzy-ball kill fluids not only mitigate H2S hazards but also protect health and safety, reduce environmental risks, and enhance the efficiency of well-killing operations.

A field study reported that Well DW-2, a high-H2S deep carbonate reservoir in the Puguang sour gas field with proven reserves exceeding 9 trillion cubic feet, was facing significant operational challenges, including high H2S concentrations (18%), low-pressure gradients, severe gas leakage, and formation damage [28]. The well, drilled to a depth of 5060 m with an average reservoir porosity of 8.84% and permeability of 3.37 mD, underwent multiple unsuccessful attempts to control its pressure using less dense kill fluids. Following these failures, an advanced fuzzy-ball kill fluid was employed, designed with a density of 0.93–0.95 g/cm3 and tailored for the well’s conditions. A total of 98 m3 of AFKF was injected, leading to effective plugging of seepage channels, a gradual reduction in oil pressure to zero, and high pump efficiency. Subsequent pressure buildup analysis over a 10-day period revealed improved bottomhole pressure stability and no detectable H2S at the wellhead, demonstrating the fluid’s effectiveness in extreme sulfur environments. This case highlights the potential of fuzzy-ball kill fluid for reliable well control and abandonment in challenging high-H2S reservoirs.

Following these successful application, fuzzy-ball kill fluids have been applied in several wells to kill wells during well workover operations.

4. Discussions

Fuzzy-ball fluids have demonstrated versatile capabilities across drilling, hydraulic fracturing, EOR, and well workover/abandonment operations. This section summarizes the main points of these applications, emphasizing their unique mechanisms, advantages, and performance metrics in Table 2.

Table 2.

Overview of fuzzy-ball fluid applications in oilfield operations [12].

Fuzzy-ball fluids, when applied to drilling, fracturing, EOR, and workover/abandonment operations, offer numerous advantages over conventional fluid systems. Their ability to adapt to various reservoir conditions and improve efficiency makes them a valuable tool for optimizing oilfield operations and enhancing production.

Fuzzy-ball fluids emerge as novel material with potential across various clean energy technologies. While their application remains underexplored, their unique properties such as self-plugging behavior, viscoelasticity, and adaptability to dynamic subsurface conditions make them suitable for addressing critical challenges in hydrogen storage, carbon capture, utilization, and storage (CCUS), and geothermal energy systems. Subsequent sections examine the theoretical roles fuzzy-ball fluids could play in these clean energy areas, providing an analysis of the advantages and the specific challenges they aim to address.

4.1. Future Application Directions

4.1.1. Hydrogen Storage Systems

The efficient and secure storage of hydrogen in subsurface reservoirs, such as depleted oilfields or salt caverns, is vital for enabling hydrogen-based energy systems. However, this process is often hindered by hydrogen leakage, reservoir instability, and even the generation of harmful gases such as hydrogen sulfide [29,30,31,32,33]. Fuzzy-ball fluids could present a compelling solution to these issues.

In subsurface reservoirs, the loss of hydrogen through micro-fractures and porous zones poses a significant threat to storage efficiency and safety [34]. The ability of fuzzy-ball fluids to dynamically plug such micro-fractures ensures that hydrogen leakage can be minimized. Additionally, the viscoelastic properties enable it to adapt to the cyclical pressure fluctuations typical of hydrogen storage operations. This adaptability helps maintain reservoir integrity, reducing the likelihood of structural failure over time.

The chemical stability of fuzzy-ball fluids under varying subsurface conditions can further enhance their suitability for hydrogen storage applications. Unlike traditional plugging materials that may degrade or interact adversely with hydrogen and reservoir minerals, fuzzy-ball fluids could exhibit minimal reactivity, ensuring long-term compatibility with reservoir environments. These attributes, if tested in laboratory or field scales, could position fuzzy-ball fluids as a revolutionary material for advancing hydrogen storage technologies.

4.1.2. Carbon Capture, Utilization, and Storage

CCUS is a significant global effort to mitigate climate change. Despite its promise, large-scale CCUS operations face significant challenges, including injectivity losses, leakage through caprock fractures, and the long-term retention of CO2 in underground formations [35,36]. Fuzzy-ball fluids could offer a multifaceted approach to addressing these obstacles.

