1. Introduction

Municipal solid waste (MSW) management remains among the most pressing environmental, economic and social challenges in Europe, reflecting the combined pressures of increasing urbanization, changing consumption patterns, and the need to align with climate-neutrality objectives [

1]. The European Union (EU) has established an ambitious policy framework aimed at transforming waste from a liability into a valuable source of raw materials and energy [

2,

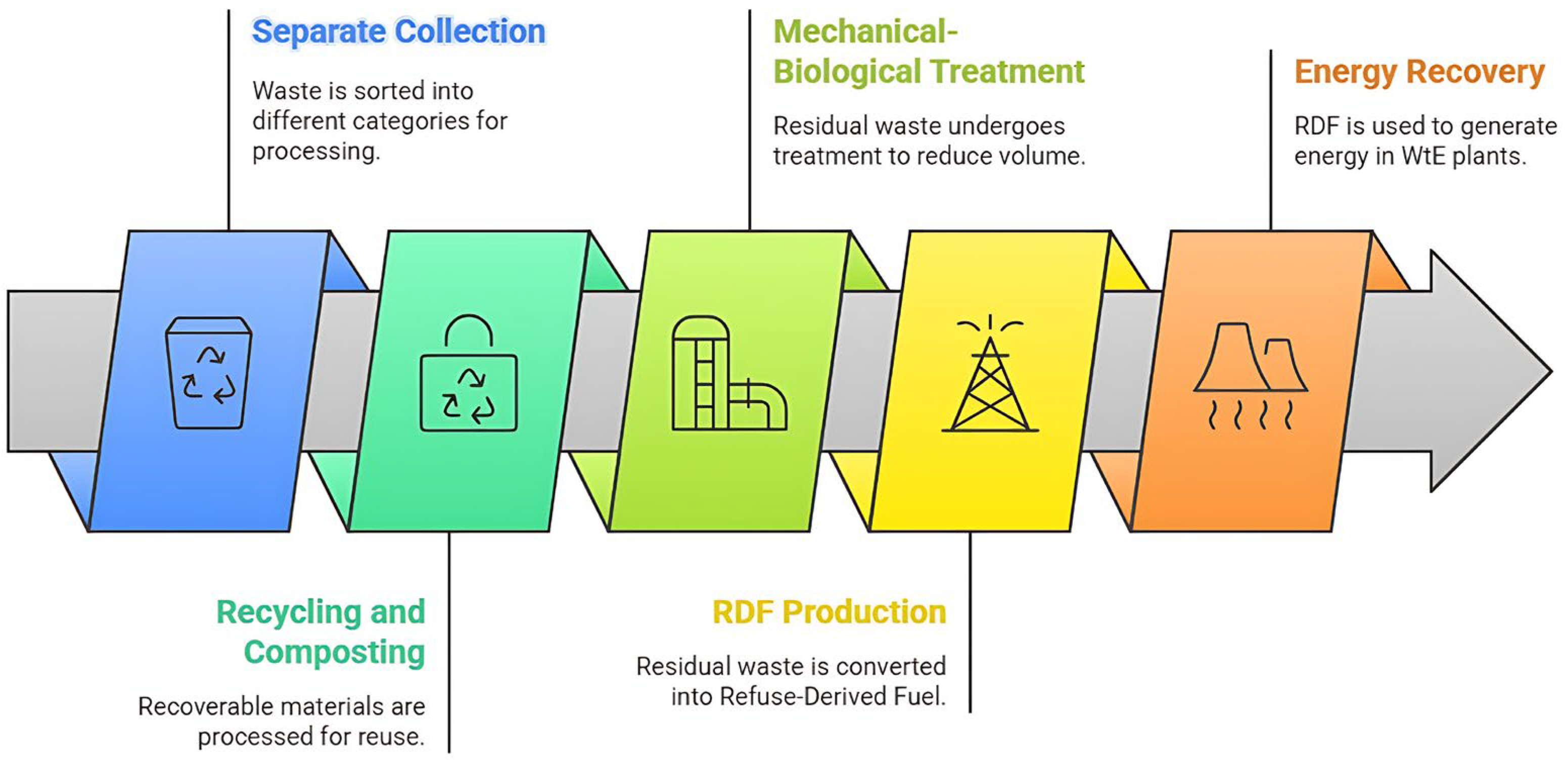

3]. Central to this framework is the implementation of the waste hierarchy (

Figure 1), which prioritizes prevention and minimization at source, followed by reuse, recycling, composting or anaerobic digestion and recovery. Recovery operations include energy recovery through Waste-to-Energy (WtE) systems that utilize Refuse-Derived Fuel (RDF), a standardized fuel produced from the non-recyclable combustible fractions of municipal waste after mechanical or mechanical–biological treatment in Recovery and Recycling Facilities (RRFs) [

4]. Finally, disposal (landfilling or incineration without energy recovery) constitutes the last and least preferred option [

5,

6].

The persistent rise in municipal waste generation, coupled with projections indicating continued growth even under optimistic recycling scenarios, underscores a structural challenge in current waste governance. As long as waste generation trajectories remain uncoupled from recycling progress, even ambitious 2025–2030 recycling targets risk being insufficient to curtail residual waste to desired levels. This tension between growing waste flows and the finite capacities of recycling systems makes it clear that technical end-of-pipe improvements alone cannot deliver the systemic reductions needed [

7,

8,

9].

Figure 1.

EU waste hierarchy scheme [

10].

Figure 1.

EU waste hierarchy scheme [

10].

The waste hierarchy, institutionalized in the EU Waste Framework Directive and widely adopted internationally, establishes a graded prioritization of waste management options based on their overall environmental desirability. Its overarching logic is straightforward: the highest sustainability outcomes stem from avoiding waste altogether, while the lowest result from uncontrolled disposal. Over time, this framework has evolved from a narrow “3R” conception to a multi-layered model integrating prevention, reuse, recycling, recovery, and disposal, reflecting both technological advancements and the broader transition toward circular economy systems [

11].

