Analysis of Cylinder Pressure and Heat Release Rate Variation in Diesel Engine Fueled with Croton Macrostachyus (CMS) Seed Oil Biodiesel as an Alternative Fuel

Abstract

1. Introduction

2. Experimental Methodologies

2.1. Preparation of Test Fuel Blends

2.2. Heat Release Rate (HRR) Calculation

2.3. Calculation of the BTE and BSFC

2.4. Experimental Setup

2.5. Uncertainty Analysis

3. Results and Discussion

3.1. Combustion Characteristics

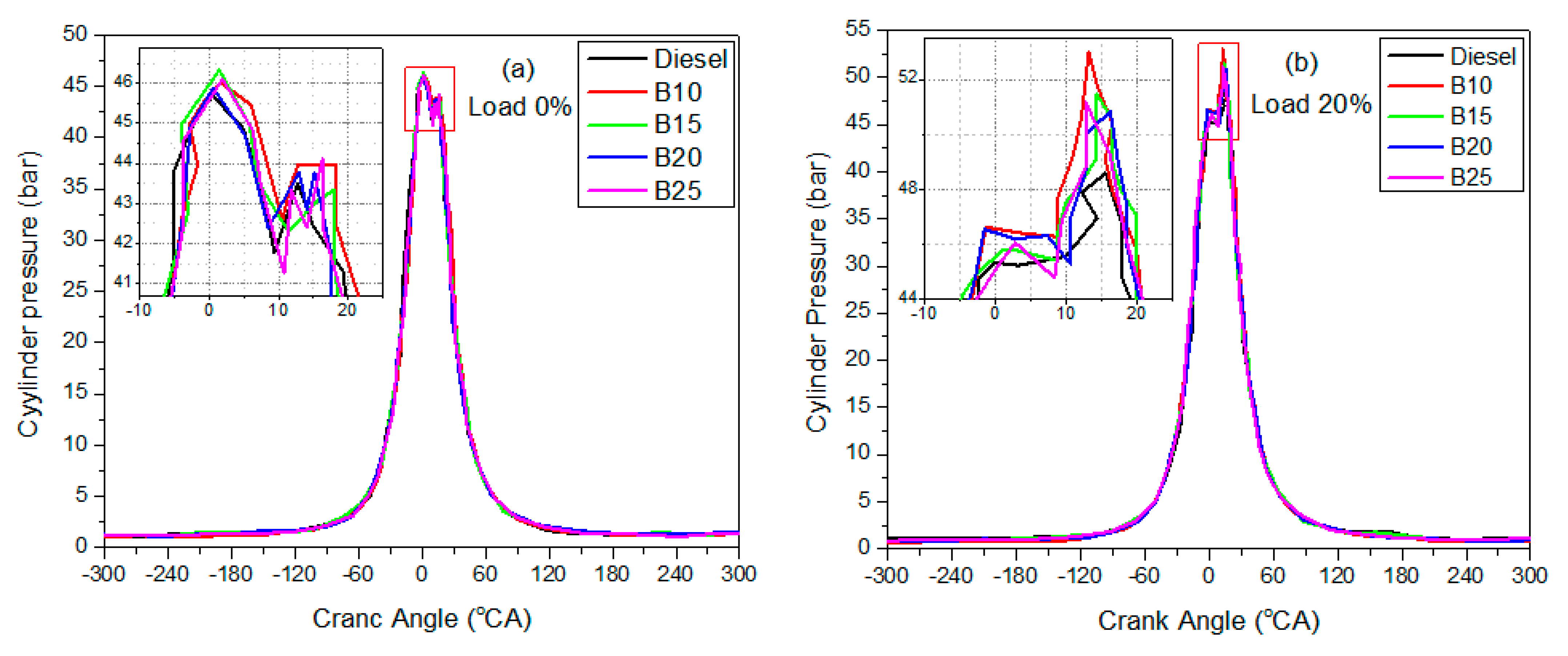

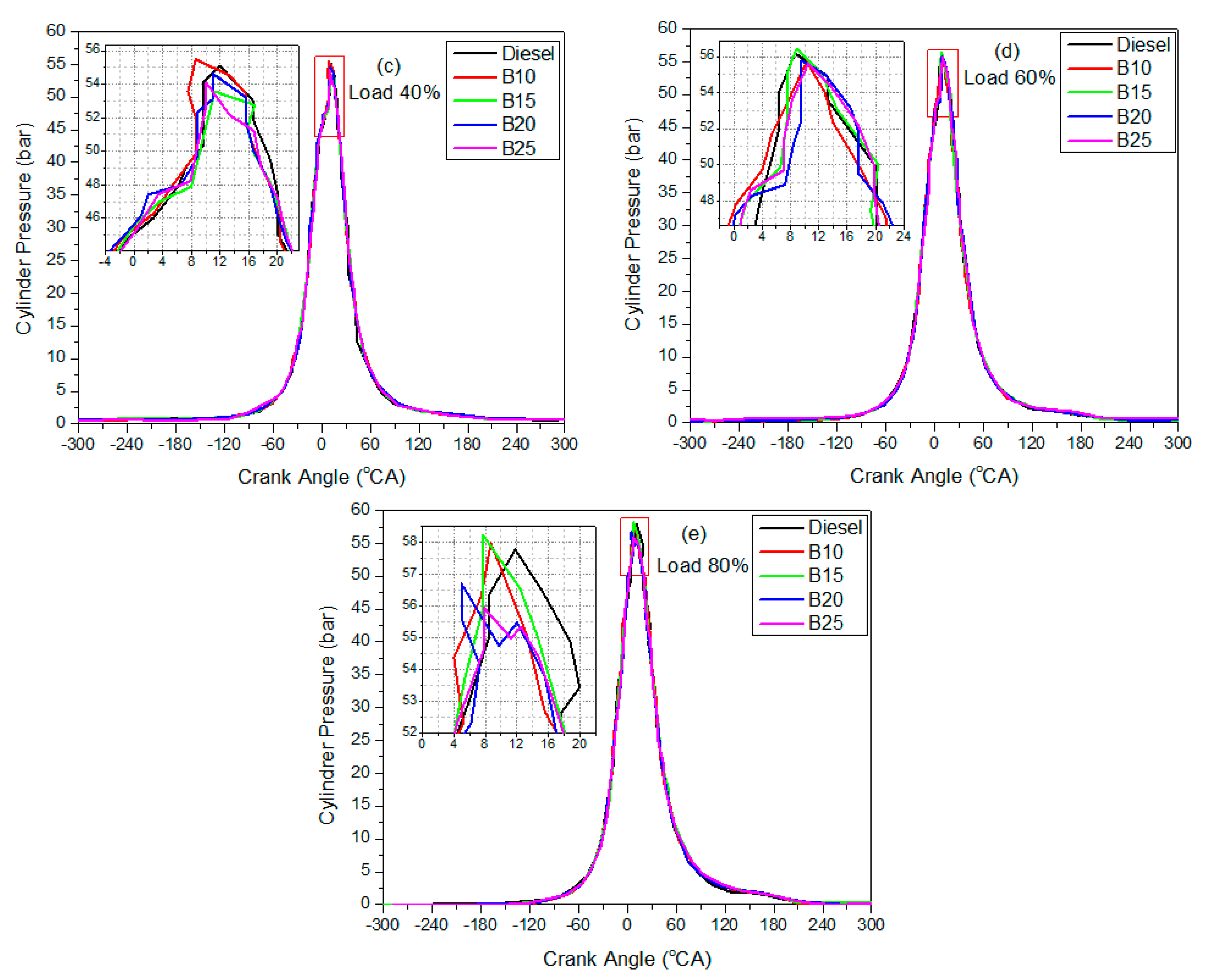

3.1.1. Cylinder Pressure (CP)

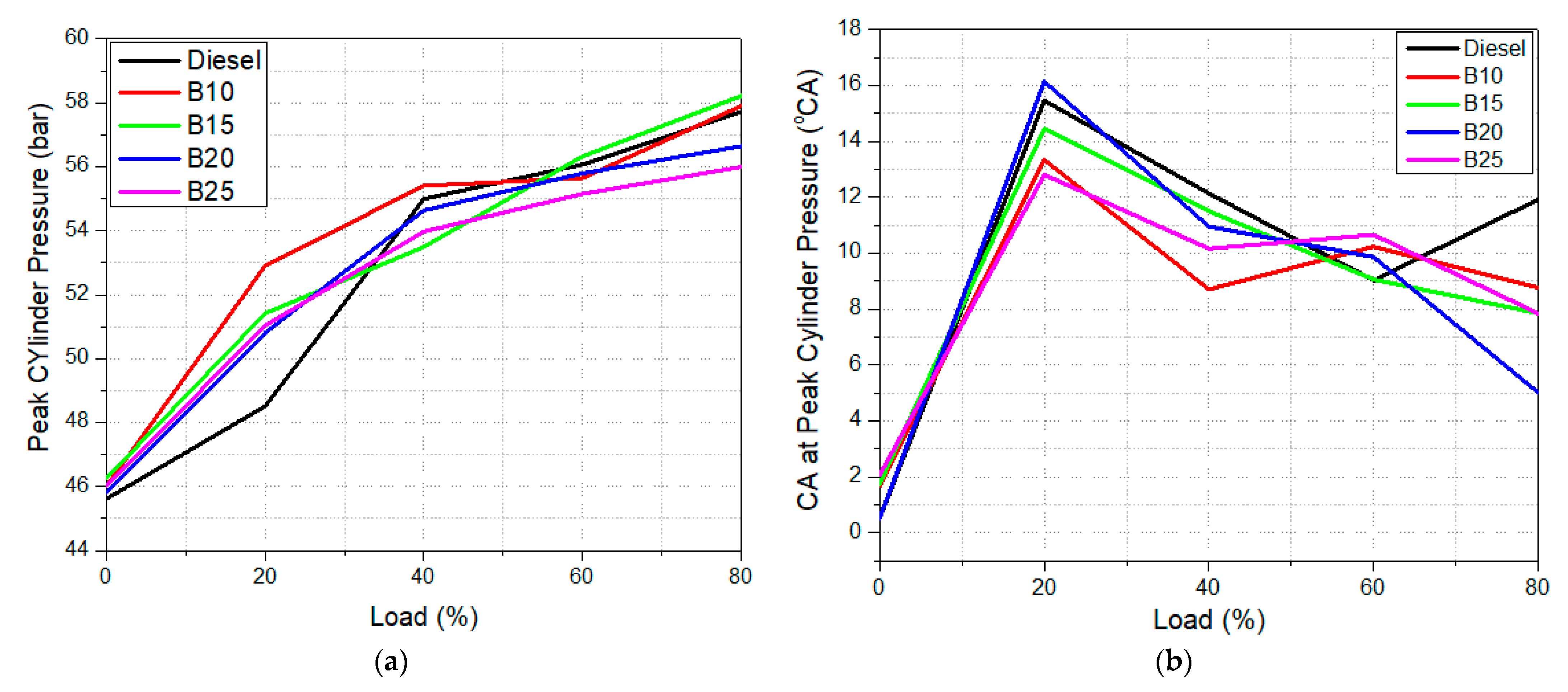

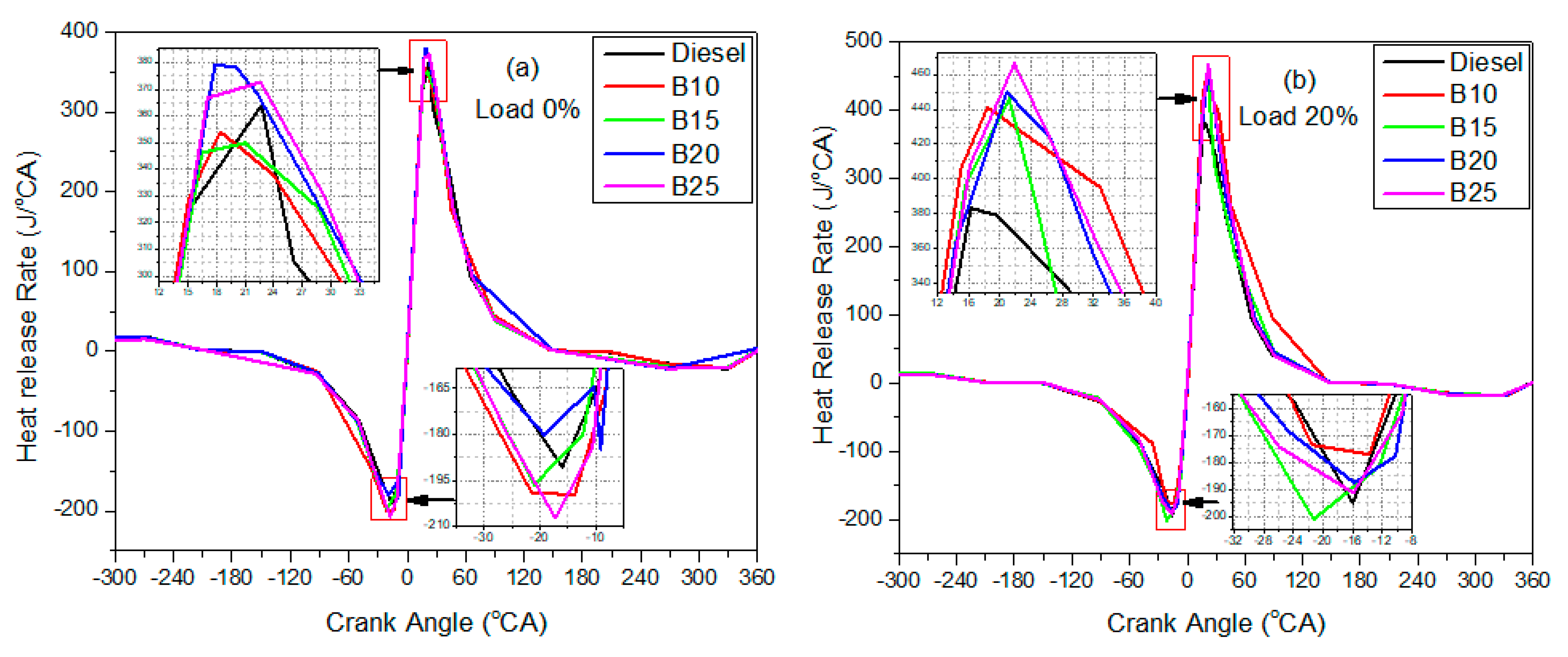

3.1.2. Heat Release Rate (HRR)

