Research on the Operation Flexibility of a Combined Heat and Power Generation Unit with Low-Temperature Return Water

Abstract

1. Introduction

2. The Calculation Model

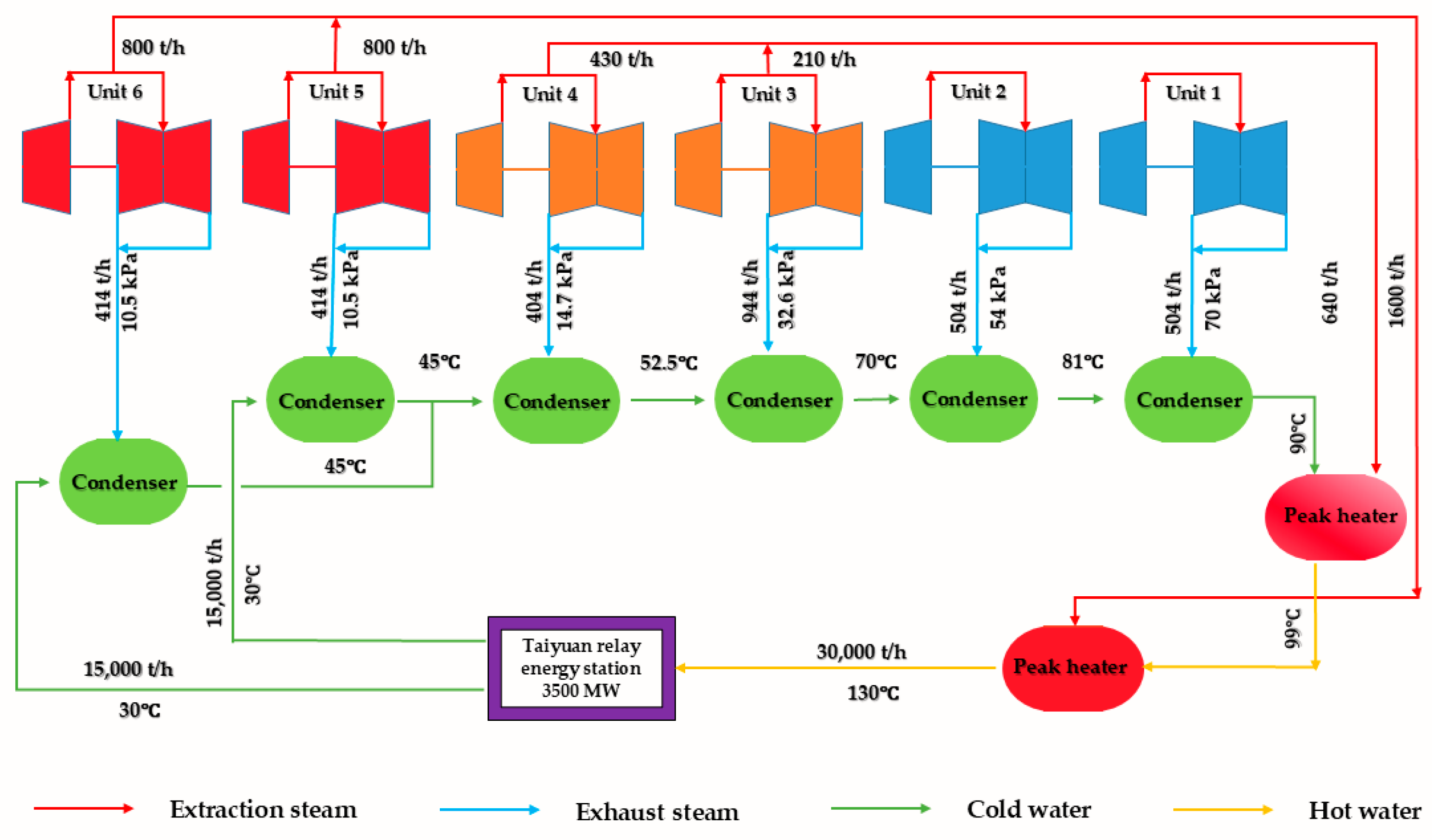

2.1. Composition of the Heating System

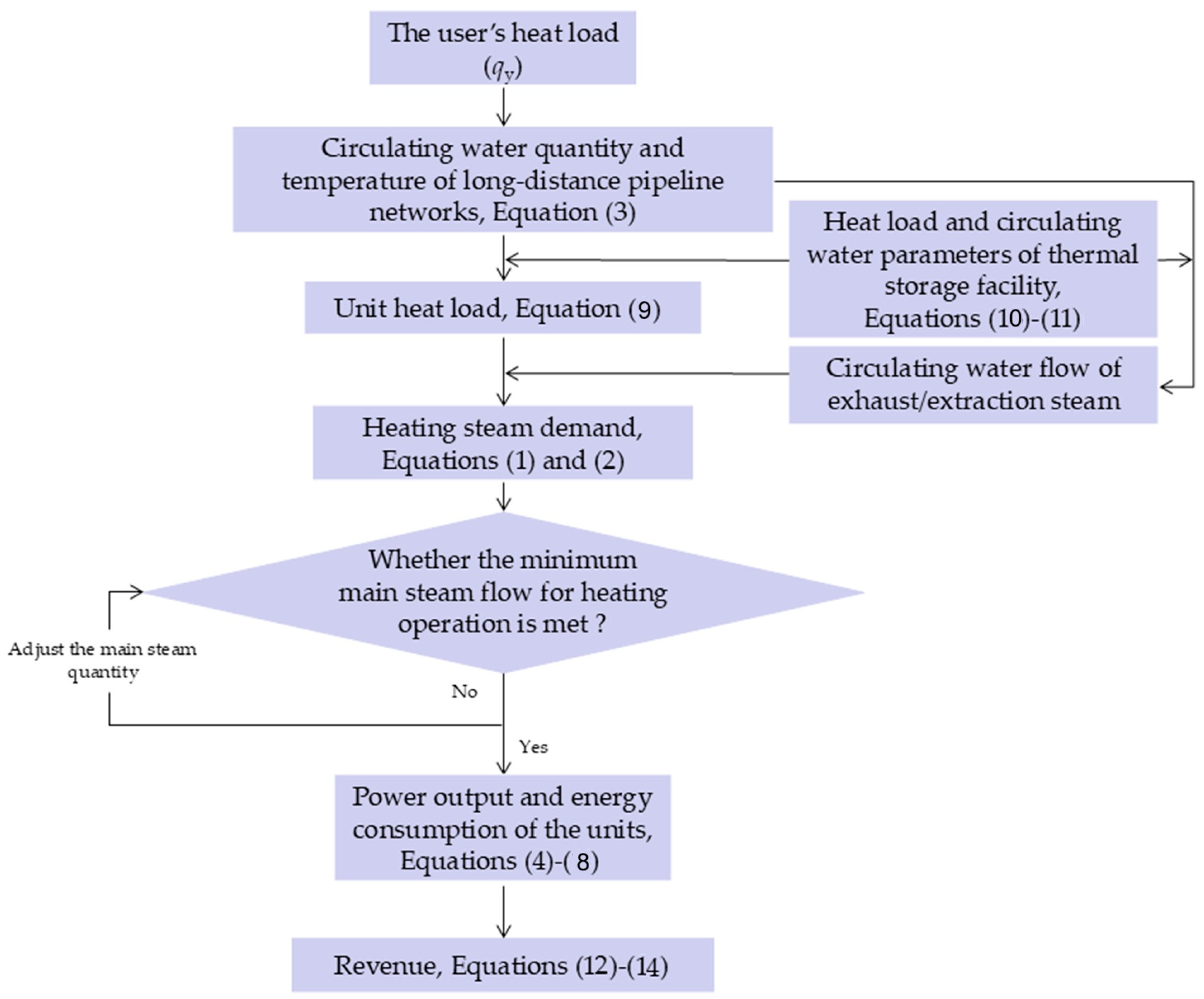

2.2. Heating Model

2.2.1. Governing Equations

- (1)

