Biogas Production from Sargassum Collected from a Coast of the Gulf of Mexico Using Ruminal Fluid as Inoculum

Abstract

1. Introduction

2. Materials and Methods

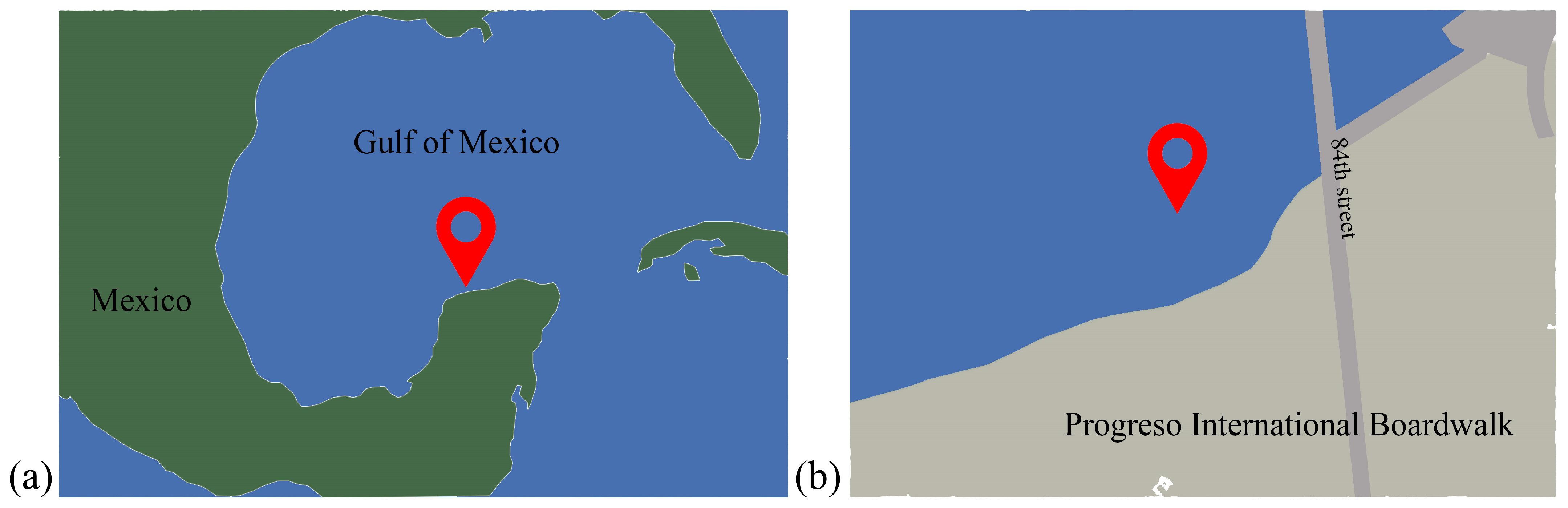

2.1. Sample Collection and Preparation

2.2. Characterization of Substrate and Inoculum

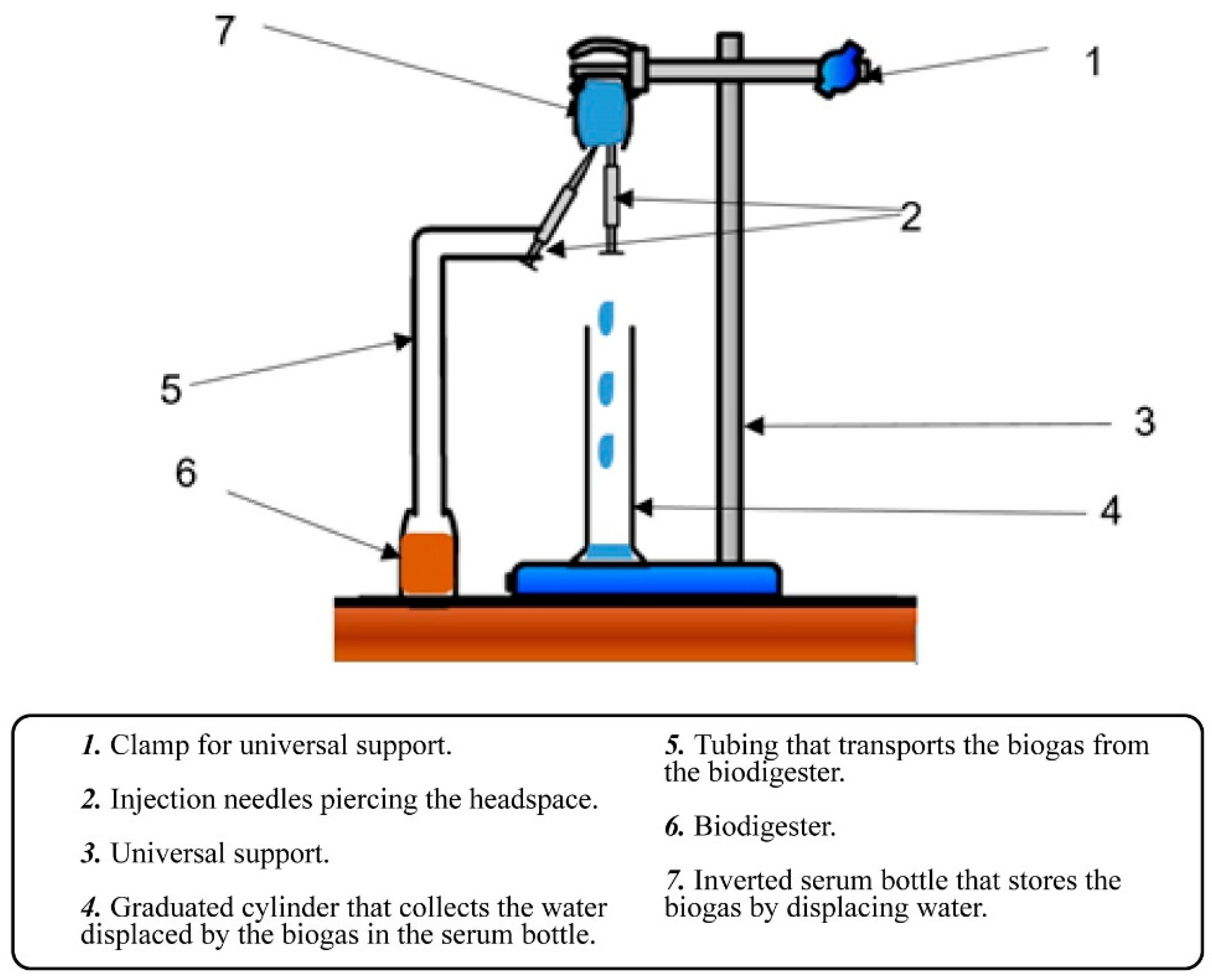

2.3. Experimental Setup

2.4. Validation of the Study

Positive and Negative Control

2.5. Experiment Design

2.6. Statistical Analysis

2.7. Data Analysis

3. Results and Discussion

3.1. Results of the Characterization of the Substrate and the Inoculum