3.1.3. Start of Combustion (SoC)

3.1.4. Ignition Delay Period (ID)

3.2. Performance Analysis

3.2.1. Brake Thermal Efficiency (BTE)

3.2.2. Brake-Specific Fuel Consumption (BSFC)

3.2.3. Exhaust Gas Temperature (EGT)

3.2.4. Mass Flow Rate of the Fuel (ṁf)

3.3. Emission Characteristics

3.3.1. Carbon Monoxide (CO)

3.3.2. Hydrocarbon (HC)

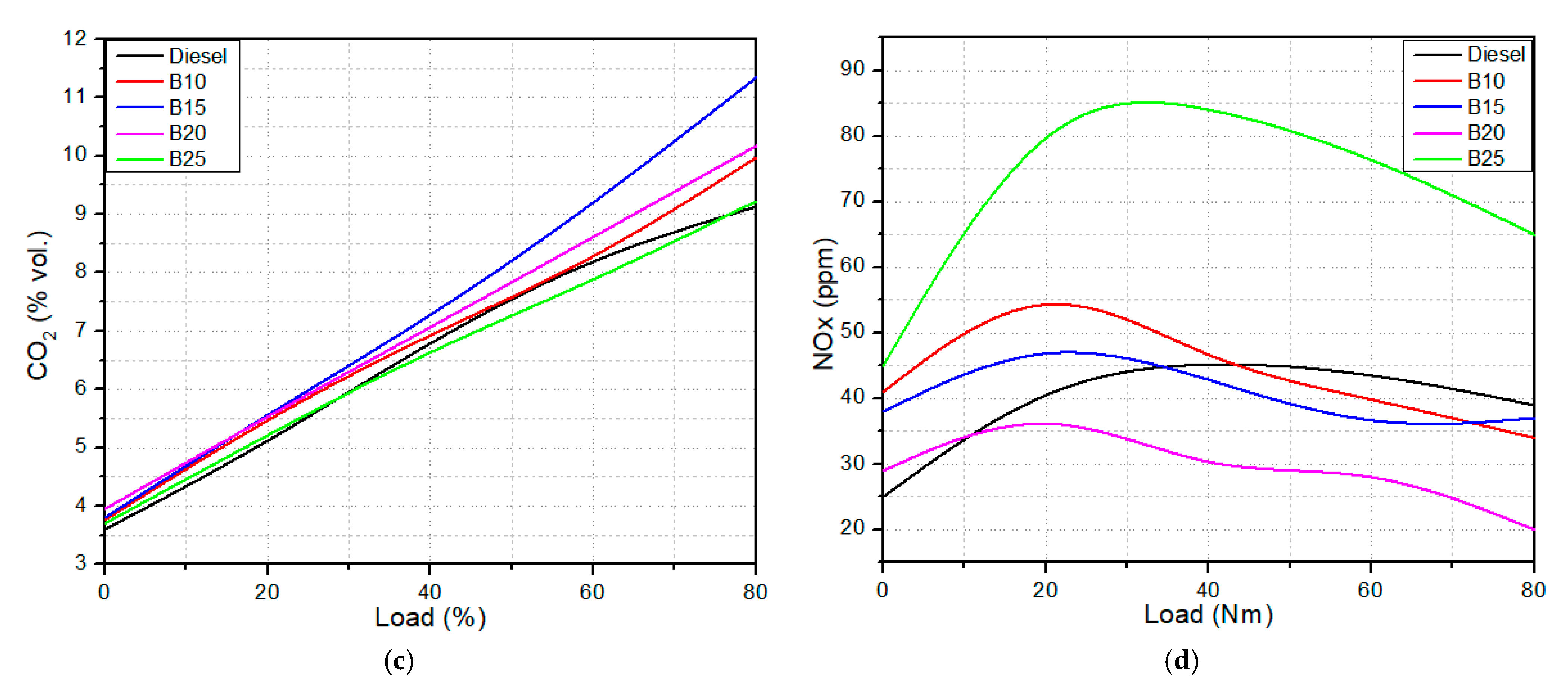

3.3.3. Nitrogen Oxide (NOx)

3.3.4. Carbon Dioxide (CO2)

4. Comparative Analysis

5. Engine Durability and Implication of Using Biodiesel

6. Conclusions

- The results indicate that at 20% load, peak cylinder pressure (CP) occurs after top dead center (TDC), and this peak shifts towards TDC as the load increases.