At its core, the waste hierarchy reflects the principle that the most environmentally beneficial waste is the waste that is never generated. This top tier—waste prevention—encompasses design, consumption, and policy interventions that minimize material throughput. Recent scholarship underscores that, although waste prevention is the most environmentally beneficial option, it is also the most challenging to implement, requiring cross-sector coordination, product redesign, behavioral change, and new business models [

12].

Below prevention, the hierarchy emphasizes preparation for reuse and reuse. These stages extend product lifetimes through repair, refurbishment, and secondary use. Reuse is materially efficient and energy-saving, but it hinges on system-level conditions such as product durability, reverse-logistics infrastructure, and service-oriented consumption models.

Recycling, positioned at the mid-level, aims to reintroduce materials into productive loops. While recycling has been a dominant focus of municipal waste management for decades, it is now widely recognized that recycling alone cannot counterbalance rising waste generation, partly because recycling requires energy and often leads to downcycled outputs with limited material value [

7,

13].

Energy recovery constitutes a lower tier, capturing residual calorific value through controlled incineration or anaerobic digestion. Although preferable to landfilling, its environmental benefits are circumscribed, and it risks locking cities into disposal-oriented infrastructures that disincentivize prevention.

Finally, landfilling and open dumping represent the least desirable outcomes, associated with long-term ecological burdens, climate-intensive emissions, and significant public-health risks—challenges that continue to affect both high-income and low-income regions globally [

11,

14].

An important conceptual development in recent years is the integration of waste hierarchy principles with circular economy (CE) frameworks. While the hierarchy provides a sequence of preferred waste management options, CE expands this into a systemic vision in which waste prevention, resource efficiency, and material recirculation are embedded across production, consumption, and end-of-life stages. The synergy of these frameworks clarifies that the hierarchy is not merely a disposal guideline but a governance tool that shapes how products are designed, how consumption unfolds, and how material loops are closed at scale. CE-oriented innovations—eco-design, material substitution, product-service systems, and high-value recycling—strengthen the upper tiers of the hierarchy, ensuring that waste management becomes aligned with holistic resource governance [

9,

11].

