2.1. Overview of the VPP

VPP is an intelligent scheduling and management platform that uses advanced information and communication technologies to aggregate DERs, flexible loads and storage devices into a unified controllable entity. Its main role is to improve energy efficiency and operational flexibility, while providing peak shaving, frequency regulation, reserve capacity and other ancillary services through market-based operation so that economic performance and system reliability can be achieved simultaneously.

In general, a VPP consists of dispersed energy units, an ICT infrastructure and a central control center. The energy units include photovoltaic panels, wind turbines, energy storage systems and electric vehicles. The ICT layer is responsible for real-time monitoring, data collection and communication, whereas the control center acts as the “brain” of the system, performing data analysis, optimization of resource scheduling and interactions with electricity markets. Functionally, a VPP can be viewed as a multi-layer architecture including an infrastructure layer, a perception–analysis layer, a decision–execution layer and a market participation layer, which together support DER aggregation, forecasting, optimal scheduling and market bidding.

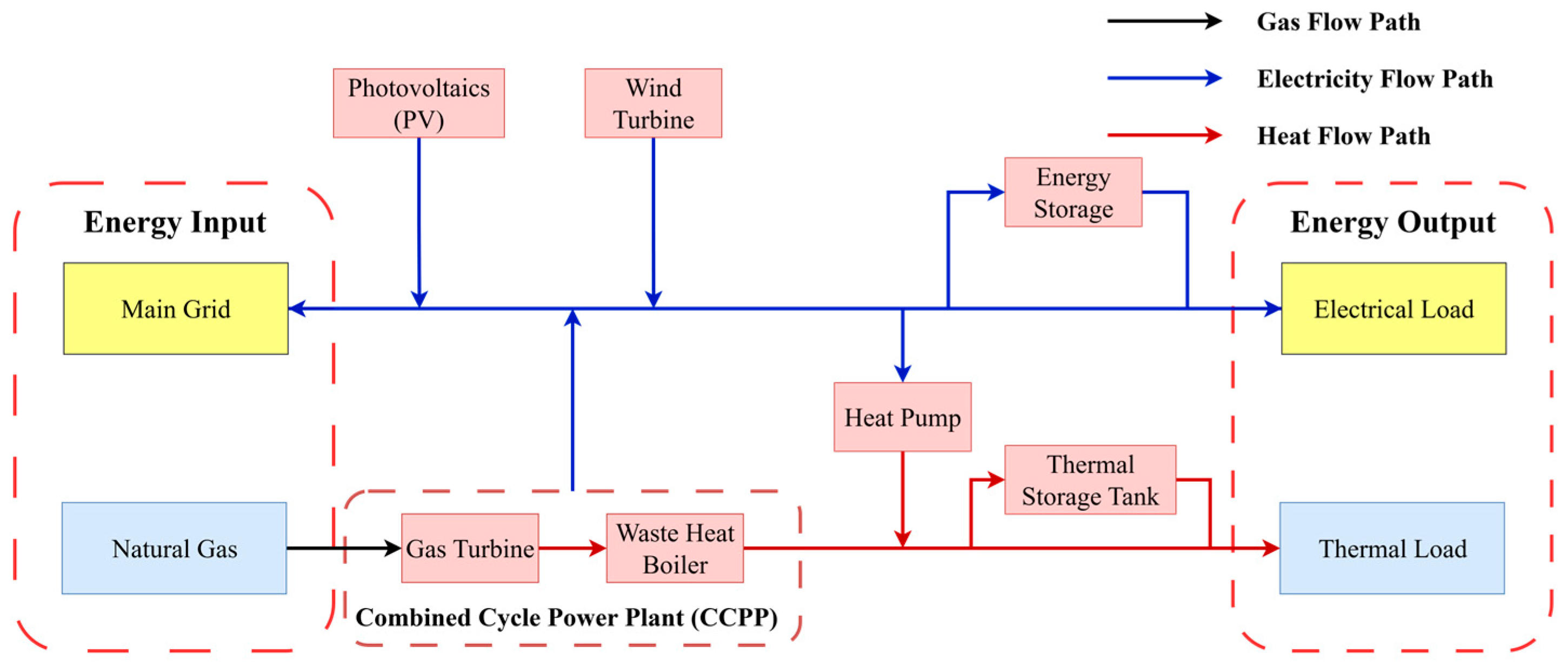

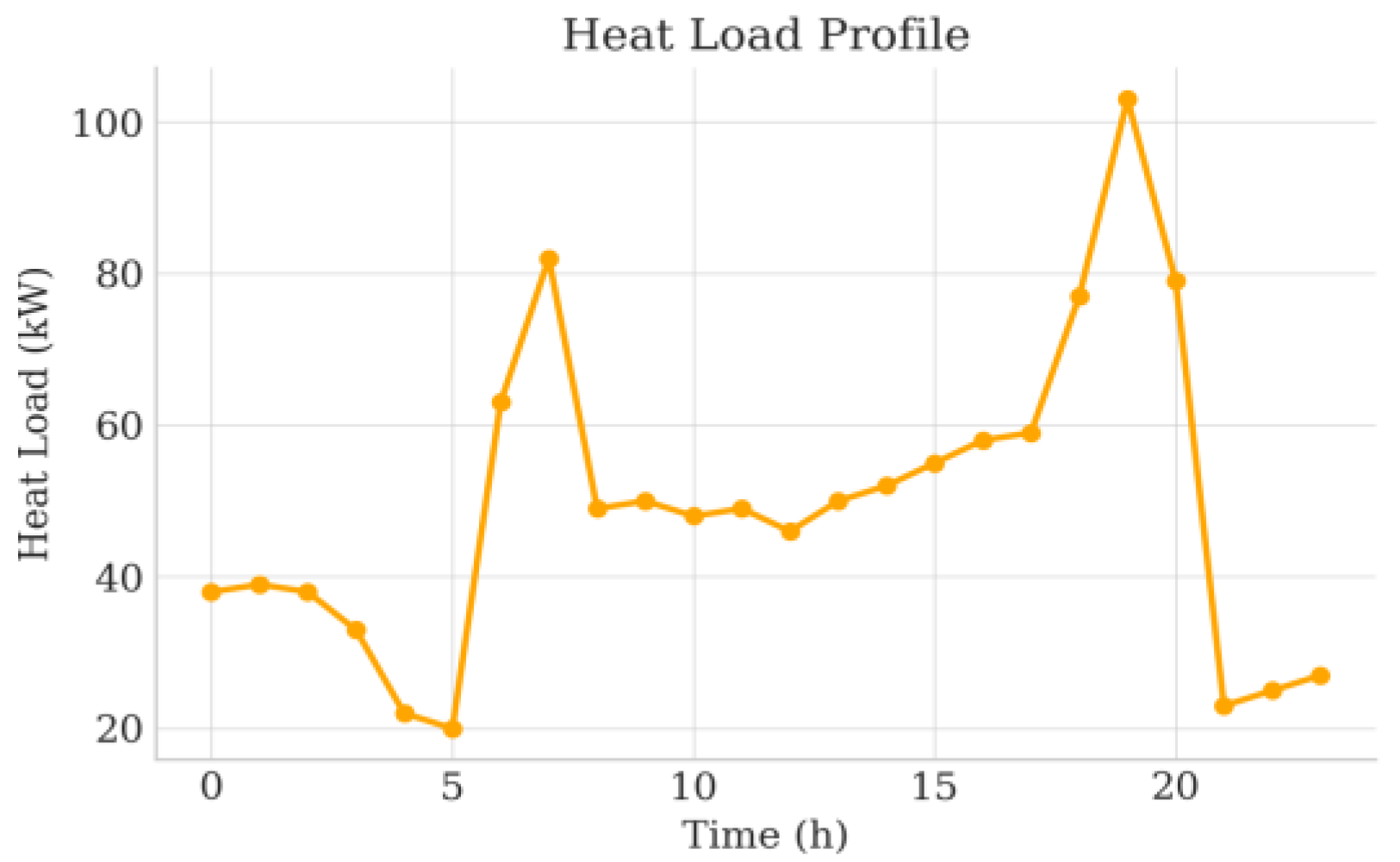

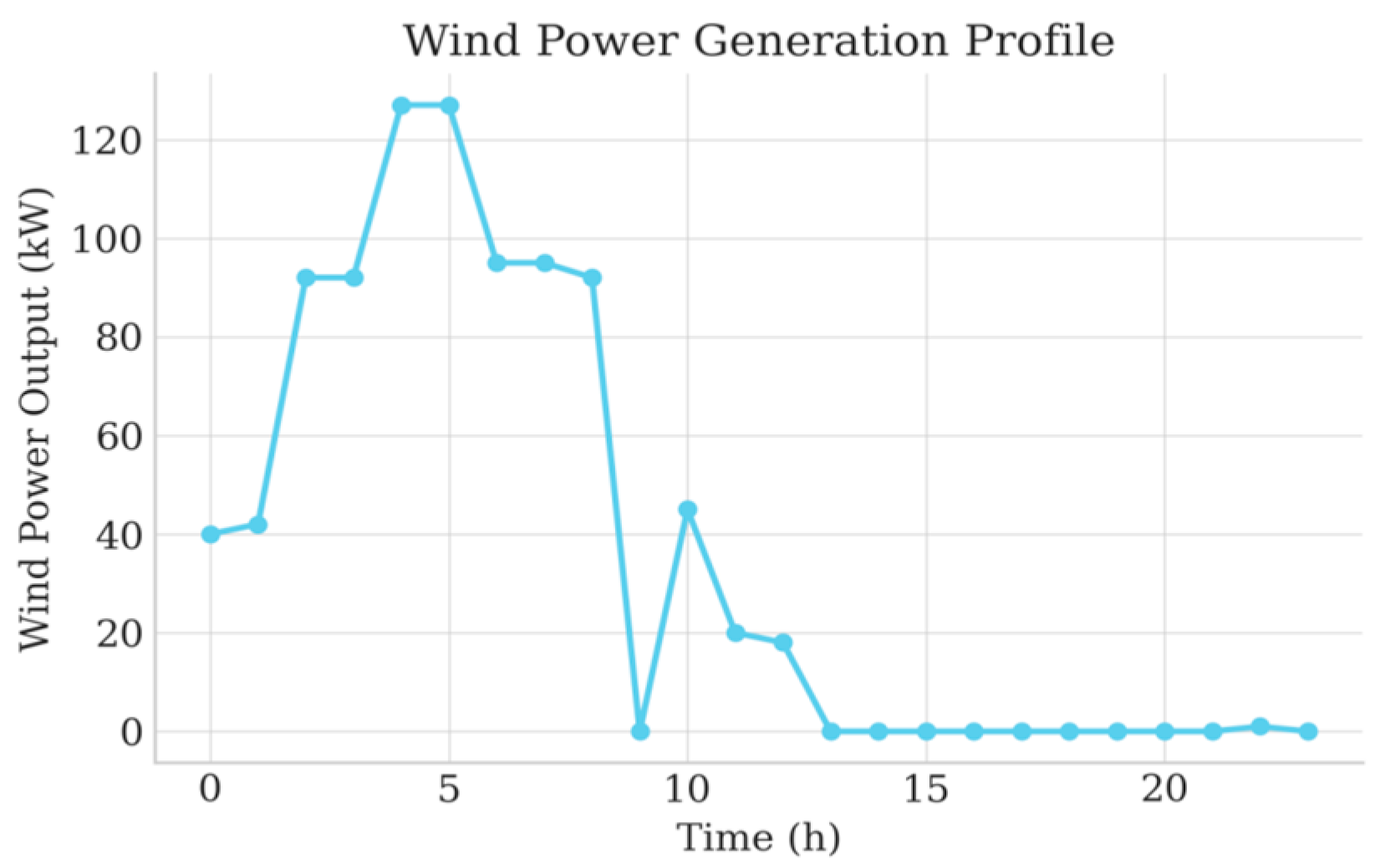

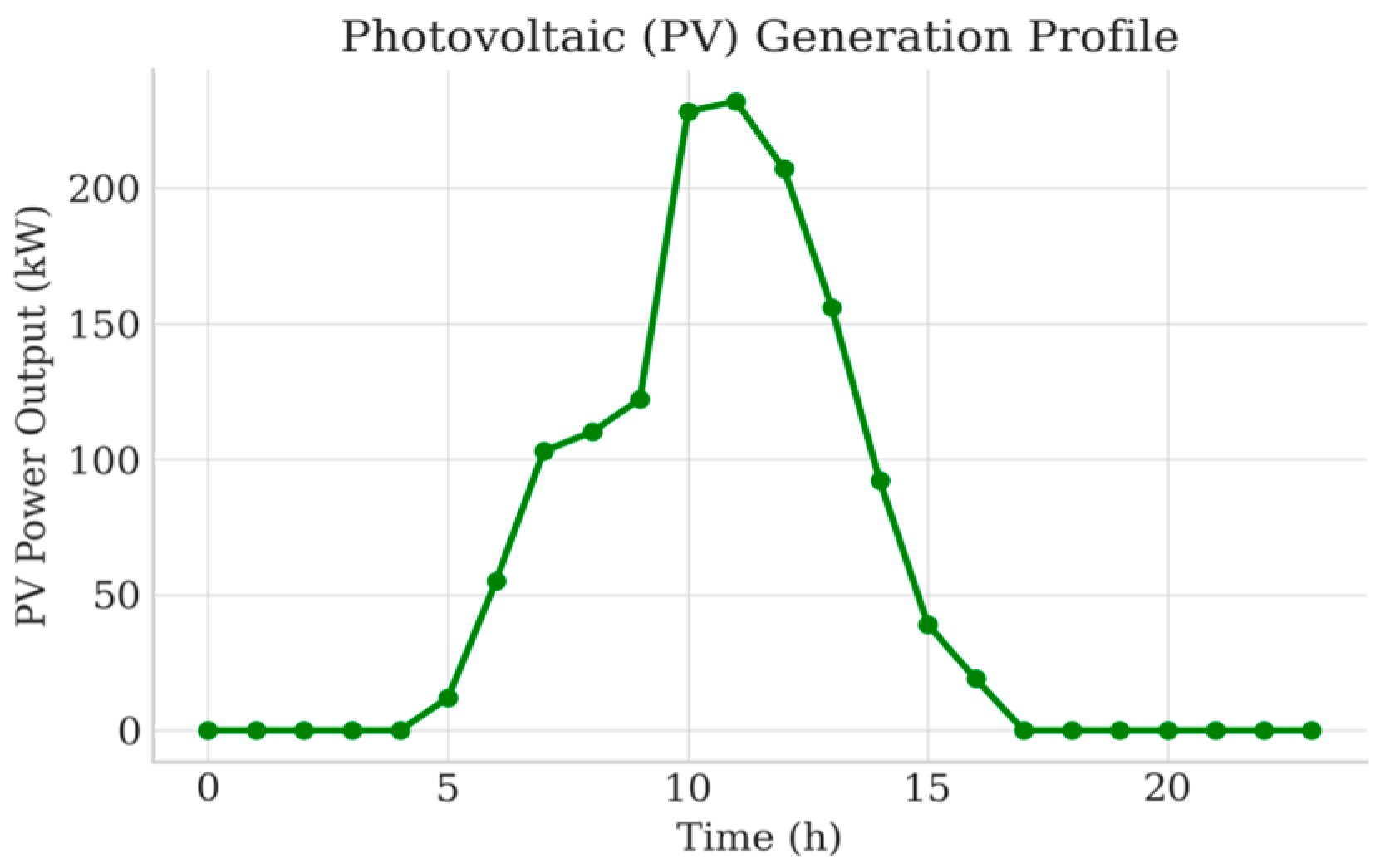

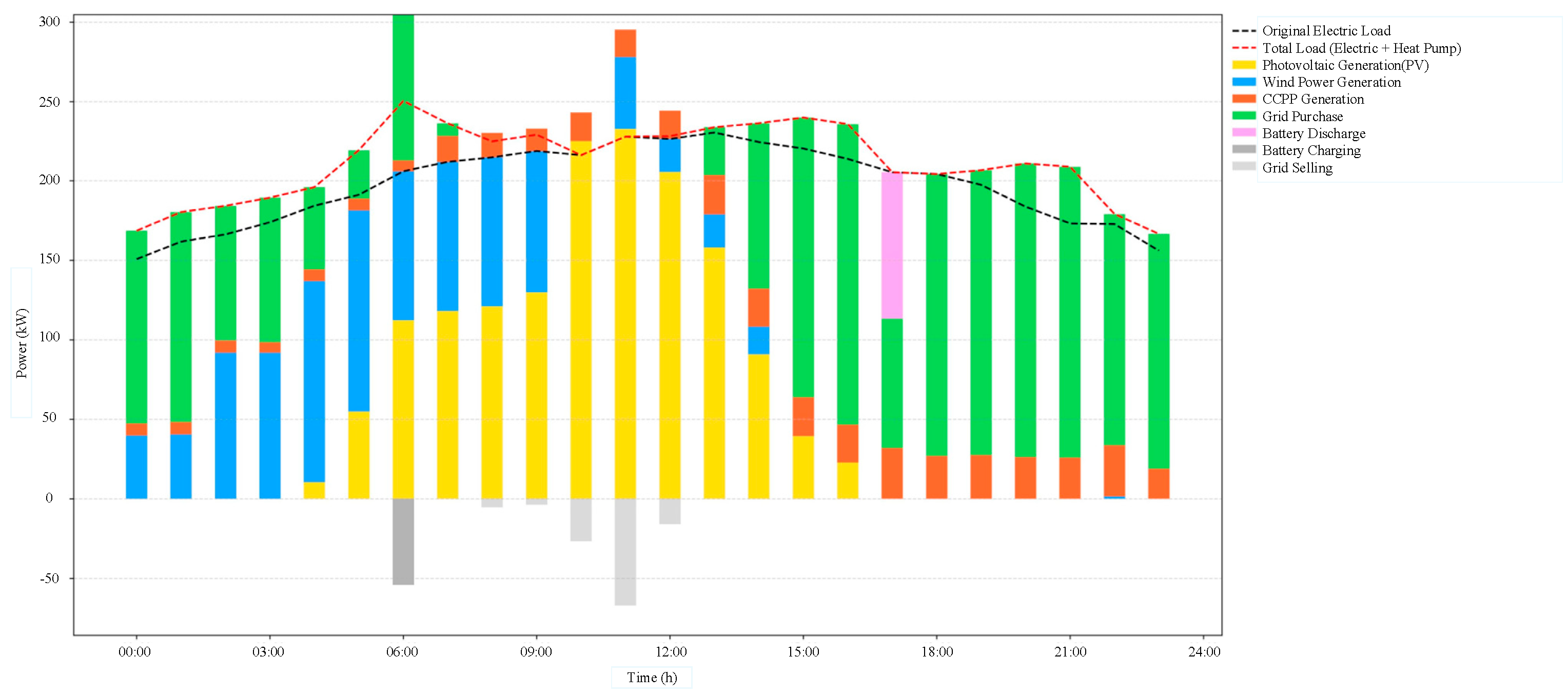

Under high renewable penetration and coupled multi-energy flows, VPPs still face challenges such as uncertainty in generation and demand forecasts, strong coupling among devices and the computational burden of real-time optimization. To investigate these issues, this paper adopts the intelligent energy management project of a university campus in Lingang, Shanghai, as a representative case. The campus-scale wind–solar–thermal–storage VPP considered in this study is shown in

Figure 1 and comprises a CCPP formed by a gas turbine and waste-heat boiler, a heat pump, photovoltaic arrays, wind turbines, battery storage and a thermal storage tank.