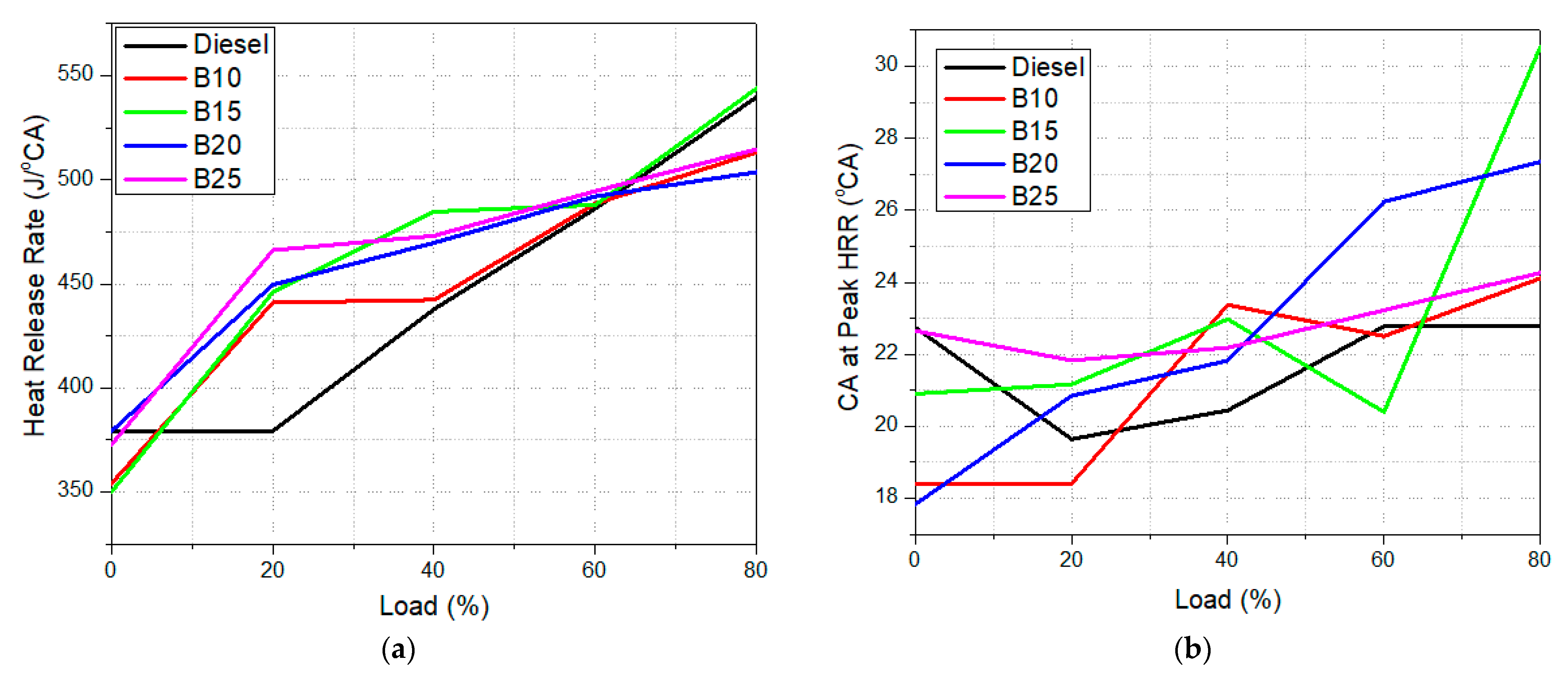

- At 80% engine load, B25 demonstrated the highest peak cylinder pressure (CP) of 58.21 bar and maximum heat release rate (HRR) of 543.9 J/CA compared to the other tested blends.

