High-Efficiency Cogeneration: A Viable Solution for the Decarbonization of Cities with District Heating Systems

Abstract

1. Introduction

- Application of the proposed calculation methodology in the case of a district heating system with a biomass cogeneration plant;

- A comparative analysis of fulfilling the qualification criteria for energy production in high-efficiency cogeneration in three scenarios;

- A comparison of district heating vs. individual heating in terms of CO2 emissions for the same amount of heat supplied to end users;

- Identifying solutions to increase energy efficiency and decarbonization for the Suceava district heating system compared to the current situation.

2. Materials and Methods

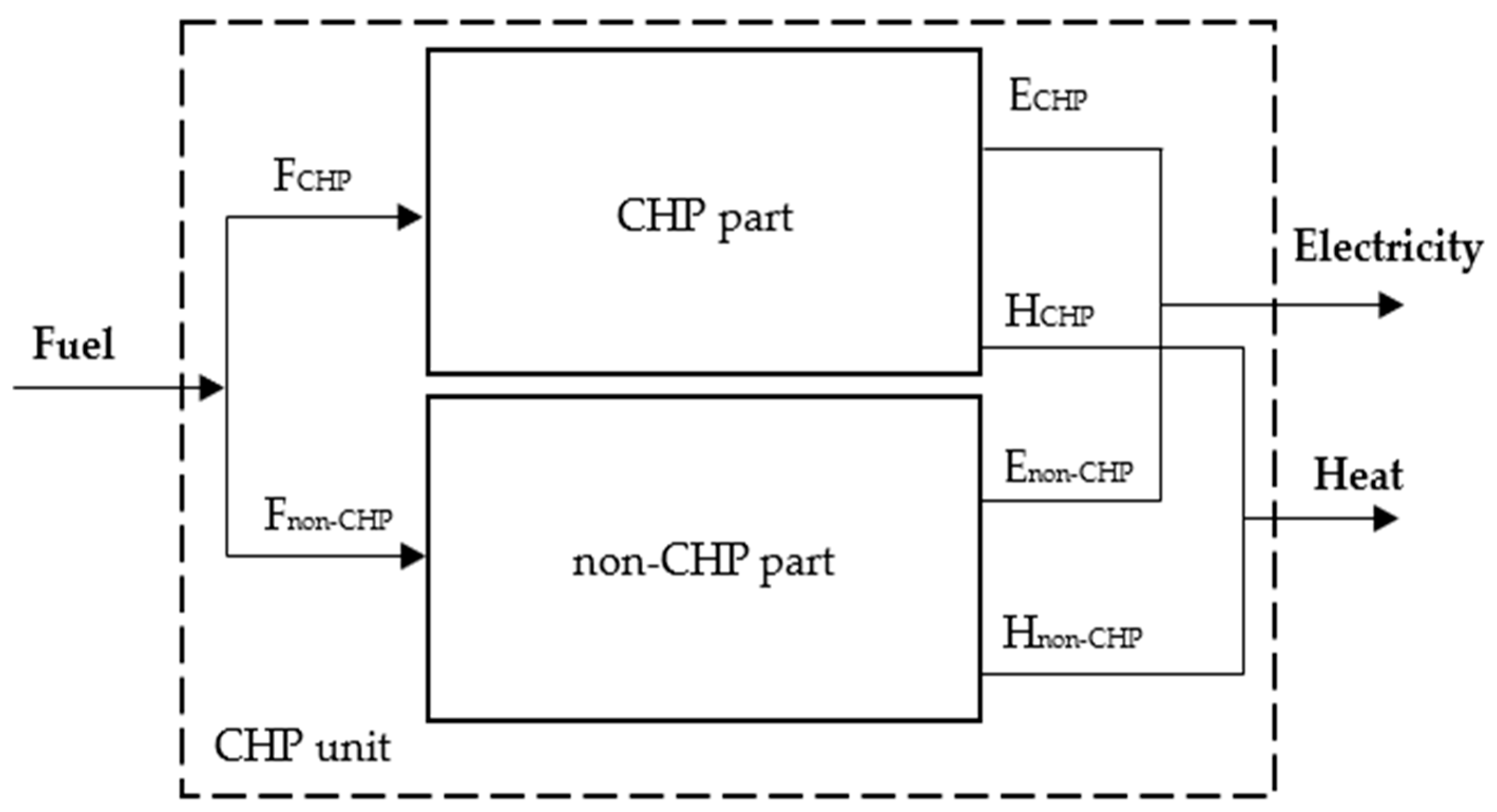

- ηe,Ref is the efficiency reference value for the separate production of electricity (%);

- ηh,Ref is the efficiency reference value for the separate production of heat (%);

- ploss is the correction factor for avoided losses in the electrical networks (-);

- ηe,CHP is the electrical efficiency in cogeneration (%);

- ηh,CHP is the heat efficiency in cogeneration (%).

- bj is the share of fuel consumption of type j in total fuel consumption (-);

- ηe,Ref,j is the efficiency reference value for the separate production of electricity when operating on fuel j (%);

- qk is the share of the delivered heat agent (direct use of exhaust gases/steam/hot water) (-);

- ηh,Ref,k(j) is the efficiency reference value for the separate production of heat related to the thermal agent used (exhaust gases/steam/hot water) and the fuel type j (%);

- Qj is the energy consumed from fuel type j (MWh).

- Ep,j is the consumption of primary energy (fuel) of type j (kWh/year);

- fCO2,j is the conversion factor into CO2-equivalent emissions for primary energy type j (kgCO2/kWh).

3. Case Study: District Heating System of Suceava City, Romania

- 1964–2015 hydrocarbon thermal plant (withdrawn from operation):

- 2 industrial steam boilers of 105 t/h (17 bar; 250 °C);

- 3 hot water boilers of 58.15 MW;

- 2 hot water boilers of 116.30 MW;

- 1 peak boiler of 17.45 MW.

- 1987–2013 coal-fired combined heat and power plant (CHP) 2 × 50 MWe (withdrawn from operation):

- 2 steam boilers of 420 t/h (137 bar; 540 °C) operating on lignite (1987–2000) followed by conversion to hard coal (2000–2013);

- 2 power units of 50 MWe (condensing steam turbines and sockets type DSL-50-1);

- 2 basic boilers 2 × 98.86 MW;

- 3 peak boilers 3 × 46.52 MW.