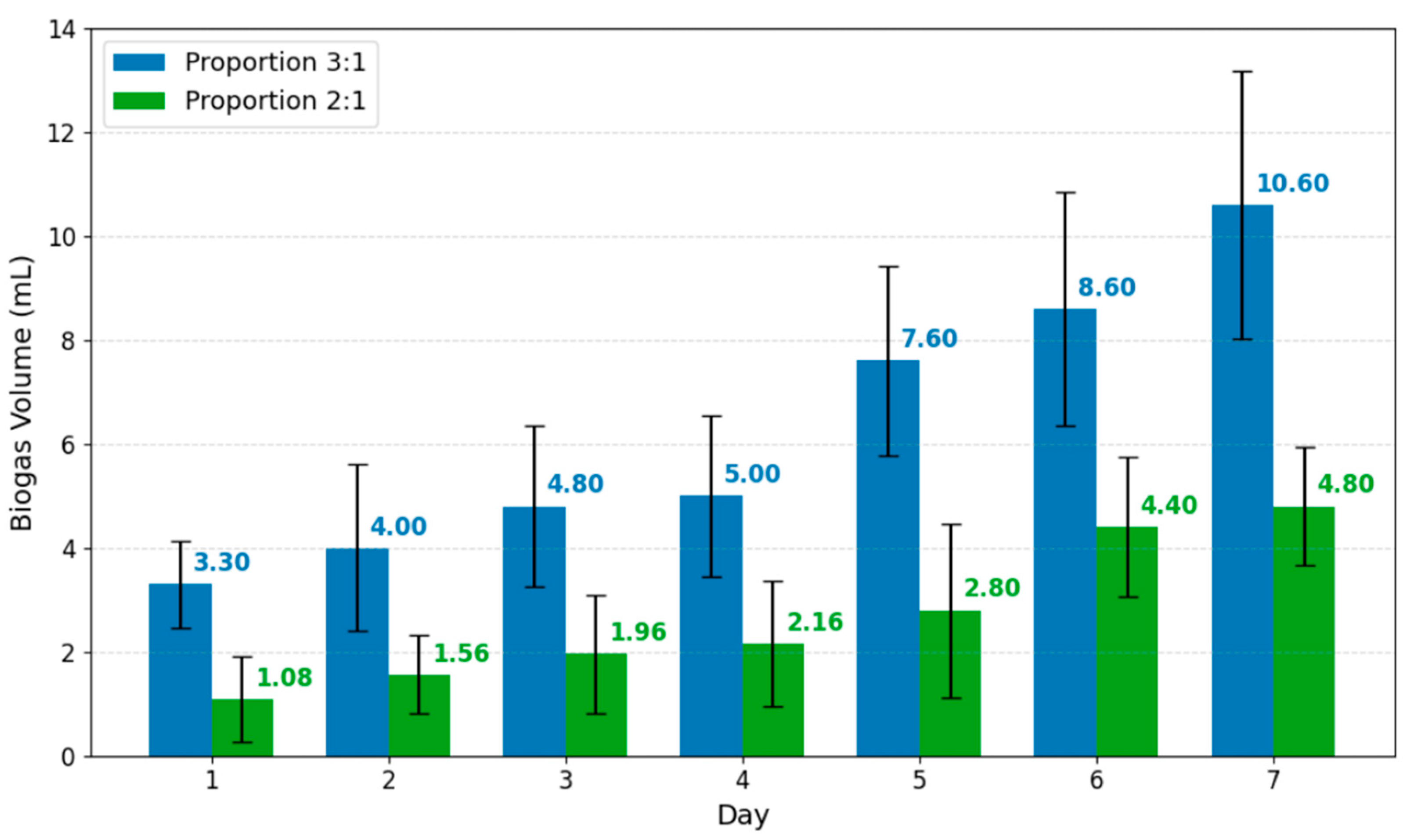

3.2. Anaerobic Digestion of Sargassum

3.3. Estimation of Biogas Composition

3.4. Prospects for the Use of Sargassum in Co-Digestion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Álvarez-Ley, J.E.; Méndez-Novelo, R.I.; Giácoman-Vallejos, G.; Paniagua Solar, L.A.; San-Pedro, L. Microbial Fuel Cells for Power Generation and Wastewater Treatment: A Review of Components, Performance and Sustainability. Int. J. Hydrogen Energy 2025, 137, 429–447. [Google Scholar] [CrossRef]

- Rial, R.C. Biofuels versus Climate Change: Exploring Potentials and Challenges in the Energy Transition. Renew. Sustain. Energy Rev. 2024, 196, 114369. [Google Scholar] [CrossRef]

- San-Pedro, L.; Coronado-Cauich, M.J.; Hernández-Núñez, E.; González-Díaz, M.O.; Álvarez-Ley, J.E.; Flota-Bañuelos, M.I. Electrochemical Characterization of a Testaceous Membrane (Chicken Eggshell) For Use in Fuel Cells. J. Membr. Sci. Res. 2024, 10, 2004886. [Google Scholar] [CrossRef]

- Dalbanjan, N.P.; Korgaonkar, K.; Kadapure, A.J.; Halladamani, S.B.; Ramangouda, G.; Kumar, S.K.P. Green Energy from Waste: Evaluating the Sustainability of Anaerobic Biofuel Technologies. Microbe 2025, 7, 100410. [Google Scholar] [CrossRef]