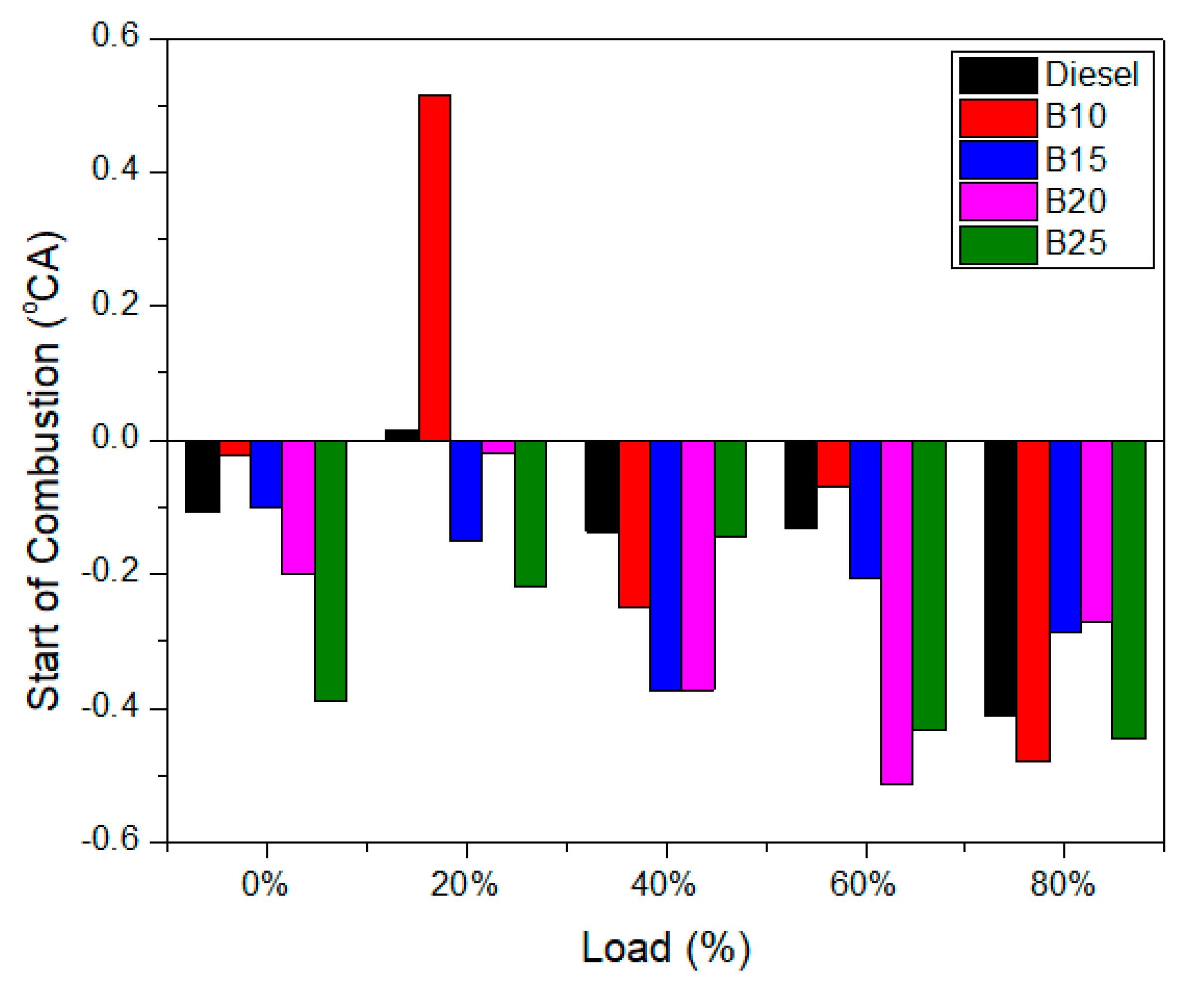

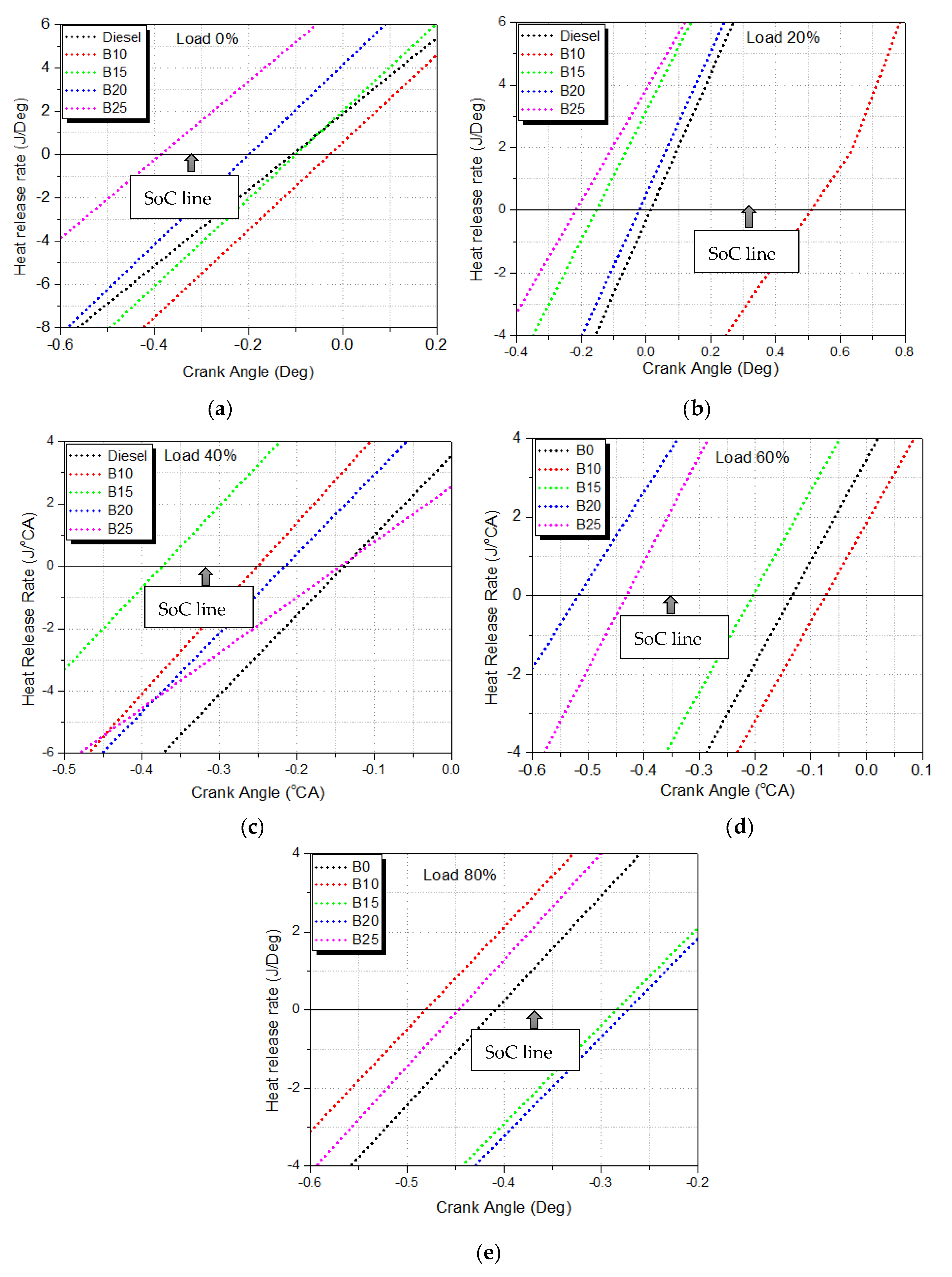

- Increasing engine load and biodiesel blend percentage resulted in the maximum heat release rate (HRR) occurring later in the expansion stroke further from top dead center (TDC). Specifically, the earliest maximum HRR was observed at 17.83 °CA after TDC for B20 at no load, while the latest occurred at 30.53 °CA after TDC for B15 at 80% load. Furthermore, ignition delay decreased with increasing engine load and biodiesel blend, and the combustion start advanced further before TDC for biodiesel blends compared to pure diesel.

- A maximum brake thermal efficiency (BTE) of 32.55% was recorded for pure diesel, which can be attributed to its superior energy density and lower viscosity relative to biodiesel blends. Consequently, pure diesel demonstrated the lowest brake-specific fuel consumption (BSFC) and exhaust gas temperature (EGT). B10 exhibited slightly higher values, while B25 showed the highest BSFC and EGT among the tested blends.

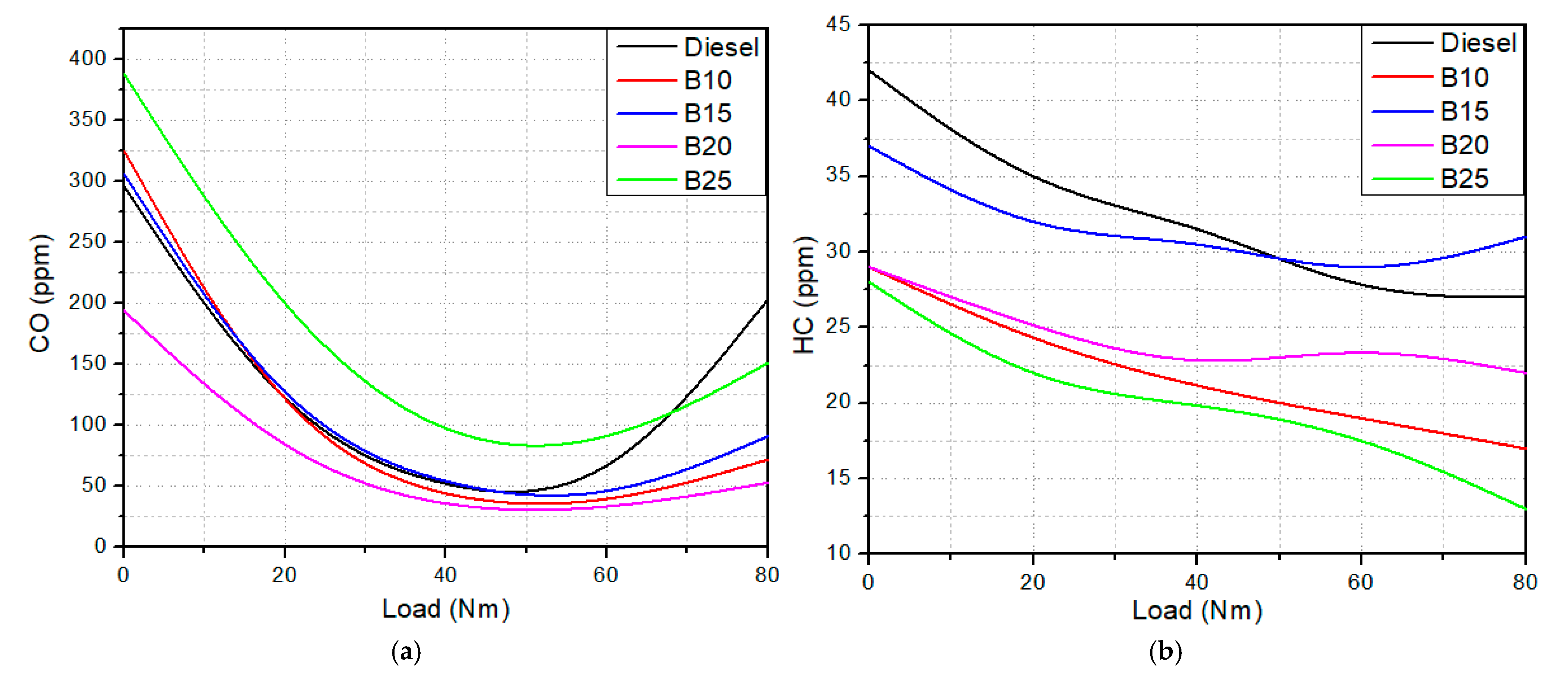

- Carbon monoxide (CO) emissions decreased with increasing biodiesel blend percentage up to B20, but increased beyond B20. Hydrocarbon (HC) emissions for B25 were reduced by 33.3–51.8% compared to diesel, which is attributed to the combined effect of cetane number and inherent oxygen content. Nitrogen oxide (NOx) emissions for B25 increased by 67–102% compared to pure diesel. Carbon dioxide (CO2) emissions peaked with B15, followed by B20 and B10. B25 exhibited the lowest CO2 emissions, which is likely due to incomplete combustion from a richer mixture and increased fuel viscosity with higher biodiesel proportions.

- Overall, this experimental research demonstrated that croton macrostachyus (CMS) seed oil biodiesel exhibits promising characteristics for use in internal combustion engines. However, accelerated field testing and economies of large-scale CMS biodiesel production need to be assessed further.

- To further optimize the utilization of CMS biodiesel, future studies should investigate its combustion, performance, and emission characteristics in multi-cylinder compression ignition (CI) engines under real-time driving cycle conditions. Key areas of focus should include the influence of exhaust gas recirculation (EGR), the addition of nanoparticles, and the optimization of fuel injection pressure and timing apart from the engine wear test.