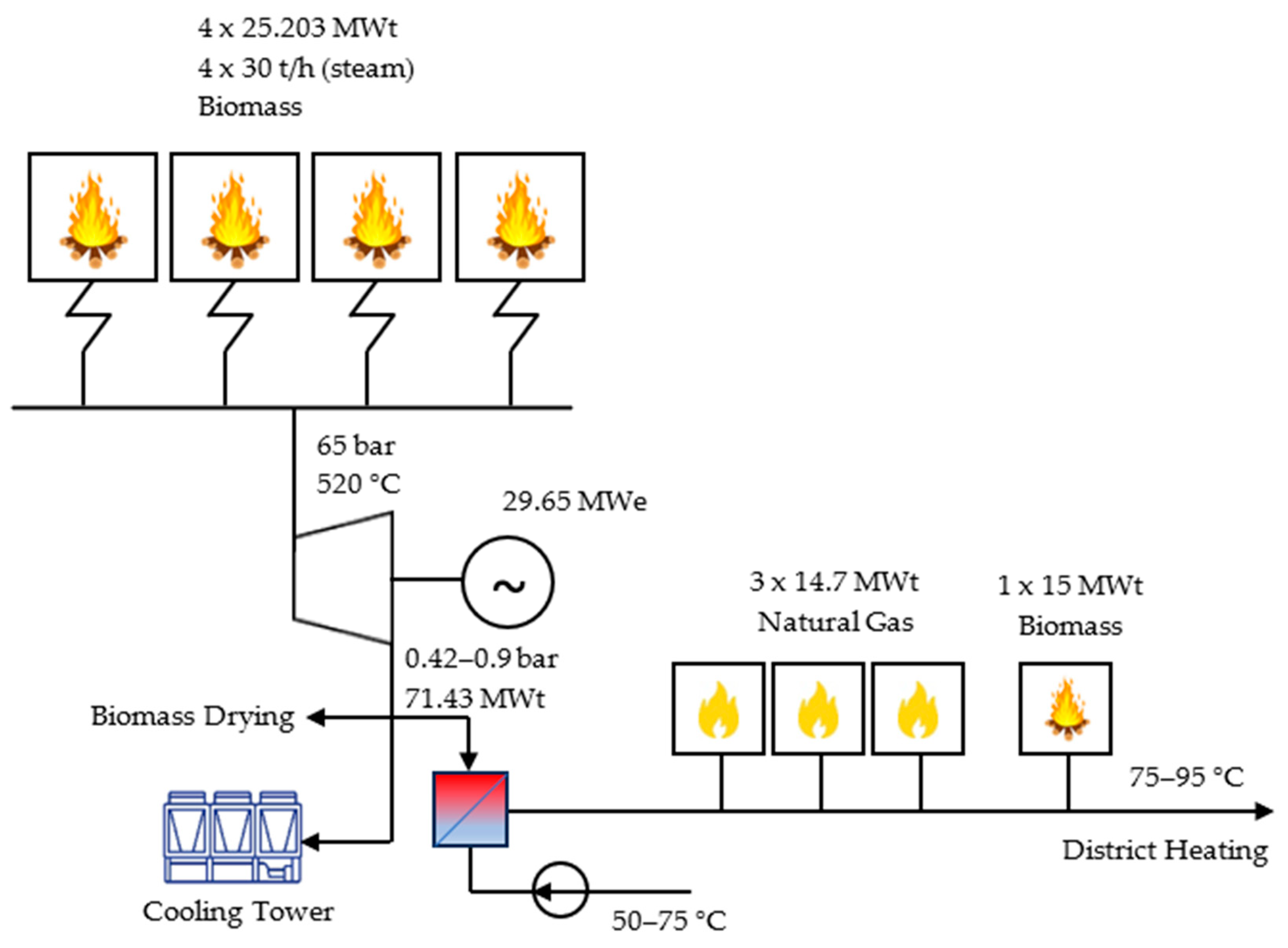

- 2015–present BIOENERGY cogeneration plant (in operation):

- Steam turbine cogeneration unit (29.65 MWe; 71.43 MWt) running on biomass;

- 1 hot water boiler operating on biomass 15 MWt;

- 3 hot water boilers operating on natural gas 3 × 14.7 MWt.

3.1. A Brief Presentation of the District Heating System and the Cogeneration Plant

- Thermal energy generating plant (Figure 5).

- Transport networks, with a length of approximately 55 km, of which approximately 72% of the route is underground, and the rest is above ground. The transport networks are made of steel pipes with diameters between Dn 800 and Dn 50, insulated with mineral wool mattresses protected with galvanized sheet metal.

- A total of 59 district heating substations with plate heat exchangers for both heating and domestic hot water. All district heating substations are metered.

- The distribution networks, with a length of 455 km, with diameters ranging from DN 15 to DN 300, are laid in thermal channels. Their thermal insulation is made of mineral wool, protected with polyethylene foil or asphalt cardboard, or polyurethane foam insulation.

- End-users: apartments, public institutions and economic agents.