One of the primary limitations in CCUS is the loss of injectivity during CO2 injection, which can result from reservoir pressure buildup or changes in fluid flow dynamics [37]. The rheological properties of fuzzy-ball fluids could enable them to enhance the mobility of injection fluids, facilitating a more uniform distribution of CO2 within the reservoir. Moreover, the ability of fuzzy-ball fluids to plug fractures into caprocks is critical for preventing the migration of CO2 out of the storage site, thereby ensuring containment integrity.

The viscoelastic nature of fuzzy-ball fluids may also contribute to the immobilization of CO2 within storage formations. By creating a stable interfacial layer between CO2 and the surrounding rock, fuzzy-ball fluids could enhance the retention of injected CO2, reducing the risk of leakage over extended timeframes. Machado et al. [38] revealed the importance of adaptable plugging mechanisms in maintaining the stability of CO2 storage sites, highlighting the potential of fuzzy-ball fluids to fulfill this role.

4.1.3. Geothermal Energy Systems

Geothermal energy systems rely on efficient fluid circulation and heat transfer to maximize energy extraction from subsurface reservoirs. However, challenges such as fluid loss through fractures, inefficiencies in heat exchange, and the stability of materials under high-temperature conditions limit the effectiveness of current geothermal technologies [39]. Fuzzy-ball fluids, with their unique viscoelastic and thermal properties, have the potential to overcome these limitations.

In geothermal wells, the loss of circulating fluids through fractures or porous zones not only reduces efficiency but also increases operational costs [40]. Fuzzy-ball fluids can mitigate this issue by plugging the fractures, ensuring that fluid loss is minimized, and flow paths are maintained. Their viscoelastic properties allow for better control over fluid movement, optimizing the transfer of heat from the reservoir to the surface.

Furthermore, the thermal stability of fuzzy-ball fluids makes them particularly suitable for the extreme conditions encountered in geothermal reservoirs. Unlike conventional materials that may degrade or lose functionality at high temperatures, fuzzy-ball fluids retain their plugging and flow-enhancing properties, which could enable sustained energy extraction.

4.2. Challenges and Limitations

Despite the promising applications of fuzzy-ball fluids in both oil and gas industries and clean energy technologies, several challenges and limitations must be addressed for effective deployment. These challenges include material stability, economic viability, and environmental impact, all of which are crucial to determining whether fuzzy-ball fluids can be widely adopted across different fields. In the oil and gas industry, the key concerns center on performance in complex and extreme subsurface conditions, including extremely high pressures, temperatures, and chemical exposure. In clean energy applications, such as hydrogen storage, carbon capture, utilization, and storage (CCUS), and geothermal energy, challenges arise from the need to maintain long-term efficiency and ensure sustainability while minimizing economic and environmental costs. This section explores these challenges in detail, providing suggestions for overcoming limitations to ensure the broader application of fuzzy-ball fluids.

4.2.1. Material Stability

Material stability is one of the foremost challenges in both oil and gas and clean energy applications of fuzzy-ball fluids. In the oil and gas field, fuzzy-ball fluids are often used to plug wells, prevent gas leaks, or enhance fluid management in harsh environments such as deep wells, offshore platforms, or reservoirs with corrosive environments. For these applications, fuzzy-ball fluids must maintain their mechanical and chemical stability under high pressure, temperature, and fluid interactions. The long-term plugging ability of fuzzy-ball fluids may be compromised if they degrade over time or if they react with the formation fluids or gases (e.g., hydrogen, CO2, brines), which can weaken the plugging and flow-regulating properties.

In clean energy applications, such as hydrogen storage or CCUS, fuzzy-ball fluids must also maintain stability over extended periods in environments subject to fluctuating pressures, temperatures, and the presence of corrosive substances. For instance, hydrogen storage in depleted oilfields or salt caverns demands materials that can withstand cyclic pressurization and chemical interactions with hydrogen gas, which can cause embrittlement or degradation in certain materials. Similarly, in CCUS, fuzzy-ball fluids must withstand the injection of CO2 under high pressures without breaking down or losing their effectiveness in plugging.

