Abstract

In this study, a numerical simulation was used to evaluate the insulation performance of polyethylene (PE) and polyvinyl chloride (PVC) under varied environmental and electrical conditions. Tests were conducted at temperatures of 22 °C and 55 °C, with current levels of 40 A and 60 A, examining key parameters such as electric field intensity, current density, and Joule heating. The results show that, under lower temperature and current conditions, PE demonstrates greater current capacity but suffers from increased Joule heating and energy loss. Conversely, PVC provides more stable insulation with lower energy dissipation. At higher temperatures and currents, PE experiences significant electrical stress and thermal loading, increasing the risk of overheating, while PVC maintains consistent performance. These findings offer valuable guidance for selecting optimal insulation materials in power distribution systems.

1. Introduction

Technological advancements and industrial growth have heightened the demand for electrical energy, necessitating high-voltage transmission to minimize loss over long distances. In densely populated areas, underground cables are preferred for safety and aesthetics. Increasingly used in smart city connections, these cables are designed for 30–40 years of service but often fail prematurely due to installation and operational challenges.

The most important factors determining the lifespan of a cable are electrical and environmental factors. Among the electrical factors are elements such as voltage level, current density, electric field distribution, and leakage currents, which create stress in the cable’s insulation, increasing internal heating and reducing the insulation’s lifespan [1]. Environmental conditions, on the other hand, are factors such as ambient temperature, humidity, chemical substances, soil composition, and the cable’s exposure to mechanical stresses that directly affect the cable. Heat and electrical factors, in particular, can lead to issues such as excessive temperature buildup, insulation degradation, and energy loss in the cable, so they need to be examined in detail during cable design [2]. In order to enhance the insulation performance of high-voltage cables directly related to the safe operation of the power system, these cables are designed during the production phase with special insulating materials and multilayer structures, and cable accessories function as one of the most critical components of this structure [3,4]. The insulating materials used in cable accessories have a specific permissible temperature limit. Exceeding these values during operation causes the cable to age prematurely. The decrease in insulation level is often the main factor in the failure of cable accessories, leading to a reduction in insulation level and an increase in leakage current, resulting in increased losses and, ultimately, an increase in temperature [5,6]. Apart from the environmental temperature, since the insulation and ground are not good thermal conductors, the heat generated by the current passing through the cable conductor cannot be effectively dissipated from the cable, creating a risk of thermal breakdown [7]. To properly dissipate the heat generated, the insulation material in cable design and maintenance should take into account the current density and electric field effects that will occur in the cable. However, determining an ideal insulation material is a challenging process that requires the consideration of multiple technical and environmental variables [8]. In the selection of cable insulation materials, mathematical, experimental, and simulation methods are used to integrate electrical, thermal, mechanical, and environmental analyses under a unified framework to facilitate scientific and engineering-based decision-making [9]. Although the analytical calculation method is fast, easy to program, and relatively simple, its results are not always entirely accurate. On the other hand, experimental methods are complex, costly, and time-consuming, and they typically conduct aging studies by considering only a single parameter. However, evaluating multiple factors that influence aging simultaneously is a significant challenge, as the aging effect caused by multiple stresses acting together differs from the damage induced by individual stresses alone. The lifespan of insulation materials may vary depending on their application and operating conditions, and the aging process can result from either a single factor or the interaction of multiple factors. Therefore, the numerical calculation method based on three-dimensional simulations enables the simultaneous evaluation of multiple factors, allowing for a more accurate analysis of insulation materials suitable for the intended cable application. In this way, the potential consequences of applying previously untested insulation materials can be safely examined, and possible risks can be anticipated in advance.

In the initial studies aimed at determining the temperature distribution in electrical cables, both empirical approaches and analytical methods based on the IEC 60287 standard were frequently used [10]. With the advancements in computer technology, these analytical methods have evolved into more advanced numerical methods such as boundary elements [11], finite differences [12,13], and finite elements [14,15]. In these numerical methods used, the iterative solution methods of Gauss–Seidel [16] and Newton Raphson [17] were employed to solve the sets of equations that arise in finding the temperature distributions. In many studies conducted, the temperature distributions and current carrying capacities of cables, electrical fields, current density values, and potential fire situations that may arise have been investigated for different cable structures, geometries, environmental and soil conditions, various burial depths, and different geometries.

In study [18], the effects of three typical defects in cross-linked polyethylene (XLPE) insulation—air voids in the XLPE insulation, metal protrusions on the surface, and metal particles on the main insulation surface—were investigated through electrical field simulations of XLPE cables using the COMSOL analysis program. In a perfect XLPE cable, it has been observed that the electric field density decreases as it approaches the surface, with lower density on the surface of the insulation layer and higher density in the inner regions.

In study [19], the faults occurring at the high voltage cable terminal ends of high-speed electric multiple units (EMU) were examined. It has been determined that the cable terminal is prone to partial discharge, and this condition threatens the safety of the EMU by leading to insulation failure. The analysis of the electric field intensity distribution of internal defects such as air gaps, moisture, semiconductors, and carbons has been examined. Additionally, the optimization effects of using nonlinear and high dielectric materials instead of the voltage tube to improve the electrical field distortion of the EMU cable terminal have been investigated. The results showed that the defects were close to the multilayer combination area between the main insulation, voltage tube, and outer semiconductor layers, and this situation increased the electrical field distortion. As the defect size increased, it was observed that the electric field density also gradually rose.

When the literature is examined, the comparison of different cable materials and their use highlights some of the dielectric properties of the insulating materials used in cables, while others provide advantages in terms of thermal performance. In study [7], calculated the thermal analyses and current-carrying capacities of underground cables with PE and XLPE insulating properties. As a result of such studies, the strengths and weaknesses of the materials are identified, and cable manufacturers also conduct research to determine the most suitable cable materials based on this information. In study [20], they examined the thermal decomposition and insulation properties of the PVC cable insulation layer while operating under low and high current conditions. Additionally, they investigated the fire risk of the cable under overload conditions. The results showed that prolonged overload application carries a relatively lower risk of combustion, but the insulation properties are compromised [20]. When the literature is examined, it is observed that the selection of insulating materials, the effect of temperature, and the application of different current values in cable design are critically important for the cable’s performance, safety, and longevity.