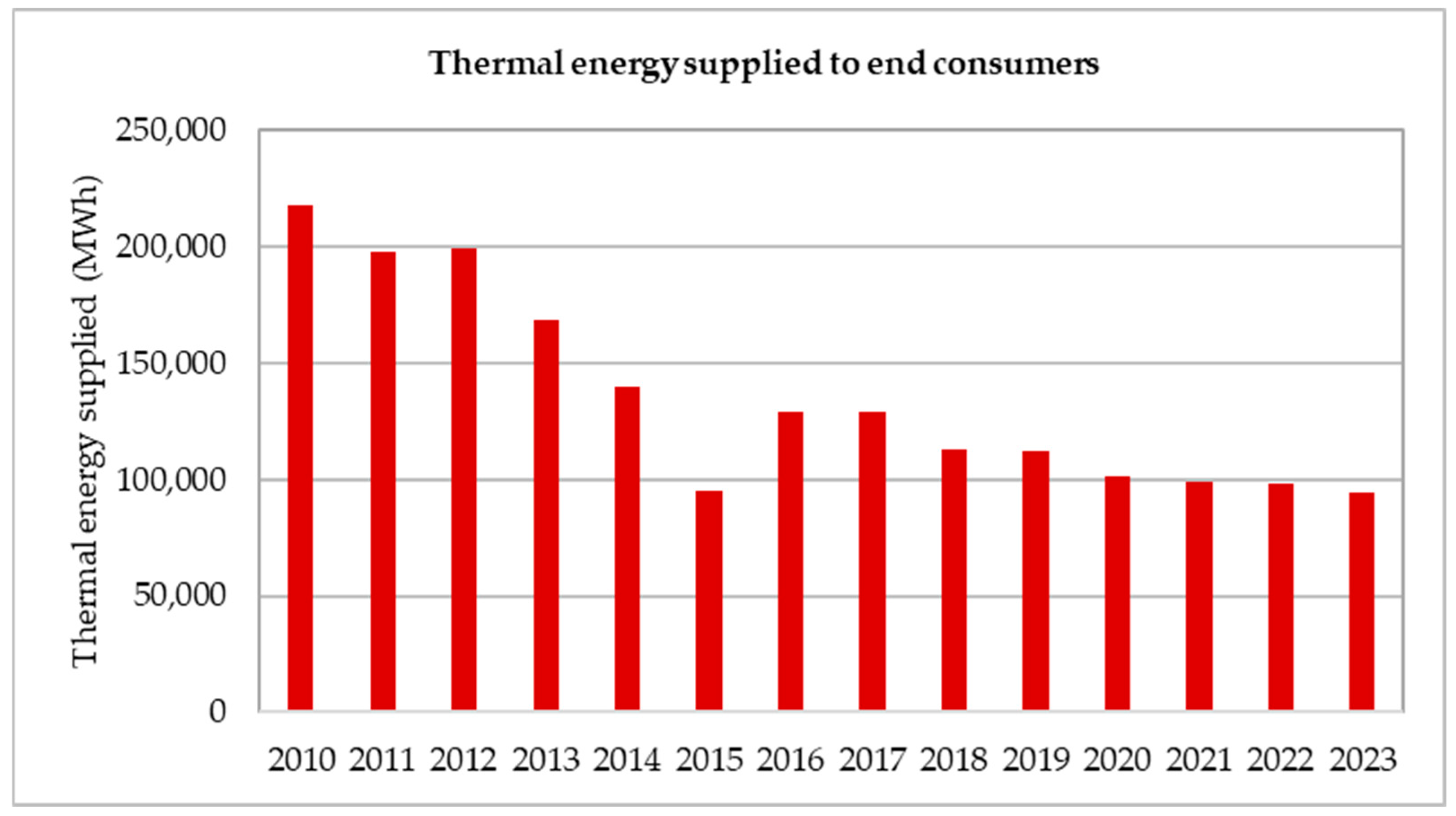

3.2. Production Data and Heating Energy Needs of Suceava City

4. Results and Discussion

- Scenario 1: Nominal technical data for the cogeneration unit;

- Scenario 2: Operating data achieved in 2023 (excluding the heat lost to the cooling tower);

- Scenario 3: Operating data obtained in 2023 (including the heat given off to the cooling tower as heat potential available for connecting new consumers).

- Primary energy saving: PES = 3.19% < 10%;

- Total efficiency: ηgl,CHP = 52.19% < 70%.

- Primary energy saving: PES = 27.99% > 10%;

- Total efficiency: ηgl,CHP = 79.59% > 70%.

- I.