- Heating equation

- (2)

- Power generation equation

- (3)

- Thermal storage equation

- (4)

- Profit calculation equation

2.2.2. Computational Flow

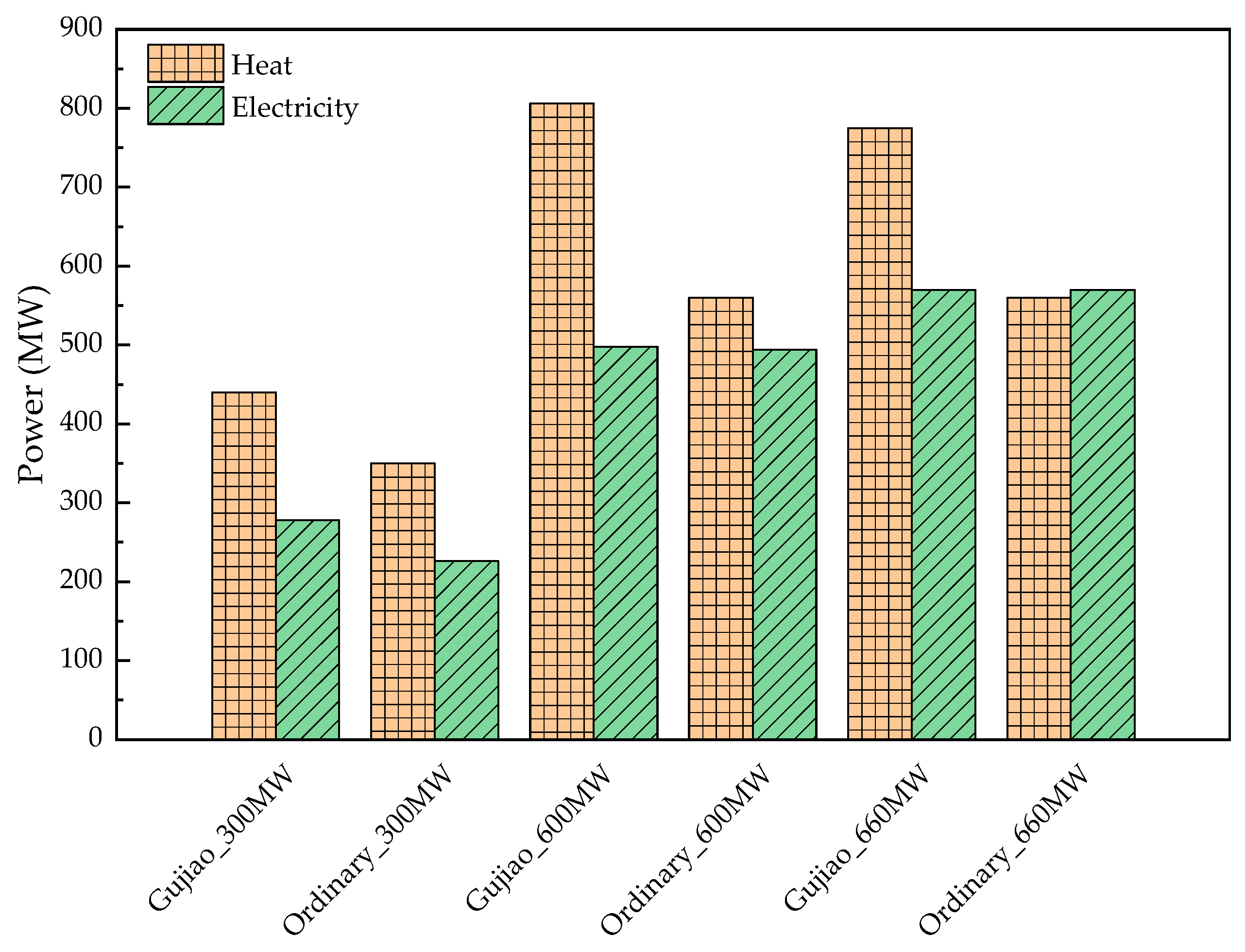

2.2.3. Analysis of Unit Flexibility

- (1)

- Heating and power generation capacity during heating season

- (2)

- Revenue from heat supply and power generation of the power plant during midday hours