Insights from zero-waste scholarship further reinforce the environmental and socio-economic rationale for privileging the upper tiers. Zero-waste frameworks argue that waste is not an inevitable by-product of economic activity but a symptom of inefficient systems [

13,

15]. Accordingly, waste prevention and reuse address root causes rather than symptoms, generating benefits that cascade across climate mitigation, resource conservation, and urban sustainability. They also generate employment in repair, remanufacturing, and refurbishment sectors, while reducing dependency on raw materials and waste-intensive supply chains.

Importantly, empirical analyses show that regions most successful in implementing the hierarchy—particularly in construction, packaging, and municipal waste streams—combine stringent policy frameworks with high stakeholder engagement, data transparency, and technological innovation. This reinforces the view that hierarchy compliance is not merely a technical challenge but an institutional one.

Positioning the waste hierarchy at the center of municipal waste governance has direct implications for the design of integrated waste management systems. It necessitates a rebalancing of policy attention and investment: shifting from downstream treatment capacities toward upstream measures targeting product design, consumption patterns, and circular business models. It also requires embracing multi-stakeholder collaboration, as highlighted by global comparative research, which shows that successful systems rely on cooperation between governments, producers, municipalities, informal sectors, and citizens [

14].

In this sense, the waste hierarchy is not an isolated conceptual model but a strategic foundation for the broader transition toward sustainable waste management. The hierarchy provides normative direction, while integrated waste management systems operationalize it through infrastructure, policy instruments, and economic incentives.

Recent analyses demonstrate that the integration of energy recovery technologies, when applied within a circular economy approach, can significantly contribute to decarbonization efforts, resource efficiency, and reduced environmental impacts [

5,

16]. However, disparities persist among Member States in achieving recycling and recovery targets, indicating the need for further innovation, decentralized waste treatment systems, and harmonized policy implementation [

17].

The EU’s legal framework for MSW is built primarily around the Waste Framework Directive (2008/98/EC, revised), the Landfill Directive (1999/31/EC, amended 2018/850), and specific directives on packaging waste, biodegradable waste, extended producer responsibility (EPR), and separate collection. Under these, legally binding targets compel Member States to increase recycling/preparing for reuse rates of municipal waste progressively: 55% by 2025, 60% by 2030, and 65% by 2035. Simultaneously, the share of MSW sent to landfill is to be reduced to no more than 10% by 2035. Member States, like Greece, with historically high landfill rates in 2013 may have temporary derogations, but the trend is clear.

The revised Landfill Directive also imposes limits on the landfilling of biodegradable waste, such as caps expressed as percentages relative to baseline years, in order to reduce methane emissions and leachate generation. Legislative push is also strong for the separate collection of organics, textiles, packaging materials, and e-waste. The Packaging & Packaging Waste Regulation has introduced measures to improve the recyclability of packaging, set reuse and refill targets, require recycled content, and reduce overpackaging [

18].

Figure 2 shows that the EU has made respectable progress, although not uniformly across Member States. As of 2022, the average MSW recycling rate in EU-27 is approximately 48.6%, just under the 50% mark. For packaging waste, the EU average recycling rate is around 64%, although differing by material: paper/cardboard and glass are generally high, whereas plastics lag behind [

19]. Many Member States are “at risk” of missing the 2025 targets: combinations of the municipal waste recycling/preparing for reuse target (55%) and the packaging waste target (65%) are not yet assured in several states. Countries at particular risk include those with low infrastructure, high reliance on landfill, or challenges in separate collection systems [

20]. Trends in waste generation also pose challenges: projections indicate that total municipal waste generation may increase unless changes in consumption, waste prevention and circular product design are implemented. Even achieving the 2025–2030 recycling targets might not be sufficient to reduce residual waste (which remains after recycling & reuse) to the levels desired, unless waste generation is also curbed.