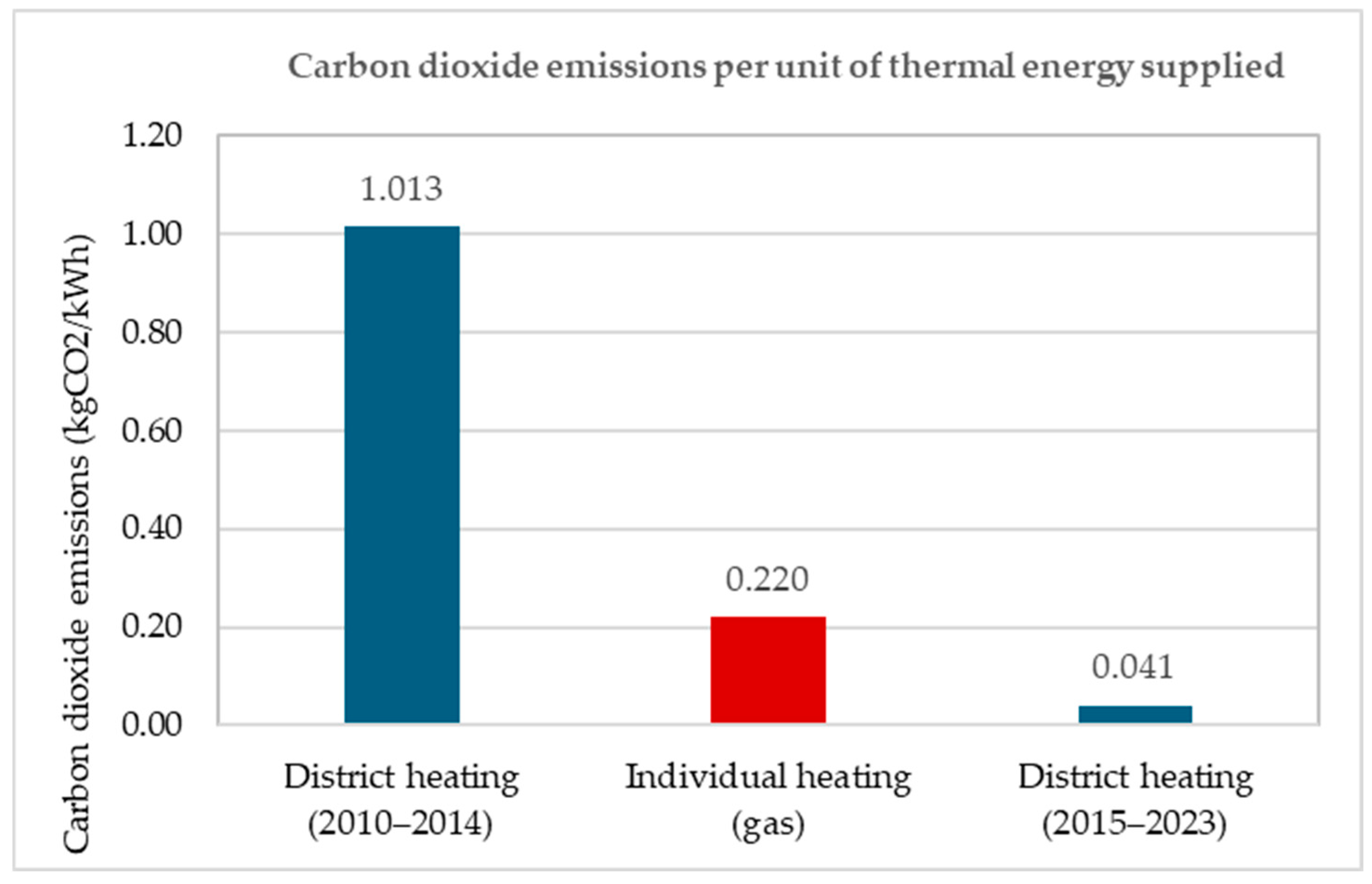

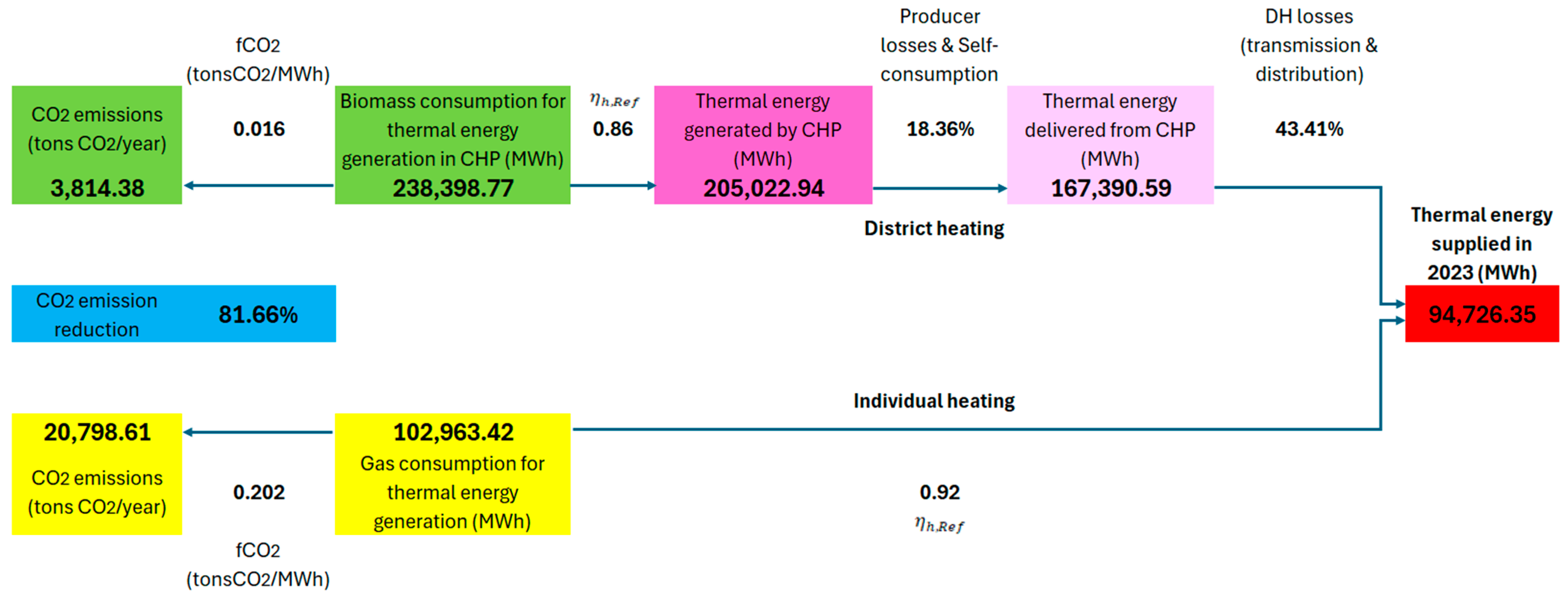

- District heatingCalculation assumptions:

- Amount of heat supplied to final consumers in 2023 from the district heating system: 94,726 MWh;

- All losses from the source to the final consumers were considered: losses on the transmission and distribution networks (43.41%), losses at the producer and self-consumption (18.36%) levels;

- The allocation of fuel consumption (biomass) for heat generation in cogeneration was made according to the “Alternative heat generation method” [45] with a reference efficiency ηh,Ref = 86%.

Result:- Carbon dioxide emissions: 3814.38 tons CO2.

- II.

- Individual heatingCalculation assumptions:

- The same amount of heat supplied to final consumers in 2023 from the district heating system if it had been generated in individual gas heating sources: 94,726 MWh;

- Individual heating source: gas boiler with a reference efficiency ηh,Ref = 92%.

- Result:

- Carbon dioxide emissions: 20,798.61 tons CO2.

- A.

- Heat use area at the level of end consumers:

- Energy renovation/rehabilitation of apartment buildings. There is a potential to increase the energy efficiency of buildings by reducing specific heating consumption below 100 kWh/m2·year. For comparison, the specific heating consumption in 2023 was 180 kWh/m2·year (calculated using Equation (13)).

- Attracting new customers. Connecting apartments/public institutions/economic agents located in the DH area:

- ○

- number of apartments connected to DH in 2023: 15,021 (44.70%);

- ○

- total number of apartments that could be connected to DH: 33,604.

- Connection of new buildings located in the DH area:

- ○

- meeting NZEB (Nearly Zero Energy Building) requirements for new buildings.

- Heat metering at apartment level (installing smart equipment that optimizes energy flows based on real demand).

- B.

- Heat transport and distribution area:

- Reducing losses in heat transport and distribution networks by replacing classic thermal pipes with pre-insulated pipes (losses in heat transport and distribution networks in 2023 were 43.41%);

- Rehabilitation of recirculation pipes for hot water consumption (ensuring optimal supply parameters);

- Refurbishment, automation and remote monitoring of district heating substations;

- Real-time monitoring of heating networks to quickly detect faults or heat loss.

- C.

- Heat generation area:

- Follow-up in operation of the efficiency of heat generation in cogeneration (fulfillment of the criteria for high-efficiency cogeneration);

- Diversification of production sources/modular sizing/use of renewable energy sources (other than biomass);

- Integration of modern technologies for the efficient utilization of primary energy sources with thermal potential at medium and low temperatures (cogeneration with ORC technology and heat pumps);

- Using heat storage to increase the flexibility of the district heating system.

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Nomenclature

| PES | Primary energy saving (%) |

| QF | Quality factor of the cogeneration unit (-) |

| ECHP | Electricity generated in cogeneration mode (MWh) |

| Enon-CHP | Electricity generated in non-cogeneration mode (MWh) |

| HCHP | Heat generated in cogeneration mode (MWh) |

| Hnon-CHP | Heat generated in non-cogeneration mode (MWh) |

| Hcooling tower | Heat lost to the cooling tower (MWh) |

| FCHP | Fuel consumed in cogeneration mode (MWh) |

| Fnon-CHP | Fuel consumed in non-cogeneration mode (MWh) |

| CSH | Specific consumption for heating buildings (kWh/m2·year) |

| Hsupplied | Thermal energy supplied to end consumers (kWh) |

| Sheated | Heated surface of buildings (m2) |

References

- Elavarasan, R.M.; Pugazhendhi, R.; Irfan, M.; Mihet-Popa, L.; Khan, I.A.; Campana, P.E. State-of-the-art sustainable approaches for deeper decarbonization in Europe—An endowment to climate neutral vision. Renew. Sustain. Energy Rev. 2022, 159, 112204. [Google Scholar] [CrossRef]

- Maya-Drysdale, D.; Krog Jensen, L.; Vad Mathiesen, B. Energy Vision Strategies for the EU Green New Deal: A Case Study of European Cities. Energies 2020, 13, 2194. [Google Scholar] [CrossRef]

- Hewitt, N.J. Decarbonizing Energy of a City: Identifying Barriers and Pathways. Energies 2024, 17, 267. [Google Scholar] [CrossRef]

- Ana, F.; Pinheiroa, M.D.; Britoa, J.; Mateus, R. Decarbonizing strategies of the retail sector following the Paris Agreement. Energy Policy 2019, 135, 110999. [Google Scholar]

- Leibowicz, B.D.; Lanham, C.M.; Brozynski, M.T.; Vázquez-Canteli, J.R.; Castejón, N.C.; Nagy, Z. Optimal decarbonization pathways for urban residential building energy services. Appl. Energy 2018, 230, 1311–1325. [Google Scholar] [CrossRef]

- Munćan, V.; Mujan, I.; Macura, D.; Anđelković, A.S. The state of district heating and cooling in Europe—A literature-based assessment. Energy 2024, 304, 132191. [Google Scholar] [CrossRef]

- Zhang, X.; Strbac, G.; Teng, F.; Djapic, P. Economic assessment of alternative heat decarbonisation strategies through coordinated operation with electricity system—UK case study. Appl. Energy 2018, 222, 79–91. [Google Scholar] [CrossRef]

- Hansen, C.H.; Gudmundsson, O.; Detlefsen, N. Cost efficiency of district heating for low energy buildings of the future. Energy 2019, 177, 77–86. [Google Scholar] [CrossRef]