Insulating material not only effectively isolates electric current but also provides protection against environmental factors. High-temperature conditions, on the other hand, adversely affect the dielectric properties of the insulating material, causing insulation losses and premature aging of the cable. At the same time, the increase in current values raises the temperature within the cable, which affects the electric field and limits the durability of the dielectric material. Analyses conducted with different current values are used to determine the cable’s cooling needs and thermal design requirements by affecting the cable’s temperature profile and, consequently, the electrical properties of the dielectric material. In cable design, electric field analyses are conducted to ensure compliance with safety standards and to minimize the risks of arcing and short circuits that high electric fields can cause, as discussed in [21]. These analyses provide better performance and safety by optimizing cable design. To shorten the decision-making process and minimize errors that may arise from the human factor, different analysis methods such as artificial intelligence, artificial neural networks, fuzzy logic, genetic algorithms, ANSYS, and COMSOL are used by scanning possible options.

In this study, a comprehensive approach was employed to investigate the impact of insulation materials on cable performance under varied environmental and electrical conditions. The cable design was created using SolidWorks, while environmental boundary conditions (22 °C and 55 °C) and electrical conditions (40 A and 60 A) were established in the analysis software. Analyses focused on key parameters including the total electric field, electric field intensity in one direction, total current density, and Joule heating for two insulation materials: polyethylene (PE) and polyvinyl chloride (PVC). The thesis of this work is that the choice of insulation material, in conjunction with temperature and current variations, plays a critical role in determining the cable’s electric field distribution and current density. By systematically comparing PE and PVC, this study aims to provide clear insights into optimizing cable insulation design for enhanced performance.

2. Materials and Methods

Leveraging advanced finite element modeling through ANSYS 2018 R1 and SolidWorks 2022, this research enables precise simulations of electrical and thermal stresses, offering robust predictions for insulation material performance in real-world scenarios.

Experimental studies generally require special laboratory conditions and equipment, while the FEM is a widely used technique in solving complex engineering problems, offering detailed analysis capabilities and the ability to quickly test multiple scenarios [22]. Especially in electrical-electronics engineering, experiments that need to be conducted under dangerous conditions such as high voltage or extreme temperature are simulated in a virtual environment, helping to prevent potential hazards. In this study, the ANSYS software program was used for the FEM.

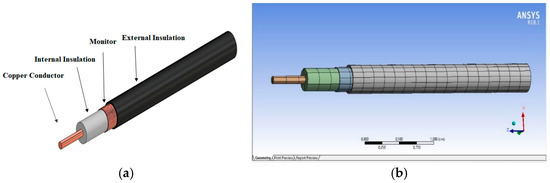

Cable Geometry: A cable is a tool that transmits electrical energy and electrical signals, electrically connects two electrical devices to each other, is electrically insulated, and consists of one or more conductors. In this study, the 3D model of the single-core cable has been designed using the SolidWorks program, as shown in Figure 1. After the cable design was created using the SolidWorks design program and the materials of the cable were defined, a mesh geometry for the finite element analysis of the cable was generated using the ANSYS program, as shown in Figure 1.

Figure 1.

Cable 3D Design and the Mesh Operation Demonstration. (a) Cable 3D Design. (b) Mesh Operation Demonstration.

In the mesh generation process, the “Use Adaptive Sizing” and “Coarse Mesh Transition” options were utilized to enhance the accuracy of the analysis by using smaller element sizes in regions where the solution is more sensitive.

In simulations involving electric field intensity (E), current density (J), directed electric field, and Joule heat, various physical phenomena are analyzed to understand the behavior of insulating materials.

where V represents the applied voltage, and d represents the distance between two points or electrodes. This relation helps describe how strongly the electric force acts in the space between the electrodes.

While the current density is related to the electric field through Ohm’s law,

where σ is the electrical conductivity of the material. This equation implies that the current flow is proportional to the applied electric field, with σ representing the material’s response to electrical excitation.

The direction of the electric field is found using the potential gradient,

This gradient shows how the potential energy per unit charge changes in space, indicating the direction and magnitude of the field in each region.

Joule heat is expressed as

or

representing the conversion of electrical energy into heat. For heat transfer, the Fourier equation

is used to calculate the effect of Joule heat on temperature distribution, where:

- ρ represents the density of the material;

- cₚ is the specific heat capacity;

- k is the thermal conductivity;

- T is the temperature;

- Q is the heat source term (in this case, the Joule heat).

Additionally, the relationship between electric potential and field can be described by the Poisson equation

and the current continuity equation

applied to static systems. Boundary conditions, such as Dirichlet and Neumann conditions, can be used to define the system, enabling accurate results for nonlinear and dynamic simulations.

In this study, the materials and properties provided in Table 1 have been used. The most commonly used cable insulation materials, PE and PVC, have been preferred. In Table 1, material properties were selected for thermal and electrical simulations and are shown in the table.

Table 1.

Model cable parameters [23].

3. Results and Discussion

In this study, the simulation results of PE and PVC used as external insulation materials are discussed based on the changes in total electric field intensity, current density, directed electric field, and Joule heat, depending on temperature and current variations. The findings of this research have direct implications for the design and selection of insulation materials in underground power cables and smart city infrastructure, addressing both efficiency and safety challenges. While PE is known for its superior current-carrying capacity, PVC stands out due to its lower Joule heating and stable insulation properties, making it a reliable choice under high-temperature conditions.

