Phase Behavior and Flowing State of Water-Containing Live Crude Oil in Transportation Pipelines

Abstract

1. Introduction

2. Materials and Methods

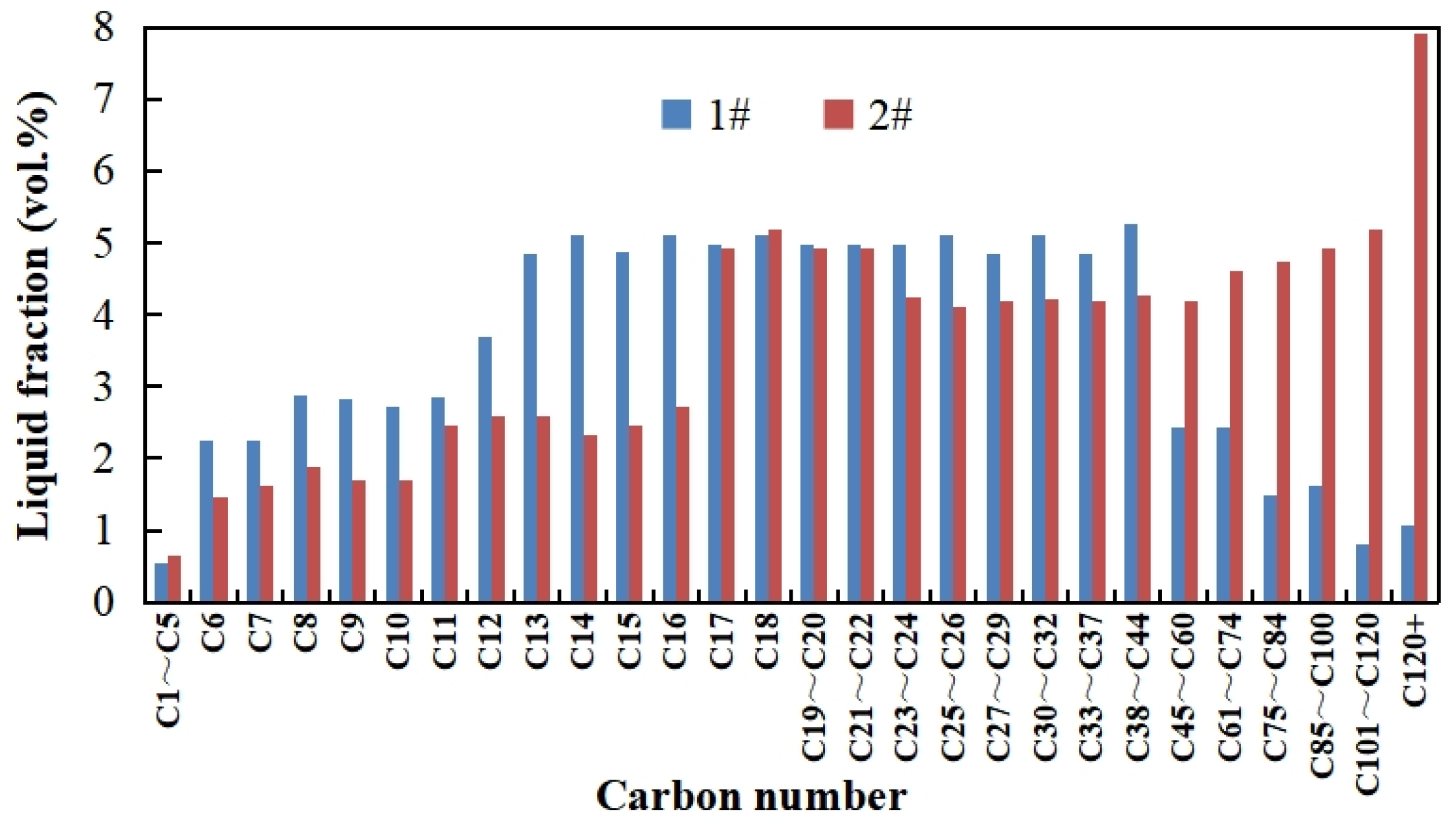

2.1. Oil Samples

2.2. Calculation and Test Methods of Phase Equilibrium Characteristics

2.2.1. Simplified Calculation Method of Equilibrium Constant

2.2.2. Aspen HYSYS Simulation of Phase Equilibrium Characteristics

2.2.3. Bubble Point Pressure Test

2.3. Simulation of the Flowing State of Water-Containing Live Crude Oil in Pipelines

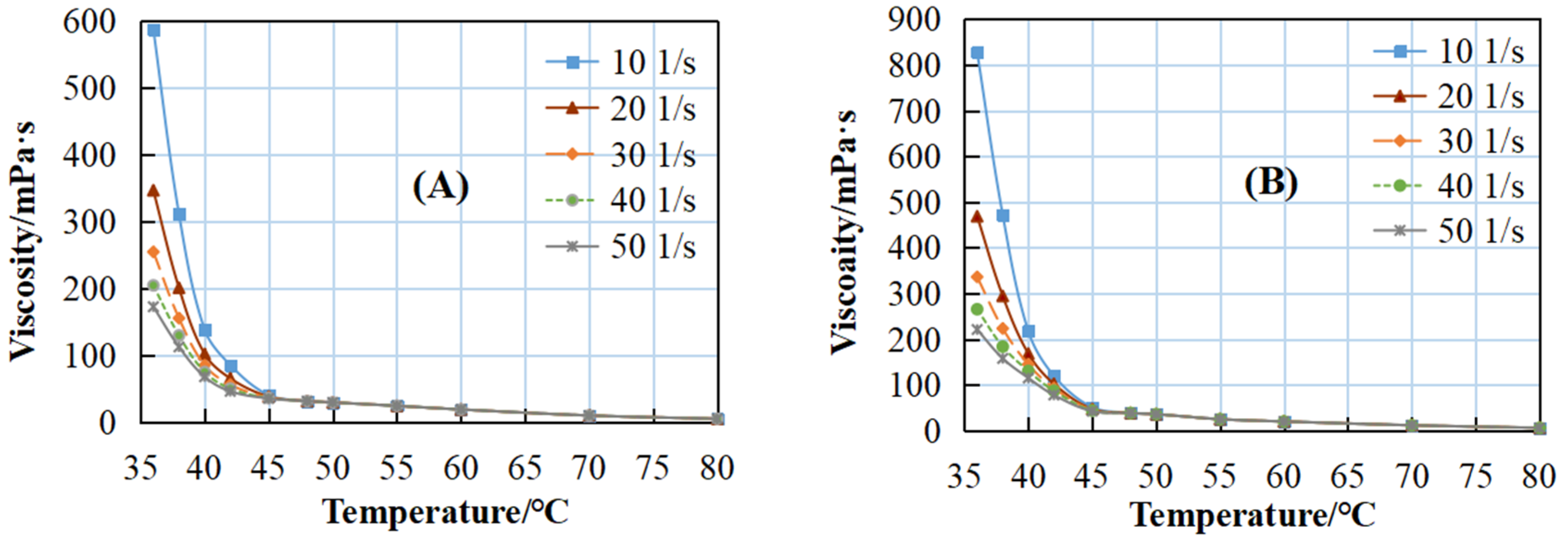

2.3.1. Properties of Water-Containing Live Crude Oil

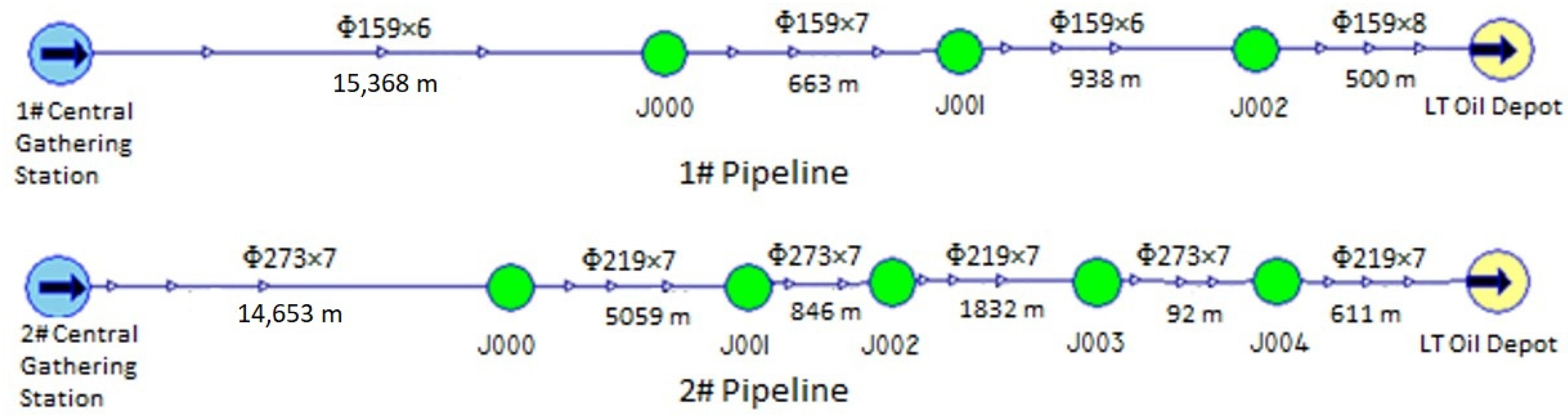

2.3.2. Pipeline Description

2.3.3. Simulation Under Different Pipeline Transportation Conditions

3. Results and Discussion

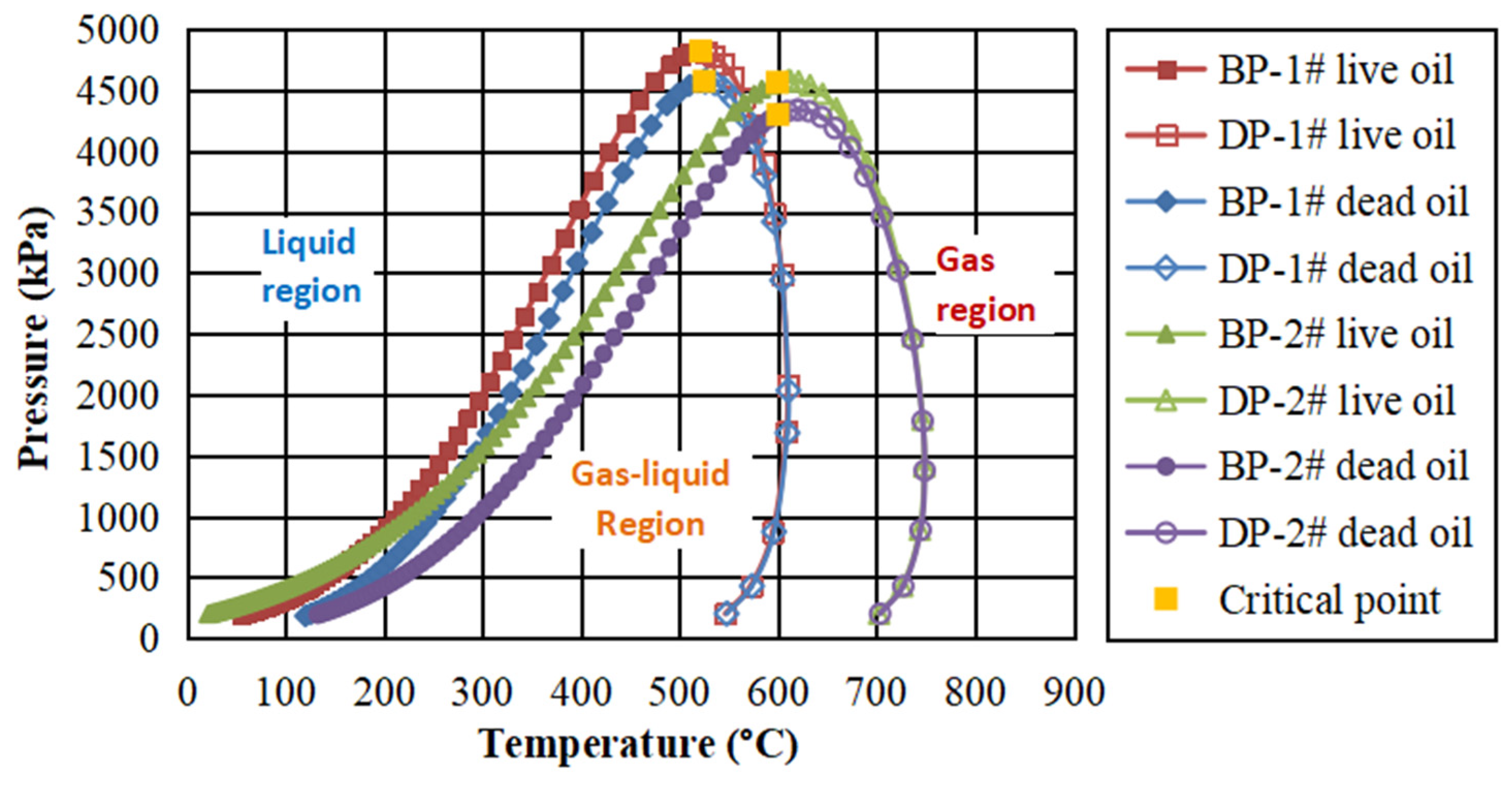

3.1. Phase Diagram of Live Crude Oil

3.1.1. p-t Phase Diagram of Live and Dead Oils

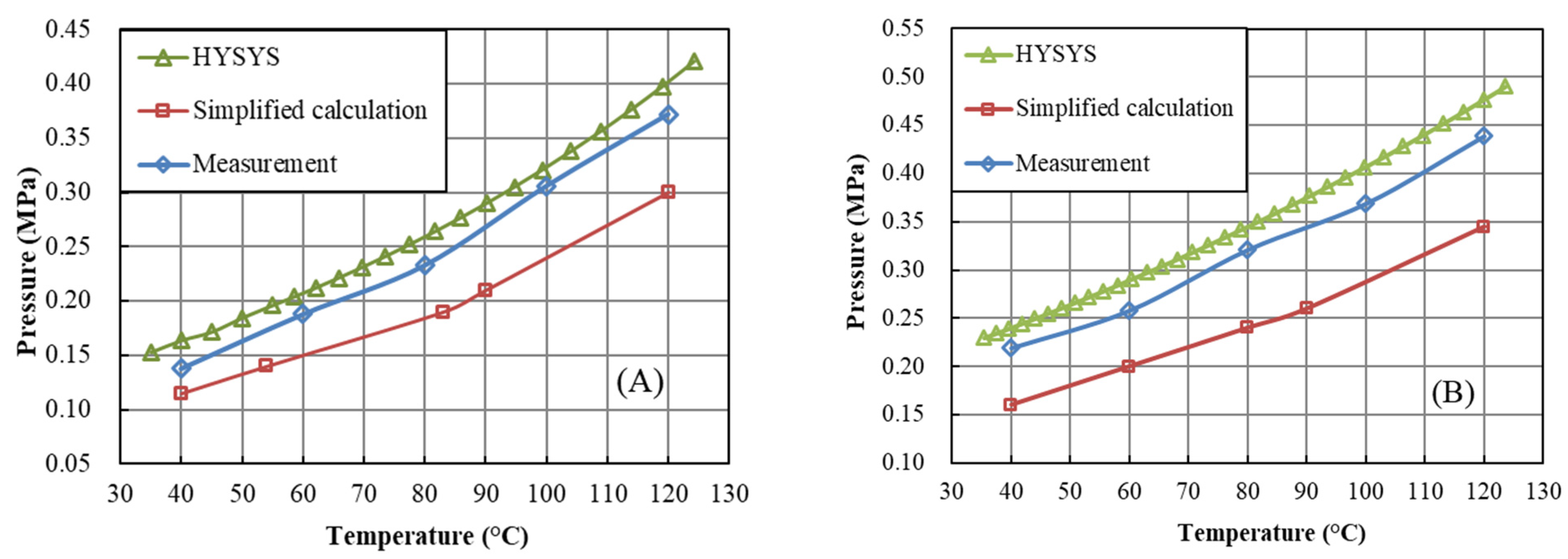

3.1.2. Comparison of Bubble Point Lines Calculated by Different Methods

3.2. Impact of Water Phase on the Gasification of Light Components

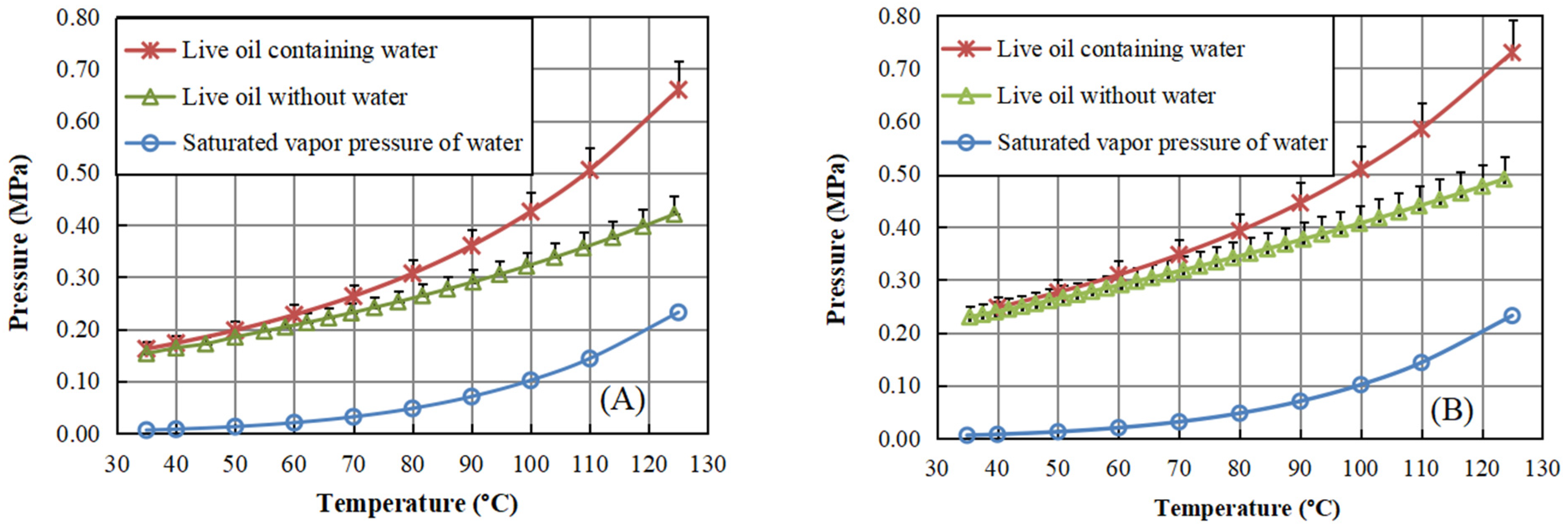