- Yoon, T.; Ma, Y.; Rhodes, C. Individual Heatings ystems vs. District Heating systems: What will consumers pay for convenience? Energy Policy 2015, 86, 73–81. [Google Scholar] [CrossRef]

- Vilén, K.; Selvakkumaran, S.; Ahlgren, E.O. Communal or individual—Exploring cost-efficient heating of new city-level housing in a systems perspective. Smart Energy 2023, 10, 100097. [Google Scholar] [CrossRef]

- Meha, D.; Thakur, J.; Novosel, T.; Pukšec, T.; Duić, N. A novel spatial–temporal space heating and hot water demand method for expansion analysis of district heating systems. Energy Convers. Manag. 2021, 234, 113986. [Google Scholar]

- Fallahnejad, M.; Kranzl, L.; Haas, R.; Hummel, M.; Müller, A.; García, L.S.; Persson, U. District heating potential in the EU-27: Evaluating the impacts of heat demand reduction and market share growth. Appl. Energy 2024, 353, 122154. [Google Scholar]

- Jimenez-Navarro, J.P.; Kavvadias, K.; Filippidou, F.; Pavičević, M.; Quoil, S. Coupling the heating and power sectors: The role of centralised combined heat and power plants and district heat in a European decarbonised power system. Appl. Energy 2020, 270, 115134. [Google Scholar] [CrossRef]

- Guelpa, E.; Verda, V. Demand response and other demand side management techniques for district heating: A review. Energy 2021, 219, 119440. [Google Scholar]

- Dattilo, A.; Melino, F.; Ricci, M.; Sdringola, P. Optimizing Thermal Energy Sharing in Smart District Heating Networks. Energies 2024, 17, 2936. [Google Scholar] [CrossRef]

- Büchele, R.; Kranzl, L.; Hummel, M. What is the impact of the policy framework on the future of district heating in Eastern European countries? The case of Brasov. Energy Strategy Rev. 2018, 19, 72–75. [Google Scholar]

- Kleinertz, B.; Timpe, C.; Bürger, V.; Cludius, J.; Ferstl, J. Analysis of the cost-optimal heat supply strategy for Munich following a clean energy transformation pathway. Energy Policy 2024, 188, 113968. [Google Scholar]

- Romanchenko, D.; Kensby, J.; Odenberger, M.; Johnsson, F. Thermal energy storage in district heating: Centralised storage vs. storage in thermal inertia of buildings. Energy Convers. Manag. 2018, 162, 26–38. [Google Scholar]

- Guelpa, E.; Verda, V. Thermal energy storage in district heating and cooling systems: A review. Appl. Energy 2019, 252, 113474. [Google Scholar]

- Świerzewski, M.; Kalina, J. Optimisation of biomass-fired cogeneration plants using ORC technology. Renew. Energy 2020, 159, 195–214. [Google Scholar]

- Ricci, M.; Sdringola, P.; Tamburrino, S.; Puglisi, G.; Donato, E.D.; Ancona, M.A.; Melino, F. Efficient District Heating in a Decarbonisation Perspective: A Case Study in Italy. Energies 2022, 15, 948. [Google Scholar] [CrossRef]

- Wyrwa, A.; Raczyński, M.; Kulik, M.; Oluwapelumi, O.; Mateusiak, L.; Zhang, H.; Kempka, M. Greening of the District Heating Systems—Case Study of Local Systems. Energies 2022, 15, 3165. [Google Scholar] [CrossRef]

- Pakere, I.; Feofilovs, M.; Lepiksaar, K.; Vītoliņš, V.; Blumberga, D. Multi-source district heating system full decarbonization strategies: Technical, economic, and environmental assessment. Energy 2023, 285, 129296. [Google Scholar]

- Narula, K.; Chambers, J.; Streicher, K.N.; Patel, M.K. Strategies for decarbonising the Swiss heating system. Energy 2019, 169, 1119–1131. [Google Scholar]

- Daugavietis, J.E.; Jelena Ziemele, J. District heating system’s development decarbonization strategy assessment by system dynamics modeling and multi-criteria analysis. J. Environ. Manag. 2024, 356, 120683. [Google Scholar]

- Wanga, H.; Yin, W.; Abdollahi, E.; Lahdelma, R.; Jiao, W. Modelling and optimization of CHP based district heating system with renewable energy production and energy storage. Appl. Energy 2015, 159, 401–421. [Google Scholar]

- Mäki, E.; Kannari, L.; Hannula, I.; Shemeikka, J. Decarbonization of a district heating system with a combination of solar heat and bioenergy: A techno-economic case study in the Northern European context. Renew. Energy 2021, 175, 1174–1199. [Google Scholar]

- Wang, Y.; Shi, H.; Fang, B.; Zakin, J.; Yu, B. Heat Transfer Enhancement for Drag-Reducing Surfactant Fluid Using Photo-Rheological Counterion. Exp. Heat Transf. 2012, 25, 139–150. [Google Scholar]

- Liu, E.B.; Peng, Y.; Peng, S.B.; Yu, B.; Chen, Q.K. Research on low carbon emission optimization operation technology of natural gas pipeline under multi-energy structure. Pet. Sci. 2022, 19, 3046–3058. [Google Scholar]

- Fesefeldt, M.; Capezzali, M.; Bozorg, M.; Karjalainen, R. Impact of Heat Pump and Cogeneration Integration on Power Distribution Grids Based on Transition Scenarios for Heating in Urban Areas. Sustainability 2023, 15, 4985. [Google Scholar] [CrossRef]

- Bernath, C.; Deac, G.; Sensfuß, F. Influence of heat pumps on renewable electricity integration: Germany in a European context. Energy Strategy Rev. 2019, 26, 100389. [Google Scholar]

- Capone, M.; Guelpa, E.; Verda, V. Optimal Installation of Heat Pumps in Large District Heating Networks. Energies 2023, 16, 1448. [Google Scholar] [CrossRef]

- Navarro, J.P.J.; Kavvadias, K.C.; Quoilin, S.; Andreas Zucker, A. The joint effect of centralised cogeneration plants and thermal storage on the efficiency and cost of the power system. Energy 2018, 149, 535–549. [Google Scholar]

- Dang, L.M.; Nguyen, L.Q.; Namb, J.; Nguyen, T.N.; Lee, S.; Song, H.K.; Moon, H. Fifth generation district heating and cooling: A comprehensive survey. Energy Reports 2024, 11, 1723–1741. [Google Scholar]