- Asaad, S.M.; Tawalbeh, M.; Ali, A.; Al Kindi, S.R.; Al-Othman, A. Definition of Bioenergy. In Renewable Energy—Volume 2: Wave, Geothermal, and Bioenergy; Elsevier: Amsterdam, The Netherlands, 2024; pp. 215–243. [Google Scholar]

- Sher, F.; Smječanin, N.; Hrnjić, H.; Karadža, A.; Omanović, R.; Šehović, E.; Sulejmanović, J. Emerging Technologies for Biogas Production: A Critical Review on Recent Progress, Challenges and Future Perspectives. Process Saf. Environ. Prot. 2024, 188, 834–859. [Google Scholar] [CrossRef]

- Ngabala, F.J.; Emmanuel, J.K. Potential Substrates for Biogas Production through Anaerobic Digestion—An Alternative Energy Source. Heliyon 2024, 10, e40632. [Google Scholar] [CrossRef] [PubMed]

- Kabeyi, M.J.B.; Olanrewaju, O.A. Biogas Production and Applications in the Sustainable Energy Transition. J. Energy 2022, 2022, 8750221. [Google Scholar] [CrossRef]

- Biswas, R.; Ahmadi, V.; Ummethala, R.; Mozumder, M.S.I.; Aryal, N. Recent Advances in Electrochemical Carbon Dioxide Reduction Strategies in Biogas Upgrading and Biomethane Production. Chem. Eng. J. Adv. 2025, 22, 100722. [Google Scholar] [CrossRef]

- Tjutju, N.A.S.; Ammenberg, J.; Lindfors, A. Biogas Potential Studies: A Review of Their Scope, Approach, and Relevance. Renew. Sustain. Energy Rev. 2024, 201, 114631. [Google Scholar] [CrossRef]

- Wang, K.; Khoo, K.S.; Chew, K.W.; Selvarajoo, A.; Chen, W.H.; Chang, J.S.; Show, P.L. Microalgae: The Future Supply House of Biohydrogen and Biogas. Front. Energy Res. 2021, 9, 660399. [Google Scholar] [CrossRef]

- Duran, A.J.F.P.; Lyra, G.P.; Campos Filho, L.E.; Bueno, C.; Rossignolo, J.A.; Alves-Lima, C.; Fiorelli, J. The Use of Sargasso Seaweed as Lignocellulosic Material for Particleboards: Technical Viability and Life Cycle Assessment. Buildings 2024, 14, 1403. [Google Scholar] [CrossRef]

- Debue, M.; Guinaldo, T.; Jouanno, J.; Chami, M.; Barbier, S.; Berline, L.; Chevalier, C.; Daniel, P.; Daniel, W.; Descloitres, J.; et al. Understanding the Sargassum Phenomenon in the Tropical Atlantic Ocean: From Satellite Monitoring to Stranding Forecast. Mar. Pollut. Bull. 2025, 216, 117923. [Google Scholar] [CrossRef]

- Thompson, T.M.; Young, B.R.; Baroutian, S. Advances in the Pretreatment of Brown Macroalgae for Biogas Production. Fuel Process. Technol. 2019, 195, 106151. [Google Scholar] [CrossRef]

- Johns, E.M.; Lumpkin, R.; Putman, N.F.; Smith, R.H.; Muller-Karger, F.E.; Rueda-Roa, D.T.; Hu, C.; Wang, M.; Brooks, M.T.; Gramer, L.J.; et al. The Establishment of a Pelagic Sargassum Population in the Tropical Atlantic: Biological Consequences of a Basin-Scale Long Distance Dispersal Event. Prog. Ocean. 2020, 182, 102269. [Google Scholar] [CrossRef]

- Orozco-González, J.G.; Amador-Castro, F.; Gordillo-Sierra, A.R.; García-Cayuela, T.; Alper, H.S.; Carrillo-Nieves, D. Opportunities Surrounding the Use of Sargassum Biomass as Precursor of Biogas, Bioethanol, and Biodiesel Production. Front. Mar. Sci. 2022, 8, 791054. [Google Scholar] [CrossRef]

- Davis, D.; Simister, R.; Campbell, S.; Marston, M.; Bose, S.; McQueen-Mason, S.J.; Gomez, L.D.; Gallimore, W.A.; Tonon, T. Biomass Composition of the Golden Tide Pelagic Seaweeds Sargassum fluitans and S. Natans (Morphotypes I and VIII) to Inform Valorisation Pathways. Sci. Total Environ. 2021, 762, 143134. [Google Scholar] [CrossRef]