3. Research on Unit Flexibility Improving Technology

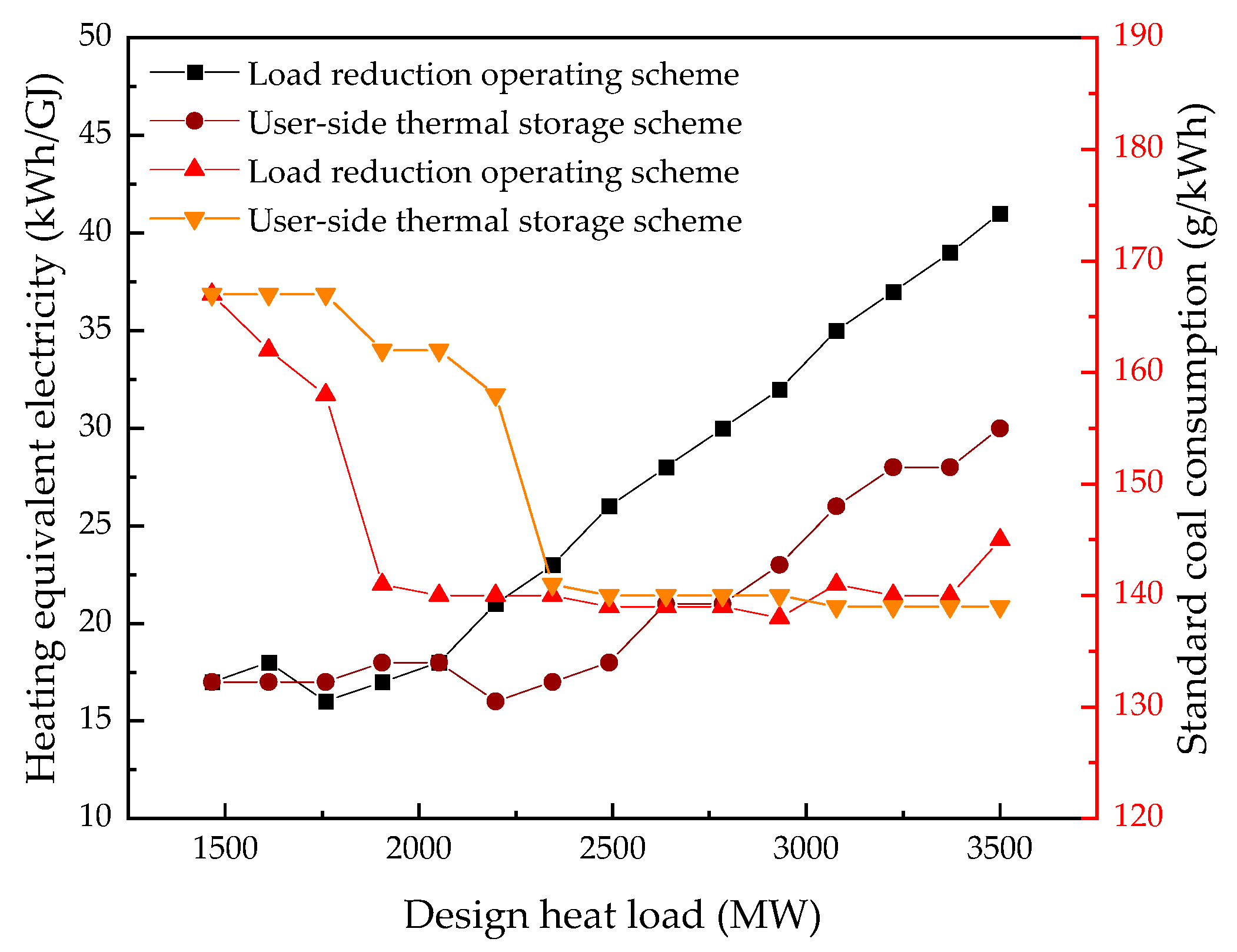

3.1. User-Side Thermal Storage

3.1.1. Operating Principle

3.1.2. Operating Mode

3.1.3. System Performance

3.2. Hot Water Tank Thermal Storage

3.2.1. Operating Principle

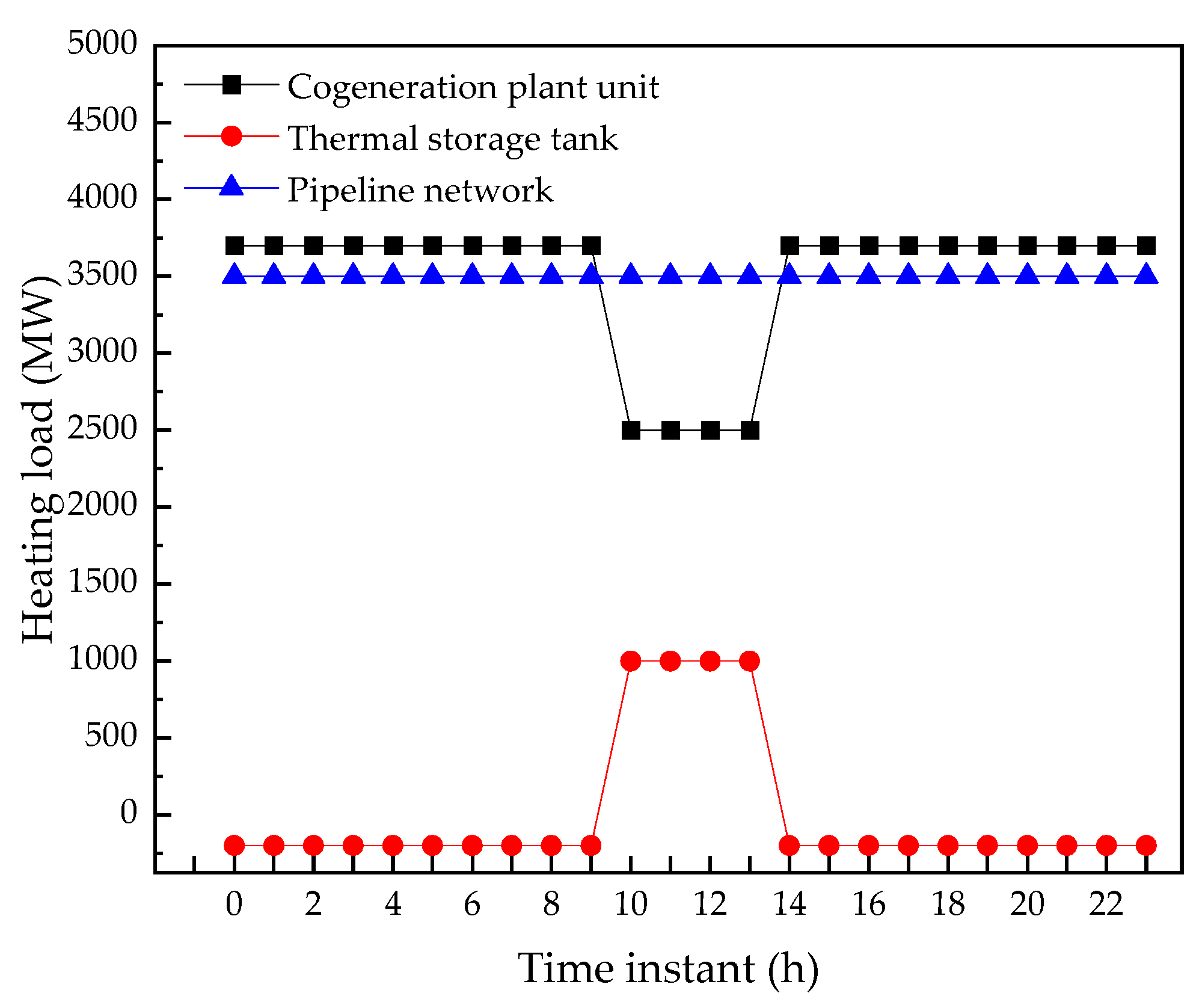

3.2.2. Operating Mode of the 1000 Mw Thermal Storage Tank System

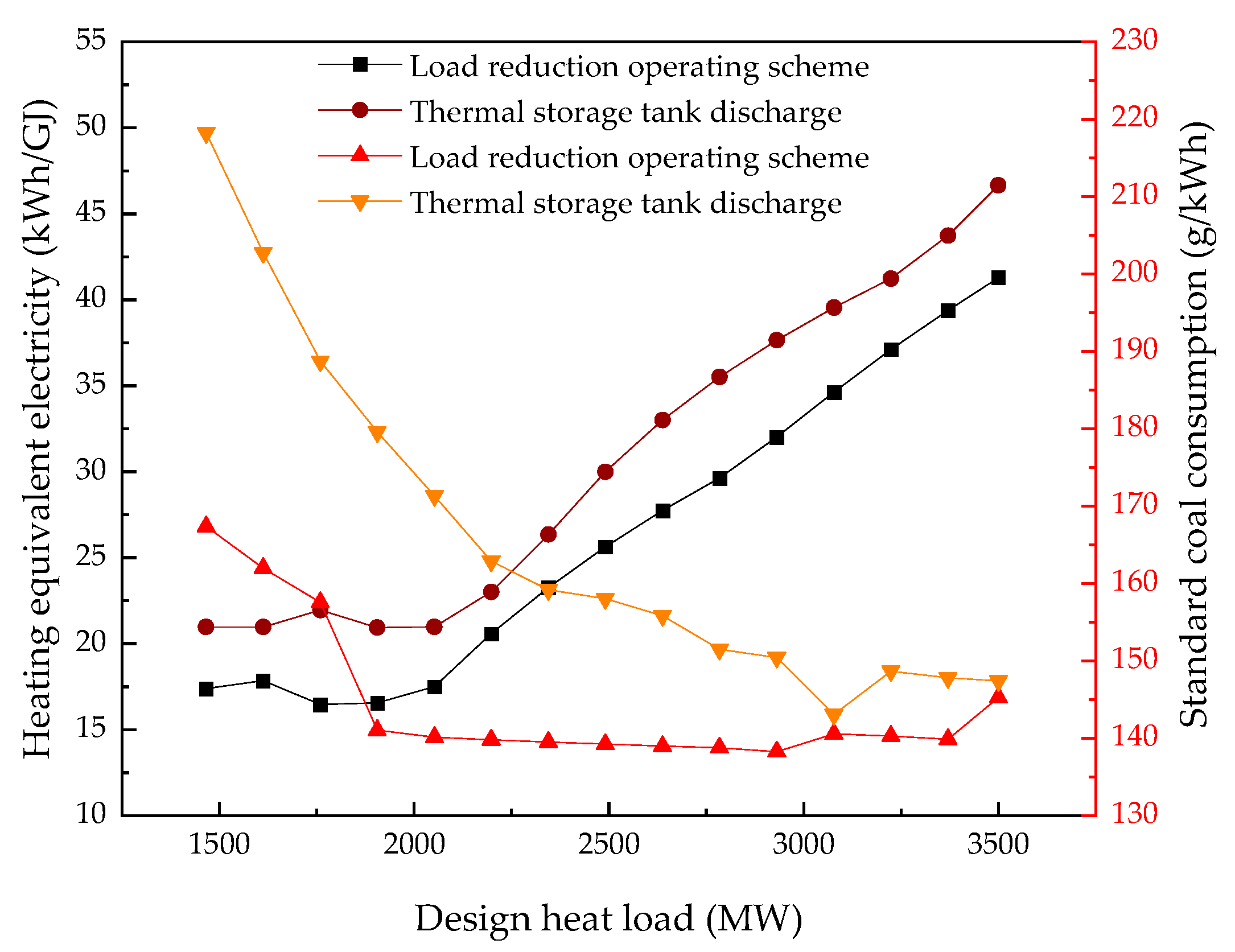

3.2.3. Performance of the 1000 Mw Thermal Storage Tank System

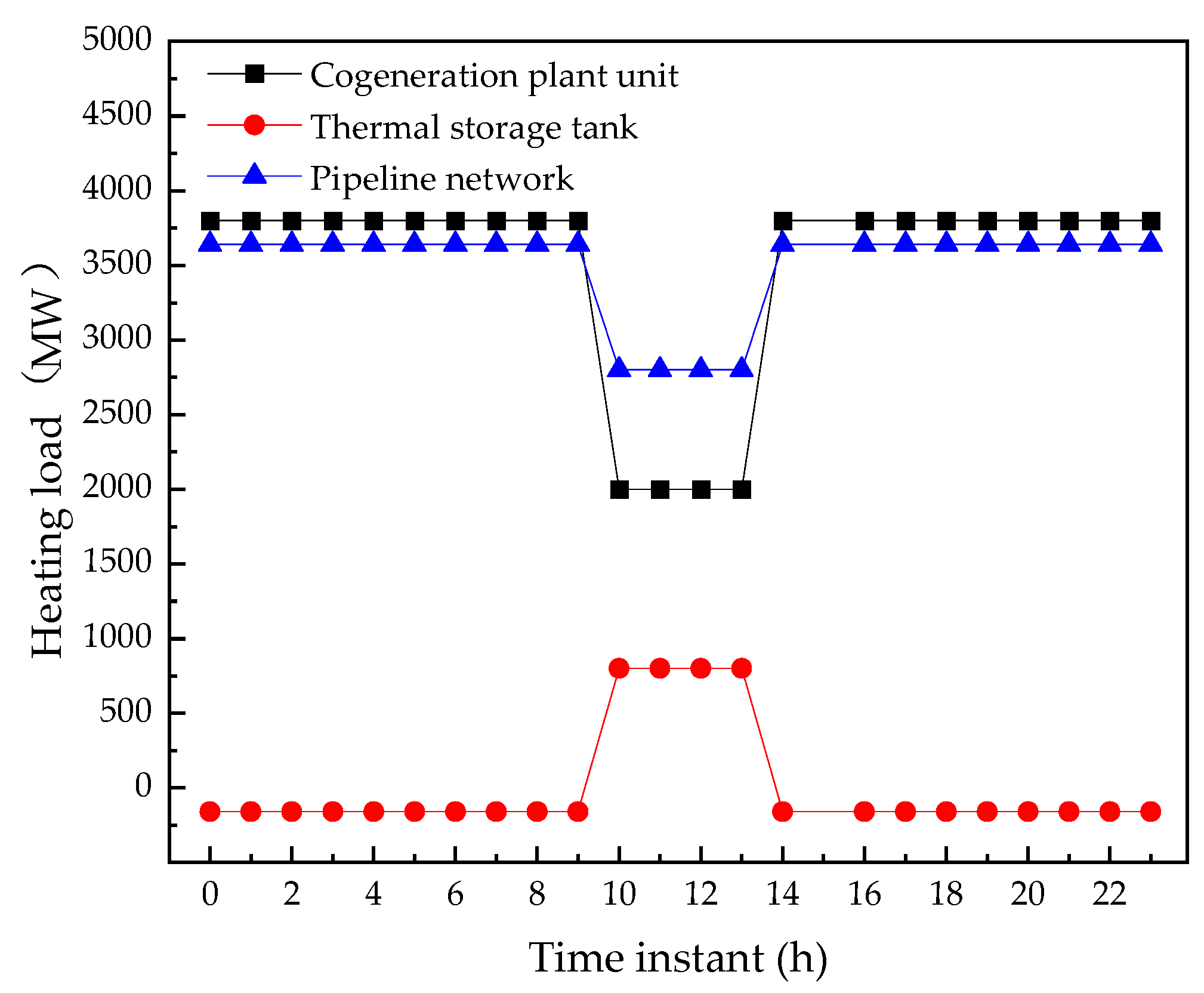

3.2.4. Operating Mode of the 1500 Mw Thermal Storage Tank System

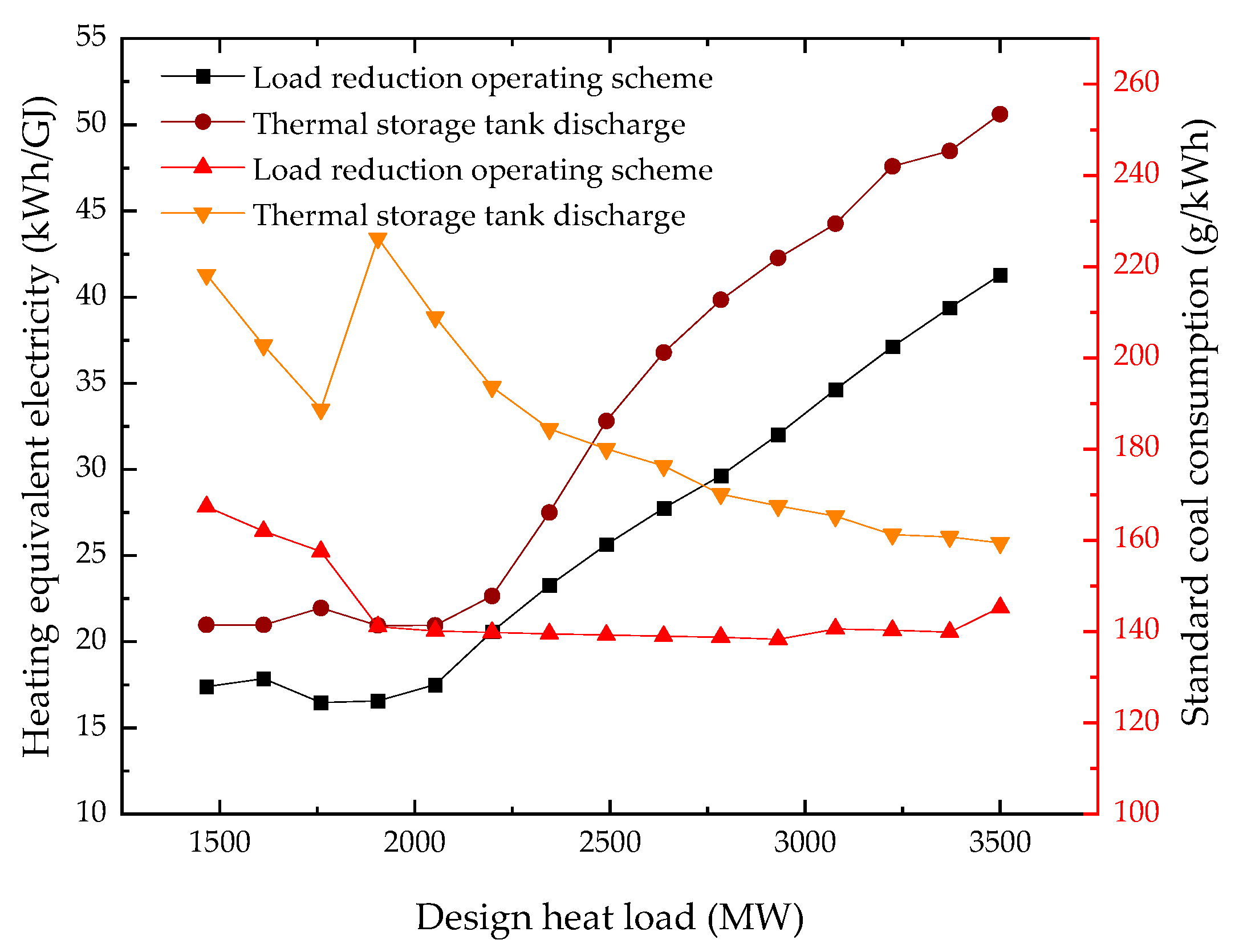

3.2.5. Performance of the 1500 Mw Thermal Storage Tank System

3.3. Combined Regulation of Tank and User-Side Thermal Storage

3.3.1. Operating Mode

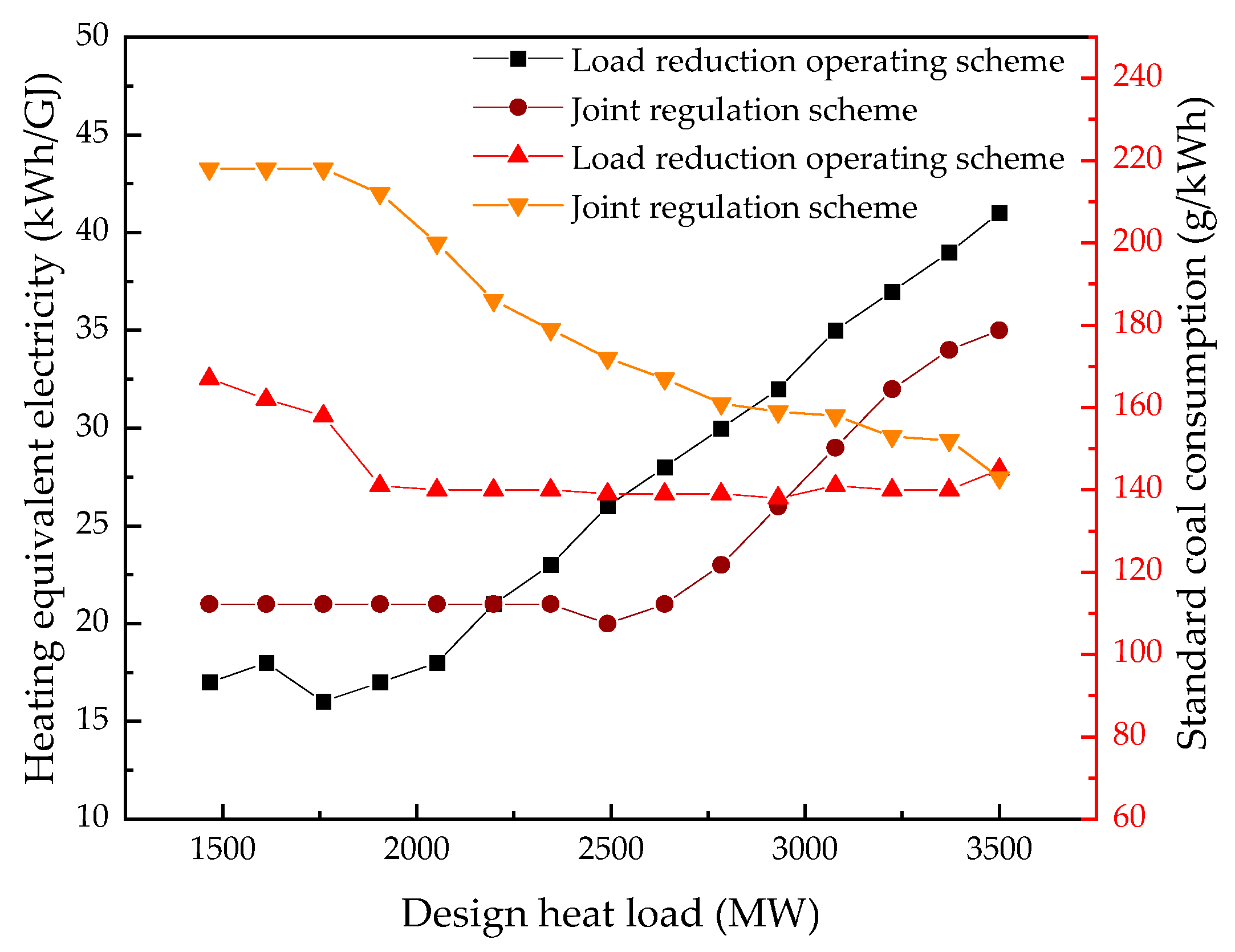

3.3.2. System Performance

3.4. Comparison of Various Schemes

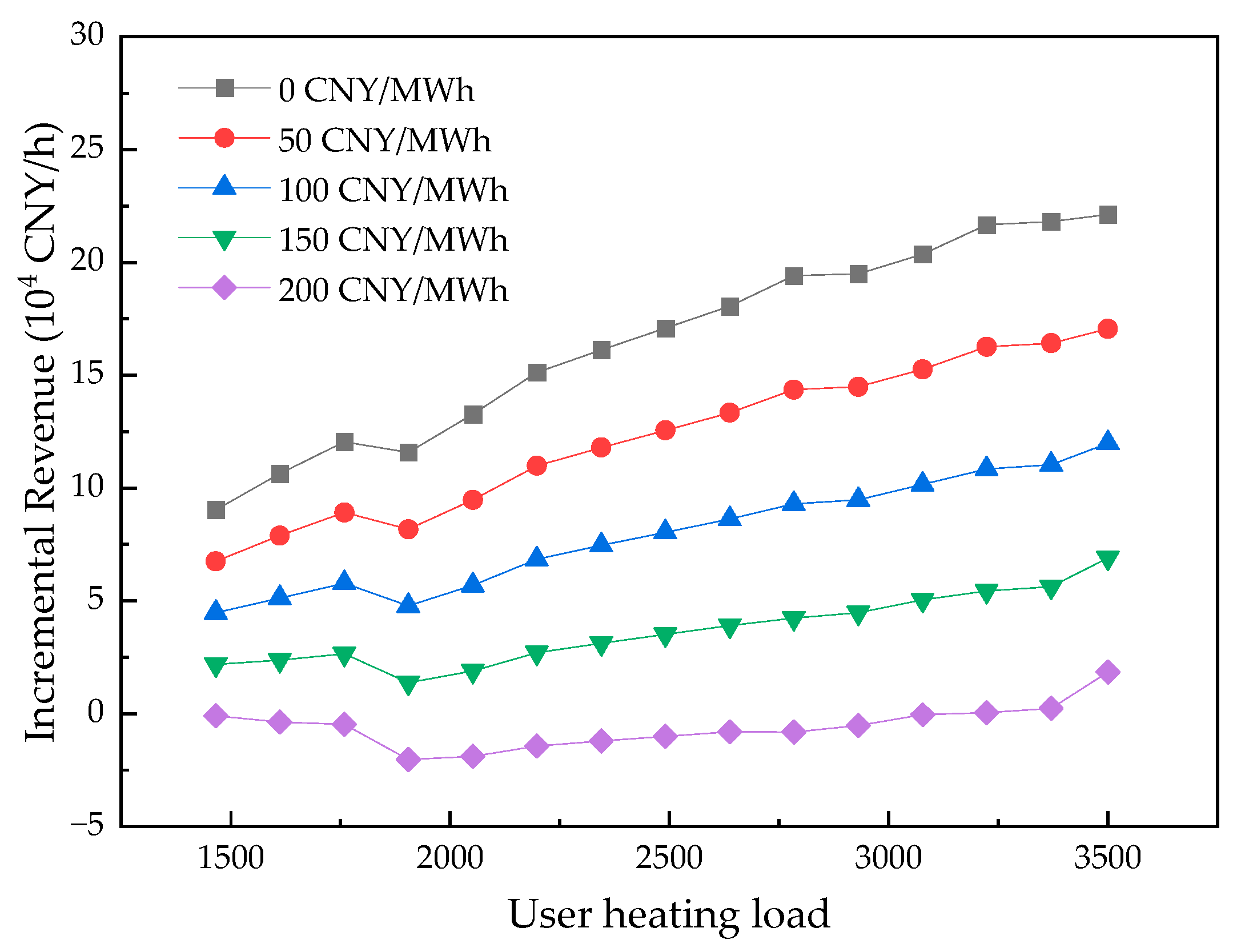

3.5. Sensitivity Analysis of Electricity Price

4. Conclusions

- (1)

- Compared with conventional heat supply units, the low-temperature return water cogeneration units exhibit a 25~40% increase in heating capacity and stronger thermo-electric coupling. While ensuring the user heating demand, the minimum power generation load rate of the Gujiao Power Plant during the heating season under load reduction conditions ranges from 44% to 85%. The unit flexibility and economic performance during the midday period are poor, urgently requiring enhancements to its flexibility.

- (2)

- Non-thermal-storage technologies such as high- and low-pressure bypasses, zero output of the low-pressure cylinder, absorption heat pumps, and steam ejectors have a limited adjustment range for their heating capacity and are unsuitable for adoption in low-temperature return water cogeneration units. The exergy efficiency of an electric thermal storage boiler is about 23%, and that of molten salt thermal storage is about 57%, both significantly lower than that of a hot water thermal storage tank (85%).