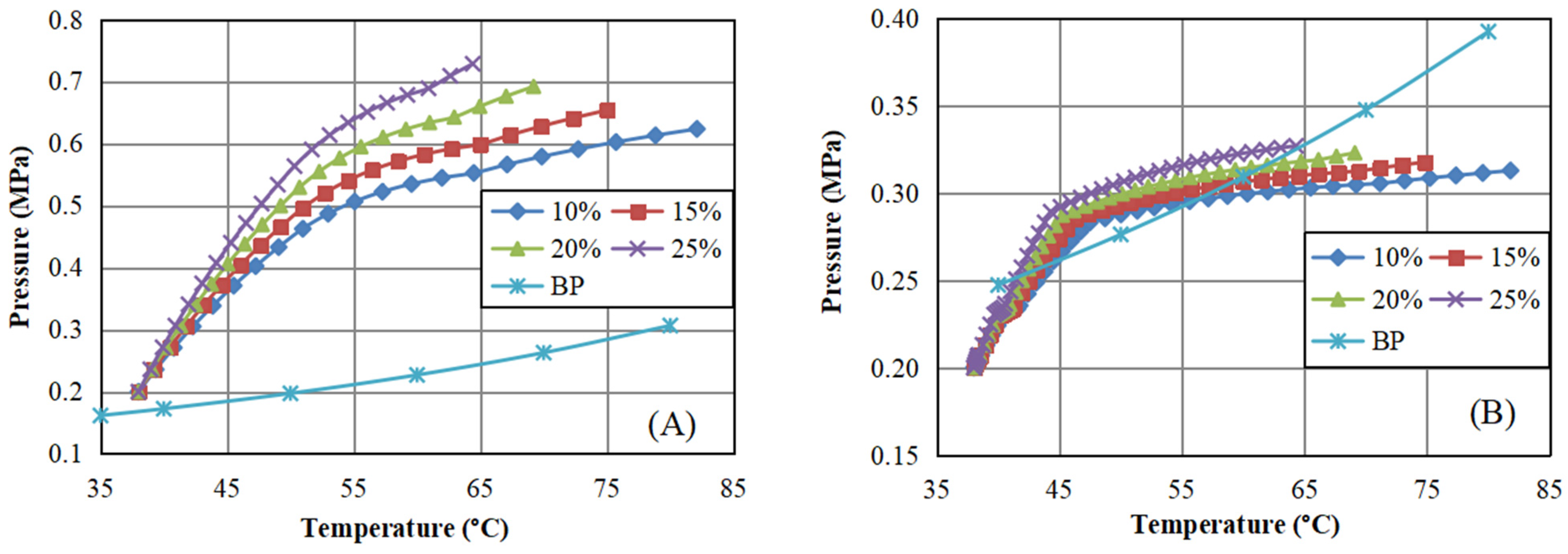

3.2.1. Bubble Point Line of Water-Containing Live Crude Oil

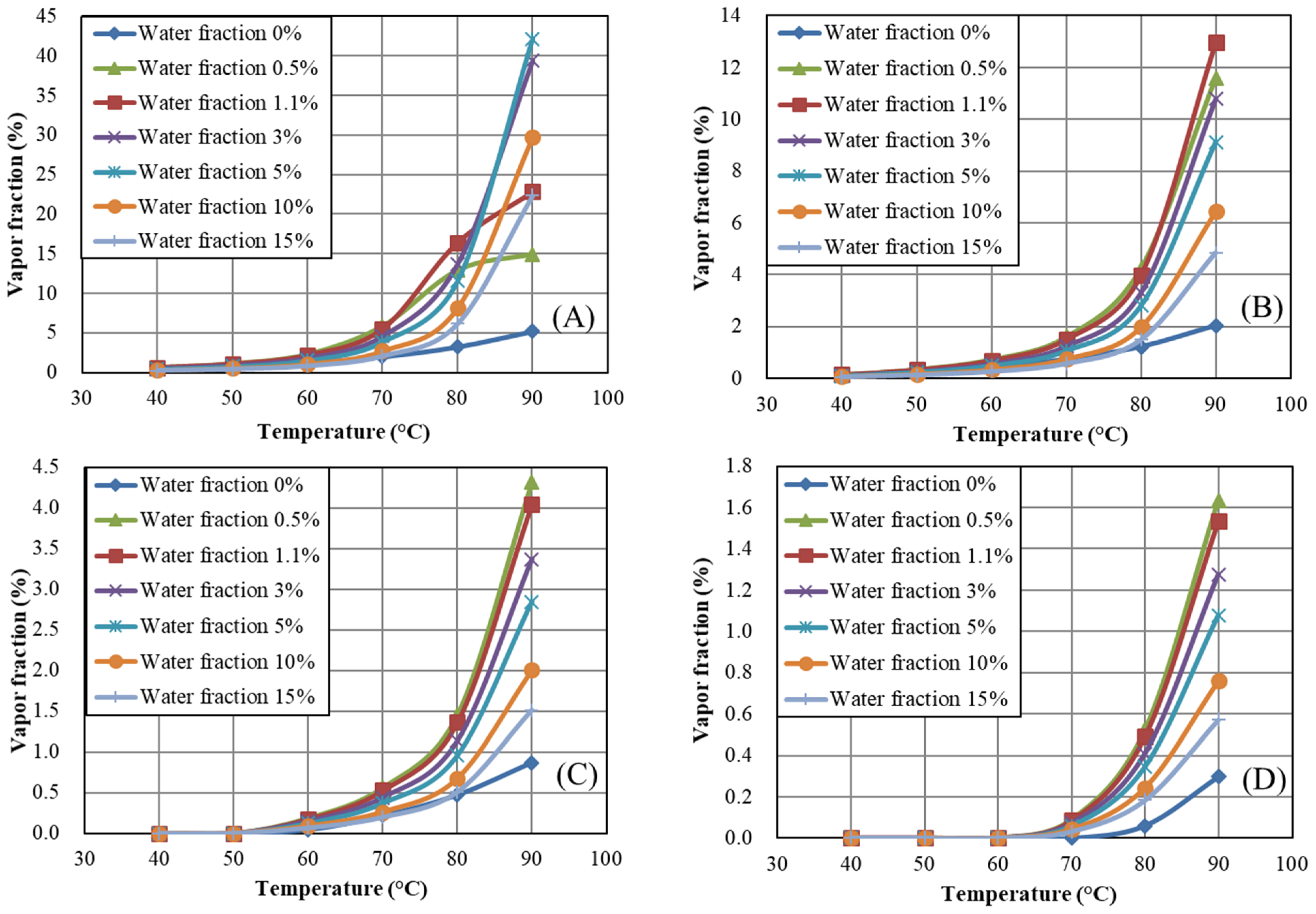

3.2.2. Influence of Water Fraction on the Vapor Fraction of Live Crude Oil

3.3. Analysis of the Pipeline Transportation Simulation Results

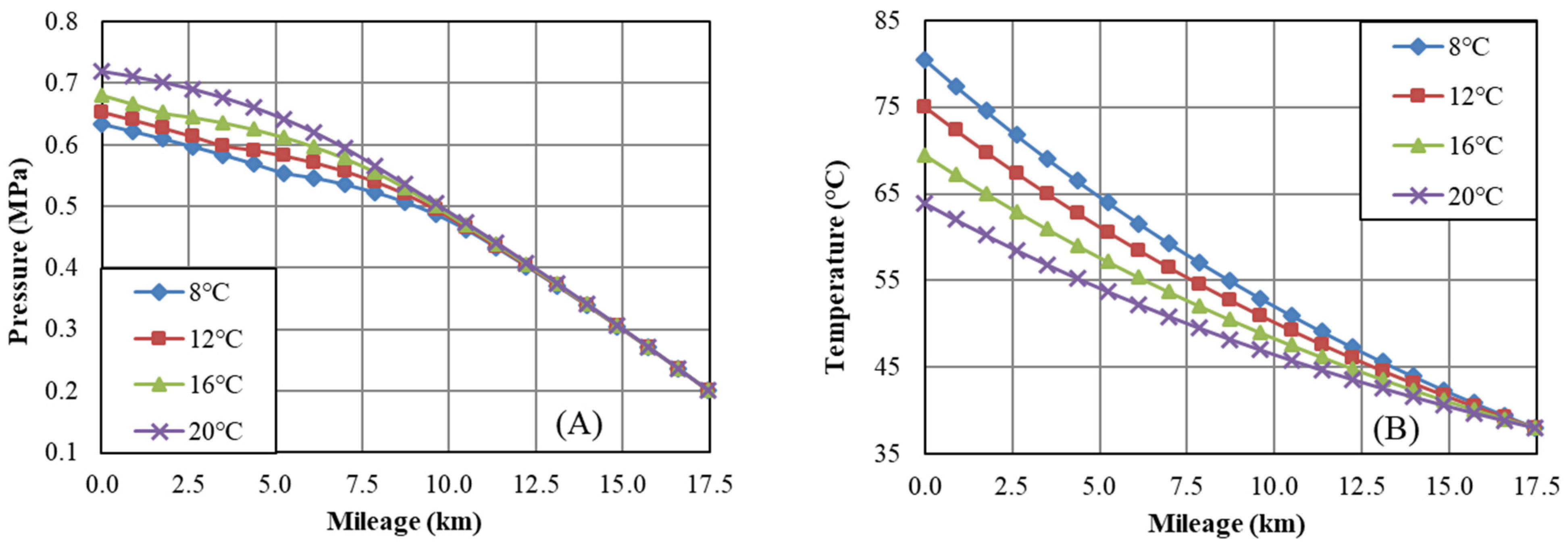

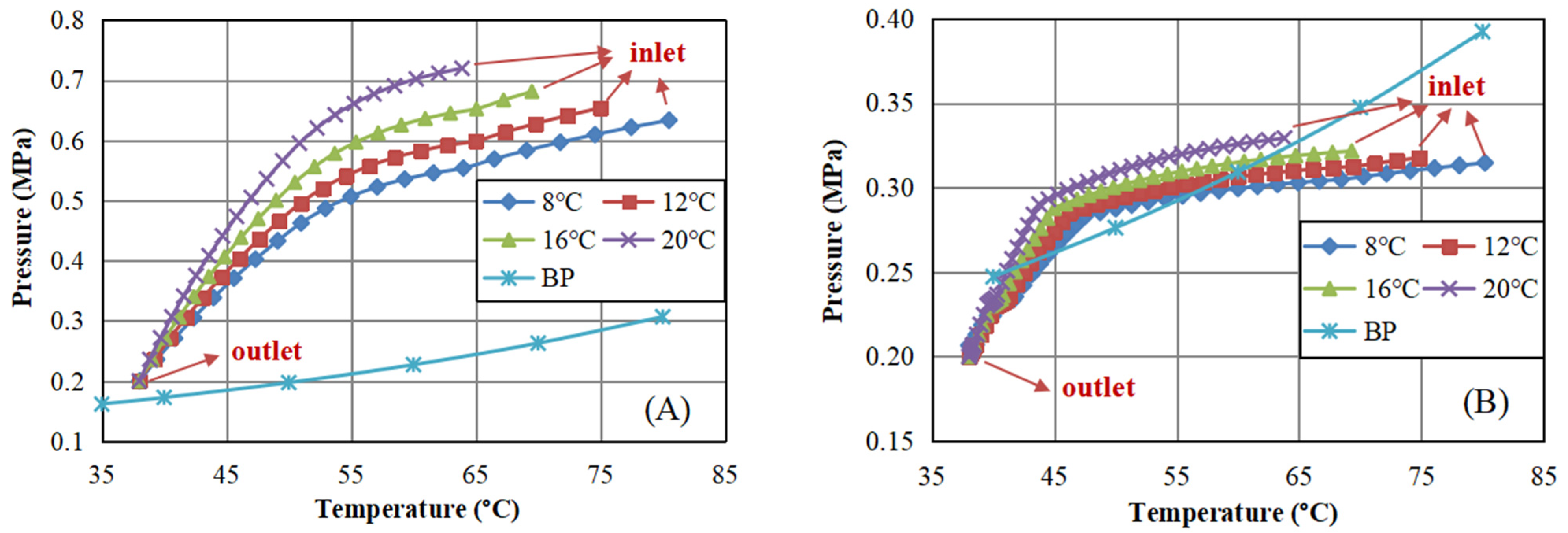

3.3.1. Impact of Soil Temperature on Fluid Flowing State

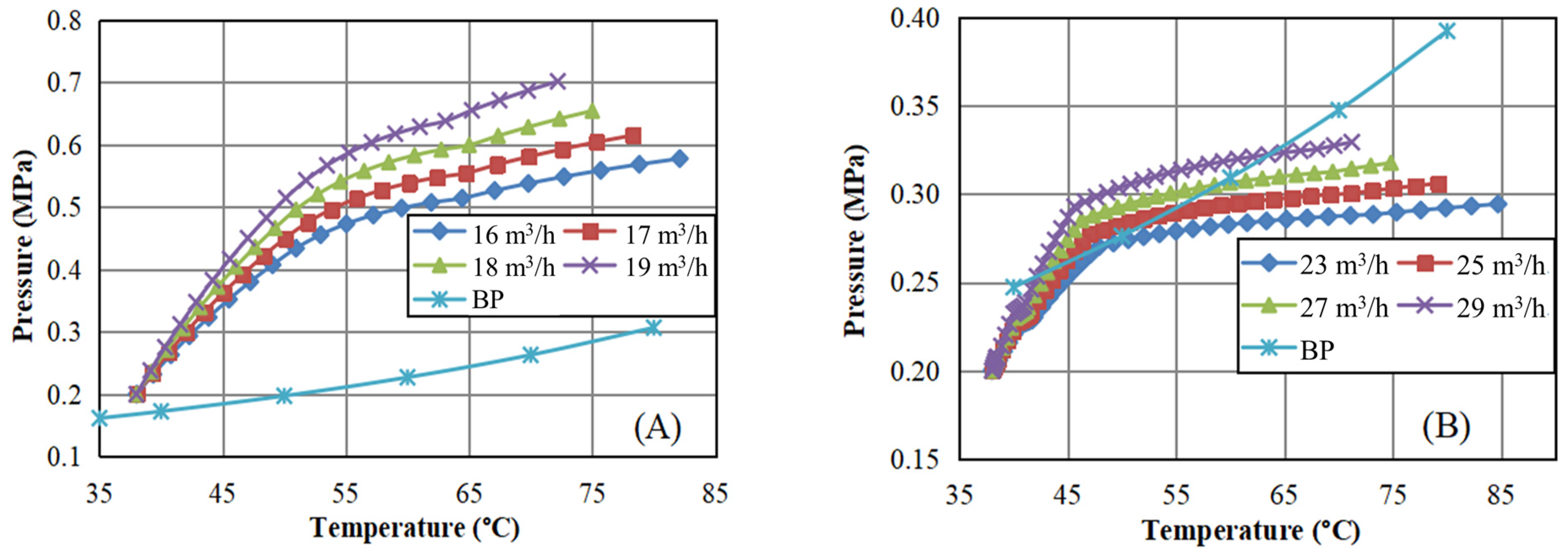

3.3.2. The Impact of Output on the Fluid Flowing State

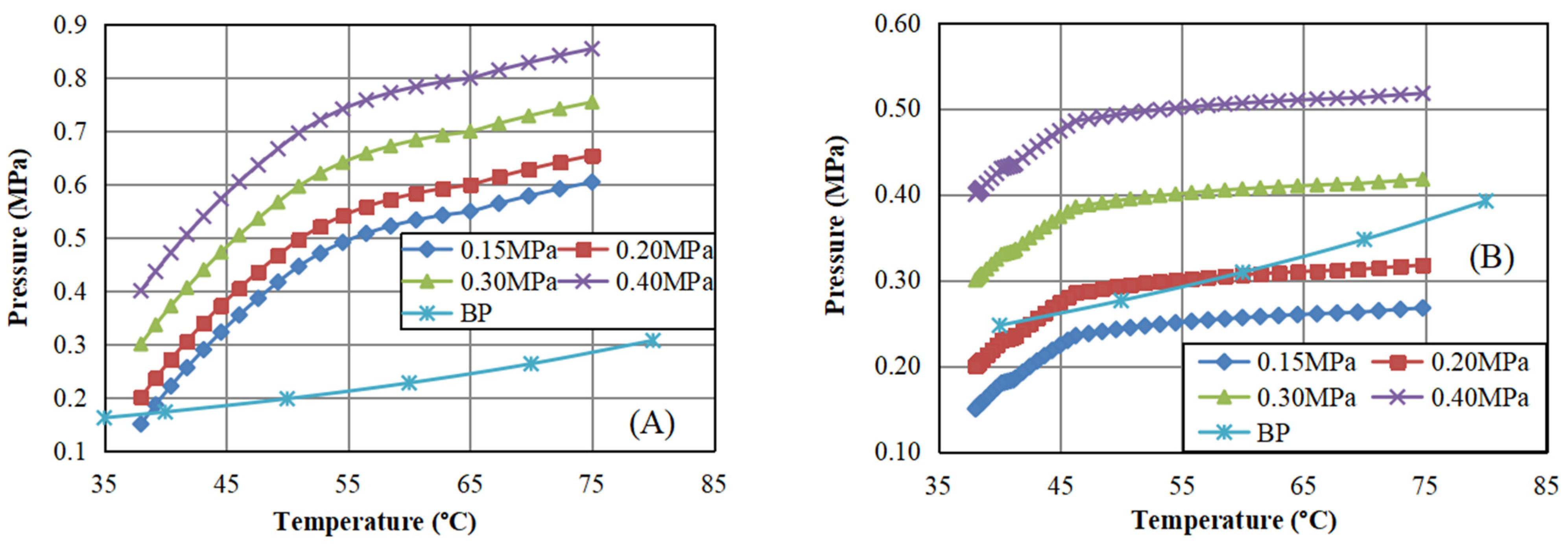

3.3.3. The Impact of Outlet Pressure on the Fluid Flowing State

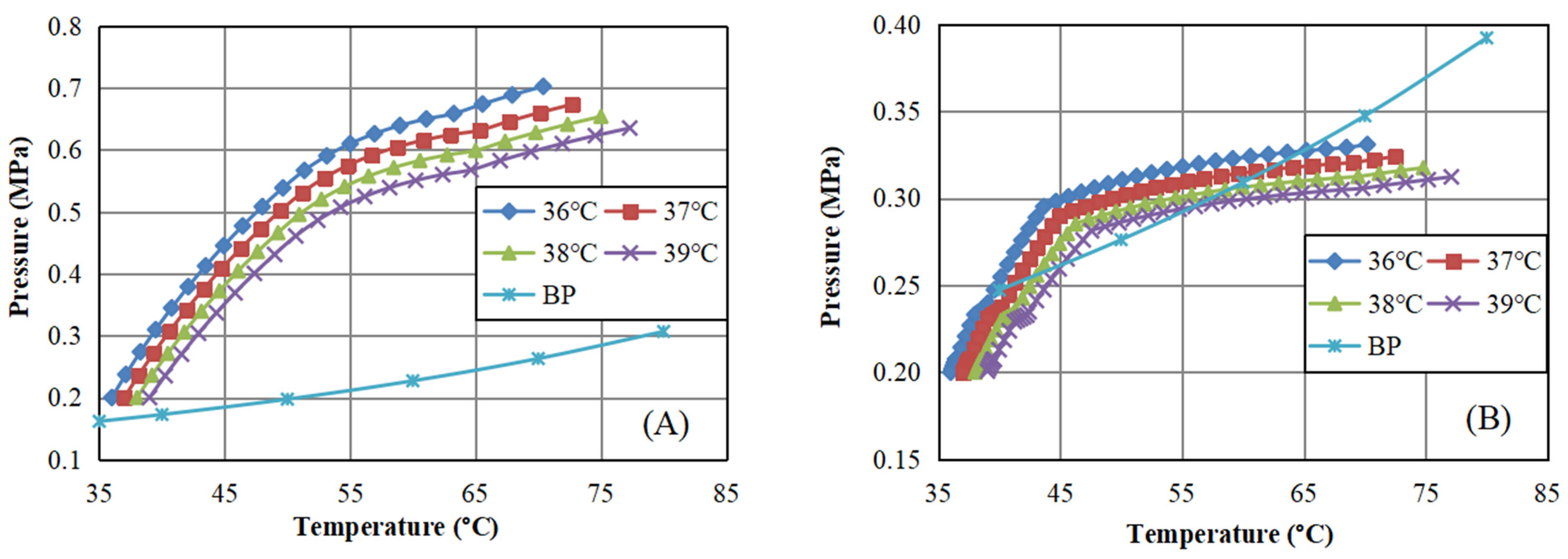

3.3.4. The Impact of Outlet Temperature on the Fluid Flowing State

3.3.5. The Impact of Water Fraction on the Fluid Flowing State

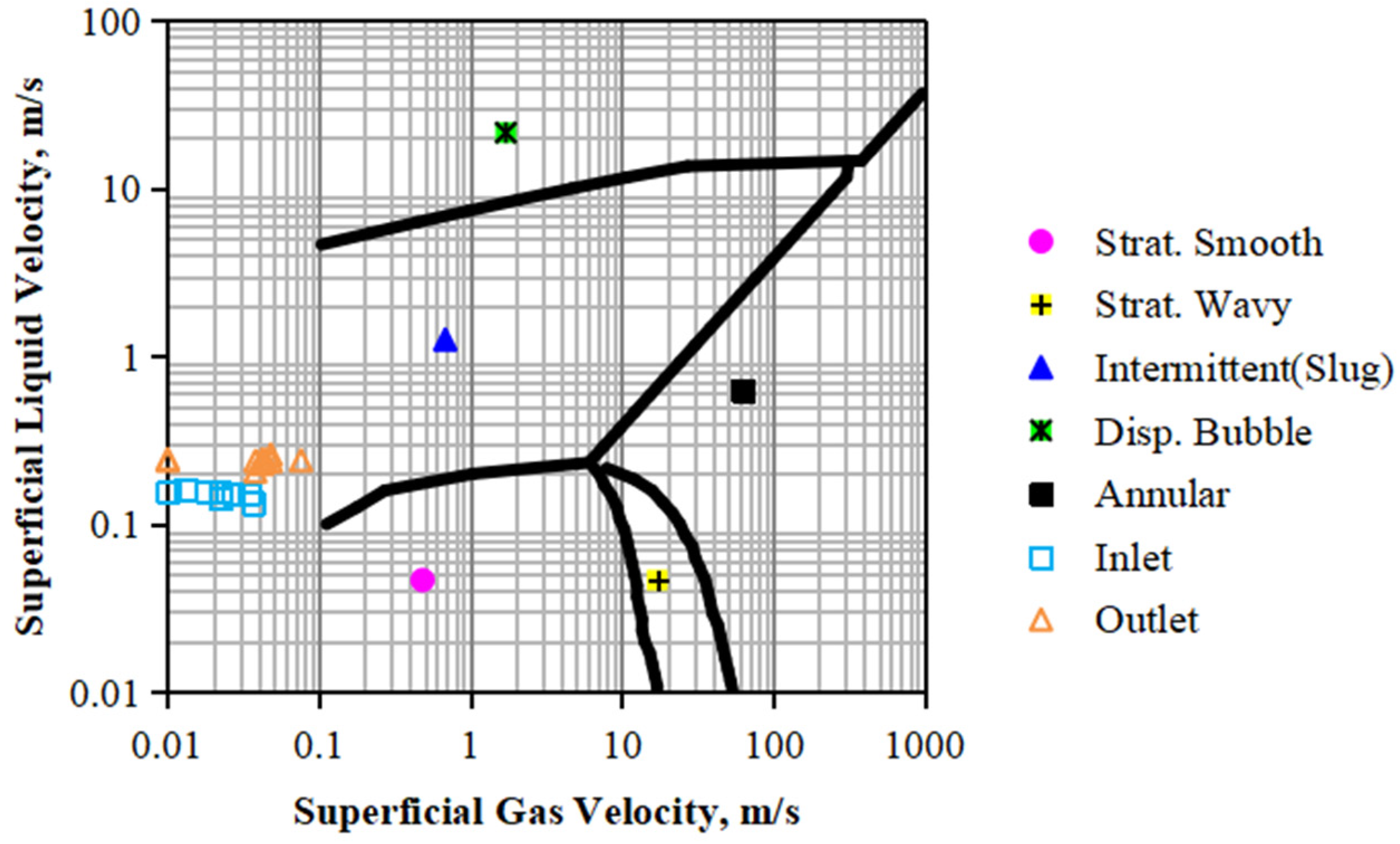

3.3.6. Characteristics and Flow Patterns of Gas–Liquid Mixed Flow in the Pipeline

3.4. Optimization of Station Process and Pipeline Operation

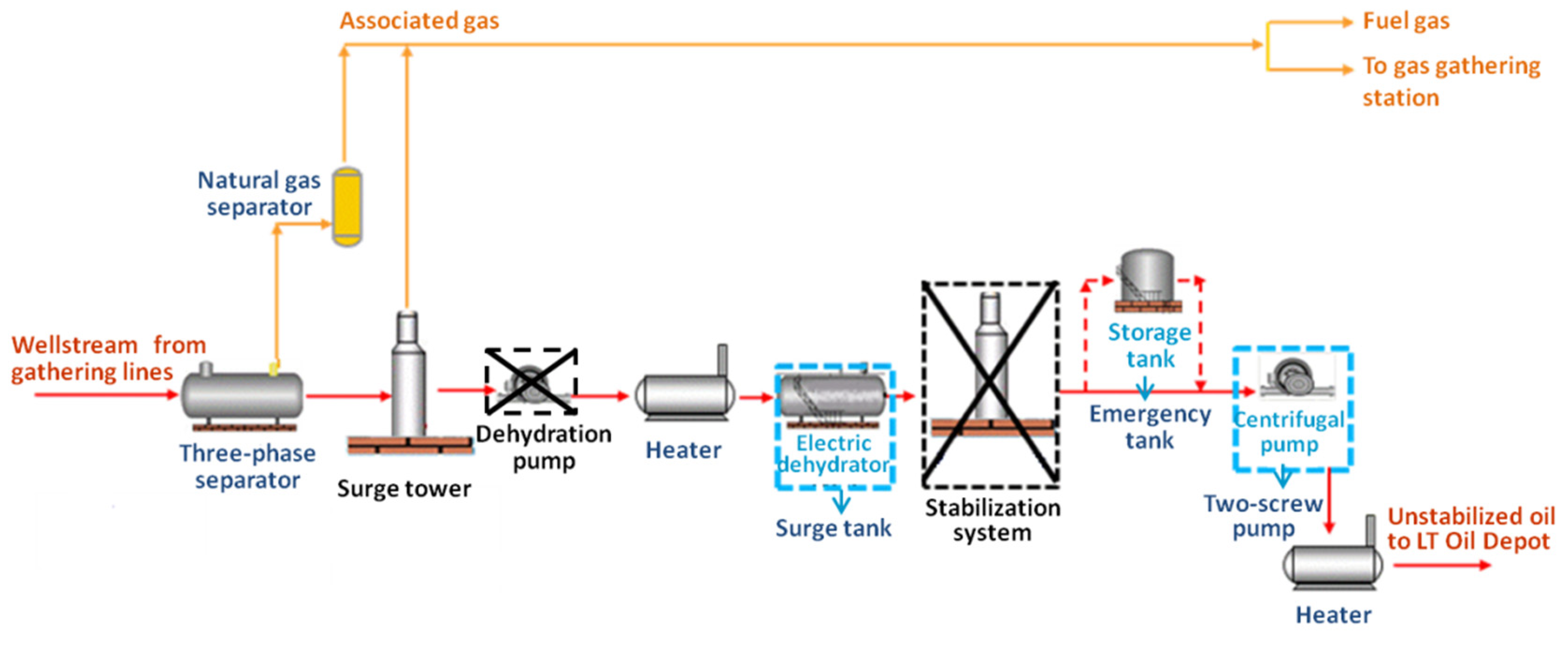

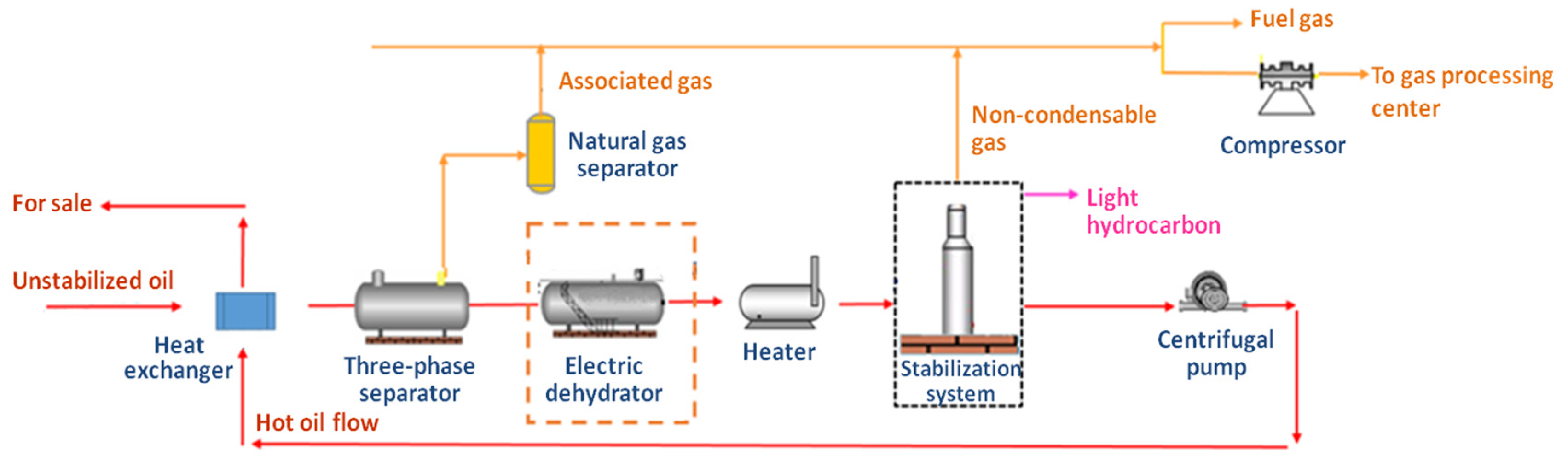

3.4.1. Optimization of the Process in the Central Gathering Station

- (1)

- Crude Oil Stabilization System:

- (2)

- Pipe Network Adjustment:

- (3)

- Dewatering System:

- (4)

- Tank Adjustments:

- (5)

- Pump Replacement:

- (6)

- Flow Measurement:

3.4.2. Optimization of Pipeline Operating Parameters

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Xu, X.X. Study on oil-water two-phase flow in horizontal pipelines. J. Pet. Sci. Eng. 2007, 59, 43–58. [Google Scholar] [CrossRef]

- Huang, X.; Li, S.; Zhu, N.; Chao, K.; Fan, K. Normal temperature gathering and transportation technology of high water-cut crude oil in Dongpuoil region of Zhongyuan oilfiled. Sci. Technol. Eng. 2021, 21, 6681–6689. [Google Scholar]

- Lu, M.; Zhu, J. Study of energy optimization technical program of Zhao II oil transfer station gathering and transportation system. Adv. Mater. Res. 2013, 765–767, 295–299. [Google Scholar] [CrossRef]

- Huang, Z.Q.; Li, X.Y.; Zheng, G.; Xue, J.Q.; Chen, Z. Energy saving measures of oil and gas gathering system in Changqing low permeable oilfield. Adv. Mater. Res. 2012, 512–515, 1137–1142. [Google Scholar] [CrossRef]

- Li, J.; Huang, C.; Ye, F.; Qin, M.; Zhang, W. Application of computer energy optimization method in oil and gas gathering and transportation system. J. Phys. Conf. Ser. 2021, 1744, 022045. [Google Scholar] [CrossRef]