Across the European Union, MSW management follows a harmonized framework structured around the waste hierarchy. Thus, waste streams that cannot be feasibly recycled or reused are directed towards recovery pathways, where they are treated, sorted, and processed into, amongst other streams, alternative fuels. This process represents the final stage of material valorization before final disposal. In practice, mixed residual waste undergoes mechanical and biological treatment (MBT) or similar pre-treatment processes in Resource Recovery Facilities (RRFs) that separate recyclable fractions, remove inert and non-combustible materials, and refine the remaining combustible fraction into Refuse Derived Fuel (RDF). RDF is therefore the product of a systematic European waste management scheme that aims to maximize material recovery while minimizing landfill dependency and greenhouse gas emissions. The common pathway can be summarized as: separate collection → recycling and composting of recoverable materials → mechanical–biological or mechanical–thermal treatment of residual waste → RDF production → energy recovery through Waste-to-Energy (WtE) plants or co-incineration in industrial facilities (

Figure 3).

RDF and WtE technologies constitute a cornerstone of the European Union’s strategy for managing residual waste that cannot be feasibly reintroduced into material recycling loops [

1,

5]. RDF enables the recovery of embedded energy from non-recyclable fractions of MSW, provided that the fuel produced meets specific standards for calorific value, moisture, and contaminant levels [

4,

22]. Once refined, RDF can be valorized through dedicated WtE plants or co-incinerated in energy-intensive industrial processes such as cement kilns, where it substitutes fossil fuels and supports industrial decarbonization efforts [

23,

24]. These applications are generally recognized as environmentally preferable to landfilling, due to their potential for partial greenhouse gas mitigation, controlled emissions, and reduced leachate generation, particularly when high-efficiency energy recovery systems and advanced flue-gas cleaning technologies are deployed [

5,

25]. The energy recovered from WtE operations can be converted into electricity and thermal energy for district heating/cooling networks, thereby enhancing local energy security and supporting the EU’s transition toward a low-carbon, circular economy [

16].