- (3)

- The discharge power selection range for the unit’s thermal storage tank is 1000~1500 MW. Under discharge conditions, installing a 1000 MW/4000 MWh thermal storage tank can reduce the unit’s minimum power generation load rate by an average of about 20%, increase the heating equivalent electricity by an average of about 4.3 kWh/GJ, and increase the standard coal consumption by an average of about 21.1 g/kWh; installing a 1500 MW/6000 MWh thermal storage tank can reduce the unit’s minimum power generation load rate by an average of about 25%, increase the heating equivalent electricity by an average of about 6.7 kWh/GJ, and increase the standard coal consumption for power generation by an average of about 39.7 g/kWh.

- (4)

- The combined regulation of a 1000 MW thermal storage tank and 20% user-side thermal storage can further enhance unit flexibility and optimize energy efficiency. During the heating season, the unit’s minimum power generation load rate ranges from 30% to 53%, with an average reduction of approximately 28%; the average heating equivalent electricity decreases by 2 kWh/GJ, the standard coal consumption for power generation increases by an average of about 35.2 g/kWh, the revenue from heat and power generation increases by an average of about 122,000 CNY/h, and a peak shaving electricity price revenue of approximately 268,000 CNY/h can be obtained.

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

Abbreviations

| CHP | combined heat and power |

| Co-ah system | cogeneration system based on absorption heat exchange |

| PSEP | peak shaving electricity price |

| THA | turbine heat acceptance |