To mitigate these issues, extensive field testing and material optimization are necessary to ensure the long-term stability of fuzzy-ball fluids. Research into advanced stabilizing agents or the development of hybrid fuzzy-ball fluid formulations that enhance durability and chemical resistance could improve their performance across both industries.

Further studies are needed to optimize the synthesis and formulation of fuzzy-ball fluids, particularly in terms of their thermal stability, viscoelastic properties, and adapting mechanisms under extreme reservoir conditions. Advances in nanotechnology and polymer chemistry can help improve long-term stability, enhancing their performance in applications such as hydrogen storage and carbon sequestration. Nanoparticles that are non-toxic and biodegradable could be prioritized, addressing environmental concerns while maintaining fluid performance.

4.2.2. Interdisciplinary Collaboration

The successful advancement and deployment of fuzzy-ball fluid technologies in clean energy applications will require interdisciplinary collaboration across fields such as renewable energy, material science, petroleum engineering, environmental science, and economics. Collaborative efforts can drive innovations in fuzzy-ball fluid design, enhance modeling and simulation tools, and integrate real-time field data for adaptive applications. Partnerships between academia, industry, and governmental organizations will also play a critical role in addressing technical challenges, conducting field trials, and developing regulatory frameworks. Establishing international research consortia focused on fuzzy-ball fluid applications could further accelerate knowledge sharing and innovation, promoting the adoption of fuzzy-ball fluid technologies on a global scale.

4.2.3. Economic Viability

The economic viability of fuzzy-ball fluids is another significant challenge for both oil and gas and clean energy applications. In the oil and gas field, the cost of producing, transporting, and injecting fuzzy-ball fluids into wells or reservoirs must be justified by the performance improvements compared to traditional methods such as cementing, mechanical plugs, or other plugging technologies. The production and application of fuzzy-ball fluids often involve higher upfront costs, particularly for specialized equipment to handle and inject the fluids into deep wells or complex reservoirs. The cost of raw materials and potential transportation expenses further increases the total cost of deployment.

In clean energy applications like hydrogen storage, CCUS, and geothermal energy, while fuzzy-ball fluids offer promising advantages in terms of plugging, flow regulation, and storage security, their economic feasibility remains a critical factor for large-scale implementation. For instance, in hydrogen storage, fuzzy-ball fluids must demonstrate cost-effectiveness relative to other plugging and containment methods, such as geological containment or mechanical plugging systems, which have established infrastructure and proven performance.

For fuzzy-ball fluids to be economically viable, further optimization of material costs, manufacturing processes, and injection techniques is needed. Cost–benefit analyses that compare long-term savings from improved plugging efficiency, reduced leakage, and enhanced operational lifespan with the initial capital and operational costs will be essential in convincing stakeholders of their economic feasibility. Additionally, scaling up production processes for fuzzy-ball fluids to achieve economies of scale could help reduce costs in the future.

Although fuzzy-ball fluids have shown promising laboratory results and several field applications in the oil and gas industry, large-scale field trials are essential in determining their real-world performance in clean energy applications. Pilot projects in hydrogen storage reservoirs, geothermal systems, and CO2 sequestration sites will be crucial in understanding how they behave under complex, multi-phase flow conditions typical in these environments. These trials will also offer insights into optimizing fluid pumping rates, injection pressures, and distribution strategies for maximizing energy efficiency.

4.2.4. Environmental Impact

The environmental impact of fuzzy-ball fluids is a critical consideration, particularly for their use in both the oil and gas industry and clean energy applications. While fuzzy-ball fluids have the potential to enhance environmental outcomes by preventing gas leaks, improving the efficiency of energy production, and facilitating the safe storage of CO2, their composition and potential for environmental contamination must be thoroughly assessed.

In the oil and gas field, the environmental risks of fuzzy-ball fluids stem from the possibility of fluid leakage or contamination during well operations. The chemical stability and non-biodegradability of some fuzzy-ball fluid formulations could result in long-lasting environmental effects if they were to escape into surface ecosystems, groundwater, or marine environments. The use of non-biodegradable synthetic polymers or additives could lead to potential long-term environmental damage, particularly if they accumulate in the environment and resist degradation.