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations and Nomenclatures

| AIT | Advanced injection timing |

| aTDC | After top dead center |

| B10 | 10 vol% biodiesel and 90 vol% diesel |

| B15 | 15 vol% biodiesel and 85 vol% diesel |

| B20 | 20 vol% biodiesel and 80 vol% diesel |

| B25 | 25 vol% biodiesel and 75 vol% diesel |

| BMEP | Brake mean effective pressure |

| BSFC | Brake-specific fuel consumption |

| bTDC | Before top dead center |

| BTE | Brake thermal efficiency |

| CA | Crank angle |

| CD | Combustion duration |

| CI | Compression ignition |

| CMS | Croton macrostachyus |

| CN | Cetane number |

| CO | Carbon monoxide |

| CO2 | Carbon dioxide |

| CP | Cylinder pressure |

| Diesel | 0 vol% biodiesel and 100 vol% diesel |

| EGT | Exhaust gas temperature |

| HC | Hydrocarbon |

| HRR | Heat release rate |

| IC | Internal combustion |

| ID | Ignition delay |

| LHVi | Lower heating value |

| ṁf | Mass flow rate of fuel |

| NOx | Nitrogen oxide |

| PB | Brake power |

| ppm | Parts per million |

| R | Crank radius to connecting rod length |

| Rc | Compression ratio |

| RIT | Retarded injection timing |

| SoC | Start of combustion |

| TDC | Top dead center |

| Ui | Uncertainty |

| Ui (%) | Percentage of uncertainty |

| V | instantaneous engine cylinder volume |

| Vc | clearance volume |

| vi, | Viscosity |

| Xi | Blending ratio |

| Xm | Arithmetic mean |

| ρi | Density |

| γ | Specific heat ratio |

| θ | Crank angle |

| σ | Standard deviation |

References

- Mohammed, A.S.; Atnaw, S.M.; Ramaya, A.V. The Effect of Alcohol Additives on Engine Performance and Emission Characteristics for Biodiesel–Diesel Blend Fuel in Compression Ignition Engine. In Lecture Notes in Energy; Springer Nature Singapore: Singapore, 2023; Volume 92. [Google Scholar] [CrossRef]

- Shameer, P.M.; Ramesh, K. Assessment on the consequences of injection timing and injection pressure on combustion characteristics of sustainable biodiesel fuelled engine. Renew. Sustain. Energy Rev. 2018, 81, 45–61. [Google Scholar] [CrossRef]

- Fayad, M.A.; Dhari, A.; Al-bayati, J.; Abdul, H.A.; Sultan, A.J.; Sabri, L.S.; Dhahad, H.A. Effect of FIPs strategy and nanoparticles additives into the renewable fuel blends on NOX emissions, PM size distribution and soot oxidation in CRDI diesel engine. Results Eng. 2024, 21, 101748. [Google Scholar] [CrossRef]

- Ewunie, G.A.; Morken, J.; Lekang, O.I.; Yigezu, Z.D. Factors affecting the potential of Jatropha curcas for sustainable biodiesel production: A critical review. Renew. Sustain. Energy Rev. 2021, 137, 110500. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhong, Y.; Lu, S.; Zhang, Z.; Tan, D. A Comprehensive Review of the Properties, Performance, Combustion, and Emissions of the Diesel Engine Fueled with Different Generations of Biodiesel. Processes 2022, 10, 1178. [Google Scholar] [CrossRef]

- Sagbansua, L. Optimum renewable oil for biodiesel production as integer programming problem. Energy Explor. Exploit. 2024, 43, 340–353. [Google Scholar] [CrossRef]

- Adib, A.R.; Rahman, M.; Hassan, T.; Ahmed, M.; Rifat, A. Al Novel biofuel blends for diesel engines: Optimizing engine performance and emissions with C. cohnii microalgae biodiesel and algae-derived renewable diesel blends. Energy Convers. Manag. X 2024, 23, 100688. [Google Scholar] [CrossRef]

- Alabi, O.O.; Gbadeyan, O.J.; Bala, A.; Olamide, G. Study of combustion characteristics of diesel-vegetable oil blends utilizing an industrial fuel burner. Fuel Commun. 2024, 18, 100104. [Google Scholar] [CrossRef]

- How, H.G.; Teoh, Y.H.; Krishnan, B.N.; Le, T.D.; Nguyen, H.T.; Prabhu, C. Prediction of optimum Palm Oil Methyl Ester fuel blend for compression ignition engine using Response Surface Methodology. Energy 2021, 234, 121238. [Google Scholar] [CrossRef]

- Elkelawy, M.; Etaiw, S.E.d.H.; Alm-Eldin Bastawissi, H.; Ayad, M.I.; Radwan, A.M.; Dawood, M.M. Diesel/ biodiesel /silver thiocyanate nanoparticles/hydrogen peroxide blends as new fuel for enhancement of performance, combustion, and Emission characteristics of a diesel engine. Energy 2021, 216, 119284. [Google Scholar] [CrossRef]

- Shah, P.R.; Gaitonde, U.N.; Ganesh, A. Influence of soy-lecithin as bio-additive with straight vegetable oil on CI engine characteristics. Renew. Energy 2018, 115, 685–696. [Google Scholar] [CrossRef]

- Hasnain, S.M.M.; Prasad, R.; Chatterjee, R.; Kumar, G.; Pandey, S.; Khan, M.; Farouk, A.; Zare, A. Investigation and impact assessment of soybean biodiesel, methyl oleate, and diesel blends on CRDI performance and emissions. Mater. Sci. Energy Technol. 2024, 7, 124–132. [Google Scholar] [CrossRef]

- Al-Dawody, M.F.; Edam, M.S. Experimental and numerical investigation of adding castor methyl ester and alumina nanoparticles on performance and emissions of a diesel engine. Fuel 2022, 307, 121784. [Google Scholar] [CrossRef]

- Tesfay, A.H.; Asfaw, S.H.; Bidir, M.G. Comparative evaluation of biodiesel production and engine characteristics of Jatropha and Argemone Mexicana oils. SN Appl. Sci. 2019, 1, 1075. [Google Scholar] [CrossRef]

- Rangabashiam, D.; Munuswamy, D.B.; Duraiswamy Balasubramanian, S.; Christopher, D. Performance, emission, and combustion analysis on diesel engine fueled with blends of neem biodiesel/diesel/ additives. Energy Sources Part A Recover. Util. Environ. Eff. 2020, 46, 8059–8069. [Google Scholar] [CrossRef]

- Abebe Debella, H.; Ramayya Ancha, V.; Mekbib Atnaw, S.; Seyoum Zeleke, D. Experimental study on performance and emissions from Prosopis Juliflora biodiesel blends with diethyl ether additives. Energy Convers. Manag. X 2024, 22, 100581. [Google Scholar] [CrossRef]

- Genet, N.; Menelik, M.; Mekonen, W.; Gzate, Y.; Leul, A.; Demisie, F. Experimental investigation on diesel engine performance and emission characteristics using waste cooking oil blended with diesel as biodiesel fuel. Discov. Energy 2024, 4, 26. [Google Scholar] [CrossRef]

- Sudarsanam, M.; Jayaprabakar, J.; Kumar, J.A.; Praveenkumar, T.R.; Rajasimman, M. Analysis of a CRDI diesel engine powered by ternary fuel blends (diesel, biodiesel, and pentanol) doped with alumina nano—Additives. Sci. Rep. 2024, 14, 16228. [Google Scholar] [CrossRef]

- Ong, H.C.; Tiong, Y.W.; Goh, B.H.H.; Gan, Y.Y.; Mofijur, M.; Fattah, I.M.R.; Chong, C.T.; Alam, M.A.; Lee, H.V.; Silitonga, A.S.; et al. Recent advances in biodiesel production from agricultural products and microalgae using ionic liquids: Opportunities and challenges. Energy Convers. Manag. 2021, 228, 113647. [Google Scholar] [CrossRef]

- Abdullah, B.; Faua’ad Syed Muhammad, S.A.F.; Shokravi, Z.; Ismail, S.; Kassim, K.A.; Mahmood, A.N.; Aziz, M.M.A. Fourth generation biofuel: A review on risks and mitigation strategies. Renew. Sustain. Energy Rev. 2019, 107, 37–50. [Google Scholar] [CrossRef]

- Iyad, M.; Alzubaidi, A.; Sami, A.; Altawwash, A.; Abbas, W.N. Study on the performance and emissions of compression ignition engine powered by diesel and biodiesel blends. Int. J. Thermofluids 2024, 24, 100869. [Google Scholar] [CrossRef]

- Mohammed, A.S.; Atnaw, S.M.; Ramaya, A.V.; Alemayehu, G. A comprehensive review on the effect of ethers, antioxidants, and cetane improver additives on biodiesel-diesel blend in CI engine performance and emission characteristics. J. Energy Inst. 2023, 108, 101227. [Google Scholar] [CrossRef]

- Rotavera, B.; Taatjes, C.A. Influence of functional groups on low-temperature combustion chemistry of biofuels. Prog. Energy Combust. Sci. 2021, 86, 100925. [Google Scholar] [CrossRef]

- Owais, M.; Sajjad, A.; Sathish, T.; Rajasimman, M.; Praveenkumar, T.R. Experimental evaluation of soapberry seed oil biodiesel performance in CRDI diesel engine. Sci. Rep. 2023, 13, 5699. [Google Scholar] [CrossRef]