| TMCR | turbine maximum continuous rating |

| B (g/kWh) | the coal consumption in power plant operation |

| bi (g/kWh) | the standard coal consumption for the power generation of Unit i |

| cp (J/(kg °C)) | the specific heat capacity of the water |

| Dcq,i (t/h) | the exhaust steam flow rate of the unit i used for heating |

| De,i (t/h) | the extraction steam flow rate of the unit i used for heating |

| Dj,i (t/h) | the flow rate of other extraction steams |

| DR,i (t/h) | the flow rate of the reheat hot-section steam |

| DZ,i (t/h) | the flow rate of the main steam |

| D1,i (t/h) | the flow rate of the first-stage extraction steam |

| E (104 CNY) | the profit from the heat supply and power generation of the power plant |

| Eb (104 CNY) | the coal-fired cost |

| Ee (104 CNY) | the power generation revenue |

| Ef (104 CNY) | the peak shaving revenue |

| Eq (104 CNY) | the heating revenue |

| G (t/h) | design circulating water flow rate |

| Gi (t/h) | the circulating water flow rate of Unit i |

| Gx (t/h) | the circulating water flow rate under the tank’s thermal energy discharge condition |

| Gxc (t/h) | the circulating water flow rate under the tank’s thermal energy storage condition |

| hc,i (kJ/kg) | the enthalpy of the exhaust steam |

| hco,i (kJ/kg) | the exhaust steam enthalpy of Unit i under THA condition |

| hcs,i (kJ/kg) | the enthalpy of the exhaust steam drainage |

| he,i (kJ/kg) | the enthalpy of the extraction steam |

| hes,i (kJ/kg) | the enthalpy of the extraction stream drainage |

| hj,i (kJ/kg) | the enthalpy of the other extraction steams |

| hL,i (kJ/kg) | the enthalpy of the cold-section steam |

| hR,i (kJ/kg) | the enthalpy of the hot-section steam |

| hs,i (kJ/kg) | the enthalpy of the feed water at the economizer inlet |

| hZ,i (kJ/kg) | the enthalpy of the main steam |