In clean energy applications such as hydrogen storage, CO2 sequestration, or geothermal energy systems, the potential environmental impact of fuzzy-ball fluids also warrants careful evaluation. The injection of fuzzy-ball fluids into subsurface reservoirs could result in the release of materials into the surrounding environment if containment is not maintained. Moreover, the lifecycle impact of fuzzy-ball fluids, from production to disposal, must be assessed through comprehensive environmental impact assessments (EIAs) or lifecycle analyses (LCAs) to determine overall sustainability.

To minimize the environmental impact, the development of biodegradable or eco-friendly fuzzy-ball fluid formulations is essential. Materials such as bio-based polymers or natural materials that degrade harmlessly over time could help reduce the environmental footprint. Additionally, effective monitoring and leakage detection systems must be in place to ensure that fuzzy-ball fluids remain contained within the intended areas. Lastly, establishing recycling or disposal programs for used fuzzy-ball fluids will be crucial to prevent environmental contamination and ensure sustainable usage.

4.2.5. Comparative Analysis of the Challenges and Limitations

A comparative analysis of the challenges and limitations associated with fuzzy-ball fluids in oil and gas versus clean energy applications offers valuable insights into shared issues and field-specific concerns. While both fields face challenges, the oil and gas industry primarily focus on immediate operational difficulties, such as material stability under extreme conditions and economic feasibility, whereas the clean energy field prioritizes long-term sustainability and lifecycle performance.

This study emphasizes the importance of interdisciplinary research to overcome shared challenges while offering solutions tailored to field-specific needs. For instance, advancements in stabilizing agents or biodegradable additives can benefit both industries by reducing environmental risks while enhancing fluid performance. Additionally, conducting comprehensive lifecycle analyses can aid in decision making, ensuring that fuzzy-ball fluids remain economically viable and environmentally sustainable throughout their use.

In the oil and gas field, environmental risks associated with fuzzy-ball fluids largely stem from the possibility of fluid leakage or contamination during well operations. The chemical stability and non-biodegradability of some formulations could result in prolonged environmental effects if the fluid escapes into surface ecosystems, groundwater, or marine environments. The use of non-biodegradable synthetic polymers or additives could contribute to long-term environmental damage, especially if they accumulate in the environment and resist degradation.

To address these concerns effectively, the integration of big data algorithms for comprehensive lifecycle analysis is critical. By leveraging advanced data analytics, the design, performance, and cost-effectiveness of fuzzy-ball fluids can be optimized across their entire lifecycle, from development to deployment and disposal. This approach would help improve material selection, predict performance more accurately, and ensure that fuzzy-ball fluids meet the needs of both the oil and gas and clean energy fields while minimizing environmental impacts.

4.3. Future Research Directions

The development of fuzzy-ball fluids presents numerous opportunities to enhance traditional oil and gas operations, emerging clean energy applications, and even applications in other scientific disciplines. For instance, ultrasonic micro-bubbles have been extensively utilized in areas such as cardiovascular and cerebrovascular diseases, gene transfer, and inhibition of cancer cells. Further investigation into the microstructure and mechanisms of fuzzy-ball fluids may offer inspiration and support for the development of novel micro-bubble technologies in medicine. Moreover, the adhesive capabilities of fuzzy-ball fluids also possess application potential in the field of architecture, enabling the repair and reinforcement of ancient buildings without impairing or altering their original aesthetic appearance.