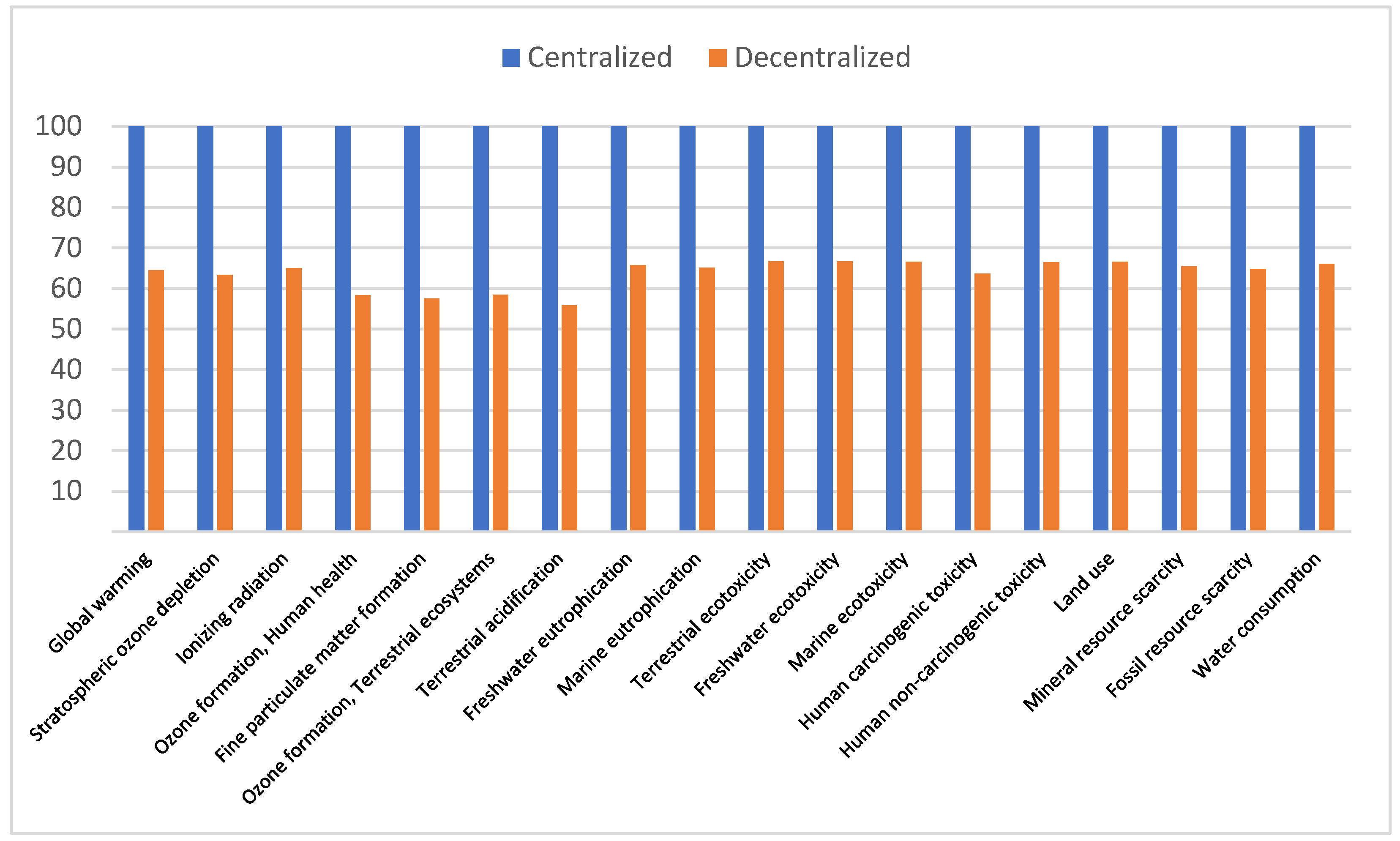

However, the environmental and economic performance of the RDF and WtE chain depends heavily on upstream processes, including the efficiency of waste collection, the level of source separation, and the effectiveness of sorting and preprocessing technologies [

26,

27]. Among these factors, transportation logistics exert a decisive influence: extended hauling distances for either unsorted MSW or pre-processed RDF can substantially increase greenhouse gas (GHG) emissions, thereby offsetting part of the environmental benefits achieved through energy recovery [

27,

28]. While large-scale, centralized WtE facilities generally achieve higher thermal efficiencies [

29,

30], their operation often entails long-distance waste transport and higher associated fuel, GHG emissions (specifically Scope 2 emissions that account for indirect GHG emissions from fuel combustion occurring during waste transport and preprocessing) and infrastructure costs. Conversely, decentralized or regionally distributed treatment facilities, strategically sited near the RRFs, can minimize transport-related GHG emissions and improve integration with local recycling networks. Moreover, recent technological developments lead to reduction of investment costs per unit of capacity, and full compliance with emission performance of smaller decentralized WtE plants. This improvement results from continuous technological advances in modular gasification, small-scale incineration, and emission-control systems, which have mitigated many of the limitations traditionally associated with smaller WtE plants [

28].

Although large centralized WtE facilities are often assumed to yield superior thermal efficiency, evidence suggests that small-scale or modular systems, when properly engineered, can approach comparable performance while achieving lower local environmental impact and full compliance with emissions standards. In real-world application, the case study in Northern Italy finds that a well-operated WtE plant’s contribution to local air pollution is orders of magnitude lower than major urban sources like road traffic, indicating that even “smaller scale” plants with proper controls can have negligible environmental burden [

28]. Moreover, life-cycle assessments show that with optimal design (including heat recovery, emissions control, and possible carbon capture), even moderately scaled WtE systems can yield favorable climate outcomes [

31].

Studies consistently show that the carbon footprint of RDF systems is dominated by fuel combustion from collection and long-haul transport activities, with transport often representing the single largest contributor to GHG impacts in RDF supply chains [

32,

33]. EU-level guidance similarly stresses the importance of minimizing logistics distances in RDF/SRF management due to both climate and cost penalties associated with long transport corridors [

34].