| h1,i (kJ/kg) | the enthalpy of the first-stage extraction steam |

| i | generator unit number |

| j | units other than Unit i |

| Pg,i (MW) | the power generation of Unit i |

| Pg (MW) | the actual power generation of the power plant |

| Pgo (MW) | the nameplate of the power plant |

| q (MW) | the heating load |

| qc,i (MW) | the exhaust steam heating power of each unit |

| qe,i (MW) | the extraction steam heating power of each unit |

| qh (MW) | the design heat load |

| qx (MW) | the heat release load of the thermal storage tank |

| qxc (MW) | the thermal storage power of the thermal storage tank |

| qy (MW) | the user-side thermal storage load |

| t (h) | the time |

| tH (°C) | the outlet water temperature of the circulating water |

| tH,i (°C) | the outlet water temperature of Unit i |

| tL (°C) | the inlet water temperature of the circulating water |

| tL,i (°C) | the inlet water temperature of Unit i |

| txH (°C) | the temperature of the hot water in the thermal storage tank |

| txL (°C) | the temperature of the cold water in the thermal storage tank |

| wc,i (kWh/GJ) | the exhaust steam heating equivalent electricity of Unit i |

| we,i (kWh/GJ) | the extraction steam heating equivalent electricity of Unit i |

| Χi (%) | the exhaust steam heating utilization rate of Unit i |

| γ (%) | the power generation load rate |

| ηb,i (%) | the boiler efficiency |

| ηp,i (%) | the pipeline efficiency |

| ηi (%) | the heat exchange efficiency |

| λb (CNY/t) | the price of standard coal |

| λe (CNY/MWh) | the on-grid electricity price |

| λq (CNY/GJ) | the heat price |

References

- Fu, L.; Jiang, Y.; Zhang, S. Cogeneration and power district heating method based on Co-ah cycle. J. Tsinghua Univ. Sci. Technol. 2008, 48, 1377–1380. [Google Scholar] [CrossRef]