- Yu, P.; Lei, Y.; Gao, Y.; Peng, H.; Zhao, H. Study on the operation safety and reliability of a waxy hot oil pipeline with low throughput using the probabilistic method. ACS Omega 2020, 5, 33340–33346. [Google Scholar] [CrossRef] [PubMed]

- Xiao, R.G.; Yi, D.R.; Yao, P.F.; Zhou, J.Q. Analysis of the operation mode and instability on the low-ffowrate running of hot-oil pipeline. Adv. Mater. Res. 2012, 614–615, 550–554. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Cao, H.; Wu, J.; Wang, F.; Wang, Y. The crack propagation behaviour of CO2 fracturing fluid in unconventional low permeability reservoirs: Factor analysis and mechanism revelation. Processes 2025, 13, 159. [Google Scholar] [CrossRef]

- Li, Q.; Li, Q.; Wu, J.; Li, X.; Li, H.; Cheng, Y. Wellhead stability during development process of hydrate reservoir in the Northern South China Sea: Evolution and mechanism. Processes 2025, 13, 40. [Google Scholar] [CrossRef]

- Li, S.; Huang, Q.; He, M.; Wang, W. Effect of water fraction on rheological properties of waxy crude oil emulsions. J. Dispers. Sci. Technol. 2014, 35, 1114–1125. [Google Scholar] [CrossRef]