- Thompson, T.M.; Young, B.R.; Baroutian, S. Enhancing Biogas Production from Caribbean Pelagic Sargassum Utilising Hydrothermal Pretreatment and Anaerobic Co-Digestion with Food Waste. Chemosphere 2021, 275, 130035. [Google Scholar] [CrossRef]

- Thompson, T.M.; Young, B.R.; Baroutian, S. Efficiency of Hydrothermal Pretreatment on the Anaerobic Digestion of Pelagic Sargassum for Biogas and Fertiliser Recovery. Fuel 2020, 279, 118527. [Google Scholar] [CrossRef]

- Zaidi, A.A.; Khan, S.Z.; Shi, Y. Optimization of Nickel Nanoparticles Concentration for Biogas Enhancement from Green Algae Anaerobic Digestion. Mater. Today Proc. 2019, 39, 1025–1028. [Google Scholar] [CrossRef]

- Castro, Y.A.; Rodríguez, A.; Rivera, E. Biomethane Production Kinetics during the Anaerobic Co-Digestion of Sargassum spp. and Food Waste Using Batch and Fed-Batch Systems in Punta Cana, Dominican Republic. Mater. Renew. Sustain. Energy 2022, 11, 287–297. [Google Scholar] [CrossRef]

- Chellapandi, P.; Bharathi, M.; Sangavai, C.; Prathiviraj, R. Methanobacterium formicicum as a Target Rumen Methanogen for the Development of New Methane Mitigation Interventions: A Review. Vet. Anim. Sci. 2018, 6, 86–94. [Google Scholar] [CrossRef]

- Orhorhoro, E.K.; Oghoghorie, O. Enhancing Biogas Yield through Anaerobic Co-Digestion of Animal Manure and Seaweed. Prog. Energy Environ. 2024, 28, 1–22. [Google Scholar] [CrossRef]

- Aparicio, E.; Rodríguez-Jasso, R.M.; Pinales-Márquez, C.D.; Loredo-Treviño, A.; Robledo-Olivo, A.; Aguilar, C.N.; Kostas, E.T.; Ruiz, H.A. High-Pressure Technology for Sargassum spp. Biomass Pretreatment and Fractionation in the Third Generation of Bioethanol Production. Bioresour. Technol. 2021, 329, 124935. [Google Scholar] [CrossRef] [PubMed]

- Chikani-Cabrera, K.D.; Fernandes, P.M.B.; Tapia-Tussell, R.; Parra-Ortiz, D.L.; Hernández-Zárate, G.; Valdez-Ojeda, R.; Alzate-Gaviria, L. Improvement in Methane Production from Pelagic Sargassum Using Combined Pretreatments. Life 2022, 12, 1214. [Google Scholar] [CrossRef] [PubMed]

- Paletta, R.; Girimonte, R.; Castro, Y.A.; De Frias, J.A.; Calabrò, V. Effect of Particle Size on the Biomethanation Kinetics of Mechanically Pretreated Sargassum spp. Biomass. Methane 2024, 3, 160–171. [Google Scholar] [CrossRef]

- Mekonnen, A.M.; Sendekie, Z.B.; Ebissa, D.T.; Bezie, Y. Optimizing Rumen Fluid Inoculation for Enhanced Biogas Production Using Organic Waste Codigestion. Int. J. Chem. Eng. 2025, 2025, 2463014. [Google Scholar] [CrossRef]

- Olguin-Maciel, E.; Leal-Bautista, R.M.; Alzate-Gaviria, L.; Domínguez-Maldonado, J.; Tapia-Tussell, R. Environmental Impact of Sargassum spp. Landings: An Evaluation of Leachate Released from Natural Decomposition at Mexican Caribbean Coast. Environ. Sci. Pollut. Res. 2022, 29, 91071–91080. [Google Scholar] [CrossRef] [PubMed]

- American Public Health Association (APHA). Standard Methods for the Examination of Water and Wastewater; American Public Health Association: Washington, DC, USA, 2017; ISBN 9780875532875. [Google Scholar]