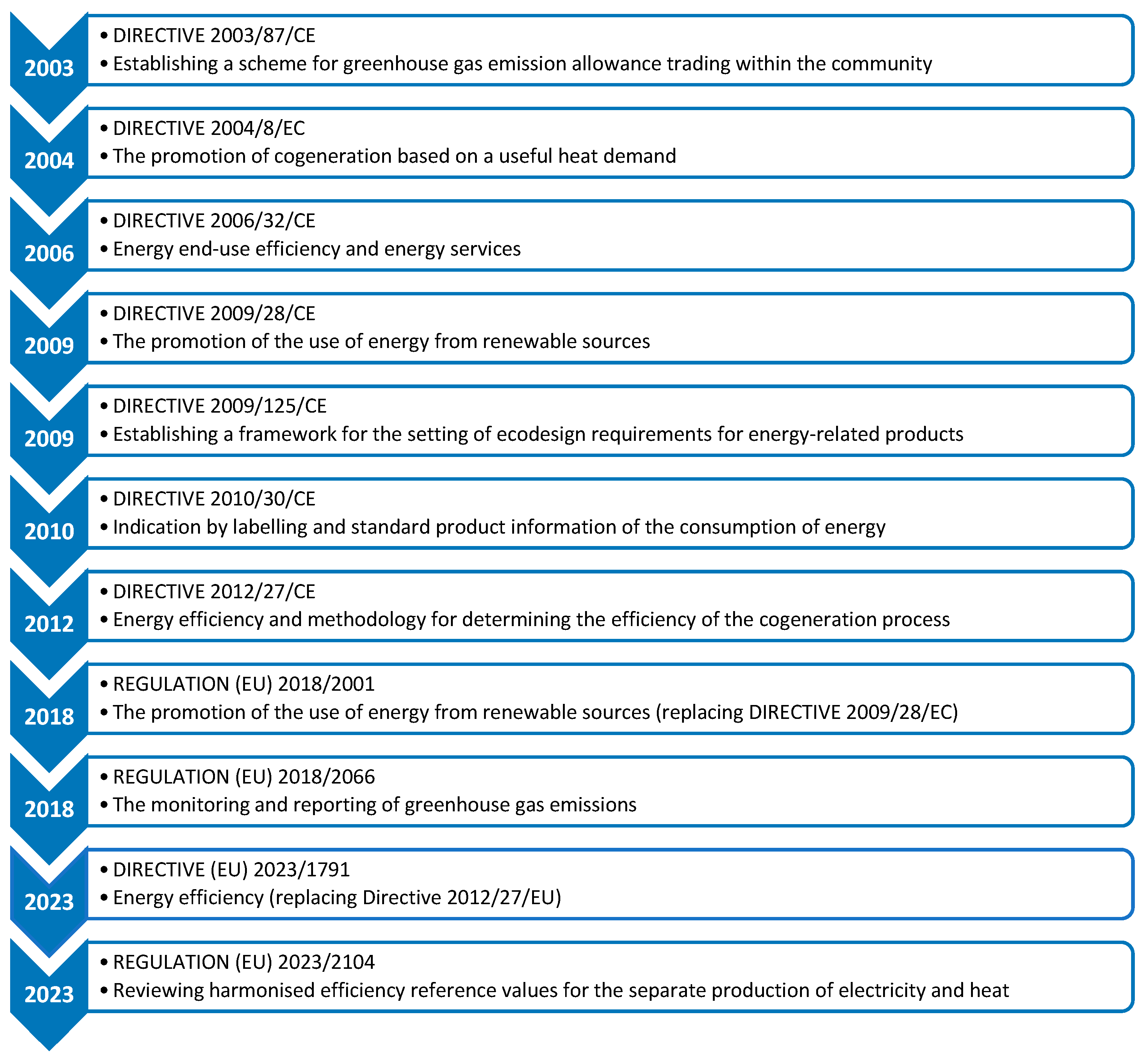

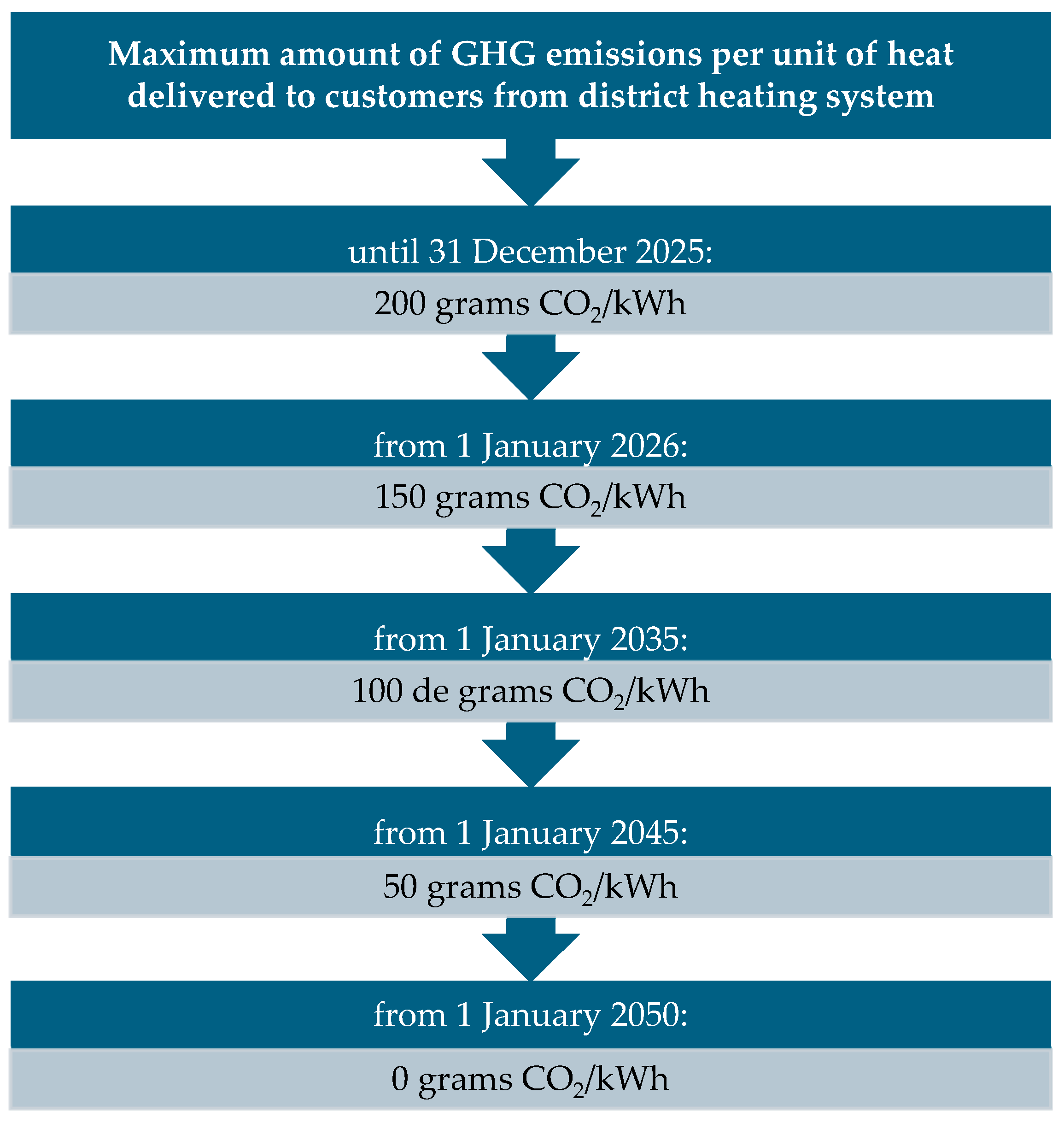

- DIRECTIVE (EU) 2023/1791 of the European Parliament and of the Council of 13 September 2023 on Energy Efficiency. Available online: https://eur-lex.europa.eu/eli/dir/2023/1791/oj/eng (accessed on 15 December 2024).