However, realizing their full potential requires focused research efforts in key areas such as material development, field trials, environmental studies, and interdisciplinary collaboration. To optimize fuzzy-ball fluids, further studies are needed to improve their synthesis and formulation, particularly regarding thermal stability, viscoelastic properties, and self-adapting mechanisms under extreme reservoir conditions. Advances in nanotechnology and polymer chemistry could enhance long-term stability, particularly for applications like hydrogen storage and carbon sequestration, with a focus on non-toxic, biodegradable nanoparticles to address environmental concerns. Despite promising laboratory results, large-scale field trials are essential to assess the real-world performance of fuzzy-ball fluids in clean energy applications, such as hydrogen storage, geothermal systems, and CO2 sequestration sites. These trials will help with understanding how the fluids behave under complex multi-phase flow conditions, optimizing pumping rates, injection pressures, and distribution strategies to maximize energy efficiency. Additionally, fuzzy-ball fluids must undergo rigorous environmental impact assessments to ensure sustainability, including lifecycle assessments to evaluate their environmental footprint from production to disposal. Studies should also assess potential ecological risks, such as groundwater contamination and fluid residue persistence, to ensure safety and compliance with environmental standards. Furthermore, regulatory frameworks must be developed in collaboration with policymakers, environmental agencies, and industry leaders to establish industry standards for the use of fuzzy-ball fluids, particularly in clean energy fields like hydrogen storage and CCUS, ensuring their safe and responsible application. Last but certainly not least, the applications of fuzzy-ball fluids in other disciplines such as medicine and architecture are still underexplored, holding promising potential for future research and development.

5. Conclusions and Recommendations

Fuzzy-ball fluids represent a promising frontier in traditional oil and gas applications, emerging clean energy technologies, and even other disciplines. Their unique properties, including viscoelastic behavior, self-adapting mechanisms, and the ability to regulate flow, offer significant advantages under various complex and extreme subsurface conditions. This review summarizes the fundamental principles, mechanisms, and performance characteristics of fuzzy-ball fluids, providing a detailed analysis of their potential to enhance efficiency and safety in oil and gas operations, as well as their critical role in advancing clean energy initiatives such as hydrogen storage, CCUS, and geothermal energy.

Despite their broad application prospects, fuzzy-ball fluids still face several challenges, particularly in terms of material stability under complex reservoir conditions, economic feasibility, and environmental impact. Further research is needed to optimize the composition and performance of fuzzy-ball fluids, with a focus on enhancing stability, reducing costs, and minimizing environmental impact. Interdisciplinary collaboration, especially between material science, petroleum engineering, and clean energy fields, is crucial for addressing these challenges and facilitating the large-scale implementation of fuzzy-ball fluid technologies.

Future research should prioritize large-scale field trials to validate theoretical concepts and assess the performance of fuzzy-ball fluids in real-world applications. Additionally, ongoing advancements in material science and nanotechnology hold the potential to improve their long-term durability, making them more adaptable to various energy technologies. By addressing the key challenges and recommendations outlined in this review, fuzzy-ball fluids could play a transformative role in both traditional and clean energy sectors, contributing to enhanced energy efficiency, reduced emissions, and sustainable energy solutions, as well as making significant contributions to other fields.

Author Contributions

Writing—review and editing and project administration, L.J.; writing—original draft preparation and validation, C.J.O.; literature research, Q.G.; field experiment, L.Z. All authors have read and agreed to the published version of the manuscript.

Funding

The authors thank the Ministry of Science and Technology of the People’s Republic of China (2016ZX05066002) for financial support.

Data Availability Statement

This study did not report any data.

Acknowledgments

The authors wish to thank the College of Petroleum Engineering, China University of Petroleum (Beijing). Chinedu J. Okere appreciates the Distinguished Graduate Student Fellowship and the Graduate Student Research Support Grant from Texas Tech University, United States.

Conflicts of Interest

The authors declare no conflicts of interest.

References

- Woon, K.S.; Phuang, Z.X.; Taler, J.; Varbanov, P.S.; Chong, C.T.; Klemeš, J.J.; Lee, C.T. Recent Advances in Urban Green Energy Development towards Carbon Emissions Neutrality. Energy 2023, 267, 126502. [Google Scholar] [CrossRef]

- Li, L.; Lu, S.; Peng, T.; Zhang, M.; Mi, F. Fuzzy-ball Workover Fluids for Formation Damage Control in Jidong Oilfield. Oil Drill. Prod. Technol. 2011, 33, 31–34. [Google Scholar] [CrossRef]

- Ilyushin, Y.; Nosova, V.; Krauze, A. Application of Systems Analysis Methods to Construct a Virtual Model of the Field. Energies 2025, 18, 1012. [Google Scholar] [CrossRef]