- Koch, K.; Hafner, S.D.; Astals, S.; Weinrich, S. Evaluation of Common Supermarket Products as Positive Controls in Biochemical Methane Potential (BMP) Tests. Water 2020, 12, 1223. [Google Scholar] [CrossRef]

- Qiu, Y.; Lower, L.; Rondon Berrio, V.; Cunniffe, J.; Kolar, P.; Cheng, J.; Sagues, W.J. Impacts of Municipal and Industrial Organic Waste Components on the Kinetics and Potentials of Biomethane Production via Anaerobic Digestion. Waste Biomass Valorization 2025, 16, 5019–5035. [Google Scholar] [CrossRef]

- Kusi, J.Y.; Empl, F.; Müller, R.; Pelz, S.; Poetsch, J.; Sailer, G.; Kirchhof, R.; Derkyi, N.S.A.; Attiogbe, F. An Evaluation of Biogas Potential of Cassava, Yam and Plantain Peel Mixtures Using Theoretical Models and Hohenheim Biogas Yield Test-Based Experiments. Energies 2025, 18, 947. [Google Scholar] [CrossRef]

- Orangun, A.; Kaur, H.; Kommalapati, R.R. Batch Anaerobic Co-Digestion and Biochemical Methane Potential Analysis of Goat Manure and Food Waste. Energies 2021, 14, 1952. [Google Scholar] [CrossRef]

- Kusi, J.Y.; Empl, F.; Müller, R.; Pelz, S.; Poetsch, J.; Sailer, G.; Kirchhof, R.; Agyemang Derkyi, N.S.; Attiogbe, F.; Siabi, S.E. Evaluation of Energetic Potential of Slaughterhouse Waste and Its Press Water Obtained by Pressure-Induced Separation via Anaerobic Digestion. Energies 2024, 17, 5522. [Google Scholar] [CrossRef]

- López-Aguilar, H.A.; Morales-Durán, B.; Quiroz-Cardoza, D.; Pérez-Hernández, A. Lag Phase in the Anaerobic Co-Digestion of Sargassum spp. and Organic Domestic Waste. Energies 2023, 16, 5462. [Google Scholar] [CrossRef]

- Bauta, J.; Calbrix, E.; Capblancq, S.; Cecutti, C.; Peydecastaing, J.; Delgado Raynaud, C.; Rouilly, A.; Simon, V.; Vaca-Medina, G.; Vandenbossche, V.; et al. Global Chemical Characterization of Sargassum spp. Seaweeds from Different Locations on Caribbean Islands: A Screening of Organic Compounds and Heavy Metals Contents. Phycology 2024, 4, 190–212. [Google Scholar] [CrossRef]

- Milledge, J.J.; Maneein, S.; López, E.A.; Bartlett, D. Sargassum Inundations in Turks and Caicos: Methane Potential and Proximate, Ultimate, Lipid, Amino Acid, Metal and Metalloid Analyses. Energies 2020, 13, 1523. [Google Scholar] [CrossRef]

- Hatt, D.C.; Bally, N.K.; Iporac, L.A.R.; Olszak, S.; Campbell, J.E.; Collado-Vides, L. Comprehensive Analysis of Biomass, Nutrient, and Heavy Metal Contributions of Pelagic Sargassum Species (Phaeophyceae) Inundations in South Florida. Phycology 2024, 4, 235–255. [Google Scholar] [CrossRef]

- Li, W.; Gupta, R.; Zhang, Z.; Cao, L.; Li, Y.; Show, P.L.; Gupta, V.K.; Kumar, S.; Lin, K.Y.A.; Varjani, S.; et al. A Review of High-Solid Anaerobic Digestion (HSAD): From Transport Phenomena to Process Design. Renew. Sustain. Energy Rev. 2023, 180, 113305. [Google Scholar] [CrossRef]

- Rocamora, I.; Wagland, S.T.; Villa, R.; Simpson, E.W.; Fernández, O.; Bajón-Fernández, Y. Dry Anaerobic Digestion of Organic Waste: A Review of Operational Parameters and Their Impact on Process Performance. Bioresour. Technol. 2020, 299, 122681. [Google Scholar] [CrossRef] [PubMed]