- Fu, L.; Li, Y. Long-distance heat-supply mode with large temperature difference using waste heat of power plants. Huadian Technol. 2020, 42, 56–61. [Google Scholar] [CrossRef]

- Chen, P.; Wang, Y. Operation, regulation and control boundary conditions of Taiyuan-Gujiao long-distance heating systems. Dist. Heat. 2019, 2, 19–22. [Google Scholar] [CrossRef]

- Jia, Z. Research on the renovation of cogeneration involving long-distance heating pipeline networks. Eng. Technol. Res. 2024, 9, 41–43. [Google Scholar] [CrossRef]

- Guan, X. Analysis of heating technology reform and scheme optimization mode for large thermal power units. Value Eng. 2019, 38, 188–189. [Google Scholar] [CrossRef]

- Sun, J.; Fu, L.; Li, W. Engineering case of recovering waste heat from power plants by reducing return water temperature of heating networks. Dist. Heat. 2015, 4, 54–58. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, H.; Ji, S.; Frate, G.F.; Duan, L.; Desideri, U.; Yang, Y. Techno-economic analysis of a novel heat-power decoupling system of molten salt coupled steam accumulator used in gas-steam combined cycle CHP unit. Appl. Energy 2025, 400, 126591. [Google Scholar] [CrossRef]

- Luan, X.; Ma, J.; Nie, S.; Ding, Y. Operation analysis of large high back pressure cogeneration unit in heating season. J. Eng. Therm. Energy Power 2024, 39, 96–103. [Google Scholar] [CrossRef]

- Zhou, C.; Zheng, J.; Liu, S.; Liu, Y.; Mei, F.; Pan, Y.; Shi, T.; Wu, J. Operation optimization of multi-district integrated energy system considering flexible demand response of electric and thermal loads. Energies 2019, 12, 3831. [Google Scholar] [CrossRef]

- THERMOFLEX®. Available online: https://www.thermoflow.com/products_generalpurpose.html (accessed on 1 December 2025).

- Chen, J.; Wang, J.; Jiang, H.; Yang, X.; Zuo, X.; Yuan, M. Parameter optimization of an absorption heat exchanger with large temperature difference. Prccesses 2024, 12, 1669. [Google Scholar] [CrossRef]

- Li, Y.; Fu, L.; Zhang, S.; Jiang, Y.; Xiling, Z. A new type of district heating method with co-generation based on absorption heat exchange (co-ah cycle). Energy Convers. Manag. 2011, 52, 1200–1207. [Google Scholar] [CrossRef]

- Li, Y.; Fu, L.; Zhang, S.; Zhao, X. A new type of district heating system based on distributed absorption heat pumps. Energy 2011, 36, 4570–4576. [Google Scholar] [CrossRef]

- Nakaishi, T.; Kagawa, S.; Takayabu, H.; Lin, C. Determinants of technical inefficiency in China’s coal-fired power plants and policy recommendations for CO2 mitigation. Environ. Sci. Pollut. Res. 2021, 28, 52064–52081. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Song, J.; Zheng, W.; Liu, Z.; Lin, C. Analysis of economy, energy efficiency, environment: A case study of the CHP system with both civil and industrial heat users. Case Stud. Therm. Eng. 2022, 30, 101768. [Google Scholar] [CrossRef]

- Qin, B.; Jiang, Y.; Fu, L. Regulation of heat-supply system during electric peak-shaving by using CHP plant. Gas Heat 2005, 25, 6–8. [Google Scholar] [CrossRef]

- Cheng, S.; Fu, Y.; Zhang, H.; Wang, Z.; Chen, W.; Tian, H. Impact of heat storage on coal consumption of supercritical thermal power units under deep peak shaving. J. Chin. Soc. Power Eng. 2025, 45, 1345–1353. [Google Scholar] [CrossRef]

- Li, G.; Li, Z.; Jiao, G. Research on heat storage tank system for long-distance thermal pipe network. Dist. Heat. 2021, 6, 12–18. [Google Scholar] [CrossRef]

- Chen, X.; Zuo, C.; Zhao, N.; Huang, K.; Wang, H. Analysis on peak regulation characteristics of thermal power units with integrated heat storage device. Power Gener. Technol. 2024, 45, 392–400. [Google Scholar] [CrossRef]

- Liu, H. Design of control scheme for thermal storage tank in thermal power plant. Electr. Power Surv. Des. 2025, 1, 84–88. [Google Scholar] [CrossRef]

| No. | Parameter | Unit | Value |

|---|---|---|---|

| 1 | The nameplate of the Gujiao Power Plant (Pgo) | MW | 3120 |

| 2 | The total power generation of the Gujiao Power Plant (Pg) | MW | 3500 |

| 3 | Design circulating water flow rate (G) | t/h | 30,000 |

| 4 | Design return water temperature of circulating water | °C | 30 |

| 5 | Design supply water temperature of circulating water | °C | 130 |

| 6 | Minimum supply water temperature of circulating water | °C | 90 |

| 7 | Boiler efficiency (ηb) | % | 92 |

| 8 | Pipeline efficiency (ηp) | % | 99 |

| 9 | Heat exchange efficiency (η) | % | 100 |

| 10 | Benchmark electricity price for coal-fired power plants | CNY/MWh | 332 |

| 11 | Electricity price at midday in the electricity spot market | CNY/MWh | 50 |

| 12 | Heat price (λq) | CNY/GJ | 15 |

| 13 | Price of standard coal (λb) | CNY/t | 800 |

| 14 | Unit investment of thermal storage tank renovation | CNY/m3 | 1500 |

| Design Heat Load (MW) | Power Generation Load Rate (%) | Heating Equivalent Electricity (kWh/GJ) | Standard Coal Consumption for Power Generation (g/kWh) | Revenue Excluding PSEP (104 CNY/h) | PSEP Revenue (104 CNY/h) |

|---|---|---|---|---|---|

| 1466 | 44 | 17 | 167 | −21.43 | 16.42 |

| 1759 | 50 | 16 | 158 | −23.59 | 9.59 |

| 2052 | 56 | 18 | 140 | −24.55 | 3.94 |

| 2345 | 62 | 23 | 140 | −27.68 | - |

| 2638 | 69 | 28 | 139 | −30.8 | - |

| 2931 | 74 | 32 | 138 | −33.67 | - |

| 3224 | 81 | 37 | 140 | −37.25 | - |

| 3500 | 85 | 41 | 145 | −41.05 | - |

| Design Heat Load (MW) | Unit Heating Load (MW) | Power Generation Load Rate (%) | Incremental Revenue Excluding PSEP (104 CNY/h) | PSEP Revenue (104 CNY/h) | Additional Revenue Compared with the Load Reduction Operating Scheme (104 CNY) |