- Hu, Y.; Zhao, J.; Chen, J.; Li, Y.; Bu, H. Practice of fuzzy-ball drilling fluid for sidetracking horizontal well Mo 80-C1. Drill. Prod. Technol. 2013, 36, 110–113. [Google Scholar]

- Wang, D.; He, Y.; Bu, Y.; Bi, Y.; Zhang, Y.; Luo, H. Practice of Fuzzy-Ball Drilling Fluid Technology in Well Ji X Coal Bed Methane. Oil Drill. Prod. Technol. 2011, 33, 93–95. [Google Scholar] [CrossRef]

- Xu, H.; Wei, P.; Wang, Z.; Zhang, M.; Yang, M.; Fan, J. A Technique of Temporary Blocking for Re-fracturing that Combines Non-solid Phase Fuzzy-Ball Fluid and Fibrous Material. Unconv. Oil Gas 2018, 5, 75–79. [Google Scholar]

- Magzoub, M.; Salehi, S.; Li, G.; Fan, J.; Teodoriu, C. Loss Circulation Prevention in Geothermal Drilling by Shape Memory Polymer. Geothermics 2021, 89, 101943. [Google Scholar] [CrossRef]

- Li, X.; Zheng, L.; Chen, Y.; Huang, X.; Zhai, X.; Wei, P.; Tao, X.; Nie, S. Fuzzy-Ball Fluids Enhance the Production of Oil and Gas Wells: A Historical Review. Energies 2023, 16, 6647. [Google Scholar] [CrossRef]

- Malkin, A.Y.; Derkach, S.R.; Kulichikhin, V.G. Rheology of Gels and Yielding Liquids. Gels 2023, 9, 715. [Google Scholar] [CrossRef]

- Wang, S.; Chen, Q.; Yuan, X.; Hua, X.; Chen, L. Research on a Nano-Composite Cement Slurry System Suitable for Low-Temperature Formations. Pet. Drill. Tech. 2021, 49, 73–80. [Google Scholar]

- Ur Rahman Awan, F.; Keshavarz, A.; Akhondzadeh, H.; Nosrati, A.; Al-Anssari, S.; Iglauer, S. Optimizing the Dispersion of Coal Fines Using Sodium Dodecyl Benzene Sulfonate. In Proceedings of the SPE/AAPG/SEG Asia Pacific Unconventional Resources Technology Conference 2019, APUR 2019, Brisbane, Australia, 18–19 November 2019. [Google Scholar] [CrossRef]

- He, J.; Okere, C.J.; Su, G.; Hu, P.; Zhang, L.; Xiong, W.; Li, Z. Formation Damage Mitigation Mechanism for Coalbed Methane Wells via Refracturing with Fuzzy-Ball Fluid as Temporary Blocking Agents. J. Nat. Gas. Sci. Eng. 2021, 90, 103956. [Google Scholar] [CrossRef]

- González, J.M.; Quintero, F.; Arellano, J.E.; Márquez, R.L.; Sánchez, C.; Pernía, D. Effects of interactions between solids and surfactants on the tribological properties of water-based drilling fluids. Colloids Surf. A Physicochem. Eng. Asp. 2011, 391, 216–223. [Google Scholar] [CrossRef]

- Li, Y.; Zhang, M.; Zhao, Z.; Tao, D.; Zhang, X. Properties of Chorionic Vesicle Fluids Prepared by Different Surfactants. Oilfield Chem. 2022, 37, 229–233. [Google Scholar] [CrossRef]

- Sun, F.; Zhang, J.; Li, J.; Li, X.; Zheng, H. Soft Capsule Drilling Fluid Technology for 215.9mm CBM Well and Horizontal Well. China Coalbed Methane 2012, 9, 18–21. [Google Scholar]

- Li, Z. Practice of fuzzy ball cementing pad fluid in leakage zone of Naiman well N-X-Y. Adv. Mater. Res. 2013, 773, 714–719. [Google Scholar]