LCA evidence show that beyond certain transport thresholds, the emissions from vehicle fuel use and the electricity-intensive SRF/RDF preprocessing chain outweigh the benefits of high-efficiency thermal treatment, effectively eroding or even reversing the net climate advantage of centralized WtE systems [

35,

36]. Conversely, decentralized systems, when optimized for logistics and waste composition, may yield lower per-ton environmental burdens despite operating at smaller scales. Similar findings in decentralized wastewater and resource-recovery systems show that distributing treatment capacity closer to generation points can significantly reduce per-ton impacts by minimizing transport intensity and enabling higher alignment between waste composition and treatment technology [

37]. In the context of RDF, decentralized deployment similarly supports logistics optimization and enhances the circular use of locally generated resources [

38]. The optimal configuration for RDF and WtE therefore lies in balancing efficiency, logistics, and spatial distribution of energy recovery plants within each national or regional context [

38]. This underscores that plant siting and transport optimization are key parameters in designing sustainable WtE systems consistent with the proximity and self-sufficiency principles embedded in the EU Circular Economy Action Plan, which urges Member States to reduce transport-related environmental burdens and establish territorially optimized waste and resource management infrastructures that support Green Deal climate objectives [

39]. Collectively, these studies underline that spatial configuration—not only plant-scale efficiency—governs the environmental performance of RDF-to-energy chains. As a result, transport minimization and regionalized siting are increasingly recognized as essential criteria for sustainable WtE planning in EU policy and investment frameworks.

Within this context, Member States face a strategic choice: pursue centralized large WtE/RDF hubs—concentrated capacity with longer transport routes—or adopt decentralized networks of smaller plants co-located with RDF preparation facilities (i.e., RRFs), characterized by shorter transport distances but more dispersed infrastructure. Each choice carries inherent trade-offs. Centralized, larger WtE plants typically achieve higher thermal efficiencies and can justify the use of sophisticated emission control technologies [

40]. However, they also concentrate waste transport flows, potentially increasing truck-kilometers and associated emissions [

41]. Decentralized, smaller WtE variants, on the other hand, can reduce haulage distances and integrate more effectively with local recycling RRFs, often improving social acceptance and system resilience [

38]. Nonetheless, they may face challenges such as reduced economies of scale and higher unit capital or operational expenditures although this is improved nowadays due to important technological advances and know-how during development of smaller WtE units. Therefore, assessing these trade-offs requires a life-cycle perspective that considers not only GHG emissions generated by the WtE plant but also Scope 2 emissions related to upstream collection, preprocessing, transport, and RDF production [

39].

Given the above context, plant siting and transportation distances are not peripheral considerations but central determinants of environmental sustainability in RDF and WtE systems [

42]. Their importance is underscored by the transport-related GHG emissions associated with heavy-duty vehicle (HDV) fleets—strongly influenced by fuel type, load factor, distance, and road conditions [

43]—and by the energy demands of preprocessing operations such as sorting, drying, and shredding, which vary with waste composition, moisture content, and residual waste quality. The trade-off between economies of scale achieved in centralized WtE plants and the penalties of long transport distances and higher vehicle GHG emissions remains a key design challenge [

44]. Moreover, the spatial distribution of infrastructure can influence social acceptance, local environmental impacts (noise, traffic, and emissions), and regional disparities in environmental burdens or costs. Consequently, sustainability assessments that omit or oversimplify these spatial and logistical factors risk overestimating the environmental benefits of centralized WtE systems or failing to identify optimal configurations that minimize total life-cycle impacts.

Despite substantial progress in the evaluation of Waste-to-Energy systems, important knowledge gaps remain regarding how national geography, transport logistics, and facility scale jointly influence the sustainability of RDF management. Existing LCAs often treat WtE infrastructure as spatially neutral, overlooking the way that transport intensity, vehicle characteristics, and siting patterns shape greenhouse gas emissions, operational costs, and wider environmental burdens. This omission is particularly significant in Greece, where long road corridors, island regions, and extensive maritime links create spatial conditions that fundamentally alter the performance of centralized waste systems. Addressing these gaps requires an assessment framework capable of examining how alternative siting configurations modify transport-related emissions, how changes in transport demand affect system-wide economic efficiency, and how shifts in spatial layout influence impacts beyond climate change. The present study adopts this perspective by integrating spatial planning principles into a national-scale LCA of centralized and decentralized RDF-to-energy scenarios, with the objective of clarifying how infrastructure geography can support a more coherent alignment between waste-system design, circular-economy goals, and long-term climate commitments.