- Pracuch, B. Experimental Investigation of Physicochemical Properties of the Produced Biodiesel from Waste Frying Oil and Its Blend. Energies 2024, 17, 4175. [Google Scholar] [CrossRef]

- Uyumaz, A. Experimental evaluation of linseed oil biodiesel/diesel fuel blends on combustion, performance and emission characteristics in a DI diesel engine. Fuel 2020, 267, 117150. [Google Scholar] [CrossRef]

- Singh, M.; Sandhu, S.S. Effect of boost pressure on combustion, performance and emission characteristics of a multicylinder CRDI engine fueled with argemone biodiesel/diesel blends. Fuel 2021, 300, 121001. [Google Scholar] [CrossRef]

- Rajak, U.; Verma, T.N. A comparative analysis of engine characteristics from various biodiesels: Numerical study. Energy Convers. Manag. 2019, 180, 904–923. [Google Scholar] [CrossRef]

- Saravanan, S.; Krishnamoorthy, N. Investigation on reduction in consequences of adding antioxidants into the algae biodiesel blend as a CI engine fuel. Fuel 2020, 276, 117993. [Google Scholar] [CrossRef]

- Zamba, Z.Z.; Reshad, A.S. Synthesis of Fatty Acid Methyl Ester from Croton macrostachyus (Bisana) Kernel Oil: Parameter Optimization, Engine Performance, and Emission Characteristics for Croton macrostachyus Kernel Oil Fatty Acid Methyl Ester Blend with Mineral Diesel Fuel. ACS Omega 2022, 7, 20619–20633. [Google Scholar] [CrossRef]

- Siraj Mohammed, A.; Ramaya Ancha, V.; Mekbib Atnaw, S. Optimization of biodiesel production from Croton Macrostachyus seed oil with calcium oxide (CaO) catalyst and Characterization: Potential assessment of seed and kernel. Energy Convers. Manag. X 2024, 24, 100791. [Google Scholar] [CrossRef]

- Benjumea, P.; Agudelo, J.; Agudelo, A. Basic properties of palm oil biodiesel-diesel blends. Fuel 2008, 87, 2069–2075. [Google Scholar] [CrossRef]

- Krisnangkura, K.; Yimsuwan, T.; Pairintra, R. An empirical approach in predicting biodiesel viscosity at various temperatures. Fuel 2006, 85, 107–113. [Google Scholar] [CrossRef]

- Allen, C.A.W.; Watts, K.C.; Ackman, R.G.; Pegg, M.J. Predicting the viscosity of biodiesel fuels from their fatty acid ester composition. Fuel 1999, 78, 1319–1326. [Google Scholar] [CrossRef]

- Ramírez-Verduzco, L.F.; Rodríguez-Rodríguez, J.E.; Jaramillo-Jacob, A.D.R. Predicting cetane number, kinematic viscosity, density and higher heating value of biodiesel from its fatty acid methyl ester composition. Fuel 2012, 91, 102–111. [Google Scholar] [CrossRef]

- Schoo, R.; Hoxie, A. Basic properties of refined, bleached and deodorized soybean oilbutanol blends. Fuel 2012, 102, 701–708. [Google Scholar] [CrossRef]

- Cihan, Ö. Experimental and numerical investigation of the effect of fig seed oil methyl ester biodiesel blends on combustion characteristics and performance in a diesel engine. Energy Rep. 2021, 7, 5846–5856. [Google Scholar] [CrossRef]

- Temizer, İ.; Eskici, B. Investigation on the combustion characteristics and lubrication of biodiesel and diesel fuel used in a diesel engine. Fuel 2020, 278, 118363. [Google Scholar] [CrossRef]

- EL-Seesy, A.I.; Hassan, H.; Ookawara, S. Performance, combustion, and emission characteristics of a diesel engine fueled with Jatropha methyl ester and graphene oxide additives. Energy Convers. Manag. 2018, 166, 674–686. [Google Scholar] [CrossRef]

- Baweja, S.; Trehan, A.; Kumar, R. Combustion, performance, and emission analysis of a CI engine fueled with mustard oil biodiesel blended in diesel fuel. Fuel 2021, 292, 120346. [Google Scholar] [CrossRef]

- Sun, Z.; Van Beers, H.; Cuijpers, M.; Somers, B.; Maes, N. Design of experiments optimized OMEx-diesel blends on a heavy-duty engine − Part 1: Combustion and emissions analysis with EGR and injection timing variation. Fuel 2025, 381, 133392. [Google Scholar] [CrossRef]

- Wang, D.; Bao, G.; He, C.; Li, J.; Chen, Y.; Zhao, L.; Yu, H. Investigation of the Impact of Combustion Chamber Geometry on Engine Combustion and Emission Performance Under Various Fuel Injection Timings With Biodiesel Blending. Energy Sci. Eng. 2024, 13, 268–289. [Google Scholar] [CrossRef]

- Hossain, F.M.; Nabi, N.; Rainey, T.J.; Bodisco, T.; Bayley, T.; Randall, D.; Ristovski, Z.; Brown, R.J. Novel biofuels derived from waste tyres and their effects on reducing oxides of nitrogen and particulate matter emissions. J. Clean. Prod. 2020, 242, 118463. [Google Scholar] [CrossRef]

- Rajasekar, E.; Selvi, S. Review of combustion characteristics of CI engines fueled with biodiesel. Renew. Sustain. Energy Rev. 2014, 35, 390–399. [Google Scholar] [CrossRef]

- Mujtaba, M.; Harveer, A.; Pali, S.; Mohsin, M.; Silver, A.; Aluminium, A.O. Feasibility of Nanoparticles Fused in Biodiesel for CI Engines: An Integrated and Historic Review; Springer International Publishing: Berlin/Heidelberg, Germany, 2024; Volume 149, ISBN 0123456789. [Google Scholar]

- Singh, A.P.; Prakash, O. Unlocking the potential of novel ternary non-edible seed oil biodiesel: Impact on diesel engine knock intensity, performance, combustion, and emissions diesel engine knock intensity, performance, combustion, and emissions. Int. J. Ambient Energy 2024, 45, 2374899. [Google Scholar] [CrossRef]

- Miron, L.; Chiriac, R.; Brabec, M.; Bădescu, V. Ignition delay and its influence on the performance of a Diesel engine operating with different Diesel–biodiesel fuels. Energy Rep. 2021, 7, 5483–5494. [Google Scholar] [CrossRef]

- Sethin, A.; Oo, Y.M.; Thawornprasert, J.; Somnuk, K. Effects of Blended Diesel − Biodiesel Fuel on Emissions of a Common Rail Direct Injection Diesel Engine with Different Exhaust Gas Recirculation Rates. ACS Omega 2024, 9, 20906–20918. [Google Scholar] [CrossRef] [PubMed]

- Alahmer, A.; Rezk, H.; Aladayleh, W.; Mostafa, A.O.; Abu-Zaid, M.; Alahmer, H.; Gomaa, M.R.; Alhussan, A.A.; Ghoniem, R.M. Modeling and Optimization of a Compression Ignition Engine Fueled with Biodiesel Blends for Performance Improvement. Mathematics 2022, 10, 420. [Google Scholar] [CrossRef]

- Babji, A.; Rambabu, G.; Naik, B.; Levi, D.; Cheworei, P.; Rao, D.S. Optimization of Compression Ignition Diesel Engine Combustion, Emission, and Performance Characteristics at Higher Blends of Biodiesel Using RSM. Process Integr. Optim. Sustain. 2024, 8, 953–973. [Google Scholar] [CrossRef]

- Saravanan, G.; Thiyagarajan, P. Performance, combustion and emission parameters of Scenedesmus obliquus methyl ester in single—Cylinder CI engine: An experimental study. J. Therm. Anal. Calorim. 2024, 149, 14325–14341. [Google Scholar] [CrossRef]

- Dhahad, H.A.; Fayad, M.A.; Chaichan, M.T.; Abdulhady, A.; Megaritis, T. Influence of fuel injection timing strategies on performance, combustion, emissions and particulate matter characteristics fueled with rapeseed methyl ester in modern diesel engine. Fuel 2021, 306, 121589. [Google Scholar] [CrossRef]

- Ramachandran, S.; Thangavelu, M.; Kamaraj, L.; Ponnappan, S.; Arumugam, R. Environmental Effects Ignition analysis of diesel engine propelled with neat biodiesel containing nanoparticles. Energy Sources Part A Recover. Util. Environ. Eff. 2021, 1–13. [Google Scholar] [CrossRef]

- Muniamuthu, S.; Kumar, K.S.; Deepa, S.; Elangovan, M. Investigation on Delonix regina biodiesel blends on diesel engine with 1-butanol-diesel blends to test engine performance, combustion and emission characteristics. J. Therm. Eng. 2025, 11, 170–180. [Google Scholar] [CrossRef]