- Pal, R. Entropy production in pipeline flow of dispersions of water in oil. Entropy 2014, 16, 4648–4661. [Google Scholar] [CrossRef]

- Sotgia, G.; Tartarini, P.; Stalio, E. Experimental analysis of flow regimes and pressure drop reduction in oil-water mixtures. Int. J. Multiph. Flow 2008, 34, 1161–1174. [Google Scholar] [CrossRef]

- Wang, W.; Gong, J.; Angeli, P. Investigation on heavy crude-water two phase flow and related flow characteristics. Int. J. Multiph. Flow 2011, 37, 1156–1164. [Google Scholar] [CrossRef]

- Li, S.; Fan, K.F.; Huang, Q.Y. Evaluation of stability for flowing water-in-oil emulsion in transportation pipeline. J. Pet. Sci. Eng. 2022, 216, 110769. [Google Scholar] [CrossRef]

- Nichita, D.V.; Broseta, D.; Elhorga, P.; Montel, F. Pseudo-component delumping for multiphase equilibrium in hydrocarbon-water mixtures. Pet. Sci. Technol. 2008, 26, 2058–2077. [Google Scholar] [CrossRef]

- Masoodiyeh, F.; Mozdianfard, M.R.; Karimi-Sabet, J. Thermodynamic modeling of PVTx properties for several water/hydrocarbon systems in near-critical and supercritical conditions. Korean J. Chem. Eng. 2013, 30, 201–212. [Google Scholar] [CrossRef]