3.1. PE Simulation Results

3.1.1. Simulating Temperature Variations of PE

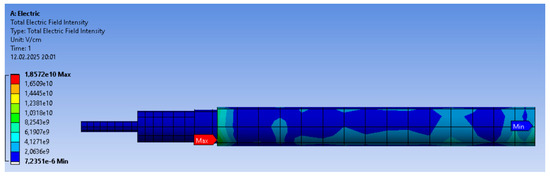

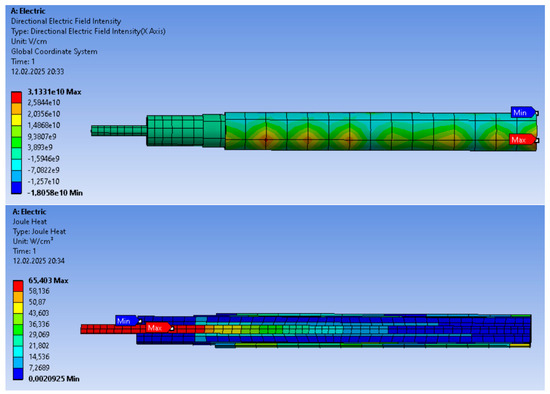

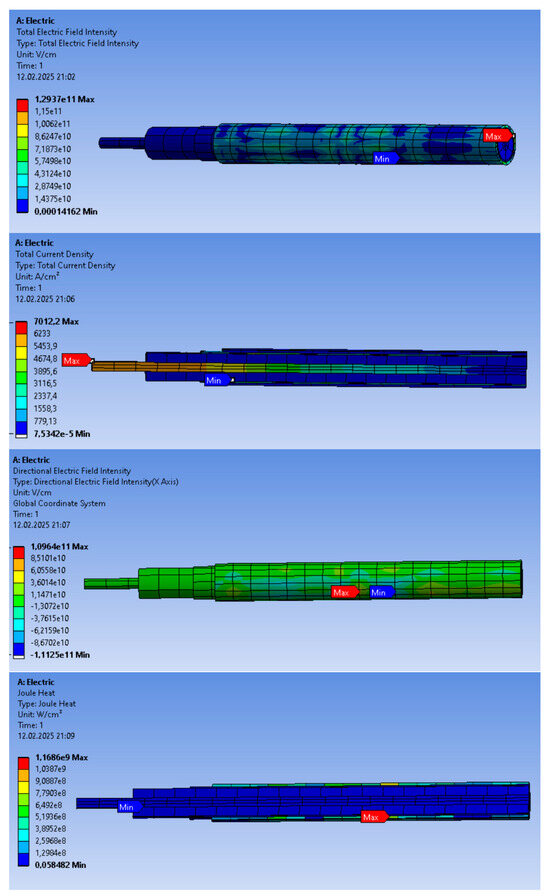

From the moment electric current starts to flow through the cable, the cables begin to heat up due to the losses that occur. The primary source of this heating is the power loss in the electrical resistance of the cable conductor. The increase in temperature caused by heating slows down from the moment the cable temperature exceeds the ambient temperature. From that moment on, the ambient temperature that causes the temperature in the cable to rise begins to have an effect in the direction of reducing the cable temperature [23]. According to the type of insulating material used in the cables, there are specific operating temperatures along with the relevant standards. The operating temperature for PE material is 70 °C [24]. In Figure 2, the cable insulation material PE was used with an environmental condition of 22 °C and an electrical boundary condition of 40 A. In Figure 2, the results of the total electric field intensity, current density, directed electric field, and Joule heating are shown.

Figure 2.

Electric field intensity, current density, directed electric field, and Joule heat simulation results in the cable in the case of PE at 22 °C with 40 A.

An analysis of Figure 2 reveals that the maximum value of the total electric field intensity is 1.825 × 1012 V/m, and the maximum value of the directed electric field is 4.571 × 1012 V/m. The electric field is observed to be denser around the conductor and reaches higher values in the terminal regions. The maximum current density is 61,537 A/m2. When the current density is examined, it shows a homogeneous distribution from the center of the conductor to the outer surface. The maximum Joule heat value is 51.246 w/m3. The heat distribution is homogeneous, but a certain amount of accumulation is observed in the end regions. In Figure 3, the environmental condition was set to a temperature of 55 °C using the cable insulation material PE. The same 40 A has been applied as the electrical boundary condition.

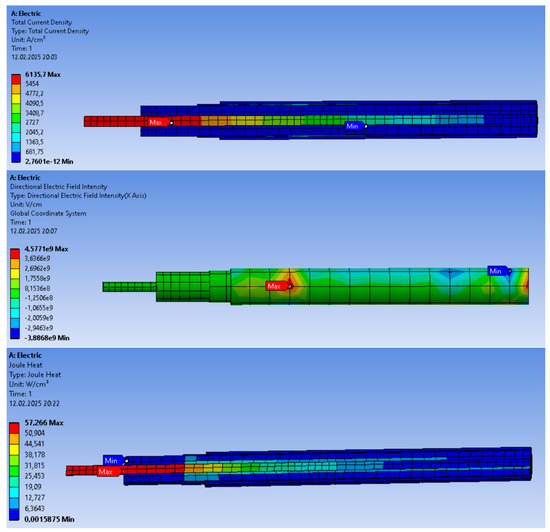

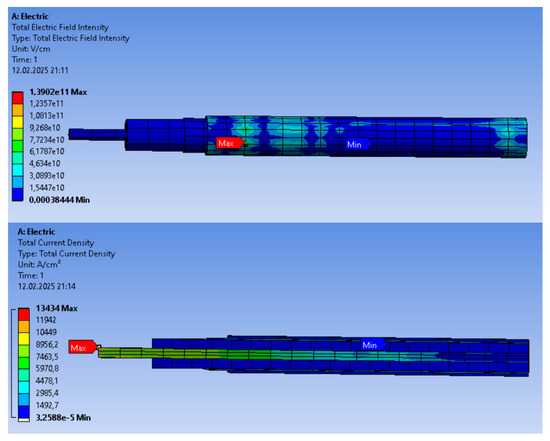

Figure 3.

Electric field intensity, current density, directed electric field, and Joule heat simulation results in the cable in the case of PE at 55 °C with 40 A.

Figure 3 illustrates that the maximum value of the total electric field intensity obtained is 8.311 × 1010 v/m, and the maximum value of the directed electric field is 2.371 × 1010 v/m. The value of the electric field intensity is observed to be lower, at 55 °C. This situation suggests that the increase in temperature may cause a change in electrical properties and can be attributed to the change in the resistance of the conductors. The maximum current density value is 99.594 A/m2. The current density significantly increased at 55 °C, indicating that the temperature rise affects the electrical conductivity of the material. The maximum Joule heat value obtained was 65.43 W/m3. In Table 2, the application of 40 A with environmental boundary conditions of 22 °C and 55 °C, and electrical boundary conditions held constant, is compared.