- Thangarasu, V.; Balaji, B.; Ramanathan, A. Experimental investigation of tribo-corrosion and engine characteristics of Aegle Marmelos Correa biodiesel and its diesel blends on direct injection diesel engine. Energy 2019, 171, 879–892. [Google Scholar] [CrossRef]

- Caligiuri, C.; Bietresato, M.; Algieri, A.; Baratieri, M. Experimental Investigation and RSM Modeling of the Effects of Injection Timing on the Performance and NOx Emissions of a Micro-Cogeneration Unit Fueled with Biodiesel Blends. Energies 2022, 15, 3586. [Google Scholar] [CrossRef]

- Öztürk, E.; Can, Ö.; Usta, N.; Yücesu, H.S. Effects of retarded fuel injection timing on combustion and emissions of a diesel engine fueled with canola biodiesel. Eng. Sci. Technol. Int. J. 2020, 23, 1466–1475. [Google Scholar] [CrossRef]

- Verma, T.N.; Rajak, U.; Dasore, A.; Afzal, A. Experimental and empirical investigation of a CI engine fuelled with blends of diesel and roselle biodiesel. Sci. Rep. 2021, 11, 18865. [Google Scholar] [CrossRef] [PubMed]

- Asif, M.; Choon, C.; Venkatesan, B.; Rajagopal, S. Parameter fine tuning on CRDI engine operated with blends of grape biodiesel and diesel Fuel Injection timing. Case Stud. Therm. Eng. 2024, 60, 104701. [Google Scholar] [CrossRef]

- Awad, O.I.; Kamil, M.; Abed, A.A.; Jamal, O.; Mohammed, O.K.; Mohammed, M.N.; Alobaid, A.; Suwaed, M.S.; Yusri, I.M.; Hasan, M.M. Effect of by-product fusel oil-diesel blends fuel on emissions of single-cylinder CI engine. Front. Mech. Eng. 2024, 10, 1459374. [Google Scholar] [CrossRef]

- Chourasia, S.; Patel, P.D.; Lakdawala, A.; Patel, R.N. Study on tribological behavior of biodiesel—Diethyl ether (B20A4) blend for long run test on compression ignition engine. Fuel 2018, 230, 64–77. [Google Scholar] [CrossRef]

- Azad, A.K.; Rasul, M.G.; Sharma, S.C.; Khan, M.M.K. The lubricity of ternary fuel mixture blends as a way to assess diesel engine durability. Energies 2018, 11, 33. [Google Scholar] [CrossRef]

- Dharma, S.; Ong, H.C.; Masjuki, H.H.; Sebayang, A.H.; Silitonga, A.S. An overview of engine durability and compatibility using biodiesel–bioethanol–diesel blends in compression-ignition engines. Energy Convers. Manag. 2016, 128, 66–81. [Google Scholar] [CrossRef]

- Singh, D.; Sharma, D.; Soni, S.L.; Inda, C.S.; Sharma, S.; Sharma, P.K.; Jhalani, A. A comprehensive review of physicochemical properties, production process, performance and emissions characteristics of 2nd generation biodiesel feedstock: Jatropha curcas. Fuel 2021, 285, 119110. [Google Scholar] [CrossRef]

- Ng, J.H.; Ng, H.K.; Gan, S. Advances in biodiesel fuel for application in compression ignition engines. Clean Technol. Environ. Policy 2010, 12, 459–493. [Google Scholar] [CrossRef]

- Kyu, H.; Sik, C. A review on atomization and exhaust emissions of a biodiesel-fueled compression ignition engine. Renew. Sustain. Energy Rev. 2016, 58, 1601–1620. [Google Scholar] [CrossRef]

- Razak, N.H.; Hashim, H.; Yunus, N.A.; Klemeš, J.J. Reducing diesel exhaust emissions by optimisation of alcohol oxygenates blend with diesel/biodiesel. J. Clean. Prod. 2021, 316, 128090. [Google Scholar] [CrossRef]

- Shahir, V.K.; Jawahar, C.P.; Suresh, P.R. Comparative study of diesel and biodiesel on CI engine with emphasis to emissions —A review. Renew. Sustain. Energy Rev. 2015, 45, 686–697. [Google Scholar] [CrossRef]

- Hassan, T.; Rahman, M.M.; Rahman, M.A.; Nabi, M.N. Opportunities and challenges for the application of biodiesel as automotive fuel in the 21st century. Biofuels Bioprod. Biorefining 2022, 16, 1353–1387. [Google Scholar] [CrossRef]

- Jiaqiang, E.; Pham, M.; Zhao, D.; Deng, Y.; Le, D.; Zuo, W. Effect of different technologies on combustion and emissions of the diesel engine fueled with biodiesel: A review. Renew. Sustain. Energy Rev. 2017, 80, 620–647. [Google Scholar] [CrossRef]

- Saleh, H.E.; Selim, M.Y.E. Improving the performance and emission characteristics of a diesel engine fueled by jojoba methyl ester-diesel-ethanol ternary blends. Fuel 2017, 207, 690–701. [Google Scholar] [CrossRef]

- Masera, K.; Hossain, A.K.; Davies, P.A.; Doudin, K. Investigation of 2-butoxyethanol as biodiesel additive on fuel property and combustion characteristics of two neat biodiesels. Renew. Energy 2021, 164, 285–297. [Google Scholar] [CrossRef]

- Broumand, M.; Albert-Green, S.; Yun, S.; Hong, Z.; Thomson, M.J. Spray combustion of fast pyrolysis bio-oils: Applications, challenges, and potential solutions. Prog. Energy Combust. Sci. 2020, 79, 100834. [Google Scholar] [CrossRef]

- Longanesi, L.; Pereira, A.P.; Johnston, N.; Chuck, C.J. Oxidative stability of biodiesel: Recent insights. Biofuels Bioprod. Biorefining 2022, 16, 265–289. [Google Scholar] [CrossRef]

- Liu, Z.; Li, F.; Shen, J.; Wang, H. Effect of oxidation of Jatropha curcas-derived biodiesel on its lubricating properties. Energy Sustain. Dev. 2019, 52, 33–39. [Google Scholar] [CrossRef]

- Nogales-delgado, S.; Encinar, J.M.; González, J.F. Safflower Biodiesel: Improvement of its Oxidative Stability by Using BHA and TBHQ. Energies 2019, 12, 1940. [Google Scholar] [CrossRef]

- João, A.F.; Squissato, A.L.; Ribeiro, M.M.A.C.; Richter, E.M.; Faria, A.M.; Muñoz, R.A.A. Potential of Mafura seed oil as a feedstock for biodiesel production. Biofuels 2020, 13, 415–421. [Google Scholar] [CrossRef]

- Sadeq, A.M. Alternative Fuels for Sustainable Combustion. 2024. ISBN 9798990783690. Available online: https://www.researchgate.net/publication/382547111_Alternative_Fuels_for_Sustainable_Combustion#fullTextFileContent (accessed on 16 February 2025).

- Zulqarnain; Yusoff, M.H.M.; Ayoub, M.; Hamza Nazir, M.; Zahid, I.; Ameen, M.; Abbas, W.; Shoparwe, N.F.; Abbas, N. Comprehensive Review on Biodiesel Production from Palm Oil Mill Effluent. ChemBioEng Rev. 2021, 8, 439–462. [Google Scholar] [CrossRef]

- Mathew, G.M.; Raina, D.; Narisetty, V.; Kumar, V.; Saran, S.; Pugazhendi, A.; Sindhu, R.; Pandey, A.; Binod, P. Recent advances in biodiesel production: Challenges and solutions. Sci. Total Environ. 2021, 794, 148751. [Google Scholar] [CrossRef]

- Ramalingam, S.; Rajendran, S. Assessment of performance, combustion, and emission behavior of novel annona biodiesel-operated diesel engine. In Advances in Eco-Fuels for a Sustainable Environment; Elsevier Ltd.: Amsterdam, The Netherlands, 2019; pp. 391–405. ISBN 9780081027288. [Google Scholar]

| Properties | Diesel (B0) | B100 | B10 | B15 | B20 | B25 |

|---|---|---|---|---|---|---|

| Lower heating value (MJ/kg) | 43 | 40.04 | 42.70 | 42.55 | 42.408 | 42.26 |

| Density at 15 °C (kg/cm3) | 830 | 846.3 | 831.63 | 832.44 | 833.26 | 834.07 |

| Kinematic viscosity at 40 °C (mm2/s) | 2.73 | 4.43 | 2.9 | 2.98 | 3.07 | 3.15 |

| Cetane number | 48 | 50.89 | 48.289 | 48.43 | 48.57 | 48.72 |

| Flashpoint °C | 58 | 175 | 69.7 | 75.55 | 81.4 | 87.25 |

| Pour point °C | −33 | −15 | −31.2 | −30.3 | −29.4 | −28.5 |

| Item | Specification |

|---|---|

| Company | Kubota (Osaka, Japan) |

| Type | EA300-E2-NB1 |

| Engine type | Water-cooled, 4-stroke, single-cylinder compression ignition DI engine |