2.2. Physical Equipment Dynamic Models

To support optimization scheduling and policy training, the main components of the VPP are modeled in a unified manner. The model adopts a node–edge energy flow representation approach, following the principles of energy conservation and efficiency constraints. An example is illustrated as follows:

The CCPP takes natural gas as input and outputs both electric and thermal power, which can be expressed as

where

and

represent the electrical and thermal efficiencies, respectively.

- 2.

Energy Storage System

The energy storage system must satisfy the energy conservation relationship:

where

and

denote the charging and discharging powers,

and

are the corresponding efficiencies, and

is the energy stored at time

.

To support optimal scheduling and policy training, the core components of the VPP adopt a unified modeling framework, which is constructed based on the principles of energy conservation and efficiency constraints through a node-edge energy flow representation approach. For other devices such as photovoltaic modules, wind turbines, heat pumps, and thermal storage tanks, their modeling logic is consistent with that of units like CCPPs and energy storage systems, all adhering to the core criteria of energy balance and efficiency orientation. This paper only presents the overall modeling framework, and the detailed quantitative formulations of specific devices can be derived in accordance with the unified logic.

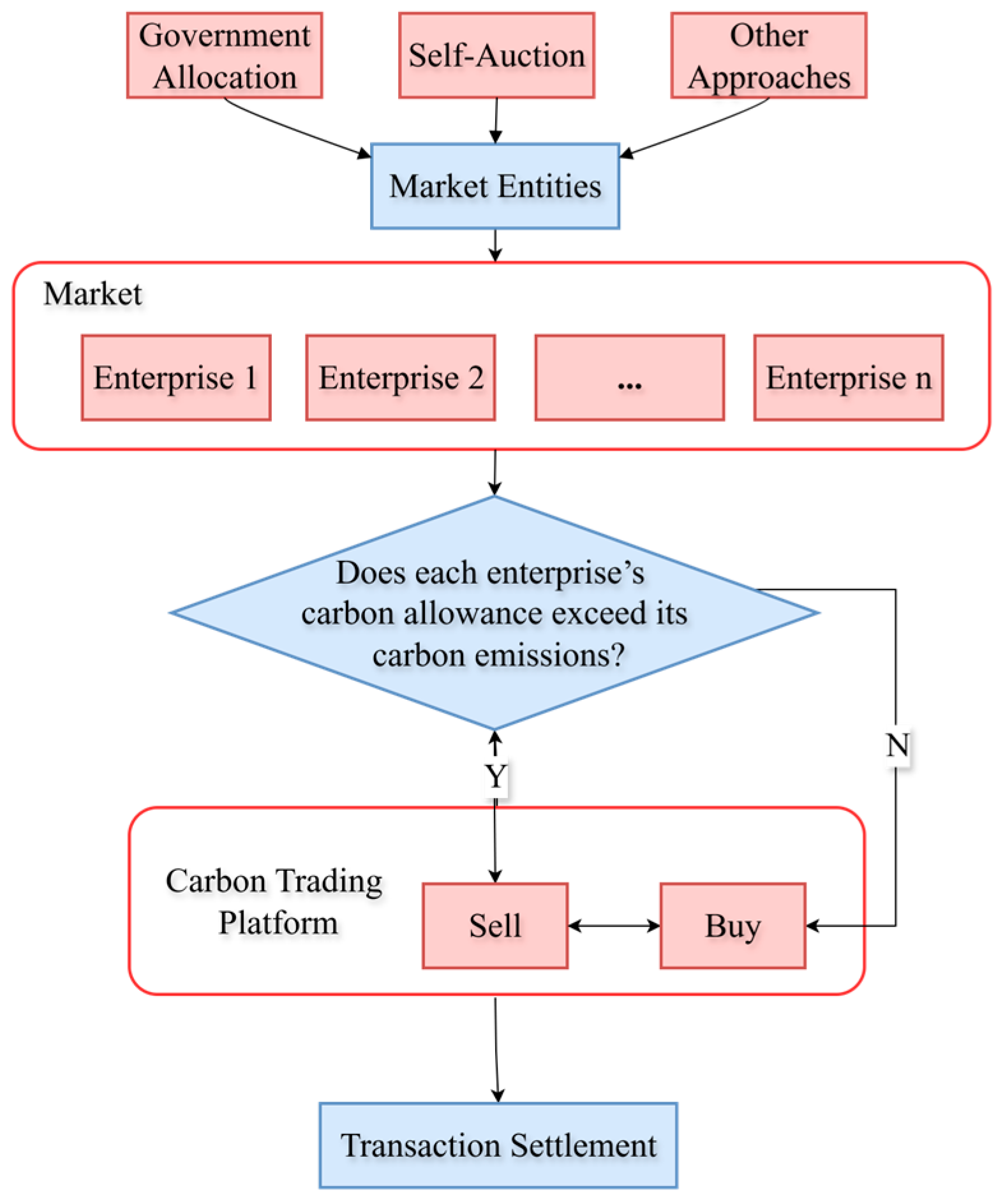

2.3. Carbon Trading Mechanism Modeling

The VPP optimizes energy utilization and reduces carbon emissions through the centralized management of distributed renewable resources such as solar and wind power, together with energy storage systems. In the carbon trading market, this emission reduction can be monetized as carbon credits or emission allowances, providing additional revenue for the VPP. Within this framework, the VPP acts as a flexible energy management platform that can freely trade emission rights in the carbon market. The overall process is illustrated in