Table 2.

Simulation results for PE at 22 °C and 55 °C with 40 A application.

An analysis of Table 2 reveals that an increase in ambient temperature may lead to a reduction in electric field values, potentially due to variations in the dielectric constant of the PE insulation material or the temperature-dependent conductivity of the conductor. The elevated electric field observed at 22 °C presents a heightened risk of insulation breakdown. As the temperature rises, the resistance of the conductor increases, resulting in a higher current density and greater energy dissipation, thereby amplifying Joule heating. At 55 °C, this increase in heat induces significant thermal stress on the PE insulation material.

3.1.2. Simulating Current Variations of PE

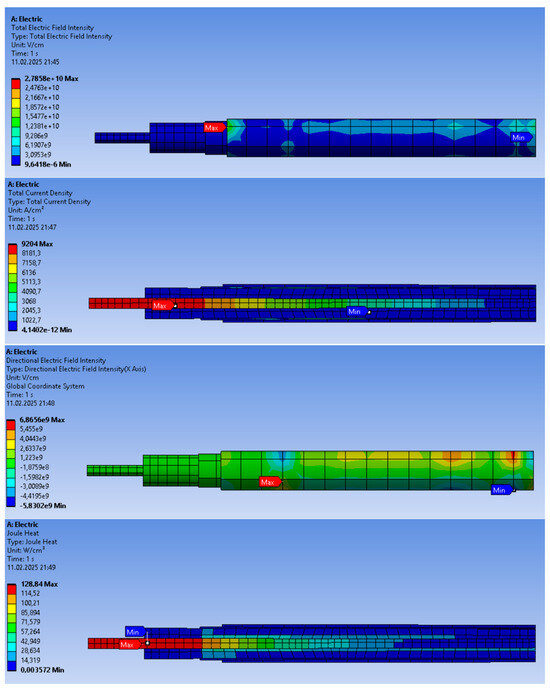

In addition to temperature effects, simulations were conducted to examine the impact of increasing the electrical current from 40 A to 60 A on the electric field, current density, directed electric field, and Joule heat. In Figure 4, PE insulation material is used, with boundary conditions set at 22 °C and 60 A. The results are presented in Figure 5.

Figure 4.

Electric field intensity, current density, directed electric field, and Joule heat simulation results in the cable in the case of PE at 22 °C with 60 A.

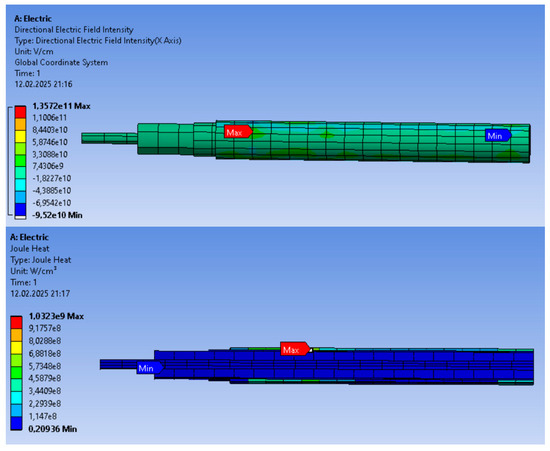

Figure 5.

Electric field intensity, current density, directed electric field, and Joule heat simulation results in the cable in the case of PE at 55 °C with 60 A.

In Figure 4, the maximum value of the total electric field intensity is shown as 2.198 × 1012 V/m, and the maximum value of the directed electric field is 5.495 × 1012 V/m. The maximum current density value is 92.094 A/m2 and the maximum Joule heat value is 72.848 W/m3. In Table 3, the comparison of PE at 22 °C under 40 A and 60 A conditions is shown.

Table 3.

Simulation results for PE at 22 °C with 40 A and 60 A application.

Examining Table 3 shows a ~20% increase in electric field intensity when the current rises from 40 A to 60 A, indicating heightened electrical stress and breakdown risk for PE insulation. Directed fields exhibit greater changes, increasing thermal risks at connection points or reduced cross-sections. Joule heat increases by ~40%, accelerating conductor heating and reducing PE insulation’s thermal durability. These findings highlight the need for careful evaluation for long-term cable use. In Figure 5, the cable insulation material PE was subjected to 55 °C and 60 A. In Figure 5, the results of the total electric field intensity, current density, directed electric field, and Joule heating are shown.

An analysis of Figure 5 reveals that the maximum value of the total electric field intensity is 1.345 × 1012 V/m, the maximum value of the directed electric field is 2.976 × 1012 V/m, the maximum value of the current density is 91.709 A/m2, and the maximum value of the Joule heat is 72.584 W/m3. In Table 4, the comparison of simulation results at 60 A, 22 °C, and 55 °C is shown.

Table 4.

Simulation results for PE 60 A at 22 °C and 55 °C.

As observed in Table 4, as the temperature increases, the dielectric constant and electrical properties of the insulating material PE undergo changes. This situation causes the electric field intensity to decrease. The intensity of the electric field is significantly affected by temperature and does not change directly with the increase in current. However, when the current increases, a temperature rise is observed due to the heat effect, and this indirectly affects the electric field. Current density is hardly affected by temperature, because this value is related to the geometric dimensions of the conductor and the applied current. At 22 °C and 55 °C, the current density at 60 A is observed to be almost constant. Joule heat is directly proportional to the square of the current. The increase in temperature has very little effect on Joule heat. When 60 A is applied, the Joule heat value is observed to be higher compared to the 40 A value.

As a result of the analyses conducted, in electrical and thermal analyses, changes in current value have the greatest impact on Joule heat and current density, while temperature changes, especially those affecting the electrical field performance of insulation materials, cause changes in dielectric properties. As the current increases, the current density also increases.