| Fuel | Diesel |

| Crank radius to connecting road length ratio | 0.25 |

| Displacement | 309 cm3 |

| Bore | 75 mm |

| Stroke | 70 mm |

| Output power | 5.1 kW at 3000 rpm |

| Oil capacity | 1.3 L |

| Noise level | 95 dB(A) |

| Compression ratio | 23:1 |

| Injection timing | 23 CA before TDC |

| Measured Parameters | Instrument | Measuring Range | Uncertainty |

|---|---|---|---|

| HC | Infralyt smart analyzer (SAXON Junkalor GmbH, Dessau, Germany) | 0–2500 ppm | ±1.67% |

| CO2 | Infralyt smart analyzer (SAXON Junkalor GmbH, Dessau, Germany) | 0–20.00% vol | ±0.08% |

| CO | Seitron S500 analyzer (Seitron Americas Inc., Trevose, PA, USA) | 0–4000 ppm | ±0.58% |

| NOx | Seitron S500 analyzer (Seitron Americas Inc., Trevose, PA, USA) | 0–2000 ppm | ±1.21% |

| Speed | CT 110 | 0–3000 rpm | ±0.11% |

| Brake torque | CT 110 | 0–14 Nm | ±1.39% |

| ṁf | CT 110 | 0–150 cm3 | ±1.63% |

| CP | Pressure transducer CT 100.13 | 0–250 bar | ±0.79% |

| EGT | Thermocouples | 0–1300 K | ±2.05% |

| Computed parameters | |||

| Brake power (BP) | Using engine torque and speed | - | ±0.15% |

| BSFC | Using brake power and fuel flow rate | - | ±0.79% |

| BTE | Using brake power and lower heating value | - | ±0.78% |

| HRR | Using CP, V, and CA | - | ±0.52% |

| Feedstock Type and Biodiesel Properties | Operating Conditions | Result | Author |

|---|---|---|---|

| Grape seed biodiesel: lower heating value of 36.45 kJ/kg, kinematic viscosity of 3.62 mm2/s, density of 869 kg/m3 | Constant speed of 1500 rpm. Engine performance and emission characteristics were optimized at variable injection timing (6–30 bTDC), injection pressure (400–1000 bar), engine load (20–100%), and biodiesel blend (0–60%). | Achieved a BTE of 31.85%, mechanical efficiency of 64%, BSFC of 0.278 kg/kWh, CO of 0.127%, NOx of 357 ppm, and HC of 8 ppm at optimal independent variables of injection timing (6° bTDC), an engine load (82%), exhaust gas recirculation (6.7%) injection pressure of 1000 bar, and a grape biodiesel blend of 33%. | [59] |

| Waste cooking oil biodiesel: kinematic viscosity of 4.64 mm2/s, lower heating value of 38.28 MJ/kg, density of 879 kg/m3 | At constant engine speed of 1500 rpm with the variation in engine load. The range of biodiesel blends from B5 to B40 wit 5% difference and B100. | Compared to pure diesel, biodiesel blends achieved lower BTE by 27%, lower brake power by 4.03%, lower torque by 16.76%, higher BSFC by 4,8%, lower CO and HC by 52.2% and 60%, and higher CO2 and NOx 28.1% and 45.4%, respectively. | [17] |

| Fusel oil: lower heating value of 30 MJ/kg, water content 15.5% density of 847 kg/m3 | Variable engine loads (0%-75%) with engine speeds of 1500 rpm and 2100 rpm. Sample fuel blend F20 of 20% vol fusel oil and 80% vol diesel | Compared to pure diesel, due to the higher water content in the fusel oil, NOx was reduced by up to 20% at 1500 rpm engine speed and 75% engine load. Both CO and HC emissions were increased and the BSFC increased. | [60] |

| Soapberry seed biodiesel: lower heating value of 37.82 MJ/kg, kinematic viscosity of 3.58 mm2/s, density of 832 kg/m3 | At a constant engine speed of 1500 Variable loads of 25%, 50%, 75%, and 100% Fuel blends B10, B20, and B30 | Compared to the biodiesel blends, pure diesel achieved a higher BTE, cylinder pressure, and HRR B30 has a lower CO and HC but higher NOx emission. | [24] |

| Roselle biodiesel: lower heating value of 38.74 MJ/kg, kinematic viscosity of 5.64 mm2/s, density of 877 kg/m3 | Fuel samples of diesel, B20–B100 at 20% increment, injection timing of 19–27 bTDC, and engine load of 25, 50, 75, and 100% at a constant compression ratio of 17.5 and engine speed of 1500 RPM. | B20 showed greater EGT, ID, and maximum PRR. Biodiesel resulted in a lower NOx emission. B20 with varying the injection timing from 19 to 27 °CA bTDC, BSFC and EGT, CO2, and NOx increased by 15.8%, 4.6%, 5.3%, and 12.9%, respectively, while BTE and smoke decreased by 4.4% and 18.8%, respectively. | [58] |

| Rapeseed methyl ester: lower heating value of 37.5 MJ/kg, kinematic viscosity of 4.48 mm2/s, density of 882.4 kg/m3 | Fuel samples of diesel and B100, Advanced injection timing (AIT) of 6, 11, 16, and 21 °CA before TDC. Retarded injection timing (RIT) of 1, 5, 10, and 15 °CA after TDC. Engine load (in Brake mean effective pressure): 2.5 and 5 bar BMEP. At a constant engine speed of 1500 RPM. | Compared to diesel, For B100, HC and CO were reduced by 21% and 31% at a load bar of 5 BMEP, respectively. AIT reduced the CO and HC compared to the RIT, whereas the NOx decreased by 24% for RIT and increased by 7% for AIT, Smoke and particulate matter were reduced for AIT compared to RIT, especially for B100. | [52] |

| Fig seed oil methyl ester; lower heating value of 39.57 MJ/kg, kinematic viscosity of 4.78 mm2/s, density of 919 kg/m3 | Fuel samples: diesel, B5, B10, and B20. At constant full load and engine speed of 1550, 1700, 1850, 2000, and 2150 RPM. | Biodiesel blends exhibited a higher CP and PRR and lower HRR compared to diesel. The CA at which the peak CP is attained is farther away from TDC. | [37] |

| Mustard oil biodiesel; | Fuel samples: diesel, B10, B20, B30, and B40 Engine load of 0, 25, 50, 75 and 100% at constant of 1500 rpm | Biodiesel blends have shown a higher CP. The CP rises with the rise in biodiesel blend percentage. The CA position of the peak CP for all biodiesel blends occurs slightly earlier than diesel. The peak HRR occurs at almost the same CA for all biodiesel blends and diesel at higher loading conditions, the peak HRR of biodiesel is closer to diesel. | [40] |

| Croton macrostachyus (CMS) seed biodiesel: lower heating value of 40.04 MJ/kg, kinematic viscosity of 4.43 mm2/s, density of 846.3 kg/m3 | Fuel samples: diesel, B10, B15, B20, and B25 Engine load 0, 20, 40, 60, and 80% At a constant speed of 2700 RPM Injection timing of 23 °CA before TDC | Compared to the biodiesel blends, pure diesel achieved an increased BTE by 5.5–14%, and BSFC by 17–26% and decreased EGT by 7–12%. Compared to diesel, CO and HC are lower, while the carbon dioxide (CO2) and NOx are higher for biodiesel blends. Peak CP and HRR rises with the rise in engine load and biodiesel blend. The SoC advances CA before TDC, while the ID period decreases with the increase in engine load and biodiesel percentage. | Present study |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mohammed, A.S.; Ancha, V.R.; Atnaw, S.M.; Desta, M.; Bhandari, R. Analysis of Cylinder Pressure and Heat Release Rate Variation in Diesel Engine Fueled with Croton Macrostachyus (CMS) Seed Oil Biodiesel as an Alternative Fuel. Energies 2025, 18, 1449. https://doi.org/10.3390/en18061449

Mohammed AS, Ancha VR, Atnaw SM, Desta M, Bhandari R. Analysis of Cylinder Pressure and Heat Release Rate Variation in Diesel Engine Fueled with Croton Macrostachyus (CMS) Seed Oil Biodiesel as an Alternative Fuel. Energies. 2025; 18(6):1449. https://doi.org/10.3390/en18061449

Chicago/Turabian StyleMohammed, Adem Siraj, Venkata Ramayya Ancha, Samson Mekbib Atnaw, Melaku Desta, and Ramchandra Bhandari. 2025. "Analysis of Cylinder Pressure and Heat Release Rate Variation in Diesel Engine Fueled with Croton Macrostachyus (CMS) Seed Oil Biodiesel as an Alternative Fuel" Energies 18, no. 6: 1449. https://doi.org/10.3390/en18061449

APA StyleMohammed, A. S., Ancha, V. R., Atnaw, S. M., Desta, M., & Bhandari, R. (2025). Analysis of Cylinder Pressure and Heat Release Rate Variation in Diesel Engine Fueled with Croton Macrostachyus (CMS) Seed Oil Biodiesel as an Alternative Fuel. Energies, 18(6), 1449. https://doi.org/10.3390/en18061449