- Jameel, M.K.; Mustafa, M.A.; Ahmed, H.S.; Jassim Mohammed, A.; Ghazy, H.; Shakir, M.N.; Lawas, A.M.; Khudhur Mohammed, S.; Idan, A.H.; Mahmoud, Z.H.; et al. Biogas: Production, Properties, Applications, Economic and Challenges: A Review. Results Chem. 2024, 7, 101549. [Google Scholar] [CrossRef]

- Salgado-Hernández, E.; Ortiz-Ceballos, Á.I.; Martínez-Hernández, S.; Rosas-Mendoza, E.S.; Dorantes-Acosta, A.E.; Alvarado-Vallejo, A.; Alvarado-Lassman, A. Methane Production of Sargassum spp. Biomass from the Mexican Caribbean: Solid–Liquid Separation and Component Distribution. Int. J. Envrion. Res. Public Health 2023, 20, 219. [Google Scholar] [CrossRef]

- Salgado-Hernández, E.; Ortiz-Ceballos, Á.I.; Alvarado-Lassman, A.; Martínez-Hernández, S.; Rosas-Mendoza, E.S.; Velázquez-Fernández, J.B.; Dorantes-Acosta, A.E. Energy-Saving Pretreatments Affect Pelagic Sargassum Composition and DNA Metabarcoding Reveals the Microbial Community Involved in Methane Yield. PLoS ONE 2023, 18, e0289972. [Google Scholar] [CrossRef] [PubMed]

- Bueno, C.; Rossignolo, J.A.; Gavioli, L.M.; Sposito, C.C.A.; Tonin, F.G.; Veras, M.M.; Moraes, M.J.B.; de Lyra, G.P. Life Cycle Assessment Applied to End-of-Life Scenarios of Sargassum spp. for Application in Civil Construction. Sustainability 2023, 15, 6254. [Google Scholar] [CrossRef]

- Canul-Ku, L.A.; Casanova-Lugo, F.; Aguilar-Urquizo, E.; Valdivieso-Pérez, I.; Arcos-Álvarez, D.; Canul-Solís, J.; Castillo-Sánchez, L.; Chay-Canul, A.; Dzib-Castillo, B.; Piñeiro-Vázquez, A. In Vitro Fermentation Characteristics of Pelagic Sargassum for Inclusion in Integral Diets for Ruminants. Fermentation 2025, 11, 390. [Google Scholar] [CrossRef]

- Rivera-Hernández, Y.; Hernández-Eugenio, G.; Balagurusamy, N.; Espinosa-Solares, T. Sargassum-Pig Manure Co-Digestion: An Alternative for Bioenergy Production and Treating a Polluting Coastal Waste. Renew. Energy 2022, 199, 1336–1344. [Google Scholar] [CrossRef]

- Hütter, M.; Sailer, G.; Hülsemann, B.; Müller, J.; Poetsch, J. Impact of Thermo-Mechanical Pretreatment of Sargassum muticum on Anaerobic Co-Digestion with Wheat Straw. Fermentation 2023, 9, 820. [Google Scholar] [CrossRef]

| Sample | Weight (mg) | C (%) | H (%) | N (%) | S (%) |

|---|---|---|---|---|---|

| S1 | 10.2 | 55.3 | - | 8.3 | 1.9 |

| S2 | 10.1 | 52.2 | 10.9 | 7.4 | 1.6 |

| S3 | 9.9 | 53.7 | 10.6 | 7.7 | 1.3 |

| Averages | 10.0667 | 53.7 | 10.8 | 7.8 | 1.6 |

| SD | 0.152 | 1.5301 | 0.1789 | 0.4709 | 0.2844 |

| C% | N% | C/N | Source |

|---|---|---|---|

| 34.15 ± 0.35 | 1.41 ± 0.02 | 24.2:1 | [28] |

| 37.477 | 0.843 | 44.4:1 | [35] |

| 35.53 ± 0.07–38.89 ± 0.03 | 0.86 ± 0.08–1.39 ± 0.02 | 35.6:1 (min) 45.2:1 (max) | [36] |