- Atănăsoae, P. Techno-Economic Assessment of High Efficiency Cogeneration. In Advances in Energy Research; Acosta, M.J., Ed.; Nova Science Publishers: New York, NY, USA, 2020; Volume 33, pp. 123–152. [Google Scholar]

- Commission Delegated Regulation (EU) 2023/2104 of 4 July 2023 Reviewing Harmonised Efficiency Reference Values for Separate Production of Electricity and Heat in Application of Directive 2012/27/EU. Available online: https://eur-lex.europa.eu/eli/reg_del/2023/2104/oj/eng (accessed on 15 December 2024).

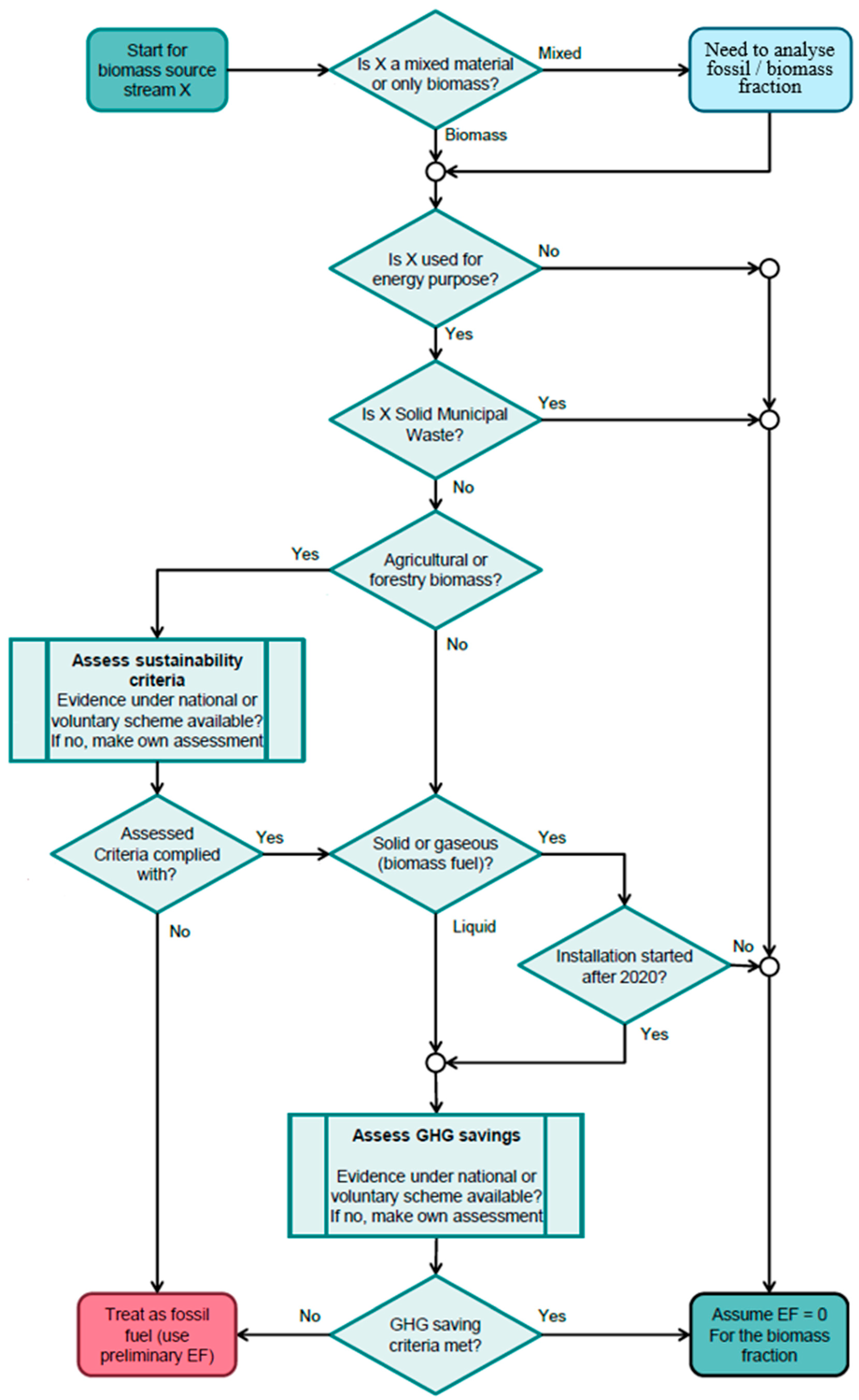

- Directive (EU) 2018/2001 of the European Parliament and of the Council of 11 December 2018 on the Promotion of the Use of Energy from Renewable Sources. Available online: https://eur-lex.europa.eu/eli/dir/2018/2001/oj (accessed on 19 December 2024).

- European Commission Directorate-General Climate Action, Directorate B—Carbon Markets & Clean Mobility, Unit B.2—ETS (II): Implementation, Policy Support & ETS Registry. Biomass Issues in the EU ETS. Available online: https://www.miteco.gob.es/content/dam/miteco/es/cambio-climatico/temas/comercio-de-derechos-de-emision/gd3_biomass_issues_en_v_17102022_tcm30-544136.pdf (accessed on 11 December 2024).

- Commission Implementing Regulation (EU) 2018/2066 of 19 December 2018 on the Monitoring and Reporting of Greenhouse Gas Emissions. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=CELEX%3A32018R2066 (accessed on 15 December 2024).

- Mc 001-2022, Methodology for Calculating the Energy Performance of Buildings (Metodologie de Calcul al Performanţei Energetice a Clădirilor). Available online: https://www.mdlpa.ro/uploads/articole/attachments/63d8dccfe6ae8244797864.pdf (accessed on 15 December 2024).

- ISO 38200:2018; Chain of Custody of Wood and Wood-Based Products. Publisher: Geneva, Switzerland, 2018.

- Annual Environmental Reports Bioenergy Suceava, National Agency for Environmental Protection. Available online: https://apmsv.anpm.ro/autorizatii-integrate-de-mediu (accessed on 10 December 2024).

- Reports on the Status of the Public Service for the Supply of Heat in a Centralized System, National Energy Regulatory Authority. Available online: https://anre.ro/participanti-la-piata-de-energie/persoane-juridice/energie-termica/ (accessed on 10 December 2024).