|---|---|---|---|---|---|

| 1466 | 1466 | 44 | 0 | 16.42 | 3228 (excluding PSEP) 4813 (including PSEP) |

| 1759 | 1466 | 44 | 2.16 | 16.42 | |

| 2052 | 1612 | 47 | 2.00 | 12.67 | |

| 2345 | 1905 | 52 | 4.72 | 7.47 | |

| 2638 | 2198 | 59 | 4.90 | 0.91 | |

| 2931 | 2345 | 62 | 5.99 | - | |

| 3224 | 2638 | 69 | 6.45 | - | |

| 3500 | 2784 | 72 | 8.69 | - |

| Design Heat Load (MW) | Unit Heating Load (MW) | Power Generation Load Rate (%) | Incremental Revenue Excluding PSEP (104 CNY/h) | PSEP Revenue (104 CNY/h) | Additional Revenue Compared with the Load Reduction Operating Scheme (104 CNY) |

|---|---|---|---|---|---|

| 1466 | 466 | 30 | 6.76 | 39.52 | 5477 (excluding PSEP) 11,746 (including PSEP) |

| 1759 | 759 | 33 | 8.23 | 34.52 | |

| 2052 | 1052 | 38 | 7.24 | 25.61 | |

| 2345 | 1345 | 42 | 8.49 | 19.12 | |

| 2638 | 1638 | 49 | 8.49 | 11.01 | |

| 2931 | 1931 | 54 | 8.49 | 5.81 | |

| 3224 | 2224 | 60 | 8.93 | - | |

| 3500 | 2500 | 64 | 9.41 | - |

| Design Heat Load (MW) | Unit Heating Load (MW) | Power Generation Load Rate (%) | Incremental Revenue Excluding PSEP (104 CNY/h) | PSEP Revenue (104 CNY/h) | Additional Revenue Compared with the Load Reduction Operating Scheme (104 CNY) |

|---|---|---|---|---|---|

| 1466 | 466 | 30 | 6.76 | 39.52 | 7104 (excluding PSEP) 17,934 (including PSEP) |

| 1759 | 759 | 33 | 8.23 | 34.52 | |

| 2052 | 552 | 31 | 9.68 | 38.00 | |

| 2345 | 845 | 34 | 11.77 | 32.68 | |

| 2638 | 1138 | 40 | 11.77 | 21.63 | |

| 2931 | 1431 | 45 | 12.23 | 15.30 | |

| 3224 | 1824 | 53 | 11.90 | 6.27 | |

| 3500 | 2000 | 56 | 14.08 | 3.63 |

| Design Heat Load (Mw) | Heat Charging Mode | Heat Discharging Mode | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| User Heating Load (MW) | Circulating Water Flow Rate of Pipelines (t/h) | Unit Heating Load (MW) | Unit Circulating Water Flow (t/h) | Unit Outlet Water Temperature (°C) | User Heating Load (MW) | Unit Heating Load (MW) | Circulating Water Flow Rate in the Exhaust Steam Section (t/h) | Tank Heating Load (MW) | Supply Water Flow Rate of Tank (t/h) | Unit Outlet Water Temperature (°C) | |

| 1466 | 1466 | 20,943 | 1666 | 23,800 | 90.0 | 1466 | 466 | 6657 | 1000 | 14,286 | 90.0 |

| 1759 | 1818 | 25,966 | 2018 | 28,823 | 90.0 | 1466 | 466 | 6657 | 1000 | 14,286 | 90.0 |

| 2052 | 2134 | 30,000 | 2334 | 32,812 | 91.0 | 1642 | 642 | 9166 | 1000 | 14,286 | 90.0 |

| 2345 | 2439 | 30,000 | 2639 | 32,460 | 99.7 | 1876 | 876 | 13,613 | 1000 | 13,187 | 90.0 |

| 2638 | 2744 | 30,000 | 2944 | 32,187 | 108.4 | 2110 | 1110 | 16,813 | 1000 | 13,187 | 90.3 |

| 2931 | 3048 | 30,000 | 3248 | 31,968 | 117.1 | 2345 | 1345 | 16,813 | 1000 | 13,187 | 97.0 |

| 3224 | 3353 | 30,000 | 3553 | 31,789 | 125.8 | 2579 | 1579 | 16,813 | 1000 | 13,187 | 103.7 |

| 3500 | 3640 | 31,200 | 3800 | 32,571 | 130 | 2800 | 2000 | 19,451 | 800 | 10,549 | 110.0 |

| Design Heat Load (MW) | Heating Load (MW) | Power Generation Load Rate (%) | Incremental Revenue Excluding PSEP (104 CNY/h) | PSEP Revenue (104 CNY/h) | Additional Revenue Compared with the Load Reduction Operating Scheme (104 CNY) |

|---|---|---|---|---|---|

| 1466 | 466 | 30 | −14.67 | 6.76 | 8150 (excluding PSEP) 20,362 (including PSEP) |

| 1759 | 466 | 30 | −14.67 | 8.92 | |

| 2052 | 642 | 31 | −15.07 | 9.48 | |

| 2345 | 876 | 35 | −15.88 | 11.80 | |

| 2638 | 1110 | 39 | −17.45 | 13.35 | |

| 2931 | 1345 | 42 | −19.19 | 14.48 | |

| 3224 | 1579 | 46 | −20.99 | 16.26 | |

| 3500 | 2000 | 53 | −23.99 | 17.06 |

| No. | Item | Load Reduction Operating Scheme | 20% User-Side Thermal Storage | 1000 MW Thermal Storage System Using Tanks | 1500 MW Thermal Storage System Using Tanks | 1000 MW Thermal Storage System Using Tank +20% User-Side Thermal Storage |

|---|---|---|---|---|---|---|

| 1 | Heating load (MW) | Baseline | About −450 | About −1000 | About −1393 | About −1450 |

| Power generation load (MW) | Baseline | About −280 | About −600 | About −800 | About −850 | |

| Minimum power generation load rate | Baseline | About −10% | About −20% | About −25% | About −28% | |

| 2 | Heating equivalent electricity (kWh/GJ) | Baseline | −5.6 | +4.3 | +6.7 | −2.0 |

| Standard coal consumption for power generation (g/kWh) | Baseline | +4.7 | +21.2 | +39.7 | +35.2 | |

| 3 | Revenue excluding PSEP (104 CNY/h) | Baseline | +4.3 | +8.6 | +10.9 | +12.2 |

| Revenue excluding PSEP (104 CNY/a) | Baseline | 3228 | 5477 | 7104 | 8150 | |

| Revenue including PSEP (104 CNY/a) | Baseline | +4813 | +11,746 | +17,934 | +20,362 | |

| 4 | Reconstruction investment (104 CNY) | 0 | 0 | +8700 | +12,900 | +8700 |

| 5 | Payback period (a, excluding PSEP) | - | - | 1.6 | 1.8 | 1.1 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Lei, L.; Li, S.; Lyu, J. Research on the Operation Flexibility of a Combined Heat and Power Generation Unit with Low-Temperature Return Water. Energies 2025, 18, 6403. https://doi.org/10.3390/en18246403

Zhao Y, Lei L, Li S, Lyu J. Research on the Operation Flexibility of a Combined Heat and Power Generation Unit with Low-Temperature Return Water. Energies. 2025; 18(24):6403. https://doi.org/10.3390/en18246403

Chicago/Turabian StyleZhao, Yaohua, Lei Lei, Shaohua Li, and Junfu Lyu. 2025. "Research on the Operation Flexibility of a Combined Heat and Power Generation Unit with Low-Temperature Return Water" Energies 18, no. 24: 6403. https://doi.org/10.3390/en18246403

APA StyleZhao, Y., Lei, L., Li, S., & Lyu, J. (2025). Research on the Operation Flexibility of a Combined Heat and Power Generation Unit with Low-Temperature Return Water. Energies, 18(24), 6403. https://doi.org/10.3390/en18246403