- Yong, W.P.; Awang, M. Vapour–liquid equilibria for hydrocarbon/water systems using thermodynamic perturbation theory. In Proceedings of the International Conference on Intergrated Petroleum Engineering and Geosciences, Kuala Lumpur, Malaysia, 19–22 May 2014. [Google Scholar]

- Di, Y.; Zhang, Y.; Wu, Y. Phase equilibrium calculation of CO2-hydrocarbons-water system based on Gibbs free energy minimization. Acta Pet. Sin. 2015, 36, 593–599. [Google Scholar]

- Delahaye, A.; Fournaison, L.; Marinhas, S.; Martínez, M.C. Rheological study of hydrate slurry in a dynamic loop applied to secondary refrigeration. Chem. Eng. Sci. 2008, 63, 3551–3559. [Google Scholar] [CrossRef]

- Gong, J.; Shi, B.H.; Wang, W.; Zhao, J.K. Numerical study the flow characteristics of gas-hydrate slurry two phase stratified flow. In Proceedings of the International Conference on Multiphase Flow, Tampa, FL, USA, 30 May–4 June 2010. [Google Scholar]

- Gong, J.; Shi, B.H.; Zhao, J.K. Natural gas hydrate shell model in gas-slurry pipeline flow. J. Nat. Gas Chem. 2010, 19, 261–263. [Google Scholar] [CrossRef]