3.2. PVC Simulation Results

A comprehensive simulation study was carried out to investigate the impact of different temperature levels and electrical currents on the insulation performance of power cables. In this context, PVC was specifically selected as the outer insulation material due to its widespread use in cable manufacturing and its known thermal and electrical properties. By simulating these varying conditions, this study aimed to provide an in-depth understanding of how temperature fluctuations and current loads affect the overall integrity, reliability, and durability of the cable insulation system under diverse operational scenarios.

3.2.1. Simulating Temperature Variations of PVC

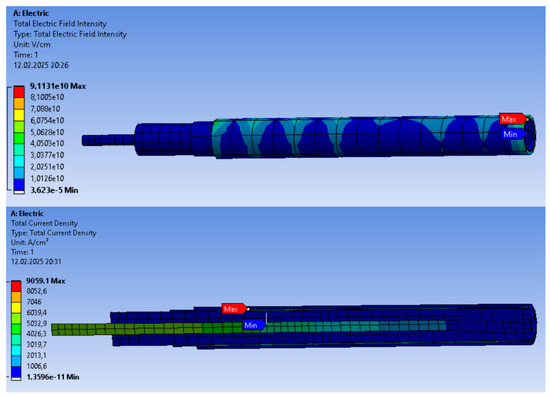

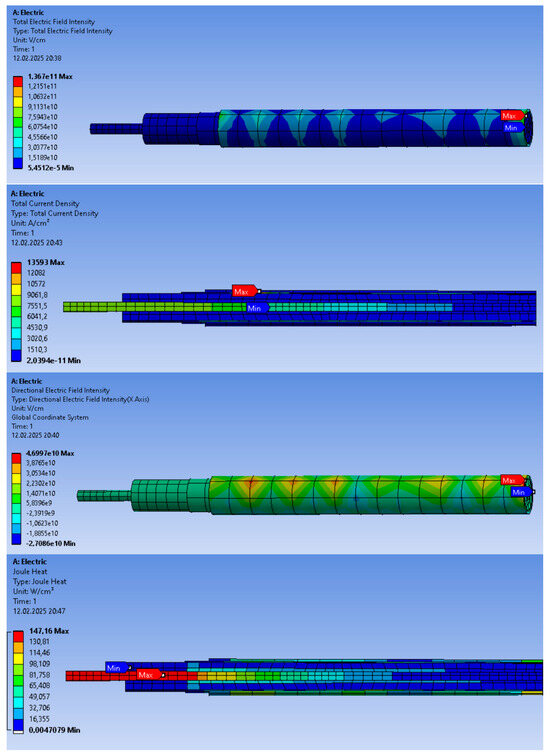

The operating temperature of PVC is 80 °C [25]. Considering this situation, the simulation temperature was examined under the conditions of 22 °C and 55 °C. In Figure 6, the cable insulation material PVC was used at 22 °C and 40 A, and the results for total electric field intensity, current density, directed electric field, and Joule heating are shown.

Figure 6.

Electric field intensity, current density, directed electric field, and Joule heat simulation results in the cable in the case of PVC at 22 °C with 40 A.

As illustrated in Figure 6, the simulation results reveal that the maximum value of the total electric field reaches a significant magnitude of 9.32 × 1010 V/m. Additionally, the maximum directional electric field intensity is calculated as 9.04 × 1010 V/m, highlighting its directional alignment within the system. The maximum value of the total current density is determined to be 8.65 × 103 A/m2, indicating the highest level of current flow per unit area in the system. Furthermore, the analysis of Joule heating demonstrates a maximum heat generation value of 4.57 × 10⁶ W/m3, underscoring the thermal effects associated with electrical losses within the insulation material.

In Figure 7, the detailed simulation outcomes for PVC under the specific conditions of a temperature of 55 °C and an applied current of 40 A are depicted. These results provide a comprehensive view of the behavior of the total electric field intensity, current density, directional electric field, and Joule heating under the stated operating parameters.

Figure 7.

Electric field intensity, current density, directed electric field, and Joule heat simulation results in the cable in the case of PVC at 55 °C with 40 A.

According to Figure 7, a total electric field maximum of approximately 9.32 × 1010 V/m was obtained. The directional electric field intensity, on the other hand, reached a maximum of 9.04 × 1010 V/m, while the total current density, when examined, reached a maximum value of 8.65 × 103 A/m2. In the Joule heating analysis, a maximum value of 4.57 × 10⁶ W/m3 was obtained. In Table 5, the environmental boundary conditions of PVC at 22 °C and 55 °C, with the electrical boundary conditions kept constant, are compared under the application of 40 A.

Table 5.

Simulation results for PVC 40 A at 22 °C and 55 °C.

When Table 5 is examined, it shows that the insulation properties of PVC were adversely affected by the temperature increase at 55 °C. Higher temperatures caused a redistribution of the electric field and current density. The increase in Joule heat at 55 °C indicates that the thermal losses of PVC have increased, and this situation could negatively affect the material’s lifespan. The increase in current density and Joule heat at 55 °C indicates that the insulation performance of the material decreases with temperature. Under high-temperature conditions, alternative insulation materials or additional cooling solutions should be considered to enhance the insulation performance of PVC.