Figure 2.

To reflect the low-carbon constraints of system operation, this study incorporates both carbon emission quotas and carbon cost terms into the scheduling model. The total carbon emissions of the VPP are defined as the sum of emissions from all individual devices:

where

is the carbon emission factor of device

, and

is its corresponding energy consumption.

When the total carbon emission exceeds the allocated carbon quota

, the VPP must purchase additional carbon allowances, and the corresponding carbon cost can be expressed as

where

denotes the carbon price coefficient.

This mechanism provides an economic incentive for the VPP to prioritize the dispatch of low-carbon energy sources, thereby achieving a coordinated balance between economic efficiency and environmental sustainability.

2.4. Objective Function and Constraints

The scheduling of a VPP requires a balance between economic efficiency, low-carbon operation, and market profitability. The comprehensive optimization objective constructed in this paper is formulated as

where

represents the energy operation cost,

denotes the carbon emission cost, and

is the market revenue. The coefficients

,

, and

are weighting factors reflecting the relative importance of each objective.

In particular, the term represents the carbon emission penalty associated with emissions from the CCPP, heat pump and other controllable devices, and is explicitly included in the total operating cost reported in the numerical results.

The main constraint conditions include the following:

where

denotes the total power output of dispatchable units (CCPP and other generators),

is the net power exchanged with the main grid,

is the electrical demand of the VPP, and

,

are the charging and discharging powers of the battery, respectively.

- 2.