2. Case Study: Greece

Greece presents a compelling case for evaluating integrated solid waste management (ISWM) systems incorporating WtE technologies due to its persistent reliance on landfilling, regional disparities in waste infrastructure, and the national drive to meet EU environmental targets [

45]. Historically, the country has faced significant challenges in diverting MSW from landfills, with over 75% of waste still being disposed of through landfilling as of 2022 [

46]. Despite gradual improvements in recycling and composting, Greece remains among the lowest performers in waste recovery rates within the European Union and still suffers from the enforcement of large penalties from the European Commission for non-performance.

The national waste generation rate averages 1.45 kg/capita/day, corresponding to approximately 5.4 million tons of MSW annually [

47]. Waste generation is highest in the Attica region—which includes the metropolitan area of Athens—and in Central Macedonia, which together account for nearly half of the total waste produced nationwide [

48]. The composition of MSW in Greece is dominated by biodegradable organic waste (≈44%), followed by paper and cardboard (20%), plastics (17%), glass (5%), metals (3%), and other residues (11%) [

49]. The high organic and plastic fractions indicate strong potential for both biological and thermal recovery pathways, especially in the non-recycled residues of the RRFs.

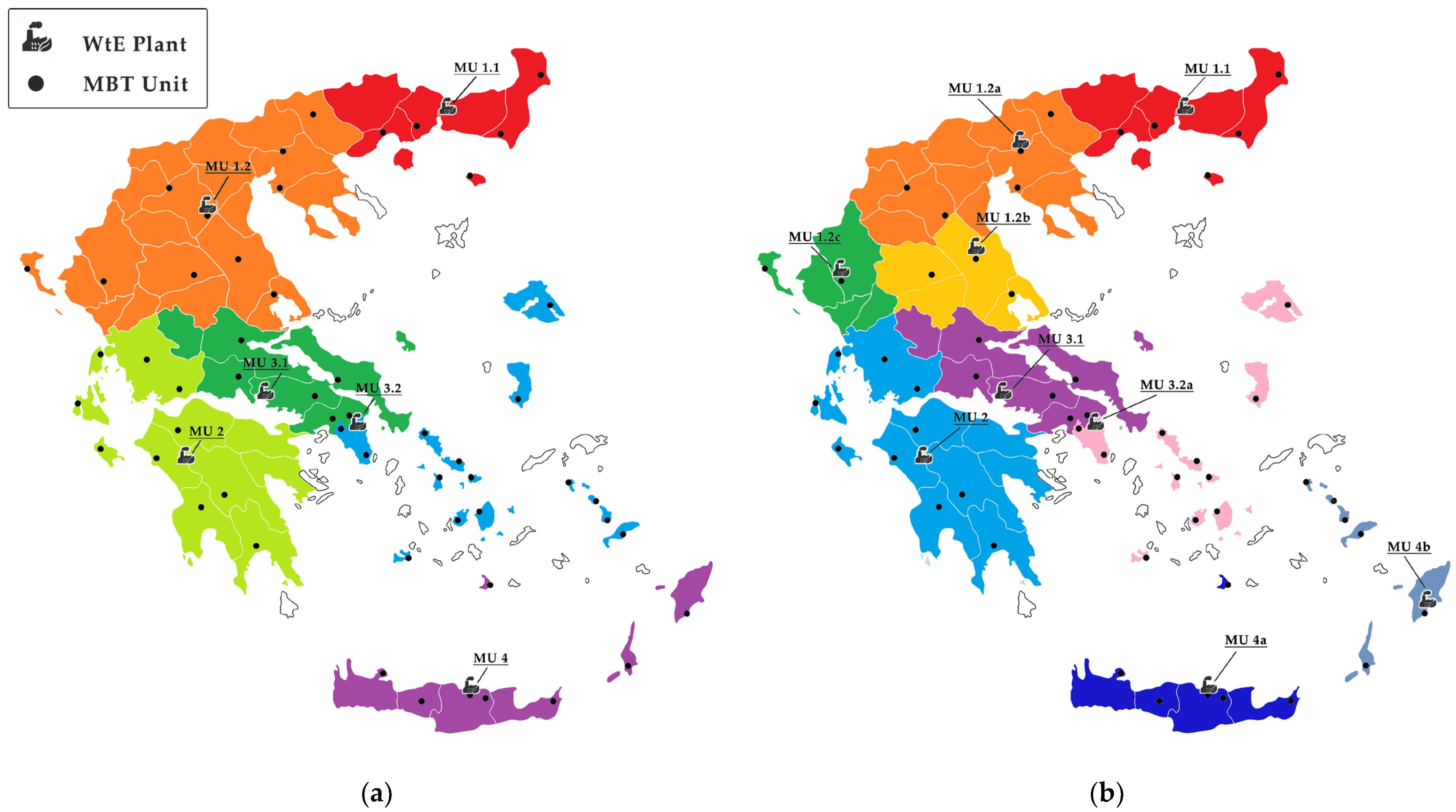

In alignment with the National Waste Management Plan (NWMP 2020–2030) and the Circular Economy Action Plan, Greece aims to reduce landfilling to below 10% of total waste by 2030 and to achieve 55% recycling of municipal waste by 2025, in compliance with EU Directive 2018/851. To achieve these objectives, the Greek government has introduced new waste valorization infrastructure through public–private partnerships (PPPs) and EU Cohesion Fund-supported projects, including the construction of MBT plants, anaerobic digestion (AD) units, and thermal valorization facilities (WtE plants) [

50].

However, current energy and waste management frameworks remain constrained by high dependence on imported fossil fuels and uneven regional infrastructure. Approximately 65% of the country’s electricity is still generated from natural gas and petroleum derivatives, while renewable sources—mainly wind and solar—account for the remaining 35% [

51]. Although Greece has made substantial progress in renewables deployment, seasonal demand fluctuations and grid limitations create opportunities for WtE plants to provide stable, dispatchable energy while simultaneously diverting waste from landfills.