3.2.2. Simulating Current Variations of PVC

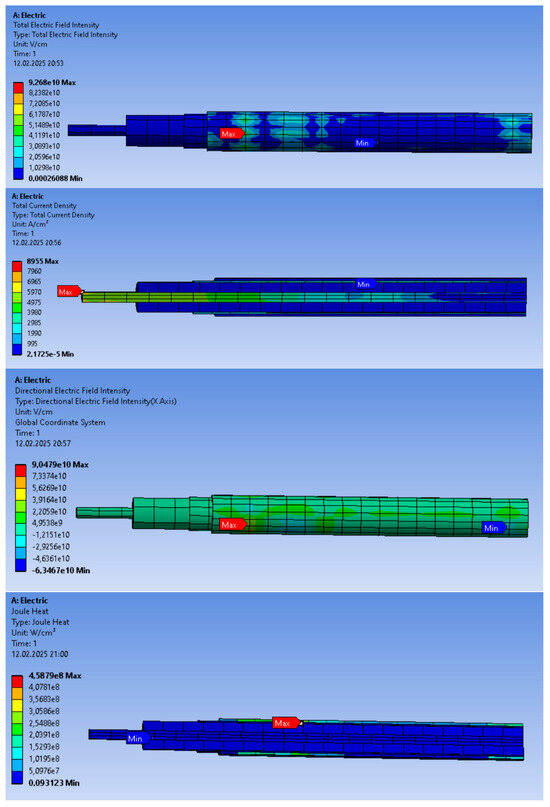

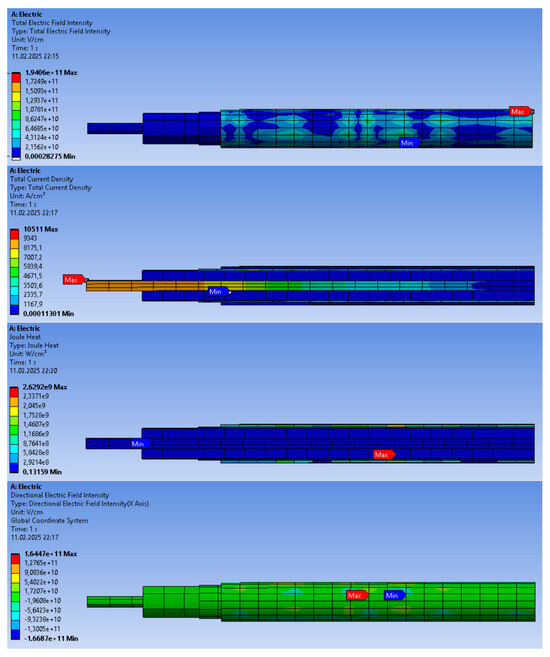

When PVC is used as the outer insulation material, increasing the current from 40 A to 60 A significantly impacts the electric field, current density, directed electric field, and Joule heating. Figure 8 shows the results for the PVC insulation at 22 °C and 60 A for total electric field intensity, current density, directed electric field, and Joule heating.

Figure 8.

Electric field intensity, current density, directed electric field, and Joule heat simulation results in the cable in the case of PVC at 22 °C with 60 A.

Figure 8 demonstrates that the total electric field reaches a maximum of approximately 5.13 × 1012 V/m, while the directional electric field intensity attains a peak value of 4.52 × 1012 V/m. The maximum current density is 134.04 A/m2, and the Joule heating analysis indicates a peak value of 8.123 W/m3.

As shown in Table 6, 60 A application to PVC insulation resulted in a significant increase in both the total and directed electric field intensities, indicating heightened electrical stress. The current density rose from 8.65 × 103 A/m2 at 40 A to 134.04 A/m2 at 60 A, contributing to increased conductor heating. The Joule heat, calculated as 8.123 W/m3 at 60 A, indicates substantial thermal stress. Overall, both electrical and thermal loading within the cable increase notably with higher current.

Table 6.

Simulation results for PVC at 22 °C, 40 A, and 60 A.

In Figure 9, the cable insulation material PVC was subjected to 55 °C and 60 A, and the results of the total electric field intensity, current density, directed electric field, and Joule heat are shown.

Figure 9.

Electric field intensity, current density, directed electric field, and Joule heat simulation results in the cable in the case of PVC at 55 °C with 60 A.

When Figure 9 is examined, the total electric field strength can be determined to be a maximum of 1.3946 × 1011 V/m. The directed electric field intensity reached a maximum value of 1.6344 × 1011 V/m. In the current density distribution, a maximum value of 10.511 A/m2 was reached, while the Joule heat was calculated to be a maximum of 2.2324 × 10⁶ W/m3.

The results of how PE and PVC materials vary with current and temperature increases are shown in Table 7.

Table 7.

Simulation results of PE and PVC materials at 22 °C, 55 °C and 40 A, 60 A application.

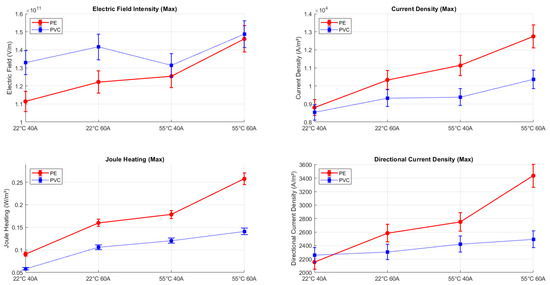

In Figure 10, the results of the total electric field strength, directed electric field strength, current density, and Joule heat values of PE and PVC insulating materials are plotted.

Figure 10.

Comparison of the total electric field intensity, directional electric field intensity, current density, and Joule heat values of PE and PVC insulating materials.

As seen in Table 7 and Figure 10, under 22 °C and 40 A, PVC has higher electric field intensity, while PE shows slightly higher current density (8804 A/m2 vs. 8536 A/m2), indicating better current-carrying capacity. PE also has higher Joule heat, leading to increased heating and reduced insulation performance. At minimum electric field and current density values, both materials show similar results, though PE exhibits a lower minimum electric field. Overall, Table 7 and Figure 10 highlight that PVC provides more stable insulation with less heating, making it more efficient than PE in terms of insulation performance.

At 55 °C and 40 A, PE exhibits higher total and directional electric field intensities than PVC, indicating greater electrical stress. PE’s current density is about twice that of PVC, and its Joule heating is approximately three times higher, making it more prone to heat buildup. Thus, PVC shows better insulation performance under these conditions, while PE experiences greater electrical stress and heating.

At 22 °C and 60 A, the electric field intensity in PVC increases by approximately 50% compared to lower currents. The rise in current significantly elevates the current density, causing PVC to carry a higher electrical load. This also increases Joule heating, raising the risk of overheating and subjecting the insulation to greater electrical stress than at 40 A.

Table 8 illustrates the key electrical parameters, including electric field intensity, current density, Joule heating, and insulation stability, highlighting how these properties change with variations in temperature and current.

Table 8.

Comparative performance of PE and PVC insulation materials under different operating conditions.