- Yan, L.; Shen, R.; Yuan, G.; Li, B.; Wei, P.; Xian, Y.; Zhao, Z. Application of Near Collapse Pressureanti-sloughing Drilling Fluids in CBM Wells at Fanzhuang Block. J. China Coal Soc. 2015, 40, 144–150. [Google Scholar] [CrossRef]

- Wang, H.; Cui, J.; Zhu, Q.; Chen, B. Fuzzy-ball Drilling Fluid Technology in CBM of Multilateral Horizontal Well Qinping 12-11-3H with Six Branch Holes. Oil Drill. Prod. Technol. 2014, 36, 39–41. [Google Scholar] [CrossRef]

- Tao, X.; Zheng, Z.; Yu, H.; Liu, H.; Li, Y.; Zhang, J.; Liu, J.; Zheng, L. Internal Blocking and Bonding to Strengthen the Mechanical Properties and Prevent Collapse and Leakage of Fragmented Coalbed Methane (CBM) Reservoirs by Cohesive Drilling Fluids. Geoenergy Sci. Eng. 2024, 241, 213136. [Google Scholar] [CrossRef]

- Jiang, J.; Zhai, X.; He, J.; Geng, Y.; Cui, J.; Wei, P. Application of A Fuzzy-Ball Temporary Plugging Agent to the Diverting Fracturing of Deep Carbonate Reservoirs. Nat. Gas Ind. 2019, 39, 81–87. [Google Scholar]

- Zhu, P.W. Effects of Sodium Dodecyl Sulfate on Structures of Poly(N-Isopropylacrylamide) at the Particle Surface. J. Phys. Chem. B 2015, 119, 359–371. [Google Scholar] [CrossRef]

- Awan, F.U.R.; Keshavarz, A.; Akhondzadeh, H.; Al-Anssari, S.; Al-Yaseri, A.; Nosrati, A.; Ali, M.; Iglauer, S. Stable Dispersion of Coal Fines during Hydraulic Fracturing Flowback in Coal Seam Gas Reservoirs—An Experimental Study. Energy Fuels 2020, 34, 5566–5577. [Google Scholar] [CrossRef]

- Lou, Z.; Li, S.; Fan, A.; Du, Z.; Song, X. Experimental Evaluation and Field Application of Pre-Cross Linked Polymer Particle Flooding in Eastern Wenliu block 25 of Zhongyuan oilfield. J. Southwest Pet. Univ. (Sci. Technol. Ed.) 2012, 34, 125–132. [Google Scholar]

- Wang, X.; Gan, M.; Yang, X.; Zhang, P.; Peng, X.; Ju, Y.; Kou, Y.; Yu, X.; Zheng, L.; Wang, C. Mechanism of Enhanced Oil Recovery by Fuzzy-Ball Fluid as a Novel Oil-Displacement Agent. Energy Rep. 2023, 9, 1447–1463. [Google Scholar] [CrossRef]

- Song, J.; Li, Y.; Wang, H. Oil-Displacing Efficiency of Polymer Flood and Successive Permeability Control and Polymer Flood Determined on Three-Dimensional Heterogeneous Physical Models. Oilfield Chem. 2002, 19, 162–166. [Google Scholar] [CrossRef]

- Yan, Z.; Okere, C.J.; Zeng, X.; Yao, Z.; Su, G.; Gan, M.; Fu, Y.; Tao, X.; Zheng, L. Preventing Sour Gas Kicks during Workover of Natural Gas Wells from Deep Carbonate Reservoirs with Anti-Hydrogen Sulfide Fuzzy-Ball Kill Fluid. Energy Sci. Eng. 2022, 10, 2674–2688. [Google Scholar] [CrossRef]

- Mandal, B.P.; Biswas, A.K.; Bandyopadhyay, S.S. Selective Absorption of H2S from Gas Streams Containing H2S and CO2 into Aqueous Solutions of N-Methyldiethanolamine and 2-Amino-2-Methyl-1-Propanol. Sep. Purif. Technol. 2004, 35, 191–202. [Google Scholar] [CrossRef]