- Atănăsoae, P. Allocation of Joint Costs and Price Setting for Electricity and Heat Generated in Cogeneration. Energies 2023, 16, 134. [Google Scholar]

- Gudmundsson, O.; Schmidt, R.R.; Dyrelund, A.; Thorsen, J.E. Economic comparison of 4GDH and 5GDH systems e Using a case study. Energy 2022, 238, 121613. [Google Scholar]

- EU’s Mission of “100 Climate-Neutral and Smart Cities by 2030”. Meet the 112 Mission Cities Paving the Way to Climate Neutrality by 2030. Available online: https://netzerocities.eu/mission-cities/ (accessed on 19 December 2024).

| CHP Unit Power | Primary Energy Saving (PES) | Quality Factor (QF) | Total Efficiency (ηgl,CHP) |

|---|---|---|---|

| Pe ≤ 1 MWe | ≥0% | ≥1.00001 | unrestricted |

| 1 < Pe ≤ 25 MWe | ≥10% | ≥1.11112 | unrestricted |

| Pe > 25 MWe | ≥10% | ≥1.11112 | ≥70% |

| Energy Source | Year of Construction | ||

|---|---|---|---|

| Before 2016 | 2016–2023 | From 2024 | |

| Hard coal | 44.2 | 44.2 | 53.0 |

| Lignite | 41.8 | 44.2 | 53.0 |

| Natural gas | 52.5 | 53.0 | 53.0 |

| Heavy fuel oil | 44.2 | 44.2 | 53.0 |

| Biomass | 33.0 | 37.0 | 37.0 |

| Energy Source | Year of Construction | |||||

|---|---|---|---|---|---|---|

| Before 2016 | 2016–2023 | From 2024 | ||||

| Hot Water | Steam | Hot Water | Steam | Hot Water | Steam | |

| Hard coal | 88.0 | 83.0 | 88.0 | 83.0 | 92.0 | 87.0 |

| Lignite | 86.0 | 81.0 | 86.0 | 81.0 | 92.0 | 87.0 |

| Natural gas | 90.0 | 85.0 | 92.0 | 87.0 | 92.0 | 87.0 |

| Heavy fuel oil | 89.0 | 84.0 | 85.0 | 80.0 | 92.0 | 87.0 |

| Biomass | 86.0 | 81.0 | 86.0 | 81.0 | 86.0 | 81.0 |

| Fuel Type | Emission Factor (t CO2/TJ) | Net Calorific Value (TJ/Gg) | Emission Factor (kg CO2/kWh) |

|---|---|---|---|

| Lignite | 101.0 | 11.9 | 0.364 |

| Hard coal | 94.6 | 28.2 | 0.341 |

| Heavy fuel oil | 73.3 | 42.3 | 0.264 |

| Natural gas | 56.1 | 48.0 | 0.202 |

| Wood/wood waste | 0 | 15.6 | 0 |

| Other primary solid biomass | 0 | 11.6 | 0 |

| Fuel Type | Emission Factor (kg CO2/kWh) |

|---|---|

| Firewood (without biomass certification/unsustainable source) | 0.390 |

| Biomass—firewood | 0.019 |

| Biomass—wood waste, sawdust | 0.016 |

| Biomass—briquettes/pellets | 0.039 |

| Biomass—agricultural waste | 0.016 |

| Biogas (from certified biomass) | 0.000 |

| Energy Flow | U.M. | 2019 | 2020 | 2021 | 2022 | 2023 |

|---|---|---|---|---|---|---|

| Electrical energy generated | MWh | 108,932 | 126,140 | 222,245 | 218,612 | 126,678 |

| Thermal energy generated | MWh | 230,360 | 253,798 | 284,501 | 265,963 | 205,023 |

| Biomass consumption | MWh | 549,965 | 592,680 | 950,335 | 1,051,639 | 635,576 |

| Natural gas consumption | MWh | 656.28 | 0 | 0 | 0 | 0 |

| Thermal energy delivered | MWh | 188,913 | 179,004 | 194,515 | 174,269 | 167,391 |

| Thermal energy sold to final consumers | MWh | 112,397 | 101,407 | 99,330 | 98,352 | 94,726 |

| Energy Flow | U.M. | Scenario 1 | Scenario 2 | Scenario 3 |

|---|---|---|---|---|

| Power, P | MWe | 29.65 | 15.92 | 15.92 |

| Heat, H | MWt | 71.43 | 20.27 | 42.56 |

| Fuel, F | MW | 126.17 | 73.48 | 73.48 |

| Reference electricity efficiency, ηe,Ref | % | 33.00 | 33.00 | 33.00 |

| Reference heat efficiency, ηh,Ref | % | 86.00 | 86.00 | 86.00 |

| Correction factor for avoided losses, ploss | - | 0.918 | 0.918 | 0.918 |

| Alternative option for separate electricity generation, X | - | 0.0330 | 0.0330 | 0.0330 |

| Alternative option for separate heat generation, Y | - | 0.0116 | 0.0116 | 0.0116 |

| Electric efficiency in cogeneration, ηe,CHP | % | 23.50 | 19.93 | 21.66 |

| Heat efficiency in cogeneration, ηh,CHP | % | 56.61 | 32.26 | 57.93 |

| Total efficiency in cogeneration, ηgl,CHP | % | 80.11 | 52.19 | 79.59 |

| Quality factor of cogeneration unit, QF | - | 1.434 | 1.033 | 1.389 |

| Primary energy saving, PES | % | 30.26 | 3.19 | 27.99 |

| Energy Flow | U.M. | 2023 |

|---|---|---|

| Electricity generated in cogeneration mode, ECHP | MWh | 102,610.94 |

| Electricity generated in non-cogeneration mode, Enon-CHP | MWh | 24,067.06 |

| Heat generated in cogeneration mode, HCHP | MWh | 161,295.35 |

| Heat generated in non-cogeneration mode, Hnon-CHP | MWh | 43,727.60 |

| Heat lost to the cooling tower, Hcooling tower | MWh | 177,424.88 |

| Fuel consumed in cogeneration mode, FCHP | MWh | 584,729.48 |

| Fuel consumed in non-cogeneration mode, Fnon-CHP | MWh | 50,846.04 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Atănăsoae, P.; Pentiuc, R.D.; Milici, L.D. High-Efficiency Cogeneration: A Viable Solution for the Decarbonization of Cities with District Heating Systems. Energies 2025, 18, 1581. https://doi.org/10.3390/en18071581

Atănăsoae P, Pentiuc RD, Milici LD. High-Efficiency Cogeneration: A Viable Solution for the Decarbonization of Cities with District Heating Systems. Energies. 2025; 18(7):1581. https://doi.org/10.3390/en18071581

Chicago/Turabian StyleAtănăsoae, Pavel, Radu Dumitru Pentiuc, and Laurențiu Dan Milici. 2025. "High-Efficiency Cogeneration: A Viable Solution for the Decarbonization of Cities with District Heating Systems" Energies 18, no. 7: 1581. https://doi.org/10.3390/en18071581

APA StyleAtănăsoae, P., Pentiuc, R. D., & Milici, L. D. (2025). High-Efficiency Cogeneration: A Viable Solution for the Decarbonization of Cities with District Heating Systems. Energies, 18(7), 1581. https://doi.org/10.3390/en18071581