Table 8 compares the performance of PE and PVC insulation materials under different temperature and current conditions. This table provides a comprehensive evaluation based on parameters such as electric field intensity, current density, Joule heating, and insulation stability. Under the conditions of 22 °C and 40 A, PVC exhibits higher electric field intensity, while PE demonstrates slightly higher current density. However, the higher Joule heating in PE reduces its insulation performance, whereas PVC offers more stable insulation with lower Joule heating. At 55 °C and 40 A, PE experiences twice the current density and three times higher Joule heating compared to PVC, leading to significant thermal stress.

This reduces the insulation stability of PE, while PVC maintains thermal stability with lower electrical stress and Joule heating. At higher current levels (22 °C and 60 A), both materials show an increase in electric field intensity and Joule heating. PVC handles the higher electrical load more stably, whereas PE faces increased thermal stress and a higher risk of overheating. Finally, under high-temperature and high-current conditions (55 °C and 60 A), PE’s electric field intensity rises significantly, while PVC exhibits a more moderate increase. With three times higher current density and extreme Joule heating, PE is at risk of severe thermal degradation, whereas PVC delivers a more balanced performance. In conclusion, the performance of PE and PVC varies significantly under different conditions. PVC, with lower Joule heating and higher insulation stability, is a more suitable choice for long-term applications requiring stable insulation. On the other hand, PE offers advantages in applications requiring high current-carrying capacity. These analyses provide valuable guidance for cable design and material selection. This table highlights that PVC provides more stable insulation in terms of thermal stress and Joule heating, while PE offers higher current-carrying capacity. However, PE’s insulation performance significantly deteriorates under higher current and temperature conditions.

4. Conclusions

Technological advancements and urbanization have significantly increased the importance of underground cable systems, necessitating a comprehensive evaluation of insulation materials in terms of performance and durability. In particular, the behavior of insulation materials under thermal stress and Joule heating is of critical importance for the long-term reliability and efficiency of energy transmission systems used in smart city infrastructure.

In this study, the performance of polyethylene (PE) and polyvinyl chloride (PVC) insulation materials under varying temperature and current conditions was compared. As highlighted in the literature, as the current passing through a cable increases, the amount of heat energy generated also rises, leading to a proportional relationship between current and Joule heating [26]. The increase in electrical current enhances energy losses due to resistance in the cable conductor, resulting in the conversion of electrical energy into thermal energy. The temperature rise caused by Joule heating can induce thermal stress and degradation in cable materials, ultimately impacting their structural integrity and overall performance [27].

The simulations conducted in this study reveal that PE provides a higher current-carrying capacity at lower temperatures; however, it also experiences greater energy losses due to Joule heating. Conversely, PVC demonstrates lower energy losses and more stable insulation performance, even under high-temperature and high-current conditions. These findings emphasize the significance of selecting appropriate insulation materials for underground cable systems, particularly in applications requiring long-term thermal stability, such as smart city infrastructure.

This study provides a comprehensive evaluation of the performance of insulation materials by analyzing the variations of key parameters such as total electric field, unidirectional electric field intensity, total current density, and Joule heating under different conditions. Unlike similar studies in the literature, it focuses on the effects of thermal and electrical stress on polymer insulation materials, offering a detailed assessment of their behavior under varying operating conditions.

The results emphasize the significance of working conditions in insulation material selection. While PE excels in current-carrying capacity, PVC provides safer and more durable insulation due to its lower Joule heating and electric field intensity. The selection of an optimal material tailored to specific applications and temperature conditions is crucial for energy efficiency and cable performance. This study highlights the importance of managing current levels to prevent excessive thermal stress and ensure cable reliability.

Future studies could expand the scope by analyzing other insulation materials such as cross-linked polyethylene (XLPE) or thermoplastic elastomers under similar conditions to provide a broader perspective on material selection. As the global consumption of electrical cables continues to rise due to increasing electrification and infrastructure projects, materials science is also evolving, introducing new-generation materials with advanced properties. In this context, in addition to traditional XLPE, the use of recyclable insulation materials can play a crucial role in supporting environmental sustainability while enhancing resource efficiency [28]. Therefore, future research may focus on improving the applicability of recyclable and higher-performance insulation materials, making them a central focus of upcoming studies.

Further research could also investigate the effects of a wider range of electrical and environmental parameters, such as higher current and voltage levels or varying humidity conditions, to enhance the applicability of the findings. Long-term aging effects on insulation materials under continuous thermal and electrical stress could be explored to predict the lifespan of power cables in real-world conditions. While this study highlights the strengths and weaknesses of PE and PVC under varying conditions, future work can build upon these findings to explore alternative materials, real-world validations, and long-term performance under diverse environmental scenarios, and it can further improve safety protocols and design standards in electrical systems.

Author Contributions

Conceptualization, G.K. and Ö.I.; literature studies, G.K. and Ö.I.; research methodology, Ö.I.; research and data analysis, G.K.; writing—original draft preparation, G.K. and Ö.I.; writing—review and editing, G.K. and Ö.I. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

The data presented in this study are available on request from the corresponding author. The data are not publicly available.

Conflicts of Interest

The authors declare no conflicts of interest.

Abbreviations

The following abbreviations are used in this manuscript:

| PE | Polyethylene |

| PVC | Polyvinyl chloride |

| A | Ampere |

| LD | Linear dichroism |

| XLPE | Cross-linked polyethylene |

References

- Pamuk, N. 2XS (FL) 2Y 87/150 (170) kV Yüksek Gerilim Güç Kablosu Yalıtım Arızasının İncelenmesi ve Elektriksel Ölçüm Testleri. Düzce Üniversitesi Bilim Teknol. Derg. 2014, 2, 284. [Google Scholar]

- Günday, A. Enerji Kablosunda Oluşan Sıcaklık ve Gerilmeleri Optik Fiberli Algılayıcılarla Algılama Benzetimleri. Master’s Thesis, Bursa Uludağ University, Bursa, Turkey, 2007. [Google Scholar]

- Chi, Q.G.; Yang, M.; Zhang, C.H.; Zhang, T.D.; Feng, Y.; Chen, Q.G. Nonlinear electrical conductivity and thermal properties of AgNPs/BN/EPDM composites for cable accessory. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1081–1088. [Google Scholar] [CrossRef]