| 27.41 | 1.71 | 16:1 | [37] |

| 36.2 | 0.97 | 37.3:1 | [38] |

| 53.7 1.5301 | 7.8 ± 0.4709 | 6.9:1 | This study |

| Parameter (%) | Sargassum | Ruminal Fluid |

|---|---|---|

| TS | 5.3 | 8.4 |

| VS | 4 | 6.6 |

| Moisture | 94.7 | 91.6 |

| Element | Moles (2:1) | Moles (3:1) |

|---|---|---|

| C | 0.0366 | 0.0244 |

| H | 0.0883 | 0.0588 |

| N | 0.0046 | 0.003 |

| S | 0.00041 | 0.00027 |

| O | 0.00041 | 0.00027 |

| Ratio | CH4 (g) | CO2 (g) | CH4 (L) | CO2 (L) |

|---|---|---|---|---|

| 2:1 | 0.43849 | 0.40324 | 0.66843 | 0.20407 |

| 3:1 | 0.29233 | 0.26882 | 0.44562 | 0.13604 |

| Study | Substrate/Conditions | Theoretical Results | Experimental Results | Observations |

|---|---|---|---|---|

| This study | Pelagic sargassum (S. natans and S. fluitans) with ruminal fluid; ratios 2:1 and 3:1; 7 days of operation | 2:1 → 0.668 L CH4 + 0.204 L CO2 (≈872 mL biogas) 3:1 → 0.446 L CH4 + 0.136 L CO2 (≈582 mL biogas) | 2:1 → 5.0 mL biogas 3:1 → 10.6 mL biogas | The overestimation of Boyle’s model is attributed to the fact that it considers ideal conditions. |

| [42] | Fractions of Sargassum spp. (RB = Raw Biomass, SF = Solid Fraction, LF = Liquid Fraction) | RB = 501.5 L CH4/kg VS SF = 336.6 L CH4/kg VS LF = 409.8 L CH4/kg VS | RB = 83.5 N L CH4/kg VS SF = 71.7 N L CH4/kg VS LF = 159.7 N L CH4/kg VS (Biomethane) | LF performed best. |

| [43] | Sargassum spp. with different pretreatments | 335.8–503.8 mL CH4/g VS | 150.4–578.6 N mL/g VS (biogas) | Best result is with manual washing pretreatment. |

| [44] | Three Sargassum spp. (life-cycle model) | TEB (Boyle): S. fluitans = 194 g CH4/kg TS S. natans I = 186 g CH4/kg TS S. natans VIII = 209 g CH4/kg TS CTEB (corrected for degradability): S. fluitans = 56.2 g/kg TS S. natans I = 56.0 g/kg TS S. natans VIII = 63.4 g/kg TS | - | Boyle’s model used for maximum emissions, then corrected with degradability indices (17 to 37%). |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2025 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Álvarez-Ley, J.E.; Landero-Godoy, L.A.; Abubakar, A.M.; Bassam, A.; Giácoman-Vallejos, G.; San-Pedro, L. Biogas Production from Sargassum Collected from a Coast of the Gulf of Mexico Using Ruminal Fluid as Inoculum. Energies 2025, 18, 6232. https://doi.org/10.3390/en18236232

Álvarez-Ley JE, Landero-Godoy LA, Abubakar AM, Bassam A, Giácoman-Vallejos G, San-Pedro L. Biogas Production from Sargassum Collected from a Coast of the Gulf of Mexico Using Ruminal Fluid as Inoculum. Energies. 2025; 18(23):6232. https://doi.org/10.3390/en18236232

Chicago/Turabian StyleÁlvarez-Ley, Jorge E., Luis A. Landero-Godoy, Abdulhalim Musa Abubakar, Ali Bassam, Germán Giácoman-Vallejos, and Liliana San-Pedro. 2025. "Biogas Production from Sargassum Collected from a Coast of the Gulf of Mexico Using Ruminal Fluid as Inoculum" Energies 18, no. 23: 6232. https://doi.org/10.3390/en18236232

APA StyleÁlvarez-Ley, J. E., Landero-Godoy, L. A., Abubakar, A. M., Bassam, A., Giácoman-Vallejos, G., & San-Pedro, L. (2025). Biogas Production from Sargassum Collected from a Coast of the Gulf of Mexico Using Ruminal Fluid as Inoculum. Energies, 18(23), 6232. https://doi.org/10.3390/en18236232