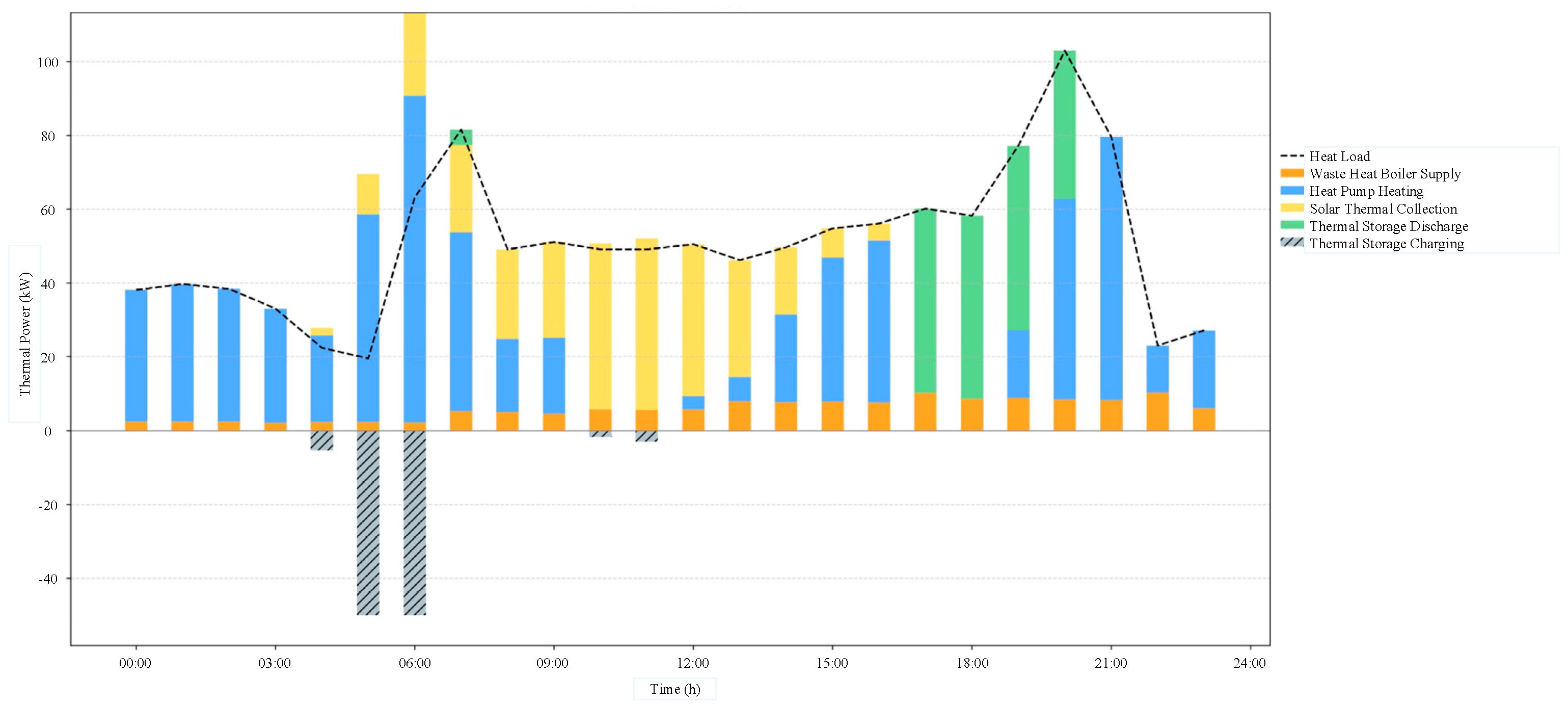

Thermal Balance

where

and

denote the heat outputs of the CCPP and the electric heat pump,

is the thermal demand, and

,

are the charging and discharging heat powers of the thermal storage tank.

- 3.

Device Boundary and Ramp Rate

where

is the output power of controllable unit

,

and

are its minimum and maximum operating limits, and

is the corresponding ramp-rate limit between consecutive time steps.

- 4.

Carbon Quota

where

denotes the total

emissions of the VPP at time

, and

is the allocated carbon emission quota in the carbon trading mechanism.

- 5.

Battery energy storage

The charging and discharging powers of the battery are bounded by

The state of charge (SOC) evolves according to

with the energy limits

where

and

denote the charging and discharging efficiencies of the battery, respectively.

- 6.

Thermal storage tank

The charging and discharging heat powers of the thermal storage tank satisfy

The stored thermal energy dynamics are

with the bounds

where

and

are the charging and discharging efficiencies of the thermal storage, respectively.

- 7.

Electric heat pump

The electrical input power of the heat pump is constrained by

The produced heat is related to the electrical input through the coefficient of performance (COP):

where

is usually bounded as

- 8.

Grid power trading

The power exchanged with the main grid is written as

where

and

denote the purchased and sold powers, respectively.

Their operating bounds are

In summary, the above model maintains conciseness while capturing the essential operational characteristics of the VPP. It establishes a solid foundation for developing a DRL-based scheduling algorithm that integrates both physical feasibility and economic efficiency.