- He, D.; Meng, F.; Liu, H.; Li, Q.; Wang, X. The influence mechanism of semiconductive material on space charge accumulation in HVDC cable accessory. IEEE Trans. Dielectr. Electr. Insul. 2019, 26, 1479–1486. [Google Scholar] [CrossRef]

- Lin, C.; Zhen, L.; Wu, Y. Summary of research on online monitoring method of cable joint temperature. Electr. Eng. 2019, 20, 1–4, 9. [Google Scholar]

- Gan, D.; Zhang, L.; Zhang, R. Surface temperature distribution and statistical characteristics of cable joints under eccentric conditions. High Volt. Appar. 2019, 55, 117–123. [Google Scholar]

- Koçar, I.; Ertaş, A. Thermal Analysis for Determination of Current Carrying Capacity of PE and XLPE Insulated Power Cables Using Finite Element Method. In Proceedings of the 12th IEEE Mediterranean Electrotechnical Conference (IEEE Cat. No.04CH37521), Dubrovnik, Croatia, 12–15 May 2004; pp. 905–909. [Google Scholar]

- Azimuddin, A.; Refaat, S.S. A comprehensive model for electrical degradation of power cable insulation. In Proceedings of the 2022 IEEE Conference on Electrical Insulation and Dielectric Phenomena (CEIDP), Vancouver, BC, Canada, 12 December 2021; pp. 133–138. [Google Scholar] [CrossRef]

- You, F.; Yusoh, M.A.T.M.; Ali, N.H.B.N.; Yang, H. Analysis on Influencing Factors of Temperature Distribution of Shore Power Cable. IEEE Access 2024, 12, 137988–137999. [Google Scholar] [CrossRef]

- Sedaghat, A.; León, F. Thermal analysis of power cables in free air: Evaluation and Improvement of the IEC Standard Ampacity Calculations. IEEE Trans. Power Deliv. 2014, 29, 2306–2314. [Google Scholar] [CrossRef]

- Anders, G.J.; Napieralski, A. Calculation of the Internal Thermal Resistance and Ampacity of 3-core Screened Cables with Fillers. IEEE Trans. Power Deliv. 1999, 14, 729–734. [Google Scholar] [CrossRef]

- Hiranandani, A. Calculation of Conductor Temperatures and Ampacities of Cable Systems Using a Generalized Finite Difference Method. IEEE Trans. Power Deliv. 1991, 6, 15–24. [Google Scholar] [CrossRef]

- Haskew, T.A.; Carwile, R.F.; Grigsby, L.L. An Algorithm for Steady—State Therma Analysis of Electrical Cables with Radiation by Reduced Newton—Raphson Techniques. IEEE Trans. Power Deliv. 1994, 9, 526–533. [Google Scholar] [CrossRef]

- Anders, G.J.; Chaaban, M.; Bedard, N.; Ganton, R.W.D. New Approach to Ampacity Evaluation of Cables in Ducts Using Finite Element Technique. IEEE Trans. Power Deliv. 1987, 2, 969–975. [Google Scholar] [CrossRef]

- Hwang, C.C. Calculation of Thermal Fields of Underground Cable System with Consideration of Structural Steels Constructed in a Duct Bank. IEEE Proc. Gener. Transm. Distrib. 1997, 144, 541–543. [Google Scholar] [CrossRef]

- Hanna, M.A.; Chikhani, A.Y.; Salama, M.M.A. Effect of Geometry Between Cables on the Heat Dissipation from Underground Cable Systems. IEEE CNF 1993, 132, 433–436. [Google Scholar]

- Hwang, C.C.; Jiang, Y.H. Extensions to the Finite Element Method for Thermal Analysis of Underground Cable Systems. Electric Power Syst. Res. 2003, 64, 159–164. [Google Scholar] [CrossRef]

- Tao, L. Field Strength Simulation of Typical Defects in XLPE Cable. Acad. J. Eng. Technol. Sci. 2022, 5, 20–26. [Google Scholar]

- Tang, Y.; Gao, G.; Liu, K.; Chen, K.; Xie, Y.; Xin, D.; Wu, G. Electric field distribution and performance optimization of high-speed train cable terminal with internal defects. Eng. Fail. Anal. 2023, 151, 107360. [Google Scholar] [CrossRef]

- Liu-Fang, C.U. Fire hazard study of PVC wire under low times of overload condition. Insul. Mater. 2013, 46, 24–27. [Google Scholar]

- Karahan, M. Sonlu Elemanlar Metodu Kullanılarak Güç Kablolarının Isıl Analizi ve Akım Taşıma Kapasitesinin Değerlendirilmesi. Ph.D. Thesis, Marmara Universitesi, Istanbul, Turkey, 2007. [Google Scholar]

- TR 62095; Electric Cables—Calculations for Current Ratings—Finite Element Method. IEC: Geneva, Switzerland, 2003.

- Aydın, T. Bulanık Mantık Sınıflandırmadan Yararlanarak Kablo Malzemesi Seçimi. Ph.D. Thesis, Fen Bilimleri Enstitüsü, Istanbul, Turkey, 2004. [Google Scholar]

- George, J.; Anders, S. Rating of Power Cables in Unfavorable Thermal Environment; IEEE Press: Ottawa, ON, Canada, 2005. [Google Scholar]

- Heinhold, L. Power Cables and Their Applications; Siemens Aktiengesellschaft: Berlin/Munich, Germany, 1990. [Google Scholar]

- Ferree, J. Heat Dissipation of Electrical Connections with Horizontal Insulated Cable. In Proceedings of the IEEE 68th Holm Conference on Electrical Contacts (HOLM), New Orleans, LA, USA, 4 October 2023; pp. 1–8. [Google Scholar]

- Akbar, M.A.; Humaidi, S.; Tarigan, K.; Ramdan, D.; Frida, E.; Siregar, Y. Overcurrent effects on copper insulated PVC cables and fire resistance via thermal imaging and macrostructure analysis. Bull. Electr. Eng. Inform. 2025, 14, 1014–1025. [Google Scholar] [CrossRef]

- Deb, A.; Naskar, M. Recyclable Polymeric Cable Insulation Materials: A Comprehensive Review. Power Res. J. CPRI 2024, 113–122. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).