- Zeng, H.; Zhu, F.; Zhang, W.; Zhang, Z.; Liu, Z.; Cai, N. Application of Fuzzy-Ball Workover Fluid Combined with Solid Plugging Agent to the Temporary Plugging of Deep Low-Pressure Gas Layers in Puguang Gas Field. Oil Drill. Prod. Technol. 2020, 42, 652–656. [Google Scholar] [CrossRef]

- Epelle, E.I.; Obande, W.; Udourioh, G.A.; Afolabi, I.C.; Desongu, K.S.; Orivri, U.; Gunes, B.; Okolie, J.A. Perspectives and Prospects of Underground Hydrogen Storage and Natural Hydrogen. Sustain. Energy Fuels 2022, 6, 3324–3343. [Google Scholar] [CrossRef]

- Fang, W.; Ding, C.; Chen, L.; Zhou, W.; Wang, J.; Huang, K.; Zhu, R.; Wu, J.; Liu, B.; Fang, Q.; et al. Review of Hydrogen Storage Technologies and the Crucial Role of Environmentally Friendly Carriers. Energy Fuels 2024, 38, 13539–13564. [Google Scholar] [CrossRef]

- Chaturvedi, K.R.; Sinha, A.S.K.; Nair, V.C.; Sharma, T. Enhanced Carbon Dioxide Sequestration by Direct Injection of Flue Gas Doped with Hydrogen into Hydrate Reservoir: Possibility of Natural Gas Production. Energy 2021, 227, 120521. [Google Scholar] [CrossRef]

- Okere, C.J.; Sheng, J.J.; Ejike, C. Evaluating Reservoir Suitability for Large-Scale Hydrogen Storage: A Preliminary Assessment Considering Reservoir Properties. Energy Geosci. 2024, 5, 100318. [Google Scholar] [CrossRef]

- Amid, A.; Mignard, D.; Wilkinson, M. Seasonal storage of hydrogen in a depleted natural gas reservoir. Int. J. Hydrog. Energy 2016, 41, 5549–5558. [Google Scholar]

- Gomez Mendez, I.; El-Sayed, W.M.M.; Menefee, A.H.; Karpyn, Z.T. Insights into Underground Hydrogen Storage Challenges: A Review on Hydrodynamic and Biogeochemical Experiments in Porous Media. Energy Fuels 2024, 38, 20015–20032. [Google Scholar] [CrossRef]

- Massarweh, O.; Abushaikha, A.S. CO2 Sequestration in Subsurface Geological Formations: A Review of Trapping Mechanisms and Monitoring Techniques. Earth Sci. Rev. 2024, 253, 104793. [Google Scholar] [CrossRef]

- Zhou, J.; Chen, Z.; Wu, S.; Yang, C.; Wang, Y.; Wu, Y. Potential Assessment and Development Obstacle Analysis of CCUS Layout in China: A Combined Interpretive Model Based on GIS-DEMATEL-ISM. Energy 2024, 310, 133225. [Google Scholar] [CrossRef]

- Hajiabadi, S.H.; Bedrikovetsky, P.; Borazjani, S.; Mahani, H. Well Injectivity during CO2 Geosequestration: A Review of Hydro-Physical, Chemical, and Geomechanical Effects. Energy Fuels 2021, 35, 9240–9267. [Google Scholar] [CrossRef]

- Barbosa Machado, M.V.; Delshad, M.; Sepehrnoori, K. Modeling Self-Sealing Mechanisms in Fractured Carbonates Induced by CO2 Injection in Saline Aquifers. ACS Omega 2023, 8, 48925–48937. [Google Scholar] [CrossRef]

- Sharmin, T.; Khan, N.R.; Akram, M.S.; Ehsan, M.M. A State-of-the-Art Review on Geothermal Energy Extraction, Utilization, and Improvement Strategies: Conventional, Hybridized, and Enhanced Geothermal Systems. Int. J. Thermofluids 2023, 18, 100323. [Google Scholar] [CrossRef]

- Hemmati-Sarapardeh, A.; Larestani, A.; Nait Amar, M.; Hajirezaie, S. Application of Intelligent Models in Drilling Engineering. In Applications of Artificial Intelligence Techniques in the Petroleum Industry; Gulf Professional Publishing: Oxford, UK, 2020; pp. 229–278. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).