Recent environmental and political developments have accelerated national discussions on WtE deployment. The Integrated Waste Management Plan for Attica foresees the establishment of a large-scale WtE plant with a processing capacity of approximately 350,000 tons/year, intended to serve as the final treatment option for residual waste following separation and recycling [

52]. Parallel projects have been proposed for Central Macedonia and Western Greece, focusing on RDF and SRF (Solid Recovered Fuel) utilization in co-processing facilities or dedicated incineration units. Such initiatives aim to reduce the significant volume of RDF currently transported to cement kilns or exported abroad, which contributes to high transport-related emissions and logistical costs.

The waste composition and quantities for Greece are summarized in

Table 1, illustrating the predominance of organics and recyclable materials within the total waste stream.

The existing waste management model in Greece (business-as-usual, BAU scenario) consists of mixed-waste collection followed by landfill disposal, with limited pre-treatment or energy recovery. There are several MBT or waste treatment units in Greece, some operational, some under construction, which produce limited RDF/SRF streams. However, none of them includes integrated energy recovery, and the majority of the RDF/SRF generated is co-incinerated in cement kilns or exported. Current MBT capacity (≈0.8 million t/year) covers only about 30% of the target set in the National Waste Management Plan [

52]. This results in increased greenhouse gas (GHG) emissions from transportation and underutilization of local energy potential.

The waste sector in Greece contributes approximately 7.97% of total national emissions [

53]. Most of these GHG emissions originate from methane released by unmanaged or semi-controlled landfills. Implementation of advanced WtE systems—particularly when integrated with pre-sorting, material recovery, and AD units—can potentially reduce GHG emissions by 40–60% relative to baseline scenarios, while generating renewable energy from the biogenic fraction of RDF.

Given its geographical configuration, Greece also faces unique logistical challenges in waste transportation. Many of its islands and remote mainland areas experience high per-unit transport costs for RDF and SRF, often exceeding the environmental benefits of centralized processing. The spatial distribution of WtE plants, therefore, is a key factor influencing both environmental and economic performance.

The case of Greece exemplifies a Southern European context where regulatory reforms, circular economy objectives, and decarbonization commitments intersect with persistent operational inefficiencies and infrastructural gaps. Applying the proposed ISWM–LCA framework allows for a comprehensive evaluation of how the deployment and spatial optimization of WtE facilities can enhance national resource efficiency, reduce landfill dependency, and align Greece with the EU’s Green Deal objectives for 2050.