- Shi, B.H.; Gong, J.; Sun, C.Y.; Zhao, J.K.; Ding, Y.; Chen, G.J. An inward and outward natural gas hydrates growth shell model considering intrinsic kinetics, mass and heat transfer. Chem. Eng. J. 2011, 171, 1308–1316. [Google Scholar] [CrossRef]

- Tang, Y.; Saha, S. An efficient method to calculate three-phase free-water flash for water−hydrocarbon systems. Ind. Eng. Chem. Res. 2002, 42, 189–197. [Google Scholar] [CrossRef]

- Mokhatab, S. Three-phase flash calculation for hydrocarbon systems containing water. Theor. Found. Chem. Eng. 2003, 37, 291–294. [Google Scholar] [CrossRef]

- Hinojosa-Gómez, H.; Solares-Ramírez, J.; Bazúa-Rueda, E.R. An improved algorithm for the three-fluid-phase VLLE flash calculation. AIChE J. 2015, 61, 3081–3093. [Google Scholar] [CrossRef]

- Pires, A.P.; Mohamed, R.S.; Mansoori, G.A. An equation of state for property prediction of alcohol-hydrocarbon and water-hydrocarbon systems. J. Pet. Sci. Eng. 2001, 32, 103–114. [Google Scholar] [CrossRef]

- Lapene, A.; Nichita, D.V.; Debenest, G.; Quintard, M. Three-phase free-water flash calculations using a new Modified Rachford–Rice equation. Fluid Phase Equilibria 2010, 297, 121–128. [Google Scholar] [CrossRef]

- Ahmadi, M.A.; Zendehboudi, S.; James, L.A.; Elkamel, A.; Dusseault, M.; Chatzis, I.; Lohi, A. New tools to determine bubble point pressure of crude oils: Experimental and modeling study. J. Pet. Sci. Eng. 2014, 123, 207–216. [Google Scholar] [CrossRef]

- Medeiros, M. Mutual solubilities of water and hydrocarbons from the cubic plus association equation of state: A new mixing rule for the correlation of observed minimum hydrocarbon solubilities. Fluid Phase Equilibria 2014, 368, 5–13. [Google Scholar] [CrossRef]

- Mortezazadeh, E.; Rasaei, M.R. A robust procedure for three-phase equilibrium calculations of water-hydrocarbon systems using cubic equations of state. Fluid Phase Equilibria 2017, 450, 160–174. [Google Scholar] [CrossRef]

- Taitel, Y.; Barnea, D.; Brill, J.P. Stratified three phase flow in pipes. Int. J. Multiph. Flow 1995, 21, 53–60. [Google Scholar] [CrossRef]

- Hewitt, G.F. Three-phase gas–liquid–liquid flows in the steady and transient states. Nucl. Eng. Des. 2005, 235, 1303–1316. [Google Scholar] [CrossRef]

- Ghorai, S.; Suri, V.; Nigam, K.D.P. Numerical modeling of three-phase stratified flow in pipes. Chem. Eng. Sci. 2005, 60, 6637–6648. [Google Scholar] [CrossRef]

- Ujang, P.M.; Lawrence, C.J.; Hale, C.P.; Hewitt, G.F. Slug initiation and evolution in two-phase horizontal flow. Int. J. Multiph. Flow 2006, 32, 527–552. [Google Scholar] [CrossRef]

- Wahaibi, T.A.; Angeli, P. Transition between stratified and non-stratified horizontal oil–water flows. Part I: Stability analysis. Chem. Eng. Sci. 2007, 62, 2915–2928. [Google Scholar] [CrossRef]

- Wahaibi, T.A.; Smith, M.; Angeli, P. Transition between stratified and non-stratified horizontal oil–water flows. Part II: Mechanism of drop formation. Chem. Eng. Sci. 2007, 62, 2929–2940. [Google Scholar] [CrossRef]

- Nan, Y.T.; Yuan, Y.H.; Ming, D.D.; Bo, Z.J. Energy equation derivation of the multiphase flow pipeline. J. Petrochem. Univ. 2011, 24, 73–76. [Google Scholar]

- Odozi, U.A. Three-Phase Gas-Liquid-Liquid Slug Flow. Ph.D. Thesis, Imperial College London, London, UK, 2000. [Google Scholar]

- Wong, W.L. Flow Development and Mixing in Three-Phase Slug Flow. Ph.D. Thesis, University of London, London, UK, 2003. [Google Scholar]

- Xu, J.Y. A simple correlation for prediction of the liquid slug holdup in gas/non-Newtonian fluids: Horizontal to upward inclined flow. Exp. Therm. Fluid Sci. 2013, 44, 893–896. [Google Scholar] [CrossRef]

- Abdul-Majeed, G.H.; Al-Mashat, A.M. A unified correlation for predicting slug liquid holdup in viscous two-phase flow for pipe inclination from horizontal to vertical. SN Appl. Sci. 2019, 1, 71. [Google Scholar] [CrossRef]

- Michelsen, M.L. The isothermal flash problem. Part I. stability. Fluid Phase Equilibria 1982, 9, 1–19. [Google Scholar] [CrossRef]

- Guo, T.M. Multicomponent Gas-Liquid Equilibrium and Distillation; Petroleum Industry Press: Beijing, China, 2002; Volume 11, pp. 161–166. [Google Scholar]

- Peng, D.Y.; Robinson, D.B. A new two constant equation of state. Ind. Eng. Chem. Fundam. 1976, 15, 59–64. [Google Scholar] [CrossRef]

- Soave, G. Equilibrium constants from a modified Redlich-Kwong equation of state. Chem. Eng. Sci. 1972, 27, 1197–1203. [Google Scholar] [CrossRef]

- SY/T 0420-97; Technology standard of petroluem asphalt coating for buried steel pipeline. Petroleum Industry Press: Beijing, China, 1997.

- SY/T 5536-2016; Specification for operation of crude oil pipeline. Petroleum Industry Press: Beijing, China, 2016.

- AГалкин, B.M. Thermal and Hydraulic Calculations of Crude Oil and Product Oil Pipelines; Petroleum Industry Press: Beijing, China, 1986. [Google Scholar]

- Beggs, D.H.; Brill, J.P. A study of two-phase flow in inclined pipes. J. Pet. Technol. 1973, 25, 607–617. [Google Scholar] [CrossRef]

- Moody, L.F. Friction factors for pipe flow. Trans. ASME 1944, 66, 671–678. [Google Scholar] [CrossRef]

- Eaton, B.F.; Knowles, C.A.; Silberberg, I.H. The prediction of flow patterns, liquid holdup and pressure losses occurring during continuous two-phase flow in horizontal pipelines. J. Pet. Technol. 1967, 19, 815–828. [Google Scholar] [CrossRef]

- Li, S.; Huang, Q.; Fan, K.; Zhao, D.; Lv, Z. Transportation technology with pour point depressant and wax deposition in a crude oil pipeline. Pet. Sci. Technol. 2016, 34, 1240–1247. [Google Scholar] [CrossRef]

| Component | 1# | 2# | ||

|---|---|---|---|---|

| Live | Dead | Live | Dead | |

| C1 | 0.0306 | 0.0016 | 0.0327 | 0.0027 |

| C2 | 0.0760 | 0.0140 | 0.1048 | 0.0268 |

| C3 | 0.1236 | 0.0488 | 0.1820 | 0.0890 |

| i-C4 | 0.2033 | 0.1198 | 0.2030 | 0.1374 |

| n-C4 | 0.2692 | 0.1766 | 0.2192 | 0.1603 |

| i-C5 | 1.2269 | 0.9945 | 0.2363 | 0.2028 |

| n-C5 | 1.4068 | 1.1882 | 0.2390 | 0.2110 |

| C6 | 0.5647 | 0.2612 | 0.6845 | 0.6295 |

| C7 | 0.5011 | 0.2388 | 0.6476 | 0.4706 |

| Total | 4.4022 | 3.0435 | 2.5491 | 1.9301 |

| Sample | Pour Point (°C) | Density at 20 °C (kg/m3) | WAT (°C) | Wax (mass%) | Asphaltenes (mass%) | Resins (mass%) |

|---|---|---|---|---|---|---|

| 1# | 33 | 862.1 | 50.7 | 22.43 | 2.2 | 10.5 |

| 2# | 33 | 880.2 | 51.8 | 25.32 | 2.4 | 14.1 |

| Sample | Temperature (°C) | Consistency Coefficient K (mPa·sn) | Flow Behavior Index n | Viscosity (mPa·s) | ||

|---|---|---|---|---|---|---|

| 10 s−1 | 20 s−1 | 50 s−1 | ||||

| 1# | 36 | 537.12 | 0.6003 | 213.98 | 162.20 | 112.46 |

| 38 | 155.40 | 0.7798 | 93.59 | 80.34 | 65.66 | |

| 41 | 50.36 | 0.9866 | 48.83 | 48.38 | 47.79 | |

| 45 | 42.03 | 1 | 42.03 | |||

| 50 | 34.90 | 1 | 34.90 | |||

| 60 | 22.05 | 1 | 22.05 | |||

| 70 | 10.20 | 1 | 10.20 | |||

| 80 | 8.53 | 1 | 8.53 | |||

| 2# | 36 | 729.06 | 0.5701 | 270.93 | 201.12 | 135.64 |

| 38 | 282.50 | 0.6595 | 128.98 | 101.86 | 74.56 | |

| 40 | 106.07 | 0.8212 | 70.27 | 62.08 | 52.70 | |

| 42 | 49.88 | 0.9807 | 47.71 | 47.08 | 46.25 | |

| 50 | 40.61 | 1 | 40.61 | |||

| 60 | 25.90 | 1 | 25.90 | |||

| 70 | 11.38 | 1 | 11.38 | |||

| 80 | 8.86 | 1 | 8.86 | |||

| NO. | 1# | 2# | ||||

|---|---|---|---|---|---|---|

| Average Boiling Point (°C) | Volume Fraction (%) | Relative Density at 15.6 °C | Average Boiling Point (°C) | Volume Fraction (%) | Relative Density at 15.6 °C | |

| 1 | 46.4 | 2.48 | 0.7130 | 65.3 | 1.55 | 0.7268 |

| 2 | 72.6 | 2.56 | 0.7320 | 97.0 | 1.89 | 0.7488 |

| 3 | 101.2 | 2.89 | 0.7516 | 116.6 | 1.71 | 0.7618 |

| 4 | 122.6 | 2.83 | 0.7657 | 137.7 | 1.69 | 0.7753 |

| 5 | 138.1 | 2.73 | 0.7755 | 163.3 | 2.46 | 0.7911 |

| 6 | 151.2 | 2.86 | 0.7837 | 193.5 | 2.59 | 0.8089 |

| 7 | 160.7 | 3.69 | 0.7895 | 219.1 | 2.59 | 0.8234 |

| 8 | 172.6 | 4.85 | 0.7967 | 238.7 | 2.32 | 0.8342 |

| 9 | 192.9 | 5.11 | 0.8085 | 256.8 | 2.46 | 0.8439 |

| 10 | 217.9 | 4.86 | 0.8227 | 277.9 | 2.73 | 0.8550 |

| 11 | 242.9 | 5.11 | 0.8365 | 297.5 | 4.91 | 0.8650 |

| 12 | 266.7 | 4.98 | 0.8491 | 315.6 | 5.18 | 0.8741 |

| 13 | 290.5 | 5.11 | 0.8615 | 333.7 | 4.91 | 0.8829 |

| 14 | 314.3 | 4.98 | 0.8734 | 353.3 | 4.91 | 0.8923 |

| 15 | 339.3 | 4.98 | 0.8856 | 375.9 | 4.91 | 0.9029 |

| 16 | 366.7 | 4.98 | 0.8986 | 403.0 | 5.18 | 0.9153 |

| 17 | 394.0 | 5.11 | 0.9113 | 431.7 | 4.91 | 0.9281 |

| 18 | 421.4 | 4.85 | 0.9236 | 461.8 | 5.18 | 0.9411 |

| 19 | 450.0 | 5.11 | 0.9361 | 505.5 | 4.77 | 0.9594 |

| 20 | 484.5 | 4.85 | 0.9507 | 553.8 | 5.18 | 0.9789 |

| 21 | 528.6 | 5.25 | 0.9688 | 599.0 | 4.91 | 0.9964 |

| 22 | 582.1 | 2.42 | 0.9899 | 659.3 | 5.05 | 1.0188 |

| 23 | 635.7 | 2.42 | 1.0102 | 718.1 | 4.91 | 1.0398 |

| 24 | 675.0 | 1.48 | 1.0245 | 767.8 | 5.18 | 1.0569 |

| 25 | 708.3 | 1.62 | 1.0364 | 819.1 | 2.46 | 1.0740 |

| 26 | 736.9 | 0.81 | 1.0464 | 880.9 | 2.46 | 1.0939 |

| 27 | 753.6 | 1.08 | 1.0521 | 2.48 | 1.50 | 1.1131 |

| 28 | - | - | - | 2.56 | 1.50 | 1.1245 |

| Pipeline | 1# | 2# |

|---|---|---|

| Size (mm) | Φ159 × 6/7/8 | Φ219 × 7/Φ273 × 7 |

| Total distance (km) | 17.46 | 23.09 |

| Overall coefficient of heat transfer (W/(m2·°C)) | 1.35 | 0.90 |

| Designed capacity (×105 t/a) | 4.50 | 9.00 |

| Actual output (×105 t/a) | 1.37 | 2.45 |

| Minimum allowable output (×105 t/a) | 1.93 | 2.59 |

| Elevation (m) | 0 | |

| Buried depth (m) | 1.5 | |

| Roughness (mm) | 0.20 | |

| Minimum/maximum soil temperature (°C) | 8/20 | |

| Maximum allowable pressure (MPa) | 1.20 | |

| Maximum allowable temperature (°C) | 80 | |

| Minimum outlet temperature (°C) | 36 | |

| Soil Temperature (°C) | Oil Output (m3/h) | Outlet Pressure (MPa) | Outlet Temperature (°C) | Water Fraction (vol%) | |

|---|---|---|---|---|---|

| 1# | 2# | ||||

| 8, 12, 16, 20 | 18 | 27 | 0.20 | 38 | 15 |

| 12 | 16, 17, 18, 19 | 23, 25, 27, 29 | 0.20 | 38 | 15 |

| 12 | 18 | 27 | 0.15, 0.20, 0.30, 0.40 | 38 | 15 |

| 12 | 18 | 27 | 0.20 | 36, 37, 38, 39 | 15 |

| 12 | 18 | 27 | 0.20 | 38 | 10, 15, 20, 25 |

| Transporting Conditions | Pipeline Inlet | Pipeline Outlet | |||||

|---|---|---|---|---|---|---|---|

| Gas Flow Rate (m3/h) | Slip Liquid Holdup (%) | Lm (m) | Gas Flow Rate (m3/h) | Slip Liquid Holdup (%) | Lm (m) | ||

| Soil temperature (°C) | 8 | 4.65 | 93.6 | 7183.4 | 5.75 | 90.2 | 10,775.6 |

| 12 | 3.74 | 95.2 | 5131.0 | 5.75 | 90.2 | 10,262.5 | |

| 16 | 2.64 | 97.3 | 2565.5 | 5.75 | 90.2 | 9749.4 | |

| 20 | 0 | 100 | 0 | 5.75 | 90.2 | 9236.3 | |

| Oil output (m3/h) | 23 | 8.02 | 90.2 | 14,366.8 | 5.36 | 90.2 | 11,288.7 |

| 25 | 4.21 | 93.8 | 7183.4 | 5.55 | 90.2 | 10,775.6 | |

| 27 | 3.74 | 95.2 | 5131.0 | 5.75 | 90.2 | 10,262.5 | |

| 29 | 0 | 98.3 | 2052.4 | 5.94 | 90.2 | 9749.4 | |

| Outlet pressure (MPa) | 0.15 | 7.02 | 91.0 | 23,093.0 | 9.37 | 88.4 | 23,093.0 |

| 0.20 | 3.74 | 95.2 | 5131.0 | 5.75 | 90.2 | 10,262.5 | |

| 0.30 | 0 | 100 | 0 | 0 | 100 | 0 | |

| 0.40 | 0 | 100 | 0 | 0 | 100 | 0 | |

| Outlet temperature (°C) | 36 | 0 | 99.1 | 1539.3 | 5.28 | 92.9 | 8723.2 |

| 37 | 1.78 | 97.5 | 3078.6 | 5.46 | 91.7 | 9749.4 | |

| 38 | 3.74 | 95.2 | 5131.0 | 5.75 | 90.2 | 10,262.5 | |

| 39 | 4.37 | 93.6 | 6670.3 | 5.84 | 89.8 | 11,288.7 | |

| Water fraction (vol%) | 10 | 5.19 | 93.1 | 6670.3 | 6.08 | 90.0 | 11,288.7 |

| 15 | 3.74 | 95.2 | 5131.0 | 5.75 | 90.2 | 10,262.5 | |

| 20 | 2.45 | 97.8 | 2565.5 | 5.51 | 90.6 | 9749.4 | |

| 25 | 0 | 100 | 0 | 5.36 | 90.8 | 9236.3 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, S.; Yang, H.; Liu, R.; Zhou, S.; Fan, K. Phase Behavior and Flowing State of Water-Containing Live Crude Oil in Transportation Pipelines. Energies 2025, 18, 1116. https://doi.org/10.3390/en18051116

Li S, Yang H, Liu R, Zhou S, Fan K. Phase Behavior and Flowing State of Water-Containing Live Crude Oil in Transportation Pipelines. Energies. 2025; 18(5):1116. https://doi.org/10.3390/en18051116

Chicago/Turabian StyleLi, Si, Haiyan Yang, Run Liu, Shidong Zhou, and Kaifeng Fan. 2025. "Phase Behavior and Flowing State of Water-Containing Live Crude Oil in Transportation Pipelines" Energies 18, no. 5: 1116. https://doi.org/10.3390/en18051116

APA StyleLi, S., Yang, H., Liu, R., Zhou, S., & Fan, K. (2025). Phase Behavior and Flowing State of Water-Containing Live Crude Oil in Transportation Pipelines. Energies, 18(5), 1116. https://doi.org/10.3390/en18051116